Summit SBC635MWKD Maintance Manual

Felix Storch, Inc.

An ISO 9001:2015 registered company

770 Garrison Avenue

Bronx, NY 10474

www.summitappliance.com

BEFORE USE, PLEASE READ AND FOLLOW ALL SAFETY RULES AND

OPERATING INSTRUCTIONS.

Keep proof of original sales date (such as your sales slip) with this manual to

establish the warranty period.

Write the Serial Number below. You‟ll find it on a plate located either on the back

of the appliance or on an interior wall.

AVANT UTILISATION, S'IL VOUS PLAÎT LIRE ET SUIVRE LES RÈGLES DE

SÉCURITÉ ET INSTRUCTIONS D'UTILISATION.

Conserver une preuve de la date d'achat d'origine (comme votre ticket de

caisse) avec ce manuel pour établir la période de garantie.

Écrire numéro de série ici. Vous le trouverez sur une plaque située soit sur

l‟arrière de l'appareil ou sur un mur intérieur.

__________________________________________________

WINE KEG DISPENSER

DISTRIBUTEUR de FÛT de VIN

Model / Modèle SBC635MWKD

Use and Care Guide

Mode d‟emploi

1

TABLE OF CONTENTS

Important Safeguards .................................................................................. 2 – 3

Location of Parts ................................................................................................ 4

Before Using for the First Time ........................................................................ 4

Placement and Installation ........................................................................... 5 - 6

Choosing the right place ........................................................................... 5

Installation ................................................................................................. 5

Applications ................................................................ ............................... 5

Connecting to power supply ...................................................................... 5

Reversing the door swing .......................................................................... 6

Wine Keg Dispenser Flow and Parts ................................................................ 7

Wine Keg Dispenser Assembly ................................................................ 8 – 10

Caster Assembly ................................ ........................................................ 8

Guardrail Installation .................................................................................. 8

Wine Tap Installation ................................................................................ 8

Gas Regulator Installation ......................................................................... 9

Gas Regulator & Tap Connection Examples ........................................... 10

How to Tap a Wine Keg ................................................................................... 11

Operation .................................................................................................. 12 – 13

Using Your Wine Keg Dispenser ............................................................. 12

Control Panel .......................................................................................... 12

Temperature Control ............................................................................... 12

Switching Between Celsius and Fahrenheit ............................................ 12

„Rapid Cooling‟ Function .................................................................. 12 - 13

Automatic Defrosting ............................................................................... 13

Error Prompts .......................................................................................... 13

Normal Functioning ................................................................................. 13

Maintenance of the Wine Keg Dispenser ................................................ 14 - 15

Cleaning .................................................................................................. 14

Storing Your Wine Keg Dispenser ........................................................... 14

Transporting the unit ............................................................................... 14

Disposing of a Worn-Out Unit .................................................................. 15

Accessories ...................................................................................................... 16

Troubleshooting ............................................................................................... 17

Limited Warranty .............................................................................................. 18

French version of this manual ................................................................. 19 - 39

2

IMPORTANT SAFEGUARDS

WARNING!

To reduce the risk of fire, electric shock or injury when using this appliance,

follow these basic precautions:

1. Read all instructions before using the appliance.

2. The appliance must be correctly connected to the power supply.

3. Immediately replace worn power cords, loose plugs and faulty power outlets.

4. Do not operate your appliance in the presence of explosive fumes.

5. Disconnect the appliance from the power supply before cleaning or repairing it. Only

a qualified technician should repair it.

6. Never stand on top of or inside this appliance or swing on the door. Avoid putting

weight on top of the appliance.

7. To reduce likelihood of injury, do not let children play with this appliance.

8. Do not operate the valve control unless the cylinder is completely installed and

connected.

9. Do not attempt to repair or replace any part unless this is recommended in this Use

and Care Guide. Leave other service matters to qualified technical personnel.

10. Keep packing materials away from children as they could become a choking hazard.

11. Do not spray or flush the wine keg dispenser with water, and avoid keeping it in a

damp place since this could damage the electrical insulation.

12. This unit is intended for UPRIGHT, FREE-STANDING USE ONLY. Do not install in

a cabinet or enclosed spaces. Do not use under a bar or counter.

DANGER! Risk of child entrapment!

Child entrapment and suffocation are not problems of the past. Junked or

abandoned appliances are still dangerous, even if they will "just sit at the curb for

a few days."

Before discarding your old appliance:

Take off the door.

Leave the shelves in place so that children may not easily climb inside.

This appliance is CFC- and HFC-free and contains small quantities of Isobutane

(R600a) which is environmentally friendly, but flammable. It does not damage the

ozone layer, nor does it increase the greenhouse effect. Care must be taken during

transportation and setting up of the appliance that no parts of the cooling system are

damaged. Leaking coolant can ignite and may damage the eyes.

In the event of any damage:

- Avoid open flames and anything that creates a spark,

- Disconnect from the electrical power line,

- Air the room in which the appliance is located for several minutes, and

- Contact the Service Department for advice.

The more coolant there is in an appliance, the larger the room it should be installed

in. In the event of a leakage, if the appliance is in a small room, there is the danger of

combustible gases building up. For every ounce of coolant at least 325 cubic feet of

room space is required. The amount of coolant in the appliance is stated on the data

plate on the back of the appliance. It is hazardous for anyone other than an

Authorized Service Person to carry out servicing or repairs to this appliance.

3

Take serious care when handling, moving, and using the appliance to avoid either

damaging the refrigerant tubing or increasing the risk of a leak.

Replacing component parts and servicing shall be done by factory authorized service

personnel so as to minimize the risk of possible ignition due to incorrect parts or

improper service.

