Page 1

INSTRUCTIONS AND

RECOMMENDATIONS FOR THE USE,

INSTALLATION AND MAINTENANCE OF

BUILT-IN GAS COOKTOPS

Dear customer,

Thank you for buying one of our products.

We are sure that this new, modern, functional and practical appliance, made using the finest quality

materials, will fully satisfy your requirements. This new appliance is very easy to use, but in order to

obtain the best results, we strongly recommend that you read this booklet carefully before use.

These instructions are valid exclusively for countries indicated on the label of the appliance.

The manufacturer cannot be considered responsible for any damages to people or to things in the

event of incorrect installation or improper use of the appliance.

Felix Storch, Inc.

Summit Appliance Division

An ISO 9001:2015 registered company

770 Garrison Avenue

Bronx, New York 10474

www.summitappliance.com

MODEL: GC22SS - GC527SS - GC5271W - GC5272B

The Manufacturer cannot be held responsible for any imprecision due to printing or copying errors

contained in this booklet. The figures shown are purely indicative. We reserve the right to make any

changes to our products which we consider to be necessary or useful, also in the interest of the user,

without affecting their essential characteristics in terms of functionality and safety.

This cooktop was designed to be used exclusively as a cooking appliance: any other use (such as

heating rooms) is to be considered improper and dangerous.

COD. 04037GT - 11..05.2017

Page 2

2

TABLE OF CONTENTS

Important Safeguards .......................................................................... 3

Location of Parts ................................................................................. 4

Installation..................................................................................... 5 - 8

Installing the Cooktop. ................................................................ 5

Sealing the Cooktop. .................................................................. 6

Room Ventilation. ........................................................................ 6

Gas Connection. ......................................................................... 7

Electrical Connection. ................................................................. 8

Adjustments ......................................................................................... 9

Conversions .................................................................................. 10-11

Using the Cooktop .............................................................................. 12

Lighting the Burners................................................................... 12

Proper Use of the Burners. .................................................. 12-13

Cleaning .............................................................................................. .14

Servicing. ............................................................................................ .15

Replacing Components

Limited Warranty................................................................................ .16

Page 3

3

IMPORTANT SAFEGUARDS

1) SAFETY INSTRUCTIONS

For all appliances:

●

The product shall be installed according to the statement that the installation must conform with local codes

or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

●

The product must be electrically grounded in accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70.

●

Make sure the gas connection complies with local codes and regulations. In the absence of local codes,

installations must comply with the American National Standard, National Fuel Gas Code ANSI Z223 / NFPA

54 or Canadian CAN / CGA_B 149.1 or CAN / CGA-149.2.

●

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ psi (3.5 kPa). The maximum

gas supply pressure is 4 inch WC and 11 inch WC and the gas pressure regulator provided is regulated

to 1 inch water column above the manufacturer’s specified manifold pressure.

●

Always disconnect all cord-connected appliances before servicing. Appliances shall include

instructions relative to location of the wall receptacle and a warning to the user to disconnect the

electrical supply before servicing the appliance.

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

●

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

2) WHAT TO DO IF YOU SMELL GAS

-

Do not try to light any appliance.

-

Do not touch any electrical switch; do not use any phone in your building.

-

Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

-

If you cannot reach your gas supplier, call the fire department.

●

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

●

Save any nozzles removed from the appliance for future use.

●

The maximum depth of cabinets installed above the cooktop should be 13 inches (330 mm).

●

Keep the appliance clear and free from combustible materials, gasoline and other flammable vapors

and liquids.

●

Do not obstruct the flow of gas or block any air vents.

●

Shut off gas to the unit by manually closing the independent gas valve before performing any pressure

testing of the gas supply system with test pressures equal to or lower than 1/2 psi (3.5 kPa).

Page 4

4

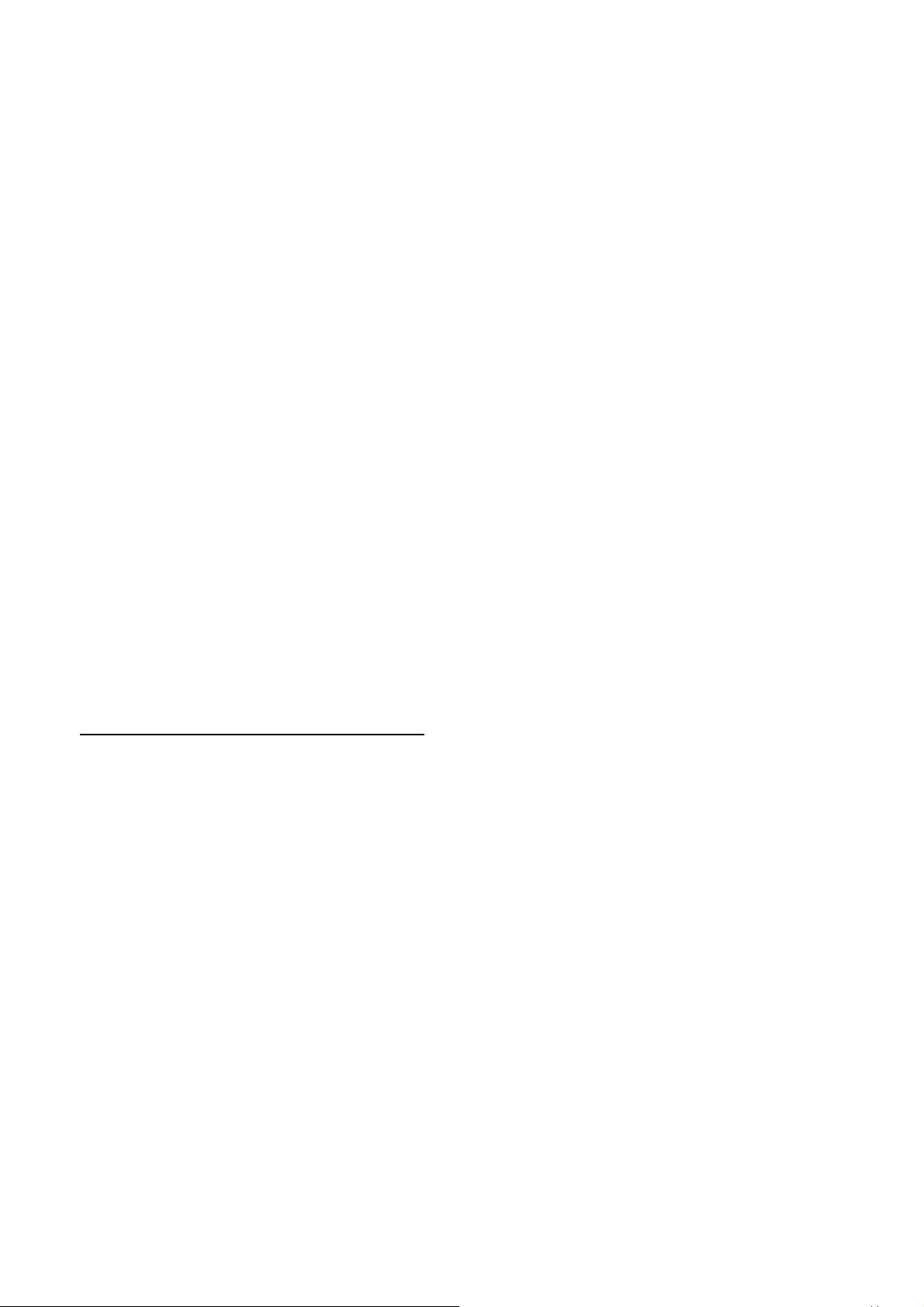

GC527SS

1

8

LOCATION OF PARTS

MODEL : GC22SS

art No.

Ultra rapid burner 11 000 Btu/h

2 Fast burner 10 000 Btu/h

Description

MODELS :

GC5271W

GC5272B

Heat supplied

3 Auxiliary burner 3 550 Btu/h

4 Semirapid burner 6 100 Btu/h

6-7

9 Burner no. 3 control knob

10

11

Grate

Burner no. 1 control knob

Burner no. 2 control knob

Burner no. 4 control knob

NOTICE: This appliance has been manufactured for residential use only.

Warning: During operation the work surfaces

of the cooking area become very hot:

Keep children away!

