Page 1

A

S

f

(

SUMMIT

®

PLATINUM D4 , D6

BUILT-IN LP GAS GRILL INSTALLATION GUIDE

THIS GAS APPLIANCE IS DESIGNED

FOR OUTDOOR USE ONLY.

42369

LOCATING YOUR GRILL

When determining a suitable location for your Summit® gas grill installation, give attention to concerns such as exposure to wind, proximity to traffi c paths, and

keeping any gas supply lines as short as possible. Never locate the Summit® gas grill in a garage, breezeway, shed, under an unprotected overhang, or other

enclosed area. Locate the grill and structure so there is enough room to safely evacuate the area in case of a fi re.

CLEARANCE FROM SURFACES OR STRUCTURES

24 inches (61 cm) Any Surface

WARNING: Clearance from any surface or structure is

24 inches (609.6 mm) from the back and sides of the grill.

Refer to “Typical Gas Supply Installation” before starting

installation.

WARNING: The structure, “island”, countertops, and

adjacent work areas for the built-in grill installation must be

built from noncombustible materials only.

NOTE: If you have questions on what materials are considered noncombustible,

contact your local building materials supplier or fi re department.

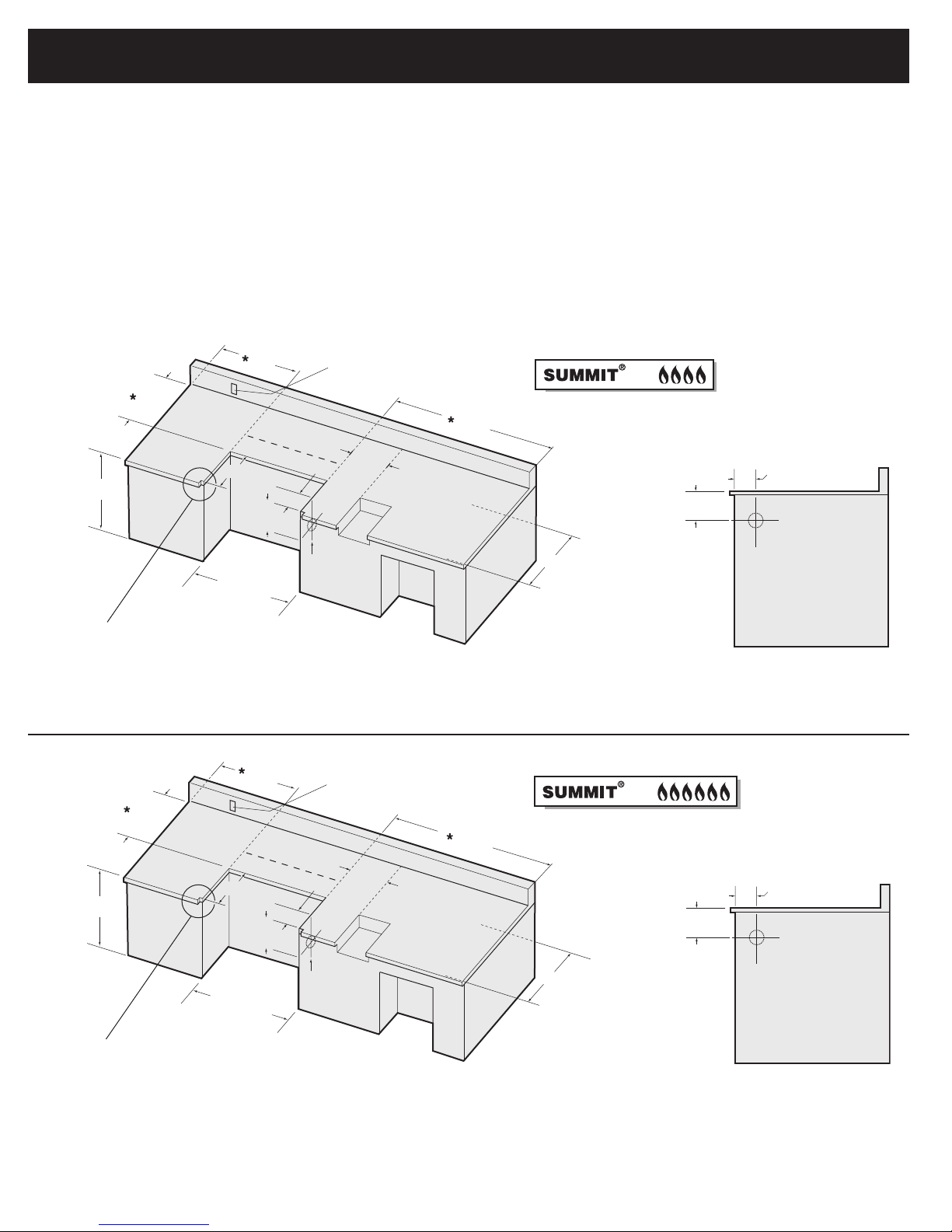

BUILT-IN STRUCTURE CUTOUT DIMENSIONS

ALL DIMENSIONS ARE TO FINISHED SURFACES.

