Summit 2196 model, 2196-LF model, 2196-R model, 2796 model Installation, Operation And Maintenance Manual

Page 1

SUMMIT PUMP

Model 2196 / 2196-LF / 2196-R / 2796

ANSI Standard Process Pump Family

Installation, Operation, and Maintenance Manual

Rev. 7/2003

Page 2

Page 3

WARRANTY

Pumping units assembled by Summit Pump, Inc., Green Bay, WI are guaranteed to be

free from defects in material and workmanship for one year from date of shipment from

factory in Green Bay, WI. The obligation under this Warranty, statutory or otherwise, is

limited to replacement or repair at Green Bay, WI, of such part as shall appear to us upon

inspection at such point, to have been defective in material or workmanship.

This Warranty does not obligate Summit Pump, Inc. to bear the cost of labor or

transportation charges in connection with replacement or repair of defective parts; nor

shall it apply to a pump upon which repairs or alterations have been made unless

authorized by Summit Pump, Inc.

No warranty is made in respect to engines, motors, or trade accessories, such being

subject to warranties of their respective manufacturers.

No express implied or statutory warranty, other than herein set forth is made or

authorized to be made by Summit Pump, Inc.

In no event shall Summit Pump, Inc. be liable for consequential damages or contingent

liabilities arising out of the failure of any Summit Pump, Inc. pump or parts thereof to

operate properly.

SUMMIT PUMP, INC.

Green Bay, WI

LIABILITY

Summit Pump, Inc. shall not be liable for personal physical injury, damage or delays

caused by failure to follow the instructions and procedures for installation, operation and

maintenance contained in this manual.

COPYRIGHT

This Installation, Operation, and Maintenance Manual contains proprietary information,

which is protected by copyright. No part of this Installation, Operation, and Maintenance

Manual may be photocopied or reproduced without prior written consent from Summit

Pump.

The information contained herein is for informational use only and is subject to change

without notice. Summit Pump assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual.

© 2003 by Summit Pump. All rights reserved.

Page 4

Page 5

Installation, Operation, and Maintenance Manual

Contents

1. INTRODUCTION 1

SAFETY 1

2196 MODEL RELATIONSHIP CHART 2

2. RECEIPT AND STORAGE 3

RECEIVING THE PUMP 3

STORING THE PUMP 3

3. INSTALLATION 4

LOCATION 4

FOUNDATION 4

PIPING CONNECTION – SUCTION / DISCHARGE 4

ALIGNMENT 5

STUFFING BOX 5

Packed Box 5

Cartridge Mechanical Seal 6

Type 1 Mechanical Seal 6

4. OPERATION 8

LUBRICATION 8

Oil Lubrication 8

Grease Lubrication 8

ROTATION 9

IMPELLER CLEARANCE 10

PRIMING 10

START UP 10

SHUT DOWN 11

APPENDIX A - IMPELLER CLEARANCE SETTING 12

FEELER GAUGE TECHNIQUE 12

Models 2196, 2196-LF and 2796 12

Model 2196R Feeler Gauge Technique 13

DIAL INDICATOR TECHNIQUE 14

Models 2196, 2196-LF and 2796 14

Model 2196-R Dial Indicator Technique 15

APPENDIX B - CENTRIFUGAL PUMP TROUBLESHOOTING 16

APPENDIX C - MAINTENANCE AND REPAIR 18

DISASSEMBLY PROCEDURES 18

ASSEMBLY PROCEDURES 20

APPENDIX D – PUMP CROSS SECTIONS AND PARTS LISTS 24

MODEL 2196 STO CROSS SECTION 24

MODEL 2196 STO PARTS LIST 24

MODEL 2196 MTO CROSS SECTION 25

MODEL 2196 MTO PARTS LIST 25

MODEL 2196 LTO CROSS SECTION 26

MODEL 2196 LTO PARTS LIST 26

MODEL 2196 XLO CROSS SECTION 27

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 i

Page 6

Installation, Operation, and Maintenance Manual

MODEL 2196 XLO PARTS LIST 27

MODEL 2196-LF CROSS SECTION 28

MODEL 2196-LF PARTS LIST 28

MODEL 2196-R CROSS SECTION 29

MODEL 2196-R PARTS LIST 29

MODEL 2796 CROSS SECTION 30

APPENDIX E – MAINTENANCE INSTRUCTIONS FOR INPRO/SEAL®

“VBX” BEARING ISOLATORS 32

DETAILS OF OPERATIONS 32

DISASSEMBLY PROCEDURES 32

INSTALLATION PROCEDURES 33

APPENDIX F – DIMENSIONAL DATA 34

MODEL 2196 DIMENSIONAL DATA 34

MODEL 2196 BASEPLATE RELATED DIMENSIONS 35

MODEL 2196-LF DIMENSIONAL DATA 36

MODEL 2196-R DIMENSIONAL DATA 37

MODEL 2796 DIMENSIONAL DATA 38

MODEL 2196 STUFFING BOX RELATED DIMENSIONS 39

APPENDIX G – CONSTRUCTION DETAILS 40

MODEL 2196 CONSTRUCTION DETAILS 40

APPENDIX H – ANSI B15.1 COUPLING GUARDS 41

INSTALLATION INSTRUCTIONS FOR SUMMIT PUMP ANSI B15.1 COUPLING

GUARDS 41

ASSEMBLY PROCEDURES 41

DISASSEMBLY PROCEDURES 45

ii SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 7

Installation, Operation, and Maintenance Manual

1. INTRODUCTION

This installation, operation, and maintenance manual is designed to help you achieve

the best performance and longest life from your Summit Pump models 2196, 2196LF, 2196-R, and 2796.

This pump is an open impeller, centrifugal model with end suction / top discharge.

The pump is designed for handling mild industrial corrosives.

If there are any questions regarding the pump or its application, which are not

covered in this manual or in other literature accompanying this unit, please contact

your Summit Pump distributor.

For information or technical assistance on the power source, contact the power source

manufacturer’s local dealer or representative.

SAFETY

The following message types are used in this manual to alert maintenance personnel

to procedures that require special attention for the protection and safety of both

equipment and personnel:

WARNING!

Failure to comply with the warnings in this

manual could result in personal injury or

death.

CAUTION!

Failure to comply with the cautions in this

manual could result in destruction of or

damage to equipment.

NOTE: Identifies a condition or

procedure which is essential to

proper equipment operation.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 1

