Summit SBC635M7SSTB, SBC635M7SSHVTWIN, SBC635M7SSHV, SBC635M7SSHHTWIN, SBC635M7SSHH User Manual

...Page 1

Felix Storch, Inc.

BEFORE USE, PLEASE READ AND FOLLOW ALL SAFETY RULES AND

BEER DISPENSER

DISTRIBUTEUR de BIÈRE

Model / Modèle SBC635M

Use and Care Guide

Mode d’emploi

OPERATING INSTRUCTIONS.

Keep proof of original sales date (such as your sales slip) with this manual to

establish the warranty period.

Write the Serial Number below. You’ll find it on a plate located either on the back

of the appliance or on an interior wall.

AVANT UTILISATION, S'IL VOUS PLAÎT LIRE ET SUIVRE LES RÈGLES DE

SÉCURITÉ ET INSTRUCTIONS D'UTILISATION.

Conserver une preuve de la date d'achat d'origine (comme votre ticket de

caisse) avec ce manuel pour établir la période de garantie.

Écrire numéro de série ici. Vous le trouverez sur une plaque située soit sur

l’arrière de l'appareil ou sur un mur intérieur.

__________________________________________________

770 Garrison Avenu e

Bronx, NY 10474

www.summitappliance.com

Page 2

1

TABLE OF CONTENTS

Important Safeguards .................................................................................. 2 – 4

Location of Parts ................................................................................................ 5

Before Using for the First Time ........................................................................ 5

Placement and Installation ......................................................................... 6 - 10

Choosing the right place ............................................................................ 6

Installation ................................................................................................. 6

Applications ............................................................................................... 6

Connecting to power supply ...................................................................... 6

Reversing the door swing .......................................................................... 7

Installation of accessories ................................................................. 8 – 10

Operation .................................................................................................. 11 – 13

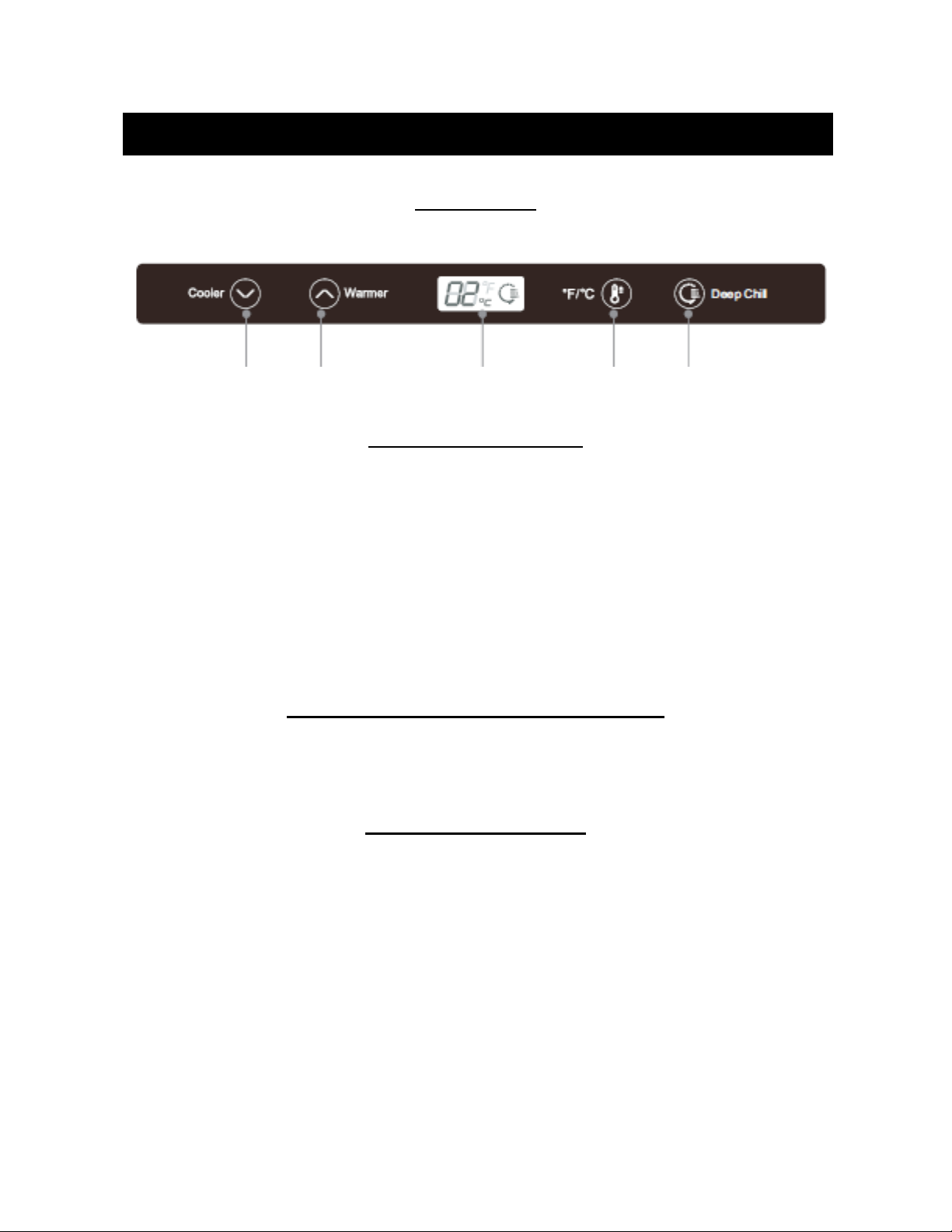

Control panel ........................................................................................... 11

Setting the temperature ........................................................................... 11

Switching between Celsius and Fahrenheit ............................................. 11

‘Rapid cooling’ function ........................................................................... 11

Automatic defrosting ............................................................................... 12

Error prompts .......................................................................................... 12

Normal functioning .................................................................................. 12

Dispensing beer .............................................................................. 12 – 13

Understanding beer temperature ............................................................ 13

Beer serving tips ..................................................................................... 13

Maintenance of the Beer Dispenser ............................................................... 14

Cleaning .................................................................................................. 14

Out of service .......................................................................................... 14

Transporting the unit ............................................................................... 14

Specifications of beer ke gs ..................................................................... 14

Disposing of a Worn-Out Appliance ............................................................... 15

Draft Beer Troubleshooting .................................................................... 16 – 17

General Troubleshooting ................................................................................ 18

Limited Warranty .............................................................................................. 19

French version of this manual ................................................................. 20 - 39

Page 3

2

IMPORTANT SAFEGUARDS

WARNING!

To reduce the risk of fire, electric shock or injury when using this

appliance, follow these basic precautions:

1. Read all instructions before using the appliance.

2. The appliance must be correctly connected to the power supply.

3. Immediately replace worn power cords, loose plugs and faulty power outlets.

4. Do not operate your appliance in the presence of explosive fumes.

5. Disconnect the appliance from the power supply before cleaning or repairing it.

Only a qualified technician should repair it.

6. Never stand on top of or inside this appliance, or swing on the door

putting weight on top of the appliance.

7. To reduce likelihood of injury,

8. Do not operate the valve control unless the cylinder is completely installed and

connected.

9. Do not attempt to repair or replace any part unless this is recommended in this

Use and Care Guide. Leave other service matters to qualified technical

personnel.

10. Keep packing materials away from children as they could become a choking

hazard.

11. Do not spray or flush the beer dispenser with water, and avoid keeping it in a

damp place since this could damage the electrical insulation.

DANGER! Risk of child entrapment!

Child entrapment and suffocation are not problems of the past. Junked or

abandoned appliances are still dangerous, even if they will "just sit at the

curb for a few days."

Before discarding your old appliance:

• Take off the door.

• Leave the shelves in place so that children may not easily climb

inside.

do not let children play with this appliance

. Avoid

.

• This appliance is CFC- and HFC-free and contains small quantities of

Isobutane (R600a) which is environmentally friendly, but flammable. It does

not damage the ozone layer, nor does it increase the greenhouse effect. Care

must be taken during transportation and setting up of the appliance that no

parts of the cooling system are damaged. Leaking coolant can ignite and may

damage the eyes.

In the event of any damage:

- Avoid open flames and anythi ng that creates a spark,

- Disconnect from the electrical power line,

Page 4

3

- Air the room in which the appliance is located for several minutes, and

- Contact the Service Department for advice.

• The more coolant there is in an appliance, the larger the room it should be

installed in. In the event of a leakage, if the appliance is in a small room, there

is the danger of combustible gases building up. For every ounce of coolant at

least 325 cubic feet of room space is required. The amount of coolant in the

appliance is stated on the data plate on the back of the appliance. It is

hazardous for anyone other than an Authorized Service Person to carry out

servicing or repairs to this appliance.

• Take serious care when handling, moving, and using the appliance to avoid

either damaging the refrigerant tubing or increasing the risk of a leak.

• Replacing component parts and servicing shall be done by factory authorized

service personnel so as to minimize the risk of possible ignition due to

incorrect parts or improper service.

SAFETY PRECAUTIONS REGARDING ELECTRICAL MATTERS

1. Do not pull on the power cord when unplugging the machine. Grasp the plug

firmly and pull it straight out of the socket. Do not pull the plug with wet hands.

2. Keep the power cord at the back of the appliance to avoid tripping accidents or

damage to the cord.

3. If the power cord is damaged or frayed, it must be replaced by a qualified

service professional.

4. Use only a standard three-hole grounded power socket rated above 10A. The

socket should not be shared with other appliances.

5. Be sure the plug fits firmly into the socket and that the socket is grounded.

6. The use of an extension cord is NOT recommended.

7. The beer dispenser requires an AC power supply of 110~120V/60Hz and pulls

a current of over 10A. The fuse or circuit breaker should be rated at 15A.

8. If the leakage of a combustible gas is detected, turn off the gas valve and

open the doors and windows. To reduce the risk of fire caused by a spark, do

not pull out the plug of the beer dispens er or of any other electrical device.

SAFETY PRECAUTIONS REGARDING CO2 (CARBON DIOXIDE) GAS

Always connect the CO2 cylinder to a regulator! Failure to do so may cause an

explosion resulting in possible injury or death when the cylinder valve is opened.

Never connect the CO2 cylinder directly to the product container.

Always keep CO2 cylinders away from heat. Store extra cylinders in a cool place

(preferably below 70°F). Securely fasten cylinders with a chain in an upright

position when storing.

Never drop or throw a CO2 cylinder.

Always check the D.O.T. (Department of Transportation) test date on the

cylinder neck before installation. If it has been more than 5 years, do not use.

Return the cylinder to your gas supplier.

