Summit VV40H, VV40HL, VV40AK, VV40L, VV40KK Installation, Operation & Maintenance Manual

...Page 1

SUMMIT PUMP MODEL SPL PROGRESSIVE CAVITY i

Page 2

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 3

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

i. WARRANTY

Pumping units assembled by Summit Pump, Inc., Green Bay, WI are guaranteed to be free from defects in

material and workmanship for one year from date of shipment from factory in Green Bay, WI. The

obligation under this warranty, statutory or otherwise, is limited to replacement or repair at Green Bay, WI,

of such part as shall appear to us upon inspection at such point, to have been defective in material or

workmanship.

This warranty does not obligate Summit Pump, Inc. to bear the cost of labor or transportation charges in

connection with replacement or repair of defective parts; nor shall it apply to a pump upon which repairs or

alterations have been made unless authorized by Summit Pump, Inc.

No warranty is made in respect to engines, motors, or trade accessories, such being subject to warranties of

their respective manufacturers.

No express implied or statutory warranty, other than herein set forth is made or authorized to be made by

Summit Pump, Inc.

In no event shall Summit Pump, Inc. be liable for consequential damages or contingent liabilities arising out

of the failure of any Summit Pump, Inc. pump or parts thereof to operate properly.

ii. LIABILITY

Summit Pump, Inc. shall not be liable for personal physical injury, damage or delays caused by failure to

follow the instructions and procedures for installation, operation and maintenance contained in this manual.

The equipment is not for use in or with any nuclear facility or fire sprinkler system. Buyer accepts the

responsibility for insuring that the equipment is not used in violation and Buyer shall indemnify and hold

Seller harmless from any and all liability (including such liability resulting from seller’s negligence) arising

out of said improper use.

iii. COPYRIGHT

This Installation, Operation, and Maintenance Manual contains proprietary information, which is protected

by copyright. No part of this Installation, Operation, and Maintenance Manual may be photocopied or

reproduced without prior written consent from Summit Pump.

The information contained herein is for informational use only and is subject to change without notice.

Summit Pump assumes no responsibility or liability for any errors or inaccuracies that may appear in this

manual.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP iii

Page 4

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 5

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

1 CONTENTS

I. WARRANTY .............................................. III

II. LIABILITY .................................................. III

III. COPYRIGHT .............................................. III

1 CONTENTS ............................. V

2 INTRODUCTION ..................... 1

7.2.3 Grease ............................................ 15

7.3 PACKING ................................................ 15

7.3.1 Packing Adjustment ....................... 16

7.3.2 Packing Lubrication ........................ 16

7.4 MECHANICAL SEALS .............................. 17

7.5 FIRST RUN CHECK .................................. 17

7.5.1 Start Up .......................................... 17

7.5.2 Shut Down ...................................... 18

3 SAFETY .................................. 2

3.1 PUMP SAFETY WARNINGS ....................... 2

4 NOMENCLATURE ................... 4

4.1.1 Model Size ........................................ 4

4.1.2 Seal Type & Material ........................ 4

4.1.3 Materials of Construction ................. 4

4.1.4 Additional Items ............................... 5

4.1.5 Special to Application ....................... 5

5 RECEIPT AND STORAGE ......... 7

5.1 RECEIVING THE PUMP .............................. 7

5.2 STORING THE PUMP ................................ 7

5.2.1 Temporary ........................................ 7

5.2.2 Long Term ......................................... 7

5.3 HANDLING ............................................... 7

5.4 LIFTING .................................................... 7

6 INSTALLATION ....................... 8

6.1 GENERAL .................................................. 8

6.2 LOCATION ................................................ 8

6.3 BASE PLATE .............................................. 8

6.4 FOUNDATION .......................................... 8

6.4.1 Concrete Sub-Base ........................... 8

6.5 BASE PLATE GROUTING............................ 9

6.6 ORIENTATION AND ROTATION .............. 11

6.6.1 Casing Orientation .......................... 12

6.7 PIPING CONNECTION – SUCTION /

DISCHARGE ............................................ 12

6.7.1 Suction Piping ................................. 12

6.7.2 Discharge Piping ............................. 12

6.8 ALIGNMENT ........................................... 13

6.8.1 Coupling Connected Units .............. 13

6.8.2 Belt Driven Units ............................. 13

6.8.3 Alignment Checks ........................... 13

7 OPERATION ......................... 14

7.1 CHECKING ROTATION ............................ 14

7.2 LUBRICATION ......................................... 14

7.2.1 Packing ........................................... 14

7.2.2 Bearings .......................................... 15

8 MAINTENANCE TIMETABLE . 19

8.1 DAILY MAINTENANCE ............................ 19

8.2 THREE MONTH MAINTENANCE ............. 19

8.3 SIX MONTH MAINTENANCE ................... 19

8.4 YEARLY MAINTENANCE ......................... 19

9 TROUBLESHOOTING ............ 20

9.1 PUMP PROBLEMS .................................. 20

9.2 PROBABLE CAUSE AND REMEDY. ........... 20

10 EXPLODED VIEWS ............... 21

10.1 VV40H & VV40HL CAST IRON.................... 21

10.2 VV40H & VV40HL STAINLESS STEEL ............ 22

10.3 VV40H & VV40HL CAST IRON & STAINLESS

STEEL – BEHIND ROTOR MECHANICAL SEAL .... 23

10.4 VV40L, LL, LQ & LS CAST IRON & STAINLESS

STEEL ....................................................... 24

11 DISASSEMBLY MODEL VV40 25

11.1 HEAD AND CASING ................................ 26

11.2 BEARING HOUSING ................................ 26

11.3 REMOVING SEALS .................................. 27

11.3.1 Packing ........................................... 27

11.3.2 Component Mechanical Seal.......... 27

11.4 BRACKET AND CASING ........................... 28

11.5 INTERNAL RELIEF VALVE ........................ 28

12 ASSEMBLY MODEL VV40 ..... 29

12.1 BRACKET & IDLER BUSHINGS ................. 29

12.1.1 Normal installation ......................... 30

12.1.2 Heated installation ......................... 30

12.1.3 Bushing Temperature Limits .......... 31

12.2 BRACKET AND CASING ........................... 31

12.3 INSTALLING SEALS ................................. 31

12.3.1 Packing ........................................... 32

12.3.2 Component Mechanical Seal.......... 32

12.4 BEARING HOUSING ................................ 33

12.5 HEAD AND CASING ................................ 34

12.6 ADJUSTING END CLEARANCE ................. 35

12.6.1 Measured Rotation Method .......... 35

12.6.2 Dial Indicator Method .................... 36

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP v

Page 6

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12.7 INTERNAL RELIEF VALVE ......................... 38

12.7.1 Mounting valve on head ................. 38

12.7.2 Setting pressure .............................. 38

13 APPENDIX E – REFERENCE

TABLES ................................ 40

13.1 TORQUE GUIDELINES ............................. 40

13.1.1 Bolt Torques .................................. 40

13.1.2 Locknut Torques ............................. 40

14 PUMP INFORMATION .......... 41

ii SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 7

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

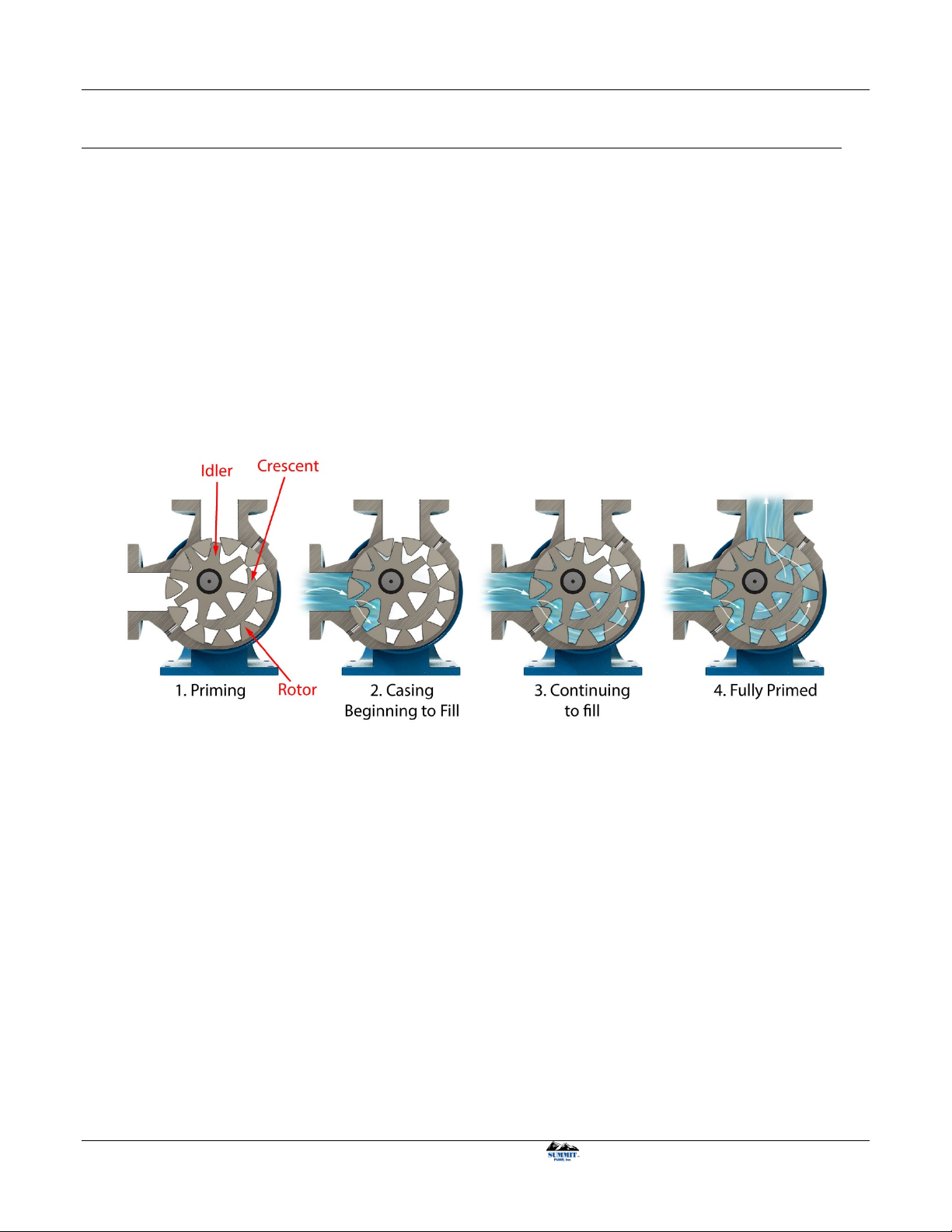

Figure 2-1: Priming cycle and gear pump design principle

2 INTRODUCTION

This installation, operation, and maintenance manual is designed to help you achieve the best performance

and longest life from your Summit Pump.

