Page 1

Felix Storch, Inc.

An ISO 9001:2008 registered company

770 Garrison Avenue

Bronx, New York 10474

www.summitappliance.com

DATA LOGGER

Model DL-SA11

R3-081016 1

User’s Manual

Page 2

Product Overview

This data logger is used mainly to record the temperature of food, pharmaceuticals,

chemicals, etc., during storage and transportation. It is especially applicable to container

transportation of temperature-sensitive goods by sea, air and road for large

export-oriented enterprises and global chain enterprises.

Specifications……………………………………………………………………….

Size (length x diameter): 131 x 24 mm (5.16‖ x 0.95‖)

Technical parameters:

Temperature measuring range: -30°C to 70°C

Resolution: 0.1°C

Sensor: Built-in NTC thermistor

Temperature accuracy: ±0.5°C (-20°C to 40°C); ±1°C (other ranges)

Record capacity: 32,000 points (MAX)

Alarm type: continuous, cumulative

Alarm setting: no alarm, upper/lower limit alarm, multiple alarms

Record interval: 10 sec to 24 hour continuously set

Data interface: USB

Report type: Excel and AI/PDF

Power supply: single-use lithium battery 3.6V (replaceable)

Battery life: at least 12 months at 25°C with 15 min record interval

In the package……………………………………………………………………..

DL-SA11 temperature data logger

User’s manual

Using the data logger ……… ……………………………………………

Download the data management software from the link below:

http://accucoldloggers.com/dlsa11

Data management software can be downloaded from the software platform by clicking the

help button.

Install the software first. Insert the data logger into the computer’s USB port and install the

drive software according to the prompt information. Open the software; the data logger will

automatically upload information after connecting to the computer. View information and

exit the interface.

Note that the software installation has added an icon to your desktop.

To access to the program, double-click on the icon.

R3-081016 2

Page 3

Default Settings

Other settings

Logging interval

5 minutes

0-11 hours; 0-59 minutes; 0-50 seconds

Stop mode:

Software

Manual stop (see pp. 3-4 )

Start Mode:

Instant on

Manual and timing start (pg. 3)

Temp. Unit

oC oF

Buffer Ring:

Disabled

Enabled

Alarm

Settings

H1 (high alarm) =

10 oC

User defined

L1 (low alarm) =

2 oC

Alarm Mode:

Single

Cumulative

Caution!

Make sure you have saved selected parameters.

Configure parameters

Refer to the data management software instructions for details (pages 8 –14)

Start the data logger

There are three modes to start the logger – instant-on, manual start, and timing start.

1. Instant-on: After parameter configuration, the data logger starts recording

immediately when it is disconnected from the USB.

2. Manual start: After parameter configuration, press and hold the button for 5

seconds to start the data logger. In this mode, it has a start delay function. If this

function is enabled, the data logger will not record data immediately after start-up

but start recording after the set delay time elapses.

3. Timing start: After parameter configuration and disconnection from USB, the data

logger starts recording when it reaches the set time.

View data instantly

If you need to view simple statistical information, you may directly press the button to turn

the page and check. The LCD screen can display MKT, average value, Max value and Min

value. Mean Kinetic Temperature (MKT) is a simplified way of expressing the overall effect

of temperature fluctuations during storage or shipment of perishable goods.

If you need detailed information, please connect the data logger to the computer’s USB.

After about 3 minutes, the data will be saved. You can open it as an Excel, AI or PDF

report.

Moreover, you can connect the data logger to a computer and analyze the data using the

data management software.

Stop the data logger

There are several modes to stop it – manual stop, stop via software, over-Maxrecord-capacity stop (enable/disable manual stop).

1. Manual stop: When the data logger is recording in this mode, you may press and hold

the button for 5 seconds to stop it.

2. Stop via software: You can stop the data logger via software

selecting the Stop recording option on the software platform.

If the record capacity reaches the Max value (32,000 points)

by

R3-081016 3

Page 4

and the data logger is not stopped manually, the data logger will save the data by

overwriting the initial data. (It keeps the statistical information of the whole

transportation process.)