Page 5

4

Never connect a product container unless there are at least two safety devices in

the pressure system: one on the CO2 regulator and the other on the product

container or in the pressurized gas line.

The recommended pressure for the CO2 system is 8-10 lbs.

SAVE THESE INSTRUCTIONS

Tips to save energy and maintain optimum performance:

When positioning this unit: If used freestanding, allow 4 inches

of clearance on top, at the sides and in the rear for sufficient

airflow.

Do not use under a bar or counter.

Page 6

5

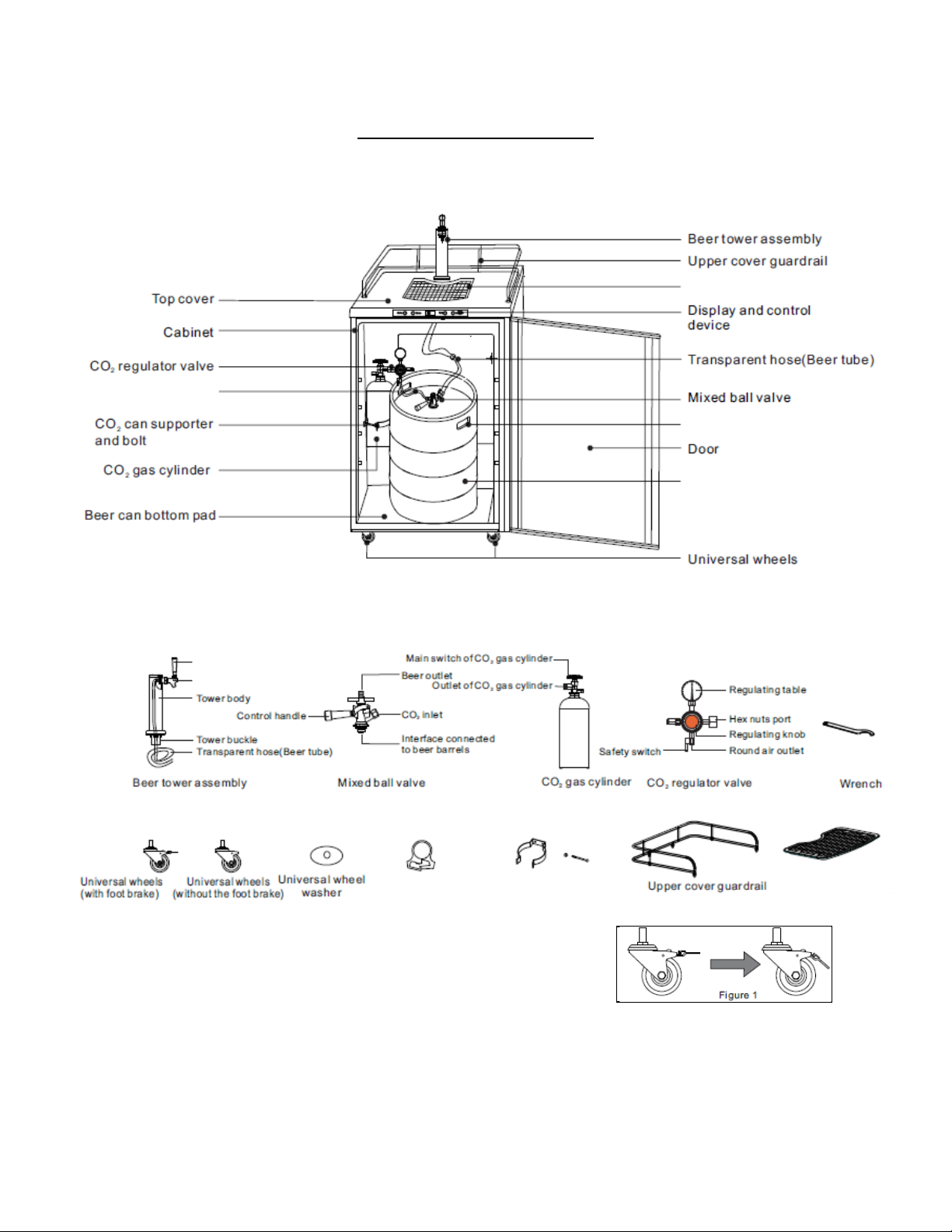

LOCATION OF PARTS

Beer tower assembly

Display and control

Evaporator

Ball valve

Door

Bottom pad

Caster

Top cover

Cabinet

regulator valve

CO2 gas cylinder

CO2 tank supporter

Control board device

Compressor

chamber cover

Upper cover guardrail

Drip tray

panel

CO2

Beer keg

BEFORE USING FOR THE FIRST TIME

The SBC635M is designed for dispensing beer only, and is not recommen ded for

storing perishable foods such as meats or dairy products

Before connecting the appliance to the power supply, leave it standing for 2 to 3

hours

. This allows the refrigerant to drain back into the compressor and reduces

the risk of malfunctions in the cooling system caused by shipping.

Clean the appliance thoroughly, especially the interior. (See Maintenance of the

Beer Dispenser.)

Proper grounding must be ensured to reduce the risk of shock

and fire. Do not cut or remove the grounding plug!

.

TIPS FOR SAVING ENERGY

Try not to open the door too often, especially when the weather is hot and humid.

Once you open the door, try to close it as soon as possible.

If possible, disconnect the power before changing a keg of beer.

Keep the unit out of direct sunlight.

Periodically, check that the beer dispenser seals well and that none of the

contents prevent the door from closing.

Page 7

6

PLACEMENT AND INSTALLATION

Choosing the Right Place

To ensure that your beer dispenser works at the maximum efficiency it was

designed for, install it in a location where there are proper air circulation and

electrical connections.

Choose a location where the beer dispenser will be away from any heat sources

and will not be exposed to direct sunlight.

Remove all packing materials before using the beer dispenser.

Place the machine on a smooth, flat and sturdy surface.

Installation

Your appliance is not designed to operate in enclosed spaces. When placing

your unit, make sure you allow at least 4” of clearance at the sides, rear and top

to allow for adequate airflow.

Applications

The SBC635M beer dispenser meets UL Standard 250 and is suitable for

residential use.

Connecting to Power Supply

Connect this appliance to a 3-prong power supply socket (which has a ground

terminal).

technician with an outlet that meets the local codes

Required nominal voltage and frequency are indicated on the rating plate. The

connection to the power supply and grounding has to be made acco r di ng to

current standards and regulations. The appliance resists temporary voltage

fluctuations with a tolerance of ±10%.

Once connected, allow the appliance to operate empty for two to three hours

before putting a beer keg inside.

If you only have a two-prong outlet, have it replaced by a qualified

.

DO NOT USE AN EXTENSION CORD

Page 8

7

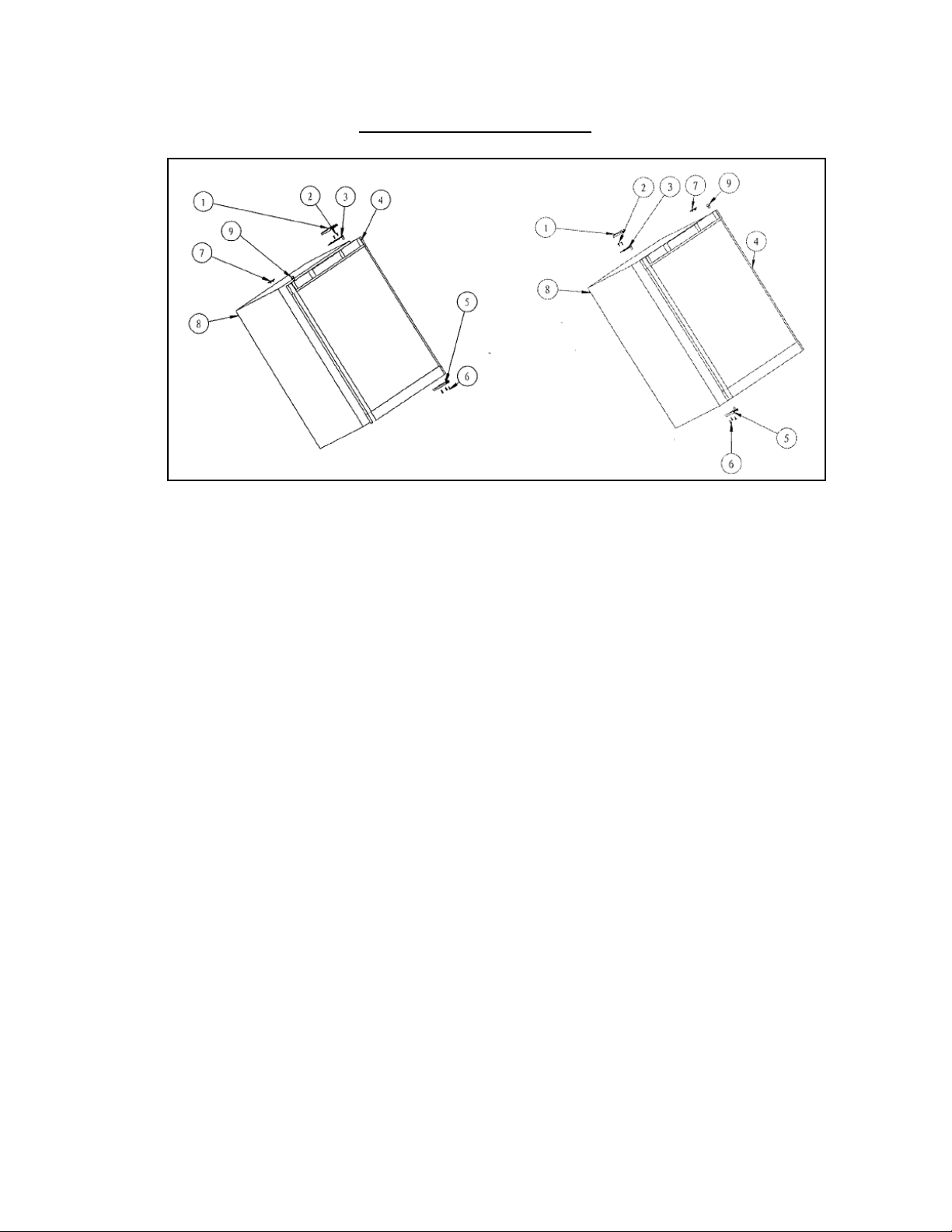

Reversing the Door Swing

Figure 1 (Default position) Figure 2 (After door reversal)

1. Upper hinge cover 6. Screws

2. Screws 7. Hole cover

3. Upper hinge 8. Cabinet

4. Door 9. Pin cap

5. Lower door hinge

The beer dispenser can be opened from either the right side or the left. By default, the

door hinge is on the right side. If you prefer it on the left, please follow these instructions:

Note: All of the parts that are removed must be kept for the reinstallation of the door.