SAFETY PRECAUTIONS REGARDING ELECTRICAL MATTERS

1. Do not pull on the power cord when unplugging the machine. Grasp the plug firmly

and pull it straight out of the socket. Do not pull the plug with wet hands.

2. Keep the power cord at the back of the appliance to avoid tripping accidents or

damage to the cord.

3. If the power cord is damaged or frayed, it must be replaced by a qualified service

professional.

4. Use only a standard three-hole grounded power socket rated above 10A. The socket

should not be shared with other appliances.

5. Be sure the plug fits firmly into the socket and that the socket is grounded.

6. The use of an extension cord is NOT recommended.

7. The wine dispenser requires an AC power supply of 110~120V/60Hz. The fuse or

circuit breaker should be rated at 15A.

8. If the leakage of a combustible gas is detected, turn off the gas valve and open the

doors and windows. To reduce the risk of fire caused by a spark, do not pull out the

plug of the wine dispenser or of any other electrical device.

SAFETY PRECAUTIONS, WARNINGS & DANGER NOTICES:

NITROGEN/CARBON DIOXIDE

Use a blend of 75% nitrogen (N2) and 25% carbon dioxide (CO2) to pressurize your wine

dispenser. This blend of gases is readily available.

1. DANGER! Pressurized gas is potentially dangerous. Canisters or cylinders are

under high pressure and proper handling is essential for safety. Familiarize yourself

with canister installation and replacement before operating this unit. HANDLE WITH

CARE. Never jostle, toss or treat cylinders roughly.

2. INTENDED FOR UPRIGHT, FREE-STANDING USE ONLY. Do not install in cabinet

or enclosed spaces.

3. Store gas cylinders away from heat or explosive gases. Keep in a cool, dry space

(lower than 70°F) and chain canisters upright to avoid tipping or knocking. Always

wear gloves and safety glasses when around chemicals.

4. Review and follow instructions for changing cylinders. To avoid a potential explosion

that could result in grave injury or even death, NEVER CONNECT A GAS

CANISTER DIRECTLY TO THE UNIT. ALWAYS CONNECT THE CANISTER TO

THE GAS REGULATOR. There are two safety valves, located separately. One is in

the regulator and one on the gas canister. DO NOT REMOVE VALVES, AND DO

NOT EXCEED 60 PSI.

5. DO NOT ATTEMPT TO REFILL GAS CANISTERS! Refills are available where most

canisters are sold (see page 9 for more information).

6. DO NOT USE PURE CARBON DIOXIDE (CO

WILL AFFECT THE TASTE OF THE WINE.