NOTE: When the record capacity exceeds the Max capacity (32,000 points) in the

manual mode, the data logger can continue recording the temperature state of the

whole transportation process but only keep the details of the last 32,000 points.

Please use the ―manual stop‖ mode with caution if you have a need to trace back

the details of the whole process.

3. Over-Max-record-capacity stop (enable manual stop): In this mode, you can stop the

data logger by hand or via software, or it will stop automatically when the record data

reaches the Max capacity (32,000 points).

Over-Max-record-capacity stop (disable manual stop): In this mode, it will stop

automatically when the record data reaches the Max capacity (32,000 points), or

you can stop it via software.

View data

Connect the data logger to the computer via USB and then view the data.

View report via the data management software: Open the software and import the data as

Excel, Adobe Illustrator Artwork (AI) or PDF report. The software will display the

configuration information and recorded data.

Display menu instructions

Different screens are displayed when the unit is running. Below are various modes of

operation of the data logger.

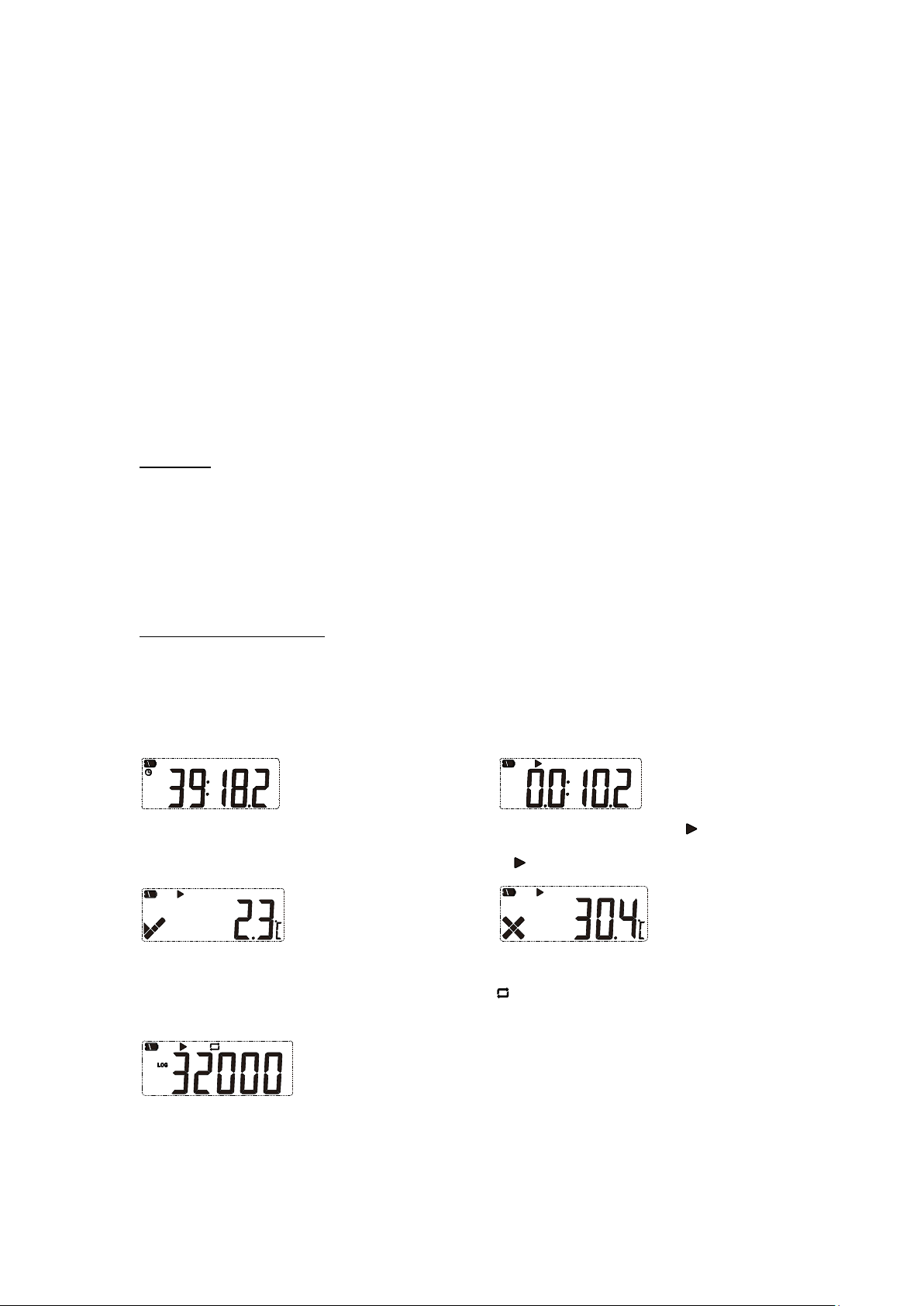

Menu 1: Start delay time or the remaining time of timing start (Hr: Min. Sec). See Figures

1 and 2. (This page is displayed only in start delay or timing start status.)

Fig.1: Start delay time Fig.2: Timing start delay ( flashing)

Menu 2: Current temperature. See Fig. 3, 4 (Static indicates it is recording.)

Fig.3 Current temperature (No alarm occurred) Fig.4 Current temperature (Alarmed)

Menu 3: Current record points. See Fig.5 (Static indicates the current record points

exceed the Max capacity and the data logger is overwriting initial data.)

