Page 1

HP

®

P4014 • P4015 • P4045

CARTRIDGE REMANUFACTURING INSTRUCTIONS

CC364X TONER CARTRIDGE

CC364A TONER CARTRIDGE

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 2

First introduced in April 2008, the HP LaserJet P4014 engine is a 45-62 ppm (depending on the model), 1200 dpi engine. These

printers will most likely replace the 4200/4300 series.

All of the machines in all three series have a first page out in less than 8.5 seconds, come with 128Mb of ram (Expandable to

640Mb),and have a 400MHz processor. All also come standard with a 10,000 page low yield cartridge. The new CC364A and

CC364X cartridges are rated for 10,000 and 24,000 pages respectively. The HY cartridges will not physically fit into the P4014

machines, only in the P4015 and P4515 series.

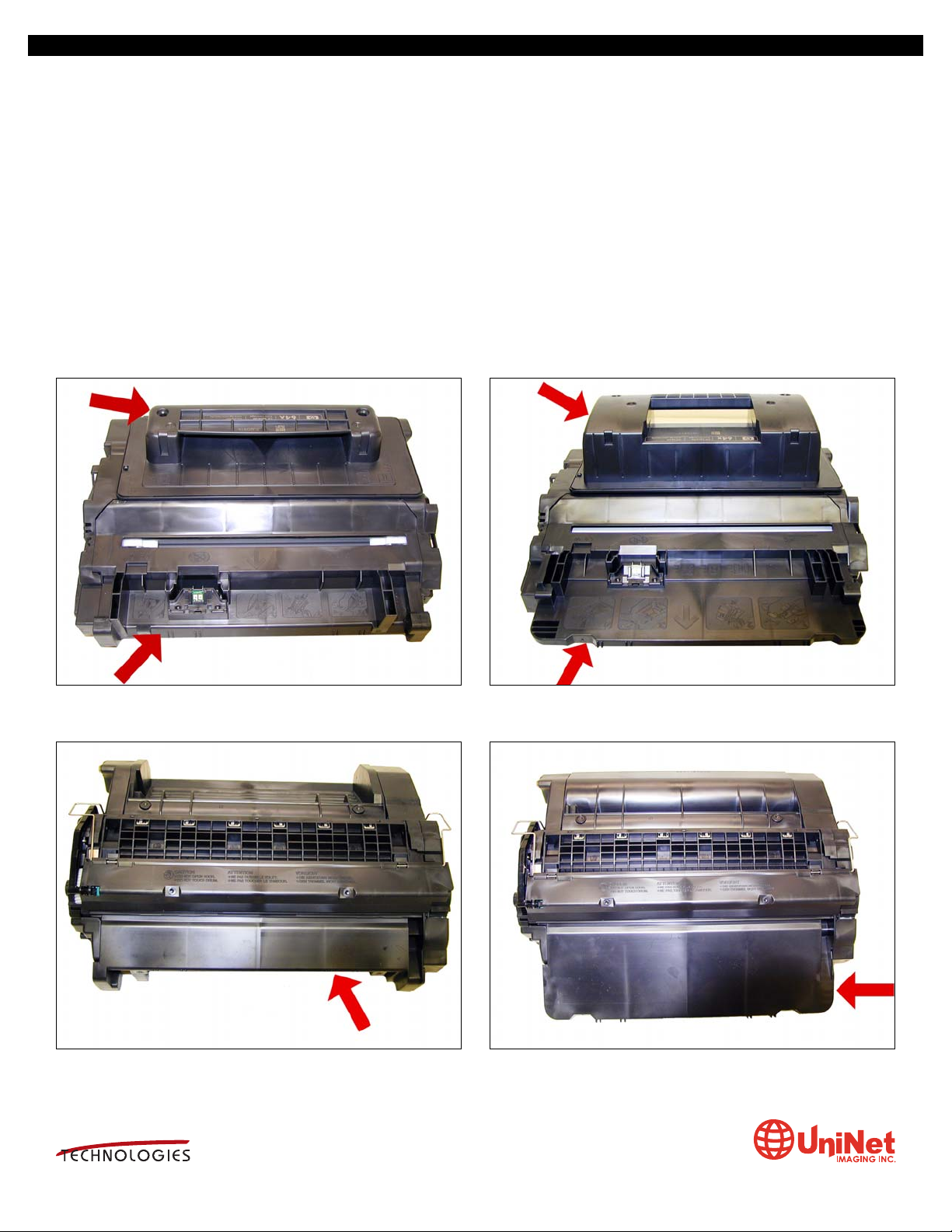

The following figures show the difference between the two cartridges:

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

REMANUFACTURING THE HP LASERJET

P4014, P4015 & P4045 TONER CARTRIDGES

By Mike Josiah

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Top of 64A Top of 64X

Bottom of 64A Bottom of 64X

Page 3

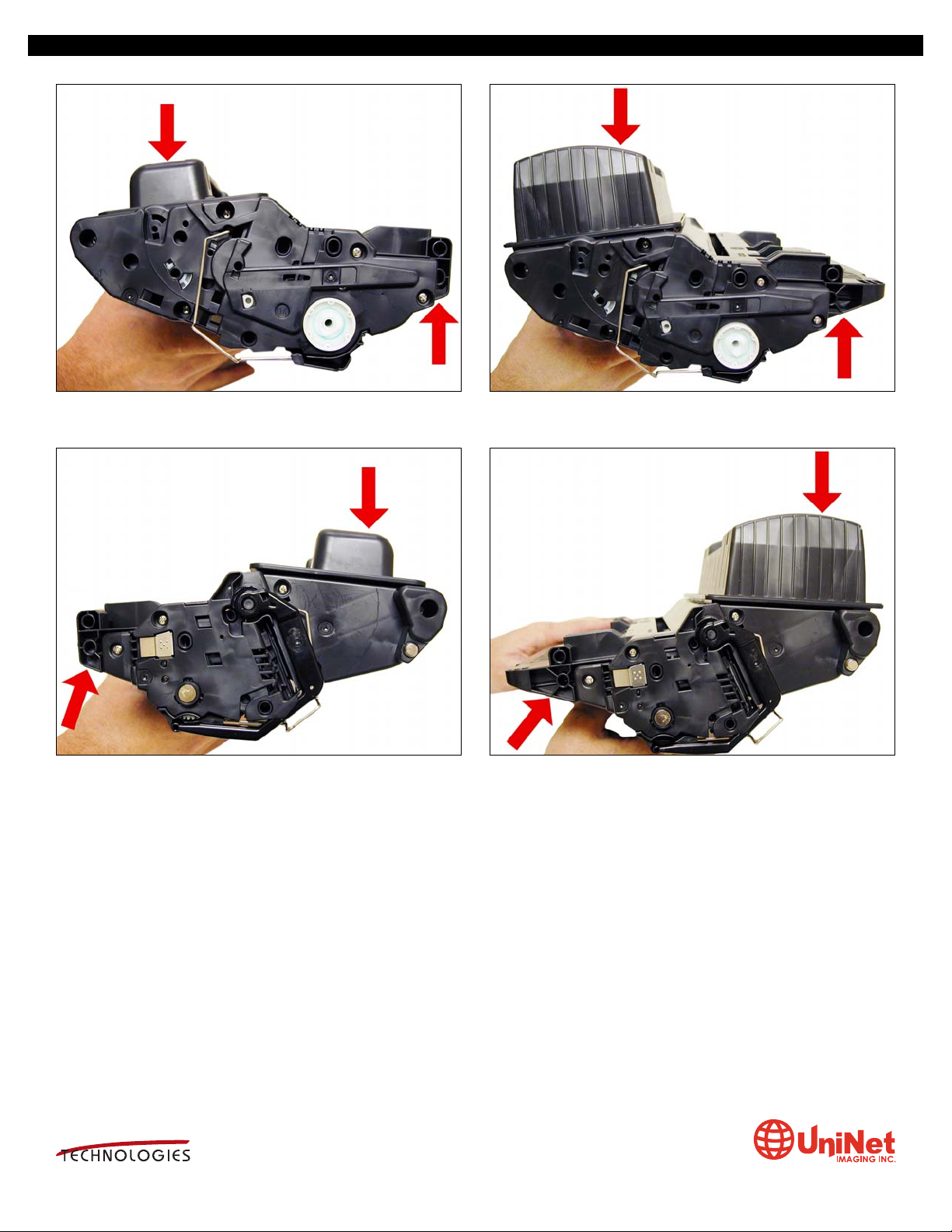

Right side of 64A Right side of 64X

Left side of 64A Left side of 64X

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

The toner used in these cartridges is also new. HP says it uses their “Enhanced Low-Melt Toner technology”. This toner according

to HP uses 15% less energy to fuse to the paper. In the fine print of the toner fact sheet they clarify that to mean 15% less as

compared to its predecessor. What exactly is the predecessor? They don’t say. Regardless, our testing has shown it to be a low

melt toner.