Any Surface

24 inches

24 inches

(61 cm)

27 inches (685.8 mm) min. for

lid clearance

Grill Frame

Note: For a countertop treatment: Recommended 3/4 inch

19.1 cm) overhang. Notch front edge for frame to fully

slide in.

(61 cm)

WARNING: All countertop fi nished surfaces must be

constructed of a noncombustible material.

ny

ur

ace

3

2

1

Built-In Cutout Dimensions

1

2

3

D4 D6 Tolerances

1

30

˝ 38

/

4

1

34

˝ 34

/

4

21˝ 21˝ +

1

˝+

/

4

1

˝+

/

4

1

” -

/

4

1

” -

/

4

1

” -

/

4

42369 US 11/22/05

1

˝

/

4

1

˝

/

4

1

˝

/

4

LP

Page 2

2

BUILT-IN CUTOUT DIMENSIONS

GENERAL CONSTRUCTION DETAILS

Summit® Built-In unit and all other accessory units should be on site before construction begins.

1

All dimensions have a tolerance of plus or minus (+/-)

The grill frame rests directly on the Island Structure top fi nished surface. Make sure this surface is level. Do not support the grill from the

bottom.

If the supporting structure is going to have an electrical outlet for a rotisserie, it should be on the left side of the structure.

Refer to Summit

®

Built-In Tank Drawer Installation Instructions for complete gas line locations.

/4 inch (.635 mm).

24"

min.

24"

min.

30

21"

1

6

"

/

4

1

"

/

4

34

1

"

/

4

Built-In

Frame

Note: For a countertop treatment:

Recommended

Notch front edge for frame to fully slide in.

3

inch overhang.

/

4

24"

min.

24"

min.

21"

38

1

6

"

/

4

1

"

/

4

34

1

"

/

4

Built-In

Frame

Access for electric

on left hand side

D4

24"

min.

3

"

/

3

4

Gas Inlet

min.

Side Burner

Opening

27 inches min.

1

6

"

/

4

3

3

Gas Inlet

1/2"

10

distance from front

edge of the cutout

for open lid clearance

*Clearance from any surface or structure is at least 24 inches from the back and

sides of the grill.

Access for electric

on left hand side

10

3

3

"

/

4

Gas Inlet

1/2"

min.

24"

min.

Side Burner

Opening

27 inches min.

distance from front

edge of the cutout

for open lid clearance

D6

3

3

1

6

"

/

4

Gas Inlet

"

/

4

"

/

4

Note: For a countertop treatment:

Recommended

Notch front edge for frame to fully slide in.

3

inch overhang.

/

4

*Clearance from any surface or structure is at least 24 inches from the back and

sides of the grill.

