Summit 325E Service Manual

325E X-RAY GENERATOR

USER AND ASSEMBLER INFORMATION

For X-ray Control Model No.: F280

and X-ray High-voltage Generator Model No. A700

01496-000 Revision G

AUGUST 2005

SUMMIT INDUSTRIES, INC.

2901 W. Lawrence Avenue

Chicago, IL 60625

773-588-2444

www.Summitindustries.net

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

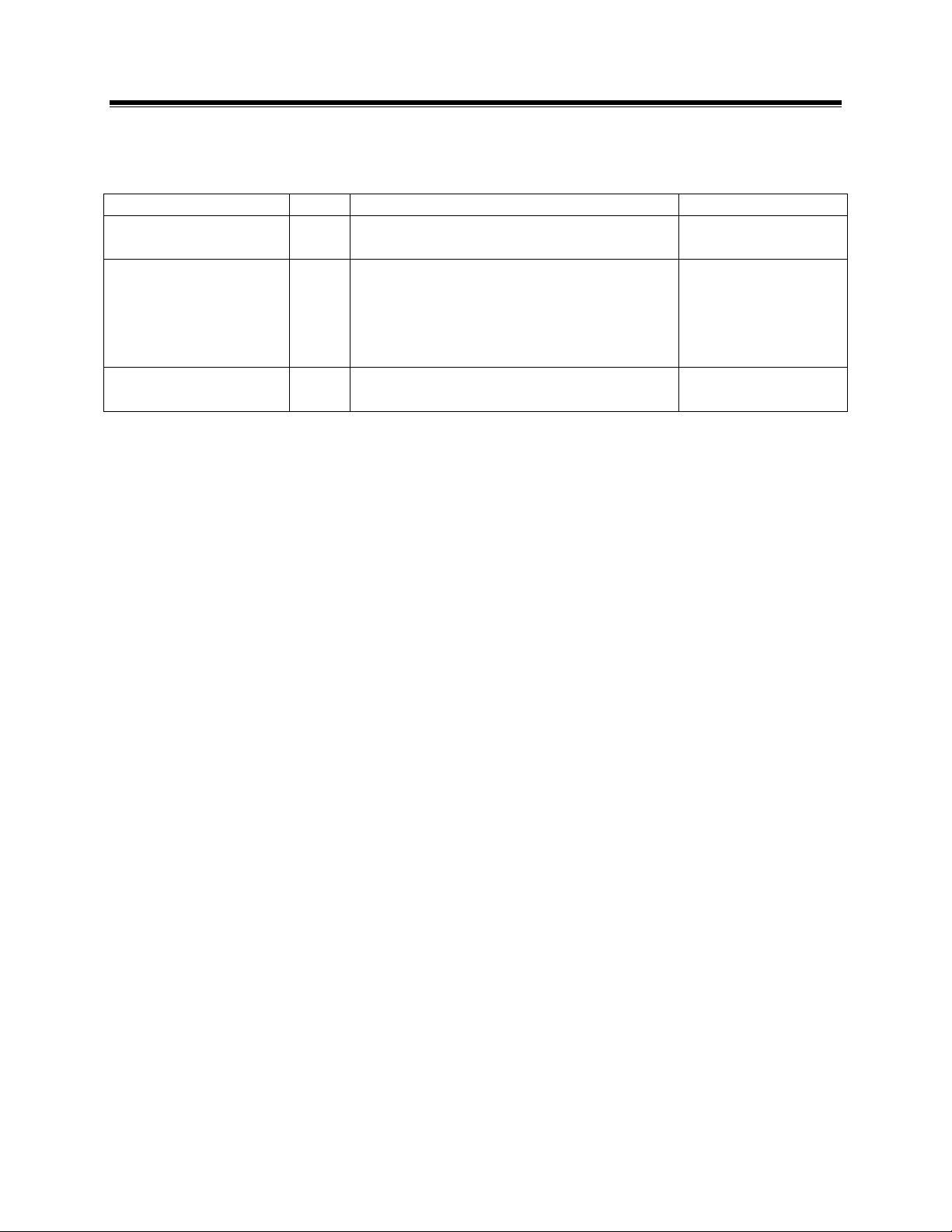

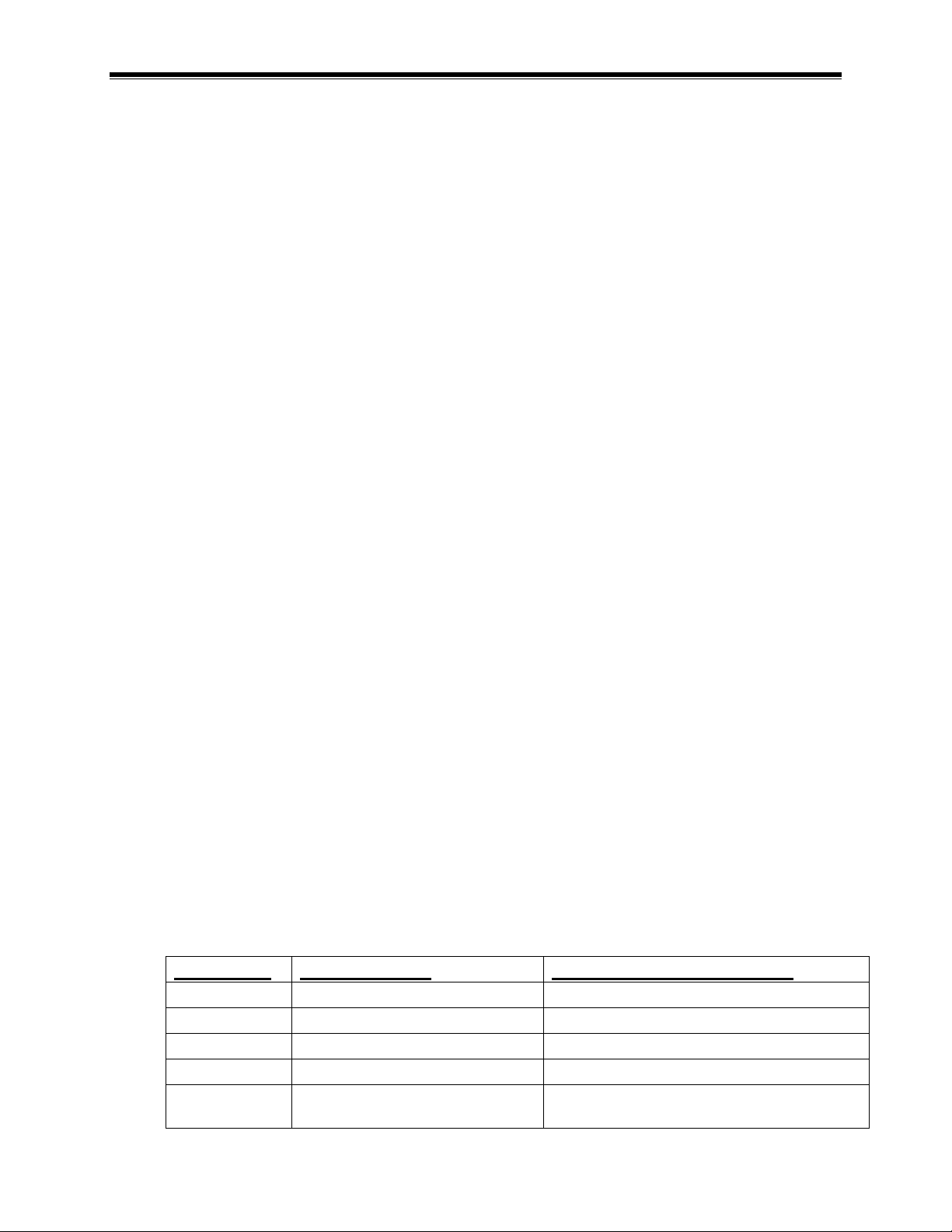

TEXT REVISION HISTORY FOR F285 MANUAL

REVISION ECR DESCRIPTION RELEASE DATE

E 4196 UPDATED COVER SHEET AND

SCHEMATICS

F 4484 ADDED ERROR CODES AND TUBE

PROTECT DIP SW. SETTINGS DUE

TO 02249-000 TIMER BOARD.