) TO PRESSURIZE THIS UNIT – IT

2

– SAVE THESE INSTRUCTIONS –

4

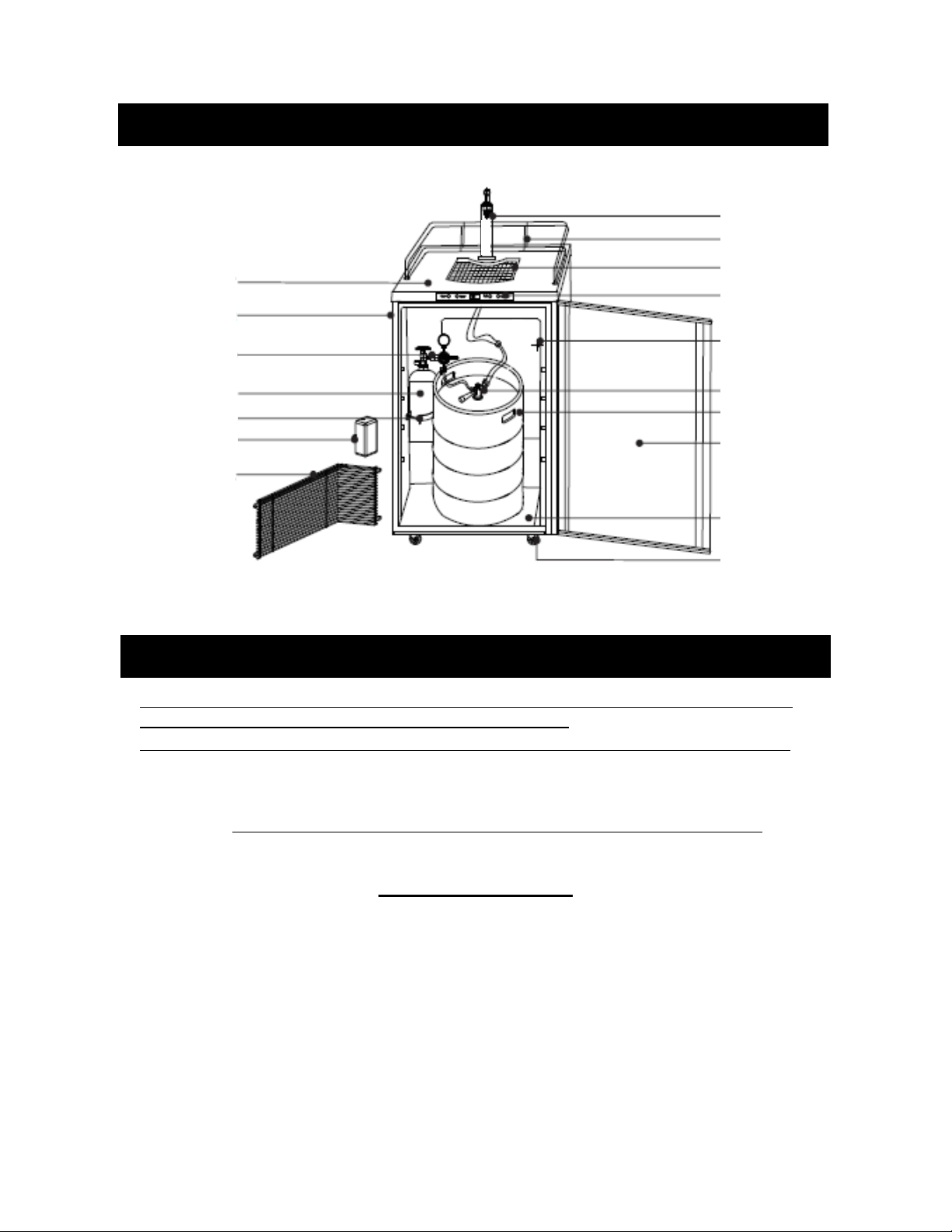

LOCATION OF PARTS

Wine tower assembly

Upper cover guardrail

Drip tray

Display and control

panel

Evaporator

Ball valve

Wine keg

Door

Bottom pad

Caster

Top cover

Cabinet

Gas regulator valve

N2/CO2 gas cylinder

N2/CO2 tank supporter

Control board device

Compressor

chamber cover

BEFORE USING FOR THE FIRST TIME

The SBC635MWKD is designed for dispensing wine only, and is not recommended for

storing perishable foods such as meats or dairy products.

Before connecting the appliance to the power supply, leave it standing for 2 to 3 hours.

This allows the refrigerant to drain back into the compressor and reduces the risk of

malfunctions in the cooling system caused by shipping.

Clean the appliance thoroughly, especially the interior. (See Maintenance of the Wine

Dispenser.) Proper grounding must be ensured to reduce the risk of shock and fire. Do

not cut or remove the grounding plug!

Tips for Saving Energy

Try not to open the door too often, especially when the weather is hot and humid. Once

you open the door, try to close it as soon as possible.

If possible, disconnect the power before changing a keg of wine.

Keep the unit out of direct sunlight.

Periodically, check that the wine dispenser seals well and that none of the contents

prevent the door from closing.

5

PLACEMENT AND INSTALLATION

Choosing the Right Place

To ensure that your wine dispenser works at the maximum efficiency it was designed for,

install it in a location where there are proper air circulation and electrical connections.

Choose a location where the wine dispenser will be away from any heat sources and will

not be exposed to direct sunlight.

Remove all packing materials before using the wine dispenser.

Place the machine on a smooth, flat and sturdy surface.

Installation

Your appliance is not designed to operate in enclosed spaces. When placing your unit,

make sure you allow at least 4” of clearance at the sides, rear and top to allow for

adequate airflow.

Applications

The SBC635MWKD wine keg dispenser meets UL Standard 250 and is suitable for

residential use.

Connecting to Power Supply

Connect this appliance to a 3-prong power supply socket (which has a ground terminal).

If you only have a two-prong outlet, have it replaced by a qualified technician with an

outlet that meets the local codes.

DO NOT USE AN EXTENSION CORD

Required nominal voltage and frequency are indicated on the rating plate. The

connection to the power supply and grounding has to be made according to current

standards and regulations. The appliance resists temporary voltage fluctuations with a

tolerance of 10%.

Once connected, allow the appliance to operate empty for two to three hours before

putting a wine keg inside.