Page 8

Installation, Operation, and Maintenance Manual

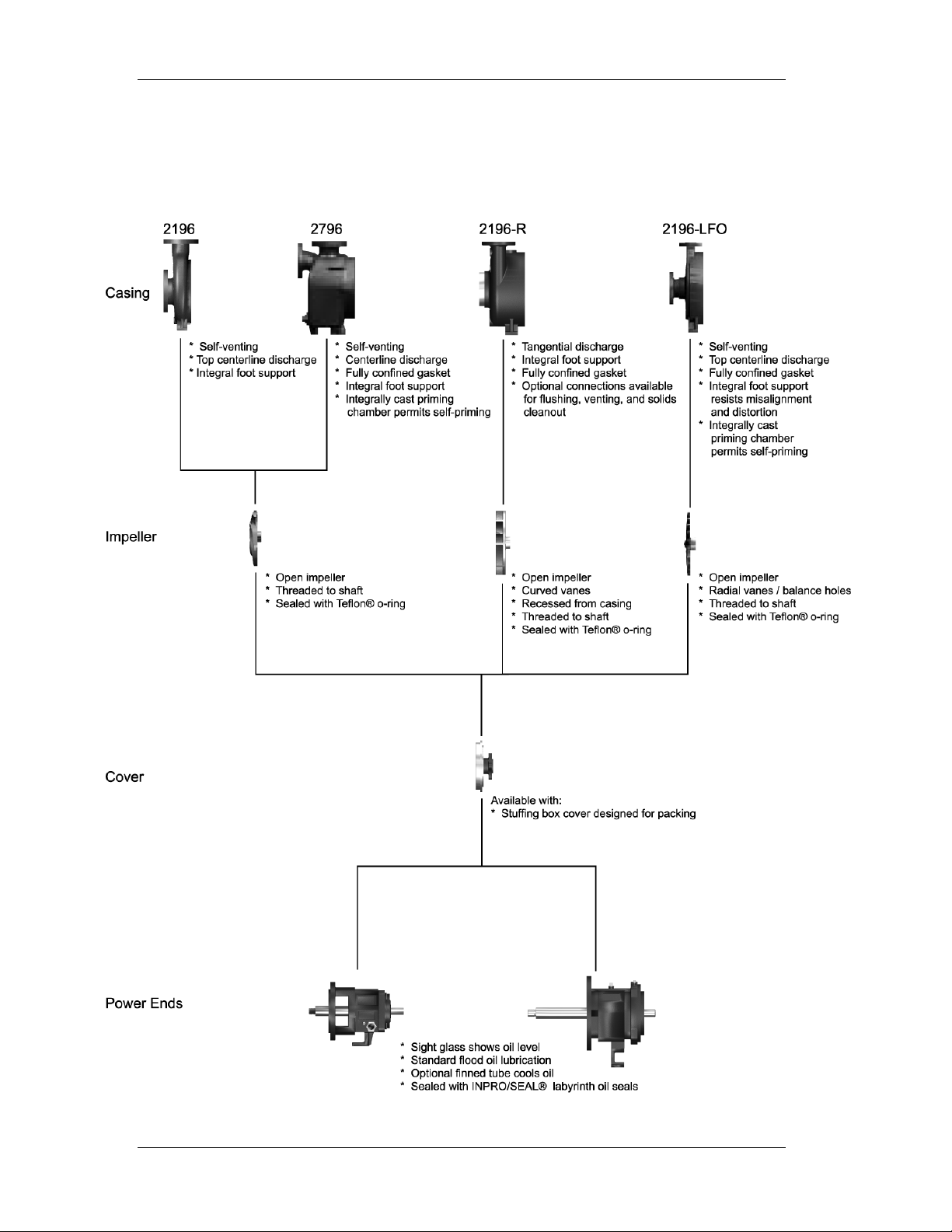

2196 MODEL RELATIONSHIP CHART

The following chart shows the relationship and parts commonality within the 2196

ANSI family model lines.

2 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 9

Installation, Operation, and Maintenance Manual

2. RECEIPT AND STORAGE

RECEIVING THE PUMP

WARNING!

Failure to properly lift and move pump

could result in serious personal injury.

Immediately upon arrival, carefully inspect the pump for evidence of damage

during transit. Immediately report any damage to your Summit Pump Distributor.

STORING THE PUMP

Store the pump in a clean dry place. Do not remove piping connection covers.

Rotate the pump shaft by hand at least once per week to maintain a protective

film of oil or grease on the bearings. If you anticipate long-term storage, special

treatment is available for purchase from Summit Pump, Inc.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 3

Page 10

Installation, Operation, and Maintenance Manual

3. INSTALLATION

LOCATION

When choosing a location for the pump, select an area that provides easy access

for inspection and maintenance. Locate the pump as close as possible to the

source which will provide NPSH (Net Positive Suction Head) equal to or greater

than that required by the pump at any capacity over its expected operating range.

FOUNDATION

Use a foundation that is sufficient enough to support all points of the pump baseplate. Level and grout the base-plate per standard construction practices (see

ANSI/HI 1.4.2-1997).

PIPING CONNECTION – SUCTION / DISCHARGE

All piping must be independently supported and accurately aligned to the pump

suction and discharge flanges. Ideally, you should place a short length of flexible

or bellows type spool piece in the connections directly next to the pump flange.

WARNING!

Lock out driver power before beginning to

work on pump.

CAUTION!

Never use force to align piping to the

pump flanges.

CAUTION!

Never operate pump with suction valve

closed.

At a minimum, use suction pipe that is one size larger than the flange. Use an

eccentric reducer to meet the suction pipe with the pump. Mount the reducer flat

side up. Elbows must be a minimum of ten diameters from the suction flange.

CAUTION!

Never operate pump with discharge valve

closed.

The discharge piping should include isolation and check valves. The check valve

prevents the pump from rotating backward. Place the check valve between the

4 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 11

Installation, Operation, and Maintenance Manual

pump and isolation valve. The isolation valve is used for priming, starting, and

shutting down the system. If you use pipe diameter increasers, place them

between the pump and the check valve.

ALIGNMENT

The alignment at the pump and drive shaft is one of the most important

considerations in the pump installation.

WARNING!

Lock out pump driver. Failure to do so

could result in serious personal injury.

TO ALIGN THE PUMP

1. Use flexible spacer couplings to achieve proper alignment.

2. Check and adjust the parallel and angular alignment to within .005 inches

prior to connecting the coupling halves.

3. Jog the motor to check rotation. Its arrow should match up with the arrow on

the pump.

4. Install a coupling guard when the pump is aligned.

Pumps in hot service will need an alignment check at operating temperatures.

STUFFING BOX

Packed Box

Braided packing is supplied as standard equipment on all pumps. Install gland

bolt nuts finger-tight only. Adjust the gland bolt nuts during start-up to achieve

40-65 drops of leakage per minute. Specific packing type is dependent on pH,

temperature, etc. of the liquid being pumped.

Table 1

Pump Model

STO MTO LTO XLO

Packing Size 7/16 5/8

Number of Rings 5

Clean and cool pumpage may be used to lubricate the packing. If the pumpage is

not suitable, you must supply an external source of lubrication.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 5

Page 12

Installation, Operation, and Maintenance Manual

CAUTION!

Do not allow packing to run dry. It must

be lubricated.

See ANSI/ASME B73.1 M-1984 for

proper seal flush plans.

Cartridge Mechanical Seal

WARNING!

Determine the effects that a failure of the

mechanical seal might have on the

environment and personnel and correct

conditions to prevent personal injury.

WARNING!

Only work on seal when the pump is

locked out and the seal is depressurized.

Refer to the Burgmann installation, operating, and maintenance instructions.

Failure to do so can result in environmental damage, personal injury, and seal

malfunction and / or seal failure. Pay particular attention to paragraphs 4.2, 4.3

and 4.4.

Start Up

Read, understand and follow the Burgmann Operation section 4.0, paragraphs 4.1

and 4.2

Storage, Assembly and Disassembly

Refer to the Burgmann Seal Storage assembly and disassembly sections 3.0, 3.1,

3.2, and 3.3, paying particular attention to the seal drawing included in the

instructions.

Type 1 Mechanical Seal

TO INSTALL TYPE 1 MECHANICAL SEAL

1. MTO, LTO, XLO Slide the stuffing box cover over the shaft/sleeve. Bolt the

cover (184) to the frame adapter(108).

STO Slide the 6” or 8” stuffing box cover (184) with adapter ring (108) over

shaft and bolt to bearing.

2. Mark / scribe the shaft at the face of the stuffing box.

3. Unbolt and remove the stuffing box cover.

6 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 13

Installation, Operation, and Maintenance Manual

4. Locate the installation reference dimension on the seal installation drawing.

Normally this is the dimension from the face of the stuffing box to the rear of

the seal.

5. Mark the shaft with a felt marker or marking tool at the dimension (i.e. 1/32”).

6. Lubricate the shaft with silicon grease or soapy water. Slide the seal onto the

shaft. Line up the face of the seal with your mark and secure with set screw.

7. Reassemble the pump.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 7

Page 14

Installation, Operation, and Maintenance Manual

4. OPERATION

LUBRICATION

CAUTION!

PUMPS ARE SHIPPED WITH NO OIL IN

THE BEARING FRAME! Oil must be

installed before operating the pump.

Ball bearings are very sensitive to both over and under lubrication, both being

detrimental to bearing performance. Either case is detrimental to bearing

performance. Use a thermometer to determine overheating. Excessive overheating

will reduce bearing life.

The relationship between temperature and pumpage temperature is an indication of

performance. Table 2 indicates the relationship between these temperatures.

Table 2

Degrees Fahrenheit

Pumping liquid temperature

Approximate normal line bearing temperature

60° 200° 300°

115° 140° 160°

The information shown in Table 2 is based on a room temperature of 70°F. Maximum

bearing temperature is 175°F. The temperatures shown above have a tolerance of plus

15°F. It is necessary to flush water on the shaft for liquid temperatures above 250°F.

This can be done either through a flushing gland or the stuffing box seal cage.

Oil Lubrication

Use only high quality turbine oil with rust and oxidation inhibitors. Service

temperatures determine oil viscosity. See Table 3.

Use a 300 SSU viscosity at 100° F for applications where pumping temperatures are

below 200° F. At pumping temperatures above 350° F, use 470 SSU at 100° F with

optional cooler.

Table 3

Bearing Temperature ISO Grade Viscosity at 100 Degrees F

Up to 150° F

150° F to 200° F

46 215 SSU

68 300 SSU

Above 200° F

100 470 SSU

Grease Lubrication

Regrease grease lubricated bearings with NLG1 No. 2 consistency grease for

8 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 15

Installation, Operation, and Maintenance Manual

pumpage temperatures -60° F to 350° F. Grease is not recommended for temperatures

above 350° F. Regrease bearings every three months.