This pump is a positive displacement internal gear type. The pump’s drive shaft turns a ring gear (rotor), with

internal teeth, which rotates the external gear (idler). The idler rotates on a pin and meshes its external teeth

with the rotor’s internal teeth.

The crescent is integrated with the pump head and spaced between the internal teeth and external teeth. As

the gear teeth disengage at the intake port, liquid enters and is trapped in the space of each gear tooth. The

liquid is carried to the discharge port. The meshing of the two gears and the space reduction, forces the liquid

from the pump through the discharge port. Figure 2-1 below illustrates the internal gear pump design

principle.

If

there are any questions regarding this pump or its application, which are not covered in this manual, please

contact your local Summit Pump, Inc. Distributor.

For information or technical assistance on the driver service, contact the driver manufacturer’s local dealer or

representative.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 1

Page 8

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3 SAFETY

The following message types are used in this manual to alert maintenance personnel to procedures that

require special attention for the protection and safety of both personnel and equipment:

DANGER

Imminently hazardous situation which, if not

avoided, will result in death or serious

injury.

WARNING

Potentially hazardous situation which, if not

avoided, could result in death or serious

injury.

CAUTION

Potentially hazardous situation which, if not

avoided, may result in minor or moderate

injury.

NOTICE

Includes Information on operation,

maintenance, rules or directions. May

indicate possible property damage.

3.1 PUMP SAFETY WARNINGS

The safety information below should be followed and observed to prevent damage to equipment or injury to

operators:

DANGER

Ensure discharge line is open and free of

clogs before operation. Negligent acts may

result in serious injury or death.

CAUTION

Feeding very hot or very cold fluid into the

pump at room temperature may result in

fracture of pump wet end.

2 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 9

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

WARNING

Follow all auxiliary equipment (motors,

drives, couplings etc.) manufacturer’s

manuals, instructions or procedures during

installation, operation and maintenance of

the pump.

NOTICE

Check all end clearances, drive to shaft

alignments, fastener torques, equipment

lubrication, gaskets and seals for leaks and

all equipment is fastened into place before

operation.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 3

Page 10

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

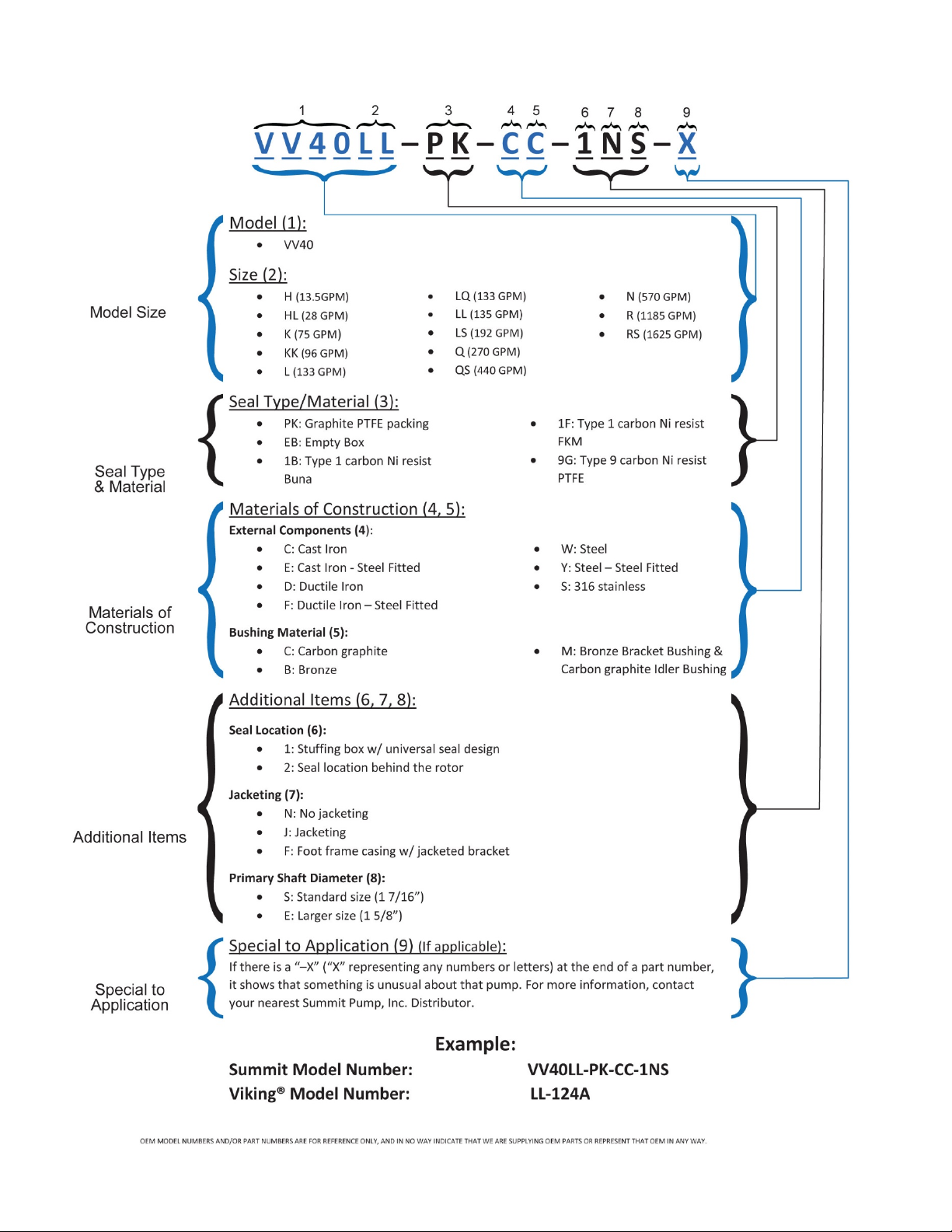

4 NOMENCLATURE

On page 41 of this manual, record the nameplate data from your pump. This will assist with any maintenance

questions or pump identification in the future.

As where “sections” are stated in section 4, NOMENCLATURE, refer to Page 6 for clarification.

Summit internal gear pumps are essentially identified by Model Size (sections 1 & 2, i.e. VV40LL). The

remaining format consists of the Seal Type & Material (section 3, i.e. “PK”), Materials of Construction

(sections 4 & 5, i.e. “CC”), Additional Items (sections 6, 7 & 8, i.e. “1NS”), and finally Special to

Application (section 9, if applicable, i.e. “X”). These items together represent the complete identification of

the pump and should be stated when ordering repair parts.

4.1.1 Model Size

(“VV40LL”, Sections 1 & 2) The format consists of the pump model (section 1) and the pump size (section

2).

Section 1 specifies a specific group or style of gear pump. This value changes when the style of gear pump is

altered. For this manual section 1 is “VV40”.

Section 2 identifies a specific pump size within the gear pump model. Sizes are justified via the capacity

(GPM) of the pump. (i.e. “LL”)

4.1.2 Seal Type & Material

(“PK”, Section 3) Section 3 identifies how the pump is sealed and with what materials. Options are packing,

type 1 or type 9 component mechanical seals, or a cartridge mechanical seal.

4.1.3 Materials of Construction

(“CC”, Sections 4 & 5) Section 4 identifies the materials of the working internals and cast parts of the pump.

Each letter represents a relationship with these components. See Figure 4-1 for specific item materials of

construction.

Section 5 identifies the type of bushing used in the bracket and idler. Options are either carbon graphite or

bronze.

