User’s Manual

Rev 3b

FCC Notice

The S CLASS 2 cutters have been tested and found to comply with the limits for Class A

digital devices, pursuant to Part 15 of the FCC Rules. These limits provide reasonable

protection against harmful interference when the equipment operates in a commercial

environment. The cutters generate, use and can emit radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

Operation of the cutters in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at own expense.

Caution!

Changes or modifications not expressly approved by Summa, who is responsible for FCC

compliance, could void the user’s authority to operate this equipment.

DOC Notice

The S CLASS 2 cutters do not exceed the Class A limits for radio noise for digital apparatus

set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Notice

Summa reserves the right to modify the information contained in this User Manual at any

time without prior notice. Unauthorized copying, modification, distribution or display are

prohibited. All rights reserved.

Waste Electrical and Electronic Equipment (WEEE) Directive

Directive 2002/96/EC of the European Parliament and of the Council

The symbol (right) is shown on this product. It indicates that the product

should not be placed in municipal waste but should be disposed of

separately.

Electrical and electronic equipment can contain materials, which are

hazardous to the environment and human health, and therefore should

be disposed of at a designated waste facility or returned to your retailer

for the appropriate recycling to take place.

If you wish to dispose of this product and the product still functions, please consider

recycling/reusing it by donating it to a charity shop, selling it or exchange parts of it with

your retailer.

Copyright © Summa

Registering Your Cutter

Please register your cutter on the following link:

http://www.summa.be/registration.html

Failure to register may result in delayed responses to your warranty and service inquiries.

Contact Information

All inquiries, comments or suggestions concerning this and other Summa manuals should

be directed to:

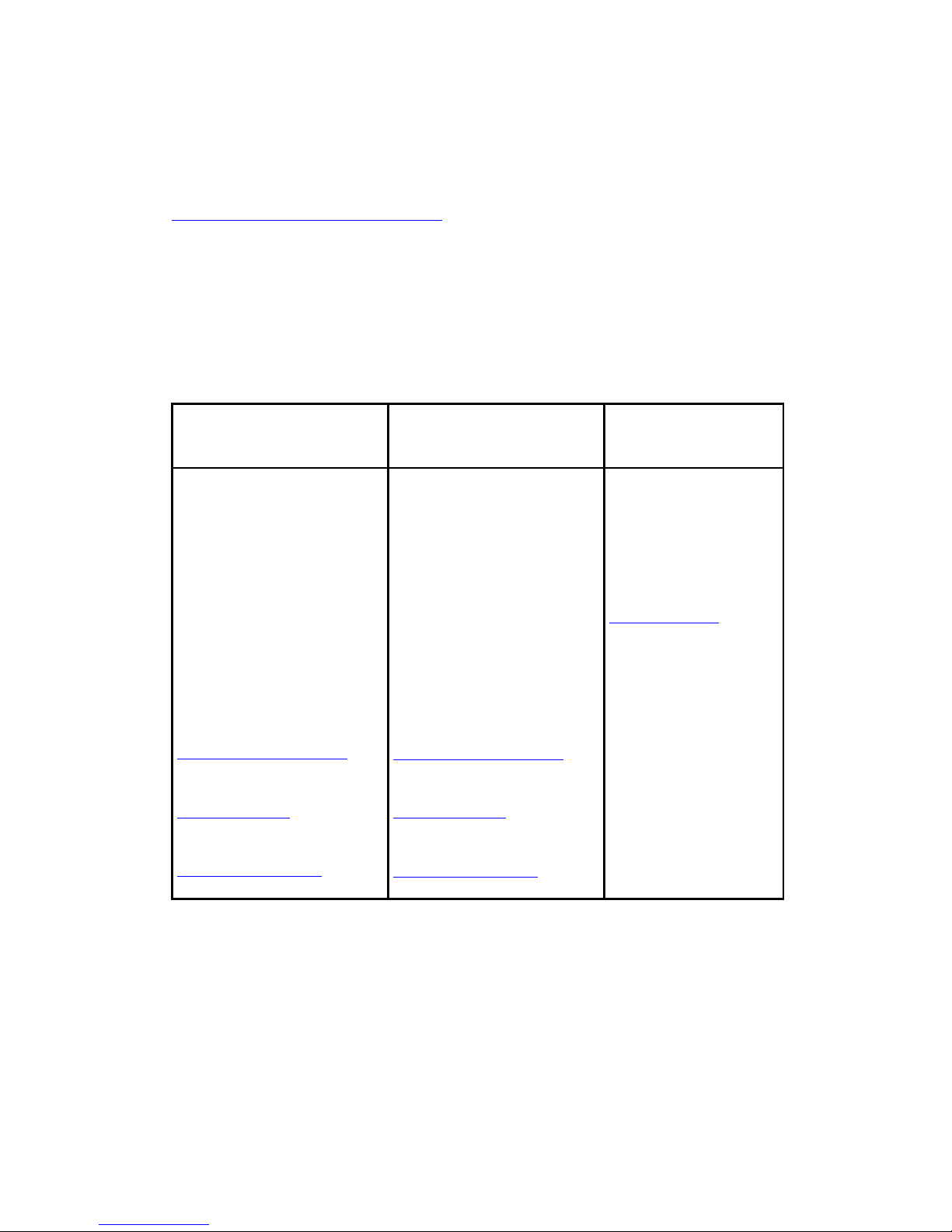

North America and Asia

Pacific

Eastern United States and

Latin America

Europe, Africa and

Middle East

Summa, Inc

10001 Lake City Way NE

Seattle, WA 98125

USA

Main Office

+1-206-527-1050

+1-800-527-7778

Fax

+1-206-527-1046

Support

support@summausa.com

Sales

sales@summa.us

Website

www.summausa.com

Summa East, Inc

222 Jubilee Drive

Peabody, MA 01960

USA

Main Office

+1-978-531-1991

+1-888-527-1050

Fax

+1-978-531-1993

Support

support@summausa.com

Sales

sales@summa.us

Website

www.summausa.com

Summa, bvba

Rochesterlaan 6

B-8470 GISTEL

Belgium

Website

www.summa.be

Welcome

Congratulations on your purchase of the new S CLASS 2 cutter!

The S CLASS 2 cutters are built for sign-makers who demand the very best in cut quality.

Four versatile modes let you switch between Cutting, Cutting in FlexCut, Plotting or

Pouncing. So even if your workspace is limited, your output options aren't.

Unrivalled tracking delivers guaranteed accuracy on cuts up to 12 meters (40 feet) long.

This way you won't have to monitor your cuts, even when you're sending through long jobs.