The current machines that use these new cartridges are as follows:

HP-LaserJet P4014 HP-LaserJet P4014n HP-LaserJet P4015n

HP-LaserJet P4015tn HP-LaserJet P4015x HP-LaserJet P4515n

HP-LaserJet P4515tn HP-LaserJet P4515x HP-LaserJet P4515xm

Printer usage, as well as some common printer/cartridge problems will be covered at the end of this article.

As these machines use new technology such as dual laser beams, we will run through the theory and explain how the new technology works.

Page 4

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

CARTRIDGE THEORY

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

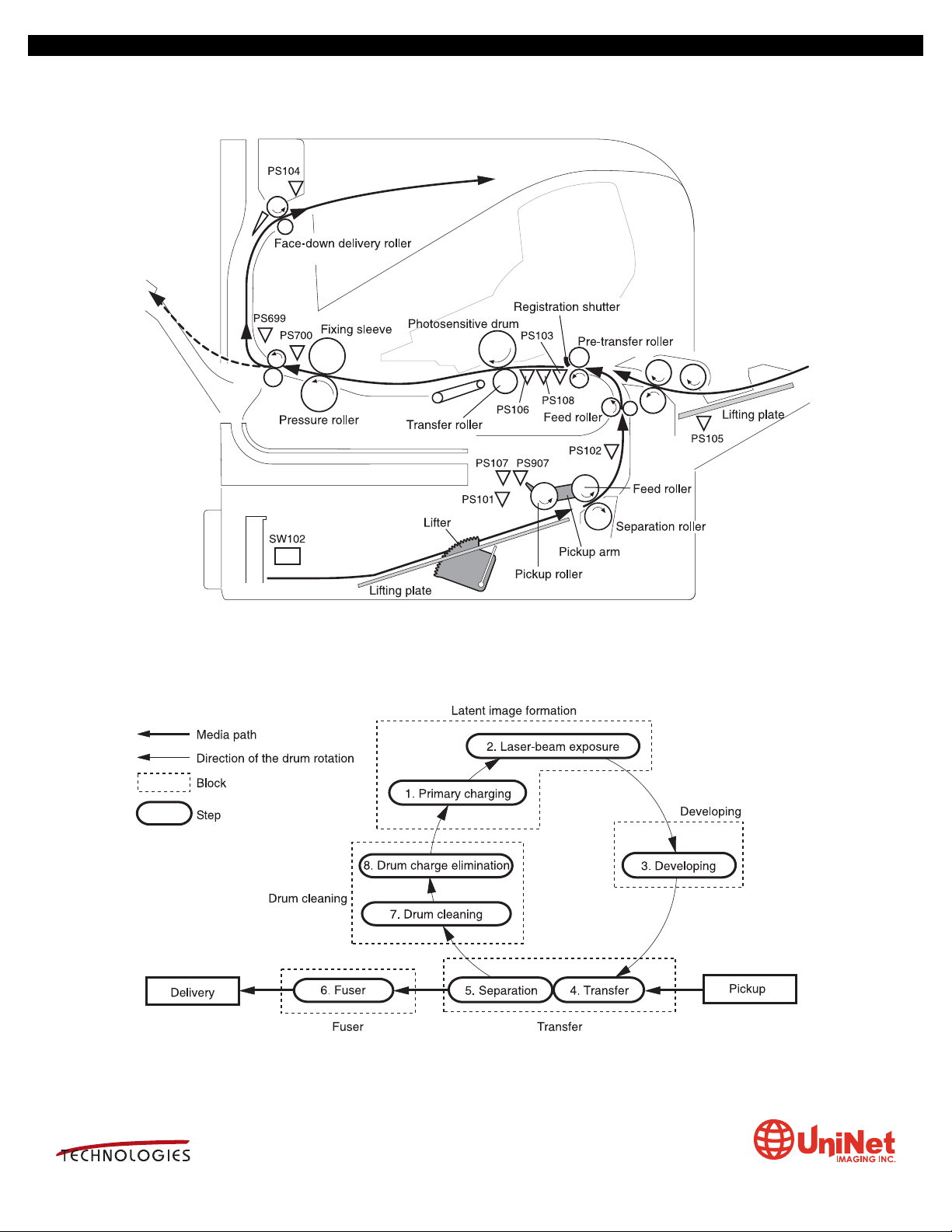

This illustration gives a nice view of the cartridge as it relates to the printer.

The image formation process consists of 8 steps which are split up into five functional blocks.