6

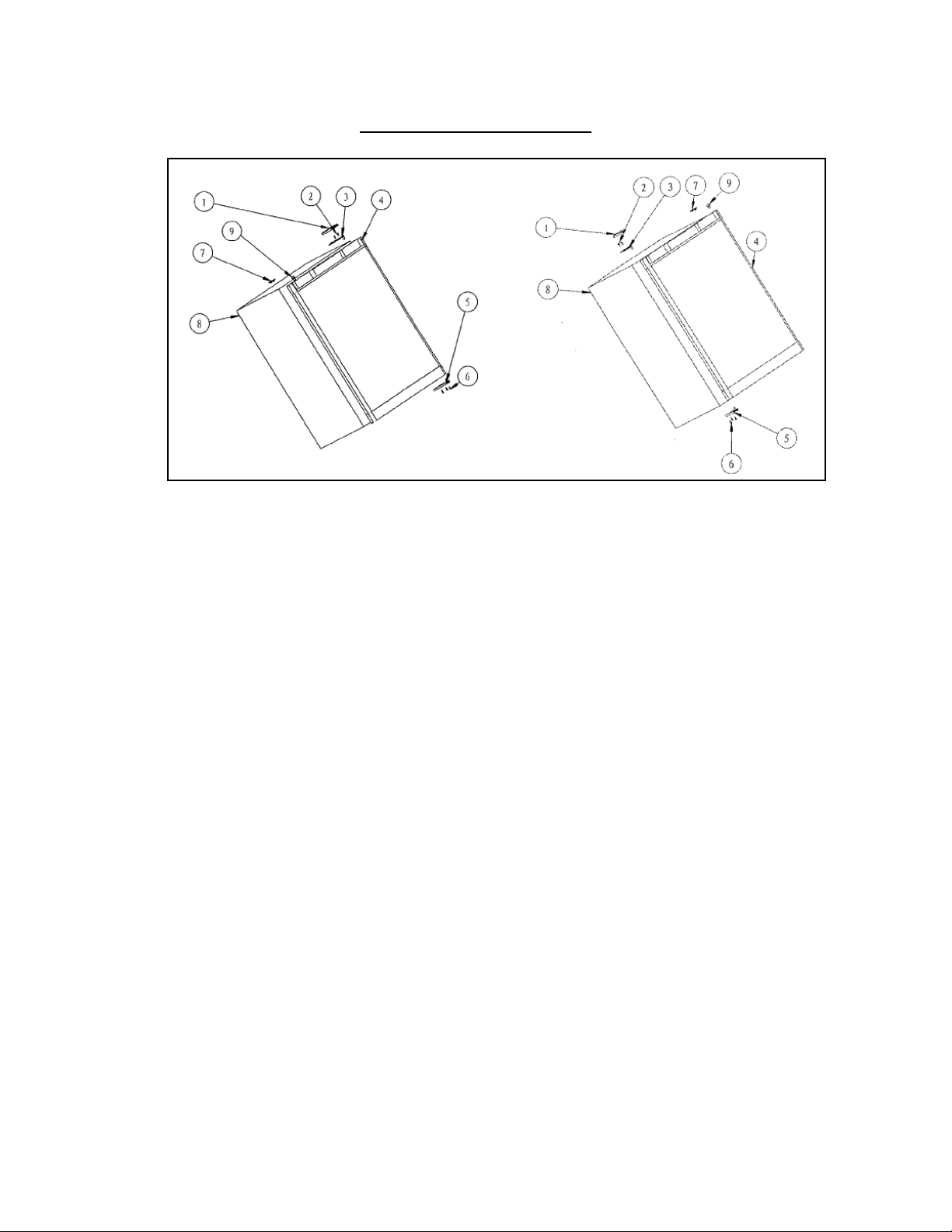

Reversing the Door Swing

Figure 1 (Default position) Figure 2 (After door reversal)

1. Upper hinge cover 6. Screws

2. Screws 7. Hole cover

3. Upper hinge 8. Cabinet

4. Door 9. Pin cap

5. Lower door hinge

The wine dispenser can be opened from either the right side or the left. By default, the

door hinge is on the right side. If you prefer it on the left, please follow these instructions:

Note: All of the parts that are removed must be kept for the reinstallation of the door.

1. Remove the three screws (6) holding lower door hinge (5). Keep hinge for later use.

2. Remove the door from the upper hinge (3), and keep the padded surface upward to

prevent scratching.

3. Remove the upper hinge cover (1), remove the two screws (2), remove the upper

hinge (3) and keep it for later use.

4. Remove the hole cover (7) and transfer it to the same location on the opposite side.

5. Insert the lower door hinge (5) into the left side, fixing the hinge into place by

tightening all the screws (6).

6. Remove the pin cap (9) from the left side of the upper door frame and then transfer it

to the same location on the opposite side.

7. Set the door on the lower door hinge (5), keep the door level, then fix the upper hinge

(3) to the body (8) by the screws (2).