Page 3

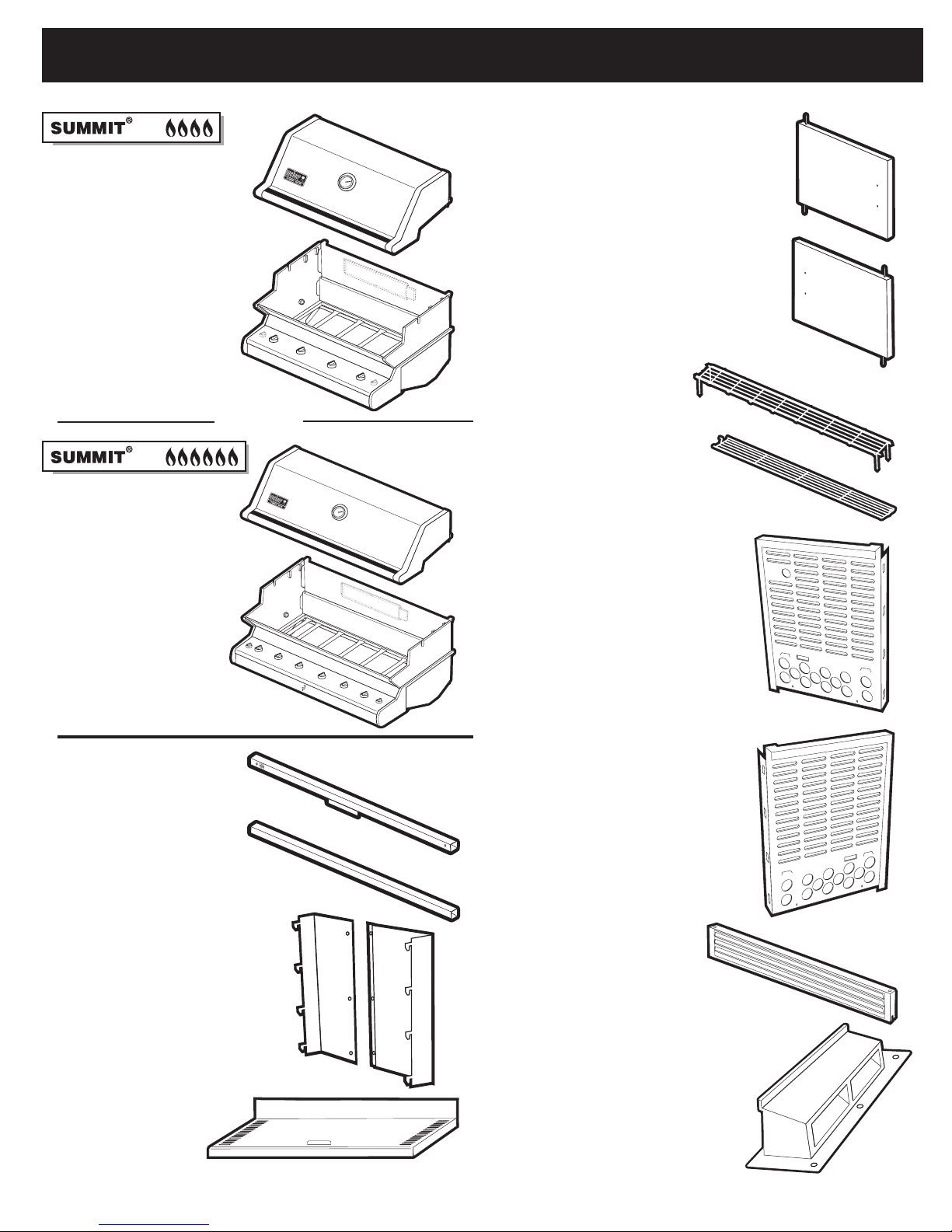

Lid - 1

D4

PARTS LIST

Left Door - 1

3

Cookbox - 1

Lid - 1

Cookbox - 1

D6

OR

Right Door - 1

Warming Rack - 1

Warm-Up

Right Enclosure Panel - 1

™

Rack - 1

Front Frame Rail - 1

Rear Frame Rail - 1

Rear Panel

Assembly - 1

Bottom Shelf - 1

Left Enclosure Panel - 1

Front Vent Panel - 1

Rear Vent - 1

Page 4

4

PARTS LIST

Flavorizer

Stainless Steel

Cooking Grates

®

Bars - 2 Sets

4B

6B

Bottom Tray - 1

Catch-Pan Holder - 1

- 2

- 3

Wrench - 1

x10 Sheet Metal Screws - 3

Plastic Anchors - 3

1/2 inch Bolts

(1/4 x 20 x 1/2 inch Bolt) - 8

#10-32 x 1/4 inch Steel Screws - 5

Nylon Washer - 8

Handle - 2

Catch-Pan - 1

Disposable Drip Pans - 2

Hinge Pin- 2

Hair Pin Cotter- 2

Corrugated gas line - 1

Right Front Vent Clip - 1

Left Front Vent Clip - 1

Handle Hardware - 4

Rotisserie - 1

Rotisserie Motor - 1

Rotisserie Bracket - 1

Keps Nuts (1/4 x 20 Blk Zinc) - 2

Rotisserie Bracket Hardware- 2

Smoker - 1

7/16 inch Wrench - 1

Page 5

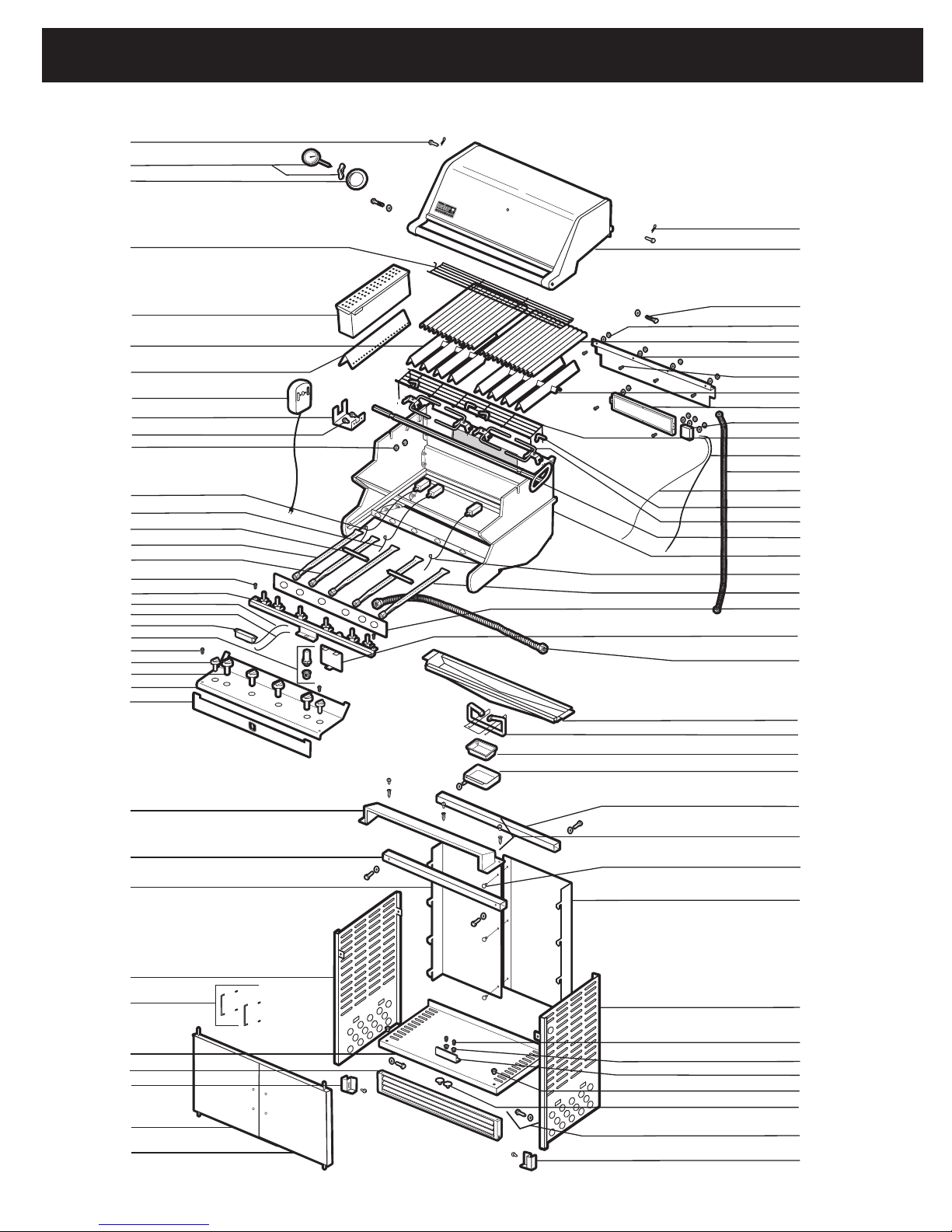

EXPLODED VIEW - PLATINUM D4

5

7740501 - Summit® Platinum D4 LP Built-In 092005

1

2

3

38

4

39

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

5

6

7

8

9

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

28

29

30

31

32

33

34

35

36

37

65

66

67

68

69

70

71

72

73

74

75

76

Page 6

6

EXPLODED VIEW - PLATINUM D6

7790501 - Summit® Platinum D6 LP Built-In 092005

1

2

3

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

4

5

6

7

8

9

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

32

33

34

35

36

37

38

39

40

41

69

70

71

72

73

74

75

76

77

78

Page 7

EXPLODED VIEW LIST - PLATINUM D4

7

1. Hinge Pin

2. Thermometer Hardware

3. Thermometer Bezel

4. Warm-Up™ Basket

5. Smoker Assembly

6. Flavorizer® Bar Assembly w/ Smoker

7. Smoker Box Chip Grate

8. Rotisserie Motor

9. Motor Bracket

10. Motor Bracket Screw

