Page 1

WATER-LINE CONNECTION INSTRUCTIONS

FOR INSTALLED (MODULAR) ICE MAKERS

Important Information

This manual gives you complete instructions on how to

connect a water line to an ice maker already installed in your

SUMMIT refrigerator. Please read the manual carefully and

follow the instructions exactly as described. Make sure you

observe all safety instructions.

A certain amount of mechanical ability is required to complete

the water connection process.

You will have to purchase a copper tubing kit that contains a

"Regular Valve and Clamp Assembly" (for refrigerators with an

automatic ice maker, or self-filling trays). The kit contains all

of the hardware necessary to connect your ice maker to the

water supply. You can purchase one at most hardware or

plumbing supply stores.

DO NOT USE PIERCING-TYPE OR 3/16" SHUT-OFF

VALVES. They reduce the flow of water to the ice maker and

are easily clogged.

DO NOT USE POLYETHYLENE TUBING to connect the ice

maker to the water line. Use only 1/4" (O.D.) copper tubing.

CUSTOMER INSTALLATION IS NOT WARRANTED BY THE

REFRIGERATOR OR ICE MAKER MANUFACTURER.

FELIX STORCH, INC.

Summit Appliance Division

770 Garrison Avenue

Bronx, New York 10474

www.summitappliance.com

Page 2

1

Installing the Water Line

Choosing a location

1. Open the copper tubing kit that you purchased previously, and lay the

contents neatly on a table where you can identify them easily. The parts from

the kit that you will use are as follows:

1 Regular valve (not the steel-piercing type)

2 Compression sleeves

2 Compression nuts

2 Clamps

2 Screws

2 Nuts

1 Gasket seal *

1 Length of coiled copper tubing

*- Not needed for 11FTA models (24ECKMF kit)

NOTE: When you work with the soft copper tubing, be careful not to kink it. If you

accidentally kink the tubing, do not use it.

IMPORTANT: Do not install water line tubing in a location where the temperature

may fall below freezing; otherwise, property damage could occur.