The S CLASS 2 T series cutters with genuine tangential operation, and not simply "tangential

emulation," handle a wider range of materials and cut with unparalleled precision.

In short, the S CLASS 2 cutters take cutting signs to a new level.

This manual is a reference guide for installing and operating the S Class series cutters.

Minimum revisions needed for this manual:

Firmware cutter: 017 (MD9981)

Cutter Control version 5.1 (installed from Cutter Tools version 2.2.0)

USB driver: version 6.4

Camera driver: revision1.0.136

Table of contents I

Table of Contents

1 Setup ............................................................................................................... 1-1

1.1 Unpacking the cutter .......................................................................................... 1-1

1.1.1 Removing the packaging from the cutter ...................................................................... 1-1

1.1.2 Setting up the stand .............................................................................................................. 1-2

1.1.3 Mounting the cutter on the stand .................................................................................... 1-4

1.2 S CLASS 2 Cutter Components ........................................................................... 1-5

1.2.1 The Cutter as viewed from the front ................................................................................ 1-5

1.2.2 The Cutter as viewed from the back ................................................................................ 1-7

1.3 Safety, Ideal Operating Environment, Connecting to the Mains ..................... 1-9

1.3.1 Safety ........................................................................................................................................... 1-9

1.3.1.1 General .............................................................................................................................. 1-9

1.3.1.2 Symbols used in the manual ..................................................................................... 1-9

1.3.1.3 Safety precautions ...................................................................................................... 1-10

1.3.2 Operating environment ..................................................................................................... 1-10

1.3.3 Connecting the cutter to the mains .............................................................................. 1-11

1.3.3.1 Grounding (“Earthing”) ............................................................................................. 1-11

1.3.3.2 Operating voltage ...................................................................................................... 1-11

1.4 Powering-on the cutter ..................................................................................... 1-12

1.5 Connecting the cutter to a computer .............................................................. 1-13

1.5.1 USB connection .................................................................................................................... 1-13

1.5.1.1 Connecting the S CLASS 2 cutter to a PC, using a USB cable...................... 1-13

1.5.1.2 Connecting the S CLASS 2 cutter to a Mac using a USB cable.................... 1-14

1.5.2 Ethernet connection ........................................................................................................... 1-14

1.6 Loading media ................................................................................................... 1-18

1.6.1 Pinch roller positioning...................................................................................................... 1-18

1.6.2 Pinch roller pressure setting ............................................................................................ 1-19

1.6.3 Loading media ...................................................................................................................... 1-20

1.6.4 Media load procedure ........................................................................................................ 1-23

1.7 Tool Installation ................................................................................................ 1-27

1.7.1 Cutters with drag head ...................................................................................................... 1-27

1.7.1.1 Knife installation ......................................................................................................... 1-27

1.7.1.2 Pen installation ............................................................................................................ 1-30

1.7.1.3 Pouncing pin installation ......................................................................................... 1-30

1.7.2 Cutters with tangential head ........................................................................................... 1-31

1.7.2.1 Tangential knife installation ................................................................................... 1-31

1.7.2.2 Pen installation ............................................................................................................ 1-34

1.7.2.3 Pouncing pin installation ......................................................................................... 1-35

1.7.2.4 Drag knife installation ............................................................................................... 1-35

1.7.3 Replacement of the separation knife blade ............................................................... 1-36

S CLASS™ 2 cutter User’s Manual

Table of contents II

2 Basic Operation.............................................................................................. 2-1

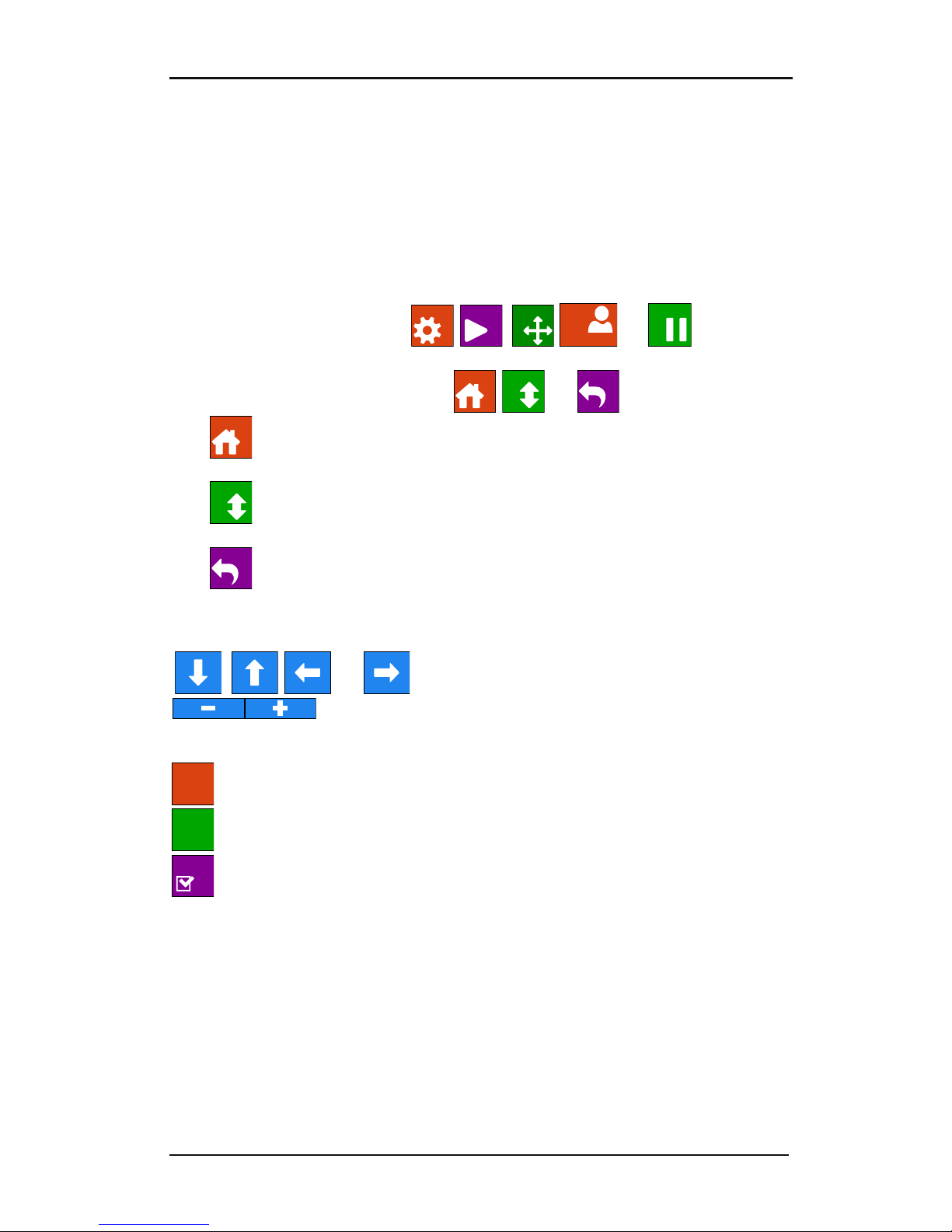

2.1 Touch Screen ....................................................................................................... 2-1