Page 5

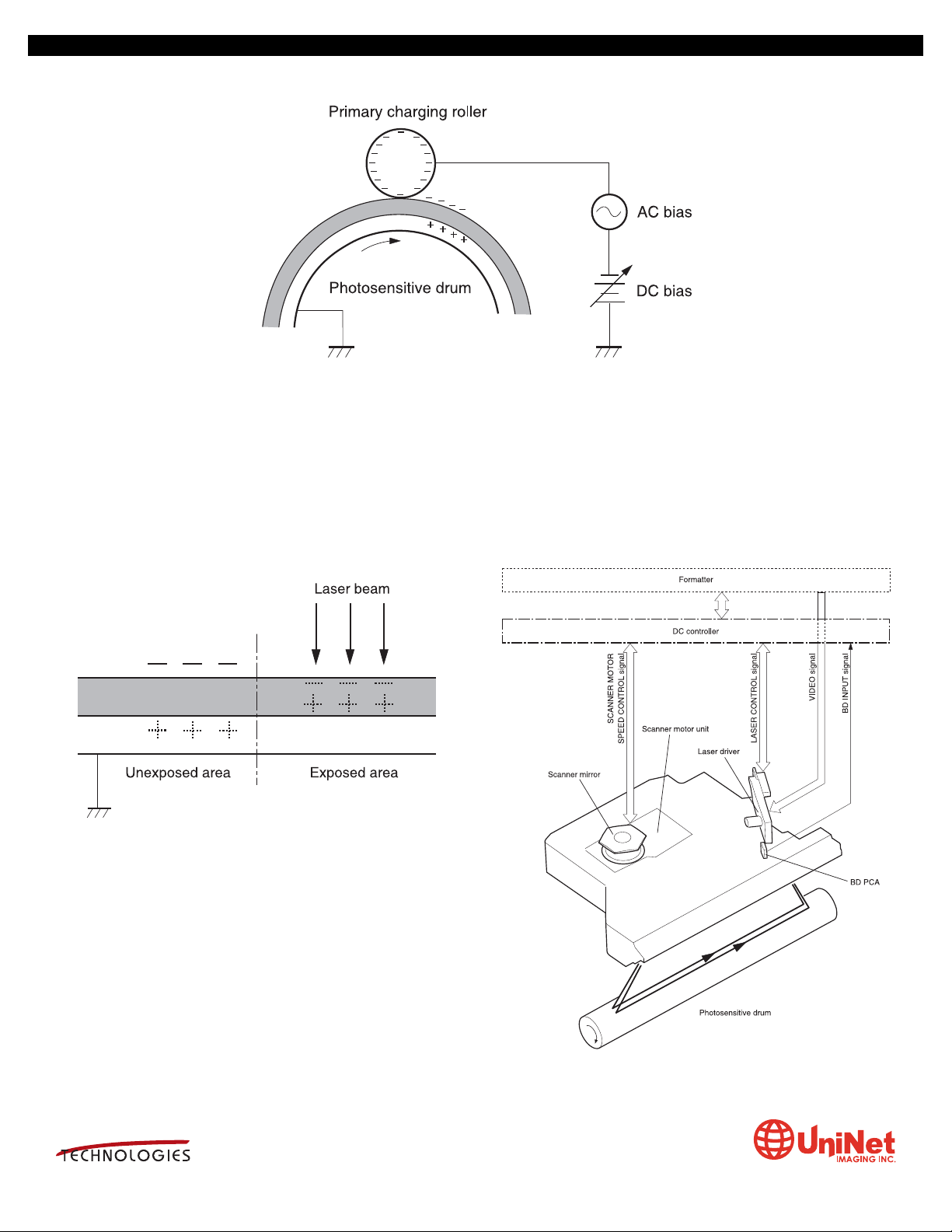

In the first step, the Primary Charge roller (PCR) places a uniform negative DC Bias voltage on the OPC drum surface. The amount

of the negative DC Bias placed on the drum is controlled by the printer’s intensity setting. This process is part of the latent Image

formation block.

