Page 1

OPERATION

Place drip tray under beer faucet. To dispense beer,

open beer faucet quickly all the way.

The recommended pressure for the CO2 system is 8-10

lbs.

CLEANING

1. To maintain good-tasting beer, periodical cleaning of

2. To clean cabinet inside and outside, mix 2 table-

To provide protective care of the painted finish:

Regular application of wax or polish provides vital protection against rust. Waxing cleans the surface and seals

out moisture and other contaminants.

Beer Keg

Keg

Support

Fig. 3

beer system is required. Complete cleaning kit is

provided for your convenience. Refer to the instructions included in cleaning kit.

spoons of baking soda with 1 quart warm water, or

use mild soap. Never use strong cleanser, scouring

powder or pads. Do no put drip tray in dishwasher, it

is not dishwasher safe. Vacuum the tubing on the

outside back twice a year.

Use a wax or polish that is suitable for appliances.

Apply the wax or polish when the refrigerator is new

and then at least twice a year.

Between waxing, clean the cabinet with the same

polish or with a CLEAN soft cloth dampened with a

mild household detergent. Rinse with a CLEAN lightly dampened cloth and DRY thoroughly.

REPLACING EMPTY KEG

Close shutoff valve on CO2 regulator then remove keg

tapper from empty keg. To tap a new keg, follow the procedures C, D and E of “Installing Keg Tapper and Beer

Keg”.

WARNING:

In the event of abnormal behavior or failure of the unit, immediately

suspend usage and unplug the power cable.

(Risk of electrical shock, smoke or fire.)

Examples of abnormal behavior or failure:

The unit does not operate when it is plugged in.

When moving the power cord, the unit switches on and off.

During operation, there are abnormal sounds and a strong odor of burn-

ing.

The unit becomes extremely hot and its shape deforms.

Immediately request service or repair from an authorized service provider.

LIMITED WARRANTY

ONE-YEAR LIMITED WARRANTY

Within the 48 contiguous United States, for one year from the date of purchase, when this appliance is operated and maintained according to instructions attached to or furnished with the product, warrantor will pay for

factory-specified parts and repair labor to correct defects in materials or

workmanship. Service must be provided by a designated service company. Outside the 48 states, all parts are warranted for one year from manufacturing defects. Plastic parts, shelves and cabinets are warranted to be

manufactured to commercially acceptable standards, and are not covered

from damage during handling or breakage.

5-YEAR COMPRESSOR WARRANTY

The compressor is covered for 5 years.

Replacement does not include labor.

ITEMS WARRANTOR WILL NOT PAY FOR:

Service calls to correct the installation of your appliance, to instruct

you how to use your appliance, to replace or repair fuses or to correct wiring or plumbing.

Service calls to repair or replace appliance light bulbs or broken

shelves. Consumable parts (such as filters) are excluded from warranty coverage.

Damage resulting from accident, alteration, misuse, abuse, fire,

flood, acts of God, improper installation, installation not in accordance with electrical or plumbing codes, or use of products not approved by warrantor.

Replacement parts or repair labor costs for units operated outside

the United States.

Repairs to parts or systems resulting from unauthorized modifications

made to the appliance.

Expenses for travel and transportation for product service in remote

locations.

The removal and reinstallation of your appliance if it is installed in an

inaccessible location or is not installed in accordance with published

installation instructions.

DISCLAIMER OF IMPLIED WARRANTIES – LIMITATION OF

REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED

WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE

YEAR. WARRANTOR SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS

MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM

STATE TO STATE.

Part Number: 8336460120300

BEER DISPENSER

INSTRUCTION MANUAL

MODEL: SBC501B

SBC501SSST

READ THIS BOOK!

It will tell you how to operate and care for your

Beer Dispenser. It also offers tips on how to get

the best, as well as lowest cost performance.

SUMMIT APPLIANCE DIV.

Felix Storch, Inc.