ADDED TEXT REVISION HISTORY

PAGE, AND UPDATED TOC

G 4727 UPDATED TOC TO INCLUDE 02581

SERVICE GUIDE

AUGUST 2004

FEBRUARY 2005

AUGUST 2005

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

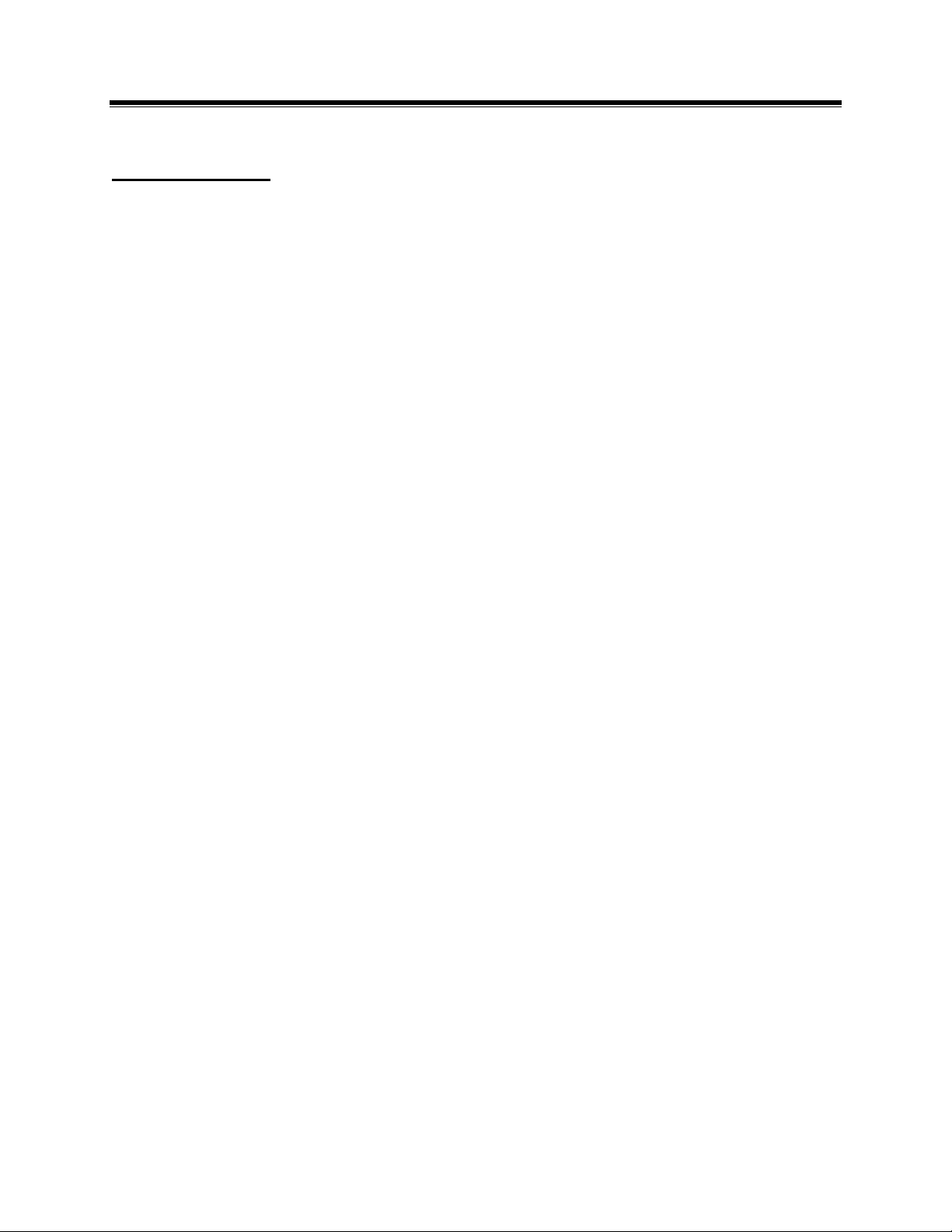

TABLE OF CONTENTS

I. INTRODUCTION..................................................................................................2

II. USER INFORMATION .........................................................................................3

A. CONTROL FEATURES................................................................................3

B. RECOMMENDED OPERATING PROCEDURES ........................................6

C. MAINTENANCE ...........................................................................................7

D. TECHNICAL INFORMATION.......................................................................9

III. ASSEMBLER INFORMATION............................................................................11

A. CERTIFICATION OF COMPATIBILITY......................................................11

B. RADIATION PROTECTION .......................................................................11

C. ELECTRICAL POWER SUPPLY REQUIREMENTS..................................11

D. UNPACKING AND OPENING CONTROL..................................................12

E. PRELIMINARY ASSEMBLY AND TUBE PROTECT SELECTIONS..........14

F. PRELIMINARY ELECTRICAL CHECKS AND ADJUSTMENTS ................18

G. CALIBRATION............................................................................................20

H. FINAL COMPLIANCE TESTS.................................................................... 26

I. ANCHORING CONTROL CABINET TO THE FLOOR...............................28

J. SCHEMATICS

1. B127 --SCHEMATIC, 325 CONTROL CIRCUIT DIAGRAM..................29

2. 02249-002 -- COMPONENT LAYOUT FOR TIMER DRIVER PCBA ..... 30

3. B130-- SCHEMATIC, MOTOR START CRCT ......................................31

4. B131--PARTS LAYOUT FOR MOTOR START CRCT (A455) ............. 32

5. B132-- SCHEMATIC FOR KV COMP. PCB ASSY. (01204) .................33

6. B133--HIGH TENSION TRANSFORMER DIAGRAM (A700)............... 34

7. 02249-003--SCHEMATIC AND COMPONENT LAYOUTS …………….35

K. SERVICE GUIDE, SINGLE-PHASE GENERATORS (02581) ................... 36

1

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

I. INTRODUCTION

The equipment, which is described in this manual, will perform reliably when installed,

operated, and maintained in accordance with the instructions of this manual.

This equipment is sold with the understanding that the user assumes sole responsibility

for radiation safety and that the manufacturer does not accept any responsibility for the

following:

1. Equipment improperly installed.

2. Equipment improperly used.