In the second step, (also part of the latent Image formation

block), the laser beam is fired onto a rotating mirror (called the

scanner). As the mirror rotates, the beam reflects into a set of

focusing lens. The beam then strikes the OPC’s surface, which

neutralizes the negative charge on the drum and leaves a

latent electrostatic image on the drum. The laser unit actually

fires 2 beams. The service manual talks about the second

bean being used to erase residual charges, but not if it also

helps to write the image.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 6

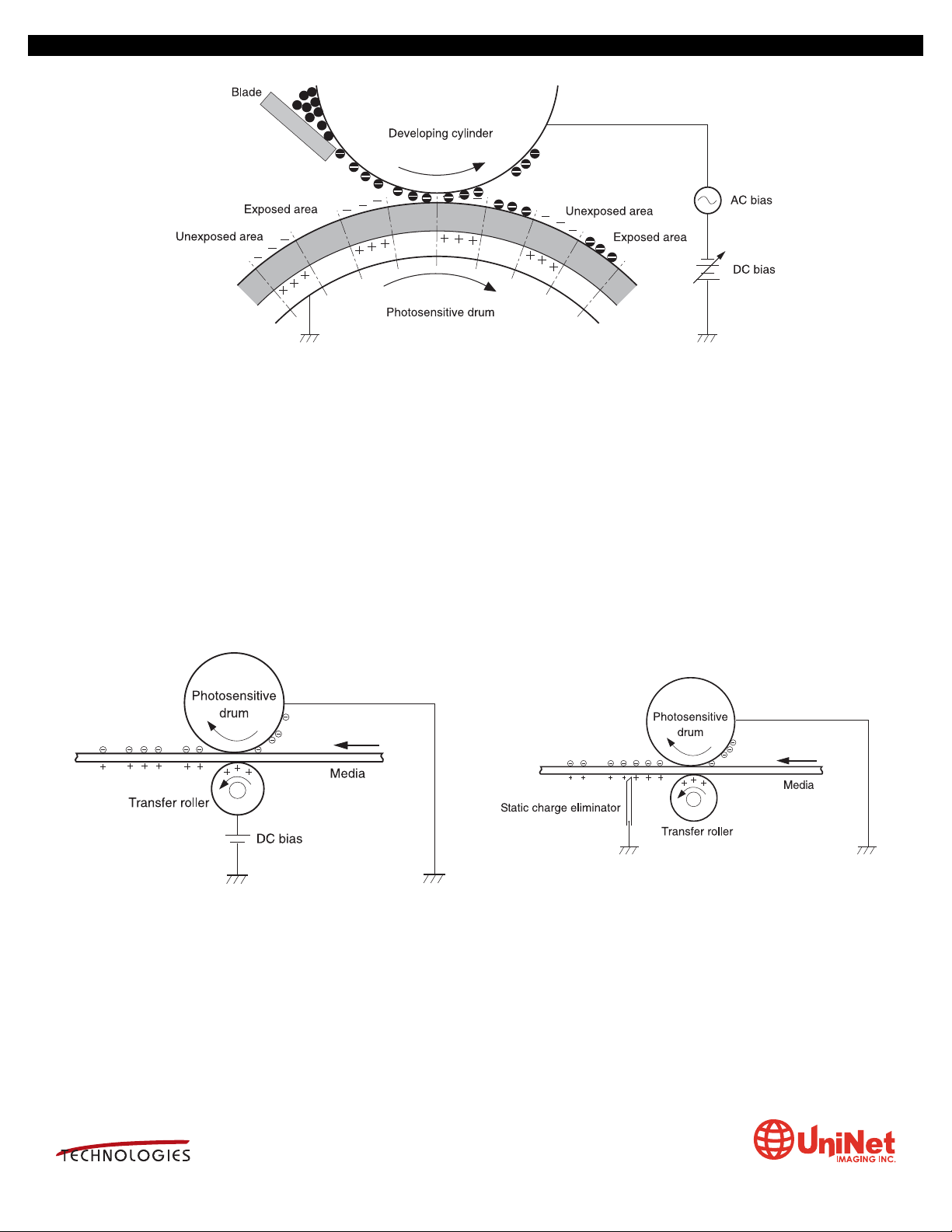

The third step (developing block) is where the toner image is developed on the drum by the developing section, (or supply chamber), which contains the toner particles. The toner is held to the magnetic roller sleeve by the stationary magnet inside the sleeve,

and a DC bias voltage supplied by the high voltage power supply. This DC bias voltage is controlled by the printer’s density setting, and causes either more or less toner to be attracted to the drum. This in turn will either increase or decrease the print density. Both the Primary Charge roller and magnetic roller DC Bias voltages are controlled by the printer’s density setting. The

amount of toner on the magnetic roller sleeve is also controlled by the rubber Doctor blade, which uses pressure to keep the

amount of toner on the magnetic roller sleeve constant. This blade also causes a static charge to build up on the toner, which

helps keep the coating of toner even, and allows easy transfer to the OPC drum.

At the same time an AC signal is also placed on the magnetic roller sleeve. This signal decreases the attraction of the toner to

the Magnetic Roller sleeve, and increases the repelling action of toner against the areas of the drum that was not exposed to the

laser beam. This AC potential improves the density, and contrast of the toner on the printed page.

As the laser exposed areas of the OPC drum approach the magnetic roller, the toner particles are attracted to the drums surface

due to the opposite voltage potentials of the toner, and laser exposed surface of the OPC drum.