1. Remove the three screws (6) holding lower door hinge (5). Keep hinge for later use.

2. Remove the door from the upper hinge (3), and keep the padded surface upward to

prevent scratching.

3. Remove the upper hinge cover (1), remove the two screws (2), remove the upper

hinge (3) and keep it for later use.

4. Remove the hole cover (7) and transfer it to the same location on the opposite side.

5. Insert the lower door hinge (5) into the left side, fixing the hinge into place by

tightening all the screws (6).

6. Remove the pin cap (9) from the left side of the upper door frame and then transfer it

to the same location on the opposite side.

7. Set the door on the lower door hinge (5), keep the door level, then fix the upper hinge

(3) to the body (8) by the screws (2).

8. Put on the upper hinge cover (1).

Page 9

8

Installation of Accessories

Beer keg handle

Soft red CO2 tube

Beer keg

Tap handle

Drip tray

Drip tray assembly

Diagram of overall structure

Installation components

Draft beer tap

CO2 hose clamp

CO2 tank bracket a nd b olt

Installation steps

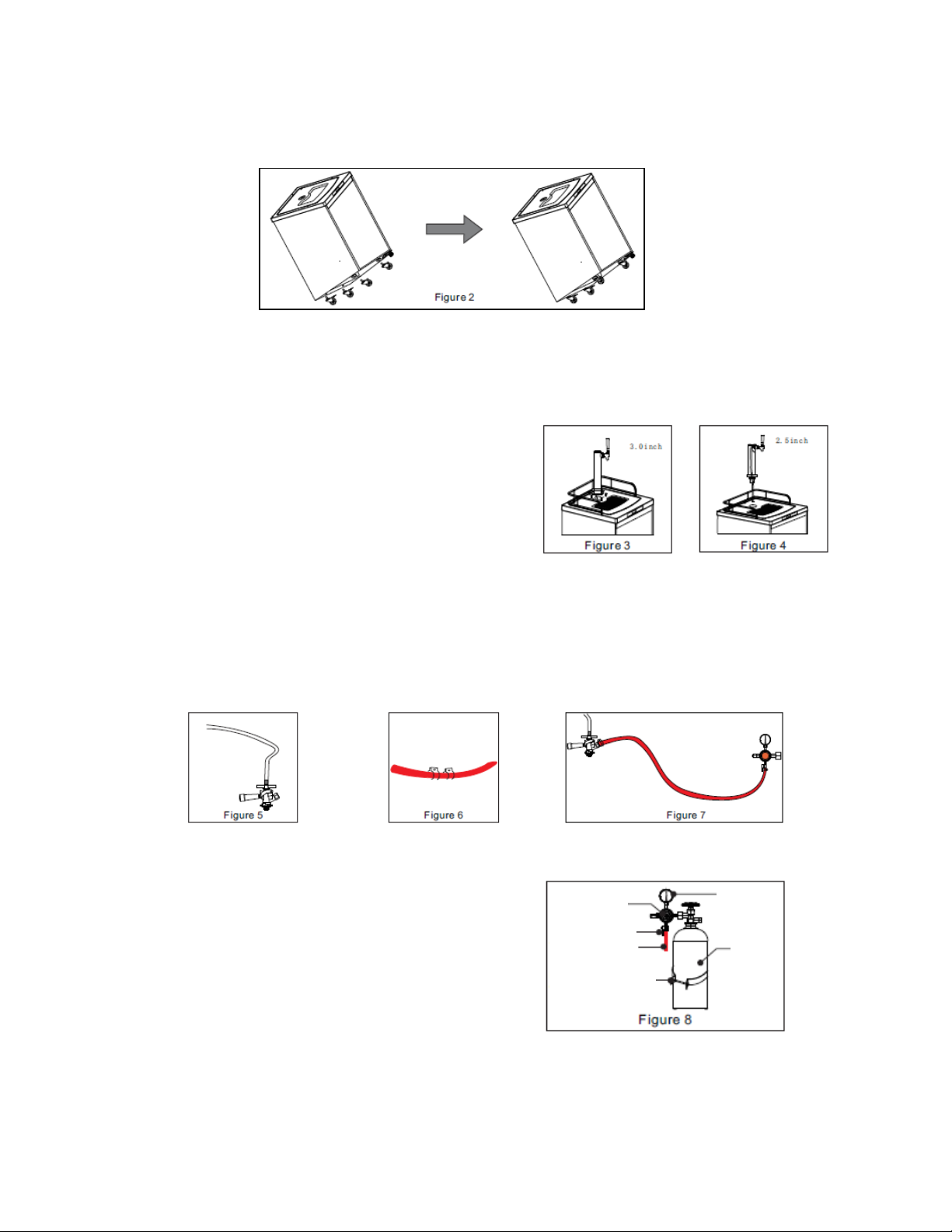

1. Install universal wheels:

Lock braking guidelines for universal wheels

with foot brakes (See Figure 1):

Install the two universal wheel washers at the front of the cabinet base, and

then install two universal wheels without foot brakes. Next, install the two

universal wheels with foot brakes at the back of the cabinet base. Once

Page 10

9

installed these rear wheels will keep the unit from moving if you step on the

CO2 regulator

valve

Safety switch

Bracket and retainer

Regulating

table

CO2 gas

foot brakes (See Figure 2):

2. Install the beer tower assembly and the mixed ball valve:

a) Plug the beer tower assembly into the top cover of the beer dispenser:

3.0” tower: This does not requir e a tow er

buckle. Put beer tower direct l y over the

hole at the top of the beer dispenser’s

upper surface. Fix the beer tower assembly with screws directly on the upper surface of the beer dispenser . (See Fig . 3).

2.5” tower: This requires the tower buckle.

Place the beer tower at the hole in the upper su rf ace o f the beer disp enser

at an inclination of 60°, and rotate 60° clockwise along the card slot. Be

sure the tap is facing toward the front of the machine. Attach the beer tower

with washers (See Figure 4).

b) Take out the accessories of the mixed ball valve. Attach the transparent

hose to the beer outlet of the mixed ball valve (See Figure 5).

3. Install CO2 gas cylinder and CO2 regulator valve:

a) Fix the two CO2 hose clamps on the red

CO2 tube (See Figure 6).

b) Connect the ends of the red CO2 tube

respectively to the CO2 intake port of the

mixed ball valve and the round outlet of

Red CO2 tube

of CO2 tank

cylinder

the CO2 regulator valve. Lock these

connections firmly with the two clamps on

the red CO2 tube (See Figure 7).

c) Using the wrench, tighten the CO2 regulator table valve with the hex nut port

to the gas outlet of the CO2 tank (See Figure 8).

Page 11

10

d) Place the CO2 tank and CO2

regulator valve component into the

cabinet and fix the CO2 tank

with tank bracket and bolt (See

Figure 8).

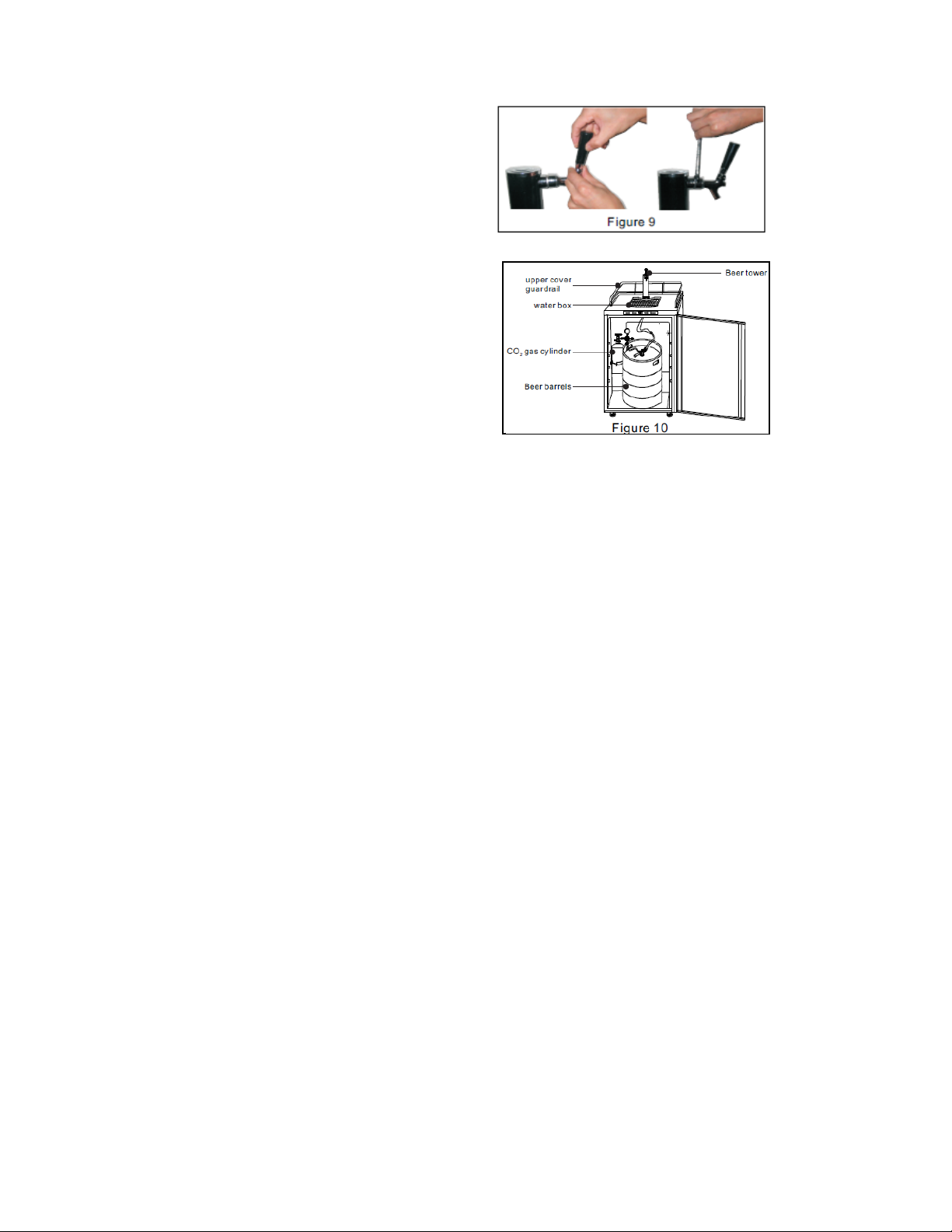

4. Install the beer keg:

Place the beer keg into the cabinet and

firmly connect the keg’s opening to the

connection port of the mix ed ball val ve

(See Figure 10).