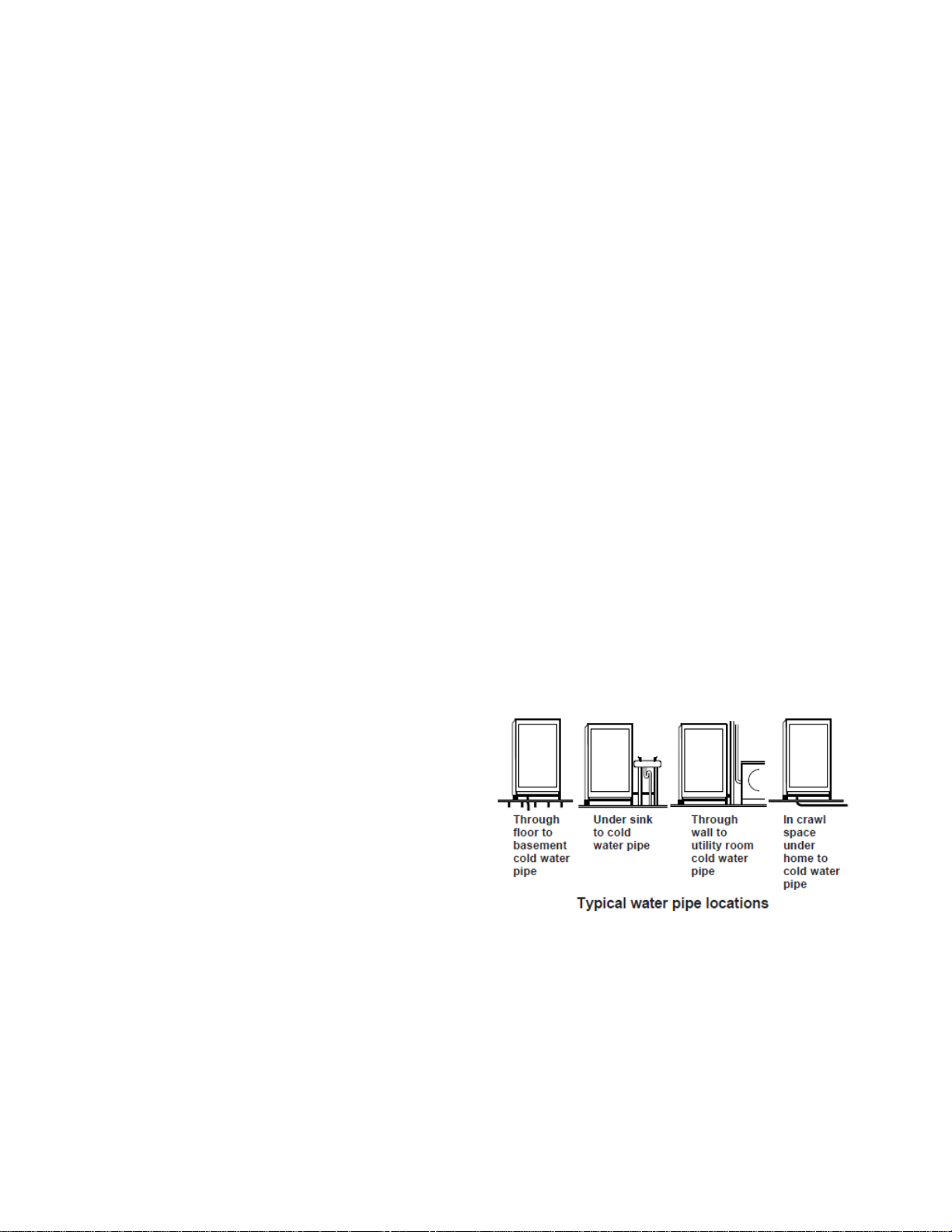

2. Choose a suitable water pipe

location to install the water shut-off

valve (see diagram at side for some

suggested locations). We

recommend installing the valve on a

vertical length of cold (not hot) water

pipe that is nearest your refrigerator.

If a vertical length of pipe is not

nearby, you can use a horizontal

length of water pipe; however, you

will have to drill the access hole for

the valve into the top or side of the

pipe (not the bottom). This will keep water in the pipe from flowing down onto

the drill, and also keep sediment from collecting in the valve later.

NOTE: Depending on the location of the horizontal pipe in relation to the floor

and wall, drilling into it may not be possible.