Fig.5 Current record points

R3-081016 4

Page 5

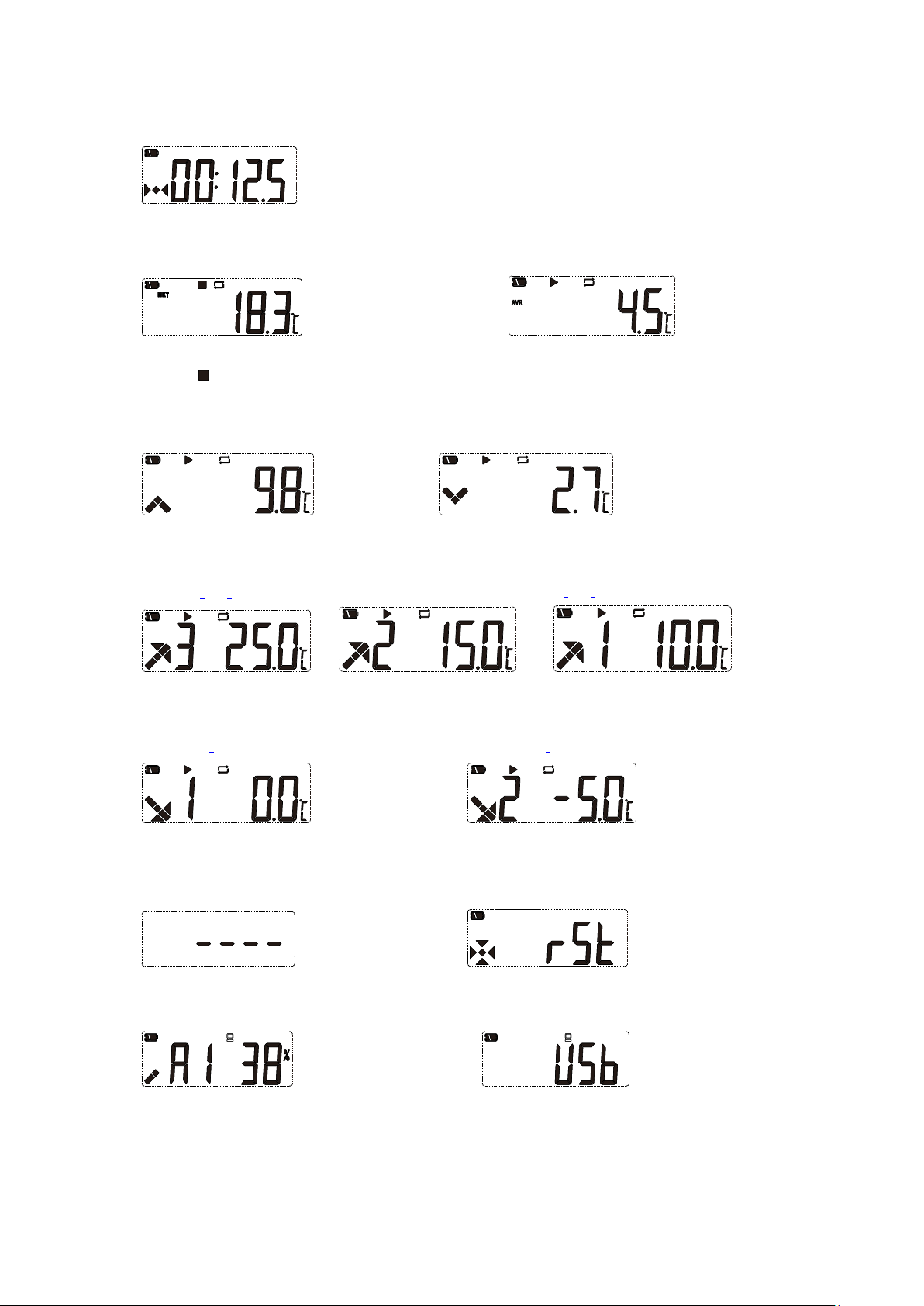

Menu 4: Current record interval. (e.g., the digit N following the decimal point represents

N*10 sec. Fig.6 shows the record interval is set to 12 min 50 sec.)

Fig.6 Record interval

Menu 5: MKT value. Menu 6: Average temperature value.

Fig.7 Fig.8

Static indicates it stopped recording

Menu 7: Max temperature value. Menu 8: Min temperature value.

Fig.9 Fig.10

Menu 9, 10, 11: Set upper limit of temperature. See Fig.11, 12, 13

Fig.11 Upper limit 3 Fig.12 Upper limit 2 Fig.13 Upper limit 1

Menu 12, 13: Set lower limit of temperature. See Fig.14, 15

Fig.14 Lower limit 1 Fig.15 Lower limit 2

Other status:

Fig.16 Deleting data Fig.17 Recovering data (Power on)

Fig.18 Generating report Fig.19 USB connection

R3-081016 5

Page 6

PLEASE NOTE

Before replacing the battery you must first shut down the data

logger. If not, when restarting the logger, the time will be incorrect.

1

USB

4 Transparent cap

2

LCD screen

5

Battery compartment

3

Button

Content of exported report

The report varies based on the set alarm types.

When unit is set to ―no alarm‖, there is no alarm info on the top right corner of the first

page or color mark among data.

When it is set to ―alarm‖, relative alarm info appears in the alarm info column based on the

selected alarms. Over high temperature data is in red. Below low temperature data is in

blue. Normal data is in black. If alarm cases occur, they will be marked as alarm status on