2.1.1 Touch screen............................................................................................................................. 2-2

2.1.2 Settings ....................................................................................................................................... 2-3

2.1.3 Actions ........................................................................................................................................ 2-3

2.1.4 Origin ........................................................................................................................................... 2-4

2.1.5 Configuration ........................................................................................................................... 2-4

2.1.6 Online/Pause ............................................................................................................................ 2-5

2.2 How to Set Tool Parameters ............................................................................... 2-6

2.2.1 Setting the tool type .............................................................................................................. 2-6

2.2.2 Changing the tool pressure ................................................................................................. 2-7

2.2.3 Changing the drag knife offset .......................................................................................... 2-7

2.2.4 Calibrating a tangential knife ............................................................................................. 2-8

2.3 How to set the cutting speed ............................................................................ 2-12

2.4 How to make sure the sign has the correct size .............................................. 2-13

3 OPOS (Optical POSitioning) .......................................................................... 3-1

3.1 Introduction......................................................................................................... 3-1

3.2 Basic OPOS operation ......................................................................................... 3-1

3.2.1 Creating the graphic .............................................................................................................. 3-2

3.2.2 OPOS XY ..................................................................................................................................... 3-3

3.2.3 Printing the graphic ............................................................................................................... 3-4

3.2.4 Orientation ................................................................................................................................ 3-5

3.2.5 Registering the marks ............................................................................................................ 3-6

3.2.6 OPOS paneling ......................................................................................................................... 3-7

3.3 Calibrating OPOS ................................................................................................ 3-8

3.3.1 OPOS calibration ..................................................................................................................... 3-8

3.3.2 Media calibration .................................................................................................................... 3-9

3.4 Automating OPOS tasks ................................................................................... 3-11

3.4.1 OPOS origin ............................................................................................................................ 3-12

3.4.1.1 In combination with OPOS X mode ..................................................................... 3-12

3.4.1.2 In combination with OPOS XY mode .................................................................. 3-12

3.4.2 Cutting multiple copies of a graphic on the same roll ........................................... 3-14

3.4.3 Cutting the same graphic on multiple media sheets.............................................. 3-15

3.4.4 OPOS Barcode ....................................................................................................................... 3-16

3.4.4.1 Introduction .................................................................................................................. 3-16

3.4.4.2 Activation of the barcode ........................................................................................ 3-16

3.4.4.3 Initiating barcode procedure ................................................................................. 3-18

3.5 OPOS CAM ......................................................................................................... 3-19

3.5.1 General ..................................................................................................................................... 3-19

3.5.2 Differences in calibrating OPOS CAM vs OPOS sensor ........................................... 3-20

3.5.2.1 OPOS calibration ......................................................................................................... 3-20

3.5.2.2 OPOS media calibration ........................................................................................... 3-20

3.6 Cutting through ................................................................................................ 3-21

S CLASS™ 2 cutter User’s Manual

Table of contents III

4 Detailed Operation ........................................................................................ 4-1

4.1 Introduction......................................................................................................... 4-1

4.2 Action Menu ........................................................................................................ 4-1

4.2.1 OPOS Barcode .......................................................................................................................... 4-1

4.2.2 OPOS sheet mode ................................................................................................................... 4-1

4.2.3 Home ........................................................................................................................................... 4-2

4.2.4 Cut Tests ..................................................................................................................................... 4-2

4.2.5 Open file ..................................................................................................................................... 4-2

4.2.6 Replot .......................................................................................................................................... 4-2

4.2.7 Load ............................................................................................................................................. 4-3

4.2.8 Cut Off ......................................................................................................................................... 4-3

4.3 Configuration Menu ............................................................................................ 4-4

4.3.1 Settings ....................................................................................................................................... 4-6

4.3.1.1 Tool ..................................................................................................................................... 4-6

4.3.1.2 Velocity .............................................................................................................................. 4-6

4.3.1.3 Knife pressure ................................................................................................................. 4-6

4.3.1.4 Calibrate Knife ................................................................................................................. 4-6

4.3.1.5 Knife offset ....................................................................................................................... 4-7

4.3.1.6 Pouncing gap .................................................................................................................. 4-7

4.3.1.7 FlexCut ............................................................................................................................... 4-7

4.3.1.8 Advanced cutting .......................................................................................................... 4-8

Overcut: ...................................................................................................................................... 4-8

OptiCut: ...................................................................................................................................... 4-9

Paneling: ..................................................................................................................................... 4-9

Panel size: ................................................................................................................................... 4-9

Panel replot: .............................................................................................................................. 4-9

Sorting Vectors:........................................................................................................................ 4-9

Long Vectors: ......................................................................................................................... 4-10

TurboCut: ................................................................................................................................ 4-10

4.3.1.9 General ........................................................................................................................... 4-10

Media sensor: ......................................................................................................................... 4-10

Recut offset: ........................................................................................................................... 4-10

Cut off margin: ...................................................................................................................... 4-11

Roll-up media: ....................................................................................................................... 4-11

Autoload: ................................................................................................................................. 4-11

Language: ............................................................................................................................... 4-11

Menu Units: ............................................................................................................................ 4-12

4.3.1.10 OPOS ............................................................................................................................... 4-12

4.3.1.11 Communication .......................................................................................................... 4-13

Tool command: ..................................................................................................................... 4-13

USB class: ................................................................................................................................. 4-13

LAN: ........................................................................................................................................... 4-13

4.3.1.12 Length calibration ...................................................................................................... 4-14

4.3.1.13 Coil setup ....................................................................................................................... 4-14

4.3.1.14 Factory defaults ........................................................................................................... 4-14

4.3.1.15 Copy current user ....................................................................................................... 4-14

4.3.1.16 Media sensor setup .................................................................................................... 4-15

4.3.1.17 Calibrate touchscreen ............................................................................................... 4-15

S CLASS™ 2 cutter User’s Manual

Table of contents IV

5 Maintenance and Cleaning ........................................................................... 5-1

5.1 Introduction......................................................................................................... 5-1