3. Drill a ⅜" hole through the floor or wall to the water pipe.

Page 3

2

Routing the copper tubing

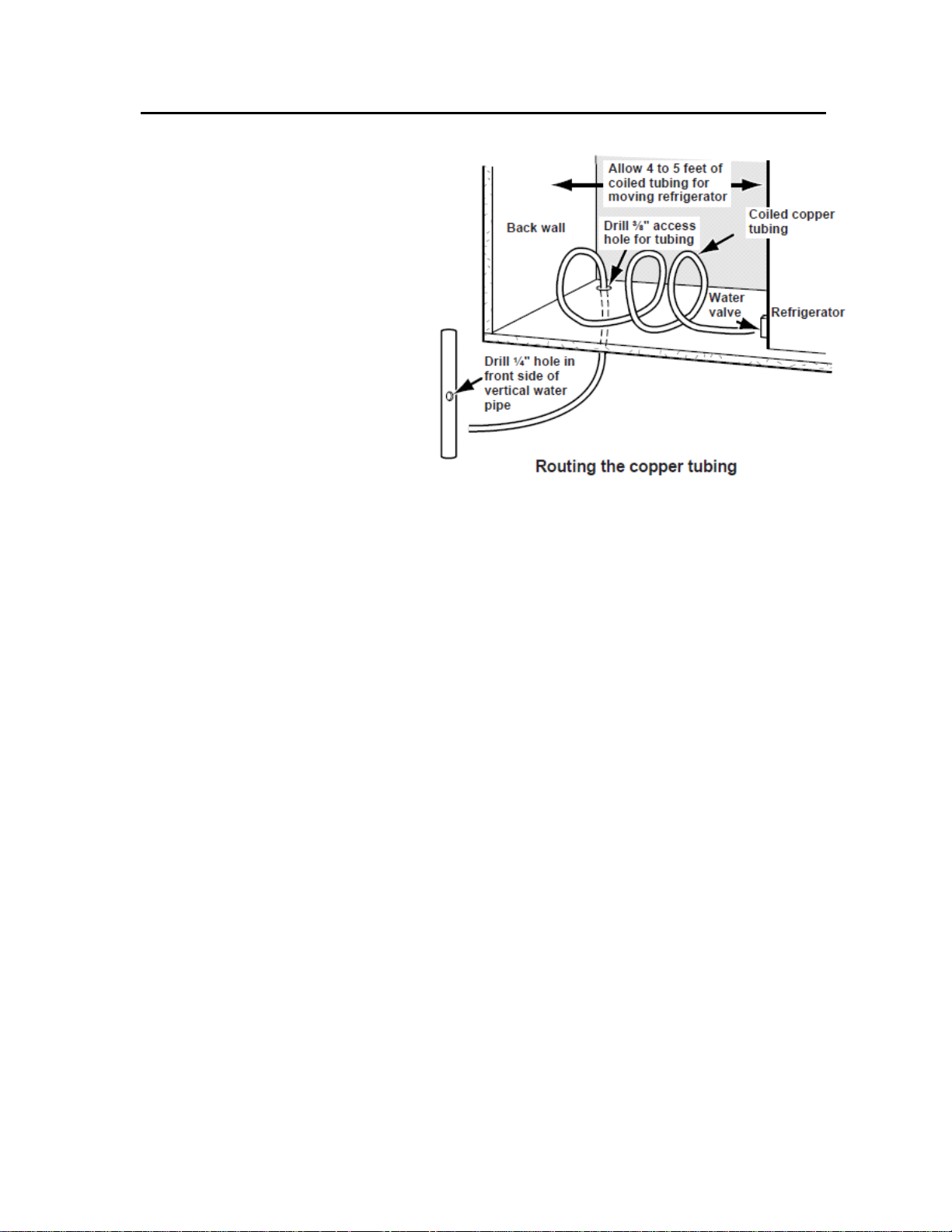

Refer to the diagram on the side

for the following steps.

1. Uncoil the necessary length of

copper tubing and straighten

it, then route the end of the

tubing through the access

hole you drilled to the location

you have chosen to install the

shut-off valve. Straighten only

enough of the copper tubing

to reach this location. Leave

the rest coiled near the

access hole.

2. At this time, make sure that

you have been supplied with

enough tubing so that when

you are finished connecting the

water line, you will have enough

coiled behind the refrigerator to

easily move it forward far enough

to clean behind it. Also make

sure that the coils are large

enough so that when the unit is

pulled forward, the winding will

not stretch too far and kink.

3. Turn off the cold water supply

going to the water pipe where

you will be installing the shut-off

valve.

4. Open a cold water tap that is

connected to the selected water

pipe and bleed off the water

pressure. Leave the tap open

until after you complete the water

line hook up.

5. Use a hammer and a center

punch, and mark the location of

the hole for the shut-off valve. If

you are marking copper tubing,

do not strike the punch hard

enough to bend it.

6. Install a ¼" bit in the drill, and

carefully drill an access hole

through just the front side (not

through both sides) of the cold

water pipe.

7. Check the hole and make sure

that you have drilled completely

through one side of the pipe. The

edges of the hole should be

smooth and round. If necessary,

use a small ¾-round file to

remove any rough edges from

inside the hole, and any burrs

from around the top of the hole.