Page 5

5

INSTALLATION

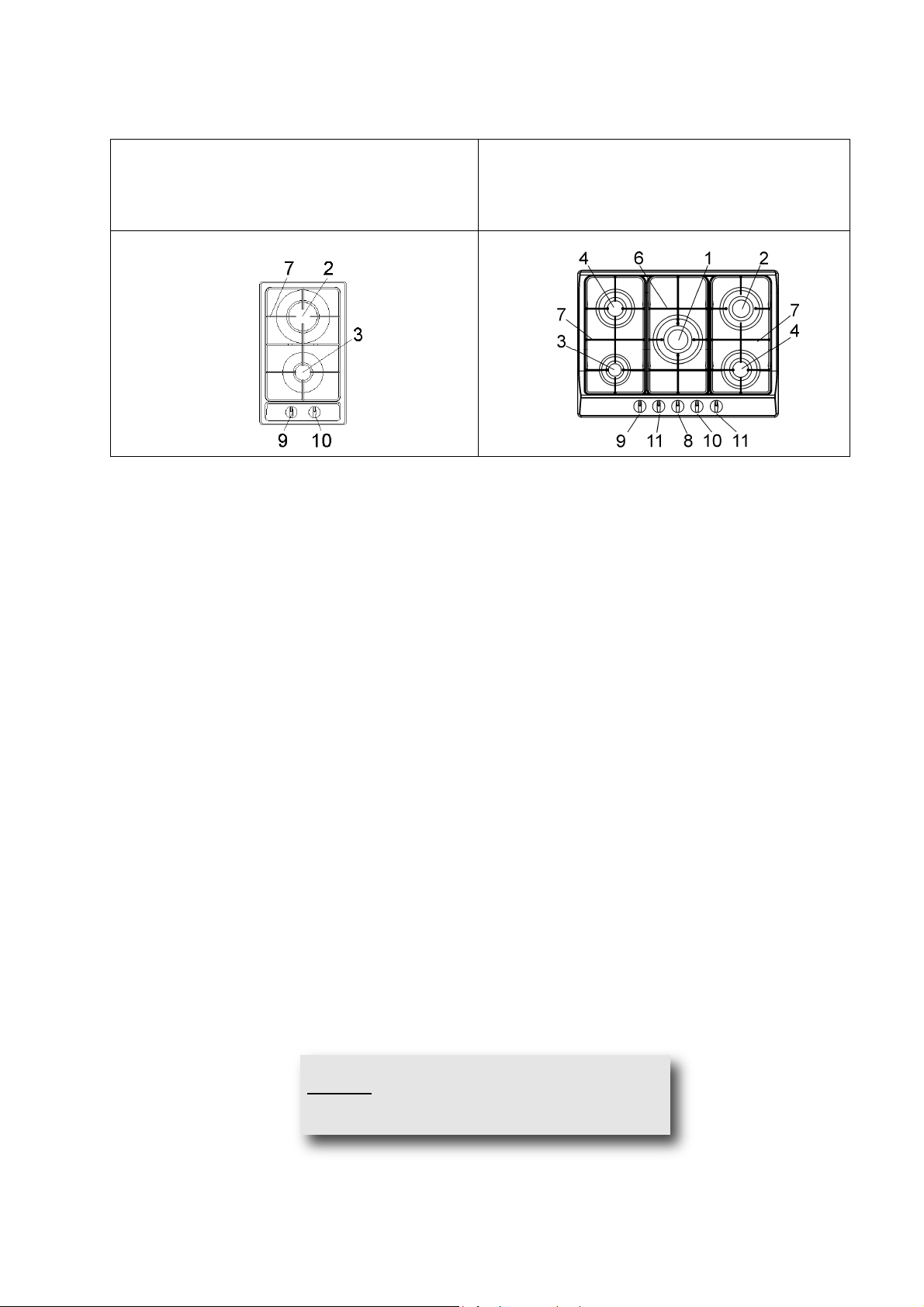

Use

These

Dimensions

(in inches)

A

D

A

D

GC5272B

Installation, adjustment of controls and maintenance must only be carried out by qualified

personnel.

Incorrect installation may cause damage to persons, animals or property for which the

Manufacturer will not be considered responsible. During the life of the system, the automatic

safety or regulating devices on the appliance may only be modified by the manufacturer or by his

duly authorized dealer.

Installing the Cooktop

Check that the appliance is in good condition after having removed the outer packaging and internal

wrappings from around the various loose parts. In case of doubt, do not use the appliance and contact

qualified personnel.

Never leave packaging materials (cardboard, bags, Styrofoam, nails, etc.) within the reach of

children since these items could become sources of danger.

The measurements of the opening made in the top of the modular cabinet and into which the cooktop will

be installed are indicated in Fig. 1 and the following chart. Always comply with the measurements given

for the hole into which the appliance will be recessed (see Figs. 1 and 2).

30”

Min. 6”

FIG. 1

FIG. 2

Model No.

GC22SS

GC527SS – GC5271W

GC5272B

Use These Dimensions (mm)

Model No.

GC22SS

GC527SS – GC5271W

11-

¼

21-49/64

282

553

B

19

18-5/8

B

482

473

C

2-½

2-

½

C

59

63,5 63,5

2-

2-½

59

½

E

2-

7/8

6 - 57/64

E

100

175

Page 6

6

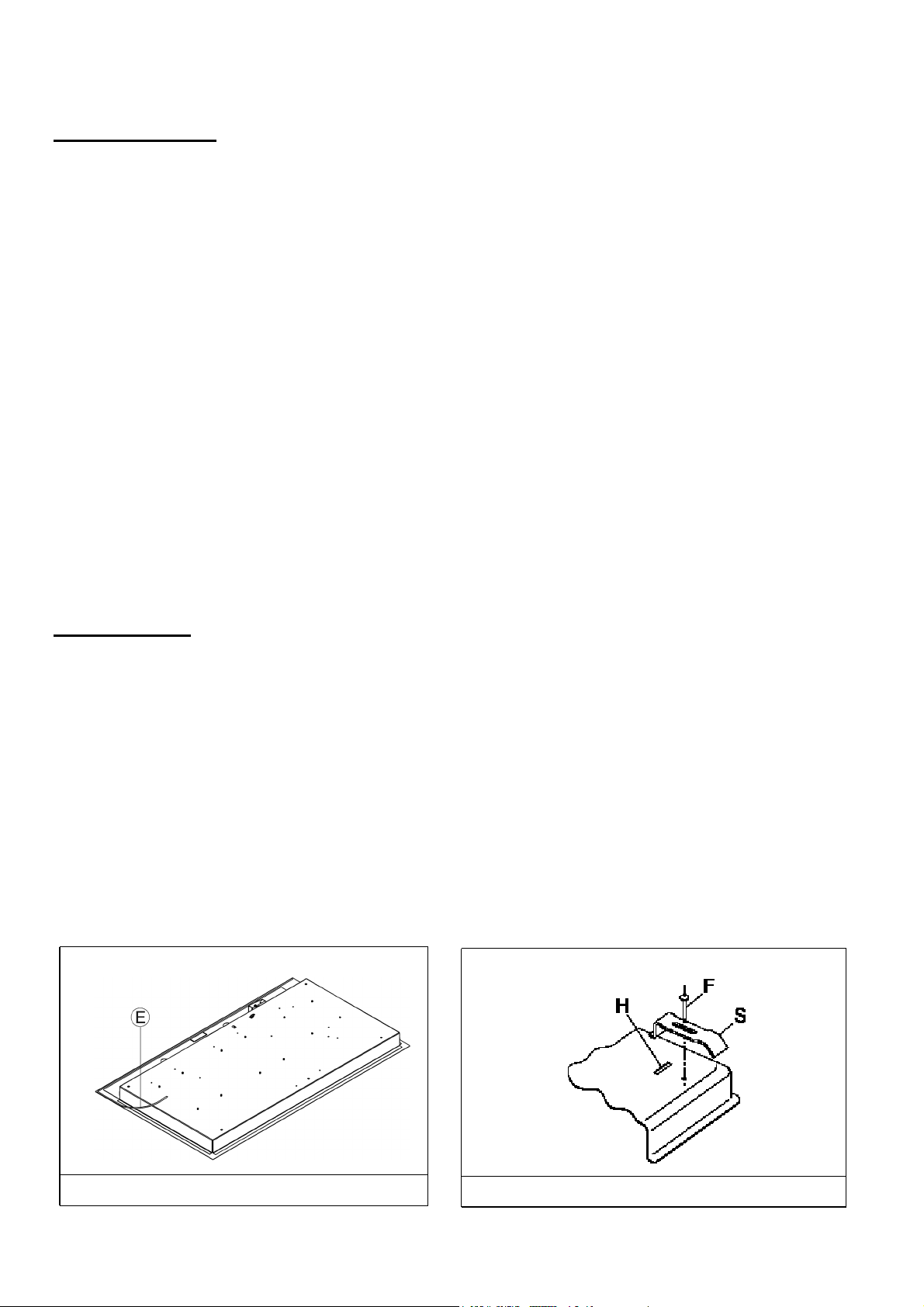

Sealing the Cooktop

The cooktop has a special seal which prevents liquid from infiltrating into the cabinet. Strictly comply with the

following instructions in order to apply this seal correctly:

-

Take off all the movable parts of the cooktop.

-

Detach the seals from their backing, checking that the transparent protection still adheres to the seal itself.

-

Overturn the cooktop and correctly position seal “E” (fig. 3) under the edge of the cooktop itself, so that the

outer side of the seal perfectly matches the outer edge of the cooktop. The ends of the strips must fit

together without overlapping.

-

Evenly and securely fix the seal to the cooktop, pressing into place with the fingers and remove the strip of

protective transparent film from the seal and set the plate into the hole made in the cabinet.

-

Fix the cooktop with the proper brackets “S” and fit the prominent part into the porthole “H” on the bottom; turn

the screw “F” until the bracket “S” touches the top (fig. 4). In fastening the brackets, do not use a mechanical

or electric screwdriver. Instead, use a hand-operated screwdriver and exert only moderate force.

The adjacent walls (left, right or behind) that exceed the cooktop in height must be at a minimum distance from

the cut hole as indicated in Fig. 1 and the chart on the preceding page.

In order to avoid accidentally touching the hot cooktop bottom, it is necessary to put a horizontal wooden insert, attached

by screws, at a minimum distance of

6"

below the lower surface of the cooktop (see Fig. 1).

Room Ventilation

To ensure proper operation of the appliance, be sure that the room where it is installed has adequate

ventilation.

The appliance should not be installed with a ventilation system that blows air downward

toward the appliance. It may cause ignition and combustion problems with the gas cooking

appliance resulting in personal injury or unintended operation.