5.1.1 Cleaning the drive system ................................................................................................... 5-1

5.1.2 Cleaning the media sensors ................................................................................................ 5-1

5.1.3 Cleaning the Y-Guide Rail .................................................................................................... 5-2

5.1.4 Cleaning the nose piece (tangential machine only) ................................................... 5-2

5.1.5 Cleaning the OPOS system .................................................................................................. 5-3

5.1.6 Changing the fuse .................................................................................................................. 5-4

6 Specs and General Information .................................................................... 6-1

6.1 Introduction......................................................................................................... 6-1

6.1.1 Product features ...................................................................................................................... 6-1

6.2 Specifications ...................................................................................................... 6-3

6.2.1 Cutter ........................................................................................................................................... 6-3

6.2.2 Media ........................................................................................................................................... 6-3

6.2.3 Knife, pen and pouncing tool ............................................................................................. 6-4

6.2.4 Interface...................................................................................................................................... 6-5

6.2.5 Firmware .................................................................................................................................... 6-5

6.2.6 Performance ............................................................................................................................. 6-6

6.2.7 Certifications ............................................................................................................................. 6-6

6.2.8 Environmental .......................................................................................................................... 6-7

6.2.9 Electrical ..................................................................................................................................... 6-7

6.3 Cutter accessories and consumables ................................................................. 6-8

S CLASS™ 2 cutter User’s Manual

Table of contents V

List of Figures

1-1 S CLASS 2 cutter fully boxed.................................................................................................................. 1-1

1-2 Contents of the Stand box ..................................................................................................................... 1-2

1-3 Mounting the horizontal panel ............................................................................................................ 1-2

1-4 Mounting feet and casters ..................................................................................................................... 1-2

1-5 Mounting the basket tubes ................................................................................................................... 1-3

1-6 Preparing to install the linen basket ................................................................................................... 1-3

1-7 Orientation of the holes in the c-shaped tubes .............................................................................. 1-3

1-8 Completely assembled stand for the S CLASS 2 cutter ............................................................... 1-4

1-9 Position of the screws .............................................................................................................................. 1-4

1-10 S CLASS 2 cutter, front view ................................................................................................................ 1-5

1-11 S CLASS 2 cutter, rear view .................................................................................................................. 1-7

1-12 Properly grounded connection ...................................................................................................... 1-11

1-13 Cutter is loaded and ready ............................................................................................................... 1-12

1-14 Cutter is ready - no media loaded .................................................................................................. 1-12

1-15 Position pinch rollers .......................................................................................................................... 1-18

1-16 reducing pressure ................................................................................................................................ 1-19

1-17 Pinch roller lever................................................................................................................................... 1-20

1-18 Media flanges ........................................................................................................................................ 1-20

1-19 Positioning the media flange on the cutter ............................................................................... 1-20

1-20 Feeding roll media without using media flanges .................................................................... 1-21

1-21 Media position ...................................................................................................................................... 1-21

1-22 Pinch roller lever................................................................................................................................... 1-22

1-23 Removing the drag knife holder from the clamp ..................................................................... 1-27

1-24 Removing the knife from the standard drag knife holder .................................................... 1-27

1-26 Dual clamp drag head ........................................................................................................................ 1-28

1-27 Knife pressure test pattern ............................................................................................................... 1-29

1-28 Removing the tangential knife holder ......................................................................................... 1-31

1-29 Removing knife from the tangential knife holder .................................................................... 1-31

1-30 Blade assembly ..................................................................................................................................... 1-32

1-31 Inserting the tangential knife holder ............................................................................................ 1-32

1-32 Knife depth adjustment ..................................................................................................................... 1-32

1-33 Knife pressure test pattern ............................................................................................................... 1-33

1-34 Razor blade for automatic separation of media ....................................................................... 1-36

2-1 Touch screen ............................................................................................................................................... 2-1

2-2 screen saver ................................................................................................................................................. 2-1

2-3 Online status screen ................................................................................................................................. 2-5

2-4 Correct knife offset pattern .................................................................................................................... 2-8

2-5 Possible knife calibrations ...................................................................................................................... 2-9

2-7 Length calibration pattern .................................................................................................................. 2-13

S CLASS™ 2 cutter User’s Manual

Table of contents VI

3-1 Positioning the media for multiple sheets .................................................................................... 3-15

3-2 Opos Barcode Job Loaded .................................................................................................................. 3-18

3-3 OposCam ................................................................................................................................................... 3-19

3-4 FLexcut principle .................................................................................................................................... 3-21

3-5 Combined contour cut and cutting through ............................................................................... 3-23

4-1 Action menu ................................................................................................................................................ 4-1

4-2 Configuration menu ................................................................................................................................. 4-4

4-3 Configuration menu ................................................................................................................................. 4-5

4-4 Overcut .......................................................................................................................................................... 4-8

4-5 Sensor setup ............................................................................................................................................. 4-15

5-1 Media sensors S Class 2 cutters ............................................................................................................ 5-1

5-2 Sliding surfaces on Y-guide rail ............................................................................................................ 5-2

5-3 Cleaning the OPOS sensor ..................................................................................................................... 5-3

5-4 Power entry module ................................................................................................................................. 5-4

List of Tables

6-1 S CLASS 2 Cutter specifications ............................................................................................................ 6-3

6-2 S CLASS 2 Media specifications ............................................................................................................ 6-3

6-3 S CLASS 2 Tools .......................................................................................................................................... 6-4

6-4 S CLASS 2 Interface specifications ....................................................................................................... 6-5

6-5 S CLASS 2 Firmware .................................................................................................................................. 6-5

6-6 S CLASS 2 Performances ......................................................................................................................... 6-6

6-7 S CLASS 2 Environmental Specifications........................................................................................... 6-7

6-8 S CLASS 2 General Accessories ............................................................................................................. 6-8

6-9 S CLASS 2 Accessories for drag series ................................................................................................ 6-9

6-10 S CLASS 2 Accessories for tangential series ................................................................................ 6-11

Setup 1-1

1 Setup

1.1 Unpacking the cutter

NOTE: Save the shipping box and any other packaging items in case the cutter

needs to be shipped. Do not ship the cutter without first completely repacking it

in its original packaging. A document explaining how to repackage is available.

WARNING: For safety reason no fewer than two people should be involved in

unpacking the cutter.

Before unpacking the cutter, make sure there is enough space to assemble the stand and to

set the cutter aside in order to insert the stand screws.

1.1.1 Removing the packaging from the cutter

1. Remove the straps and the staples and open the lid of the box.

2. The cutter is packed in foil and is situated in front of the box. The box, containing the

stand, is situated behind the cutter. The accessories are located at the bottom in a

separate box. Firstly, check whether everything is present.