770 Garrison Avenue

Bronx, New York 10474

Tel.: 1-718-893-3900

Fax: 1-718-842-3093

www.summitappliance.com

Page 2

Read and understand these instructions thoroughly before installing beer dispenser.

ASSEMBLY

1. Carton Inventory

Unpack and inspect the parts. Make sure all items are present

and in good condition.

1 Draft arm assembly (Package includes 1 gasket for draft arm

and 1 washer for connection to keg tapper)

1 CO2 regulator

1 CO2 cylinder

1 Keg tapper (Sankey type)

1 Cleaning kit

1 Pressure tube

2 Hose clamps

2 Keg supports (plastic plates)

1 CO2 cylinder retainer (spring)

1 Guard rail

1 Drip tray

4 Wheel casters

4 Hex head screws (5mm dia x 15mm long)

16 Machine screws (5mm dia x 12mm long)

8 Small screws (3mm dia x 10mm long)

2. Install casters

a. Empty the cabinet and then lay down the beer dispenser

sideways so that the door hinge side comes to the top. Be

careful not to cause dents or scratches on the cabinet.

Placing outer carton underneath the cabinet is recommended.

b. Install casters to the four bottom corners of the cabinet with

the four machine screws (5mm dia x 12mm long) for each

caster.

c. Stand the cabinet upright.