In the fourth step (transfer block) the toner image is then

transferred to the paper as it passes below the drum by the

transfer charge roller, which places a positive charge on the

back of the paper. This positive charge causes the negatively

charged toner on the drum’s surface to be attracted to the

page. The small diameter of the drum, combined with the stiffness of the paper causes the paper to peel away from the

drum.

In the fifth step (also part of the transfer block) the paper separates from the drum. The static charge eliminator weakens

the attractive forces between the negatively charged drum surface, and the positively charged paper. This prevents toner

dropouts onto the paper at low temperatures and humidity

and also prevents paper from wrapping around the drum.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 7

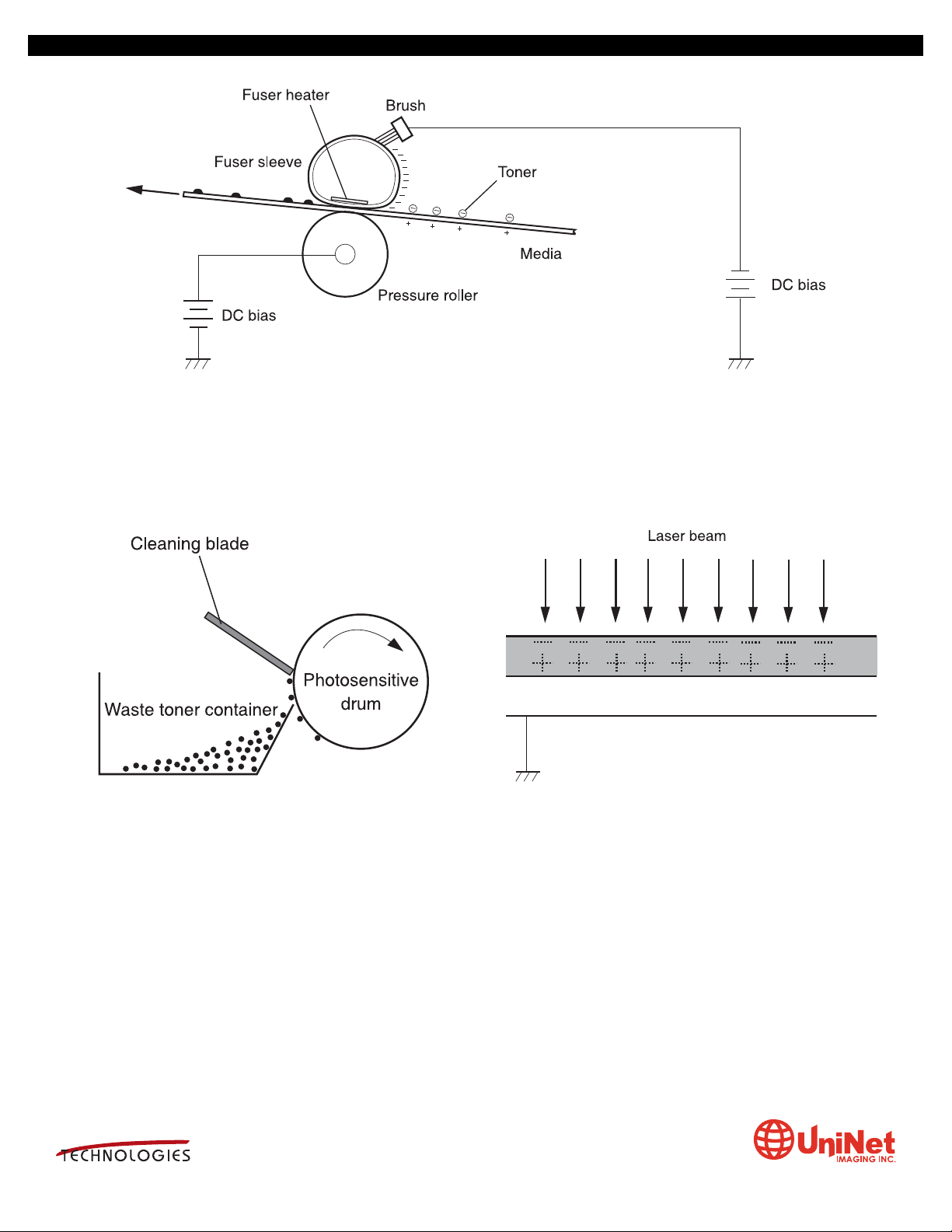

In the sixth step (fusing block) the image is then fused on to the paper by the fuser assembly, which is comprised of the upper

fixing film assembly and the lower fuser roller. The paper passes between a heated upper fixing film assembly and a soft lower

rubber roller. The upper heated element then melts the toner into the paper. The fixing film assembly consists of a Teflon sleeve

with a ceramic heating element inside. These fusers are a bit different in that they have a Brush which has a DC Bias charge on

it to help keep the film clean.