8. Put on the upper hinge cover (1).

7

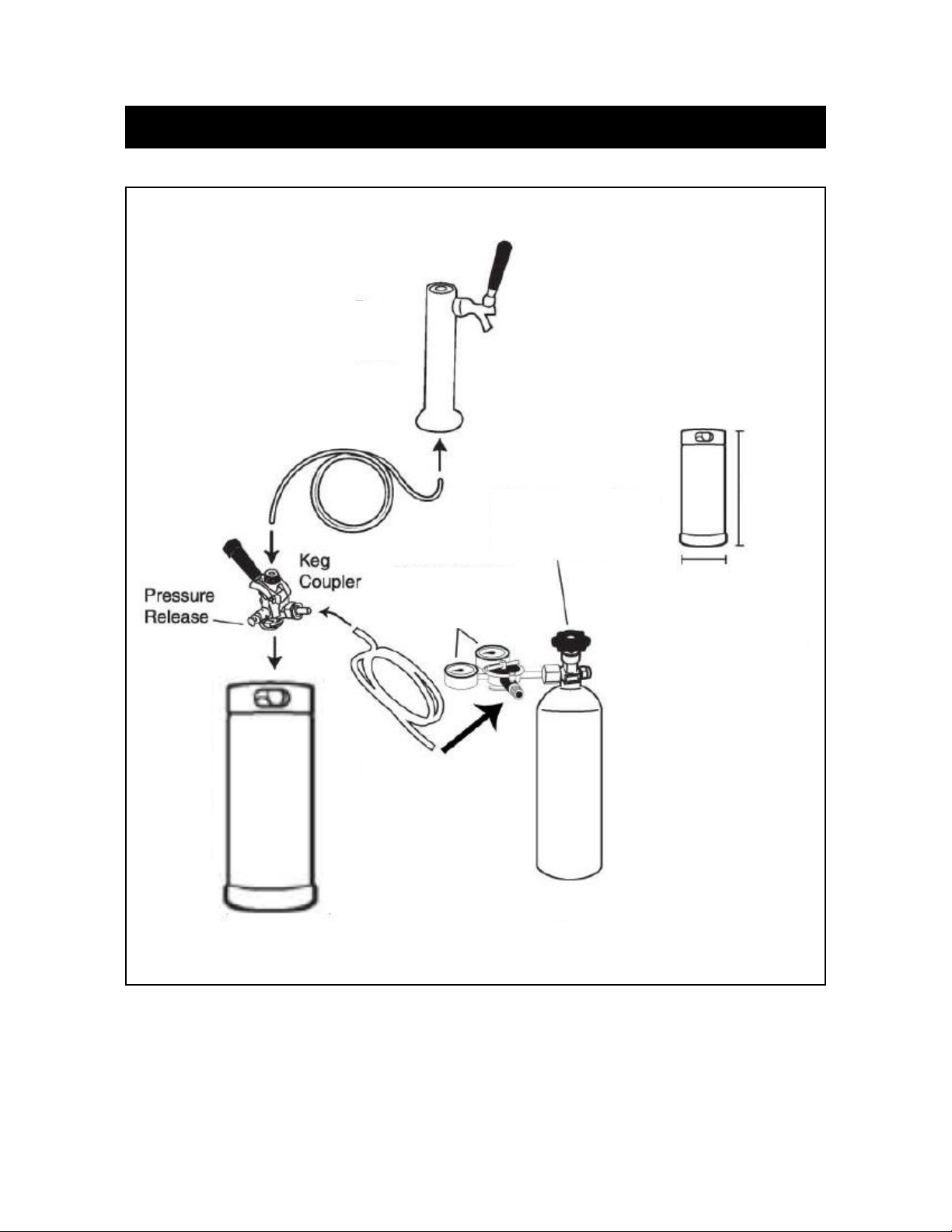

WINE KEG DISPENSER FLOW AND PARTS

Wine

Dispenser

Tower

Wine Line

(NSF-certified

Barrier Tubing)

High-Pressure Valve

Gas Canister

Shut Off Safely

Double Gauge

Gas Regulator

Low Pressure Valve

Gas Line

Gas Tank

1/6 Barrel Wine Keg

(Not Included)

23⅜”

9¼”

Wine Keg

Dimensions

8

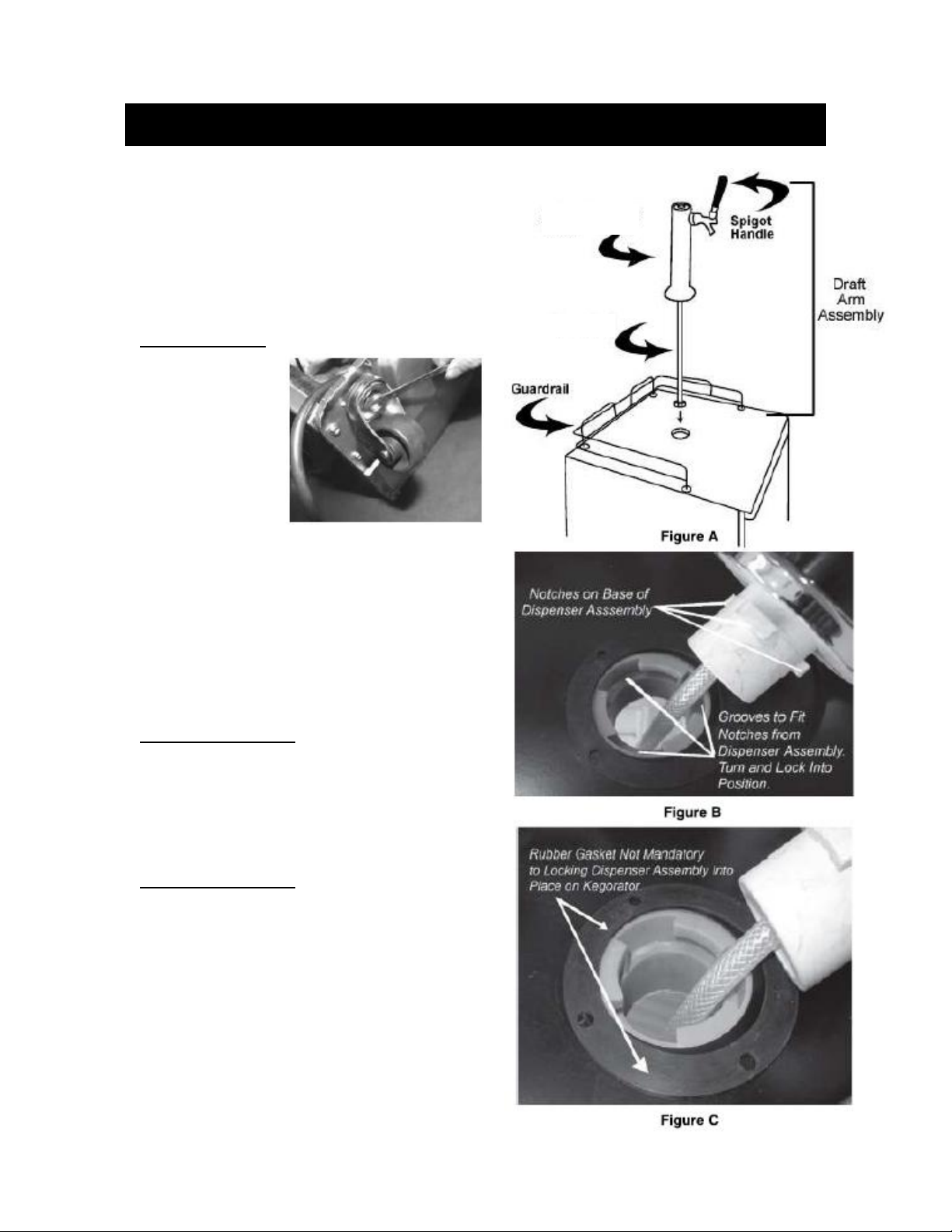

WINE KEG DISPENSER ASSEMBLY

Wine Dispenser

Tower

Wine Duct

Be sure you have a thorough familiarity with the

assembly and installation process before turning

on your wine keg dispenser.

NOTE: Once casters are assembled, place your

unit in an upright position and allow it to sit for at

least 8-10 hours before plugging into an outlet.

This will allow the refrigerant to settle before

operation.

Caster Assembly

1. Remove everything from the

cabinet and lay

the unit on a

clean, dry and

padded surface.

2. Install casters

into holes on

bottom of unit

as shown and

tighten with a wrench. Two of the four casters

provided are equipped with locks to prevent

slippage of the unit on smooth surfaces such

as hardwood floors, linoleum or tile. These

casters should be installed on the front of

the unit.