3. Do not throw away the packaging. Shipping it without the original box voids any

warranty.

FIG 1-1

1-1 S CLASS 2 CUTTER FULLY BOXED

S CLASS™ 2 cutter User’s Manual

Setup 1-2

1.1.2 Setting up the stand

1. Verify whether the stand is complete. The box containing the stand should contain

following:

a. 2 legs, left and right

b. 2 feet, left and right

c. A horizontal panel

d. Media flanges

e. A total of 7 tubes for the [media] basket

f. A linen media basket

g. A bag of 4 casters, screws and other accessories to mount the stand

FIG 1-2

1-2 CONTENTS OF THE STAND BOX

2. Mount the horizontal panel between the two legs of the stand with four screws at each

side.

FIG 1-3

1-3 MOUNTING THE HORIZONTAL PANEL

3. Turn the stand upside down and mount the 2 feet at each side with four screws. Make

sure to position the feet in this way all the holes in the feet correspond to the holes in

the legs (left and right), as in the picture below (1). The four holes in the feet all point

towards the middle (2). Screw in the four casters.

FIG 1-4

1-4 MOUNTING FEET AND CASTERS

S CLASS™ 2 cutter User’s Manual

Setup 1-3

4. Attach the four tubes for the basket on the left and right, as shown in figure 1-5 below.

Put the end cap (1) and the two saddle clips (2) on each tube in order to fix the tube in

its place. Position the shorter tube (3) at the rear side (side of the horizontal panel).

FIG 1-5

1-5 MOUNTING THE BASKET TUBES

5. Turn the stand upright and put the media basket on the horizontal panel as shown in

figure 1-6 below.

FIG 1-6

1-6 PREPARING TO INSTALL THE LINEN BASKET

6. Take one of the large c-shaped tubes and put it through the front hem in the linen

basket. Make sure the holes are oriented with the right side upwards, so that the tubes

click in place securely. Then put the tube on the two front tubes that stick out of the

feet. Slide the tubes together while pressing down the spring-loaded ball stopper until

the ball locks into place.

FIG 1-7

1-7 ORIENTATION OF THE HOLES IN THE C-SHAPED TUBES

7. Click a saddle clip onto one side of the tube. Insert the other end of the tube through

the middle hem of the linen basket and then into the hole in the leg of the stand. Guide

the other end of the tube into the hole on the leg and secure with a saddle clip.

S CLASS™ 2 cutter User’s Manual

Setup 1-4

8. Make sure the linen basket is guided under the horizontal panel. Take the last large c-

shaped tube and feed it through the rear hem in the linen basket. Then put the tube on

the two rear tubes that stick out of the feet. Make sure the holes are orientated with the

right side upwards, so that the tube clicks securely on the tubes. The finished stand

should look like the stand in the picture below (Figure 1-8).

FIG 1-8

1-8 COMPLETELY ASSEMBLED STAND FOR THE S CLASS 2 CUTTER

9. The right leg contains a hole in the foot and a cutout in the leg in order to guide the

power cable and data cable. If you plan to use these cable guides, then put the cables in

place before mounting the cutter on the stand.

1.1.3 Mounting the cutter on the stand

1. Carefully take the cutter out of the box and lay it on its back (first spread out the

cardboard of the stand box, and then rest the cutter on that cardboard). Insert the left

and right two screws and turn them 3 turns in. Do not put a screw in at the front.

FIG 1-9

1-9 POSITION OF THE SCREWS

2. Put the cutter on its stand. Put a lockwasher on the two remaining screws and put them

in the two remaining holes. Then secure all six screws.

3. Loosen the cutting head. Raise the pinch rollers to remove the protection strip from

underneath the pinch roller assemblies.

S CLASS™ 2 cutter User’s Manual

Setup 1-5

1.2 S CLASS 2 Cutter Components

1.2.1 The Cutter as viewed from the front

FIG 1-10

1-10 S CLASS 2 CUTTER, FRONT VIEW

1. Pinch rollers: The pinch rollers clamp the media to the drive system to ensure accurate

tracking. The S120(T) has one and the S160(T) and S 140(T) have two extra pinch rollers

to ensure that wide media stays flat in the middle. The outer drive pinch rollers have a

selectable pressure; the extra rollers in the middle can be enabled or disabled. Extra

pinch rollers can be added.

Number of pinch rollers S75 S120 S140 S160

Dual pressure 2 2 2 2

Low pressure 0 1 2 2

2. Touch panel: All cutter activity can be initiated from the 320x240 dot touch panel. The

panel displays information about the cutter’s current status and/or actions that need to

be taken.

3. Pinch roller lever: This lever is used to raise and lower the pinch rollers for media

loading.

S CLASS™ 2 cutter User’s Manual

Setup 1-6

4. Media drive sleeves: The media drive sleeves only move the media when the pinch

rollers are in the “down” position. The following table lists the number of sleeves

installed on each model of the S CLASS 2 cutters.

Number of sleeves

S75 (T) S120 (T) S140 (T) S160 (T)

Short sleeve 4 7 8 9

Long sleeve 1 1 1 1

5. Tool carriage: The tool carriage is the carriage for the knife holder, pen or pouncing

tool. It also holds the Optical POSitioning sensor (OPOS) and a cut-off knife to cut a

sheet from the roll when a job is finished.

6. Cutting strip: A self-healing orange strip helps avoid any damage to the knife tip when

no media has been loaded. Since cutting is done on the cutting strip, it is essential that

the strip remains intact.

7. Pouncing strip: An extra black strip to pounce on.

8. Tool holder: The left end cap has a rim so it can be used for tool storage.

9. Screws to secure the cutter base: Make sure all three screws are secured at each side

before the cutter is used.

10. Media basket: The stand and linen media basket come standard with all S CLASS 2

cutters.

S CLASS™ 2 cutter User’s Manual

Setup 1-7

1.2.2 The Cutter as viewed from the back

FIG 1-11

1-11 S CLASS 2 CUTTER, REAR VIEW

1. AC power cord receptacle: It is located at the left-hand side of the power entry

module. The power-up procedure is explained in detail in section 1.3. Always use a

power cord that was delivered with your cutter.

2. Power On/Off switch: This rocker switch, in the middle of the power entry module, sets

the cutter’s power to ON or OFF. To switch on the power, press the “I” side of the rocker

switch. To switch off the power, press the “O” side of the rocker switch.

3. The fuse box: The fuse is located at the right side of the power entry module. Check the

specification section to see which fuse is used in the S CLASS 2 cutter.