Table 4

Acceptable Lubricating Oils

ISO VG 32 46 68 100

Keystone: KLC Antiwear 32 46 68 100

Lubriplate AC0 AC1 AC2 AC3

Mobil: DTE Light - Medium Heavy

Mobil: Synthetic 624 525 626 627

Phillips: Magnus 32 46 68 100

Synthetic, syndustrial mist 100

Shell: Tellus Fluids HD 32 46 68 100

Table 5

Acceptable Greases

Citgo Mystic EP2

Keystone 81EP2

Mobil Mobilux EP2

Mobil Synthetic SCH 100

TO REGREASE LUBRICATED BEARINGS

1. Wipe dirt and foreign matter from the fittings.

2. Remove grease relief plugs from the bottom of the frame.

3. Fill grease through fittings until it comes out through the relief holes.

4. Reinstall grease relief plugs.

ROTATION

TO ROTATE THE PUMP

1. Lock out power to the pump driver.

2. Remove the coupling guard and coupling.

3. Momentarily restore power and energize the motor to determine rotation.

4. Confirm that motor rotation coincides with proper pump rotation. The proper

pump rotation is counterclockwise when facing the pump’s suction. Lock out

power to pump driver.

WARNING!

Operating the pump in the opposite

rotation may dislodge the impeller

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 9

Page 16

Installation, Operation, and Maintenance Manual

causing severe damage to the impeller

and/or casing.

5. Reinstall the coupling and coupling guard.

6. Unlock power to pump driver.

IMPELLER CLEARANCE

WARNING!

Check impeller clearance prior to starting

pump. Setting may have changed during

transit.

WARNING!

Lock out power prior to working on pump.

Impeller clearance is the measurement between the impeller vanes and the surface of

the casing. This clearance is set at .015 inches during assembly, but may need to be

adjusted before initial startup. (See APPENDIX A for detailed procedures on setting

the impeller clearance.)

PRIMING

Prior to starting a centrifugal pump, it is imperative that you prime the pump by

flooding the suction piping and casing with fluid. Priming will occur when you open

the suction isolation valve and the packing sealing liquid valve.

CAUTION!

Do not operate the pump without liquid in

the casing.

START UP

TO START UP THE PUMP

1. Rotate the pump by hand; making sure that the rotating element is spinning freely.

2. Be sure the suction valve is open.

3. Partially close the discharge valve.

CAUTION!

Do not operate the pump with the

discharge valve closed for an extended

period of time.

10 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 17

Installation, Operation, and Maintenance Manual

4. Unlock power to the pump driver.

5. Slowly open the discharge valve as soon as the motor reaches operating speed.

6. Check stuffing box leakage and adjust, if necessary, to achieve leakage of 40-65

drops per minute.

7. Adjust the discharge valve as needed while checking piping for leaks.

8. Check mechanical operation of the pump and motor.

WARNING!

Do not operate the pump without the

proper guard. See ANSI/ASME

B15.1-1996.

SHUT DOWN

TO SHUT DOWN THE PUMP

1. Gradually close the discharge valve and turn off the power to the motor.

2. Lock out power to the pump driver.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 11

Page 18

Installation, Operation, and Maintenance Manual

APPENDIX A - IMPELLER CLEARANCE SETTING

A gradual loss in head and/or capacity can occur. You may restore performance by

adjusting the impeller clearance, which is the measurement between the impeller

vanes and the surface of the casing.

Table 6

Temperature Impeller Clearance

200° F (93°C)

250° F (121°C)

300° F (144°C)

350° F (177°C)

400° F (204°C)

.015” (.38 mm)

.017” (.43 mm)

.019” (.48 mm)

.021” (.53 mm)

.023” (.58 mm)

FEELER GAUGE TECHNIQUE

Models 2196, 2196-LF and 2796

TO USE THE FEELER GAUGE TECHNIQUE FOR IMPELLER CLEARANCE SETTING

FOR MODELS 2196, 2196-LF & 2796

1. Lock out power to the pump driver.

2. Remove the coupling guard.

3. Loosen jacking bolts (370D) and jam nuts (423).

4. Tighten bearing housing bolts (370C) evenly, while slowly rotating the shaft until

the impeller starts to rub on the casing.

5. Using a feeler gauge, set the gap between the 3 housing bolts (370C) and the

bearing housing (134). (Refer to Table 6 for settings.)

6. Tighten jack bolts (370D) evenly until bearing housing backs out and contacts the

bearing housing bolts (370C).

7. Tighten jam nuts (423) evenly, rotating the shaft to make sure the assembly turns

freely.

8. Reinstall the coupling guard.

9. Unlock power to the pump driver.

12 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 19

Installation, Operation, and Maintenance Manual

Model 2196R Feeler Gauge Technique

TO USE THE FEELER GAUGE TECHNIQUE FOR IMPELLER CLEARANCE SETTING

FOR MODEL 2196-R

1. Lock out power to the pump driver.

2. Remove the coupling guard.

3. Remove coupling.

4. Loosen bearing housing bolts (370C) several turns.

5. Loosen jam nuts (423) and turn jackbolts (370D) evenly around several turns until

impeller contacts stuffing box cover (184). Turn shaft to ensure contact is

complete.

6. Use feeler gauge to measure the gap between the bearing frame (228) and the

bearing housing (134). Reduce the measurement by .060” and place the resulting

feeler gauge thickness between the bearing housing (134) and the bearing frame

(228).

7. Loosen the jacking bolts (370D) several turns. Tighten the locking bolts (370C) to

move the impeller away from the stuffing box cover (184) until the bearing

housing (134) snugs up the feeler gauge between the bearing housing (184) and

the bearing frame (228).

8. Turn jacking bolts (370D) in and tighten jam nuts (423) evenly, rotating the shaft

to make sure the assembly turns freely.

9. Reinstall the drive coupling.

10. Reinstall the coupling guard.

11. Unlock power to the pump driver.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 13

Page 20

Installation, Operation, and Maintenance Manual

DIAL INDICATOR TECHNIQUE

Models 2196, 2196-LF and 2796

TO USE THE DIAL INDICATOR TECHNIQUE FOR IMPELLER CLEARANCE SETTING

1. Lock out power to the pump driver.

2. Remove the coupling guard.

3. Place a dial indicator with a magnetic base on the pump base plate. Place the

indicator against the end of the pump shaft or coupling face.

4. Loosen jack bolts (370D) and jam nuts (423).

5. Tighten bearing housing bolts (370C) evenly while slowly rotating the shaft until

the impeller starts to rub on the casing.

6. Set the dial indicator to zero.

7. Tighten the jack bolts (370D) evenly until they contact the frame. Continue to

tighten until the dial indicator reads the proper clearance as shown in Table 6.

8. Tighten bearing housing bolts (370C) evenly; then tighten jack bolts (370D)

evenly. Be sure the dial indicator does not move from the proper setting.

9. Rotate the shaft to be sure it turns freely.

10. Reinstall the coupling guard.

11. Unlock power to the pump driver.

14 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 21

Installation, Operation, and Maintenance Manual

Model 2196-R Dial Indicator Technique

1. Lock out power to the pump driver.

2. Remove the coupling guard.

3. Remove coupling.

4. Place a dial indicator with a magnetic base on the pump base plate. Place the

indicator tip in contact with either the shaft end or coupling face. (See diagram on

page14.)

5. Loosen bearing housing bolts (370C) several turns.

6. Loosen jam nuts (423) on jack bolts (370D) evenly around several turns until

impeller contacts the stuffing box cover (184). Turn the shaft to ensure contact is

made.

7. Set the dial indicator to zero.

8. Loosen the jacking bolts (370D) evenly several turns and tighten the bearing

housing bolts (370C) to move the impeller away from the stuffing box cover until

the dial indicator shows a 0.060” clearance.

9. Turn in the jacking bolts (370D) and tighten the jam nuts (423) evenly.

10. Rotate the shaft to be sure it turns freely.

11. Reinstall coupling.

12. Reinstall the coupling guard.

13. Unlock power to the pump driver.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 15

Page 22

Installation, Operation, and Maintenance Manual

APPENDIX B - CENTRIFUGAL PUMP TROUBLESHOOTING

The following table provides possible solutions for symptoms that you may encounter

with your centrifugal pump.

WARNING!