FIG. 3

FIG. 4

Page 7

7

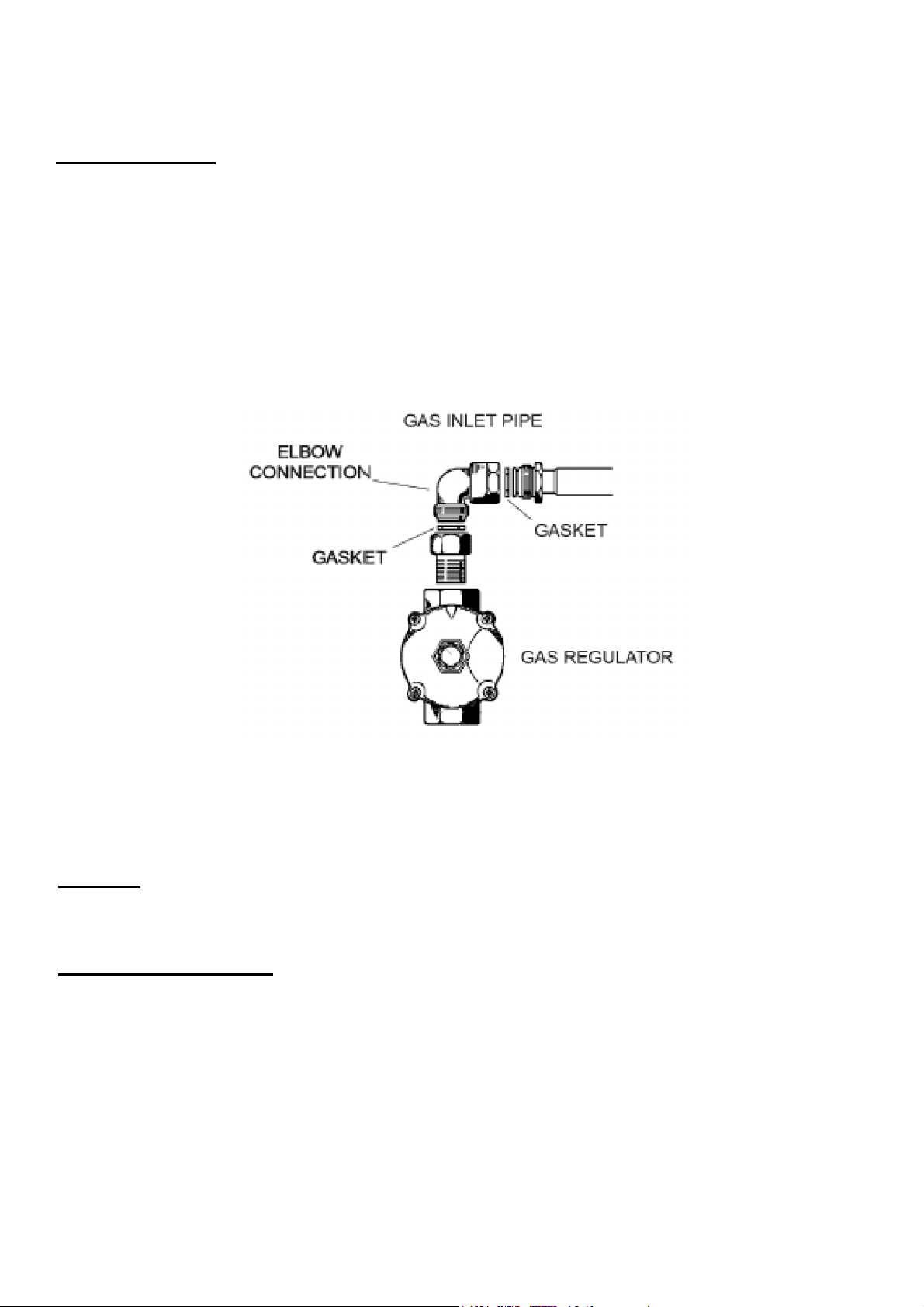

Gas Connection

Natural Gas and Propane Gas

Natural gas installations require the connection of a gas regulator to the cooktop. You will find this

regulator among the accessories supplied with the appliance.

Assemble the regulator (noting the direction of gas flow) and transition pieces (supplied) in accordance

with the figure below.

The transition piece on the supply side of the regulator must be provided by the installer. Unions

compatible with the hose fittings must be used and connections tested for gas leaks.

Be sure that the supply connection point is accessible with the appliance installed.

WARNING:

Be sure the hose assembly is restrained from accidental contact with the flue or flue outlet of an undercounter oven.

Electrical Connection

The electrical connections of the appliance must be carried out in compliance with local standards and

provisions.

Before connecting the appliance, check that:

1.

The electrical capacity of the main electrical supply and current sockets suit the maximum power

rating of the appliance. (See the data label attached to the bottom of the cooktop.)

2.

The socket or system has an efficient ground connection in compliance with local standards and

provisions. The manufacturer is not responsible for failure to comply with these provisions.

Page 8

8

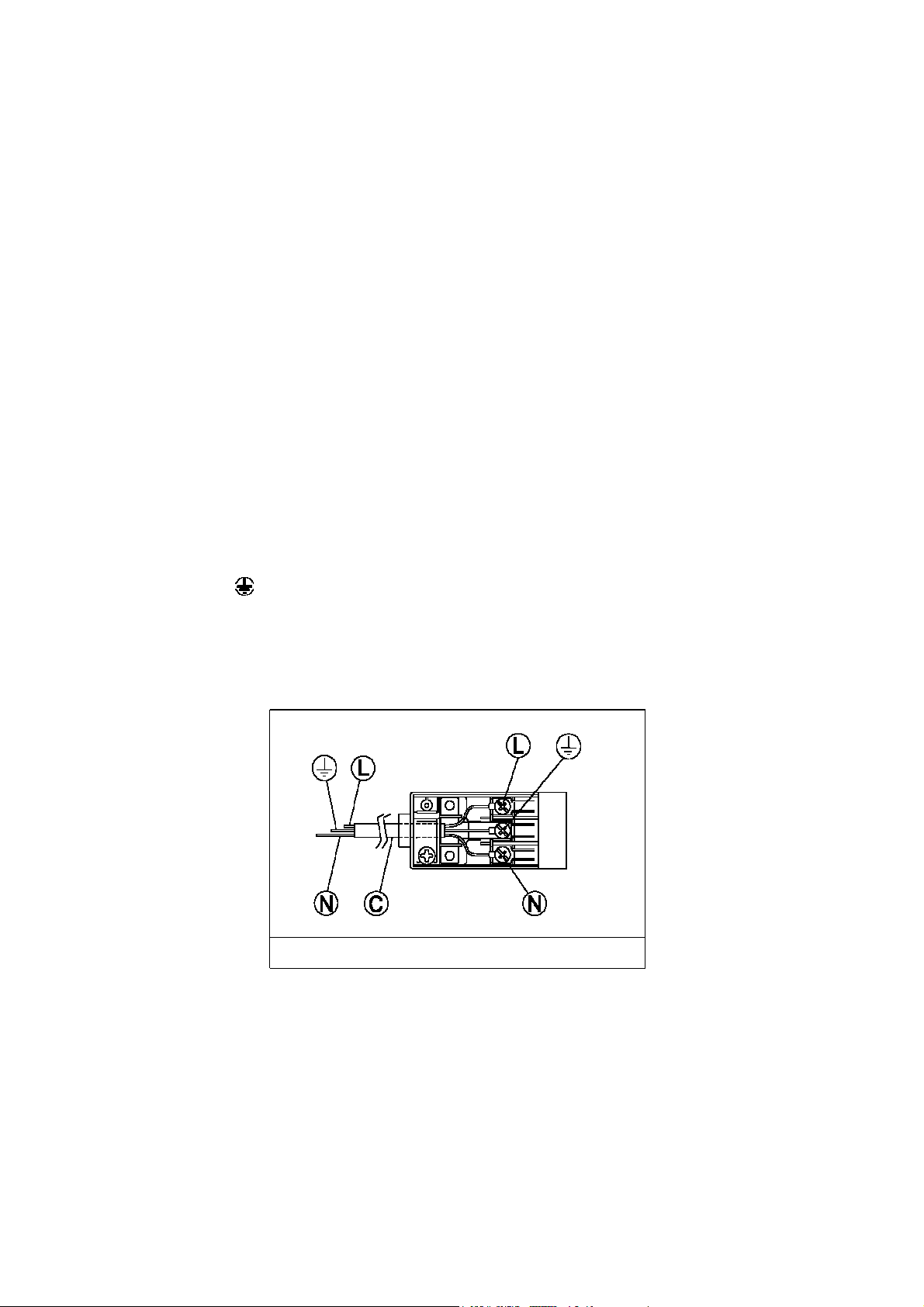

Electrical Connection

The electrical connections of the appliance must be carried out in compliance with

local standards and provisions.

Before connecting the appliance, check that:

1.

The electrical capacity of the main electrical supply and current sockets suit the

maximum power rating of the appliance. (See the data label attached to the bottom

of the cooktop.)

2.

The socket or system has an efficient ground connection in compliance with local

standards and provisions. The manufacturer is not responsible for failure to comply

with these provisions.

When the appliance is connected to electrical power by a socket:

• Fit a standard plug suited to the load indicated on the data label to the cable.

• Fit the wires following Fig. 5, noting the following correspondences:

Letter L (live) = wire

Letter N (neutral) = wire

Ground symbol = green or yellow-green wire

• Never use adapters or shunts for connection since these could create false

contacts and lead to dangerous overheating.

•The outlet must be accessible after the cooktop is built in.

FIG. 5

When the appliance is connected directly to the electrical main:

• Install an omnipolar circuit-breaker between the appliance and the electrical main.

This circuit-breaker should be sized in compliance with local installation

regulations.

• Remember that the ground wire must not be interrupted by the circuit-breaker.

• For optimum safety, the electrical connection may also be protected by a highsensitivity differential circuit-breaker.

You are strongly advised to fix the yellow-green ground wire to an efficient

grounding system.