4 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 11

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

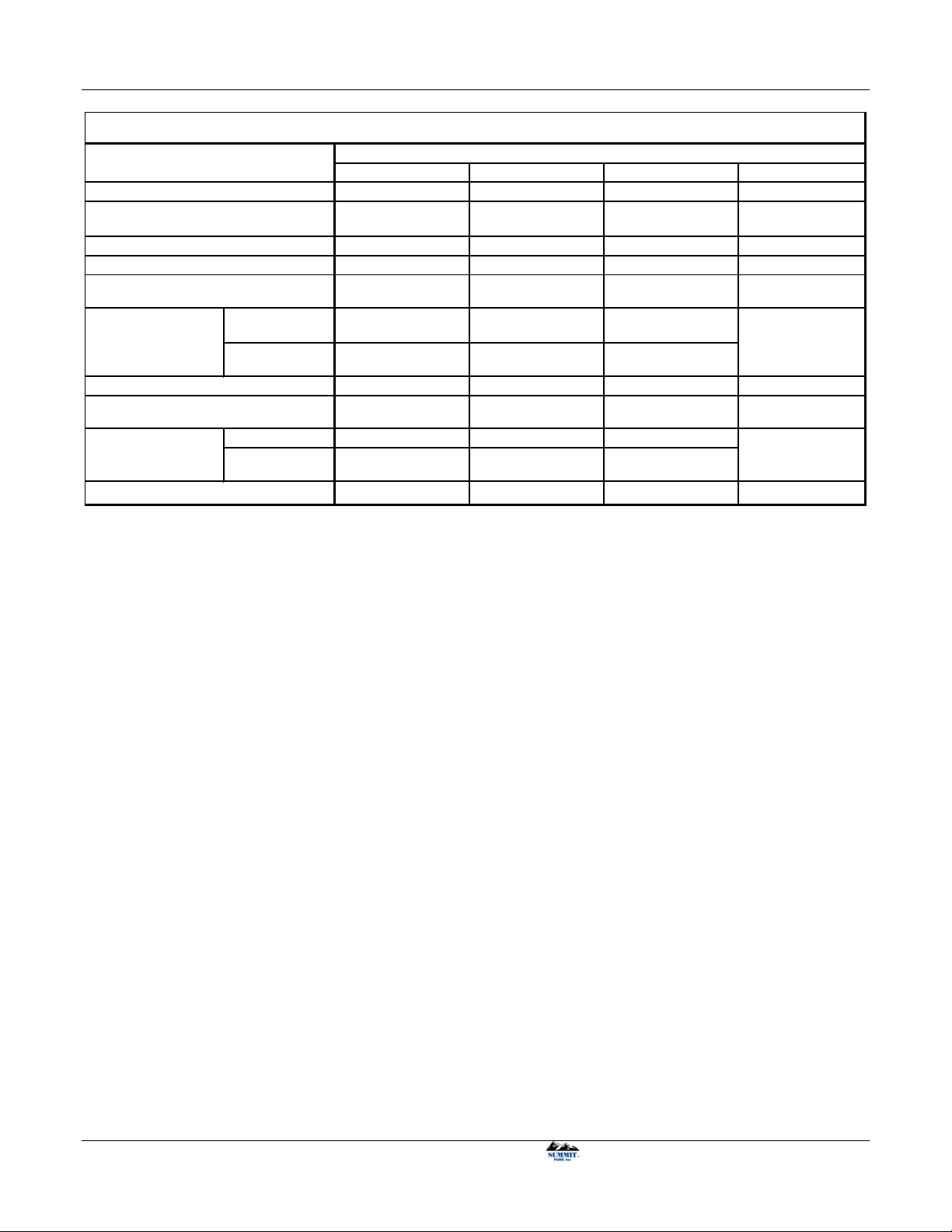

(C) CAST IRON (D) DUCTILE IRON (W) STEEL (S) STAINLESS STEEL

CAST I RON DUCTILE IRON STEEL STAINLESS STEEL

CAST I RON DUCTILE IRON STEEL

STAINLESS STEEL

CAST I RON STEEL STEEL CAST I RON

CAST I RON DUCTILE IRON STEEL STAINLESS STEEL

*CAST I RON *CAST I RON *CAST I RON

STAINLESS STEEL

STANDARD

MATERIAL

**CAS T IRON **CAS T IRON **CAS T IRON

STEEL

CONSTRUC TION

STEEL

("E" in NOMENCLATURE)

STEEL

("F" in NOMENCLATURE)

STEEL

("Y" in NOMENCLATURE)

STEEL STEEL STEEL STAINLESS STEEL

HARDENED STEEL HARDENED STEEL HARDENED STEEL

HARD COATED

STAINLESS STEEL

PACKED BRONZE BRONZE BRONZE

MECHANIC AL

SEAL

^ CARB ON GRAPHITE ^ CARB ON GRAPHITE ^ CARB ON GRAPHITE

CAST I RON STEEL STEEL

STAINLESS STEEL

* STEEL FOR Q AND QS STEEL FITTED OPTION. H AND HL ARE POWERED METAL

** KK, LS, QS HAVE DUCTILE IRON ROTOR

^ BEHIND ROTOR SEAL: ALL BUSHINGS ARE BRONZE EXCEPT SIZES H TO KK HAVE CARBON GRAPHITE IDLER BUSHINGS

INTER NAL PRESSURE RELI EF VALVE (4 7)

SECTION "4" EXTERNAL COMPONENTS IN NOMENCLATURE

ITE M (ITEM NUMB ER)

STAINLESS STEEL

^ CARB ON GRAPHITE

MODEL VV40 MATERIALS OF CONSTRUCTION

ROTOR (3 6)

IDLER BUSHING (38)

& B RACKET B USHIN G (25 )

CASING (31)

HEAD (40)

JAC KET HEAD PLATE (4 2)

BRAC KET (27 )

IDLER (37)

SHAF T (36)

IDLER PIN (39)

4.1.4 Additional Items

(“1NS”, Sections 6, 7 & 8) These sections define additional information about the options of the pump.

Section 6 identifies the sealing location, either behind the rotor or in the stuffing box.

Section 7 identifies the type of bracket and casing. There is an option to jacket these parts to induce a heat

exchanger for high temp applications.

Section 8 identifies the standard or larger shaft diameter.

4.1.5 Special to Application

(“X”, Section 9) Section 9 may or may not be present. Usually, there will be no “X” following the pump

identification. If there is an “X”, you will need to contact your nearest Summit Pump, Inc. Distributor to

determine exactly what makes this pump special.

See following page for nomenclature definitions and examples

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 5

Page 12

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 4-1: Materials of Construction; Reference Summit Pump VV40 nomenclature

6 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 13

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5 RECEIPT AND STORAGE

5.1 RECEIVING THE PUMP

Immediately upon arrival, carefully inspect the pump for evidence of damage during transit. Immediately

report any damage to your local Summit Pump, Inc. Distributor.

5.2 STORING THE PUMP

5.2.1 Temporary

Temporary storage: less than six months.

1. Flush the pump with clean water. If pumped product is water reactive, remove the pump head, and

with compressed air blow all liquid from cavity. Lightly cover all internal metal parts with oil and

replace the head.

2. Store pump in a clean, dry place, free from extreme swings in temperature and humidity.

3. Cover with a protective covering to reduce dust contamination.

4. Loosen the packing gland nuts; remove the gland, packing rings and lantern ring. Apply grease to the

stuffing box I.D. and packing rings. Return the packing and lantern rings to their position in the

stuffing box. Snug down the packing gland nuts finger tight. Do not use grease if gland is water

flushed. Only a small amount of light oil should be applied in this scenario.

5. Rotate the shaft once a week to protect the bearings from being indented into the raceway.

5.2.2 Long Term

Long Term Storage: more than six months.

1. Follow temporary storage guidelines 1-5.

2. Coat all unpainted and machined surfaces with a rust inhibitor, such as LPS-3.

5.3 HANDLING

Pump unit boxes and crates may be unloaded using a forklift or slings depending on size and package

construction.

WARNING

Pump and assemblies are heavy, improper

handling could result in serious injury.

5.4 LIFTING

To avoid damage to pump and/or motor use a nylon, chain, or a wire rope sling. The slings should be placed

so lift is equally supported at four or more points.

Be sure all components are securely

fastened to baseplate before lifting.

WARNING

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 7

Page 14

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6 INSTALLATION

6.1 GENERAL

Summit Pumps are fully assembled at the factory. The pumps are ready to be installed and put into service.

Follow all instruction tags on the pump.

6.2 LOCATION

If the pump is going to have a water flush, it should be located as close as possible to the supply of water.

Other location considerations are: easy access for inspection, maintenance and ample overhead space for

lifting with crane or hoist.

6.3 BASE PLATE

Each pump unit should be mounted on a fabricated steel base plate. Common base configurations are inline,

piggyback and L-shape. The base plate should be mounted on a concrete sub base 4” to 8” longer and wider

than the fabricated base plate.

6.4 FOUNDATION

6.4.1 Concrete Sub-Base

The concrete sub foundation performs a number of functions. It must support the weight of the entire pump

assembly, maintain the alignment of all system components, and absorb the loads, forces and vibrations that

are developed under normal operating conditions. The concrete material used must be top quality and

conform to local building codes as well as the contractor’s strength requirements. Reinforcing bars and mesh

should be used as required. The mounting surface of the concrete foundation must be flat and level beneath

the footprint of the sub-base, or the pump could be installed out of square. This could create problems

aligning the piping, place extra loads on the couplings and bearings, and alter the operating levels of

lubricants or hydraulic fluids in the system. It is recommended that the top surface of the slab be held flat and

level to at least F50 according to American Concrete Institute (#117) and the Canadian Standards

Association (#A23.1) which is approximately 1/8” per 10 foot. The sub base height is usually determined by

the process piping runs and elevation.

The weight of the sub foundation should be 3-5 times the weight of the pump, motor and baseplate.

Dimensionally, it should be 4” to 8” longer and wider than the polymer concrete or fabricated steel base

plate. Anchor bolts are installed in pipe sleeves. The pipe diameter is 2.5 times larger than the anchor bolt

diameter. This sleeve/bolt assembly is embedded in the base when poured.

The pipe sleeve should be filled with sand or plastic foam to the top of the sleeve. This will prevent the grout

material from spilling into the sleeve and reducing the movement of the sleeve when pouring the grout.

Anchor bolt sizes: 1”-8UNC. Length is 7.5” to 10”, depending on base thickness and overall size.