11. 1/4 - 20 inch Keps Nut

12. Smoker Electrode Assembly

(10 1/2 inch wire)

13. Electrode Assembly (8 3/4 inch wire)

14. Crossover® Tube

15. Smoker Burner Tube

16. Left Burner Tube

17. 10 - 24 x 1/2 inch Black Screw

18. Manifold

19. Negative Ignition Switch Wire

20. Positive Ignition Switch Wire

21. Four Output Ignition Module Assembly

22. Ignition Switch Button Assembly

23. 10 - 24 x 1/2 inch Black Screw

24. Small Control Knob

25. Control Knob

26. Control Panel

27. Front Panel

28. Vent Cover Assembly

29. Front Frame Rail

30. Left Rear Panel

31. Left Panel

32. Handle Assembly

33. Bottom Shelf

34. Toe Kick Vent

35. Left Vent Bracket

36. Left Door Assembly

37. Right Door Assembly

38. Hair Pin Cotter

39. Lid Assembly

40. 1/4 - 20 x 1 1/4 inch Bolt

41. IR Rain Cover Hardware

42. 12 inch Cook Grate

43. IR Rain Cover

44. 10 - 24 x 1/2 inch Stainless Steel Screw

45. Right Flavorizer® Bar Assembly

46. IR Burner

47. IR Cover Box

48. Warming Rack

49. Thermocouple

50. IR Gas Line

51. IR Electrode Wire

52. Rotisserie Fork Screw

53. Rotisserie Fork

54. Rotisserie Shaft

55. Cookbox Assembly

56. Electrode Assembly (16 1/4 inch wire)

57. Right Burner Tube

58. Heat Shield

59. Battery Shield Assembly

60. Main Gas Line

61. Bottom Tray

62. Summit Catch Pan Holder

63. Summit Catch Pan

64. Summit Drip Pan

65. Rear Frame Rail

66. Rear Vent Hardware

67. Rear Panel Hardware

68. Right Rear Panel

69. Right Panel

70. 10 -16 x 3/4 Screw w/ Washer

71. Plastic Plug

72. Door Stop

73. Door Bushing

74. Door Plug

75. 1/4 - 20 x 1/2 inch Black Bolt

76. Right Vent Bracket

EXPLODED VIEW LIST - PLATINUM D6

1. Hinge Pin

2. Thermometer Hardware

3. Thermometer Bezel

4. Warm-Up™ Basket

5. 8 inch Cooking Grate

6. Smoker Assembly

7. Smoker Box Chip Grate

8. Flavorizer

9. Rotisserie Fork

10. Rotisserie Motor

11. Motor Bracket

12. Motor Bracket Screw

13. 1/4 - 20 inch Keps Nut

14. Smoker Electrode Assembly

(10 1/2 inch wire)