top right corner of the first page; otherwise, it is in normal status.

Finish viewing

Exit the data logger after viewing the report.

Product diagram……………………………………………………………………

Replacing the battery……………………………………………………………….

Step 1. Rotate the transparent cap and remove it in the direction shown in Fig. 20.

Fig.20

R3-081016 6

Page 7

Step 2. Press the snap to remove the compartment. See Fig. 21.

Fig.21

Step 3. Remove the battery compartment. See Fig. 22.

Fig.22

Step 4. Remove the old battery and Install the new one. See Fig. 23.

Fig.23

Step 5. Adjust the button and the internal light pipe to the same side; snap the

compartment shut. See Fig. 24.

Fig.24

Step 6. To re-install the transparent cap, rotate it in the direction shown in Fig. 25.

Fig.25

R3-081016 7

Page 8

Hardware environment:

Operation system:

CPU:above PII600MHZ

Hard disk:above 40G

Memory:above 512M

Windows XP(32bit、64bit, Windows Vista(32bit、

64bit, Win7(32bit、64bit), Windows8(x86/x64)

Tool buttons:

Function

Download recording data from logger

Database query interface

displays all saved data

information

Manually save data: if current data is not saved

into database, then press this button to save

data. For first time recording data, the system will

automatically save the data and display the prompt of auto data

saving. If new data is recorded and logger is inserted into

computer once more, user needs to save the data manually by

clicking the button, and it will display a dialog box to save the

data.