Note: To place a keg into the cabinet,

use the keg handle to move the keg

to the front of the open beer

dispenser, then carefully tip the keg

so that the raised bottom edge contacts the edge of the cabinet. Finally, lift

the keg handle to raise the keg to the level of the floor of the cabinet and

push the keg into place.

5. Install tap handle and beer tap:

Screw the tap handle clockwise into the beer tap to make a firm connection.

Then connect the tap to the beer tower components and tighten with a wrench

(See Figure 9).

6. Install upper cover guardrail and drip tray:

Set the upper cover guardrail and drip tray on top of the beer dispenser (See

Figure 10).

Notes:

• When replacing the beer keg, first turn off the safety switch on the CO2

regulator valve and remove the mixed ball valve to take out the keg.

• When replacing the CO2 gas cylinder, remember to turn off the main

switch of the CO2 gas cylinder and the safety switch on the CO2 regulator

valve. Afterwards, use a wrench to loosen the hexagonal nut port

connecting the CO2 regulator valve with the CO2 tank. Then, using a

wrench, remove the fixed bolt of the CO2 tank to take out the CO2 tank.

• During the installation process, be sure that all parts are connected tightly

and that there are no gas leaks.

• When connecting the hose to the connection port, you can dip the ends

into warm water to make the connection easier.

• If the high-pressure compressed gas in the CO2 tank is not handled

properly, it could be danger ous:

a. Make a note of the D.O.T. testing date on the cylinder neck before

installation. If it is more than 5 years old, don’t use the product. Return

it to the gas supplier.

b. Keep gas cylinder away from heat sources. Unused cylinders should

be placed upright in a cool, ventilated place (preferably at 70°F).

Page 12

11

OPERATION

DOWN: Lowers UP: Raises Display module Fahrenheit/Celsius Rapid

Control Panel

The control panel is located just above the door, and looks like this:

temperature temperature switching cooling

Setting the Temperature

Adjust the DOWN or UP button on the control panel until the display module

shows the desired temperature.

The display module shows the set temperature, and the temperature-controlled

range varies from 32 to 50°F (0 to 10°C).

The display module shows 5°C at the initial power up. Each press of the DOWN

or UP button decreases or increases the temperature displayed by 1°C (1°F).

The optimal temperature for the storage and distribution of beer is 34 - 38°F (1.1

to 3.3°C.

Switching between Celsius and Fahrenheit

You can switch between a Celsius and Fahrenheit temperature displ ay by

pressing the °F/°C button. When the displayed temperature is in Celsius, the “°C”

symbol will be illuminated; with a Fahrenheit display, “°F” will be illuminated.

‘Rapid Cooling’ Function

Press the Deep Chill button to enter the Rapid Cooling state. The “rapid cooling”

icon on the display module will light and the temperature display will read “00”.

After entering the Rapid Cooling mode, the appliance will work continuously for

24 hours and the icon will remain lit. After that time, the icon will turn off and the

appliance will return to its former state.

You can cancel the Rapid Cooling mode any time during the 24 hour period by

simply pressing the Deep Chill button again.

Note: The Rapid Cooling function is normally used only for cooling the first keg of

beer in the appliance, w hen that keg is to be used as soon as p ossible. To

prevent over-cooling the beer, do not use Rapid Cooling for succeeding kegs.

Page 13

12

Automatic Defrosting

Prompt

E1

E4

E7

Temperature sensor

Defrosting sensor

Ambient

There is usually no need to defrost the beer dispenser because the ice deposited

on the inner back wall is automatically defrosted. Ice deposits on the inner back

wall during compressor operation. Later on, when the compressor is not

operating, the ice defrosts and water drains through the outlet in the inner back

wall into the drain pan situated above the compressor where it evaporates. If you

see water building up in the rear of the unit, check that the drain trough is not

clogged. Use a pipe cleaner or a piece of flexible wire. During extremely hot and

humid weather, some ice may build up. If necessary, remove contents of the

beer dispenser, unplug the unit and allow defrosting. A hair dryer may facilitate

the process.

Error Prompts

When the following prompts appear in the display module, there is a failure in the

appliance. Althoug h one of the faul t co ndi ti on s occur s, the beer di sp ense r may

still work. However, you should contact our Service Department as soon as

possible to obtain advice on handling the situation.

Fault

failure in the

refrigerated zone

failure in the refrigerator

compartment

temperature

sensor fault

Note: When two or more sensors fail simultaneously, all fault codes will display

alternately on the display module. If the ambient temperature and defrost

sensors fail, any key may be pressed. The temperature is adjustable. The

fault display will be restored after 15 seconds.

Normal Functioning

• If there is a sound of rushing water when the machine is in use, the noise is

caused by the refrigerant flowing in the cooling pipes and running through the

compressor. This is a normal pheno m eno n.

• The beer dispenser has no heating function. When the temperature is set

higher than the ambient temperature, the machine will not run.

Dispensing Beer

Follow these steps to dispense beer:

1. Make sure the beer dispenser is plugged in properly to a 120V, 60Hz, 15 amp

grounded AC outlet.

2. Place the drip tray under the beer tap.

3. Open the beer faucet by pulling the tap towards you quickly and completely to

4. Increase the pressure if the beer runs too slowly. At the correct pressure and

dispense the beer.

temperature, a 10-oz glass should be filled in 4 seconds.

Page 14

13

5. Hold the glass steady at a 45° angle. When it is 2/3 full, start straightening the

glass. Proper foam should be a tight, creamy head and the collar on an

average glass should be 3/4" to 1" high.

Note: It is normal to see condensation forming on the tap. It is caused by the

difference in temperature between the cold beer and the inner surfaces of the

tap when beer is flowing throug h the line.

Understanding Beer Temperature

The recommended temperature for serving chilled beer is between 38° and 43°F.

To maintain this temperature in average room conditions of 70°F, set the

thermostat accordingly.

Notes: During the summertime when temperatures are warmer, we recommend

that you adjust the control to a cooler setting. Selecting and maintaining the

proper temperature inside the refrigerator cabinet is necessary for maintaining

the flavor and freshness of beer. Excessively cold or warm temperatures

inside the refrigerator cabinet may cause a loss of flavor.

The best temperature for storing a keg is approximately 38°F.

Sour beer is produced as a result of secondary fermentation above 45°F.

Beer Serving Tips

The following tips will help you serve the perfect beer. To serve beer from the

tap similar to the way it left the vat, check the following:

• Cleanliness (see Maintenance of the Beer Dispenser)

• Temperature (see Setting the Temperature and Understandi ng Beer

Temperature)

• Pressure (The recommended pressure for the CO

• Use only CO

gas

2

system is 8-10 lbs.)

2

Page 15

14

MAINTENANCE OF THE BEER DISPENSER

Cleaning

To optimize cooling and to save energy at the same time, dust the back of the

beer dispenser periodically.

The interior should be cleaned regularly. Use a soft towel or sponge that has

been dampened in a solution of mild detergent. Rinse with clean water and dry

with a cloth. Leave the door open for a while to allow the unit to dry thoroughly

before turning the power back on.

Do not use a hard brush, steel wool, wire brush, or abrasives such as toothpaste,

or organic solvents like alcohol or acetone to clean the beer dispenser.

When cleaning or rinsing the unit, be careful not to let the control panel or any

electrical components become wet.

Out of Service

If the machine will be out of service for more than three weeks, unplug it and

clean and dry it thoroughly. Allow the door to remain open slightly to prevent the

buildup of mold and odors .

Transporting the Unit

Firmly fix any loose items inside the beer dispenser with tape. Tape the door shut

so it will not open during transportation.

Loosen the two foot brakes before moving the unit.

Specifications of Beer Kegs

Keg sizes that can be used in your beer dispenser:

1/2 barrel 59 liters 15.5 gals. 1,984 oz. 164 / 12-oz. Glass

1/4 barrel 30 liters 7.8 gals. 992 oz. 82 / 12-oz. Glass

1/6 barrel 20 liters 5.2 gals. 661 oz. 55 / 12-oz. Glass

1/8 barrel 15 liters 4.0 gals. 496 oz. 41 / 12-oz. Glass

Note: Our beer dispenser accepts almost all brand name 1/2 kegs. H owever,

Coors’ kegs do not fit in our unit.

Page 16

15

DISPOSING OF A WOR N-OUT APPLIANCE

• When your appliance finally wears out, dispose of it.

• Before you dispose of an old appliance: Take the door or doors off but leave

any shelves or drawers in place so that children cannot easily climb inside.

• The refrigerating system of the appliance is filled with refrigerant and insulating

substances that should be recycled separately. Either have a licensed

appliance repair company or dealer remove the appliance or call your local

recycling office for the appro pr i ate di sp os al in for ma ti on.

• For the sake of environmental protection, when moving the appliance, be

careful not to damage the rear wall (the condenser unit or the tubes) or any

part of the refrigeration system inside the appliance.

• This beer dispenser is 100% CFC -free, but the coolant is under pressure and

inflammable, and puncturing the sealed system could be dangerous. The

coolant used in the sealed system is non-toxic.

• Many older appliances may contain refrigerants that are harmful to the

environment, and should be recycled by a lawfully licensed company.

Page 17

16

DRAFT BEER TROUBLESHOOTING

Problem

Cause

Correction

periods of time.

Drain a few ounces before drinking.

cause beer to go flat.

where health laws permit.

to remove all fatty substances (e.g., lipstick).

Do not use soap.

corrugated metal sheet.

glass.

of being flat.

pressure to the keg before drawing beer.

Beer is cloudy:

The beer in the

glass appears

hazy and not clear.

Excessively low

temperatures

may cause

hazy or cloudy

beer,

particularly

when the beer

lies in the cold

coil for long

Glasses may

not have been

cleaned

properly.

Raise the temperature setting of the unit.

Do not wash beer glasses together with glasses

that have contained milk or any other fatty

substance. An excessive amount of germicide

build-up may also leave a fatty film, which will

It is preferable to steam and sterilize glasses

Wash glasses thoroughly with a good detergent

Do not wipe the glasses dry. Permit glasses to

air-dry by placing them on a wire rack or

Rinse the glasses in fresh cold water just before

serving beer. It is best to serve beer in a wet

Improper

drawing of beer

into glass

Not enough

pressure

Open the faucet quickly and completely; proper

foam should be a tight creamy head. The collar

on the average glass should be ¾" to 1" high.

Beer drawn without a head has the appearance

Increase the pressure if beer runs too slowly.