15. Electrode Assembly (8 3/4 inch wire)

16. Crossover

17. Smoker Burner Tube

18. Left Burner Tube

19. Right Burner Tube

20. 10 - 24 x 1/2 inch Black Screw

21. Manifold

22. Negative Ignition Switch Wire

23. Positive Ignition Switch Wire

24. Six Output Ignition Module Assembly

25. Ignition Switch Button Assembly

26. 10 - 24 x 1/2 inch Black Screw

®

Bar Assembly w/ Smoker

®

Tube

27. Small Control Knob

28. Control Knob

29. Control Panel

30. Front Panel

31. Vent Cover Assembly

32. Front Frame Rail

33. Left Rear Panel

34. Left Panel

35. Door Stop

36. Handle Assembly

37. Bottom Shelf

38. Left Vent Bracket

39. Toe Kick Vent

40. Left Door Assembly

41. Right Door Assembly

42. Hair Pin Cotter

43. Lid Assembly

44. 1/4 - 20 x 1 1/4 inch Bolt

45. 12 inch Cook Grate

46. IR Rain Cover Hardware

47. Right Flavorizer® Bar Assembly

48. IR Rain Cover

49. 10 - 24 x 1/2 inch Stainless Steel Screw

50. Warming Rack

51. Rotisserie Fork Screw

52. IR Burner

53. IR Cover Box

54. Thermocouple

55. IR Gas Line

56. Rotisserie Shaft

57. IR Electrode Wire

58. Cookbox Assembly

59. Electrode Assembly (16 1/4 inch wire)

60. Electrode Assembly (25 1/2 inch wire)

61. Heat Shield

62. Main Gas Line

63. Battery Shield Assembly

64. Bottom Tray

65. Summit Catch Pan Holder

66. Summit Catch Pan

67. Summit Drip Pan

68. Rear Frame Rail

69. Rear Vent Hardware

70. Rear Panel Hardware

71. Right Rear Panel

72. Right Panel

73. 10 -16 x 3/4 Screw w/ Washer

74. Plastic Plug

75. Door Bushing

76. Door Plug

77. 1/4 - 20 x 1/2 inch Black Bolt

78. Right Vent Bracket

Page 8

8

ASSEMBLY

1

2

1

2

1

Arrow stickers on

Frame Rail (1) and

Left Side Panel (2)

should point toward

each other (shown

above). Door Stop

Bracket (3) should

3

be positioned as

shown (left).

2

ATTENTION!

Do not fully tighten screws.

Clips should slide freely when

installed.

Page 9

3

ASSEMBLY

9

4

Page 10

10

ASSEMBLY

5

Page 11

6

ASSEMBLY

CAUTION: Use two people to lift and install the Summit® Built-In frame assembly.

a.) Lift the frame assembly into the “island” structure opening. Make sure the frame is resting level on the fi nished surface of the

structure.

b.) Adjust the Front Vent to rest squarely on ground.

c.) Apply a bead of silicone sealant (1) around the perimeter and front edges of the grill that are in contact with the “island”

structure. This will prevent moisture seepage. The sealant you use must have a temperature rating above 120°F (48.8° C).

Any Surface

24 inches (610mm)

11

a.

c.

(1)

24 inches

(610mm)

24 inches

(610mm)

Note: For a countertop treatment

Recommended 3/4 inch (19.1 mm)

overhang. Notch front edge for

frame to fully slide in.

Frame

Any Surface

24 inches (610mm)

Frame

24 inches

(610mm)

24 inches

(610mm)

b.

Page 12

12

ASSEMBLY

7

D4

D6

(1)

(2)

(3)

Page 13

8

ASSEMBLY

13

(1)

D4

D6

(2)

Page 14

14

ASSEMBLY

9

D4

D6

a

Match Holder

b

c

Page 15

10

ASSEMBLY

15

1/4" Drill Bit

11

Page 16

16

12

13

ASSEMBLY

14

15

Page 17

GAS SUPPLY

17

BUILT-IN GAS LINE LOCATIONS

Note: Leave an access in the “island” structure for gas supply and regulator

service that is not inside the grill structure. Weber® has a gas line and

regulator access door (part # 36311) available from your dealer or call

Customer Service at 1-800-446-1071.

Note: Area should be kept clear of sharp, jagged, or extremely abrasive

surfaces to avoid possible damage to gas supply lines. Exercise caution when

pulling gas lines through built-in structure.

Plan View Left Side

3

"

3

/

4

1

6

/

Gas Inlet

"

4

B (6

1

")

/

4

A (3

C

3

")

/

4

Gas Inlet

Side view

TYPICAL BULK PROPANE GAS SUPPLY INSTALLATION

We recommend that this installation be done by a LICENSED professional.

General Specifi cations for Piping

Note - Contact your local municipality for building codes regulating outdoor

gas grill installations. In absence of Local Codes, you must conform to the

latest edition of the National Fuel Gas Code ANSI Z223.1/NFPA 54.