3. Once all four casters are attached, return the

wine keg dispenser to an upright position and

allow to remain for at least 8-10 hours. (See

Note above.)

Guardrail Installation

To install the guardrail,

1. Place the guardrail on top of the wine keg

dispenser and line up the feet of the guardrail

with the holes on top of the cabinet.

2. Using the screws provided, secure each foot to

the cabinet.

Wine Tap Installation

To install the wine tap, first line up the draft arm

notches with the notches in the hole in the top of

the wine keg dispenser. Feed the arm into the

hole, making sure that the notches are aligned

properly. Slide arm down and twist until the arm is

secure. (No screws or fasteners are necessary.)

While not required, we recommend the use of the

black rubber gasket when installing the wine tap.

Using the gasket will provide a more secure

seating for the arm assembly. (See figures A, B

and C in the next column.)

9

WINE KEG DISPENSER ASSEMBLY, continued

Gas Regulator

Gas

Cylinder

Connect to

Gas Cylinder

75% N

2

25% CO2

Gas Line

Use a gas mixture consisting of 75% nitrogen (N2) and 25% carbon dioxide (CO2).

Gas Regulator Installation

Proper installation of your gas

regulator and a thorough

understanding of gas canisters are

essential to the safe use of this

product. Review and follow

instructions for handling gas cylinders

and this section in particular to ensure

your safety and the safety of others.

NEVER CONNECT A GAS

CANISTER DIRECTLY TO THE

UNIT! To avoid potential explosion

that could result in grave injury or

even death, ALWAYS CONNECT

THE CANISTER TO THE GAS

REGULATOR.

IMPORTANT! The gas canister is

shipped to you EMPTY for safety

reasons. You will need to get this

canister filled before you can use your unit. In most areas, you can get canisters filled at:

stores that sell kegs

party stores or convenience stores

fire and welding supply stores.

DO NOT ATTEMPT TO REFILL GAS CANISTERS YOURSELF!

DANGER! Any pressurized gas is potentially dangerous. Canisters or cylinders are under

pressure and proper handling is essential to safety. ALWAYS HANDLE WITH CARE!

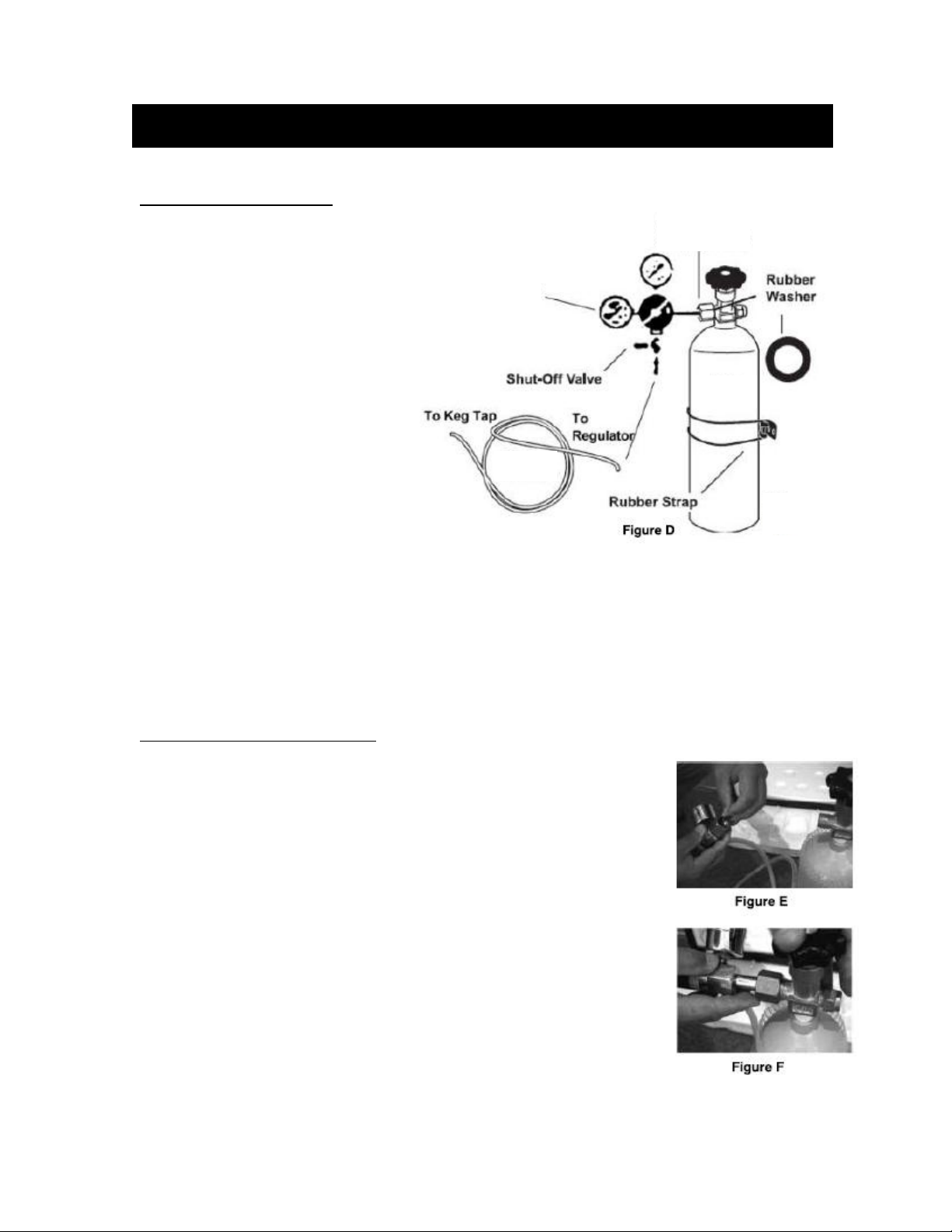

To install the dual-gauge regulator:

1. Insert the end of the gas line with the green coupler onto the bottom end

of the regulator. (See Figure D above and Photo 1, next page.) Secure

line to regulator by tightening the green coupler.