The correct flow should fill a 10-oz glass in 4

seconds (approx. 8 oz of liquid). Check the

pressure source to determine whether there are

obstructions in the air line. Replace a sluggish

air source or the CO

tank pressure must always be higher than the

pressure used on the keg. Always apply

regulator and gauge. The

2

Page 18

17

Beer has off taste:

taste.

tap

beer dispenser.

Often bitter and

bite-y; sometimes

completely lacking

flavor and zest. It

may also have an

oily or foul odor

which may carry

an unpleasant

Improper

cleaning of the

Contaminated

air line

Brush and clean the tap properly. It should be

scoured using a detergent, then rinsed clean.

Beer tube should be examined. If contaminated,

it should be replaced.

Condensation is

forming on the tap.

It is normal to

see condensation forming

on the tap. It is

caused by a

difference in

temperature

between the

cold beer and

the surfaces of

the tap when

beer is flowing

through the line.

Beer that is left

in the tap is not

cooled by the

After a period of non-use, a few ounces should

be drained before drinking.

Page 19

18

GENERAL TROUBLESHOOTING

Problem

Possible Cause

Tripped circuit breaker or blown fuse.

Temperature control is not set correctly.

Metal plate or beer kegs are out of place.

pops and crackles.

If there is a problem with the beer dispenser itself, see if you can find it listed in

the chart below. You may be able to save yourself the cost of a service visit.

The beer dispenser doesn’t

work.

The machine switches on

and off frequently.

Door cannot be closed

properly.

Noise Rushing noise may be the sound of refrigerant

Power supply not firmly connected.

Supplied voltage is too low.

Indoor temperature is higher than usual.

Machine door is opened frequen t ly.

Door is not completely closed.

Beer keg not properly placed.

Beer dispenser is not level.

Door was reversed and re-installed incorrectly.

flow, which is normal.

As each cycle ends, the gurgle of refrigerant flow

may be heard.

Contraction and expansion of inner wall may cause

Page 20

19

LIMITED WARRANTY

FELIX STORCH, INC.

For parts and accessory ordering,

WARNING! This product may contain chemicals known to the state of California

higher than threshold limits: NONE.

Revised March 2015

ONE-YEAR LIMITED WARRANTY

Within the 48 contiguous United States, for one year from the date of purchase, when this appliance is

operated and maintained according to instructions attached to or furnished with the product, warrantor will

pay for factory-specified parts and repair labor to correct defects in materials or workmanship. Service must

be provided by a designated service company. Outside the 48 states, all parts are warranted for one year

from manufacturing defects. Plastic parts, shelves and cabinets are warranted to be manufactured to

commercially acceptable standards, and are not covered from damage during handling or breakage.

5-YEAR COMPRESSOR WARRANTY

1. The compressor is covered for 5 years.

2. Replacement does not include labor.

ITEMS WARRANTOR WILL NOT PAY FO R:

1. Service calls to correct the installation of your appliance, to instruct you how to use your appliance, to

replace or repair fuses or to correct wiring or plumbing.

2. Service calls to repair or replace appliance light bulbs or broken shelves. Consu ma ble parts (such as

filters) are excluded from warranty coverage.

3. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with electrical or plumbing codes, or use of products not approved by

warrantor.

4. Replacement parts or repair labor costs for units operated outside the United States.

5. Repairs to parts or systems result ing fr om una uthor iz ed mod ific ations made to the appliance.

6. Expenses for travel and transportation for product service in remote locations.

7. The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not

installed in accordance with published installation instructions.

DISCLAIMER OF IMPLIED WARRANTIES;

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIR AS PROVIDED HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR.

WARRANTOR SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME

STATES DO NOT ALLOW THE EXCLUSION O R LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, OR LIMITATIONS ON THE DURA TION OF IMPLIED W ARRANTIES OF MERCHANTABILI TY

OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE.

to cause cancer or birth defects or other reproductive harm. For more information,

visit: www.summitappliance.com/p rop 65

Chemicals known by the manufacturer t o be present in this produc t in concentrations

770 Garrison Avenue

Bronx, NY 10474

Phone: (718) 893-3900

Fax: (844) 478-8799

www.summitappliance.com

LIMITATION OF REMEDIES

troubleshooting and helpful hints, visit:

www.summitapplianceparts.com

Page 21

20

TABLE DES MATIÈRES

Mesures de sécurité importants ............................................................. 21 – 23

Emplacement des pièces ................................................................................ 23

Avant d’utiliser pour la première fois ............................................................. 24

Placement et installation .......................................................................... 24 - 30

Choisir le bon endroit ............................................................................... 24

Installation ............................................................................................... 24

Applications ............................................................................................. 24

Raccordement à l’alimentation ................................................................ 25

Inversion de l’ouverture de la porte ......................................................... 26

Installation des accessoires ............................................................. 27– 30

Opération .................................................................................................. 30 – 33

Panneau de commande .......................................................................... 30

Réglage de la température ...................................................................... 30

Changement entre Celsius et Fahrenheit ......................................... 30 - 31

Fonction de refroidissement rapide ......................................................... 31

Le dégivrage automatique ....................................................................... 31

Les messages d’erreur ..................................................................... 31 - 32

Fonctionnement normal .......................................................................... 32

Distribution de la bière ............................................................................. 32

Comprendre la température de la bière .................................................. 32

Conseils pour servir la bière ............................................................. 32 - 33

Entretien du distributeur de bière .................................................................. 33

Nettoyage ................................................................................................ 33

Hors service ............................................................................................ 33

Transporter l’appareil ............................................................................... 33

Spécifications des fûts de bièr e ............................................................... 33

Mise au rebut d’appareil usagé ....................................................................... 34

Dépannage de bière pression ................................................................... 35– 36

Dépannage général .......................................................................................... 37

Garantie limitée ................................................................................................ 39

Page 22

21

MESURES DE SÉCURITÉ IMPORTANTES

Avant d'utiliser l'appareil, celui-ci doit être convenablement positionné et

installé comme décrit dans ce manuel. Veuillez lire attentivement le manuel.

Pour réduire le risque d'incendie, d'électrocution ou de blessure lors de

l'utilisation de l'appareil, suivre les précautions nécessaires, y compris ce qui

suit:

•

Brancher sur une prise à 3 broches de sortie, ne pas retirer la broche de terre, ne pas utiliser

un adaptateur ni de rallonge.

•

Remplacer tous les panneaux avant de faire fonctionnement.

•

Il est recommandé d'utiliser un circuit distinct pour alimenter uniquement votre appareil. Utilisez

des récipients qui ne peuvent pas être désactivés par un interrupteur ou une chaîne de traction.

•

Ne jamais nettoyer des pièces d'appareils avec des liquides inflammables. Les émanations de

ces produits peuvent pr ovo quer un incend ie ou une ex plosi on. Ne pas entreposer ni utiliser

d'essence ou autres vapeurs et liquides inflammables à proximité de cet appareil ou de tout

autre. Les vapeurs peuvent créer un risque d'inc e nd ie ou d'exp los ion.

•

Avant de procéder à des opérations de nettoyage et d'entretien, assurez-vous que la ligne

d'alimentation de l'appareil soit débranché.

•

Ne pas brancher ou débrancher la prise électrique lorsque vos mains sont mouillées.

•

Débranchez l'appareil ou coupez le courant avant de netto yer ou de répar er. L e non-respect de

cette consigne peut entraîner un choc électrique ou la mort.

•

Ne tentez pas de réparer ou de remplacer une partie quelconque de votre appareil à moins qu'il

ne soit spécifiquement recommandé de le faire dans ce manuel. Toute autre réparation doit

être confiée à un technicien qualifié.

•

Cet appareil est libre de CFC et de HFC et contient de petites quantités d'isobutane (R600a),

qui est respectueux de l'environnement, mais inflammable. Il n’endommage pas la couche

d'ozone, et n’augmente pas l'effet de serre. Il faut prendre soin pendant le transport et la mise

en place de l'appareil à ce qu'aucune partie du système de refroidissement n’est endommagée.

Liquide de refroidissement qui fuit peut se enflammer et peut endommager les yeux. Dans le

cas de dégâts:

-

Éviter les flammes nues et tout ce qui crée une étincelle,

-

Débrancher la ligne d'énergie électrique,

-

Aérez la pièce dans laquelle se trouve l'appareil pendant plusieurs minutes, et

-

Contactez le Service pour obtenir des conseils.

•

Plus la quantité de réfrigérant qu'il est dans un appareil, plus grande la pièce où il doit être

installé. Dans le cas d'une fuite, si l'appareil est dans une petite pièce, il y a le danger de

l‘accumulation de gaz combustibles. Pour chaque once de liquide de refroidissement au moins

325 pieds cubes d'espace de la pièce sont nécessaires. La quantité de liquide de

refroidissement dans l'appareil est indiquée sur la plaque signalétique à l'arrière de l'appareil. Il

est dangereux pour quiconque autre qu' u ne personne autorisée à procéder à l'entretien ou

réparation de cet appareil.

•

Prenez soin sérieux en manipulant, en mouvant, et en utilisant l'appareil pour éviter soit

d'endommager le tube de réfrigérant soit d’augmenter le risque d'une fuite.

•

Remplacement de composants et l'entretien doivent être effectués par un personnel de service

agréé par l'usine de manière à minimiser le risque d'inflammation possible en raison de

modules incorrects ou d'utilisation non conforme.

Page 23

22

AVERTISSEMENT

Suivez la légende AVERTISSEMENT ci-dessous que lorsque applicables à votre

modèle.

•

Deux personnes ou plus devraient déplacer et installer l'appareil. Le non-respect de cette

consigne peut entraîner des blessures au dos ou autre.

•

Pour assurer une bonne ventilation de votr e appar e il, le devant de l'unité doit être

complètement dégagé. Choisissez un endroit bien aéré, avec des températures supérieures à

60°F (16°C) et au-dessous de 90°F (32°C). Cet appareil doit être installé dans une zone

protégée contre les éléments, comme le vent, la pluie et les éclaboussures d'eau.

•

L'appareil ne doit pas être placé à proximité de fours, grilles ou d'autres sources de chaleur

élevée.

•

L'appareil doit être installé avec toutes les connexions électriques, d'eau et de vidange

conformes aux codes nationaux et locaux. Une alimentation électrique standard (115 V CA

seulement, 60 Hz), mise à terre en conformité avec le National Electrical Code et les codes et

ordonnances locaux, est requise.

•

Ne pas plier ou pincer le cordon d'alimentation de l'appareil.

•

La taille du fusible (ou disjoncteur) doit être de 15 ampères.

•

Il est important que l'appareil soit mis à niveau afin de fonctionner correctement. Vous devrez

peut-être faire plusieurs ajustements pour y arriver.