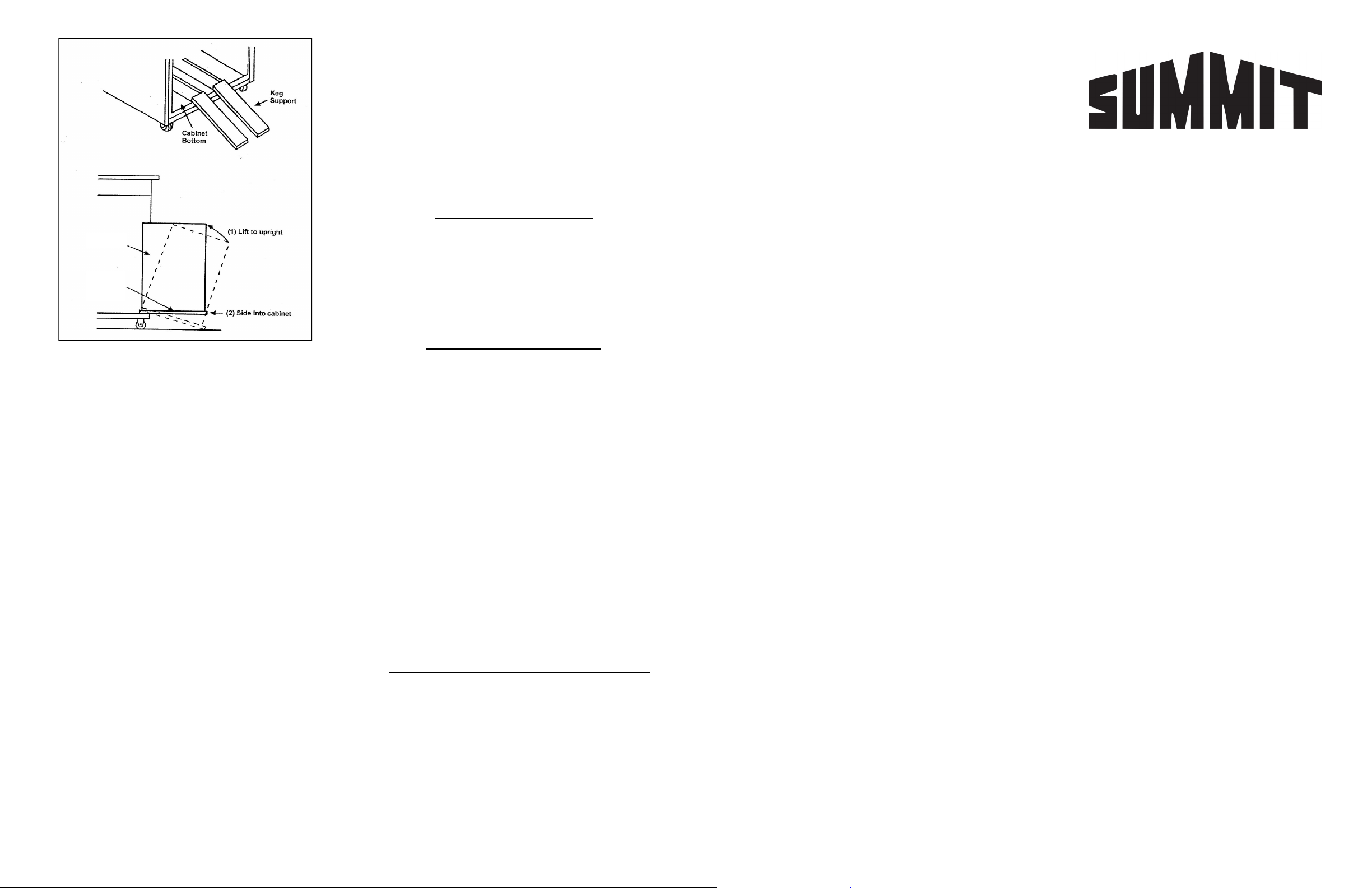

3. Install Draft Arm Assembly (See Fig. 1 ).

a. Slide gasket over wing nut on bottom of draft arm assembly

beer tube. Slide gasket up beer tube to draft arm base.

b. Push wingnut and beer tube of draft arm assembly through

hole in top of cabinet until draft arm is resting on cabinet

top.

c. Align holes in draft arm base with holes in gasket and pilot

holes in cabinet top, then secure draft arm to cabinet top

with four hex head screws (5mm dia x 15mm).

4. Install Guard Rail (See Fig. 1).

a. Place guard rail on cabinet top and secure guard rail with

eight small screws.

INSTALLATION

1. Install beer dispenser on strong level floor. Avoid direct sun-

light, heat sources and moisture. This beer cooler is designed

to be FREE STANDING, the appliance is to be installed so

that the coils on the back of the unit are at least 4" away from

the wall, 4” on both sides, 4” at the top and the cabinet bottom at least 3/4" to 1" from the floor.

2. Connect to 120V, 60Hz, 15 Amp grounded AC outlet. Do not

use extension cord. Use three-prong plug with three-prong

grounded wall outlet.

WARNING: Unless the above grounding method is followed,

you are not protected against severe or lethal shock in the

event of a short circuit of an electrical component or wiring of

beer dispenser.

TEMPERATURE CONTROL

1. Control is located on rear. First set the control at NORMAL

position. Wait for 24 hours to check the temperature then

adjust temperature control, if needed.

DEFROST

1. Beer dispenser will not require much defrosting since the

door opening is at a minimum. Defrost when ¼ inch frost is

built up on the cold plate. The best time to defrost is when the

keg is changed. To defrost, set temperature control at OFF

position and leave door open until ice melts. Defrost water will

accumulate at the bottom of interior cabinet which can be

absorbed with a sponge or towel. Do not use heating de-

vices or sharp objects to speed defrosting as this could

damage cabinet liner of cold plate. Reset temperature con-

trol after defrosting is completed.

INSTALLATION OF BEER SYSTEM

1. Installing CO2 Cylinder and CO2 Regulator

WARNING: CO2 GAS CAN BE DANGEROUS

a. Your CO2 cylinder is shipped empty to avoid any possible

accident during transportation. When you purchase the first

keg of beer, get CO2 cylinder filled by your beer distributor.

NOTE: Shutoff valve on CO2 cylinder may be different in

shape. Do not open shutoff valve until pressure tube, keg

tapper and beer keg are connected to CO2 regulator.

OPERATING INSTRUCTIONS FOR CO2 CYLINDERS

Do not operate valve control unless cylinder is completely

installed and connected.