Page 4

3

Installing the shut-off valve

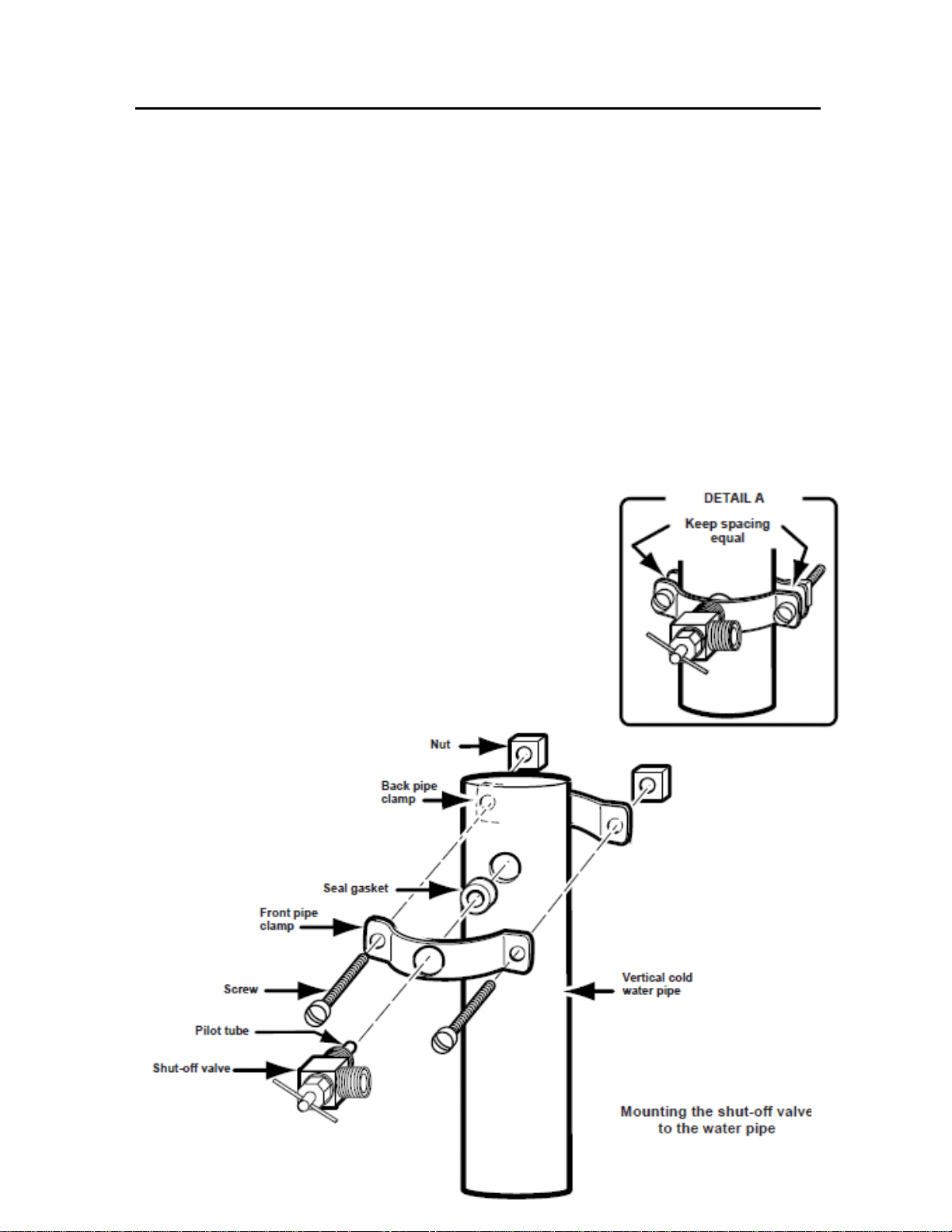

Refer to the diagram below for the

following steps.

1. Locate the shut-off valve and the

front pipe clamp (with the

threaded hole in the center) from

the copper tubing kit. Then, being

careful not to cross-thread the

valve, screw the end with the pilot

tube into the threaded hole of the

clamp. Hand-tighten the valve as

far as it will go (the threaded

shaft is slightly tapered and can

only be tightened so far).

2. Use a ½" open-end (or

adjustable) wrench, and turn the

body of the shut-off valve an

additional ⅛-turn to secure it to

the clamp.

3. Slide the rubber seal gasket

(from the copper tubing kit) over

the pilot tube (the unthreaded

portion) of the shut-off valve.

4. Carefully slide the pilot tube of

the shut-off valve into the water

pipe access hole so it is against

the seal gasket, and install the

back pipe clamp over the water

pipe. Secure the clamps to the

pipe with the two screws and nuts

that were supplied with the

copper tubing kit. Tighten the

nuts equally so that the space

between the clamps is the same

(see DETAIL A). DO NOT

OVERTIGHTEN the nuts or you

could deform the clamps and

damage the seal gasket.