2. Next, insert the black rubber washer that comes with this unit into the

attachment nut on the regulator (as shown in figure E).

3. Connect the regulator to the canister by screwing the attachment nut

onto the canister valve (see Figure F). Tighten with an adjustable

wrench (not provided), but DO NOT OVERTIGHTEN.

4. Secure the canister with the rubber restraining strap (on side of wine

keg dispenser cabinet) as shown in Figure D. Be sure to situate the

canister so that the gauges are easily readable and the shut-off valves

are easily accessible.

See following page for examples of correct connections.

SPECIAL PRECAUTIONS: Ensure that the safety devices for your

pressurized system are installed and remain installed. Once installed,

NEVER remove the rubber washers in the regulator attachment nut to the

canister or in the tap mechanism. NEVER bypass these safety features.

Failure to comply will void your warranty and could result in serious injury or death!

10

WINE KEG DISPENSER ASSEMBLY, continued

Gas

gas

gas

Wing Nut Connecting Wine Hose to Tap

Gas Regulator & Tap Connection Examples

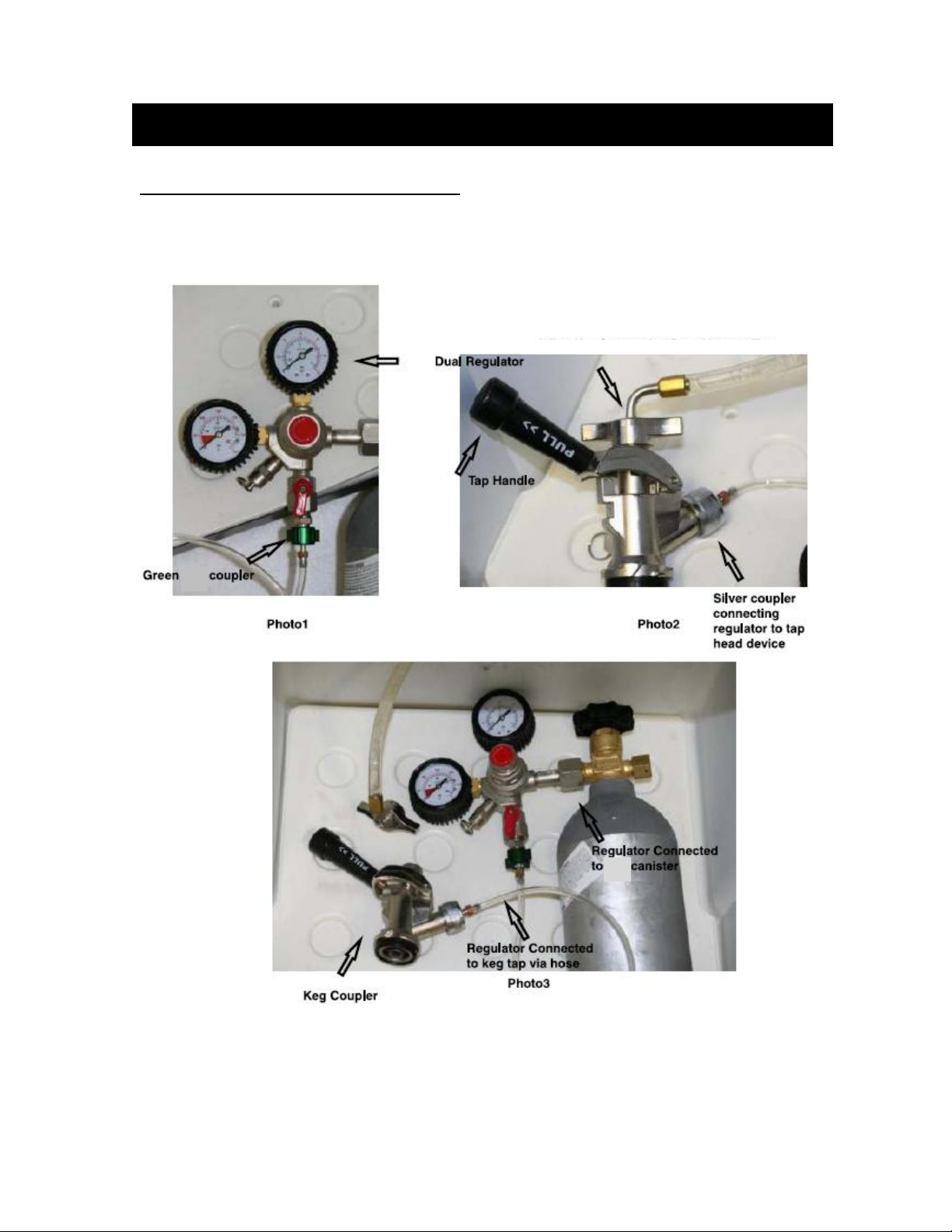

PLEASE NOTE: Your gas hose comes equipped and assembled with coupling connections for

the regulator (green coupler) and the tap connection (silver coupler). The photos below show

correct connections.