Page 9

9

ADJUSTMENTS

Always disconnect the appliance from the electrical power source before making any

adjustments. All seals must be replaced by the technician when any adjustments are completed.

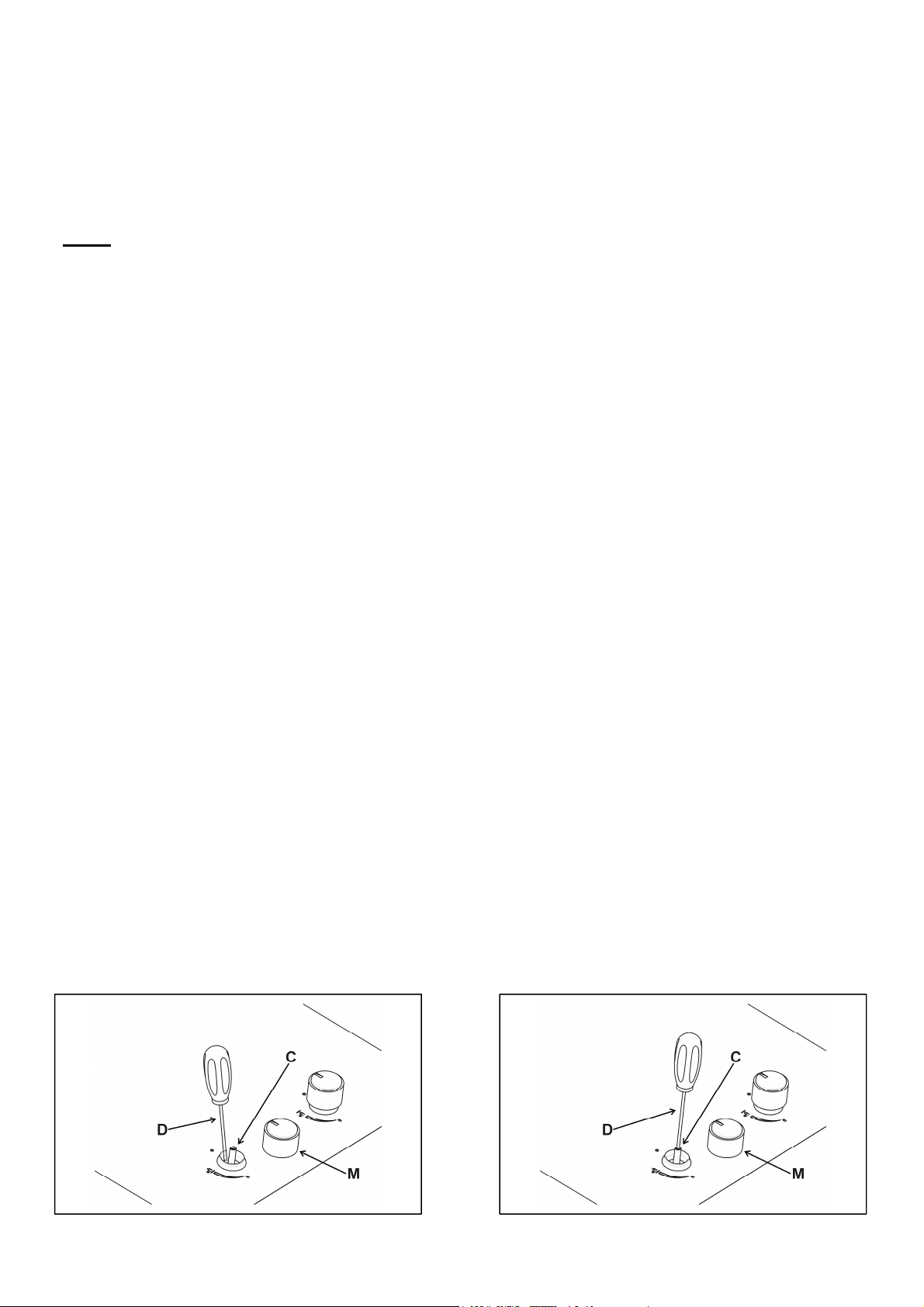

Taps

"Reduced rate" adjustment:

1.

Switch on the burner and turn the relative knob to the “Reduced rate” position (small flame fig. 8 page

10).

2.

Remove knob “M” (fig. 6 and 6/A) of the tap, which is simply pressed on to its rod.

3.

The by-pass for minimal rate regulation can be: beside the tap (fig. 6) or inside the shaft. In any case,

to access to regulation, it can be done trough the insertion of a small screwdriver ‘’D’’ beside the tap (fig.

6) or in the hole ‘’C’’ inside the shaft of the tap (fig 6/A).

Turn the throttle screw to the right or left until the burner flame has been adequately regulated to the

“Reduced rate” position.

The flame should not be too low: the lowest small flame should be continuous and steady. Re-assemble

the several components.

It is understood that only burners operating with Natural Gas or City Gas should be subjected to

the above-mentioned adjustments. The screw must be fully locked when the burners operate with

Propane (turn clockwise).

The operations described above can be carried out easily, whatever the position of the cooktop or

however it is fastened to the work surface.

THE BURNERS DO NOT REQUIRE ANY REGULATION OF INCOMING AIR

FIG. 6 FIG. 6/A

.

Page 10

10

CONVERSIONS

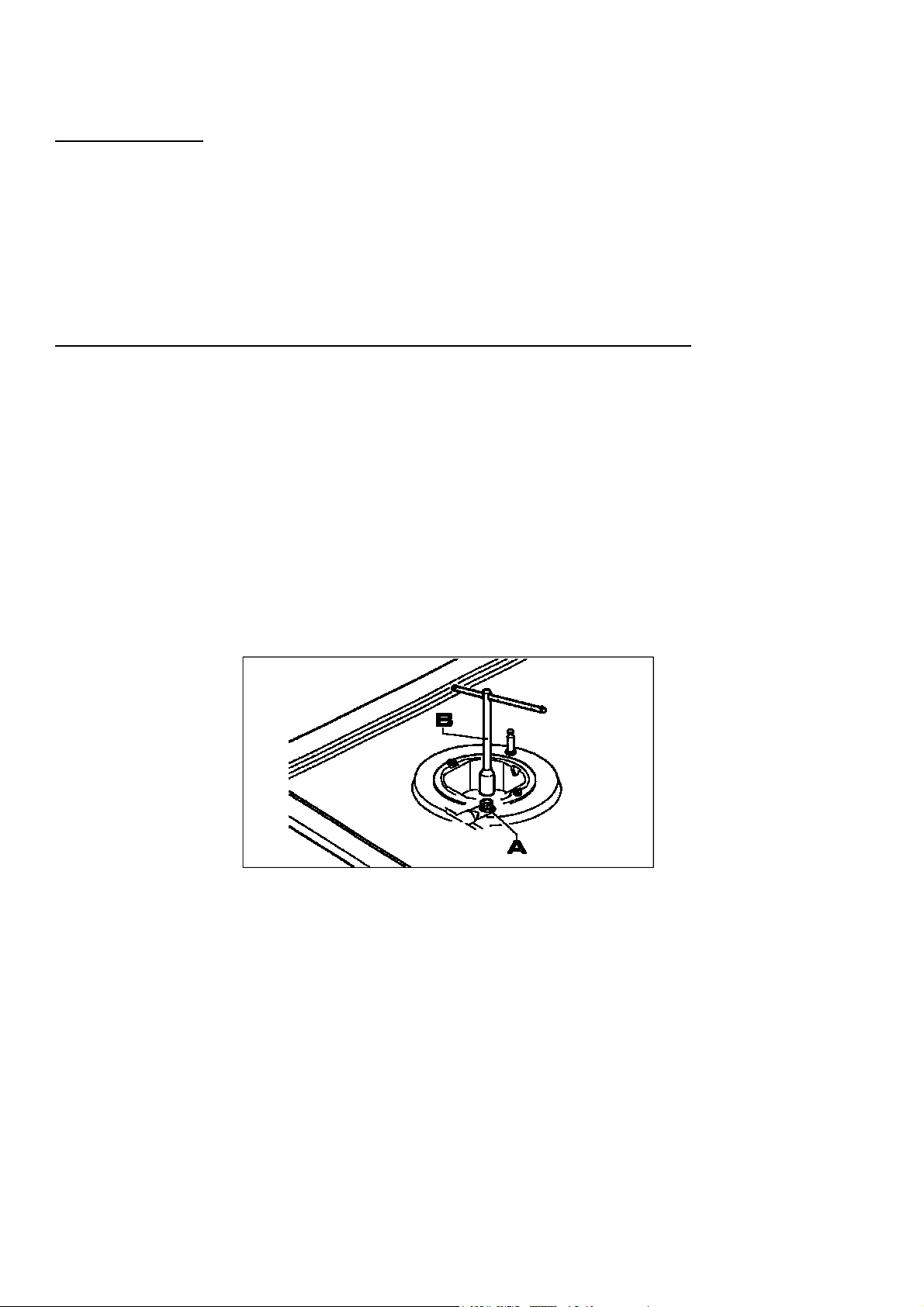

Replacing Nozzles

The burners can be adapted to suit different types of gas by fitting the nozzles that correspond to the gas

used. To do this, it is necessary to remove the burner heads and use a straight key "B" to unscrew the

nozzle "A" (see Fig. 7) and replace it with a nozzle corresponding to the gas used.

Be sure the nozzle is seated tightly.

After making these replacements, the technician must regulate the burners as described in

Adjustments on the previous page and apply the label corresponding to the new gas type in place

of that previously applied. This label is contained in the spare nozzle bag.

How to change the setting of the pressure regulator supplied with the cooktop:

The gas regulator was set up to Natural Gas. To convert to LP Gas:

1.