Page 5

4

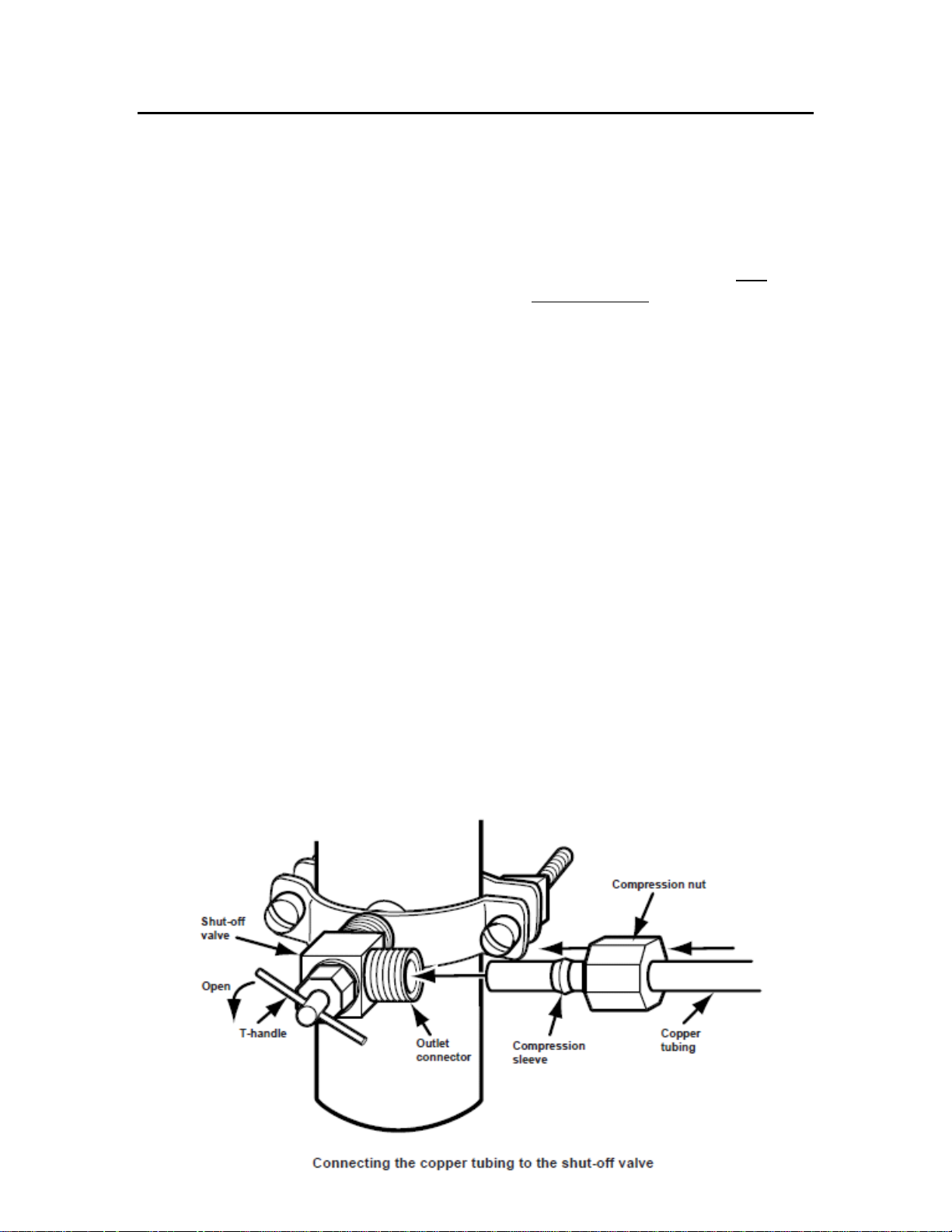

Connecting the copper tubing to the shut-off valve

Refer to the diagram below for the

following steps.

1. Straighten a 2" section of copper

tubing and make sure that the

opening is round and cut evenly

across the end. If necessary, use

a tubing cutter (or a hacksaw)

and cut the end off, then file it so

it is even, and remove any burrs

from around the inside and

outside edges so it is smooth and

round. When you are finished,

clean the filings from inside the

tubing as much as possible.

2. Position the compression nut as

shown, and slide it over the end

of the copper tubing.

3. Slide a compression sleeve over

the copper tubing until it is

approximately 1" from the end.

4. Insert the end of the copper

tubing into the outlet connector of

the shut-off valve as far as it will

go, and then hand tighten the

compression nut as much as

possible.

5. Using a ½" open-end wrench,

further tighten the compression

nut on the shut-off valve one

additional turn. If necessary, you

will tighten the nut further after

you turn on the water supply.