Before attempting to service the pump:

1. Follow the shut down procedures.

2. Lock out the power source.

3. Allow the pump to cool.

4. Close the suction and discharge

valves.

5. Drain the pump.

Table 7

CENTRIFUGAL PUMP TROUBLESHOOTING

Symptom Cause Solution

Pump not

delivering liquid

Low flow and low

head

• Pump not primed. • Re-prime pump.

• Suction lift too high. • Install shorter suction pipe.

• Wrong direction of

rotation.

• Impeller clogged. • Back-flush pump.

• Suction line plugged. • Remove debris.

• Air leak in stuffing box. • Replace or adjust packing.

• Worn suction side plate. • Replace defective part.

• Impeller worn or

damaged.

• Air leak in suction line. • Replace gasket.

• Impeller clogged. • Back-flush pump.

• Wrong direction of

rotation.

• Change motor wiring.

• Inspect and replace impeller, if

needed.

• Change motor wiring.

16 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 23

Installation, Operation, and Maintenance Manual

Table 7 (continued)

CENTRIFUGAL PUMP TROUBLESHOOTING

Symptom Cause Solution

Pump loses prime

Bearings are

running hot

Motor requires

excessive

amperage

Stuffing box is

leaking

excessively

• Pump not primed

correctly.

• Air leak in suction line. • Replace gasket or pipe plug.

• Lantern ring in wrong

location.

• Misalignment. • Realign drive coupling.

• Low or insufficient

lubricant.

• Stuffing box gland is too

tight.

• Total dynamic head is too

low.

• Rotary part rubbing

stationary part.

• Liquid is heavier than

specified.

• Stuffing box is incorrectly

packed.

• Shaft sleeve is scored or

worn.

• Re-prime pump.

• Repack moving lantern ring to

correctly align with flush hole.

• Check oil level and or grease.

• Readjust or replace packing.

• Install throttle or reduce impeller

diameter.

• Adjust part or replace parts.

• Check specific gravity of liquid.

• Repack stuffing box.

• Replace shaft sleeve as required.

• Wrong type of packing. • Install correct packing.

• Shaft is bent. • Replace shaft.

• Worn mechanical seal

parts.

• Rebuild seal; replace parts.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 17

Page 24

Installation, Operation, and Maintenance Manual

APPENDIX C - MAINTENANCE AND REPAIR

WARNING!

WEAR EYE PROTECTION. Failure to do

so can result in serious personal injury.

DISASSEMBLY PROCEDURES

(See APPENDIX D for cross-section of corresponding model.)

TO DISASSEMBLE YOUR MODEL 2196, 2196-LF, OR 2196-R PUMP

1. Lock out power supply at the motor starter.

2. Close off discharge, suction, sealing fluid, and cooling fluid.

3. Drain casing and flush, if needed.

WARNING!

Pump parts are heavy. Use proper lifting

methods to avoid personal injury.

4. Place lifting sling through frame to ensure safe handling during disassembly/

assembly.

5. Remove bolts (370) holding the frame adapter (108) to casing (100).

6. Pull the frame adapter back from casing.

7. Take the frame assembly to bench and secure for further work.

8. Scribe the location of coupling half on the shaft (122) and remove the coupling.

WARNING!

Never use heat to remove impeller. Heat

combined with trapped fluid could cause

an explosion, which can result in personal

injury.

9. Remove the impeller (101) from the shaft (122) while holding the shaft with a

strap wrench or suitable tool that will not mark the shaft.

NOTE: Threads are right-handed.

18 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 25

Installation, Operation, and Maintenance Manual

NOTE: XLO – Remove impeller plug

(428Y) from the impeller (101). Do not

save impeller gasket (428D).

For a packed pump:

a. Remove the packing gland nuts (353A).

b. Slide gland toward frame (228).

c. Remove seal chamber nuts (423B).

d. Slide off stuffing box cover (184).

e. Remove packing (106) and lantern ring (105).

For a mechanical seal:

a. Remove the seal gland nuts (353).

b. Remove seal gland nuts (353A).

c. Slide gland toward frame (228), exercising care so as to not drop stationary set

from gland.

d. Remove seal chamber nuts (423B).

e. Slide off stuffing box cover (184).

f. Remove mechanical seal rotating element (383) and sleeve (128) from pump

shaft.

g. Loosen set screws if present. Refer to cartridge seal manufacturer’s

instructions.

h. Slide off seal gland with stationary seal and o-ring gasket.

10. Remove the frame adapter (108) by removing two dowel pins (469B) and four

adapter bolts (370B) and then separate the adapter (108) from the bearing frame

(228).

NOTE: This step does not apply to the

6” STO Model.

11. Remove the bearing housing bolts (370C) and loosen the jam nuts (423).

12. Tighten the jack-bolts (370D) evenly to push the bearing housing out of frame.

13. Slide shaft assembly, with housing, out of bearing frame.

14. On the STO and MTO, remove the bearing housing snap ring (361A).

On the LTO

and XLO, remove bearing cover screws (370G) and remove bearing

cover (109C). Then remove the bearing housing (134) by tapping with a rubber

hammer.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 19

Page 26

Installation, Operation, and Maintenance Manual

15. Remove bearing lock nut (136) and bearing lock washer (382).

16. Remove inboard bearing (168A) and outboard bearing (112). Use an arbor press

or bearing puller to facilitate. On LTO models only, do not remove oil ring

(248A) unless it is damaged.

NOTE: Do not use a hammer, which

may cause damage to the shaft.

17. Complete disassembly of bearing frame (228). Remove oil plug (408A) (not

shown), oil sight glass (145), oil cooler inlet (408L), outlet plugs (408M), and

frame foot attachment bolt (529) and foot (241), where applicable.

18. Inspect all parts for cracks, erosion, pitting, rusting, damaged threads, corrosion,

and groove worn shaft/sleeve. Replace casing if grooves and pits are greater than

1/8” deep. Replace impeller if grooves are greater than 1/16” or even wear

exceeds 1/32”. Inspect shaft sleeve if grooved or pitted. Shaft run out or bearing

shoulder damage is cause for replacement.

ASSEMBLY PROCEDURES

(See APPENDIX D for cross-section of corresponding model.)

TO ASSEMBLE YOUR PUMP

1. Clean the bearing frame and inspect all tapped holes. Chase as needed.

2. Install oil fill plug (113A), oil sight glass (144), and frame lubrication plugs

(408H).

3. Attach bearing frame foot (241) with bolts (529), where applicable.

4. On the LTO model, install oil ring (248A) on shaft (122), if removed. Oil ring is a

press fit onto shaft.

NOTE: Use proper size drive tool to

prevent damage.

5. On the LTO

6. Install outboard bearing (112) on shaft (122).

If grease lubricated, install with shield away from impeller end.

If oil lubricated

model, install bearing cover (109C) over shaft (122).

, there should be no seals or shields.

20 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 27

Installation, Operation, and Maintenance Manual

The recommended bearing installation method is heating the bearing using an

induction heater.

WARNING!

WEAR INSULATED GLOVES when using

heater. Failure to do so can result in

serious personal injury while handling hot

bearings.

NOTE: LTO frames use duplex angular

contact bearings.

Make sure bearings are mounted

in the correct order, back to

back.

7. Install a bearing lock washer (382) on the shaft.

a. Place tang of lock washer in shaft keyway.

b. Install lock-nut (136) on shaft.

c. Using a spanner wrench, tighten the nut until snug; then bend any one of the

tangs into a lock-nut slot.

8. Install inboard bearing (168A) on shaft (122).

If grease lubricated, install with shield toward impeller end.

If oil lubricated, there should be no seals or shields.

9. Install the outboard labyrinth oil seal (332A) in the bearing housing (134). Follow

Maintenance instructions in Appendix E.

NOTE: Make sure drain slots face down.

10. Apply a thin coating of lubricant to the inside of the bearing housing (134).

11. Slide the bearing housing (134) over the outboard bearing assembly (112) and

shaft (122). Place the coupling end of the shaft into the bearing housing through

the labyrinth oil seal.

On the XLO model, install the bearing cover gasket (360G).

On the STO and MTO models, install the bearing housing snap ring (361A) into

the groove on the bore of the bearing housing. Make sure the flat side is toward

the bearing.

On the LTO

and XLO models, install bearing cover (109C) and bolts (370G).

12. Install a new O-ring (496) over the O.D. of the bearing housing.

13. Apply a thin coating of lubricant to the outside of the bearing housing (134) and

slide the assembly into the bearing frame (228).