TURN HANDWHEEL FULLY COUNTERCLOCKWISE AS

IMPORTANT: If valve is not fully opened the stem may not

seal properly against the upper packing washer and the valve

may leak. If leak occurs when fully opened, tighten down

packing nut under hand wheel then open and close valve fully

several times. Replacement packing washer must be ordered

directly from valve manufacturer whose name is stamped on

valve.

Do not remove valve from CO

CO

cylinder should be handled only by trained, experi-

2

enced personnel and in accordance with the safe handling

practices recommended by the current C.G.A. pamphlet

P-1 *.

FAR AS IT WILL GO

PRESSURE VESSEL

cylinder.

2

Keep out of reach of children.

Visually inspect monthly or more frequently. If cylinder

shows evidence of corrosion or mechanical damage, it should

be inspected and tested in accordance with the current

C.G.A. pamphlets C-1* or C-6* or it should be replaced.

CHARGE ONLY WITH DRY CARBON DIOXIDE

Do not charge with carbon dioxide unless the pressure rat-

ing stamped on CO

cylinder is 1800 PSI or greater.

2

When charged with carbon dioxide do not exceed a fill den-

sity of 68%. (fill density is a percent ratio of the weight of gas

in the cylinder to the weight of water that the cylinder will hold

at 60°F).

If cylinder has been exposed to temperatures in excess of

350°F, it must be destroyed.

Improper use of cylinder could cause serious bodily injury or

property damage.

C.G.A. pamphlets are published by the Compressed Gas

Association, 500th Ave., New York, N.Y.