8 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 15

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

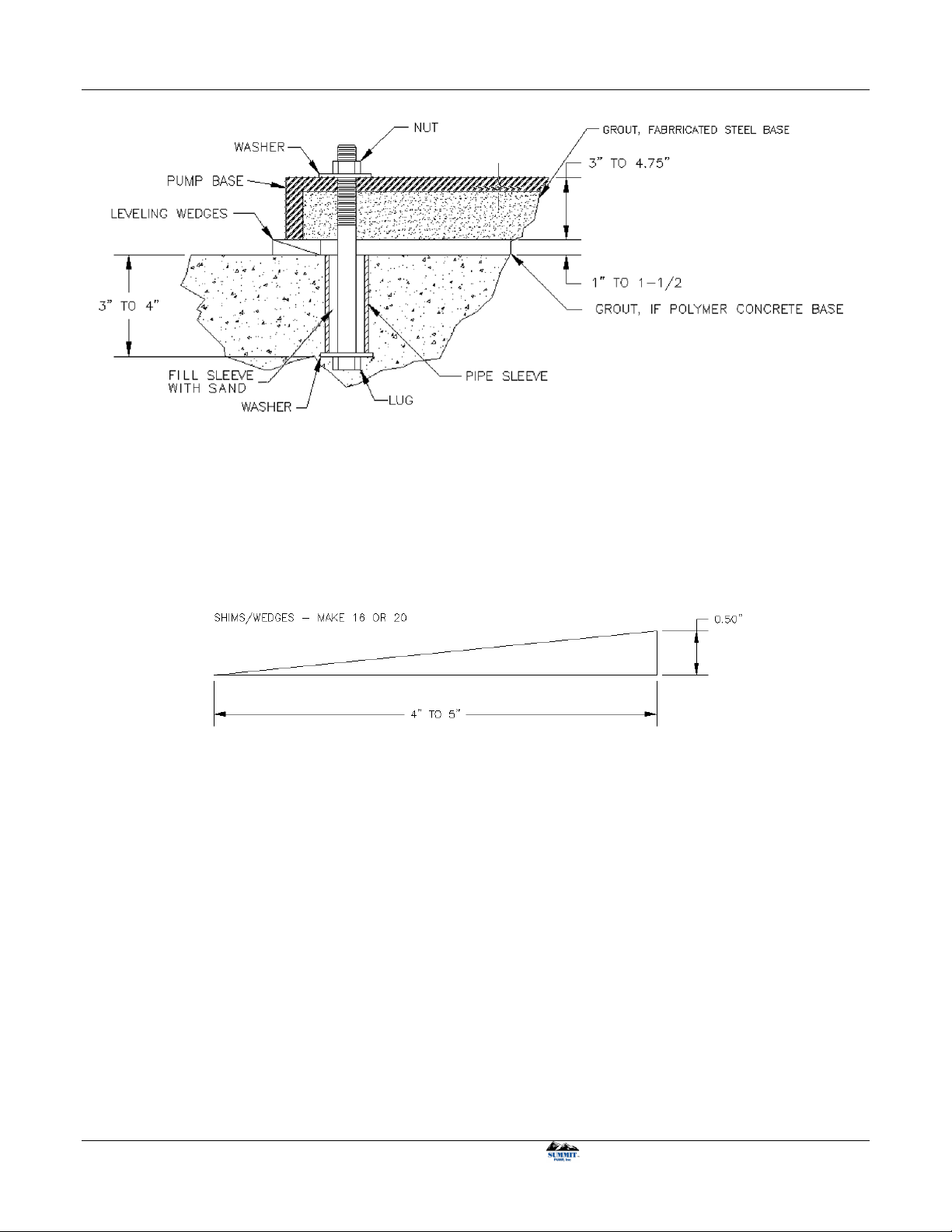

Figure 6-1: Anchor Bolt configuration

Figure 6-2: Wooden Wedges

6.5 BASE PLATE GROUTING

1. This grouting instruction assumes a concrete sub base has been put in place to accept the baseplate.

The subbase should be clean of dirt, oil and any other debris.

2. Shims/wedges should be wood.

3. Shims/wedges should be placed on the sub base, as shown in Figure 6-3. Use 2 to 3 per stack to

obtain desired gap between baseplate and sub-base. Normal gap is 1” to 1-1/2”.

4. Carefully lower baseplate with pump and motor onto sub base over anchor bolts.

5. Level baseplate to 0.125” over length and 0.088” in over width.

6. When leveling is complete, uniformly hand tighten the anchor bolts.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 9

Page 16

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 6-3: Wedge Locations

7. Build a plywood form around baseplate supported on the sub base. It should be 3” high and 1” to 1.5”

larger than the baseplate. Its size should be large enough to include the shims or wedges that are left

in place.

8. Use a high quality non-shrinking epoxy grout, following manufacturer’s mixing and installation

instructions.

9. When grout has cured, per grout manufacturer’s recommended cure time, tighten anchor bolts till

secure.

10. When grouting is complete, check coupling alignment and re-align as necessary.

10 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 17

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 6-4: Wet end configurations

6.6 ORIENTATION AND ROTATION

There are four main different wet end configurations for the VV40 pump. Refer to Figure 6-4 for the

different configurations. The configurations are dependent on two variables, casing orientation and shaft

rotation. The configurations are important to understand when installing the casing to the bracket and the

internal relief valve on the head. The internal relief valve must be positioned correctly or the valve will not

work correctly, potentially damaging equipment, severely injuring or causing death to personnel.

DANGER

Install pressure relief valve correctly to

avoid equipment failure, severe injury or

death.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 11

Page 18

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6.6.1 Casing Orientation

To change the casing orientation, unbolt the casing from the bracket and rotate the casing and head 90degrees. Be careful as not to damage the idler, rotor or crescent shape inside the casing. The head plate

should rotate with the casing.

NOTICE

Rotate casing carefully as to not damage

internal parts.

6.7 PIPING CONNECTION – SUCTION / DISCHARGE

DANGER

Lock out driver power before beginning to

work on pump.

Connect piping in a manner that is as short and direct as possible. Independent pipe supports and anchors

must be used in all installations. Never support piping with pump flanges or threaded connections.

Ideally, you should place a short length of flexible or bellows type spool directly adjacent to the pump

flange.

CAUTION

Never use force to align piping to the pump

flanges or threaded connections.

6.7.1 Suction Piping

The piping used should be as short as possible from suction source. Piping line size should be the same

diameter as the suction nozzle. Although, this may not always be the case, as high viscosity, flow velocity or

system constraints may cause a change in size. All elbows 90° or 45° should be a long-sweep. Any piping

that causes air to become trapped should be avoided.

6.7.2 Discharge Piping

Generally, the diameter of the discharge piping should be the same diameter as the discharge nozzle. In

certain circumstances, this will not be the case, as the fluid being pumped will cause the use of a different

sized pipe. In these circumstances, the use of a threaded or flanged reducer/expansion fitting is needed.

It is recommended to install an isolation discharge valve to isolate the pump from the system when down for

maintenance.

12 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 19

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6.8 ALIGNMENT

NOTICE

Careful alignment is extremely important to

ensure long pump life.

6.8.1 Coupling Connected Units

In-line configurations are shipped with the pump and motor leveled on the base plate with the coupling

disconnected. If the pump and driver were aligned at the factory, that alignment will be disturbed during

shipment. Alignment must be rechecked. If alignment is necessary, align the motor to the pump not the pump

to the motor. Check both parallel and angular alignments. Final alignment should be within 0.005" in all

planes at operating temperature.

6.8.2 Belt Driven Units

Check belt and sleeve alignment. Check belts for proper belt tension. Tension requirements will vary with

the type of belt, centerline distance and belt speeds. Consult belt manufacturer for specific recommendations.

6.8.3 Alignment Checks

Alignment checking needs to be done several times prior to pump start up. Alignment is accomplished by

adding or removing shims under the motor feet and moving the motor as required eliminating the

misalignment. Those alignment recommendations are as follows:

DANGER

Lock out driver power before beginning to

work on pump.

1. Prior to grouting, to remedy misalignment caused by transportation.

2. After grouting, to correct any changes that occurred during grouting.

3. After piping is connected, check alignments to ensure possible pipe strains have not changed

alignment.

4. Hot alignment, after the pump has reached operating temperature, if the pump is used in high

temperature service.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 13

Page 20

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 7-1: Lubrication locations

7 OPERATION

7.1 CHECKING ROTATION

The pump can operate equally well in a clockwise or counterclockwise rotation. The desired port to be

suction determines shaft rotation. Port closest to where pumping elements (gear teeth) come out of mesh is

suction port. If fitted with a pressure relief valve ensure the adjustment knob is near the suction port. See

Figure 6-4 for illustration.

DANGER

Lock out power to avoid personal injury or

death.

1. Lockout power to drive.

2. Remove coupling guard.

3. Remove coupling grid/sleeve element so that the motor half of coupling can spin free from the pump

half.

4. Unlock power to motor.

5. Clear personnel from immediate area, jog motor just enough to determine direction of rotation.

6. If the motor is rotating in the wrong direction the electrical wiring will need to be adjusted by

qualified personnel. Then repeat Step 4, 5 and 6.

7. Once rotation is in the desired direction, lockout motor and reassemble coupling grid/sleeve to

connect pump half.

8. Check alignment and install coupling guard.

9. Unlock motor, pump is ready to run.

7.2 LUBRICATION

7.2.1 Packing

The packing should be greased with 2 to 3

pumps of grease for grease lubricated

packing. Acceptable greases are shown in

Table 7-1. Lubrication intervals may vary

depending on application. In general, regrease the packing every 500 hours or every

six months using the stuffing box grease

zerk shown in Figure 7-1. See Section 7.3.2

for more details.

14 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 21

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

NOTICE

Packing is not greased at the factory.

Lubricate packing before operation.

7.2.2 Bearings

The bearing(s) on Summit’s VV40 pumps are grease lubricated at the factory. Depending on pump

application, speed and size of bearing(s), the amount the bearing(s) is lubricated changes. In general, regrease the bearing(s) every 500 hours or every six months using the bearing grease zerk shown in Figure 7-1.

Bearing housing “free” volume should approximately be 50% full of grease, higher percentage in lower

speed applications and lower percentage in higher speed applications.

NOTICE

Avoid over greasing bearings. This will

induce heat and damage bearing(s).

If pump is disassembled ensure bearing is cleaned and repacked with fresh grease. Ensure all dirt and foreign

matter is removed before reassembly. When pump is assembled use a hand grease gun to grease port shown

in Figure 7-1.

7.2.3 Grease

Recommended grease lubrication for bearings and packing is NLG1 No. 2 for pumping temperatures -60⁰F

to 350⁰F. Any type of Ep Lithium soap based grease is acceptable. Sodium or Calcium based grease is not

acceptable. A list of some acceptable bearing grease is shown in Table 7-1.

Table 7-1: Acceptable Bearing Greases NLG1 No. 2 Grade

Acceptable Greases

Citgo Mystic EP2

Keystone 81EP2

Mobil Mobilux EP2

Mobil Synthetic SCH 100

NOTICE

Grease lubricated pumps are intended to

use grease only. Do NOT add oil

7.3 PACKING

Packing must be lubricated and adjusted correctly to avoid seizing of packing and failure. Greased packing is

standard and is not lubricated at the factory. Packing lubrication must be done before operation.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 15

Page 22

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

IN

OUT

A B

C

D E F

DANGER

Lock out power to avoid personal injury or

death when working on pump.

7.3.1 Packing Adjustment

There are many variables that go into packing a pump correctly. Refer to the packing manufacture to

correctly set packing for specific application and material.

In general, before installing the packing, ensure all surfaces are clean of debris and packing size and material

are correct for specific application. Packing has a break-in period which is approximately two hours of

operation. During this time, allow liberal leakage which will set up a good sealing job.

After the break-in period, gradually tighten the packing gland using small incremented adjustments. Patience

is required between adjustments, having the gland too loose, rather than over tight, is ideal for reducing

shaft/packing wear resulting in sealing issues. A general drip rate guideline is 10 drops per minute per inch

of shaft diameter. (Example: 2.5 inch diameter shaft = 25 drops per minute)

7.3.2 Packing Lubrication

Packing can be grease lubricated or water lubricated. Water lubrication can be supplied from either an

external source or from the pumped product.

CAUTION

Packing must be lubricated to avoid seizing

of packing and sealing failure.