In the seventh step (Drum cleaning block) the OPC drum is

cleaned. On average, approximately 95% of the toner is transferred to the paper during the print cycle. As the drum rotates

during printing, the remaining 5% of the toner that is on the

OPC drum is cleaned off the drum by the wiper blade. It is then

guided into the waste chamber by the recovery blade, and

stored in the waste chamber.

Step 8 is where the residual charge is eliminated. Here is

where there is a major difference from previous HP cartridges/printers. In all previous PCR based cartridges, the

Primary Charge Roller places an AC voltage across the drum

surface that erases any residual charges left on the drum surface.

These machines use the new second laser beam to eliminate

the residual charges. This drum charge elimination is only

turned on during the last rotation period of the drum.

With the higher speeds of these new machines, my guess is

that using the PCR to erase the residual charges was not efficient at these speeds... This new laser process is.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 8

REQUIRED TOOLS

1. Toner approved vacuum

2. A small common screwdriver

3. A Phillips head screwdriver

4. Needle nose pliers

SUPPLIES NEEDED

1. Dedicated P4015 series toner: 465g for the 64A & 1065g for the 64X (preliminary weights)

2. Replacement drum

3. Wiper blade

4. Doctor blade

5. PCR

6. Magnetic roller sleeve

7. Conductive grease

8. Hot glue gun (see text)

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 9

1. Place the cartridge with the toner hopper facing up and

towards you. This will orient the cartridge for right and left

sides.

2. Open the drum cover towards the back of the cartridge.

Remove the right side metal bar.

3. On the opposite side of the cartridge, carefully pry off the

drum cover plastic arm. The spring will probably pop off, take

care not to loose it. We will go over the installation at the end

of this article. Remove the drum cover assembly.

4. Remove the metal bar from the left side, and remove the

entire drum cover assembly. Make sure you put the spring in a

safe place.

5. Remove the five screws on the right side end cap.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 10

6. Remove the five screws from the left end cap. 7. Remove the right and left side end caps from the cartridge.

Note that the gears do not come off the gear (right) end cap.

8. Separate the toner hopper and waste chamber. 9. On the large gear side of the waste chamber, remove the

screw and white plastic drum bushing.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 11

10. Remove the drum. 11. Remove the PCR.

12. Remove the two screws from the wiper blade. 13. Remove the wiper blade from the cartridge and clean out

the waste toner.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 12

14. Due to the high speed and page counts of these car-

tridges, we recommend that the wiper blades be replaced.

Make sure that the wiper blade foam seals are clean.

15. Install the new wiper blade and two screws.

16. Clean the PCR with your standard PCR cleaner.

17. Install the cleaned PCR. Place a small amount of conduc-

tive grease on the black PCR saddle. Remember, when using

conductive grease, more is not better!

18. On the drum axle pin, clean off the old conductive grease

and replace with new.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 13

19. Install the drum small gear side first onto the drum axle

pin

20. Install the white plastic drum bushing and screw. If the

OEM drum grease is dirty, clean it off with alcohol, and replace

with white lithium grease.

21. On the supply chamber, carefully pry off the Magnetic

roller (MRS) cover, and remove.

22. Remove the MRS drive gear.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 14

23. Note the location of the spring that sits between the

MRS holder and the hopper.

Remove the two screws, spring and the holder.

24. Remove the MRS assembly.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 15

25. Remove the two doctor blade screws and the doctor blade. Note the clear plastic strip that covers the DB screws. Slide the

screwdriver under the strip. Be careful not to damage the strip!

26. Remove the fill plug and clean out all the remaining toner

in the supply hopper

27. Note the magnetic seals on the MRS and the DB sealing

foam. Make sure both are clean.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 16

28. Note also the new heavy duty style magnetic roller contact.

This when combined with the new larger diameter of the roller,

allow the cartridge to run at the higher speeds that these

machines are capable of.

29. There are HP-4000 style magnetic roller bushings on each side of the roller. While these are holding up well in our initial tests,

this may be an area where wear will cause banding. One will stay in the hopper, and one comes off with the mag. Roller assembly.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 17

30. Unlike the HP-4300 series where there are three separate

mixing blades in the toner hopper. These cartridges just use

one large mixing blade inside the toner hopper.

31. The upper mag. roller section of the toner hopper is different in that is “Floats” on a series of foam seals. The upper half

can be removed from the hopper, but some of the seals will be

destroyed. This may become necessary in order to seal the cartridge we will keep you informed as our testing continues. The

foam isolates the mag roller from the vibrations of the mixing

augers, and allows smoother prints.