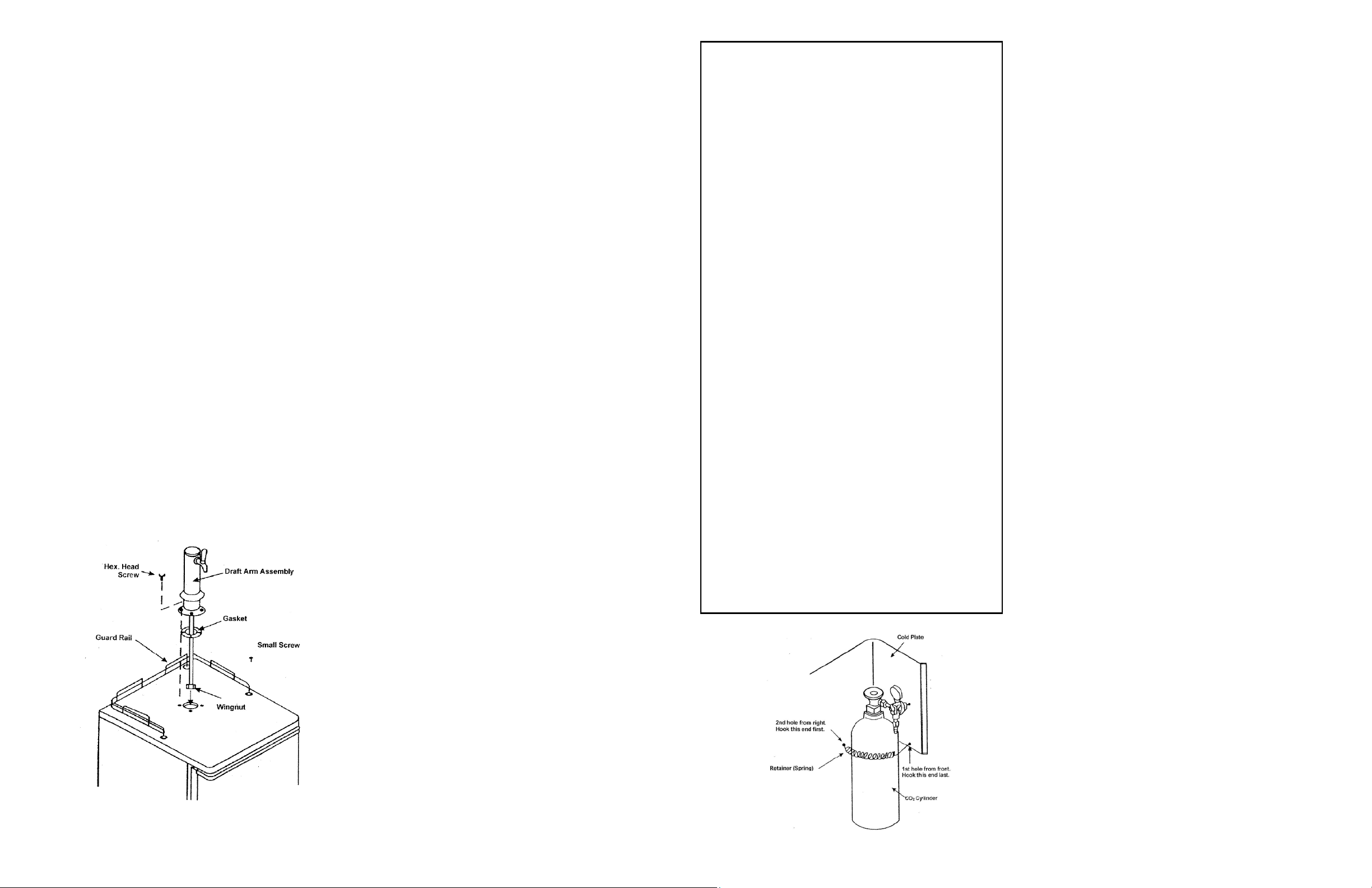

b. Connect pressure tube (clear plastic tube) to CO2 regulator

at nipple. Secure connection with hose clamp. To do this,

place hose clamp over tube and squeeze both ends of hose

clamp so that locking teeth will mate.

c. Place CO2 cylinder at right rear corner inside beer dis-

penser cabinet in upright position. Fasten CO2 cylinder with

CO2 cylinder retainer (spring) provided. Hook both ends of

retainer to holes in cold plate. (See Fig. 2).

WARNING: To avoid personal injury and/or property damage, always secure CO2 cylinder with retainer to prevent it

from falling. Should CO2 cylinder valve become accidentally

damaged or broken off, CO2 cylinder can become an unguided missile.

2. Installing Keg Tapper and Beer Keg.

a. The Sankey type keg tapper supplied with beer dis-

penser is the most widely used in the United States.

However, some other type keg tappers, such as Golden-Gate, European Sankey or Hoff-Stevens are still

being used. Before installing keg tapper, check with

your beer distributor to make sure that the Sankey type

keg tapper can be used. If you need a keg tapper other

than Sankey type, it is recommended to purchase the

tapper you need from your beer distributor keeping the

Sankey type keg tapper for future use because the

Sankey system is becoming more widely used.

If you wish to have the Sankey type keg tapper exchanged with

another type keg tapper, please return collect the Sankey type

keg tapper to the address below specifying the type of keg tapper

you need.

Panasonic Appliances Refrigeration Systems Corporation of America

2055 Sanyo Avenue

San Diego, California 92154

ATTN.: Customer Service Dept.

b. Make sure shutoff valve on CO2 regulator is in closed

position. Connect pressure tube to nipple of keg tapper

(use hose clamp). Connect beer tube from draft arm to

keg tapper (fasten securely with washer and wingnut).

c. Make sure that beer faucet and keg tapper are in

closed position, then tap a keg. Open keg tapper valve.

d. Make sure the keg is properly tapped, then open

shutoff valve on CO2 regulator. To install beer keg into

cabinet follow the steps below (See Fig. 3).

Wet the surface of keg supports (plastic

plates).

Lean keg supports on the front bottom edge

of cabinet. Place keg on supports supporting

keg by hands.

Push the upper part of keg to stand in up-

right position then slide keg supports into

cabinet.

Make sure that keg and beer tube do not

touch cold plate and that keg and keg supports are properly positioned not to interfere

with door closing.

e. Release air caught in draft arm assembly by opening

beer faucet unit foam appears. Now dispenser is ready

to use.

Fig. 1

Fig. 2

Loading...

Loading...