11

HOW TO TAP A WINE KEG

Connect to the

Wine Line Tube

Connect to

Gas Line

Tube

Wine Keg Neck

Wine Keg

INSTALLING KEG TAP ON SINGLE BARREL TYPE KEG

This wine dispenser's coupler is compatible only with a single 1/6 barrel keg, although a second

untapped keg can be stored behind the tapped keg to keep it cold. Each 1/6 barrel keg holds

approximately 5 gallons of wine.

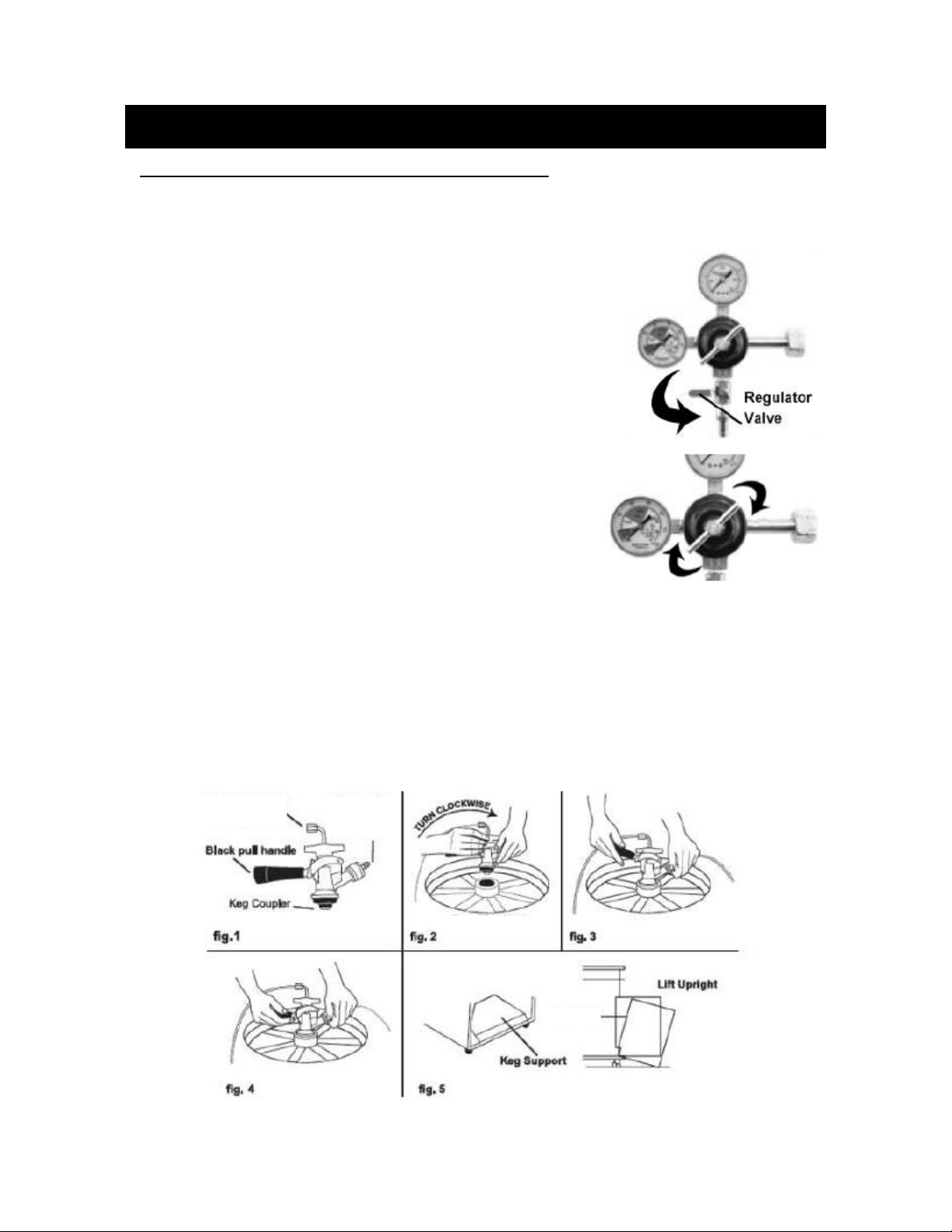

To tap a keg:

1. First be sure that the black dispenser handle of the keg coupler is

closed (pushed up, see Fig. 1 below). Also, make sure the tower

dispenser (on top of wine dispenser) handle is closed before

proceeding with tap-to-keg connection.

2. Insert the keg coupler mechanism into the top of the keg neck

and perform a quarter-turn clockwise to lock the coupler and keg

together (Fig. 2).

3. Before proceeding, make sure that you insert a black rubber

washer into the wing nut connector for the wine line (see page

7, bottom photo) before connecting the line to the tap. Take

off the black protective cap from the tap and screw the wing

nut with the washer to a firm finger-tightness.

4. Insert the end of the gas line with the silver coupler to the gas

connection on the tap. Make sure the coupler connection is

secure. Next, secure the connection between the wine line

and tap with pliers (Fig. 3 and Photo 2, previous page). Make

sure there are no leaks.

5. To finalize the connection, pull the black tap handle out and push down until it clicks securely.

There will be an audible click, signaling that the gas and wine connections have been opened

and that your keg is tapped (Fig. 4). Now you may open the regulator valve (top right photo)

and open the valve on the gas tank itself as well. Set the regulator to read 5-7 psi by turning

the regulator handle (bottom photo, right) clockwise.

6. Carefully tilt the keg onto the lip of the cabinet (using the keg support shown in Fig. 5) and

position slowly into the cabinet body until the door can close. HANDLE CAREFULLY. Do not

jostle or bang keg on gas canister.

Note: The left regulator gauge indicates total tank pressure.