Unscrew the aluminum cap

2.

Remove and turn the plastic pin 180°

3.

Screw in the plastic pin

4.

Screw in the aluminum cap

To make it easier for the fitter, we have prepared a table indicating the flow capacities, the heat

capacities of the burners, the diameter of the nozzles and the working pressure for the various types of

gas.

FIG. 7

Page 11

11

3

BURNERS

N°

DESCRIPTION

GAS

NORMAL

PRESSURE

inches water

column

INJECTOR

DIAMETER

1/100 mm

NOMINAL HEAT

INPUT (Btu/h)

Min.

Max.

1

2

3

4

ULTRA RAPID

FAST

AUXILIARY

SEMIRAPID

PROPANE HD - 5

NATURAL GAS

PROPANE HD - 5

NATURAL GAS

PROPANE HD - 5

NATURAL GAS

PROPANE HD - 5

NATURAL GAS

11

4

11

4

11

4

11

4

94

176

91

155

53

90

70

120

4 400

4 400

2 500

2 500

1 200

1 200

1 500

1 500

11 000

11 000

10 000

10 000

3 550

3 550

6 100

6 100

Page 12

12

USING THE COOKTOP

Lighting the burners

A diagram is screened beside each knob on the control panel of your cooktop. This diagram indicates to

which burner the knob in question corresponds. After having opened the gas main or bottled gas tap,

light the burners as described below:

The knobs of the burners are equipped with a safety cut-off device. They must be turned in a counterclockwise direction until they reach the full-on position (large flame icon, Fig. 8) and come to a stop. Now

push down on the knob. The burner should ignite in 2 or 3 seconds. Keep the knob depressed as you turn

it toward the reduced rate position (small flame icon, Fig. 8) to adjust the flame. Should the flame

accidentally go out, turn the burner control knob off and wait at least 1 minute before attempting to light it

again.

FIG. 8

FIG. 9

Proper use of the burners

To achieve maximum efficiency with the least possible gas consumption, keep the following instructions

in mind:

•

Use the correct pan size for each burner. (See the following table and Fig. 9.)

•

When the pan comes to a boil, set the knob to a reduced rate position (small flame icon, Fig. 8).

•

Always put lids on the pans.

•

Use only flat-bottomed pans.

Page 13

13

Burners

Power Ratings

Pan Diameter

In cm

ULTRA RAPID

FAST

SEMIRAPID 6 100

AUXILIARY

11 0000

10 000

3 550

9" to 10

½"

8" to 9 ½"

6"

to 7 ½"

4" to 5 ½"

24 - 26

20 - 22

16 - 18

10 – 14

•

Burners will only ignite when the corresponding knob has been set to the Full-on position (large flame icon,

Fig. 8).

•

Matches can be used to ignite the burners during a power outage, but use caution.

•

Never leave the appliance unattended when the burners are being used. Make sure there are no children in

the vicinity. In particular, make sure that the pan handles are correctly positioned. Keep checking on foods

that require oil or other grease to cook since these products can easily catch fire.

•

The appliance must not be used by people (including children) with impaired mental or physical capacities,

or without experience of using electrical devices, unless supervised or instructed by an adult responsible for

their safety and care. Children should not be allowed to play with the equipment.

•

Never use aerosol sprays near the appliance when it is operating.

•

Containers wider than the unit are not recommended.

NOTES:

•

The use of a gas cooking appliance produces heat and moisture in the room in which it is installed. The

room must therefore be well ventilated.

•

Intensive and lengthy use of the appliance may require additional ventilation. This can be achieved by

opening a window or by increasing the power of the mechanical exhaust system if installed.

WARNINGS:

WARNING!

NEVER use this appliance as a space heater

to heat or warm the room. Doing so may result

in carbon monoxide poisoning and

overheating of the appliance.

Page 14

14

CLEANING

IMPORTANT:

Always disconnect the appliance from the gas

and electricity supplies before carrying out

any cleaning operation.

Periodically wash the hot plate, the enameled steel

pan support, the enameled burner caps “A”, “B”

and “C” and the burner heads "T" (see fig. 10 and

11) with lukewarm soapy water. Also clean plugs

"AC" and flame detection "TC" (see fig. 10). Clean

them gently with a small nylon brush as shown (see

fig. 12) and allow to dry fully. Do not wash in the

dishwasher. It is very important to clean the surface

soon after every use, while the glass is still

somewhat warm.

Do not allow vinegar, coffee, milk, salt water,

lemon or tomato juice to remain in contact with

the enameled surfaces for long periods of time.

Do not clean using abrasive metal scourers,

abrasive powders or corrosive sprays.

Note: Continuous use can cause the

burners to change color due to the

high temperature.

or

WARNINGS:

Comply with the following instructions, before

remounting the parts:

- Check that burner head slots have not

become clogged by foreign bodies.

- Check that enameled burner caps “A-B-C”

(fig. 10-11) have bee n correctly positioned

on the burner head. They must be steady.

- The exact position of the pan support is

established by the rounded corners, which

should be set towards the side edge of the

hot plate.

- Do not force the taps if they are difficult to

open or close. Contact customer service for

technical assistance or repairs.

- Correctly preserve the plate after use by

treating it with special, easily available

products. This will keep the surface of the

plate clean and bright. The operation will

also prevent the formation of rust.

- Don’t use steam jets to clean the

equipment.

- Food b u r n t onto an electric plate must

be removed dry.

- After use, pour a little lukewarm oil on the

plate and wipe it with a cloth.

FIG. 10

FIG. 11

FIG. 12

Page 15

15

SERVICING

Always disconnect the appliance from the electric and gas supplies before proceeding with

any servicing operation.

Replacing Components

To replace the components housed inside the appliance, remove the trivets and the burners from the upper

part of the cooktop. Remove the fixing screws "V" of the burner (Fig. 13) and the knobs using hand pressure

to remove them from the appliance.

After having carried out these operations, the burners (Fig. 14), taps (Fig. 15) and electrical components can

all be replaced (Fig. 16).

It is advisable to change seal "D" (Fig. 15) whenever a tap is replaced to ensure a perfect tightness.

Greasing the taps (See Fig. 17-18)

If a tap becomes stiff to operate, it must be immediately greased in compliance with the following

instructions:

1.

Remove the tap.

2.

Clean the cone and its housing using a cloth soaked in solvent.

3 .Lightly grease the cone.

4 .Fit the cone back into place, operate it a few times and then remove it again. Eliminate any excess

grease and check that the gas ducts have not become clogged.

5.

Fit all parts back into place, following the disassembly order in reverse.

6.

The tight closure test must be done using a foaming liquid.

Never use a flame for this test.

WARNING:

MAINTENANCE MUST ONLY BE PERFORMED

BY AUTHORIZED PERSONS.

FIG. 13

FIG. 14

FIG. 15

FIG. 16

FIG. 17

FIG. 18

Page 16

LIMITED WARRANTY

Within the 48 contiguous United States, for one year from the date of purchase, when this appliance is

operated and maintained according to instructions attached to or furnished with the product, warrantor will

pay for factory-specified parts and repair labor to correct defects in materials or workmanship. Service

must be provided by a designated service company. Outside the 48 states, all parts are warranted for one

year from manufacturing defects. Plastic parts, shelves and cabinets are warranted to be manufactured to

commercially acceptable standards, and are not covered from damage during handling or breakage.

ITEMS WARRANTOR WILL NOT PAY FOR:

•

Service calls to correct the installation of your appliance, to instruct you how to use your appliance, to

replace or repair fuses or to correct wiring or plumbing.

•

Service calls to repair or replace appliance light bulbs or broken glass shelves. Consumable parts (such

as filters) are excluded from warranty coverage.

•

Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with electrical or plumbing codes, or use of products not approved by

warrantor.

•

Replacement parts or repair labor costs for units operated outside the United States.

•

Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

•

The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not

installed in accordance with published installation instructions.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIR AS PROVIDED HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR.

WARRANTOR SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE.

WARNING!

known to the State of California to cause cancer.

For more information go to www.P65Warnings.ca.gov

Note: Nickel is a component in all stainless steel and some other metal components

This product can expose you to chemicals including Nickel (Metallic) which is

Call customer service toll free in the U.S.A. @ 1-800-932-4267, Monday to Friday 9:00 am. - 5:00 p.m. (ET).

Order parts online at www.summitappliance.com/support

Felix Storch, Inc.

Summit Appliance Division

770 Garrison Avenue

Bronx, NY 10474

Phone: (718) 893-3900

Fax: (844) 478-8799

Web Site:

www.summitappliance.com

Page 17

INSTRUCTIONS ET RECOMMENDATIONS

POUR L’UTILISATION, L’INSTALLATION ET

L’ENTRETIEN DE LA TABLE DE CUISSON

AU GAZ ENCASTRABLE

Cher client, nous vous remercions d’avoir choisi nos produits.

Nous vous assurons que ce nouvel appareil moderne, fonctionnel et pratique à la fois, fabriqué

avec des matériaux de première qualité, sera satisfaire pleinement vos exigences. Ce nouvel

appareil est très facile d’utilisation, mais afin d’obtenir les meilleurs résultats, nous vous

recommandons tout particulièrement, de lire attentivement cette notice avant toute utilisation.

Ces instructions sont valables uniquement pour les pays dont les symboles

d’identification figurent sur l'étiquette de l’appareil.

Le fabriquant ne peut être tenu pour responsable en cas de dommages corporels ou matériels en

raison d’une installation incorrecte ou un usage abusif de l’appareil.

Felix Storch, Inc.