7.3.2.1 Greased Lubricated Packing (Standard)

A grease zerk is located in Figure 7-1. The packing should be greased after 500 hours of operation or sooner

when needed. More details can be found in Section 7.2.1

7.3.2.2 Water Lubricated Packing

A water flush is recommended when highly abrasive material is being pumped. The flush will prevent

packing leakage and excessive shaft wear. A clean water flush system is shown in Figure 7-2. Replace the

grease zerk with customer’s choice of fitting. The outlet can either be a tapped NPT hole in the stuffing box

opposite the inlet line or allow the water to leak out near the gland and into the casing. In either case, this

discharge of the flush water should be approximately 10-15 psi higher than the pressure in the casing.

16 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 23

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 7-2: Water Flush System

A) Y-strainer

B) Pressure regulating valve

C) Sight flow meter

D) Solenoid valve

E) Pressure gauge

F) Needle valve

7.4 MECHANICAL SEALS

For maximum seal life it is recommended to install a water flush line to keep seal faces free of debris. A

general example of a water flush system is shown in Figure 7-2 on page 17. Follow the steps necessary for

water flushed packing and apply to water flushed mechanical seals.

For component mechanical seal assembly refer to section 12.3.2 on page 32 and disassembly in section

11.3.2 on page 27.

7.5 FIRST RUN CHECK

Several items need to be checked before you put your pump into service. Each of the following items needs

to be addressed to make certain that your equipment is correctly installed.

1. Proper alignment of pump, coupling, driver and sheaves.

2. All electrical connections.

3. All instruments and gauges should be in working order.

4. Water flush connection to the stuffing box (if applicable).

5. Correct pump rotation as desired, see Figure 6-4 on page 17.

6. Open the valves on the suction and discharge.

DANGER

This is a positive displacement pump.

NEVER operate it against a closed valve or

clogged discharge.

NOTICE

Do not operate pump dry. Dry operation can

cause premature damage to pump

internals.

7.5.1 Start Up

1. Before operating the pump it must be filled with liquid. This can be done by removing the piping or pipe

plugs (item 30 in Figure 10-1 on page 24) and fill with pumping liquid or water. (Only use water if it will

not contaminate the pumping liquid.)

2. Ensure the motor rotation coincides with desired pump rotation. Refer to Section 6.6 on page 11 and 11

for specific shaft rotation direction.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 17

Page 24

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3. If an internal relief valve is installed, make sure the threaded adjustment side is closest to the suction side

of the pump. See Figure 6-4 on page 11 for illustration.

4. If water flushed, turn on water to the stuffing box.

5. Start the pump.

DANGER

Do not operate the pump without the proper

coupling guard. See ANSI/ASME B15.1-

1996.

7.5.2

Shut Down

1. If possible, flush the pump with clean water. (Only use water if it will not contaminate the pumping

liquid.)

2. Shut down the pump.

3. If water flushed or water lubricated packing, turn off water to the stuffing box.

4. Close both the discharge and suction valves.

18 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 25

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8 MAINTENANCE TIMETABLE

8.1 DAILY MAINTENANCE

1. Check the lip seals (05, Figure 10-1 on page 24) in the bearing housing for tears, worn areas and/or

leaks.

2. Inspect the packing or mechanical seal for correct flow, drip rate, noise and pressure.

8.2 THREE MONTH MAINTENANCE

1. Daily maintenance and the following:

2. Inspect and adjust packing so that drips are as stated in section 7.3.1 on page 16. If packing is grease

lubricated, lube the packing with 2 to 3 grease gun pumps, after 500 hours of operation or sooner

when needed.

8.3 SIX MONTH MAINTENANCE

1. Daily maintenance and the following:

2. The packing should be replaced.

3. Check lip seal (05, Figure 10-1 on page 24) and drive shaft for wear. The suction and discharge piping

spool pieces should be inspected internally for their condition.

4. Lubricate all grease fittings using a hand grease gun.

8.4 YEARLY MAINTENANCE

1. All of the above and the following:

2. Depending on the fluid pumped and pump operating hours, check pump performance with published

performance curve. These inspections can range from once a year, to once every three to five years.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 19

Page 26

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Pump has run dry.

2

Liquid temperature higher than stated.

4

Viscosity higher than stated.

5

Parts not hardened.

8

Suction or differe ntial pressure too high.

9

Discharge valve not open or partially open.

12

Clogged strainer.

13

Wrong clearance setting for application.

17

Packing gland too tight or skewed.

19

Improper seal installed.

20

Relief valve improper pressure setting.

22

Relief valve reversed.

23

Mater ial compatibility.

24

Drive misalignment

27

Base plate loose

28

Drive not sized for horsepower required.

29

9 TROUBLESHOOTING

9.1 PUMP PROBLEMS

Pump turns, no flow. 1,2,3,10,12,13,14,15,16,17,18

Pump flow rate below expected capacity. 1,2,3,4,5,6,7,10,11,12,13,16,17,18,22,25

Pump will not produce rated pressure. 1,2,3,4,11,13,16,17,18,22,29

Pump develops too much pressure. 6,7,9,12,17,21,23

Pump no longer self-primes. 2,3,4,5,7,10,11,13,14,15,16,17,18,20,24,26

Pump won't turn/motor overloads. 5,6,7,12,15,17,19,21,24,26,27,29

Pump is very noisy/excessive vibrat ion. 1,2,3,5,6,7,10,11,13,14,18,20,21,26,27,28

Pump runs hot. 4,5,6,7,12,17,18,19,21,22,24,26,27,29

Pump seals short life. 1,2,3,4,5,6,7,9,10,11,12,13,17,18,19,20,21,22,23,24,26,27,28

Packing short life. 2,3,4,6,7,9,10,11,12,13,14,17,18,19,20,21,24,27,28

Excessive internal wear. 1,2,3,6,7,8,9,12,13,14,16,17,18,19,21,23,24,26,27,28

9.2 PROBABLE CAUSE AND REMEDY.

NPSHA not sufficient. 1

Air leaking into the pump. 3

Pump running too fast for application. 6

Abrasives in liquid. 7

Suctio n valve not open. 10

Suctio n valve partia lly open. 11

Supply vessel e mpty. 14

Pump rotation wrong. 15

Incorrect head placement. 16

Worn pump internals. 18

Inadequate lubrication. 21

Bad bearing (thrust). 26

20 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 27

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 10-1: VV40H & VV40HL Exploded View – Cast Iron

Table 10-1: Itemized Parts

01

LOCK NUT 17 PAC KING GL AND CAP SCREW 35 HEAD GASKET

02 LOC K WASHER 19

PAC KING RING/MEC HANICAL S EAL

36

ROTOR AND SHAFT

03 END CAP FOR BEARING HOUSING 20 RETAINING RING 37 IDLER AND BUSHING ASSEMBLY

04 BEARI NG SPACER C OLLAR 21 MECHANIC AL SEAL COLL AR 38 IDLER BUSHING

05 LIP SEAL 25 BRAC KET BUSHING 39 IDLER PIN

06 BAL L BEARI NG 27 BRAC KET AND B USHIN G 40 HEAD AND IDLER PIN ASSEMBLY

07 BEARING HOUSING 28 CAP SCREW FOR BRACKET 43 CAP SCREW FOR H EAD

12 GREAS E FITTING 29 BRAC KET GASK ET 45 REL IEF VALVE GASK ET

15 PAC KING GL AND 30 PIPE PLUG 46 CAP SCREW FOR VAL VE

16 NUT, SELF LOCKING 31 CASI NG 47 REL IEF VALVE

MODEL VV4 0H & HL INTERNAL GEAR PUMP

1

THROUGH

7

BEARI NG HOUSING ASSEMBL Y (COMPL ETE)

INCLUD ES BEARING HOUSING SET SCREW, INSERTS, END CAP SET SCREW

10 EXPLODED VIEWS

Use below figures and tables with respect to Section 11 DISASSEMBLY MODEL VV40 and Section 12

ASSEMBLY MODEL VV40

10.1 VV40H & VV40HL Cast Iron

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 21

Page 28

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

01 LOCK NUT 17 PAC KING GL AND CAP SCREW 36 ROTOR AND SHAFT

02 LOC K WASHER 19

PAC KING RING/MEC HANICAL S EAL

37 IDLER AND BUSHING ASSEMBLY

03 END CAP FOR BEARING HOUSING 20 RETAINING RING 38 IDLER BUSHING

04 BEARI NG SPACER C OLLAR 25 BRAC KET BUSHING 39 IDLER PIN

05 LIP SEAL 27 BRAC KET AND B USHING 40 HEAD AND IDLER PIN ASSEMBLY

06 BAL L BEARI NG 28 CAP SCREW FOR BRACKET 43 CAP SCREW FOR HEAD

07 BEARING HOUSING 29 BRACK ET GASKET 45 REL IEF VALVE GASK ET

12 GREAS E FITTING 30 PIPE PLUG 46 CAP SCREW FOR VALVE

15 PAC KING GL AND 31 CASING 47 RELIEF VAL VE

16 NUT, SELF LOCKING 35 HEAD GASKET

MODEL VV40H VV40HL INTERNAL GEAR PUMP

1

THROUGH

7

BEARI NG HOUSING ASSEMBL Y (COMPL ETE)

INCLUD ES BEARING HOUSING SET SCREW, INSERTS, END CAP SET SCREW

Figure 10-2: VV40H & VV40HL Exploded View - Stainless Steel

Table 10-2: Itemized Parts

10.2 VV40H & VV40HL Stainless Steel

22 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 29

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

01 LOCK NUT 19 COMP ONENT MECHANIC AL SEAL 36 ROTOR AND S HAFT

02 LOC K WASHER 25 BRACKET BUSHING 37 IDLER AND BUSHING ASSEMBLY

03 END CAP FOR BEARING HOUSING 26 PRESSURE RELIEF PLUG 38 IDLER BUSHING

04 BEARI NG SPACER C OLLAR 27 BRACKET AND B USHING 39 IDLER PIN

05 LIP SEAL 28 CAP SCREW 40 HEAD AND IDLER PIN ASSEMBLY

06 BAL L BEARI NG 29 BRACKET GASK ET 43 CAP SCREW FOR HEAD

07 BEARING HOUSING 30 PIPE PLUG 45 RELI EF VALVE G ASKET

12 GREAS E FITTING 31 CASING 46 CAP SCREW FOR VALVE

18 LI P SEAL (FOR CHAMBER) 35 H EAD GASK ET 47 RELI EF VALVE

BEHIND ROTOR SEAL : VV40H & VV40HL INTERNAL GEAR PUMP

1

THROUGH

7

BEARI NG HOUSING ASSEMBL Y (COMPL ETE)