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 21

Page 28

Installation, Operation, and Maintenance Manual

14. Install bearing housing bolts (370C) into bearing frame (228) and install jack bolts

(370D) and jam nuts (423). Hand-tighten evenly.

15. Attach frame (228) to adapter (108).

a. Align dowel pins (469B) and adapter bolt (370B).

b. Tighten using criss-cross pattern.

c. Rotate shaft 360 degrees. It should be free.

NOTE: These steps do not apply to the

6” STO Model.

16. Set frame (228) and adapter (108) upright. Clamp to bench for safety as assembly

continues.

17. Install inboard bearing labyrinth seal in adapter frame. Make sure that the seal’s

drain slots face down. Follow Maintenance instructions in Appendix E.

18. Put anti-seize compound on the shaft and, if equipped, install shaft sleeve (126)

onto shaft (122).

19. Align anti-rotation pin with notch in sleeve (126).

For mechanical seal pumps, read manufacturer’s instructions for assembly. (See

STUFFING BOX on page 5.)

20. Install stuffing box cover (184) onto adapter with studs (353) and nuts (353A).

21. Install impeller (101) with new O-ring (496A).

22. Using an impeller wrench or strap wrench on the coupling end of the shaft,

tighten by rotating clockwise. Make sure coupling is tight to the shaft.

23. For packed pumps, install the appropriate packing (106) in the stuffing box cover

(184) according to fluid being pumped (105).

a. First, insert two packing rings into bottom of box.

b. Next, insert the lantern ring (105). Make sure to stagger packing joints and

lantern ring joint by 90 and be sure lantern ring lines up with flushing

connection. Install gland halves (107).

c. Hand-tighten nuts (353A). You must make final adjustments after the pump

has begun operation.

For mechanical seal

pumps, continue by following manufacturer’s instructions

noted in Step 19.

24. Install casing gasket (351) onto stuffing box cover (184). At this point, the power

end is ready for reinstallation into the casing or for storage for future use.

25. If returning to service, slide assembly into casing (100).

26. Install casing bolts (370) into frame to pull assembly into casing.

27. Rotate the shaft to ensure that no rubbing exists.

22 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 29

Installation, Operation, and Maintenance Manual

28. Adjust impeller clearance according to the instructions beginning on page 12.

29. Align drive coupling according to the instructions beginning on page 5, in

addition to coupling manufacturer instructions.

30. If the motor was replaced, check rotation prior to reconnecting coupling halves.

(See rotation instructions on page 9).

31. Reinstall coupling guard and return pump to service.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 23

Page 30

Installation, Operation, and Maintenance Manual

APPENDIX D – PUMP CROSS SECTIONS AND PARTS LISTS

MODEL 2196 STO CROSS SECTION

MODEL 2196 STO PARTS LIST

Item # Qty Description Item # Qty Description

100 1 Casing 360Q 1 Gasket; Gland, Mech. Seal

101 1 Impeller 361A 1 Snap Ring, Bearing

105 1 Ring, Lantern 365 1 Seal, Mechanical Stationary Element

106 5 Packing 370 3 Bolt, Casing

107 1 Gland, Packing 370B** 4 Bolt, Frame / Adapter

108** 1 Adapter Ring 370C 3 Bolt, Bearing Housing

112 1 Bearing, Outboard 370D 3 Jack Bolt, Bearing Housing

113A 1 Plug, Oil Fill 370H 2 Stud, SBC / Adapter

122 1 Shaft 382 1 Lockwasher, Bearing

126 1 Sleeve, Shaft 383 1 Seal, Mechanical Rotating Element

134 1 Housing, Bearing 400 1 Key, Coupling

136 1 Locknut, Bearing 408A 1 Plug, Frame Lubrication Port

168A 1 Bearing, Inboard 408L 1 Plug, Oil Cooler Inlet (Not Shown)

184 1 Cover, Stuffing Box 408M 1 Plug, Oil Cooler OutIet (Not Shown)

228 1 Frame 412 1 O-ring, Impeller

250 1 Gland, Mechanical Seal 423 3 Jamnut, Bearing Housing / Frame

319 1 Sight Glass 423B 2 Nut, Box Cover/Adapter Stud

332A 1 Labyrinth, OB 496 1 O-ring,, Bearing Housing / Frame

333A 1 Labyrinth, IB 500 1 Pin, Sleeve

351 1 Gasket, Case

353 4 Stud, Gland

353A 4* Nut, Gland Stud * Packing Gland has only 2 Studs & Nuts

358A 1 Plug, Casing Drain ** Only Required on 8" Pump

24 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 31

Installation, Operation, and Maintenance Manual

MODEL 2196 MTO CROSS SECTION

MODEL 2196 MTO PARTS LIST

Item # Qty Description Item # Qty Description

100 1 Casing 360D 1 Gasket, Frame/Adapter

101 1 Impeller 360Q 1 Gasket; Gland, Mech. Seal

105 1 Ring, Lantern 361A 1 Snap Ring, Bearing

106 5 Packing 365 1 Seal, Mechanical Stationary Element

107 1 Gland, Packing 370

108 1 Adapter 370B 4 Bolt, Frame / Adapter

112 1 Bearing, Outboard 370C 3 Bolt, Frame / Bearing Housing

113 1 Plug, Oil Fill 370D 3 Jack Bolt, Bearing Housing

122 1 Shaft 370F 2 Bolt, Frame Foot

126 1 Sleeve, Shaft 370H 2 Box Cover/Adapter Stud

134 1 Housing, Bearing 382 1 Lockwasher, Bearing

136 1 Locknut, Bearing 383 1 Seal, Mechanical Rotating Element

168 1 Bearing, Inboard 400 1 Key, Coupling

184 1 Cover, Stuffing Box 408A 1 Plug, Frame Drain (Not Shown)

228 1 Frame 408H 4 Plug, Frame Lubrication Port

241 1 Foot Frame 408L 1 Plug, Oil Cooler Inlet

250 1 Gland, Mechanical Seal 408M 1 Plug, Oil Cooler OutIet

319 1 Gauge; Sight, Oil 412 1 O-ring, Impeller

332A 1 Labyrinth, Outboard Frame 423 3 Jamnut, Bearing Housing Jack Bolt

333A 1 Labyrinth, Inboard Frame 423B 2 Nut, Box Cover/Adapter Stud

351 1 Gasket, Case 469B 2 Dowel Pin, Frame / Adapter

353 4 Stud, Gland 496 1 O-ring, Bearing Housing / Frame

353A 4* Nut, Gland Stud 529 2 Washer, Frame Foot to Frame

358A 1 Plug, Casing Drain * Packing Gland has only 2 Studs & Nuts

8, 12, 16

Bolt, Casing

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 25

Page 32

Installation, Operation, and Maintenance Manual

MODEL 2196 LTO CROSS SECTION

MODEL 2196 LTO PARTS LIST

Item # Qty Description Item # Qty Description

100 1 Casing 360D 1 Gasket, Frame/Adapter

101 1 Impeller 360Q 1 Gasket; Gland, Mech. Seal

105 1 Ring, Lantern 361A 1 Snap Ring, Bearing

106 5 Packing 365 1 Seal, Mechanical Stationary Element

107 1 Gland, Packing 370

108 1 Adapter 370B 4 Bolt, Frame / Adapter

109C 1 Cover; Bearing, Outboard 370C 3 Bolt, Bearing Housing

112 2 Bearing, Outboard 370D 3 Jack Bolt, Bearing Housing

113 1 Plug, Oil Fill 370F 2 Bolt, Frame Foot

122 1 Shaft 370G 6 Bolt, Bearing Cover

126 1 Sleeve, Shaft 370H 2 Box Cover/Adapter Stud

134 1 Housing, Bearing 382 1 Lockwasher, Bearing

136 1 Locknut, Bearing 383 1 Seal, Mechanical Rotating Element

168 1 Bearing, Inboard 400 1 Key, Coupling

184 1 Cover, Stuffing Box 408A 1 Plug, Frame Drain (Not Shown)

228 1 Frame 408H 4 Plug, Frame Lube Port (Not Shown)

241 1 Foot Frame 408L 1 Plug, Oil Cooler Inlet

248A 1 Ring, Oil 408M 1 Plug, Oil Cooler OutIet (Not Shown)