•

Toutes les installations doivent être conformes aux exigences du code de plomberie.

•

Assurez-vous que les tuyaux ne sont pas pincé, noués ou endommagés lors de l'installation.

•

Vérifier s'il y a des fuites après la connexion.

•

Ne jamais laisser les enfants utiliser, jouer ou ramper à l'intérieur de l'appareil.

•

Ne pas utiliser de produits de nettoyage à base de solvants ou de produits abrasifs à l'intérieur.

Ces nettoyants peuvent endommager ou décolorer l'intérieur.

•

Servez-vous de cet appareil uniquement pour son usage prescrit, tel que décrit dans ce

manuel.

•

Gardez vos doigts loin des zones de "pinçage". Les espaces entre les portes sont toujours

étroits. Fermez les portes soigneusement lorsque les enfants sont à proximité.

DANGER!

Risque d'emprisonnement des enfants!

Des enfants pris au piège et suffoqués n'est pas un scénario du passé. Les appareils jetés ou

abandonnés sont encore dangereux, même s'ils sont "simplement entreposés dans le garage

pendant quelques jours".

Avant de jeter votre vieux réfrigérateur:

• Enlever les portes

• Laissez les étagères en place afin que les enfants ne puissent pas y pénétrer

facilement.

MESURES DE SÉCURITÉ CONCERNANT LE GAZ CO

Toujours connecter la bouteille de CO

à un régulateur! Ne pas le faire peut causer une explosion

2

(anhydride carbonique)

2

entraînant des blessures ou la mort lorsque le robinet de la bouteille est ouvert.

Ne raccordez jamais la bouteille de CO

Toujours tenir les bouteilles de CO

directement au récipient du produit.

2

de la chaleur. Entreposer les bouteilles supplémentaires

2

dans un endroit frais (de préférence inférieure à 70°F ou 21°C). Fixez solidement les bouteilles

avec une chaîne en position verticale lors du stockage.

Ne jamais laisser tomber ou jeter une bouteille de CO

.

2

Toujours vérifier la date du test du D.Ö.T. (Département de Transportation) sur le col de la

bouteille avant l'installation. S’il y a été plus de 5 ans, ne pas utiliser. Rapporter le cylindre à votre

fournisseur de gaz.

Page 24

23

Ne raccordez jamais un récipient de produit à moins qu'il y ait au moins deux dispositifs de

Conseils pour économiser de l'énergie et de maintenir

Rambarde du couvercle supérieur

Bac d'égouttage

Affichage et panneau de

Evaporateur

Tonnelet de bière

Porte

Tampon de fond

Roulette

Couverture supérieure

Bouteille de gaz de CO

Support de la cannette de CO

2

Dispositif de la carte de contrôle

Couverture de la chambre

sécurité dans le système de pression: l'une sur le régulateur de CO

produit ou dans la conduite de gaz sous pression.

La pression recommandée pour le système de CO

est de 8-10 livres (3,6 à 4,5 kg).

2

- CONSERVER CES INSTRUCT IONS -

et l'autre sur le récipient du

2

performance optimale:

Lors du positionnement de l'appareil: S'il est utilisé

autonome, permettre 4 pouces (10 cm) de dégagement audessus, sur les côtés et à l'arrière pour la circulation d'air

suffisante.

Ne pas utiliser sous un bar ou un comptoir.

EMPLACEMENT DES PIÈCES

Vanne régulatrice de CO

du compresseur

2

2

Assemblage de la tour de bière

commande

Robinet à bille

Page 25

24

AVANT D'UTILISER POUR LA PREMIÈRE FOIS

Le SBC635M est conçu uniquement pour distribuer de la bière, et n'est pas

recommandé pour l'entreposage des aliments périssables tels que les viandes

ou les produits laitiers.

Avant de connecter l'appareil à l'alimentation, laissez-le reposer 2 à 3 heures.

Cela permet au réfrigérant de s'écouler dans le compresseur et réduit le risque

de dysfonctionnements dans le système de refroidissement causés par

l'expédition.

Nettoyez soigneusement l'appareil, en particulier à l'intérieur. (Voir Entretien du

distributeur de bière.) Mise à la terre doit être garantie pour réduire le risque de

choc et du feu. Ne pas couper ou retirer la fiche de mise à la terre!

Conseils pour économiser l'énergie

Essayez de ne pas ouvrir la porte trop souvent, surtout lorsque le temps est

chaud et humide. Une fois que vous ouvrez la porte, essayez de fermer-la dès

que possible.

Si possible, débranchez l'alimentation avant de changer un tonnelet de bière.

Conservez l'appareil hors de lumière directe du soleil.

Périodiquement, vérifier que le distributeur de bière fer me parfaitement et

qu'aucun des contenus empêchent la fermeture de la porte.

PLACEMENT ET INSTALLATION

Choisir le bon endroit

Pour vous assurer que votre distributeur de bière fonctionne à l'efficacité

maximale pour laquelle il a été conçu, installez-le dans un endroit où il y a une

bonne circulation de l'air et les connexions électriques appropriées.

Choisissez un endroit où le distributeur de bière sera loin de toute source de

chaleur et ne sera pas exposé à la lumière directe du soleil.

Retirez tous les matériaux d'emballage avant d'utiliser le distributeur de bière.

Placez la machine sur une surface lisse, plane et stable.

installation

Votre appareil n'est pas conçu pour fonctionner dans des espaces clos. Lorsque

vous placez votre appareil, assurez-vous de prévoir au moins 4 "de dégagement

sur les côtés, à l'arrière et en haut pour permettre une ventilation adéquate.

Applications

Le distributeur de bière SBC635M rencontre la norme UL 250 et est adapté pour

un usage résidentiel.

Page 26

25

Raccordement à l'alimentation

Connectez cet appareil à une prise d'alimentation à 3 broches (qui a une borne

de terre).

par un technicien qualifié avec une prise conforme aux codes locaux .

La tension nominale et la fréquence exigées sont indiquées sur la plaquette

signalétique. La connexion à l'alimentation et la mise à la terre doit être faites

selon les normes et règlements en vigueur. L'appareil résiste à des variations de

tension temporaires avec une tolérance de ±10%.

Une fois connecté, permettre à l'appareil de fonctionner à vide pendant deux à

trois heures avant de mettre un tonnelet de bière à l'intérieur.

Si vous avez seulem ent une prise à deux broches, le faire remplacer

NE PAS UTILISER UNE RALLONGE

Page 27

26

Inversion de l’ouverture de la porte

Figure 1 (La position par défaut) Figure 2 (Après l'inversion de la porte)

1. Couvercle du gond supérieur 6. Des vis

2. Des vis 7. Couvercle du trou

3. Gond supérieur 8. Cabinet

4. Porte 9. Capuchon de goupille

5. Gond inférieur de la porte

Le distributeur de bière peut être ouvert du bord droit ou gauche. Par défaut, le

gond de la porte est sur le côté droit. Si vous le préférez à gauche, s'il vous plaît

suivez ces instructions:

Remarque: Toutes les pièces qui sont enlevées doivent être conservées pour la

réinstallation de la porte.

1. Retirez les trois vis (6) qui maintiennent le gond inférieur de la porte (5).

Gardez le gond pour une utilisation ultérieure.

2. Enlevez la porte du gond supérieur (3), et garder la surface rembourrée vers

le haut pour éviter les rayures.

3. Retirez le couvercle du gond supérieur (1), retirer les deux vis (2), retirer le

gond supérieur (3) et le conserver pour un usage ultérieur.

4. Enlever le couvercle du trou (7) et le transférer vers le même emplacement

sur le côté opposé.

5. Insérer le gond inférieur de la porte (5) sur le côté gauche, fixant le gond en

place en serrant les vis (6).

6. Retirer le capuchon de goupille (9) du côté gauche du cadre supérieur de la

porte et le transférer ensuite vers le même emplacement sur le côté opposé.

7. Réglez la porte sur le gond inférieur (5), maintenir la porte nivelée, puis fixer

le gond supérieur (3) sur le cabinet (8) par les vis (2).

8. Mettez le couvercle du gond supérieur (1).

Page 28

27

Soupape de régulation

de CO

2

Capot supérieur

Tampon de fond

pour fût de bière

et boulon

Tube rouge souple de CO2

Bouteille à gaz CO

Porte

Fût de bière

Roues universelles

(tube de bière)

de bière

Boîte à eau

Poignée de commande

Corps de la tour

Robinet de la bière

Poignée pour distribuer de la bière

Interrupteur principal de

bouteille à gaz CO2

Assemblage

Tuyau transparent (tube de bière)

Boucle de la tour

Entrée de CO

2

Interrupteur

de sécurité

Bouteille à gaz CO2

Soupape à bille mixte

Bouton de régulation

Sortie ronde d'air

Roues universelles

Roues universelles

Clé

la boîte à eau

couvercle supérieur

Support de bouteille

Élément de fixation

Schéma de la structure générale

Support de bouteille de CO

Composants d'installation

de la tour de bière

(avec pédale de frein)

(sans pédale de frein)

Les étapes d’installation

1. Installez roues universelle:

Verrouiller le mécanisme de freinage pour les roues

universelles de freins à pied (voir figure 1):

Installez les deux rondelles de roues universelles à l'avant de la base du

cabinet, puis installer deux roues universelles sans freins à pied. Ensuite,

installez les deux roues universelles avec freins à pied à l'arrière de la base du

Installation des acce sso ir e s

Assemblage de la tour

Rambarde du couvercle supérieur

Affichage et

appareil de commande

Tuyau transparent

Soupape à bille mixte

2

2

Sortie de la bière

Rondelle pour

roue universelle

Sortie de bouteille à gaz CO

Interface connectée

au fût de bière

pour tube de CO2

2

Soupape de régulation

de CO2 et boulon

Poignée du fût de bière

Jauge de régulation

Orifice d’écrou hexagonal

de CO2

Rambarde du

Assemblage de

Page 29

28

cabinet. Une fois installées, ces roues vont garder l'unité de se déplacer si

3.0 ”

vous appuyez sur les freins à pied (voir figure 2):

2. Installez l'assemblage de la tour de bière et la soupape à bille mixte:

a) Branchez l ensemble de la tour de bière dans le couvercle supérieur du

distributeur de bière:

Tour de 3.0 ": Cela ne nécessite pas une

boucle de la tour. Mettez la tour de bière

directement sur le trou au dessus de la

surface supérieure du distributeur de

bière. Fixer l' asse m blage de la tour de

bière au moyen de vis directement sur la

surface supérieure du distributeur de bière. (Voir Fig. 3).