• This grill is designed to operate at 10.5 inches of water column pressure.

An LP in line regulator may be necessary for this pressure.

Caution: If young children are in the area, a

locking valve should be considered.

• Pipe compound should be used which is resistant to the action of liquid

propane gas when gas connections are made.

• The gas connections must be fi rmly attached to rigid, permanent

construction.

Note: The information provided in this manual is general for typical

installations. We cannot cover all possible installation ideas. We recommend,

prior to installation, that you contact your municipality for local building codes

and your local fi re department for installation verifi cation.

If you have any questions, contact Customer Service at 1-800-446-1071.

Built-In Gas Line Dimensions

D4 D6 Tolerances

A

B

Dimensions

C

Table

10-1

Nominal

Iron Pipe

Size

(Inches)

1/4 .364 32 22 18 15 14 12 11 11 10 98876

3/8 .493 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2 .622 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4 .824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1 1/4 1.380 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1/12 1.160 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

2 1/2 2.469 4800 3300 2700 2300 2000 1850 1700 1600 1500 1400 1250 1130 1050 980

3 3.068 8500 5900 4700 4100 3600 3250 3000 2800 2600 2500 2200 2000 1850 1700

4 4.026 17500 12000 9700 8300 7400 6800 6200 5800 5400 5100 4500 4100 3800 3500

3

3

/

"3

4

1

6

/

"6

4

1

/

"2

2

2

Maximum Capacity of Pipe in Cubic Feet of Gas per Hour for Gas Pressures of 0.5 psi or Less and a Pressure Drop of 0.3 Inch

Internal

Diameter

(Inches)

© 1997 National Fire Protection Association, Inc,. and International Approval Services - U.S., Inc. All Rights Reserved.

3

/

"" +

4

1

/

"+

4

1

/

"+

2

10 20 30 40 50 60 70 80 90 100 125 150 175 200

1

1

1

Water Column. (Based on a 0.60 Specifi c Gravity Gas)

/

" -

8

/

" -

8

/

" -

8

1

/

"

8

1

/

"

8

1

/

"

8

Length of Pipe (Feet)

Page 18

18

GAS SUPPLY

GAS LINE PIPING

• Refer to the piping chart at the bottom of previous page.

• The corrugated gas line from the manifold is 58 inches long. Do not

extend the gas line.

• We have provided the means to make an SAE 45° fl are connection. Do

not use pipe sealant on this connection.

• If the length of line required does not exceed 50 feet, use a 5/8” O.D.

tube. One size larger should be used for lengths greater than 50 feet.

Refer to piping chart.

• Gas piping may be copper tubing, type K or L; polyethylene plastic tube,

with a minimum wall thickness of .062 inch; or standard weight (schedule

40) steel or wrought iron pipe.

• Copper tubing must be tin-lined if the gas contains more than 0.3 grams

of hydrogen sulfi de per 100 cubic feet of gas.

• Plastic tubing is suitable only for outdoor, underground use.

• Gas piping in contact with earth, or any other material which may corrode

the piping, must be protected against corrosion in an approved manner.

• Underground piping must have a minimum of 18” cover.

TEST CONNECTIONS

All connections and joints must be thoroughly tested for leaks in accordance

with local codes and all listed procedures in the latest edition of the National

Fuel Gas Code ANSI Z223.1/NFPA 54.

DANGER

Do not use an open fl ame to check for gas leaks. Be

sure there are no sparks or open fl ames in the area

while you check for gas leaks. This will result in a fi re

or explosion which can cause serious bodily injury or

death, and damage to property.

TYPICAL 20 LP PROPANE GAS SUPPLY INSTALLATION

We strongly recommend that you use the Summit® Built-In

Tank Cabinet (#21280) for installations using a 20 lb LP cylinder, mounted

remotely in an “island” structure.

The Summit

remote mounted 20 lb LP cylinder, in an “island” structure. Summit® Built-In

Tank Cabinet has a hose and regulator assembly and gas connections, for

connecting a remote mounted LP cylinder to the Summit® Built-In gas grill. The

hose and regulator is listed as a required part of the CSA listed Summit® BuiltIn gas grill.

The Summit® Built-In Tank Cabinet also meets the requirements for venting,

tank retention and separation of the LP cylinder from a heat source as outlined

in the ANSI Standard for Outdoor Cooking Gas Appliances, Z21.58/CSA 1.6

for LP enclosures.

The Summit® Built-In Tank Cabinet has its own installation guide.

If you do not use the Summit® Built-In Tank Cabinet, you need to hire

a licensed contractor or licensed plumber and they need to follow the

requirements described in the ANSI Standard for Outdoor Cooking Gas

Appliances, Z21.58/CSA 1.6 for LP enclosures.