Summit Appliance Division

Une compagnie enregistrée d'ISO 9001: 2015

770 Garrison Avenue

Bronx, New York 10474

www.summitappliance.com

MODÈLE : GC22SS - GC527SS-GC5271W-GC5272B

Le fabriquant ne peut être tenu pour responsable des imprécisions dues à l’impression ou des erreurs de

reproduction dans la présente notice. Les images présentées ont un caractère purement indicatif. Nous

nous réservons le droit d’apporter des modifications à nos produits, que nous jugeons nécessaires ou

utiles, notamment dans l’intérêt de l’utilisateur, tout en conservant ses caractéristiques essentielles en

termes de fonctionnement et sécurité.

Cette table de cuisson a été conçue pour être utilisée exclusivement comme appareil de cuisson :

toute autre utilisation (telle que dispositif de chauffage de la pièce) est considérée comme étant

abusive et dangereuse.

COD. 04037GT (FR)

Page 18

18

TABLE DES MATIÈRES

Précautions importantes .................................................................. 19

Position des composants ................................................................ 20

Installation .................................................................................................... 21 - 24

Installation de la table de cuisson. ........................................................... 21

Fixation de la table de cuisson. ................................................................ 22

Ventilation de la pièce. ............................................................................... 22

Raccordement au gaz. ............................................................................... 23

Branchement électrique.......................................................23 - 24

Réglages ............................................................................................ 25

Conversions ................................................................................................. 26 - 27

Utilisation de la table de cuisson ............................................ 28 - 29

Allumage des brûleurs ............................................................................. 28

Utilisation correcte des brûleurs ....................................................... 28 - 29

Nettoyage ........................................................................................... 30

Entretien ............................................................................................. 31

Remplacement des composants

Garantie limitée ................................................................................. 32

Page 19

19

PRÉCAUTIONS IMPORTANTES

1) CONSIGNES DE SÉCURITÉ

Pour tous les appareils :

● Le produit doit être installé conformément à la déclaration que l'installation doit être conforme aux

codes locaux ou, en l'absence de codes locaux, avec le National Fuel Gas Code, ANSI Z223.1 / NFPA

54.

● Le produit doit être mis à la terre conformément aux codes locaux ou, en l'absence de codes locaux,

avec le National Electrical Code, ANSI / NFPA 70.

●

Assurez-vous que la connexion de gaz est conforme aux codes et règlements locaux. En l'absence de

codes locaux, les installations doivent être conformes à la norme nationale américaine, National Fuel

Gas Code ANSI Z223 / NFPA 54 ou canadien CAN / CGA_B 149.1 ou CAN / CGA-149.2.

●

Cet appareil et son robinet d’arrêt doivent être coupés de l’arrivée de gaz lors des essais de pression

effectués à une valeur supérieure à ½ psi (3.5 kPa). La pression maximale d’alimentation en gaz est de

4 pouces d’eau et 11 pouces d’eau et le régulateur de pression du gaz est réglé à 1 pouce d’eau audessus de la pression d’admission spécifiée par le fabriquant.

●

Toujours débrancher le câble d’alimentation ; les appareils sont fournis avec les instructions relatives à

l’emplacement de la prise murale et les précautions à prendre pour couper l’alimentation électrique avant

d’effectuer les opérations d’entretien.

AVERTISSEMENT : Le non-respect des instructions du présent manuel peut

être à l’origine d’un incendie ou explosion causant des dommages matériels,

corporels ou le décès.

●

Ne pas entreposer ou utiliser d’essence ou autres gaz ou liquides inflammables à proximité de cet ou

tout autre appareil.

2) QUE FAIRE SI ÇA SENT LE GAZ

-

N’allumez aucun appareil.

-

Ne touchez aucun interrupteur ; n’utilisez aucun téléphone se trouvant dans le bâtiment.

-

Appelez immédiatement votre fournisseur de gaz utilisant le téléphone d’un voisin.

Suivez les instructions données par le fournisseur de gaz.

-

Si vous n’arrivez pas à joindre votre fournisseur de gaz, contactez les pompiers.

●

L’installation et la mise en service doivent être effectuées par un installateur qualifié, un centre agréé

ou le fournisseur de gaz.

●

Conservez les buses retirées de l’appareil en vue d’un usage futur.

●

La profondeur maximale des meubles installés au-dessus de la table de cuisson doit être de 13 pouces

(330 mm).

●

Maintenez à distance de l’appareil toute matière combustible, essence ou autres gaz et liquides

inflammables.

●

N’obstruez pas le débit de gaz ou les bouches d’aération.

●

Couper l’arrivée du gaz à l’appareil en fermant manuellement le robinet du gaz indépendant avant

d’effectuer tout essai de pression de l’installation d’arrivée du gaz avec des pressions d’essai égales ou

inférieures à 1/2 psi (3,5 kPa).

Page 20

20

Ultra rapide

4

r semirapide

POSITION DES COMPOSANTS

MODÈLE : GC22SS MODÈLE : GC527SS

GC5271W

GC5272B

No. de la pièce

1

Description

Chaleur fournie

11 000 Btu/h

2

Brûleur rapide 10 000 Btu/h

3 Brûleur auxiliaire 3 550 Btu/h

6-7

8

Brûleu

Grille

Manette de commande du brûleur n° 1

6 100 Btu/h

9 Manette de commande du brûleur n° 3

10

11

Manette de commande du brûleur n° 2

Manette de commande du brûleur n° 4

NOTE : Cet appareil a été conçu pour un usage domestique uniquement.

Avertissement : Lors du fonctionnement,

les surfaces de travail de la zone de

cuisson

laissez pas les enfants s’approcher !

deviennent très chaudes : ne

Page 21

21

INSTALLATION

A

D

Dimensions

à

respecter

(en

mm)

A

GC527SS

L’installation, le réglage des commandes ainsi que l’entretien doivent être effectués uniquement

par du personnel qualifié.

Une installation incorrecte peut entraîner des dommages corporels ou matériels pour lesquels le

fabricant ne sera pas tenu responsable. Pendant toute la durée de vie du système, les dispositifs

de sécurité et de réglage automatique des appareils doivent être modifiés uniquement par le

fabricant ou un fournisseur dûment agréé.

Installation de la table de cuisson

Assurez-vous que l’appareil est en bon état après l’avoir déballé et retiré les emballages des différentes

pièces conservées à part. En cas de doute, n’utilisez pas l’appareil et contactez un technicien qualifié.

Ne laissez jamais des matériaux d’emballage (carton, sachets, polystyrène, pointes, etc.) à la

portée des enfants représentant une source de danger.

Les mesures du trou prévu au-dessus du meuble modulaire et dans lequel sera installée la table de

cuisson sont spécifiées sur la Fig. 1 et le tableau suivant. Veuillez respecter les mesures indiquées pour le

trou dans lequel sera encastré l’appareil (voir Figures 1 et 2).

30”

Min. 6”

FIG.1

FIG.2

Dimensions à respecter (en pouces)

Modèle No.

GC22SS

GC5271W - GC5272B

11-

¼

21- ¾

B

19

18-

5/8

GC527SS

Modèle No.

GC22SS

GC5271W-GC5272B

282

553

B

482

473

C

2-

½

2-

½

C

59

63.5

2-½

2-

½

D

59

63.5 175

6 -

2-

7/8

57/64

E

100

E

Page 22

22

Fixation de la table de cuisson

La table de cuisson est équipée d’un joint spécial destiné à éviter toute infiltration de liquide dans le meuble.

Pour appliquer ce joint correctement, suivez attentivement les instructions suivantes :

-

Enlevez tous les éléments mobiles de la table de cuisson.

-

Retirez les joints de leur support, en vérifiant que la protection transparente ne se décolle pas du joint.

-

Retournez la table de cuisson et placez correctement le joint « E » (fig. 3) sous le bord de la table de

cuisson de sorte que l’extérieur du joint corresponde exactement au contour de la table. Les extrémités

des bandes doivent se rencontrer sans se chevaucher.

-

Fixez uniformément et solidement le joint à la table de cuisson, en appuyant avec vos doigts et retirez la

bande de protection transparente du joint et placez la plaque dans le trou du meuble.

- Fixez la table de cuisson à l’aide des crochets « S » prévus à cet effet et insérez l’élément dans l’orifice « H » ;

tourner la vis « F » jusqu’à ce que le crochet « S » colle à la surface (fig. 4). Pour fixer les crochets, n’utilisez pas

de tournevis mécaniques ou électriques. Utilisez un tournevis manuel tout en exerçant une pression modérée.

Les parois adjacentes (latérales et arrières) qui dépassent la table de cuisson en hauteur doivent être placées à

une distance minimale du trou comme indiqué dans la Fig. 1 et le tableau de la page précédente.

Afin d’éviter tout contact éventuel avec la partie inférieure chaude de la table de cuisson, un revêtement

horizontal en bois doit être installé et fixé à l’aide de vis, à une distance minimale de

surface inférieure de la table de cuisson (voir Fig. 1).

Ventilation de la pièce

Pour assurer le bon fonctionnement de l’appareil, assurez-vous que la pièce où ce dernier est installé soit

dûment aérée.

6”

en-dessous de la

L'appareil ne doit pas être installé avec un système de ventilation qui souffle de l'air vers le

bas en direction de l'appareil. Cela peut causer des problèmes de départ de feu et de

combustion avec l'appareil de cuisson au gaz, entraînant des blessures ou un fonctionnement

imprévu.

FIG. 3

FIG. 4

Page 23

23

RACCORDEMENT

DE COUDE

Raccordement au gaz

Gaz naturel et Gaz propane

Les installations au gaz naturel nécessitent le branchement d’un régulateur de gaz à la table de cuisson.

Ledit régulateur fait partie des accessoires fournis avec l’appareil.