Tour de 2.5 ": Cela nécessite la tour boucle. Placez la tour de bière au trou

dans la surface supérieure du distributeur de bière à une inclinaison de 60°,

et tourner dans le sens horaire 60° long de la fente de la carte. Assurezvous que le robinet soit dirigé vers l'avant de la machine. Fixez la tour de

bière avec des rondelles. (Voir Figure 4).

b) Prendre les accessoires de la soupape à bille mixte. Fixer le tuyau

transparent à la sortie de bière de la soupape à bille mixte. (Voir figur e 5).

3. Installez la bouteille de gaz CO2 et la soupape de régulati on de C O2:

a) Fixer les deux colliers de serrage de CO2 sur le tube rouge de CO2. (Voir

Figure 6).

b) Raccorder les extrémités du tube rouge de CO2 respectivement à l'or i fice

d'admission de CO2 de la soupape à bille mixte et la sortie ronde de la

soupape de régulation de CO2. Verrouiller ces connexions fermement avec

les deux pinces sur le tube rouge de CO2 (voir Figure 7).

2.5 ”

Page 30

29

c) A l'aide de la clé, serrer la soupape de régulation de CO2 avec l'orifice de

Interrupteur

Soupape de regulation

Bouteille de

Jauge du

régulateur

Support et retenue

de bouteille de CO

2

Le tube rouge do ux

de CO

2

Tour de bière

Bouteille

2

du

couvercle supérieur

Fût de bière

l'écrou hexagonal à la sortie de gaz de la bouteille de CO2. (Voir Figure 9.)

d) Placez la bouteille de CO2 et la soupape de régulation de CO2 dans le

cabinet et fixer la bouteille de CO2 avec le support et la retenue de la

bouteille. (Voir Figure 8.)

de CO

de sécurité

2

gaz de CO

2

4. Installez le fût de bière:

Rambarde

Placez le fût de bière dans le cabin et et

branchez fermement l'ouverture du fût au port

Boîte à eau

de connexion de la soupape à bille mixte.

(Voir Figure 10).

Remarque: Pour placer un fût dans le

de gaz CO

cabinet, utiliser la poig née de fût de

déplacer le fût à l'avant du distribut eur de

bière ouvert, puis se pencher attentivement

le fût de sorte que le bord inférieur soulevé

touche le bord du cabinet. Enfin, soulevez la poignée de fût à élever le fût

au niveau du fond de l'armoire et pousser le fût en place.

5. Installer la poignée et le robinet à bière:

Visser la poignée du robinet dans le sens horaire dans le robinet pour faire la

connexion. Connectez ensuite le robinet aux composants de la tour de la bière

et serrer avec une clé. (Voir Figure 9.)

6. Installez la rambarde du couvercle supérieur et la boîte à eau:

Réglez la rambarde de couvercle supérieur et la boîte à eau sur le dessus du

distributeur de bière. (Voir Figure 10.)

Remarques:

• Lors du remplacement du fût de bière, d'abord éteindre l'interrupteur de

sécurité sur la soupape de régulation de CO2 et enlever la soupape à bille

mixte pour sortir le fût.

• Lors du remplacement de la bouteille de gaz de CO2, souvenez-vous de

fermer l'interrupteur principal de la bouteille et l'interrupteur de sécurité de

la soupape de régulation de CO2. Ensuite, utiliser une clé pour desserrer

l'écrou hexagonal au port de connexion de la soupape de régulation avec la

bouteille de CO2. Puis, à l'aide d'une clé, enlever le boulon fixe de la

bouteille de CO2 pour sortir la bouteille.

Page 31

30

• Pendant le processus d'inst al lat ion, assurez-vous que toutes les pièces

Commutation de

Refroidissement

rapide

Chute de

Module d'affichage

sont bien connectées et qu'il n'y a aucune fuite de gaz.

• Lors du raccordement du tuyau au port de connexion, vous pouvez tremper

les extrémités dans l'eau chaude pour faire la connexion facile.

• Si le gaz comprimé sous haute pression dans la bouteille de CO2 n’est pas

manipulé correctem ent, il pourrait être dangereux:

a. Prenez note de la date du test sur le col de la bouteille avant

l'installation. Si elle est âgée de plus de 5 ans, ne pas utiliser le produit.

Rapportez-le à votre fournisseur de gaz.

b. Tenir la bouteille de gaz loin des sources de chaleur. Des cylindres non

utilisés doivent être placés debout dans un endroit frais et aéré (de

préférence au 70°F).

OPÉRATION

Panneau de commande

Le panneau de commande est situé juste au-dessus de la porte, et ressemble à

ceci:

température

Montée en

température

Fahrenheit / Celsius

Réglage de la température

Réglez le bouton ▼ ou ▲ sur le panneau de commande jusqu'à ce que le

module d'affichage indique la température souhaitée.

Le module d'affichage indique la température de consigne, et la gamme à

température contrôlée varie de 32 à 50°F (0 à 10°C).

Le module d'affichage i ndi q ue 5°C à la mise sous tension initiale. Chaque

pression sur le bouton ▼ ou ▲ diminue ou augmente la températur e affichée par

1°C (1°F).

La température optimale pour le stockage et la distribution de bière est de 34 38°F (1,1 à 3,3°C).

Changement entre Celsius et Fahrenheit

Vous pouvez alterner l’affichage de la température entre Celsius et Fahrenheit

en appuyant sur le bouton °F / °C. Lorsque la température est affichée en degrés

Page 32

31

Celsius, le symbole "°C" sera illuminé; avec un affichage en degrés Fahrenheit,

Indication

E1

E4

E7

Défaillance du

Défaut en capteur de

Défaut de

"°F" sera éclairé.

Fonction de refroidissement rapide

Appuyez sur le bouton Deep Chill à entrer dans l'état de refroidissement rapide.

L'icône "Rapid cooling" (refroidissement rapide) sur le module d'affichage allume

et l'affichage de température indique "00". Après être entré dans le mode de

refroidissement rapide, l'appareil fonctionner en continu pendant 24 heur es et

l'icône reste allumée. Après ce temps, l'icône se met hors tension et l'appareil

revient à son état antérieur.

Vous pouvez annuler le mode de refroidissement rapide tout moment au cours

de la période de 24 heures en appuyant simplement sur le bouton Deep Chill à

nouveau.

Remarque: La fonction de refroidissement rapide est normalement utilisée pour

refroidir le premier fût de bière dans l'appareil, lorsque que le fût doit être

utilisé dès que possible. Pour éviter un sur-refroidissement de la bière, ne pas

utiliser la fonction de refroidissemen t rapid e pour fût s successifs.

Le dégivrage automatique

Il n’est généralem ent pas nécessaire de dégivrer le distributeur de bière parce

que la glace déposée sur la paroi arrière est auto ma ti q uem ent décongelée. La

glace se forme sur la paroi arrière pendant le fonctionnement du compresseur.

Plus tard, lorsque le compresseur ne fonctionne pas, la glace fond et l'eau est

évacuée par la sortie dans la paroi arrière dans le bac de récupération situé audessus du compresseur où il évapore. Si vous voyez une accumulation d'eau à

l'arrière de l'appareil, vérifiez que le bac de vidange ne soit pas bouché. Utilisez

un cure-pipe ou un morceau de fil souple. Par temps très chaud et humide, un

peu de glace peut s'accumuler. Si nécessaire, retirez le contenu du distributeur

de bière, débranchez l'appareil et permettre un dégivrage. Un sèche-cheveux

peut faciliter le process us.

Lorsque les indications suivantes apparaissent dans le module d'affichage, il ya

une défaillance dans l'appareil. Bien que l'une des conditions d'erreur se produit,

le distributeur de bière peut encore fonctionner. Cependant, vous devez

contacter notre Service dès que possible pour obtenir des conseils sur la gestion

de la situation.

Défaillance

Remarque: Lorsque deux ou plusieurs capteurs tombent simultanément en

panne, les codes d'erreur afficheront alternativement sur le module

d'affichage. Si les capteurs de température ambiante et de dégivrage

Les messages d'erreur

capteur de

température dans la

zone réfrigérée

dégivrage dans le

compartiment

réfrigérateur

capteur de

température

ambiante

Page 33

32

échouent, une touche quelconque peut être actionnée. La température est

réglable. L'affichage de défaut sera rétabli après 15 se co ndes.

Fonctionnement normal

• S'il y a un bruit de l'eau précipitée lorsque la machine est en cour s d'utilisation, le

bruit est provoquée par le réfrigérant circulant dans les tubes de refroidissement

et circulant à travers le compresseur. Ceci est un phénomène normal.

• Le distributeur de bière n'a pas de fonction de chauffage. Lor sq ue la température

réglée est plus élevée que la température ambiante, la machine ne fonctionne pas.

Distribution de la bi ère

Suivez ces étapes pour dist r i buer de la bière:

1. Assurez-vous que le distributeur de bière est correctement branché à une prise

de courant mise à terre de 120V CA, 60Hz, 15 ampères.

2. Placez le bac d’égouttage sous le robinet de bière.

3. Ouvrez le robinet de bière en tirant le robinet vers vous rapidement et

complètement à distribuer la bière.

4. Augmenter la pression si la bière est trop lente. A la pression et la température

correcte, un verre de 10 oz doit être rempli en 4 secondes.

5. Tenez le verre stable à un angle de 45 °. Quan d il est rempli aux 2/3, commencer

redressant le verre. La mousse appropriée devrait êtr e serrée et crémeuse et le

collier sur un verre moyenne de vrait être de 3/4 "à 1" de haut.

Remarque: Il est normal de voi r la formation de condensation sur le r obinet. Elle est

causée par la différence de température entre la bière et les surfaces intérieures

du robinet quand la bière est circulante à travers la ligne.

Comprendre la température de la bière

La température recommandée pour servir la bière froide est entre 38° et 43°F. Pour

maintenir cette tem pér ature en des conditions ambiantes moyennes de 70°F, régler

le thermostat en conséquence.

Remarques: Pendant l'été, lorsque les températures sont plus chaudes, nous vous

recommandons de régler la commande à un réglage plus froid. La sélection et le

maintien de la températ ur e co nvenable à l'intérieur du cabinet de r éfrigérateur est

nécessaire pour maintenir la fraîcheur et la saveur de la bière. Des températures

trop froides ou chaudes à l'i ntérieur du réfrigérateur peu vent entraîner une perte

de saveur.

La température optim ale pour le stockage d'un fût est d'environ 38°F.

Bière sure est produite à la suite de la fermentation secondaire au-dessus de 45°F.