WARNING: For continued protection against risk of fire, replace only with the

same type and rating of fuse.

4. USB port type A female: For plugging in a USB stick.

5. Ethernet port RJ45: For connecting the cutter to the LAN.

6. USB port Type B female: This interface is based on the standards, specified in the

Universal Serial Bus Specifications Revision 1.1. It allows a high-speed bi-directional

communication between the host computer and the cutter.

7. Pinch roller lever: This lever is used to raise and lower the pinch rollers for media

loading.

8. Roll media guide bushes: The two flange guides serve to keep the media roll in place

when media is pulled from the roll.

S CLASS™ 2 cutter User’s Manual

Setup 1-8

9. Pinch rollers: The pinch rollers clamp the media to the drive system to ensure accurate

tracking. The S2120(T) has one and the S2160(T) and S2140(T) have two extra pinch

rollers to ensure that wide media stays flat in the middle. The outer drive pinch rollers

have a selectable pressure; the extra rollers in the middle can be enabled or disabled.

Do not move the pinch roller assemblies when holding them from this side.

10. Screws to secure the cutter base: Screws (3 left and 3 right) hold the cutter base on its

stand. All the screws must be properly secured before using the cutter.

11. Tubes for the media basket: Tubes in the back and front hold the media basket. They

can easily be pulled outwards to put the basket in its place.

12. Casters: The casters on the stand are equipped with locking brakes. Once the cutter has

been moved to its new location, press the brakes with your foot to lock the casters.

13. Media support rollers: Rotating support rollers for the media roll.

14. Media basket: The stand and linen media basket come as standard equipment with all

S CLASS 2 cutters.

S CLASS™ 2 cutter User’s Manual

Setup 1-9

1.3 Safety, Ideal Operating Environment, Connecting to the Mains

1.3.1 Safety

1.3.1.1 General

The purpose of the user’s manual is not only to explain the operating procedures of this

machine, but it also provides the owner, users and operators with precaution procedures

for safe and proper machine operation for its intended purpose.

All information in this manual must be read and understood before any attempt is made to

operate the machine.

The manufacturer has no direct control over the machine operation and application. Proper

safety practice is the sole responsibility of the owner, user and operator.

All instructions and safety warnings in this manual are based upon the use of this machine

under proper operating conditions without alterations from the original design.

Any use of the cutter that is beyond the capabilities of the combination knife/material is

considered as improper use and may result in injury and serious damage to the machine

and will lead to loss of warranty.

1.3.1.2 Symbols used in the manual

Warning with dark (red) symbol: Refers to immediate threat that

can cause serious injuries and effects on health and safety.

Warning with light (yellow) symbol: Refers to a dangerous

situation that can cause injuries and serious damage to the

machine.

Attention with dark (red) symbol: Refers to useful information to

prevent damage to the equipment and prolong the service live of

the machine.

Attention with light (yellow) symbol: Refers to useful tips to

enhance the user-friendliness

and make the work significantly

easier.

Note: Can be considered as a general tip; something that is useful

to know.

S CLASS™ 2 cutter User’s Manual

Setup 1-10

1.3.1.3 Safety precautions

WARNING: The S CLASS 2 cutters use razor-sharp knives. Touching the knife

with bare hands may cause injury. Do not touch the knives while the machine is

cutting.

The cutter comes with a tool to insert the knives in the knife holder. Use this tool to prevent

injury. Put used blades in their original packaging for disposal.

The entire base plate should be considered as a dangerous area when the cutter is switched

on and off. The tool carriage can move from the left to the right and the yellow media

sleeves are sharp and can grab loose objects, clothing or body parts.

The cutter constantly measures the current through the motors. If the machine detects the

current is too high, then the current will be cut off to the motors and a fatal error message

will be displayed on the control panel.

Make sure to observe all the caution labels on the cutter.

1.3.2 Operating environment

Environmental conditions can significantly affect the machine’s performance.

The environmental conditions of the machine (without media) are as follows:

Operating Temperature

15 to 35° C

59 to 95° F

Storage temperature

-30 to 70° C

-22 to 158° F

Relative humidity

35 - 75 %, non-condensing

35 - 75 %, non-condensing

It is possible that the environmental conditions of the used media are stricter than those of

the machine itself. Please refer to the documentation about the used media.

Moreover, make sure that the media has had enough time to acclimatize.

NOTE: Keep the cutter away from direct sunlight or a strong indoor light source.

The optical sensors in the machine may be affected, thus causing unexpected

behavior of the cutter.

WARNING: There is a risk of injury from being caught or trapped in moving

machine parts.

Keep hands, hair, clothing and jewelry away from moving parts. Do not wear

jewelry, loose clothing, scarves, open jackets or shirtsleeves.

S CLASS™ 2 cutter User’s Manual

Setup 1-11

1.3.3 Connecting the cutter to the mains

1.3.3.1 Grounding (“Earthing”)

FIG 1-12

1-12 PROPERLY GROUNDED CONNECTION

1.3.3.2 Operating voltage

The power supply detects the line voltage and switches automatically between 110V and

230V.

Fuse Rate: T2.0A, 250V SCHURTER SPT OR EQUIVALENT.

WARNING: Before changing the fuse, make sure that the cutter is completely

disconnected from its power source.

WARNING: For continued protection against risk of fire, replace only with the

same type and rating of fuse.

WARNING: An insulated ground conductor must be installed as part of the

branch circuit that supplies power to the wall outlet, connected to the cutter..

The ground conductor must have the same size, insulation material and

thickness as the grounded and ungrounded branch-circuit-supply-

conductors,

but the insulating seat should be green or green with yellow striping.

The ground conductor described above m

ust be grounded at the electrical

distribution board or, if power is supplied by a separate system, at the power

supply transformer/motor generator set.

The wall sockets, into which the cutter is plugged-in,

must be of the grounded

type. The grounded conductors, serving the wall socket,

must be properly

connected to the ground.

For emergency access, the cutter should be installed near the socket-outlet for

easy access.

S CLASS™ 2 cutter User’s Manual

Setup 1-12

1.4 Powering-on the cutter

WARNING: Make sure the power switch is turned off before connecting the

power cord (the “0” side of the ON/OFF rocker switch should be pressed).

WARNING: Do not use the power cord if it is visibly damaged. Disconnect the

power cord by pulling the plug, not the cable.

WARNING: Keep fingers and other body parts away

from the cutting area.

There are hazardous moving parts.

1. Plug the female end of the AC power cord into the receptacle, located in the power

entry module at the cutter’s rear panel.