Montez le régulateur (prenant en considération le sens du flux du gaz) ainsi que les éléments

intermédiaires (fournis) conformément à la figure ci-dessous.

TUYAU D’ENTRÉE DE GAZ

La pression d’alimentation en gaz

pour correctement régler le

régulateur doit être d’au moins

JOINT

JOINT

RÉGULATEUR DE GAZ

1 po. d’eau (249 Pa) au-dessus de

la pression d’admission spécifiée).

La pièce intermédiaire du côté alimentation du régulateur doit être fournie par l’installateur. Utiliser des

raccordements compatibles avec les raccords de flexible et tester les raccordements pour s’assurer qu’il

n’y ait pas de fuites.

S’assurer que le point de branchement à l’alimentation reste accessible une fois l’appareil installé.

AVERTISSEMENT :

Éviter tout contact accidentel des flexibles avec le conduit ou buse d’évacuation d’un

four encastré.

Branchement électrique

Les branchements électriques de l’appareil doivent répondre aux exigences des réglementations et

dispositions locales.

Avant de brancher l’appareil, vérifiez que :

1.

La puissance électrique de la principale source d’électricité et des prises de courant soit adaptée à la

puissance nominale maximale de l’appareil. (Se référer à l’étiquette de données présente sur la

partie inférieure de la table de cuisson)

2.

La prise ou le système soit dotée d’une prise de terre efficace conformément aux réglementations et

dispositions locales. Le fabriquant n’est pas responsable du non-respect des dispositions susmentionnées.

Page 24

24

Branchement électrique

Les branchements électriques de l’appareil doivent répondre aux exigences des

réglementations et dispositions locales.

Avant de brancher l’appareil, vérifiez que :

1.

La puissance électrique de la principale source d’électricité et des prises de

courant soient adaptées à la puissance nominale maximale de l’appareil. (Se

référer à l’étiquette de données présente sur la partie inférieure de la table de

cuisson)

2.

La prise ou le système soit doté d’une prise de terre efficace conformément aux

réglementations et dispositions locales. Le fabriquant n’est pas responsable du

non-respect des dispositions susmentionnées.

En cas de raccordement au réseau d’alimentation électrique au moyen d’une prise :

• Installez une fiche standard sur le câble en vous assurant qu’elle est adaptée à la

charge indiquée sur la plaque signalétique.

• Installez les câbles comme indiqué sur la Fig. 5, où :

Lettre L (sous tension) = câble

Lettre N (neutre) = câble

Symbole de masse = câble vert ou vert/jaune

• N’utilisez jamais d’adaptateurs ou dérivations pour le raccordement car ils

pourraient provoquer de faux contacts entraînant une surchauffe potentiellement

dangereuse.

• La prise électrique doit restée accessible même une fois la table de cuisson encastrée.

FIG. 5

En cas de raccordement direct au réseau d’alimentation électrique :

• Installez un disjoncteur omnipolaire entre l’appareil et l’alimentation.

La taille dudit disjoncteur doit respecter les prescriptions locales d’installation en

vigueur.

• Le câble de terre ne doit pas être interrompu par le disjoncteur.

• Pour un maximum de sécurité, le raccordement électrique peut également être

protégé par un disjoncteur différentiel à haute sensibilité.

Il est vivement conseillé de brancher le câble de terre vert/jaune à une installation

de mise à la terre efficace.

Page 25

25

RÉGLAGES

Débranchez l’appareil du réseau d’alimentation électrique avant d’intervenir pour des réglages.

Tous les joints doivent être changés par le technicien une fois les réglages terminés.

Robinets

Réglage du “débit réduit” :

1.

Allumez le brûleur et tournez la manette correspondante sur la position “débit réduit” (petite flamme fig.

8 page 28).

2.

Retirez la manette « M » (fig. 6 et 6/A) du robinet, qui est simplement enfoncée sur sa tige.

3.

Le by-pass pour le réglage du débit minimal peut être : à côté de la manette de commande (fig. 6) ou

dans la tige. Dans tous les cas, le réglage peut être effectué à l’aide d’un petit tournevis « D » inséré à

côté du robinet (fig. 6) ou dans le trou « C » dans la tige du robinet (fig 6/A).

Tournez la vis papillon vers la droite ou la gauche jusqu’à ce que la flamme du brûleur soit correctement

réglée sur la position correspondant au “débit réduit”.

La flamme ne doit pas être trop petite : la flamme la plus petite doit être continue et régulière. Remontez

les différents composants.

Il est entendu que seuls les brûleurs aux gaz naturel ou gaz de ville sont soumis à de tels

réglages. Dans le cas du propane, la vis doit être complètement verrouillée (tournez dans le sens

des aiguilles d’une montre).

Les opérations susmentionnées sont faciles à mener, quelle que soit la position de la table de cuisson ou

la fixation au plan de travail.

IL N’EST PAS NÉCESSAIRE DE RÉGLER L’AIR D’ARRIVÉE DES BRÛLEURS.

FIG. 6 FIG. 6/A

Page 26

26

CONVERSIONS

Remplacement des buses

Il est possible d’adapter les brûleurs aux différents types de gaz en installant des buses qui

correspondent au gaz utilisé. Pour ce faire, retirez les têtes des brûleurs et utilisez une clé droite « B »

pour dévisser la buse « A » (voir fig. 7) puis remplacez-la par une buse correspondante au gaz utilisé.

Assurez-vous que la buse soit bien fixée.

Après avoir effectué ces remplacements, le technicien doit régler les brûleurs comme décrit au

paragraphe “Réglages” à la page précédente et apposer l’étiquette correspondant au nouveau

type de gaz utilisé sur l’appareil à la place de la précédente. Cette étiquette se trouve dans le

sachet de la nouvelle buse.

Comment modifier le réglage du régulateur de pression fourni avec la table de cuisson :

Le régulateur de gaz a été réglé pour une utilisation au gaz naturel. Convertir au GPL :

1.

Dévissez le capuchon en aluminium

2.

Retirez et tournez la cheville en plastique à 180°

3.

Vissez la cheville en plastique

4.

Vissez le capuchon en aluminium

Pour faciliter la tâche à l’installateur, nous avons préparé un tableau indiquant les débits, les capacités

calorifiques des brûleurs, le diamètre des buses et la pression de service des différents types de gaz.

FIG. 7

Page 27

27

N°

BRÛLEURS

GAZ

DESCRIPTION

ORDINAIRE

COLLECTEUR

PRESSION

pouces

colonne d’eau

DIAMÈTRE DE

L’INJECTEUR

1/100 mm

APPORT NOMINAL

DE CHALEUR

(Btu/h)

Min.

Max.

1

2

3

4

ULTRA RAPIDE

RAPIDE

AUXILIAIRE

SEMIRAPIDE

PROPANE HD - 5

GAZ NATUREL

PROPANE HD - 5

GAZ NATUREL

PROPANE HD - 5

GAZ NATUREL

PROPANE HD - 5

GAZ NATUREL

11

4

11

4

11

4

11

4

94

176

91

155

53

90

70

120

4 400

4 400

2 500

2 500

1 200

1 200

1 500

1 500

11 000

11 000

10 000

10 000

3 550

3 550

6 100

6 100

Page 28

28

UTILISATION DE LA TABLE DE CUISSON

nominales

casserole

“Cm”

Allumage des brûleurs

Un symbole est présent à côté de chaque manette sur le panneau de commande de votre table de cuisson.

Ce symbole indique à quel brûleur correspond la manette de commande en question. Après avoir ouvert

l’arrivée de gaz ou le robinet de la bouteille à gaz, allumez les brûleurs comme indiqué ci-dessous :

Les manettes de commande des brûleurs sont équipées d’un dispositif d’arrêt d’urgence. Elles doivent

être tournées dans le sens inverse des aiguilles d’une montre jusqu’à atteindre la position de débit

maximal (représenté par une grande flamme, Fig. 8) jusqu’à butée. Puis appuyez sur la manette. Le

brûleur s’allume en deux ou trois secondes. Continuez d’appuyer en tournant vers la position de débit

minimal (représenté par une petite flamme, Fig. 8) pour régler la flamme. En cas de sortie accidentelle

d’une flamme, arrêter le brûleur et attendre au moins 1 minute avant de rallumer.

FIG. 8 FIG. 9

Utilisation correcte des brûleurs

Pour une efficacité maximale en consommant le moins possible de gaz, respectez les instructions

suivantes :

•

Utilisez des casseroles à la bonne taille pour chaque brûleur. (Voir le tableau suivant et la Fig. 9.)

•

Lorsque le contenu d’une casserole bout, baissez la flamme au minimum (représenté par une petite

flamme, Fig. 8).

•

Mettez toujours un couvercle sur les casseroles.

•

Utilisez uniquement des casseroles à fond plat.

Puissances

Diamètre de

En

Brûleurs

Ultra rapide

Brûleur rapide

11 000

10 000

9″ à 10½″

8″ à 9½″

24 - 26

20 - 22

Semi rapide

Auxiliaire

6 100

3 550

6″ à 7

4″ à 5½″

½

″

16 - 18

10 - 14

Page 29

29

AVERTISSEMENTS :

•

Les brûleurs ne s’allument que lorsque la manette correspondante est réglée sur la position de débit

maximal (représentée par une grande flamme, Fig. 8).

•

Il est possible d’utiliser des allumettes pour allumer les brûleurs en cas de panne de courant, mais soyez

prudent.

•

Ne laissez jamais l’appareil sans surveillance lorsque les brûleurs sont allumés. Assurez-vous qu’aucun

enfant ne se trouve à proximité. Assurez-vous notamment que les poignées des casseroles soient

correctement positionnées. Vérifiez fréquemment que le contenu ait suffisamment d’huile ou autre graisse

car les produits alimentaires peuvent facilement s’enflammer.