INCLUD ES: BEARING HOUSING SET SCREW, INSERTS & END CAP SET SCREW

10.3 VV40H & VV40HL Cast Iron & Stainless Steel – Behind Rotor Mechanical Seal

Figure 10-3: VV40H & VV40HL Behind Rotor Seal

Table 10-3: Itemized Parts

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 23

Page 30

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 10-4: VV40L, LL, LQ, LS Exploded view Cast Iron and Stainless Steel. Note: VV40L in not

available in Stainless

Table 10-4: Itemized Parts

ITEM D ESCRIPTION ITEM D ES CRIPTION ITEM DESCRIPTION

01 LOC K NUT PACKI NG 36 ROTOR AND SHAFT

02 LOCK WASHER COMP ONENT MECHANICAL SEAL 37 IDLER AND BUSHING ASSEMBLY

03 END CAP FOR BEARING HOUSING 20 PAC KING RETAINING W ASHER 38 IDLER BUSHING

04 BEARI NG SPACER COL LAR (OUTER ) 21 MECHANIC AL SEAL COLL AR 39 IDLER PIN

05 LI P SEAL 22** SEAL HOLD ER 40 HEAD AND IDLER PIN ASSEMBLY

06 BEARI NG(S) 23** S EAL HOL DER PLATE 41* O-RING FOR J ACKET HEAD P LATE

07 BEARING HOUSING 25 BRAC KET BUSHING 42* J ACKET H EAD PL ATE

08 BEARING SPACER COLLAR (INNER) 27 BRAC KET AND B USHING 43 CAP SCREW FOR PL AIN OR VALVE TYP E HEAD

11 RING, HALF ROUND 28 CAP SCREW FOR BRACKET 45 REL IEF VALVE GASK ET

12 GREAS E FITTING 29 BRACKET GASKET 46 CAP SCREW FOR VALVE

15 PAC KING /MECHANICAL SEAL GL AND 30 PIPE PLUG 47 I NTERNAL RELIEF VAL VE

16 PAC KING /SEAL GL AND NUT SELF LOCK ING 31 CASING BEARING HOUSING ASSEMBLY

17 PAC KING /SEAL GL AND CAP SCREW 35 HEAD GASKET BEARING HOUSING SET SCREW

* NOT SHOWN INS ERTS

** NOT SHOWN; LS, Q AND QS SIZES ONLY END C AP SET SC REW

19

1

THROUGH

11

MODEL VV4 0 INTERN AL GEAR PUMP

10.4 VV40L, LL, LQ & LS Cast Iron & Stainless Steel

Note: Item 21 is not present with Stainless Steel externals

24 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 31

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11 DISASSEMBLY MODEL VV40

This section will cover sizes: H, HL, AK, AL, K, KK, L, LQ, LL, LS, Q, and QS. It must be noted that

although there are slight differences within these sizes, the disassembly and assembly procedures follow the

same progression. Use the following steps as a general guideline, as it is impractical to cover every situation.

Refer to Figure 10-1 and Table 10-1 on page 24 for part’s item number reference.

Notes:

• Sizes H though L, for cast iron externals, have a NPT suction and discharge port. Ductile iron, steel

and stainless steel externals may or may not have a NPT pipe connections. Although, this will not

affect disassembly or assembly of the pump, it will alter how piping will be connected and

disconnected.

• Sizes Q and QS have two tapered roller bearings (06). These sizes also utilize threaded studs and nuts

for piping connections, as well as head (40) to casing (31) connections. For Q and QS component

seals, item number (15) becomes items: seal holder (22) and seal holder plate (23). During assembly

or disassembly refer to item (15) as items (22) and (23).

• The casing on size QS will have suction and discharge ports 180 degrees apart from each other

versus 90 degrees on other sizes.

• Item 36, rotor and shaft (36) is one piece. This may be referenced as “shaft (36)”, “rotor (36)” or

“rotor and shaft (36)”.

DANGER

Lock out power to avoid personal injury or

death when working on packing.

DANGER

Properly vent any pressure in pump, fittings

and connecting lines.

WARNING

Understand material being pumped. Obtain

MSDS information for product. Take all

necessary precautions.

WARNING

Wear eye protection and proper personal

protective equipment.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 25

Page 32

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

NOTICE

Secure pump before disassembly to avoid

damage. Pump’s center of gravity changes

when removing parts.

11.1 HEAD AND CASING

1. Remove pipe plug (30) in lower section of bracket (27) to drain fluid from casing and piping.

2. Mark head (40) and casing (31) alignment using a permanent marker before disassembly. It is critical

to keep head (40) and casing (31) orientation the same for proper performance.

3. Remove cap screws (43), head (40) and, if equipped, internal relief valve (47) (Instructions for

internal relief valve disassembly refer to Section 11.5).Take care not to damage the head gasket (35)

and idler (37). When removing, tilt the head (40) away from the casing to avoid the idler (37) falling

off the idler pin (39), to avoid damaged.

If pump is jacketed, remove jacket head plate (42) and O-ring (41) at this point. Note: Items (42) and

(41) are not shown in Figure 10-1.

4. Remove idler and bushing assembly (37). Visually check for wear and damage, replace if needed. If

necessary, remove idler bushing (38) using a press. Refer to Section 12.1 on page 29 for more

bushing details.

5. Separate head gasket (35) from head (40) and set aside, replace if damaged or needed. Press out idler

pin (39) if needed.

11.2 BEARING HOUSING

1. Bend up the locking tang on the lock washer (02). To remove locknut (01) place a hard wood board

or a soft brass bar through the suction or discharge ports and into the teeth of the rotor (36). This will

keep the rotating components from moving. Using a spanner wrench turn the locknut (01) counterclockwise to remove and discard. Upon reassembly replace with new locknut (01)

2. Slide off lock washer (02) and discard. Upon reassembly replace with a new lock washer (02).

3. Remove set screws (Bearing Housing Set Screw) on bearing housing (07) flange and set aside.

Remove the bearing housing (07) assembly by rotating counter-clockwise (as viewed from the drive

end).

4. Remove set screws (End Cap Set Screws) and white inserts (Inserts) in the bearing housing (07)

flange. This will allow the end cap (03) to be removed. Rotate the end cap (03) counter-clockwise to

remove from the bearing housing (07).

26 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 33

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

NOTICE

Do not change positions of inner and outer

tapered roller bearing – for Q and QS sizes.

5. Remove outboard lip seal (05), outer bearing spacer collar (04), bearing (06), inboard lip seal (05),

inner bearing spacer collar (08) and half round ring (11). Check all components for wear or damage,

it is recommended to replace lip seals (05). Note: half round ring (11) is not present for H, HL, Q

and QS sizes.

11.3 REMOVING SEALS

1. Remove the packing/seal gland nuts (16) and packing/seal gland cap screw (17).

2. Slide the packing/mechanical seal gland (15) off the rotor and shaft (36) and place next to gland nuts

(16) and gland cap screw (17).

Continue to step three in sections 11.3.1 and 11.3.2 for packing or component mechanical seal

respectively.

11.3.1 Packing

3. Using a packing hook, remove the packing (19) from the stuffing box. Be careful not to damage

stuffing box bore. Refer to packing manufacturer for recommended hours of use before needing

replacement.

4. Remove packing retaining washer (20).

5. With a mirror, inspect the shaft (36) for wear. If worn, the shaft (36) will need to be replaced; see

Section 11.4 for rotor and shaft (36) removal. Note: Rotor and shaft (36) is one piece.

11.3.2 Component Mechanical Seal

3. Remove the mechanical seal (19) from the bracket (27) being careful not to damage the elastomers or

sealing faces.

4. To remove the mechanical seal collar (21), remove pipe plugs (30) from the bracket (27) located on

the stuffing box to access the set screws on the mechanical seal collar (21). Rotate the rotor and shaft

(36) to line up set screws with the pipe plug (30) hole opening. Use a hex-head wrench on the

mechanical seal collar’s (21) set screws and loosen all set screws.

5. It is a good idea to mark the shaft (36) where the mechanical seal collar (21) was originally set to

assist with reassembly. Slide the mechanical seal collar (21) off the rotor and shaft (36).

6. Inspect bracket (27), rotor and shaft (36) and mechanical seal (19) for damage or wear. If needed

replace parts.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 27

Page 34

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11.4 BRACKET AND CASING

1. Carefully slide out rotor and shaft (36) as not to damage the bracket bushing (25). Do not separate

rotor and shaft (36).

2. Remove cap screws (28) from the bracket (27). Support the weight of the casing (31) as not to

damage threads on cap screws (28) or the casing (31) when removing.

3. Remove bracket gasket (29), replace if damaged.

4. Remove bracket bushing (25), if needed, utilizing a press.

11.5 INTERNAL RELIEF VALVE

1. Mark the orientation of the internal relieve valve (47) with the head (40). Note the side with the

adjustment screw is always nearest the suction port. If installed improperly the valve will act as a

plug and will not bypass fluid when pressure limit is reached.

DANGER

Mark valve orientation. Improper installment

may result in equipment loss, serious injury

or death.

2. Remove cap screws (46) and pull off internal relief valve (47). Be careful as not to damage relief

valve gaskets (45).

28 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 35

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12 ASSEMBLY MODEL VV40

This section will cover sizes: H, HL, AK, AL, K, KK, L, LQ, LL, LS, Q, and QS. It must be noted that

although there are slight difference within these sizes the disassembly and assembly procedures follow the

same progression. Use the following steps as a general guideline as it is impractical to cover every situation.

It is vital during assembly to ensure cleanliness. Especially for bearings, mechanical seal, packing and lip

seals. Check all parts for damage, nicks and wear. Inspect all tapped holes; chase threads as needed. If

damage or wear is found, replace parts to avoid premature failure.

Notes:

• Sizes H though L, for cast iron externals, have a NPT suction and discharge port. Ductile iron, steel

and stainless steel externals may or may not have a NPT pipe connections. Although, this will not

affect disassembly or assembly of the pump, it will alter how piping will be connected and

disconnected.