3. Equipment improperly maintained or repaired.

4. Equipment, which has been modified or altered in any way.

5. Injury or damage to patient or other personnel for any of the above

causes.

We are proud of our products and are confident they will provide many years of useful

and enjoyable service.

Summit Industries Inc.

2

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

USER INFORMATION

II.

This x-ray generator is both easy to use and very versatile. It consists of an x-ray

control and a high voltage generator (H.V. generator).

A.

CONTROL FEATURES

Refer to photo on page 6 for location of the following controls and indicators:

Note: Refer to Section B, “Recommended Operating Procedure” for detailed

description of proper use of these controls and indicators.

A)

Power “on” – “off” switch – Controls power to the system.

B)

Power “on” light – Indicator light lights when power is “on”.

C)

Bucky selector switch – Allows selection of either wall bucky, table bucky, or

no bucky.

D)

Line check rocker switch – When depressed, this switch causes the kVp

meter (O) to indicate if the line voltage compensator (E) is adjusted properly.

E)

Line voltage compensator – Allows operator to adjust input circuit of x-ray

control to match the line voltage easily and effectively.

F)

Tube current (mA) selector switch – Rotary switch allows operator to select

the optimum tube current and focal spot for the desired technique.

G) D

igital display – This display provides three very useful features:

1. Pre-exposure indication of mAs (the product of mA and exposure time).

2. Post-exposure indication of the number of x-ray pulses counted during

the previous exposure.

3. Error codes to indicate generator status or inappropriate selection.

Error Code Indicated Fault Corrective Action Required

E01 Tube Limits Exceeded Reduce kVp, mA or Time

E02 kVp too high (>128 kVp) Select 125 kVp or less

E03 kVp too low (<37 kVp) Select 40 kVp or more

E04 Invalid mA setting Reselect mA station

E06

We recommend that the above chart be kept available for easy reference.

Invalid Time Selection

or Leaking SCR

Reselect Time station, call for

service if error won’t clear.

3

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

X-ray exposure switch – Two level switch: Partial depression (PREP) causes

H)

anode rotation and filament current boost. Full depression (EXPOSE)

initiates the production of x-rays.

I)

Exposure time selector switch – Provides the operator capability to select any

one of 23 different exposure times.

J)

Exposure interlock “ready” light – Indicator light lights when all exposure

interlocks are closed. (Collimator interlock, tube thermal protection, misc.

exposure interlock devices, etc.) When this light is “off”, exposures will not be

allowed.