Conseils pour servir la bière

Les conseils suivants vous aideront à servir la bière parfait e. Pour servir la bière du

robinet semblable à la façon dont il a quitté la cuve, vérifier les points suivants:

• Propreté (voir Entretien du distributeur de bière)

• Température (voir Réglage de la température et Comprendre la température de

bière)

Page 34

33

• Pression (La pression recom mandée pour le système de CO

livres.)

• Utilisez uniquem ent du gaz CO

.

2

est de 8 à 10

2

Entretien du distributeur de bière

Nettoyage

Pour optimiser le refroidissement et d'économiser l'énergie en même temps,

épousseter à l'arrière du distributeur de bière périodiquement.

L'intérieur doit être nettoyé régulièrement. Utilisez une serviette ou une éponge

qui a été trempée dans une solution de détergent doux. Rincer à l'eau propre et

sécher avec un chiffon. Laissez la porte ouverte pendant un certain temps pour

permettre à l'appareil sécher complètement avant de mettre l'appareil sous

tension.

Ne pas utiliser une brosse dure, la laine d'acier, une brosse métallique, ou

abrasifs tels que le dentifrice, ou des solvants organiques comme l'alcool ou de

l'acétone pour nettoyer le distributeur de bière.

Lors du nettoyage ou de rinçage de l'appareil, veillez à ne pas laisser le panneau

de contrôle ou des composants électriques se mouiller.

Hors service

Si la machine est hors service pour plus de trois semaines, débranchez-le et

nettoyez et séchez soigneusement. Laisser la porte rester ouvert légèrement

pour éviter l'accumulation de moisissure et les odeurs.

Transporter l'appareil

Fixer solidement les articles en vrac à l'intérieur du distributeur de bière avec du

ruban adhésif. Tape le porte fer m ée a fin de n e pas ouvr i r pendant l e transport.

Desserrez les deux freins à pied avant de déplacer l'appareil.

Spécifications des fûts de bière

Les tailles de fûts qui peuvent être utilisés dans votre distributeur de bière:

1/2 tonneau 59 litres 15.5 gals. 1,984 onces 164 / 12-once verre

1/4 tonneau 30 litres 7.8 gals. 992 onces 82 / 12-once verre

1/6 tonneau 20 litres 5.2 gals. 661 onces 55 / 12-once verre

1/8 tonneau 15 litres 4.0 gals. 496 onces 41 / 12-once verre

Remarque: Notre distributeur de bière accepte presque tous les noms de

marque de1/2 fûts. Cependant, les fûts Coors ne rentrent pas dans notre unité.

Page 35

34

Mise au rebut d’un appareil usagé

• Lorsque votre appareil est finalement usé, jetez-le.

• Avant de jeter d'un ancien appareil, enlever la porte ou les portes mais laisser

des étagères ou des tiroirs en place afin que les enfants ne peuvent pas y

pénétrer facilement.

• Le système de réfrigération de l'appareil est rempli de réfrigérant et les

matériaux d'isolation qui doivent être recyclés séparément. Appelez votre

service de recyclage local pour les informations d'élimination appropriées.

• Pour des raisons de protection de l'environnement, lors du déplacement de

l'appareil, veillez à ne pas endommager la paroi arrière (l'unité de condenseur

ou les tubes) ou une partie du système de réfrigération à l'intérieur de

l'appareil.

• Ce distributeur de bière est à 100% sans CFC, mais le liquide de

refroidissement est sous pression et inflammable, et la perforation du système

scellé pourrait être dangereuse. Le réfrigérant utilisé dans le système fermé

est non toxique.

• Beaucoup de vieux appareils peuvent contenir des fluides frigorigènes qui

sont nocifs pour l'environnement, et doivent être recyclés par une entreprise

légalement autorisée.

Page 36

35

Problème

Cause

Solution

de temps.

Égoutter quelques onc es av ant de boi re.

fera la bière éventée.

permettent.

exemple, de rouge à lèvres).

Ne pas utiliser de savon.

ou tôle ondulée.

bière dans un verre mouillé.

l'apparence d'être éventée.

d'air. Remplacer une source d'air lente ou le

Dépannage de bière pression

La bière est

nuageux: La

bière dans le

verre semble un

peu floue et pas

clair.

Températures

excessivement

basses peut

provoquer bière

floue ou nuageux,

en particulier

lorsque la bière

est dans la

bobine à froid

pendant de

longues périodes

Verres peuvent

ne pas avoir été

correctement

nettoyés.

Augmenter le réglage de la tempér a tur e de

l'appareil.

Ne pas laver les verres de bière avec des verres

qui ont contenus du lait ou tout autre substance

grasse. Une accumulation excessive de

germicide peut aussi laisser un film gras, ce qui

Il est préférable de stériliser à la vapeur les

verres où les lois en matière de santé le

Laver les verres à fond avec un bon détergent

pour enlever tous les substances grasses (par

Ne pas essuyer les verres secs. Permettez les

verres sécher à l'air en les plaçant sur une grille

Rincez les verres à l'eau fraîche juste avant de

servir la bière. Il est préférable de servir de la

Tirage incorrect

de bière en verre

Pas assez de

pression

Ouvrez le robinet rapidement et complètement;

mousse appropriée devrait être crémeuse et

serrée. Le collier sur le verre moyen devrait être

de ¾ " à 1" de haut. Bière tirée sans tête a

Augmenter la pression si la bière court trop lent.

Le débit correct devrait pouvoir remplir un verre

de 10 onces en 4 secondes (env. 8 onces de

liquide). Vérifier la source de pression afin de

déterminer s’il existe des obstacles à la conduite

Page 37

36

régulateur de CO2 et la jauge. La pression de la

bouteille doit toujours être supérieure à la

une pression sur le fût avant de tirer la bière.

désagréable.

robinet

rincé.

de bière.

pression utilisée dans le fût. Toujours appliquer

La bière a un

goût tourné:

Souvent amère;

parfois

complètement

dépourvue de

saveur et de

zeste. Il peut

aussi avoir une

odeur d'huile qui

peut porter un

goût

La condensation

se forme sur le

robinet.

Nettoyage

inapproprié du

Conduit d'air

contaminé

Il est normal de

voir la formation

de condensation

sur le robinet. Elle

est provoquée

par une

différence de

température entre

la bière et les

surfaces du

robinet lorsque la

bière est

circulante à

travers la ligne.

Bière qui reste

dans le robinet

n’est pas refroidie

par le distributeur

Brossez et nettoyez le robinet correctement. Il

doit être écumé à l'aide d'un détergent, puis

Le tube de la bière doit être examiné. En cas de

contamination, il doit être remplacé.

Après une période de non-utilisation, quelques

onces de bière devraient être vidées avant de

boire.

Page 38

37

Problème

Cause possible

Disjoncteur déclenc hé ou fusi bl e gr i l lé.

correctement.

position.

peuvent provoquer des pops et craquements.

Dépannage général

S’il y a un problème avec le distributeur de bière lui-même, voyez si vous pouvez

le trouver dans le tableau ci-dess ous. V ous pouvez être en mesure de vous faire

économiser le coût d'une visite de service.

Le distributeur de bière ne

fonctionne pas.

La machine se met en

marche et s’éteint

fréquemment.

La porte ne peut être

fermée correctement.

Bruit Un bruit ruant peut être le son de l'écoulement de

Alimentation pas bien branchée.

Tension fournie est trop faible.

La température d'intérieur est plus élevée que

d'habitude.

La porte de la machine est souvent ouverte.

La porte n’est pas com plèt e me nt fer mé e.

Le contrôle de température n’ est pas rég l é

Le fût de bière n’est pas correctement placé.

Le distributeur de bière n’est pas à niveau.

La porte a été renversée et pas réinstallée

correctement.

La plaque de métal ou le fût de bière est hors de

fluide frigorigène, ce qui est normal.

À la fin de chaque cycle, le gargouillis de

l'écoulement fluide fri g or i g ène peut êt re ent e ndu.

La contraction et l'expansion de la paroi interne

Page 39

38

Notes

Page 40

39

Garantie limitée

Révisé mars 2015

FELIX STORCH, INC.

Pour les pièces et la commande des

www.summitappliance.com/support

causer le cancer ou des défauts de naissance et d’autres dangers pour la reproduction. Pour plus

uits chimiques reconnus par le fabricant qui sont présents dans ce produit en concentrations

UN AN DE GARANTIE LIMITÉE

Dans les 48 États américains contigus, pendant un an à partir de la date d'achat, lorsque cet appareil est utilisé et

entretenu conformément aux instructions jointes à, ou fournies avec le produit. Le garant paiera pour les pièces spécifiées

en usine et pour la main-d’œuvre pour corriger les vices de matériaux ou de fabrication. Le service doit être fourni par une

compagnie de service désignée. En dehors des 48 États, toutes les pièces sont garanties pendant un an pour les défauts

de fabrication. Les pièces en plastique, étagères et armoires sont garanties être fabriqués conformément aux normes

acceptées dans le commerce et ne sont pas couvertes contre les dommages ou le bris pendant la manipulation.

. Le compresseur est couvert par la garantie pendant 5 ans.

1

2. Le remplacement n'inclut pas la main-d’œuvre.

LE GARANT NE SERA PAS TENU DE PAYER POUR CES POINTS :

1. Les appels de service pour rectifier l'installation de votre appareil, pour vous indiquer comment utiliser votre

appareil, remplacer ou réparer des fusibles ou rectifier le câblage ou la plomberie.

2. Les appels de service pour réparer ou remplacer des ampoules ou des étagères cassées. Les pièces à usure

(telles que des filtres) sont exclues de la couverture de la garantie.

3. Les dommages résultant d'un accident, modification, usage impropre ou abusif, incendie, inondation, actes de

Dieu, mauvaise installation, une installation non conforme aux codes d'électricité ou de plomberie, ou l'utilisation

de produits non approuvés par le garant.

4. Les pièces de rechange ou les frais de réparation pour les appareils utilisés hors des États-Unis.

5. Les réparations aux pièces ou systèmes résultant de modifications non autorisées apportées à l'appareil.

6. Les frais de déplacement et de transport pour le service produit dans des endroits éloignés.

7. Le retrait et la réinstallation de votre appareil s’il est installé dans un endroit inaccessible ou n'est pas installé

conformément aux instructions d'installation.

LE SEUL ET UNIQUE RECOURS DU CLIENT EN VERTU DE CETTE GARANTIE LIMITÉE EST LA RÉPARATION DU

PRODUIT TEL QUE PRÉCÉDEMENT DÉCRIT. GARANTIE IMPLICI TE, Y COMPRIS LES GA RA NTIE S DE QUALI TÉ

MARCHANDE OU D'ADÉQUATION À UN USAGE PARTICULIER, SONT LIMITÉES À UN AN. LE GARANT NE SERA PAS