6. Turn the T-handle on the shut-off

valve to its fully "open"

(counterclockwise rotation)

position.

Page 6

5

Connecting the copper tubing to the water valve

Refer to the diagram below for the

following steps.

1. Check to make sure that the free

end of the tubing is round and cut

even. If necessary, prepare the

end in the same manner as you

did earlier. Be sure to clean the

filings from inside the tubing after

you prepare the end.

When you perform the next step, be

careful not to kink the copper tubing.

2. Starting at the free end,

straighten approximately 20" of

the copper tubing.

3. Close the water tap you left open

earlier to bleed the water lines.

4. Insert the end of the copper

tubing into a pail, and have

someone turn on the water

supply. Allow enough water to

flow through the lines to

thoroughly flush them out. Once

the water runs clear, turn off the

supply and bleed the lines.

5. Remove the strain relief clamp

from the rear of the cabinet and

slide it over the end of the copper

tubing. Make sure you position

the flanges as shown.

6. Slide a compression nut over the

free end of the copper tubing.

7. Slide a compression sleeve over

the copper tubing and position it

1" from the end.

8. If one is installed, remove the

plastic cap from the water inlet

fitting on the water valve and

discard the cap.

9. Insert the end of the tubing into

the water inlet connector at the

top of the water valve as far as it

will go, and hand tighten the

compression nut as much as

possible.

10. Use a ½" open-end wrench, and

further tighten the compression

nut on the water inlet connector

one additional turn. If necessary,

you will tighten the nut further

after you turn on the water

supply.

11. Mount the strain relief clamp to

the back of the cabinet with the

hex-head screw you removed

earlier.

Page 7

6

Turning the water on

NOTE: Be very careful when you

tighten the compression nuts that

you do not overtighten them and

destroy the compression sleeving

and the end of the soft copper

tubing. If this happens, you will have

to cut off the end of the tubing,

purchase a new compression sleeve,

and start over. Be careful and go

slowly!

1. Turn on the water supply and

check the shut-off valve for

leakage. If necessary, refer to the

side diagram, and tighten the

compression nut on the shut-off

valve in small increments until the

leakage just stops. Wipe off the

connection with a cloth each time

you check for leaks.

2. Check the water valve for any

leakage. If necessary, tighten the

compression nut (see the side

diagram) in small increments until

the leaking just stops.

Page 8

7

Final Installation

Forming the copper tubing

Loop the copper tubing coming from

the water valve as shown. Position

the coiled copper tubing near the

center of the unit so that it forms an

"accordion-fold" (as shown in the

diagram below) when it is moved toand-from the wall.

Page 9

8

Connecting the power/Leveling the unit

1. Plug the power cord into its AC

outlet, and carefully push the

refrigerator back against the wall

2. Place a level on top of the

cabinet. If you need to re-level

the refrigerator, follow the

procedure to adjust the front

casters, as outlined in your

refrigerator's Use and Care

Guide.

3. Check the position of the ice

maker. If it is crooked and needs

to be adjusted, loosen the bottom

bracket screws (see the side

diagram) and position the unit as

desired, then tighten the bracket

screws.

Page 10

9

Starting the Ice Maker

1. Wash out the ice bucket, and

then slide it under the ice maker

(see the side diagram) as far as it

will go. The ice bucket will be

sitting on top of the freezer shelf.

2. Place the items back into the

freezer compartment.

3. Lower the arm on the ice maker

(see diagram below) to its "on"

position, and close the freezer

door. The ice maker will begin to

make ice within 24 hours.

NOTE: It usually takes

approximately 24 hours for the ice

maker to begin producing ice. Once

ice is available, you may notice that

it has an "off" taste. If this happens,

make two or three batches of ice and

discard them. After that, the "off"

taste should be gone. If you have

any problems, refer to "Troubleshooting " on the following page.

This completes the installation of

your Ice Maker.

Page 11

10

Troubleshooting

Operational notes

1. The Ice Maker water valve

contains a flow washer that acts

like a pressure regulator to

control the water flow. For the Ice

maker to work properly, the water

pressure in your home must be

between 20 and 120 pounds-persquare-inch (psi). If you

encounter problems with your Ice

Maker's ability to product ice, call

your water utility company and

have the water pressure

checked.