Export data in the format of AI,

EXCEL or ELT

Logger parameter setting

Data Management Software Instructions

Data Management Software can upload all recorded data to a computer and

systematically analyze, collect and manage data.

1. Installation environment

2. Main functions

2.1:Main interface

R3-081016 8

Page 9

Serial Number——Data logger ID

Stop Time——Stop time

Log Interval——Record interval

Data points——Total record points

Time Base——Time Zone

Elapsed time——Total record time

Start Mode——Logger start mode

MKT——Mean kinetic temperature

Start Delay——Logger start delay time

Over——Alarm upper limit

Buffer Ring——Buffer Ring

Below——Alarm lower limit

Trip ID——Trip ID number

Allow Time——Alarm delay time

Description—Trip description

Total time——Accumulated alarm time

Highest ——Max. Temperature

Violations——Times alarm occurs

Lowest ——Min. Temperature

Status ——Logger alarm status

Average ——Average Temperature

RH% - Relative Humidity

Stop Mode——Stop mode Set

Status ——Logger alarm status

Stop mode (actual)——Actual stop mode

T ---Temperature

Start Time——Start time

RH% - Relative Humidity

Multiple Work——Permits logger to be started or stopped several times

Function buttons

Stretches curve

horizontally

Contracts curve

horizontally

Zooms in

Zooms out

Returns curve to

original size

Parameter information:

Data Graph

R3-081016 9

Page 10

Data table

——Displays first page data

——Displays previous page data

——Displays next page data

——Displays last page data

——Skips to a specific page

R3-081016 10

Page 11

Selects all loggers

Views the detailed information of the selected logger

Deletes the data of selected logger

Displays all loggers that have exceeded upper/lower limit

Displays all recording (including normal temperature data

and over temperature data)

Data management function

Back to home page

3. Data query page

R3-081016 11

Page 12

4. Data management page

——Data backup (saves data in the format of ELT)

——Data restore (restores ELT file and reads it by software)

——Back to home page

5. Parameter setting page

R3-081016 12

Page 13

Parameter information:

Serial Number——Data logger ID

Start Mode——Logger start mode

Trip ID——Travel ID number

Travel DSC——Travel description

Log Interval——Record interval

Report Language——Report Language

Time Base——Time Base

Battery——Battery display

Cycle—— Total record time available

No Alarm ——Alarm threshold not set

Password——Setting password

Stop Mode——Logger stop modes

Multiple Alarm——Set several alarm thresholds

Multiple Work——Permit logger to be started or stopped several times

Probe Type——Temperature sensor type (internal or external)

Start time——Logger starts automatically at set time

Saves

parameters

Saves

parameter

setting

Loads parameter

setting

Back to home page

Sensor

adjustment

6. Sensor Adjustment

R3-081016 13

Page 14

Export data in the

EXCEL format

Export data in the

AI format

Export data in the

ELT format

Restore/insert

ELT data to the

software

accucoldloggers.com

Phone: 718-893-3900

Fax: 844-478-8799

Accucold, Felix Storch, Inc., Summit Appliance Division | 770 Garrison Avenue | Bronx, NY 10474

7. Export data page

Customer Support …………………………………………………………….………

For technical support, please call 800-932-4267 (U.S. and Canada) or email

info@summitappliance.com; for calibration services please contact calibration@summitappliance.com .

Limited Warranty…………………………………………………………….………

Within the 48 contiguous United States, for 90 days from the date of purchase, when this

appliance is operated and maintained according to instructions furnished with the product,

warrantor will pay for factory-specified parts and repair labor to correct defects in materials

or workmanship. Service must be provided by a designated service company. Outside the

48 states, all parts are warranted for 90 days from manufacturing defects. Plastic parts are

warranted to be manufactured to commercially acceptable standards, and are not covered

from damage during handling or breakage. Warrantor will not pay for damage resulting

from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with electrical codes, or use or modifications of products not

approved by warrantor.

R3-081016 14

Loading...

Loading...