•

L’appareil ne doit pas être utilisé par des personnes (y compris enfants) dont les capacités mentales ou

physiques sont réduites, ou qui n’ont pas l’expérience suffisante pour utiliser des appareils électriques, à

moins d’être surveillé ou accompagné d’un adulte responsable de leur sécurité et santé. Les enfants ne

doivent pas jouer avec l’appareil.

•

N’utilisez jamais de bombes aérosols près de l’appareil lorsque celui-ci est allumé.

•

Les contenants plus larges que l’appareil ne sont pas recommandés.

NOTES :

•

L’utilisation d’un appareil de cuisson au gaz génère de la chaleur et humidité dans la pièce où celui-ci est

installé. C’est pourquoi la pièce doit être correctement aérée.

•

Une utilisation intensive et sur une longue durée de l’appareil peut exiger une ventilation complémentaire.

Cela peut se faire en ouvrant une fenêtre ou en augmentant la puissance du dispositif d’aspiration, le cas

échéant.

ATTENTION !

N’utilisez JAMAIS cet appareil comme

appareil de chauffage pour chauffer ou

réchauffer la pièce. Il existe un risque

d’intoxication au monoxyde de carbone et de

surchauffe de l’appareil.

Page 30

30

NETTOYAGE

IMPORTANT :

Débranchez toujours l’appareil du réseau

d’alimentation électrique ou en gaz avant toute

opération de nettoyage.

Nettoyez périodiquement la plaque chauffante, la

grille émaillée, les chapeaux émaillés « A », « B »

et « C » ainsi que les têtes de brûleurs « T » (voir

fig. 10 et 11) à l’eau tiède savonneuse. Nettoyez

également les chevilles « AC » ainsi que le

détecteur de flamme « TC » (voir fig. 10).

Nettoyez-les délicatement à l’aide d’une petite

brosse en nylon comme illustré (voir fig. 12) et

laissez sécher entièrement. Ne les lavez pas au

lave-vaisselle. Il est très important de nettoyer la

surface après chaque utilisation, lorsque le verre

est encore tiède.

Évitez le contact prolongé du vinaigre, du café, du

lait, de l’eau salée, du jus de citron ou de tomate

sur les surfaces émaillées.

N’utilisez pas d’éponges métalliques abrasives,

poudres abrasives ou de sprays corrosifs.

Note : Une utilisation continue entraîne une

décoloration des brûleurs due à la

température élevée.

AVERTISSEMENTS :

Respectez les instructions suivantes avant

de réinstaller les pièces :

- Vérifiez que les fentes des têtes de brûleurs

ne soient pas obstruées par un corps

étranger.

- Vérifiez que les chapeaux émaillés « A-B-C »

(fig. 10 - 11) soient correctement installés sur

les têtes de brûleurs. Ils ne doivent pas

bouger.

- L’emplacement correct de la grille est indiqué

par les angles arrondis, qui doivent

correspondre avec la partie latérale de la

plaque chauffante.

- Ne forcez pas les robinets si vous rencontrez

des difficultés à les ouvrir ou fermer.

Contactez le service technique pour une

réparation.

- Conservez correctement la plaque après

l’utilisation en la traitant avec des produits

spéciaux, en vente dans le commerce. Cela

permettra de conserver une surface propre et

brillante. Cette opération empêche également

la formation de rouille.

- N’utilisez pas de jets de vapeur pour nettoyer

l’appareil.

- Toute nourriture brûlée sur la plaque

électrique doit être retirée à sec.

- Après toute utilisation, versez un peu d’huile

tiède sur la plaque et nettoyez avec un

chiffon.

FIG. 10

FIG. 11

FIG. 12

Page 31

31

ENTRETIEN

Débranchez toujours l’appareil du réseau d’alimentation électrique ou en gaz avant toute opération

d’entretien.

Remplacement des composants

Pour remplacer les composants installés à l’intérieur de l’appareil, enlevez les grilles et les brûleurs de la

table de cuisson. Enlevez les vis de fixation « V » du brûleur (fig. 13) et les manettes en appuyant avec les

mains, afin de retirer de l’appareil.

Une fois ces opérations effectuées, les brûleurs (Fig. 14), robinets (Fig. 15) ainsi que les composants

électriques peuvent être remplacés (Fig. 16).

Il est conseillé de changer le joint « D » (Fig. 15) à chaque remplacement de robinet afin de garantir une

étanchéité parfaite.

Graissage des robinets (Voir Fig. 17-18)

Lorsqu’un robinet devient raide, il doit immédiatement être graissé en respectant les instructions suivantes :

1.

Retirez le robinet.

2.

Nettoyez le cône et son logement à l’aide d’un chiffon imbibé de solvant.

3 .Graissez légèrement le cône.

4 .Replacez le cône, manipulez-le légèrement puis enlevez-le à nouveau. Essuyez l’excès de graisse et

vérifiez que les conduits de gaz n’aient pas été obstrués.

5.

Remettez toutes les pièces à leur place, en suivant les instructions de démontage dans l’ordre inverse.

6.

L’étanchéité doit être testée à l’aide d’un liquide moussant.

N’utilisez jamais de flamme pour cet essai.

AVERTISSEMENT : SEULES DES

PERSONNES AUTORISÉES PEUVENT

EFFECTUER LES ACTIVITÉS D’ENTRETIEN.

FIG. 13

FIG. 14

FIG. 15

FIG. 16

FIG. 17

FIG. 18

Page 32

32

GARANTIE LIMITÉE

Dans les États-Unis contigus, pendant un an à compter de la date d’achat, si l’appareil est utilisé et entretenu

conformément aux présentes instructions ou celles fournies avec le produit. Le garant s’engage à payer les

pièces de rechange spécifiées par l’usine et la main-d’œuvre de réparation pour corriger un vice de matériau

ou de fabrication. Ledit service doit être assuré par une société désignée. En dehors des 48 États, toutes les

pièces sont garanties contre tout défaut de fabrication pendant une période d’un an. Les pièces en plastique,

rayonnages et meubles sont garantis être fabriqués selon des normes commercialement acceptables et ne

sont pas couverts en cas de dommage lors de la manipulation ou rupture.

LE GARANT DE L’OBJET NE PAIERA PAS :

•

Les appels de service pour corriger l’installation de votre appareil, pour vous apprendre à utiliser

votre appareil, pour remplacer ou réparer ou pour des problèmes de plomberie ou câblage.

•

Les appels de service pour réparer ou changer les ampoules de l’appareil ou les plateaux en verre

cassés. Les pièces d’usure (telles que les filtres) ne sont pas couvertes pas la garantie.

•

Tout dommage causé par un accident, modification, usage abusif, incendie, inondation, catastrophes

naturelles, installation incorrecte, installation ne respectant pas les codes en matière de plomberie

ou d’électricité, ou toute utilisation du produit n’étant pas approuvé par le garant.

•

Pièces de rechange ou la main d’œuvre affectée à la réparation pour les dispositifs utilisés hors des

États- Unis.

•

Réparations de pièces ou systèmes découlant de modifications non autorisées apportées à l’appareil.

•

Le retrait et la réinstallation de votre appareil si celui-ci est installé dans un endroit inaccessible ou n’est

pas installé conformément aux instructions d’installation fournies.

EXCLUSION DE GARANTIES T ACITES ; LIMITATION DE RECOURS

LE SEUL ET UNIQUE RECOURS POUVANT ÊTRE ENGAGÉ PAR LE CLIENT EN VERTU DE CETTE

GARANTIE LIMITÉE EST LA RÉPARATION DU PRODUIT CONFORMÉMENT AUX DISPOSITIONS DE

LA PRÉSENTE. LES GARANTIES TACITES, Y COMPRIS LES GARANTIES DE QUALITÉ MARCHANDE

OU D’ADAPTATION À UN USAGE SPÉCIFIQUE, SONT LIMITÉES À UN AN. LE GARANT NE SERA

PAS RESPONSABLE DES DOMMAGES ACCIDENTELS OU EN RÉSULTANT. CERTAINS ÉTATS

N’AUTORISENT PAS L’EXCLUSION OU LA LIMITATION DE DOMMAGES ACCIDENTELS OU EN

RÉSULTANT, OU LES LIMITATIONS SUR LA DURÉE DE GARANTIES TACITES DE QUALITÉ

MARCHANDE OU D’ADAPTATION. LE CAS ÉCHÉANT, CES EXCLUSIONS OU LIMITATIONS NE VOUS

CONCERNENT PAS. CETTE GARANTIE VOUS ACCORDE DES DROITS JURIDIQUES SPÉCIFIQUES

ET VOUS POUVEZ BÉNÉFICIER D’AUTRES DROITS QUI VARIENT SELON LES ÉTATS

AVERTISSEMENT : Ce produit peut vous exposer à des produits chimiques, y compris le nickel (métallisé), qui

est connu de l'État de Californie pour causer le cancer.

Pour plus d'informations, visitez le site www.P65Warnings.ca.gov

Remarque : Le nickel est un composant de tout acier inoxydable et d'autres composants métalliques.

Contactez sans frais le Service à la clientèle des États-Unis au 1-800-932-

4267, du lundi au vendredi, de 9h00 à 17h00 (ET).

Commandez vos pièces en ligne à www.summitappliance.com/support

Felix Storch, Inc.

Summit Appliance Division

770 Garrison Avenue

Bronx, NY 10474

Téléphone : (718) 893-3900

Fax : (844) 478-8799

Site Internet :

www.summitappliance.com

Loading...

Loading...