2. The Ice Maker's water valve is

equipped with two strainers: a

plastic basket type and a wiremesh screen. Both of these can

be cleaned by turning off the

water and disassembling the

water valve (your service center

should be able to provide this

service). If local water conditions

require periodic cleaning, or if

you use a well as a water source,

you should consider installing a

second water strainer in the

water line. You can obtain a

water strainer from your local

appliance dealer.

Troubleshooting chart

The following chart lists several common problems that could occur with your Ice Maker.

PROBLEM CAUSE

One or more of the following

sounds is heard:

Buzzing

Trickling water

Thud (clatter of ice)

Ice tastes stale. The ice is old. Make a new batch.

Water in Ice Maker overflows. Refrigerator or Ice Maker is not level. If the Ice

Not enough ice. It will take 48 hours to fill the ice bucket. The ice

Ice making has stopped. Be sure that the bail arm is lowered into the ice

The water valve is operating.

Water is entering the Ice Maker to fill cup.

Ice is being dumped into the ice bin.

Maker still overflows after leveling, turn off the Ice

Maker's water supply at the shut-off valve, and

raise the Ice Maker's bail arm to the "off" position

(see previous page); then contact your local

service center.

maker will make ice every 2 to 3 hours. For more

ice, adjust the freezer control to a colder setting.

bucket (see previous page).

Make sure that the water shut-off valve is open.

The water shut-off valve or the water valve screen

is clogged. (Contact your local service center.)

Page 12

11

The modular ice maker service sheet

Module test points

Specifications

MOLD HEATER — 185 WATTS, 72 OHMS

THERMOSTAT — CLOSE 17° ± 3°

(BIMETAL) OPEN 32° ± 3°

WATER FILL — 140CC, 7.5 SEC.

MOTOR — 1.5 WATTS, 8800 OHMS

MODULE — STAMPED CIRCUIT,

PLUG-IN CONNECTORS

CYCLE — ONE REVOLUTION

(EJECTS AND WATER FILL)

FOR 120 VOLT MODEL

Water level adjustment

TURNING THE SCREW CLOCKWISE

DECREASES THE WATER FILL.

½ TURN EQUALS 20CC OR 1.2 SEC.

FULL TURN EQUALS 40CC OR 2.4 SEC.

MAXIMUM ADJUSTMENT IS ONE FULL TURN

EITHER DIRECTION. ADDITIONAL ROTATION

COULD DAMAGE MODULE.

Service Procedures

COVER

PULL WATER ADJUSTMENT KNOB FIRST AND SNAP

OFF COVER. INDEX KNOB AND REINSTALL IN SAME

POSITION FOR WATER FILL.

MODULE, MOTOR AND

INSERT PHILLIPS DRIVER IN ACCESS PORTS IN

MODULE. LOOSEN BOTH SCREWS. DISCONNECT

SHUT-OFF ARM. PULL MOLD FROM SUPPORT

ASSEMBLY.

SHUT-OFF ARM

PULL OUT FROM SUPPORT. REINSERT TO FULL

DEPTH.

MOLD AND HEATER

REMOVE MODULE, MOTOR AND SUPPORT

ASSEMBLY.

BIMETAL

REMOVE MODULE, MOTOR AND SUPPORT ASSEMBLY. PULL OUT RETAINING CLIPS WITH BIMETAL.

FILL CUP

REMOVE MODULE, MOTOR AND SUPPORT ASSEMBLY. REMOVE EJECTOR BLADES AND SHUT-OFF

ARM. PULL FILL CUP FROM MOLD.

EJECTOR BLADES OR STRIPPER

REMOVE MODULE, MOTOR AND SUPPORT ASSEMBLY.

WHEN REINSTALLING EJECTOR BLADES, REALIGN "D"

COUPLING WITH MODEL CAM.

SUPPORT ASSEMBLY

Page 13

12

Page 14

/

13

FELIX STORCH, INC.

770 Garrison Avenue

Bronx, NY 10474

Phone: (718) 893-3900

Fax: (718) 842-3093

www.summitappliance.com

For parts and accessory ordering,

troubleshooting and helpful hints, visit:

www.summitappliance.com

or call Customer Service toll-free

at (800)-932-4267

support

Loading...

Loading...