2. Plug the male end of the AC power cord into a properly grounded wall socket.

3. Power on the cutter by pressing the “I” side of the ON/OFF rocker switch, which is

located on the power entry module at the rear panel.

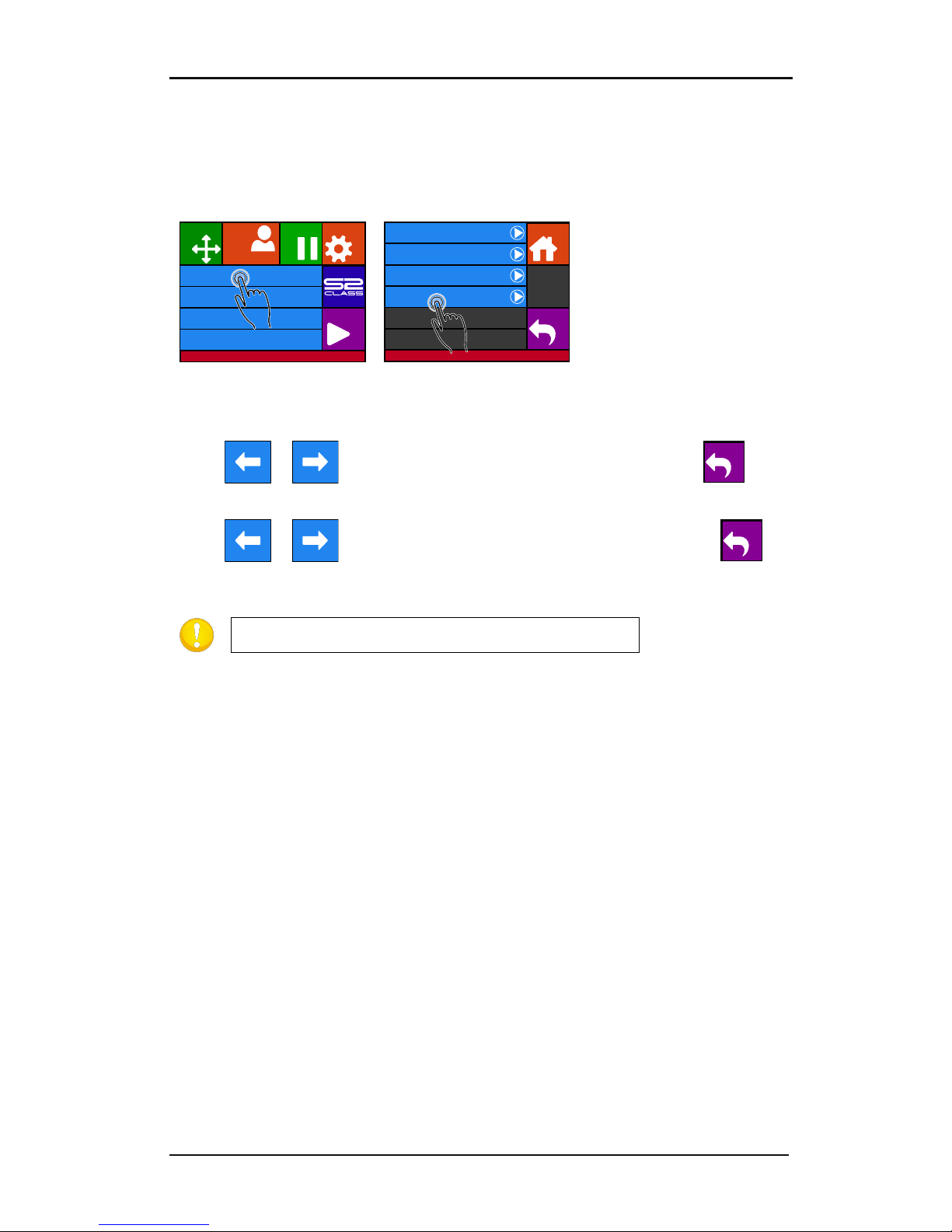

4. The touch screen will activate and the initialization process will begin. If media is

loaded, the cutter will check the size and load the media.

FIG 1-13

1-13 CUTTER IS LOADED AND READY

FIG 1-14

1-14 CUTTER IS READY - NO MEDIA LOADED

Knife pressure 95 gr

Velocity 800 mm/s

Tool Tangential knife

Media size 50000 x 718 mm

Actions

Settings

Configuration 1

PauseOrigin

Summa USB port 1

Action

s

Settings

Configuration 1

I n s e r

t m e d i

a a n

d l o w e

r t h

e p i n c h r o l l e r s

.

S CLASS™ 2 cutter User’s Manual

Setup 1-13

1.5 Connecting the cutter to a computer

The S CLASS 2 cutters support bi-directional USB and Ethernet connectivity. When both

ports are connected at the same time, the port that receives the data first will remain active

and the other port will be deactivated.

1.5.1 USB connection

The USB cable should be 5 meters (16 feet) or less in length. The connector on the cutter

side of the cable should be USB series B 4-pin. The connector on the computer side of the

cable should be USB A 4-pin.

1.5.1.1 Connecting the S CLASS 2 cutter to a PC, using a USB cable

NOTE: When installing a cutter, make sure the user has administrative rights

and UAC is deactivated or set it to its lowest level (not applicable for Windows

XP or earlier versions).

1. Power-off the cutter.

2. Insert the S CLASS 2 CD into the computer’s CD-ROM drive.

3. Choose to run Windows_autostart.

4. Choose the language and click on install USB driver. Wait for the driver to install.

5. Connect one end of the USB cable to a USB port on the computer.

6. Connect the other end of the USB cable to the USB port on the back of the cutter.

7. Power on the cutter (see section 0) and return to the computer.

The Found New Hardware Wizard should appear on the computer screen and install the

USB driver.

8. Click “OK” and follow the instructions, provided by the Wizard.

9. Restart the computer.

NOTE: When connecting a cutter to a computer for the first time, using the USB

cable, the computer will detect the cutter and install the USB driver if the setup

program was run. If the setup program was not run prior to connection, then

install the program while the

cutter is connected and switched on. After the

progr

am is run, the computer will detect a new device and install the correct

driver automatically.

NOTE: In order to connect more than one cutter to one computer, see the

section on the USB class.

NOTE: It is recommended to always use the latest version of the driver. The CD

is made this way it downloads the latest version automatically. If no internet

connection is available, then it is possible that the driver on the CD is outdated.

S CLASS™ 2 cutter User’s Manual

Setup 1-14

1.5.1.2 Connecting the S CLASS 2 cutter to a Mac using a USB cable

Mac OSX

Most recent cutting software does not need a driver installation when a computer is

connected to the cutter. The software that controls the driver is built into the cutting

software.