• Sizes Q and QS have two roller bearings (06). These sizes also utilize threaded studs and nuts for

piping connections and head (40) to casing (31) connections. For Q and QS component seals, item

number (15) becomes items, seal holder (22) and seal holder plate (23). During assembly or

disassembly refer to item (15) as items (22) and (23).

• The casing on size QS will have suction and discharge ports 180 degrees apart from each other

versus 90 degrees on other sizes.

DANGER

Lock out power to avoid personal injury or

death.

NOTICE

Secure pump before assembly to avoid

damage. Pump’s center of gravity changes

when adding parts.

DANGER

Operation of any positive displacement

pump with a clogged discharge or closed

discharge valve generates a pressure

vessel. Ensure a safety valve is fitted

correctly in system.

12.1 BRACKET & IDLER BUSHINGS

The following steps are written in terms of the bracket bushing (25) and bracket (27). When installing the

idler bushing (38) with the idler (37), replace the verbiage: “bracket bushing (25)” with “idler bushing (38)”

and “bracket (27)” with “idler (38)”.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 29

Page 36

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

These steps are both written for bronze and carbon graphite bushings. Take extreme care with the carbon

graphite bushing, as they are very brittle and easily cracked.

12.1.1 Normal installation

1. Inspect bracket (27) for wear or damage and clean to avoid contamination of bearings and bracket

bushing (25).

2. Chamfer the leading edge of bracket bushing (25) and the bore entry on bracket (27), if not already.

This will assist with lining up both parts. Lubricate bracket bushing’s (25) outer diameter and

bracket’s (27) inner diameter.

3. Use a press to install bracket bushing (25). Ensure both parts are square to each other and if bracket

bushing (25) has a groove install bushing so that groove is in the 6-oclock position.

Once pressing, do not stop until bracket bushing (25) is located in the proper position; which is even

with the bracket’s (27) machined surface. Starting and stopping will crack the bracket bushing (25)

and cause premature failure.

4. Check for cracks in the bracket bushing (25). Any cracks will reduce bushing life and increase shaft

ware. It is recommended to remove and replace bushing if any cracks are detected.

12.1.2 Heated installation

CAUTION

Wear proper personal protective equipment

to avoid burns from hot parts.

This is the recommended installation process for the carbon graphite bushing. Since the carbon graphite

bushing is very brittle, there is less risk of cracking in this process.

1. Inspect bracket (27) for wear or damage and clean to avoid contamination of bearing and bracket

bushing (25).

2. Slowly and thoroughly heat bracket (27) in the bracket bushing (25) installation location. The lower

the bracket (27) temperature the higher the risk of cracking the bushing.

3. Use a press to install a cool bracket bushing (25). Ensure both parts are square to each other and if

bracket bushing (25) has a groove install bushing so that groove is in the 6-oclock position.

Once pressing, do not stop until bracket bushing (25) is located in the proper position; which is even

with the bracket’s (27) machined surface. Starting and stopping will crack the bracket bushing (25)

and cause premature failure.

4. Check for cracks in the bracket bushing (25). Any cracks will reduce bushing life and increase shaft

ware. It is recommended to remove and replace bushing if any cracks are detected.

30 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 37

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Bronze

Iron

Stainless

Steel

All

VV40H

VV40HL

600 375 450

VV40K

VV40KK

575 350 450

VV40L

VV40LQ

VV40LL

525 350 450

VV40LS

540 345 450

VV40Q

VV40QS

400 270 450

Bushing Material

Carbon Graphite

Pump Material

Temperature (°F)

Pump

Size

Table 12-1: Fluid temperature limits for bushings.

12.1.3 Bushing Temperature Limits

Table 12-1 shows fluid temperature limits for Bronze and Carbon Graphite bushings when installed in

corresponding idler materials for different pump sizes.

The carbon graphic temperature limits are based on thermal expansion rates and the requirement of an

interference fit. The temperature limit with the bronze bushing is a limit of the bronze material and not an

interference fit issue.

12.2 BRACKET AND CASING

1. Install new bracket gasket (29), hold in place by conservatively applying compatible light grease or

oil.

2. Attach casing (31) and orientate casing in desired configuration as shown in Figure 6-4 on page 11.

3. Support casing (31) while attaching cap screws (28) and hand tighten. Sequence tighten cap screws

(28) and tighten per bolt torque in Table 13-1 in Section 13.1.

4. Clean shaft and rotor (36). Closely inspect for wear or damage paying particular attention to the

bearing journal.

5. Carefully slide shaft and rotor (36) though bracket bushing (25) as not to damage the bracket bushing

(25). Slide shaft and rotor (36) until rotor mates with the bracket (27).

12.3 INSTALLING SEALS

There are three primary ways to seal the VV40 pumps; packing (standard), component mechanical seal or

cartridge mechanical seal. For third party mechanical seal assembly and disassembly, refer to seal

manufacturer’s installation and operation manual.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 31

Page 38

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Model

and Size

VV40H

VV40HL

VV40AK

VV40AL

VV40K

VV40KK

VV40L

VV40LQ

VV40LL

VV40L

VV40LQ

VV40LL

"E"

si z e d

shaft

(1 5/8")

VV40LS

VV40Q

VV40QS

Number of

Rings

5 6 6

7 7

Pa cking

Size

7/16" 7/16" 3/8"

3/8" 1/2"

Table 12-2: Packing sizes and number of rings

12.3.1 Packing

1. Inspect the stuffing box for debris or damage. If needed, replace the bracket (27). Clean bracket (27)

and shaft (36) thoroughly to avoid any sealing issues.

2. Choose packing carefully, depending on pumped fluid. Follow all packing manufacturer’s

instructions.

3. Prepare packing rings by wrapping the packing around a mandrel which has the same diameter as the

shaft (36). The number of wraps should equal the number of rings needed for the particular pump as

shown in Table 12-1. Cut packing at a 45 degree or 90 degree angle.

4. Install packing retaining washer (20) into the stuffing box, followed by packing (19) rings. Install one

ring at a time ensuring a square fit. If desired, lubricate packing (19) and shaft (36) conservatively

with compatible grease. When adding packing (19) rings, allow ring joints to be kept at least 90

degrees apart from adjacent ring joints.

5. When final packing (19) ring is installed, slide packing/seal gland cap screw (17) into bracket (27).

6. Install the packing/mechanical seal gland (15) and secure using the packing/seal gland nut (16) finger

tight. More adjustments will be needed during operation to achieve desired drip rate.

For Q and QS sizes, do not tighten packing/mechanical seal gland nuts (16) until after the cap screw

(03) has been installed and properly tightened per instructions in Section 12.4 step 8. If gland nuts

(16) are tight it will make it difficult to rotate shaft by hand.

12.3.2 Component Mechanical Seal

The component mechanical seal is a type 1 or type 9 mechanical seal. It is an alternative to packing or a

cartridge seal.

1. Inspect the stuffing box for debris or damage. Clean bracket (27) and shaft (36) thoroughly to avoid

any sealing issues, if needed, replace parts. It is recommended that component seals be replaced each

time pump is rebuilt.

2. Remove pipe plugs (30) from the bracket (27) located on the stuffing box. These are the access ports

32 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

to lock down the mechanical seal collar (21) to the shaft (36).

Page 39

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3. Install the mechanical seal collar (21) over the shaft (31) and into the stuffing box. Line up the

locking set screws in the mechanical seal collar (21) with the previous marks on the shaft (36) or

marked location created during disassembly. If no marks are visible, approximate the mechanical seal

collar (21) set distance.

4. Tighten the set screw in the mechanical seal collar (21) with a hex wrench via pipe plug ports located

on the stuffing box. Rotate the shaft to access the set screws in the mechanical seal collar (21).

5. Coat the shaft (36), tapered installation sleeve, and mating parts of the component mechanical seal

(19) with a generous amount of compatible lubricant; grease is not recommended.

6. Slide the component mechanical seal (19) over the shaft and tapered installation sleeve into the

stuffing box until set against the mechanical seal collar (21). Be careful not to bump the threads on

the shaft (36) potentially damaging the elastomers on the component mechanical seal (19). If holding

clips are present to hold spring in place, remove clips to free spring after seal is installed.

7. Remove the tapered installation sleeve and replace pipe plugs (30) from bracket (27) located on the

stuffing box.

8. Install the packing/mechanical seal gland (15) and secure using packing/seal gland nut (16) finger

tight.

For Q and QS sizes, do not tighten packing/mechanical seal gland nuts (16) until after the cap screw

(03) has been installed and properly tightened per instructions in Section 1 step 8. If gland nuts (16)

are tight it will make it difficult to rotate shaft by hand.

12.4 BEARING HOUSING

This section will cover the assembly of parts with item numbers 01 to 11. Carefully examine all parts for

wear or damage and replace when needed. Replace locknut (01), lock washer (02) and lip seals (05) with

new parts.

1. Slide on half round rings (11) on to shaft (36) to shoulder with radial groove. Hold half round rings

(11) in place with one hand. Note: sizes H, HL, Q and QS do not have half round rings (11).

2. Orientate inner bearing spacer collar (08) with the other hand so that the recessed end is facing the

casing (31). Slide inner bearing spacer collar (08) over the shaft and mate with half round rings (11).

Note: sizes H, HL, Q and QS inner bearing spacer collar (08) will not have recessed end.

3. Install lip seal (05) into the bearing housing (07). Position lip seal (05) with sealing lip facing the

drive end (spring side open to the drive end). Slide lip seal (05) into the bearing housing (07) until

the lip seal (05) rests against the deepest shoulder.

4. Position the bearing housing (07) over the shaft and thread in the bearing housing (07) to the bracket

(27). Be careful as not to damage the lip seal (05) on the threads for the locknut (01).

5. Pack the ball bearing (06) with acceptable grease. Acceptable grease is stated in Section 7.2.3 on

page 15. Position the bearing (06) over the shaft and push or press into the bearing housing (07).

Q and QS have two bearings and they are tapered roller bearings (06), orientation does matter for

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 33

Page 40

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

installation. Large end of inner raceways must mate together letting the rollers angle away from each

other.

6. Slide the outer bearing spacer collar (04) over the drive end side of the shaft (36) and mate it with the

bearing (06).