K)

Tube ratings exceeded light – Indicator light lights when internal electronic

circuitry detects that selected technique factors exceed the single exposure

ratings of the x-ray tube. Under these conditions, x-ray exposures are not

allowed.

L)

Milliampere meter – Indicates actual tube current during an x-ray exposure.

Meter deflection is the visual indication of x-ray production.

M)

kVp minor selector – Provides fine adjustment of peak tube potential (kVp).

N)

kVp major selector – Provides coarse adjustment of peak tube potential

(kVp).

O)

KILOVOLT meter – Pre-reading meter, which indicates selected peak tube

potential (kVp). This meter also serves as an indicator of line voltage

adjustment in conjunction with item (D) above.

4

O

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

N

L

A

B

5

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

RECOMMENDED OPERATING PROCEDURES

B.

Note: It is important to turn the generator “on” at least 15 minutes before making

an exposure. This will provide sufficient “warm-up” time for the circuitry to

stabilize.

1. Turn the system “on” by slowly snapping the power switch (A) to the right.

Power “on” light (B) should light.

2. Check the line voltage by depressing “line check rocker switch” (D) while

observing the kVp meter (O). Rotate the knob of the “line voltage

compensator” (E) as necessary until the needle of the kVp meter falls within

darkened area of the scale marked “V”, (as near the center of the area as

possible.)

Note: If you are unable to position the needle within this area, it is an

indication that the line voltage is not correct and the equipment should

not be used. Either wait for line voltage to change or call for service.

3. Determine the desired technique factors Note: Do not exceed the x-ray

tube ratings. Refer to x-ray tube rating charts provided with the x-ray

tube. If the technique factors are set beyond the x-ray tube limits “E01”

should appear in the digital display window, preventing exposure.

Note: Proper warm-up of the anode must be done on a cold unit prior to

making exposures. The specific details may be found in “General

Information for Installing and Operating X-Ray Tubes”, that is included

with each tube shipped. The warm-up procedure tags are attached to

each unit. Basically this procedure will reduce the chance of tube

damage due to thermal shock.

4. Select the desired tube current. Selecting the 50 or 100 mA stations

automatically determine that the small Focal Spot will be used. The 150, 200,

and 300 mA stations are internally connected to the large F.S.

Note: Select the desired tube current (mA) prior to selecting the desired

peak tube potential (kVp).

If at any time, a different tube current is selected, it will be necessary to

reset the kVp selector switches.

5. Rotate the exposure time selector switch (I) to the desired time setting.

6

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

6. Observe the digital display (G) to confirm that the correct mAs has been

selected.

7. Select the desired peak tube potential (kVp) by observing the kVp meter (O)

while rotating the kVp selectors (M&N)

8. This generator is equipped with tube protect circuitry that compares the

selected technique factors to the “single exposure ratings” of the x-ray tube.

Exposures will only be allowed if the selected values are less than or equal to

the x-ray tube limits. Refer to the chart below for description of “E01” error.

9. If the x-ray system includes a bucky (wall or table or both) and it is desired to

use a bucky technique, select the appropriate bucky by depressing the bucky

selector switch. If a non-bucky technique is desired select the center “off”

position of the bucky selector switch.

10. This generator is also equipped with an indicator light identified as “exposure

interlocks ready” light, which monitors the status of all auxiliary exposure

interlock circuitry. When all interlocks are ready the light will light. If the light

is not “on”, x-ray exposures will not be allowed. Such interlocks might be SID

interlock switches, tube thermal protectors, collimator interlock, etc.

11. Depress the exposure switch approximately halfway. This action will cause

the rotating anode of the x-ray tube to accelerate to full speed and the

selected filament of the x-ray tube to heat up to its proper emission

temperature. Depress the exposure switch fully and hold. A beep tone will

indicate the termination of the exposure, and the mA meter deflection will

provide a visual indication of x-ray production.

Note: It is permissible to depress the exposure switch fully in one

motion. There will be however, a one second delay before x-ray

production begins.

After the exposure terminates, but while the exposure switch is still

depressed, the digital display will flash “on” and “off” indicating the number of

x-ray pulses produced. This is primarily a service feature provided for the xray serviceman to verify proper operation.