The requirements described in the Standard for Outdoor Cooking Gas

Appliances, Z21.58/CSA 1.6. are as follows;

A remote enclosure for an LP gas cylinder shall be ventilated by openings at

both the upper and lower levels of the cylinder. This shall be accomplished by

one of the following:

a). One side of the remote LP cylinder enclosure shall be completely open;

b). If the remote LP cylinder enclosure is designed to have four sides, a top

1). There should be at least two ventilation openings, (a hole or group

2). Ventilation openings (a hole or group of holes, for the purpose of

3). The minimum size of the ventilation hole (s) should not be less than

4). The ventilation openings in the sidewalls should not allow venting into

®

Built-In Tank Cabinet is a CSA listed accessory for installing a

or

and a bottom, ventilation is required for the remote LP cylinder enclosure;

of holes, for the purpose of ventilation) in the sidewalls of the island

structure. The openings should be located within 5 inches (127mm) of

the top of the enclosure. The ventilation openings should be equally

sized and spaced at a minimum of 90 degrees, and be unobstructed.

The openings shall have a total free open area of not less than 20

square inches. (This relates to 1 square inch of ventilation area, per

pound of stored fuel capacity).

ventilation) should be provided at fl oor level. The ventilation openings

should have a total free area of not less than 10 square inches. (This

relates to 1/2 square inch of ventilation area, per pound of stored

fuel capacity). There should be at least two ventilation openings

if the ventilation openings at fl oor level are in the sidewall. The

ventilation openings should be within 5 inches (127mm) of the fl oor.

The ventilation openings should be of equal size and be spaced at a

minimum of 90 degrees, and should be unobstructed.

1/4 inch.

the empty or “hollow” area of the “island”. If a gas leak should occur

or the LP cylinder should vent in the LP cylinder enclosure, the gas

should not be allowed to vent or migrate into the empty or “hollow”

area of the “island”. Ventilation openings in the sidewalls of the

enclosure should only communicate with the outside of the “island”

structure, so that the gas can dissipate outside of the “island” structure.

Page 19

GAS SUPPLY

19

c). If the remote LP cylinder enclosure has four sides, a top and a bottom,

and is intended for installation in a built-in “island” enclosure;

1). At least one ventilation opening (a hole or group of holes, for the

purpose of ventilation) needs to be on one side of the enclosure

that communicates with the outside of the “island” structure. If a gas

leak should occur or the LP cylinder should vent in the LP cylinder

enclosure, the gas should not be allowed to vent or migrate into the

empty or “hollow” area of the “island”. Ventilation openings should

only communicate with the outside of the “island” structure, so that

the gas can dissipate outside of the “island” structure. The ventilation

opening should be located within 5 inches (127mm) of the top of the

enclosure, and should have a total free area of 20 square inches. (This

relates to 1 square inch of ventilation area, per pound of stored fuel).

2). At least one ventilation opening (a hole or group of holes, for the

purpose of ventilation) needs to be on one side of the enclosure that

communicates with the outside of the “island” structure, at the bottom.

If a gas leak should occur or the LP cylinder should vent in the LP

cylinder enclosure, the gas should not be allowed to vent or migrate

into the empty or “hollow” area of the “island”. Ventilation openings

should only communicate with the outside of the “island” structure,

so that the gas can dissipate outside of the “island” structure. The

ventilation opening should be located within 5 inches (127mm) of

the bottom of the enclosure, and should have a total free area of 10

square inches. (This relates to 1/4 square inch of ventilation area, per

pound of stored fuel).

3). The minimum size of the ventilation hole (s) should not be less than

1/4 inch.

d). The remote LP cylinder enclosure should be constructed with non-

combustible materials. The remote LP cylinder enclosure should isolate

the LP cylinder from the burner compartment, so that it provides shielding

from radiation, be a fl ame barrier and provide protection from foreign

material such as hot drippings.

e). There should be a minimum of 2 inches (50.8mm) between the ground

and the fl oor of the remote LP cylinder enclosure.

f). The LP cylinder valve should be readily accessible for hand operation.

A door on the remote LP cylinder enclosure to gain access to the LP

cylinder valve is acceptable, provided it is non-locking and can be

opened without the use of tools.

If your licensed contractor or licensed plumber builds an LP cylinder enclosure

following the guidelines in the ANSI Standard for Outdoor Cooking Gas

Appliances,

Z21.58 CSA 1.6, you need to order kit number (#21287), which will contain the

hose and regulator assembly, mounting bracket for the regulator, connection

fi ttings and LP tank bracket for retaining the LP cylinder that must be used

with the Summit® Built-In gas grill. The hose and regulator in the kit (#21287) is

listed as part of the CSA listed Summit® Built-In gas grill.

DANGER

Use of any other hose and regulator assembly could be

dangerous, and may not provide adequate gas supply

®

to the Summit

Built-In gas grill, and could result in a

fi re or an explosion causing serious bodily injury or

death, and damage to property.

DANGER

Failure to use the Summit® Built-In Tank Cabinet for a

20 lb cylinder or failure to build a LP cylinder enclosure

for a 20 lb cylinder following the requirements for

ventilation, cylinder retention and separation of the LP

cylinder from a heat source, listed in the ANSI Standard

for Outdoor Cooking Gas Appliances, ANSI Z21.58 CSA

1.6, could be dangerous, and could result in a fi re or an

explosion causing serious bodily injury or death and

damage to property.