32. Install the doctor blade and two screws. Make sure that

the clear strips are not damaged!

33. Install the MRS assembly. Make sure the clear strips from the DB ride on top of the magnetic roller.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 18

34. Remove the right side small bushing from the magnetic

roller sleeve and install it onto the holder. Make sure the tab

on the bushing aligns with the slot in the holder.

35. Install the holder 2 screws and spring. Make sure the screw holes line up, and that the two locking tabs on the bottom of the

holder are in the correct place.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 19

36. Install the MRS drive gear. 37. Install the keyed MRS cover. Make sure that the keyed hole

in the cover matches the keyed end of the magnet in the MRS

assembly.

38. Fill with appropriate amount of P4015 toner, install the fill

plug.

39. Hold the two sections of the cartridge together, and install

the left (Contact side) end cap. Install a screw in the waste and

supply sections to hold everything together.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 20

40. Install the right side end cap and five screws. 41. Install the remaining three screws on the left end cap.

42. Install the spring into the drum cover arm as shown. Pull

the upper tail of the spring until it fits into the notch in the arm

hub.

43. Install the metal bars from the drum cover on both sides

of the cartridge.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

Page 21

44. Install the arm onto the cartridge. Pull the arm fully back

to release the spring from the notch. Check to make sure the

drum cover operates properly.

45. Remove the old chip from the top of the cartridge by slicing the melted plastic off with a sharp X-Acto knife. Replace

the chip, then lock in place with a small dab of glue from a hot

glue gun. Replacing this chip will enable the toner low functions of both the cartridge and the machine again.

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

REPETITIVE DEFECT CHART

OPC Drum: 94mm

Upper fuser sleeve 94mm

Lower fuser pressure roller 94mm

Tray 2 - Separation roller 79mm

Tray 2 - Pickup roller 79mm

Tray 2 - Feed Roller 79mm

Tray 1 - Separation Roller 79mm

Tray 1 - Feed Roller 79mm

Tray 1 - Pickup roller 63mm

Magnetic roller 63mm

Transfer Roller 47mm

PCR 37.7mm

Page 22

UNINET IMAGING INC. • BROTHER 1240/1650 • ASSEMBLING THE TONER CARTRIDGEUNINET IMAGING INC. • BROTHER 1240/1650 • DISASSEMBLING THE TONER CARTRIDGE

HP P4014, P4015 & P4045 CARTRIDGE REMANUFACTURING INSTRUCTIONS

3232 West El Segundo Blvd., Los Angeles, California 90250 USA • Ph +1 310 280 9620 • Fx +1 310 838 7294 • techsupport@uninetimaging.com • www.uninetimaging.com

© 2008 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not warrant downloaded information.

SU

MMIT

RUNNING THE CLEANING PAGE

1. Press “MENU” on the control panel.

2. Press the down arrow until “CONFIGURE DEVICE” shows on the display.

3. Press the down arrow until “PRINT QUALITY” shows on the display.

4. Press the down arrow until “CREATE CLEANING PAGE” shows on the display.

5. Press OK.

5. Remove all the paper from tray 1.

6. Remove the cleaning page from the output bin and load it face down in tray 1.

7. Press the down arrow until “PROCESS CLEANING PAGE” appears on the display.

8. Press OK.

RUNNING TEST PAGES

1. Press “MENU” on the control panel

2. Press the down arrow until “INFORMATION” shows on the display

3. Press the down arrow until either:

PRINT MENU MAP

PRINT CONFIGURATION

PRINT SUPPLIES STATUS PAGE

PRINT USAGE PAGE

PRINT PCL FONT LIST or

PRINT PS FONT LIST appears on the display

4. Choose the page(s) desired.

PRINTER ERROR CODES

Most of the error codes are self explanatory but there are a few that are part text, and part number.

It is those codes that we will list here.

10.10.00 Supply Memory Error: Bad chip

10. XX.YY Supply Memory Error: An error has occurred in one or more of the printers supplies.

XXOO = Memory is defective

XX01 = Memory is missing

YY00= Bad cartridge

Error 10.94.YY: Remove the shipping locks from the cartridge. Remove the shipping lock(s).

Error 41.X: This code is a Temporary Printer error.

Error 50.X: This code is a Fuser error.

50.1 Low Fuser Temperature

50.2 Fuser warm up slow

50.3 High Fuser Temperature

50.4 Faulty Fuser

Error 51.X: This code is a laser/scanner error

Error 53.XY.ZZ: This code is a Printer Memory error.

Error 54.XX: This code is a typically a sensor issue.

Loading...

Loading...