7. Install lip seal (05) in the end cap (03) with sealing lip facing the drive end when end cap (03) is

installed (spring should be open to the drive end side after installation of end cap (03)).

8. Thread the end cap (03) into the bearing housing (07) and tighten with a spanner wrench against the

bearing (06). Insert inserts and end cap set screws to lock the end cap (03) in place.

Q and QS sizes have tapered roller bearings and preload must be set for proper operation. Preload is

set by turning the end cap (03) in or out of the bearing housing (07).

a. Thread in end cap (03) until it lightly touches the bearing (06).

b. Turn the shaft (36) by hand to reference the amount of resistance while rotating.

c. Thread in the end cap (03) with a spanner wrench until the shaft (36) is no longer able to turn

by hand.

d. Back out the end cap (03) until the shaft (36) is able to turn again with slight but noticeable

resistance.

9. Place lock washer (02) and locknut (01) over the shaft. Tighten locknut to corresponding values in

Table 13-2 on page 40. Once locknut (01) is properly torqued, bend down tang on lock washer (02)

to prevent locknut (01) from rotating.

Install bearing housing set screws after adjusting the end clearance.

12.5 HEAD AND CASING

1. Press idler pin (39) into the head (40). If idler pin (39) is lube type, ensure the end with the threaded

hole is facing outward away from the casing (31).

2. Fit a new head gasket (35) onto the head (40). Add a small amount of grease or oil to keep head

gasket (35) in place.

3. Slide idler and bushing assembly (37) over idler pin (39). If idler bushing (38) is not installed in idler

(37) refer to Section 12.1 BRACKET & IDLER BUSHINGS on page 29 for installation of idler

bushing (38).

4. Identify orientation marks that were made during disassembly in Section 11.1 on page 26. It is

critical to get head (40) orientation correct for proper pump performance. As rule-of-thumb, the

crescent shape on the head (40) should be about 135 degrees away from discharge and suction ports.

5. Once head (40) is in the correct orientation, mate head (40) with the casing (31) lining up the cap

screw (43) holes. Hold head (40) in place and hand tighten cap screws (43). Torque the cap screws

(43) in proper sequence to torque values shown in Table 13-1 on page 40.

34 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 41

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 12-1: Dimension CL defined

Figure 12-2: Dimension AC defined

If pump is jacketed, install jacket head plate (42) and O-ring (41) at this point using cap screws (43).

Note: Items (42) and (41) are not shown in Figure 10-1.

12.6 ADJUSTING END CLEARANCE

12.6.1 Measured Rotation Method

Standard end clearance is set at the factory. End clearance

adjustment is needed to provide proper pump performance

and spacing between the rotor (36), idler (37) and head (40).

End clearance is adjusted by rotating the bearing housing

(07) clockwise or counter clockwise. Clockwise to make

tighter clearances and counter clockwise to open clearances.

The following steps explain the process of setting the correct

end clearance.

1. Loosen bearing housing set

screws, if installed, on the

flange of the bearing housing

(07).

2. Rotate bearing housing (07)

clockwise by hand until it

can no longer be turned.

Ensure rotor and shaft (36)

cannot be rotated by hand.

3. Rotate bearing housing (07)

counter clockwise until shaft

(36) can be turned with only

a slight noticeable drag. This will be the “zero” setting.

4. Table 12-3 shows the standard end clearances for available VV40 models. To set end clearance,

rotate bearing housing (07) counter-clockwise as indicated by arc length “AC” in Table 12-2.

5. After setting end clearance, replace bearing housing set screws to lock bearing housing (07) in place

during operation.

6. It may be necessary to add extra end clearance for higher viscosity fluids. Contact your local Summit

Pump, Inc. Distributor for specifications.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 35

Page 42

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Table 12-3: End clearances, arc lengths and arc lengths per 0.001” of

end clearance.

Standard End

Clearance

(in)

Distance on OD of

Bracket for

Standard End

Clearance

(in)

Distance on Bracket OD

for 0.001" End

Clearance

(in)

CL

AC AC for CL=0.001"

(C) Cast Iron,

(D) Ductile Iron,

(W) Steel

0.003 0.750 0.25

(S) Stainless

Steel

0.005 1.125 0.23

(C) Cast Iron,

(D) Ductile Iron,

(W) Steel

0.005 1.250 0.25

(S) Stainless

Steel

0.008

2.000 0.25

(C) Cast Iron,

(D) Ductile Iron,

(W) Steel

0.005

1.250 0.25

(S) Stainless

Steel

(C) Cast Iron w/

"E" sized shaft

(1 5/8")

0.010 2.500 0.25

(C) Cast Iron,

(D) Ductile Iron,

(W) Steel,

(S) Stainless Steel

0.010 3.100 0.31

(C) Cast Iron w/

"E" sized shaft

(1 5/8")

0.015 4.650 0.31

VV40H

VV40HL

VV40AK

VV40AL

VV40K

VV40KK

VV40L

VV40LQ

VV40LL

VV40LS

VV40Q

VV40QS

Dimens ion

Model

and Size

Material

12.6.2 Dial Indicator Method

The dial indicator method

measures the distance the shaft

moves from the “zero” point to the

set clearance distance (CL), shown

in Table 12-2 on page 15. To set

the end clearance using a dial

indicator follow the procedure

below.

1. Loosen bearing housing set

screws, if installed, on the flange of

the bearing housing (07).

2. Rotate bearing housing (07)

clockwise by hand until it can no

longer be turned. Ensure rotor and

shaft (36) cannot be rotated by

hand.

3. Rotate bearing housing (07)

counter clockwise until shaft (36)

can be turned with only a slight

noticeable drag. This will be the

“zero” setting.

4. Secure the dial indicator to

either the pump’s base plate or

bracket (27). Position the probe on the end of the shaft as shown in Figure 12-3.

5. Refer to Table 12-2 on page 36 to determine the standard end clearances (CL) for corresponding size

and material.

6. Set the indicator to “zero”.

7. Turn the bearing housing (07) counter-clockwise, as viewed from the drive end, until the dial

indicator reads the desired end clearance (CL).

8. After setting the end clearance, replace bearing housing set screws to lock bearing housing (07) in

place during operation.

9. It may be necessary to add extra end clearance for higher viscosity fluids. Contact your local Summit

Pump, Inc. Distributor for specifications.

36 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 43

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 12-3: Dial Indicator Position

NOTICE

End clearance must be set for proper

performance. Incorrect settings could

damage pump internals.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 37

Page 44

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12.7 INTERNAL RELIEF VALVE

There are two sets of instructions for internal relief valve (47) assembly. One is to adjust the pressure setting

of the valve and the other is attaching the internal relief valve (47) to the head (40).

If pump is not equipped with an internal relief valve, there must be other means of system pressure release.

All positive displacement pumps operate at the pressure required of the system with a constant flow rate. If

there is a clog or closed valve in the system, the pump will keep building pressure until a way of pressure

release is found.

WARNING

Install pressure relief outlet. Negligent acts

may result in equipment loss, serious injury

or death.

12.7.1 Mounting valve on head

It is critical to mount the internal relief valve (47) in the correct orientation on the head (40). Align marks

created in Section 11.5 on page 28. If installed incorrectly the valve will not work properly. The system will

exceed valve set pressure setting, causing damage to equipment, serious injury or death.

WARNING

Align alignment marks for valve orientation.

Improper installment may result in

equipment loss, serious injury or death.

If no alignment marks have been made, the adjusting screw of the internal relief valve (47) should always be

closest to the suction port. See Figure 6-4 on page 11 for illustration.

1. Inspect internal relief valve (47) for damage or debris. Check mating parts for damage, replace if

needed.

2. Place relief valve gaskets (45) on internal relief valve (47) flanges. Applying a light coating of grease

or oil may be necessary to hold relief valve gaskets (45) in place.

3. Position internal relief valve on head in correct configuration as determined by alignment marks or as

shown in Figure 6-4 on page 11.

4. Secure internal relief valve (47) using cap screws (46) and tighten by hand. Torque cap screws (46)

in a tightening sequence to torque values shown in Table 13-1 on page 40.

12.7.2 Setting pressure

The internal pressure relief valve (47) pressure setting is set at the factory to a standard 100 psi when the

valve is fully open. Relief valve pressures are only set differently if stated on customer’s purchase order.

38 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 45

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Figure 12-4: Internal relief valve (47) effects on system flow when differential pressure approaches

internal relief valve (47) set pressure.

The valve will begin to open at a lower pressure than the pressure setting; this is called the “cracking

pressure”. A percentage of pump capacity will be lost from the discharge line once the cracking pressure is

reached.

For example, the internal relief valve (47) is set to 150 psi. Observe the differential pressure (between

suction and discharge) and the system flow meter while slowly closing a valve beyond the discharge pressure

gauge. Figure 12-4 shows the pressure and flow rate relationship when increasing the pressure in the piping

system (i.e. closing the discharge valve).

Note: Figure 12-4 shows a general relationship and not actual tested data.

SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP 39

Page 46

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Size Max. Torque Size Max. Torque

10-24 22 inlb 5/16-18 10 ftlb

1/4-20 75 inlb 3/8-16 20 ftlb

5/16-18 132 inlb 1/2-13 43 ftlb

3/8-16 236 inlb 5/8-11 86 ftlb

1/2-13 517 inlb 3/4-10 150 ftlb

Stainless Steel Bolts

Carbon Steel Bolts

Table 13-1: General bolt torque values

Model

and Size

Torque

(ft-lbs)

Locknut

Size

Lock

Washer

Size

VV40H

VV40HL

50-70 #N-05 #W-05

VV40AK

VV40AL

VV40K

VV40KK

VV40L

VV40LQ

VV40LL

100-130 #N-07 #W-07

VV40LS

120-150 #N-08 #W-08

VV40Q

VV40QS

170-190 #N-11 #TW-111

Table 13-2: VV40 Locknut torque values

13 APPENDIX E – Reference Tables

13.1 TORQUE GUIDELINES

13.1.1 Bolt Torques

13.1.2 Locknut Torques

40 SUMMIT PUMP MODEL VV40 INTERNAL GEAR PUMP

Page 47

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

14 PUMP INFORMATION

Purchase Date: _____________________

Purchase Order#: ___________________

Serial Number: _____________________

Equipment Number: _________________

PO Box 12145 Green Bay, WI 54307

www.summitpump.com

Rev. 09/2018