12. Error codes and corrective action for digital display window.

Error Code Indicated Fault Corrective Action Required

E01 Tube Limits Exceeded Reduce kVp, mA or Time

E02 kVp too high (>128 kVp) Select 125 kVp or less

E03 kVp too low (<37 kVp) Select 40 kVp or more

E04 Invalid mA setting Reselect mA station

E06

Invalid Time Selection

or Leaking SCR

7

Reselect Time station, call for

service if error won’t clear.

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

MAINTENANCE

C.

Periodic inspection and preventative maintenance of this equipment is necessary to

assure continued safe performance and compliance with applicable state and federal

regulations. The following maintenance program must be closely followed.

Q: Who should perform the service?

A: Service personnel specifically trained, experienced, and familiar with this type of

medical x-ray equipment.

Q: When and How often?

A: Appropriate inspection and service shou ld be performed 30 days after installation

and every 6 months thereafter.

Q: Specifically, what must be inspected, tested and/or serviced?

A: Several things:

1. Verify that the knob on exposure time selector is mounted solidly and

indicates the proper value.

2. Verify that all push-button and rocker switches operate freely with no sticking

or hanging up.

3. Verify proper operation of all pilot lights.

4. Verify proper operation of audible and visual indicators of x-ray termination

and production respectively.

5. Verify the accuracy of exposure timer, tube current, and peak tube potential,

and adjust as necessary.

6. Perform reproducibility and linearity tests and verify compliance.

7. Inspect electro-mechanical contactor for pitting and/or burned contacts.

Replace if necessary.

8. Examine terminal connections of high voltage generator. All terminals should

be tight.

9. Examine oil level of H.V. generator and refill as necessary. There should be

approximately ½ to ¾” air space between the oil and the inside edge of the

generator cover.

10. Examine the plugs of the high voltage cables. They should be clean with no

signs of carbon tracking.

Note: This x-ray generator should not be altered or modified in any way

as such action may invalidate its regulatory compliance and void the

factory warranty.

8

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

TECHNICAL INFORMATION

D.

Rated line voltage – 240 VAC, 60 Hz., single phase.

Range of line voltage regulation at max. line current = 1-5%

Maximum line current based on input voltage of 240 VAC -140A.

Technique factors that constitute the maximum line current – 300 mA @ 125 kVp.

Generator rating-

Output Current = 50-300mA.

Output Voltage = 40-125kVp.

Generator duty cycle-

100mA @ 125 kVp – 4%

200mA @ 125kVp – 2%

300mA @ 125kVp – 1%

Maximum Deviation

The following maximum deviation statements are broad and considered “worst case”

conditions.

Typical performance will normally be significantly better.

Peak Tube Potential (kVp)

The Maximum Deviation of the Peak Tube Potential during an exposure from its pre-

indicated value is

upon which the peak tube potential is defined is a calibrated high voltage divider unit

such as the Machlett Dynalyzer.

Tube Current

The Maximum Deviation of the tube current during an exposure from its pre-indicated

value is

of selected value within a kVp range of 40-50 kVp (exclusive). The measurement basis

upon which the tube current is defined is a calibrated D.C. milliammeter in series with

the x-ray tube.

+10% of selected value within a kVp range of 50-125 kVp (inclusive), and +20%

+ 20% of the kVp meter’s full-scale value. The measurement basis

9

325E X-Ray Generator

Summit Industries, Inc. Model Numbers F280 / A700

Exposure Time

The maximum deviation of the measured exposure time from its pre-indicated values is

The measurement basis upon which the exposure time is defined as the number of half

cycle impulses of the 60 Hz power line measured either at the primary of the high

voltage generator with an oscilloscope or in the secondary of the high voltage generator

by means of a high voltage divider unit and an oscilloscope.

Tube Current-Exposure Time Product

The digital display of mAs provided is not a primary indication of technique factors. It is

intended solely as an auxiliary indication to verify the product of the primary control

settings: tube current and exposure time. As such, a statement of maximum deviation

is not provided.

+ 1 pulse for selected times within the range of 1/120 – 1/10 sec.

+ 15% of selected times within the range of 3/20-6 sec.

10

Loading...

Loading...