250 1 Gland, Mechanical Seal 412 1 O-ring, Impeller

319 1 Gauge; Sight, Oil 423 3 Jamnut, Bearing Housing Jack Bolt

332A 1 Labyrinth, Outboard Frame 423B 2 Nut, Box Cover/Adapter Stud

333A 1 Labyrinth, Inboard Frame 469B 2 Dowel Pin, Frame / Adapter

351 1 Gasket, Case 496 1 O-ring, Bearing Housing / Frame

353 4 Stud, Gland 500 1 Pin, Sleeve

353A 4* Nut, Gland Stud 529 2 Washer, Frame Foot to Frame

358A 1 Plug, Casing Drain * Packing Gland has only 2 Studs & Nuts

8, 12, 16

Bolt, Casing

26 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 33

Installation, Operation, and Maintenance Manual

MODEL 2196 XLO CROSS SECTION

MODEL 2196 XLO PARTS LIST

Item # Qty Description Item # Qty Description

100 1 Casing 360 1 Gasket, End Cover

101 1 Impeller 360D 1 Gasket, Frame/Adapter

105 1 Ring, Lantern 370 16/24

106 5

107 1 Gland 370C 4

108 1

109 1

112 2

113 1

122 1

126 1 Sleeve 400 1 Coupling Key

134 1 Housing, Bearing 408A 1 Drain Plug

136 1 Locknut, Bearing 408H 1 Plug, Frame Lubrication Port

168 1 Bearing, Radial, Inboard 408J2 1 Oiler Plug

184 1 Cover, Stuffing Box 408L2 1 Cooler Plug

210 1 Packing, Gland 408M

228 1 Bearing Frame 408N2 1 Sight Plug

319 1 Sight Glass 412 1 O-Ring, Impeller

332 1

333 1

351 1 Gasket, Casing 469B 2 Pin, Frame / Adapter

353 2 Stud, Gland 496 1 O-Ring, Bearing Housing

355 2 Nut, Gland

1

Item # 370: (16) – 6X8-13, 8X10-13, (24) – 6X8-15, 8X10-15, 8X10-15G

2

408J, 408L, 408M & 408N – NOT SHOWN ON THE DRAWING

Stuffing Box Packing

Frame Adapter

Bearing End Cover, Outboard

Bearing, Thrust, Outboard

Oil Fill Plug

Shaft, Sleeve Type

Labyrinth Seal, Outboard

Labyrinth Seal, Inboard

370B 4 Bolt, Frame / Adapter

370D 4

370F 2

370H 2

371C 6

382 1 Lockwasher

2

418 3 Bolt, Case Jackout

423 4 Housing Jam Nut

1

Bolt, Adapter / Case

Bolt, Housing / Frame

Jack Bolt, Housing Adjustment

Bolt, Frame Foot

Stud, Cover / Adapter

Bolt, Cover/Housing

1 Cooler Plug

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 27

Page 34

Installation, Operation, and Maintenance Manual

MODEL 2196-LF CROSS SECTION

MODEL 2196-LF PARTS LIST

Item # Qty Description Item # Qty Description

100 1 Casing 360D 1 Gasket, Frame/Adapter

101 1 Impeller 360Q 1 Gasket; Gland, Mech. Seal

105 1 Ring, Lantern 361A 1 Snap Ring, Bearing

106 5 Packing 365 1 Seal, Mechanical Stationary Element

107 1 Gland, Packing 370

108 1 Adapter 370B 4 Bolt, Frame / Adapter

112 1 Bearing, Outboard 370C 3 Bolt, Frame / Bearing Housing

113 1 Plug, Oil Fill 370D 3 Jack Bolt, Bearing Housing

122 1 Shaft 370F 2 Bolt, Frame Foot

126 1 Sleeve, Shaft 370H 2 Box Cover/Adapter Stud

134 1 Housing, Bearing 382 1 Lockwasher, Bearing

136 1 Locknut, Bearing 383 1 Seal, Mechanical Rotating Element

168 1 Bearing, Inboard 400 1 Key, Coupling

184 1 Cover, Stuffing Box 408A 1 Plug, Frame Drain (Not Shown)

228 1 Frame 408H 4 Plug, Frame Lubrication Port

241 1 Foot Frame 408L 1 Plug, Oil Cooler Inlet

250 1 Gland, Mechanical Seal 408M 1 Plug, Oil Cooler OutIet

319 1 Gauge; Sight, Oil 412A 1 O-ring, Impeller

332A 1 Labyrinth, Outboard Frame 423 3 Jamnut, Bearing Housing Jack Bolt

333A 1 Labyrinth, Inboard Frame 423B 2 Nut, Box Cover/Adapter Stud

351 1 Gasket, Case 469B 2 Dowel Pin, Frame / Adapter

353 4 Stud, Gland 496 1 O-ring, Bearing Housing / Frame

353A 4* Nut, Gland Stud 529 2 Bolt , Frame Foot to Frame

358A 1 Plug, Casing Drain * Packing Gland has only 2 Studs & Nuts

8, 12, 16

Bolt, Casing

28 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 35

Installation, Operation, and Maintenance Manual

MODEL 2196-R CROSS SECTION

MODEL 2196-R PARTS LIST

Item # Qty Description Item # Qty Description

100 1 Casing 360Q 1 Gasket; Gland, Mech. Seal

101 1 Impeller 361A 1 Snap Ring, Bearing

105 1 Ring, Lantern 365 1 Seal, Mechanical Stationary Element

106 5 Packing 370 3 Bolt, Casing

107 1 Gland, Packing 370B** 4 Bolt, Frame / Adapter

108** 1 Adapter Ring 370C 3 Bolt, Bearing Housing

112 1 Bearing, Outboard 370D 3 Jack Bolt, Bearing Housing

113 1 Plug, Oil Fill 370F 1 Bolt, Foot to Frame

122 1 Shaft 370H 2 Stud, SBC / Adapter

126 1 Sleeve, Shaft 382 1 Lockwasher, Bearing

134 1 Housing, Bearing 383 1 Seal, Mechanical Rotating Element

136 1 Locknut, Bearing 400 1 Key, Coupling

168A 1 Bearing, Inboard 408H 4 Plug, Frame Lubrication Port

184 1 Cover, Stuffing Box 408L 1 Plug, Oil Cooler Inlet (Not Shown)

228 1 Frame 408M 1 Plug, Oil Cooler OutIet (Not Shown)

250 1 Gland, Mechanical Seal 412A 1 O-ring, Impeller

319 1 Sight Glass 423 3 Jamnut, Bearing Housing / Frame

332A 1 Labyrinth, OB 423B 2 Nut, Box Cover/Adapter Stud

333A 1 Labyrinth, IB 496 1 O-ring,, Bearing Housing / Frame

351 1 Gasket, Case 500 1 Pin, Sleeve

353 1 Stud, Gland 529 2 Washer, Foot to Frame

353A 4* Nut, Gland Stud * Packing Gland has only 2 Studs & Nuts

358A 1 Plug, Casing Drain ** Only Required on 8" Pump

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 29

Page 36

Installation, Operation, and Maintenance Manual

MODEL 2796 CROSS SECTION

MODEL 2796 PARTS LIST

Item # Qty Description Item # Qty Description

100 1

101 1

105 1

106 5

107 1

108 1

112 1

113A 1

122 1

126 1

134 1

136 1

144 1

168A 1

184 1

228 1

241 1

250

332A 1

333A 1

351 1

353 4

353A 4*

358A 1

Casing

Impeller

Ring, Lantern

Packing

Gland, Packing

Adapter

Bearing, Outboard

Plug, Oil Fill

Shaft

Sleeve, Shaft

Housing, Bearing

Locknut, Bearing

Gauge; Sight, Oil

Bearing, Inboard

Cover, Stuffing Box

Frame

Foot Frame

Gland, Mechanical Seal

Labyrinth, Outboard Frame

Labyrinth, Inboard Frame

Gasket, Case

Stud, Gland

Nut, Gland Stud

Plug, Casing Drain

360D 1

360Q 1

361A 1

365 1

8, 12, 16

370

370B 4

370C 3

370D 3

370F 2

370H 2

382 1

383 1

400 1

408A 1

408H 4

408L 1

408M 1

412A 1

423 3

423B 2

469B 2

496 1

529 2

* Packing Gland has only 2 Studs & Nuts

Gasket, Frame/Adapter

Gasket; Gland, Mech. Seal

Snap Ring, Bearing

Seal, Mechanical Stationary Element

Bolt, Casing

Bolt, Frame / Adapter

Bolt, Bearing Housing

Jack Bolt, Bearing Housing

Bolt, Frame Foot

Box Cover/Adapter Stud

Lockwasher, Bearing

Seal, Mechanical Rotating Element

Key, Coupling

Plug, Frame Drain (Not Shown)

Plug, Frame Lubrication Port

Plug, Oil Cooler Inlet

Plug, Oil Cooler Outlet

O-ring, Impeller

Jamnut, Bearing Housing Jack Bolt

Nut, Box Cover/Adapter Stud

Dowel Pin, Frame / Adapter

O-ring, Bearing Housing / Frame

Washer, Frame Foot to Frame

30 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 37

Installation, Operation, and Maintenance Manual

(This page was intentionally left blank.)