If you do not follow the DANGER statements exactly, the Warranty on the

Summit® Built-In gas grill will be voided.

ATTENTION: This product has been safety tested and

is only certifi ed for use in a specifi c country. Refer to

country designation located on outer carton.

These parts may be gas carrying or gas burning components. Please

contact Weber-Stephen Products Co., Customer Service Department for

genuine Weber-Stephen Products Co. replacement part(s) information.

WARNING: Do not attempt to make any repair to

gas carrying or gas burning components without

contacting Weber-Stephen Products Co., Customer

Service Department. Your actions, if you fail to follow

this product Warning, may cause a fi re or an explosion

resulting in serious personal injury or death and

damage to property.

Page 20

20

®

®

®

®

®

®

GAS SUPPLY

CONNECT GAS SUPPLY

A 58 inch corrugated gas line is supplied with the grill. This line needs to

pass through the gas inlet opening to the main gas supply.

1) Connect the corrugated gas line to the manifold located on the right

hand side of grill under the control panel. Use the 1/2” fl ared gasket (1)

to ensure proper seal.

Note: 1/2” fl ared gaskets are included in the Summit

cabinet (#21280) or the hose and regulator connection from kit # 21287.

Note: Leave an access in the “island” structure for gas supply and regulator

service not inside the grill structure. Weber® has a gas line and regulator

access door (part # 36311) available from your dealer or call Customer

Service at 1-800-446-1071.

®

Built-In tank

VENTILATION

WARNING: Air holes must be provided in the structure

at the top and bottom to provide ventilation in the event of

a gas leak.

Air holes can be located in a low visibility area and should be protected by

screening material to prevent rodents and insects from entering the structure.

Air holes will also help dry moisture.

®

Summit

Service at 1-800-446-1071.

Note: These drawings are only a reference.

• Cross ventilation must be incorporated in the supporting structure. We

• Vents should be on two sides of the structure.

Built-In cabinet vents are available from your dealer or call Customer

recommend a minimum of 100 square inches of venting per side.

OR

Right Side

Left Side

top view

(1)

The corrugated line passes through the “Island Structure” cavity to the

regulator connection inside the Summit® Built-In tank cabinet (#21280) or the

hose and regulator connection from kit # 21287. (Shown below)

Typical tank cabinet

or tank enclosure location

Front View

• The above drawings are for reference only.

• Location of the vents should be from the center, outward.

• Locate the vents at both the bottom of the structure and at the top of the

structure.

• The bottom vents should be as close to ground level as possible. Make

sure the vent area is not blocked by interior supports of the structure.

• We recommend vents with screens.

• Access doors to the structure are not considered vents.

• Clean the vents periodically.

DANGER: Failure to follow recommended minimum

venting instructions can cause gas to collect in the

structure in the event of a gas leak. This may result in a

fi re or an explosion which can cause serious bodily injury

or death, and damage to property.

WEBER-STEPHEN PRODUCTS CO.

©2006 The following trademarks are registered in the name of Weber-Stephen Products Co., an Illinois corporation, located at 200 East Daniels Road, Palatine, Illinois 60067 U.S.A.

Australia; Smokey Joe, Weber, Kettle Silhouette

tion, Botswana; Weber, Canada; Smokey Joe, Genesis, China; Kettle Silhouette

Smokey Joe, Weber, One-Touch, Germany; Smokey Joe, Weber, One-Touch, Greece; Smokey Joe, Ireland; Kettle Silhouette

Joe, Weber, Korea; Smokey Joe, Weber, New Zealand; Weber, Smokey Joe, Nigeria; Weber, Norway; Smokey Joe, Weber, Portugal; Weber, South Africa: Smokey Joe, Weber, Kettle

Confi guration, Spain; Smokey Joe, Weber, Sweden; Kettle Silhouette

One-Touch, U.S.A..; Kettle Confi guration, Kettle Silhouette

vorizer, Crossover, Flamgo, Performer, Rapidfi re, Tuck ‘N Carry, Jumbo Joe, Bar-B-Kettle, Master-Touch, Spirit, Grill Out, Summit, Platinum, 1-800-Grill-Out, Ranch, Matchless Flame,

Zimbabwe; Weber, Kettle Confi guration, Kettle Silhouette

, Genesis, Austria; Kettle Silhouette®, Smokey Joe, Weber, Benelux; Kettle Silhouette®, Smokey Joe, Weber, Compact Grill Confi gura-

, Denmark; Kettle Silhouette®, Smokey Joe, Weber, Finland; Smokey Joe, France; Kettle Silhouette®,

, Smokey Joe, Switzerland; Kettle Silhouette®, Smokey Joe, Weber, United Kingdom; Smokey Joe, Weber, Weber

, Smokey Joe, Weber, One-Touch, Firespice, Go-Anywhere, U.S.A.;Kettle Confi guration, Kettle Silhouette, Genesis, Fla-

.

www.weber.com

®

, Smokey Joe, Italy; Smokey Joe, Weber, Japan; Smokey

Loading...

Loading...