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 31

Page 38

Installation, Operation, and Maintenance Manual

APPENDIX E – MAINTENANCE INSTRUCTIONS FOR INPRO/SEAL®

“VBX” BEARING ISOLATORS

DETAILS OF OPERATIONS

The Inpro Bearing Isolator is a Labyrinth type seal, which performs two functions:

1. Maintains the clean oil in the bearing housing.

2. Keeps contaminates from entering the bearing housing.

The unit is comprised of three major components: the rotor, the stator, and the

“VBX”

®

ring.

The rotor fits over the shaft and is held in place by an elastometric drive ring. The

drive ring causes the rotor to turn with the shaft and also provides a positive static

seal on the shaft. There is no metal-to-metal contact between the shaft and rotor, thus

no wear and friction concerns.

The stator is held in the housing by a nominal .002” interference fit. An o-ring

gasket on the outside diameter of the stator secures a positive seal between the stator

and the housing bore. The designed Labyrinth grooves and lube return trough on the

stator inside diameter retains the lubricant inside the bearing housing.

The rotor and stator act together to keep contamination out of the bearing housing.

The “VBX” ® ring, stator, and rotor are a unit and must not be pulled apart. If the unit

is pulled apart or comes apart, it must be replaced with a new unit. The “VBX” ® is

intended to be an inseparable design.

Repairs or replacement of seals are only necessary if excessive oil leakage is visible.

If or when the bearing housing is disassembled, it is recommended that the rotor orings be replaced.

DISASSEMBLY PROCEDURES

1. Remove shaft assembly (122) per instructions for pump disassembly. (See page

18.)

2. STO removal. Insert a bar (wood or plastic) through the outboard bearing

housing end of the bearing frame (228). Contact the inboard bearing isolator

(333A). Remove by tapping the bar or pushing with an arbor press.

MTO and XLO

removal. Disassemble the bearing frame adapter (108) per pump

disassembly instructions. Remove the inboard bearing isolator (333A) with a bar

(wood or plastic) by tapping or by pushing with an arbor press.

3. STO, MTO, and XLO outboard bearing isolator (332A) removal. Block up the

outboard bearing housing (134) on the bench, coupling the end toward the bench

top. Tap the isolator out of the housing or use an arbor press.

4. Inspect the bearing isolators. If the unit pulls apart, a new isolator is needed for

reassembly.

5. Replace the rotor 0-rings and stator 0-rings each time the units are removed from

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 32

Page 39

Installation, Operation, and Maintenance Manual

the pump assembly.

INSTALLATION PROCEDURES

1. STO, MTO, and XLO Inboard Isolator. Position the bearing frame (228) or

adapter (108) inboard bearing side up. Place the isolator seal (333A) stator side in

the bore. THE EXPULSION PORT MUST BE IN THE 6 O’CLOCK

POSITION. While using a block large enough to cover the entire flange of the

isolator, use an arbor press to press the stator into the bore. Press into place until

the location ramp begins. (See Figure 1.)

Figure 1

2. Outboard Isolator (332A)

Place the isolator in the bore and press into place using the same technique as in

Step 1 above.

3. Lightly lube the sleeve end of the shaft and rotor drive ring. Slide the bearing

frame (228) or adapter (108) over the shaft per assembly instructions.

4. To assemble the outboard end, tape the shaft (122) keyway with black tape. Lube

the tape and rotor drive ring. Slide the bearing housing (134) over the shaft (122)

end and continue per assembly instructions.

MAKE SURE EXPULSION PORT AND LUBE RETURN ARE IN THE 6

O’CLOCK POSITION IN FINAL ASSEMBLY.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 33

. Position the bearing housing (134) outside flange up.

Page 40

Installation, Operation, and Maintenance Manual

APPENDIX F – DIMENSIONAL DATA

MODEL 2196 DIMENSIONAL DATA

2196 DIMENSIONS

PUMP

FRAME

ANSI DIS SUC IMP X D B A SP E1 E2 F H U KEYWAY V

AA 1 1.5 6 85

AB 1.5 3 6 90

STO 2 3 6 6 1/2 5 1/4 4 13 1/2 3 3/4 3 0 7 1/4 5/8 .875 3/16 X 3/32 2 95

AA 1 1.5 8 100

AB 1.5 3 8 110

A60 2 3 8 9 1/2 200

A70 3 4 8 11 MTO MTO 220

MTO A70 3 4 8G 11 1.125 1/4X1/8 220

A05 1 2 10 8 1/2 8 1/4 200

A50 1.5 3 10 8 1/2 220

A60 2 3 10 9 1/2 230

or A70 3 4 10 11 4 19 1/2 3 3/4 4 7/8 3 5/8 12 1/2 5/8 2 5/8 265

A40 3 4 10H 12 1/2 275

A80 4 6 10 13 1/2 305

A80 4 6 10H 13 1/2 305

LTO A20 1.5 3 13 10 1/2 LTO LTO 245

A30 2 3 13 11 1/2 10 1.875 1/2X1/4 275

A40 3 4 13 12 1/2 330

A80 4 6 13 13 1/2 405

A90 6 8 13 16 560

A100 8 10 13 18 670

XLO A110 6 8 15 18 14 1/2 6 27 7/8 5 1/4 8 4 1/2 18 3/4 7/8 2.375 5/8 X 5/16 4 610

A120 8 10 15 19 740

A120 8 10 15G 19 710

SIZE

FOOT PATTERN SHAFT APPROX.

BARE PUMP WT.

(LBS.)

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 34

Page 41

Installation, Operation, and Maintenance Manual

MODEL 2196 BASEPLATE RELATED DIMENSIONS

PUMP

FRAME

STO

MTO

XLO

BASEPLATE

NUMBER

1

2

3

4

5

6

7

8

9

10

BASEPLATE RELATED DIMENSIONS

MAX MOTOR

FRAME

145

215

286

215

286

365

444

286

365

447

HA HB HE HF HP HG HH HL

10 35 4 32 1/2 1 1/4 3 3/4 4 1/2

12 39 4 1/2 36 1/2 1 1/4 3 1/4 3/4 4 1/2

15 46 6 43 1/2 1 1/4 4 1/8 3/4 4 1/2

12 45 4 1/2 42 1/2 1 1/4 3 3/4 3/4 4 1/2

15 52 6 49 1/2 1 1/4 4 1/8 3/4 4 1/2

18 58 7 1/2 55 1/2 1 1/4 4 3/4 1 4 1/2

18 60 7 1/2 57 1/2 1 1/4 4 3/4 1 4 1/2

26 62 9 1/2 59 1/2 1 1/4 4 3/4 1 6 1/2

22 68 9 1/2 65 1/2 1 1/4 4 3/4 1 6 1/2

22 80 9 1/2 77 1/2 1 1/4 4 3/4 1 6 1/2

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 35

Page 42

Installation, Operation, and Maintenance Manual

MODEL 2196-LF DIMENSIONAL DATA

2196-LF DIMENSIONS

PUMP

FRAME

STO

MTO/LTO A05 1 2 10 8.5 19.5 4.0 8.25 3.75

LTO A20 1.5 3 13 10.5 19.5 4.0 10.0 3.75 285

ANSI

AA 1 1.5 4 6.5 13.5 4.0 5.25 3.75 84

AA 1 1.5 8 6.5 13.5 4.0 5.25 3.75 100

SIZE

DIS SUC IMP

X A B D SP

BARE PUMP WT. (LBS.)

APPROX.

200

245

36 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 43

Installation, Operation, and Maintenance Manual

MODEL 2196-R DIMENSIONAL DATA

2196-R DIMENSIONS

Pump

Frame

STO 2x2-8 4.25 6.5 15.38 2.75 2.5 6 3 0 7.25 0.875 .19 x .09

MTO

or

LTO

LTO 4x6-13

Size Z X A B C D SP

2x2-10 5.25 8.5 21.75 3.5 2.25

3x3-10 5.13 9 22.50 4.25 2.94

2x3-13 22.38 2.81

3x4-13

6.63

10.5

11.5 23.13 4.75 3.63

22.81

4.12

3.31

8.25

3.75

10

Foot Pattern Shaft

E1 E2 F H U KEYWAY

1.125 .25 x .125

4.88 3.63 12.5

.63

1.875 .5 x .25

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 37

Page 44

Installation, Operation, and Maintenance Manual

MODEL 2796 DIMENSIONAL DATA

2796 DIMENSIONS

PUMP

FRAME

STO

MTO/LTO 2 2 21.75 6.5 370

3 3 22.63 6.75 315

4 4

3 3 22.63 6.75 400

4 4

6 6

SIZE FOOT PATTERN

DIS SUC IMP

1 6 7.25

1.5

1.5

8 7.88

10 10

13

X A B D D2

15.5 5 7.5 4 3 0 7.25 170

23.38 9.19 370

11.5

15 15.25 10 12 8

22.38 9.19

10 6

E E2 F H

4.88 3.63 12.5

.63

APPROX.

BARE PUMP

WT. (LBS.)

470

690

38 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 45

Installation, Operation, and Maintenance Manual

MODEL 2196 STUFFING BOX RELATED DIMENSIONS

STUFFING BOX RELATED DIMENSIONS

PUMP C G PACKING LANTERN

FRAME

STO 2.00

MTO 2.50

LTO 2.87

XLO 3.37

A B

2.12

2.62

2.62

3.00

B.C TAP

3.25 3/8-18 UNC 0.97 1/4-18 NPT 2.39 2.18 5/16 5 7/16

4.12 1/2-13 UNC 1.56 3/8-18 NPT 3.01 3.00 3/8 5 5/8

4.50 1/2-13 UNC 1.56 3/8-18 NPT 3.52 3.00 3/8 5 5/8

5.37 5/8-11 UNC 1.75 3/8-18 NPT 4.37 2.93 7/16 5 5/8

D E F

OBSTRUCTION SIZE # OF RINGS RING WIDTH

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 39

Page 46

Installation, Operation, and Maintenance Manual

APPENDIX G – CONSTRUCTION DETAILS

MODEL 2196 CONSTRUCTION DETAILS

Construction Details All dimensions in inches and (mm).

STO MTO LTO XLO

Diameter at Impeller .75 (19) 1 (25) 1.25 (32) 1.5 (38)

Shaft

Diameter in Stuffing Box

(Solid shaft const.)

Diameter Between Bearings 1.5 (38) 2.125 (54) 2.5 (64) 3.125 (79)

Diameter at Coupling .875 (22) 1.125 (29) 1.875 (48) 2.375 (60)

Overhang 6.125 (156) 8.375 (213) 8.375 (213) 9.969 (253)

Maximum Shaft Deflection 0.002 (0.05)

Shaft Deflection Index (L3/D4)

(With Sleeve)

(Less Sleeve)

1.375 (35) 1.75 (45) 2.125 (54) 2.5 (64)

143

64

116

63

48

29

62

25

Sleeve

Bearings

Stuffing Box

Power Limits

O.D. thru Stuffing Box/Seal Chamber 1.375 (35) 1.75 (45) 2.125 (54) 2.5 (64)

Radial SKF 6207 SKF 6309 SKF 6311 SKF 6313

Thrust

Bearing Span 4.125 (105) 6.75 (171) 6.875 (164) 9.25 (235)

Bore 2 (51) 2.5 (64) 2.875 (73) 3.375 (86)

HP (kW) per 100 RPM 1.1 (.82) 3.4 (2.6) 5.6 (4.2) 14 (10.5)

SKF 5306

A/C3

SKF 5309

A/C3

SKF 7310

BECBM

SKF 5313

A/C3

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 40

Page 47

Installation, Operation, and Maintenance Manual

APPENDIX H – ANSI B15.1 COUPLING GUARDS

INSTALLATION INSTRUCTIONS FOR SUMMIT PUMP

ANSI B15.1 COUPLING GUARDS

WARNING!

Before assembling or disassembling the coupling guard, de-energize the

motor, lock out the motor controller/starter, and place a caution tag at

the starter indicating that it is disconnected. Before resuming normal

pump operation, replace the coupling guard. Summit Pump assumes no

liability when these procedures are avoided.

Figure H-1

The design’s simplicity allows complete coupling guard assembly, including the end

plate (pump end), in about fifteen minutes.

ASSEMBLY PROCEDURES

TO ASSEMBLE YOUR COUPLING GUARD

NOTE: If the end plate (pump end) was

previously installed, make any

necessary adjustments to the

coupling and skip to Step 2.

1. On the STO, MTO, and LTO, align the end plate (pump end) to the bearing

frame. (Impeller adjustment is not required.)

On the XLO-X

the small slots on the end plate aligned to the impeller adjusting bolts and the

large slots clearing the bearing housing tap bolts. Then attach the end plate to the

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 41

, align the end plate (pump end) to the pump bearing housing with

Page 48

Installation, Operation, and Maintenance Manual

bearing housing using the jam nuts on the impeller adjusting bolts as shown in

Figure H-3.

After attaching the end plate to the bearing housing, check and reset the impeller

clearance as detailed in APPENDIX A - IMPELLER CLEARANCE SETTING.

NOTE: Complete the coupling

adjustments before proceeding

with the coupling guard

assembly.

Figure H-2

STO, MTO, LTO

Figure H-3

XLO-X

2. Slightly spread the bottom of the coupling guard half (pump end) and place it over

the pump end plate as shown in Figure H-4. The annular groove in the guard half

is located around the end plate. (See Figure H-5.)

42 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 49

Installation, Operation, and Maintenance Manual

Figure H-4

3. After placing the coupling guard half (pump end) around the pump end plate,

secure it with a bolt, nut and two (2) washers through the round hole in the front

end of the guard half as shown in Figure H-6. Tighten securely. (See Figure

H-7.)

Figure H-5

Figure H-6 Figure H-7

4. Slightly spread the bottom of the coupling guard half (driver end) and place it

over the coupling guard half (pump end) so that the annular groove in the

coupling guard half (driver end) faces the motor as shown in Figure H-8.

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 43

Page 50

Installation, Operation, and Maintenance Manual

Figure H-8

5. Place the end plate (driver end) over the motor shaft as shown in Figure H-9.

Position the end plate in the annular groove at the rear of the coupling guard half

(driver end) and secure it with a bolt, nut, and two (2) washers through the round

hole at the rear of the guard half. Finger-tighten only.

Figure H-9 Figure H-9.5

6. Adjust the length of the coupling guard to completely cover the shafts and

coupling as shown in Figure H-10, by sliding the coupling guard half (driver end)

toward the motor. After adjusting the length, secure the guard with a bolt, nut and

44 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 51

Installation, Operation, and Maintenance Manual

two (2) washers through the slotted holes at the center of the guard and tighten.

Check tightness on all of the nuts on the guard assembly.

WARNING!

Before assembling or disassembling the

coupling guard, de-energize the motor,

lock out the motor controller/starter, and

place a caution tag at the starter

indicating that it is disconnected. Before

resuming normal pump operation, replace

the coupling guard. Summit Pump

assumes no liability when these

procedures are avoided.

Figure H-10

DISASSEMBLY PROCEDURES

TO DISASSEMBLE YOUR COUPLING GUARD

It is necessary to remove the coupling guard for certain pump maintenance and

adjustments, such as coupling adjustment, impeller clearance adjustment, and so

forth. Replace the coupling guard after completing maintenance.

DO NOT resume normal pump operation while the coupling guard is removed.

NOTE: Refer to the illustrations for

assembly beginning with Figure

H-10 and working in reverse

order.

1. Remove the nut, bolt and washers from the center-slotted hole on the coupling

guard. Slide the motor end of the coupling guard half toward the pump. (See

Figure H-10.)

2. Remove the nut, bolt and washers from the driver end of the coupling guard half

and remove the end plate. (See Figure H-9.)

3. Slightly spread the bottom of the coupling guard half and lift it off. (See Figure

H-8.)

4. Remove the remaining nut, bolt and washers from the pump end of the coupling

guard half. Slightly spread the coupling guard half and lift it off. (See Figure

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 45

Page 52

Installation, Operation, and Maintenance Manual

H-4.)

This concludes the coupling guard disassembly procedures.

NOTE: It is unnecessary to remove the

end plate (pump end) from the

bearing housing. If internal

pump part maintenance is

necessary, the bearing housing

tap bolts are accessible without

removing the end plate. Refer to

APPENDIX C - MAINTENANCE

AND REPAIR before removing the

pump bearing housing.

46 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

Page 53

Loading...

Loading...