1.5.2 Ethernet connection

A couple of parameters need to be set when connecting a cutter to the Ethernet. It is best to

check a couple of network settings or ask the network administrator for following info:

Is the network working with a DHCP server or not?

If so, what is the lease time and what is the IP pool range of the DHCP server.

If not, then find out what the used IP range is.

Also ask for the value of the subnet mask.

If the network administrator can already provide a free IP address and the value of the

subnet mask, then go directly to the procedure Case set everything manual

.

If the values are not known at front and need to be searched for, then follow the below

procedure.

In case the DHCP server is used:

If no lease time is set (the lease time is infinite) then no parameters have to be set on the

cutter. Just connect the cutter and write down the IP address to set up the cutting software.

Check the IP address in the communication menu:

1. Power on the cutter (see section 1.4) and connect the Ethernet cable.

2. Press status bar

3. Press LAN

4. Press Status

The IP address (and other

network settings) are shown

on the screen.

If a lease time is set, then use a static IP address. If the IP pool range is known, use an

address outside this range. If this is not possible, try and change the IP pool range of the

network so a couple of addresses are vacant to be used as a static address.

Knif e pres sure 95 gr

Velocity 800 mm /s

Tool Tangential knife

Media size 50000 x 718 mm

Acti ons

Settings

Configur ation 1

PauseOrigin

Summa USB port 1Eth. 192.68.1.7

Comm unication

Back

Home

USB C lass Summa USB port 1

Tool comma nds Accept

LAN ...

Status

Configure

DHCP On

Comm unication | LAN

Back

Home

Calibrez la longeur

S31212-10088

IP:192.168.1.11

Subnet:255.255.255.0

Gateway:0 .0.0.0

DNS1 :0.0.0.0

DNS2 :0.0.0.0

S CLASS™ 2 cutter User’s Manual

Setup 1-15

NOTE: Be careful when changing the IP pool range of a network. Check if there

are no devices attached to the network that uses IP addresses outside the new

IP pool range (use the ping command– see

ping).

If such devices are found,

switch them off and back on after the pool range is changed.

If an address can be chosen outside the IP pool range, check if this address is vacant with

the ping command on a computer in the network (use the ping command– see ping

).

If no address can be chosen outside the IP pool range (the range is not known, or the range

cannot be changed), check the manual of the router if it is possible to link a static IP address

to a mac address. If so, choose a free IP address (use the ping command for this – see

check

if chosen IP is free) and link it to the mac address of the cutter in the router setup or DHCP

setup.

NOTE: it is recommended to work with a static IP address because cutting

software uses a static IP address to send the data to.

If the lease time of the

DHCP server isn’t infinite or if no static IP address is used, it is possible that the

IP address of the cutter suddenly changes and that the cutter software does not

function anymore.

When it was impossible to obtain an address with the above procedures, a ‘trick’ exists to

find a vacant address. In order to do so, check the IP address and subnetmask from the

computer and choose an IP address that is ‘far’ from the IP address of the computer ( add or

subtract 98, but make sure it stays in de range of 2 – 250 )

Check IP config of the computer:

For Windows:

Press simultaneously and . Type “Cmd” (without the “ “) and click on OK. A

program box opens. Type IP config in this box.

For Mac:

Click on the apple menu, system preferences and network. The IP address and subnet mask

are visible.

For Linux:

Go to the Applications Accessories Terminal (or search for terminal). Once the terminal

window is opened, type ifconfig.

Check if the chosen IP address (xxx.xxx.xxx.xxx) is vacant:

S CLASS™ 2 cutter User’s Manual

Setup 1-16

For Windows:

Press simultaneously and . Type “Cmd” (without the “ “) and click on OK. A

program box opens. In this box type ping xxx.xxx.xxx.xxx (xxx.xxx.xxx.xxx being the IP

address that is chosen for the cutter). If there is a reply, this means that the IP address is in

use and cannot be used for the cutter. If there is no reply, this address is vacant and can be

used for the cutter.

For Mac:

Press simultaneously the , and key to open the applications

folder. Then click on Utilities, and Network utilities. In the newly opened window, click on

the ping tab. Enter the IP address (xxx.xxx.xxx.xxx) and click on . If there is a

reply, this means that the IP address is in use and cannot be used for the cutter. If there is no

reply, this address is vacant and can be used for the cutter.

For Linux:

Go to applications Accessories terminal (or search for terminal). Once the terminal window

is opened, type ping xxx.xxx.xxx.xxx (xxx.xxx.xxx.xxx being the IP address that is chosen for

the cutter). If there is a reply, this means that the IP address is in use and cannot be used for

the cutter. If there is no reply, this address is vacant and can be used for the cutter.

Once the subnet mask and IP address are chosen, set these parameters in the cutter.

S CLASS™ 2 cutter User’s Manual

Setup 1-17

In case everything is set manually:

1. Power on the cutter (see section 1.4) and connect the Ethernet cable.

2. Press the status bar

3. Press LAN

4. Press DHCP

5. Press off and then Apply

6. Press Configure

7. Press the parameter that

has to be changed

8. Set the address correctly

and

press apply

9. Press the parameter that

needs to be changed

10. Set the address correctly

and press apply

Knif e pres sure 95 gr

Velocity 800 mm /s

Tool Tangential knife

Media size 50000 x 718 mm

Acti ons

Settings

Configur ation 1

PauseOrigin

Summa USB port 1Eth. 192.68.1.7

Comm unication

Back

Home

USB C lass Summa USB port 1

Tool comma nds Accept

LAN ...

Status

Configure

DHCP Off

Comm unication | LAN

Back

Home

On

Off

Cance l

Apply

Comm unication | LAN

Status

Configure

DHCP Off

Comm unication | LAN

Back

Home

IP 192.168.1.11

Comm unication | LAN

Appli quer

255.255.255.0Subnet

0.0.0.0Gateway

0.0.0.0DNS 1

0.0.0.0DNS 2

Apply

Apply

█00.000.000.000

Comm unication | LAN

0

IP 192.168.1.11

Comm unication | LAN

Appli quer

255.255.255.0Subnet

0.0.0.0Gateway

0.0.0.0DNS 1

0.0.0.0DNS 2

Apply

Apply

█00.000.000.000

Comm unication | LAN

0

S CLASS™ 2 cutter User’s Manual

Setup 1-18

1.6 Loading media

The following procedures apply mainly to the use of roll media. If you are using sheets,

there are two options:

For long sheets, roll up the sheet so that the alignment is identical to that of a roll.

For short sheets, the alignment is not so important. If the sheet is cut off perpendicularly, it

can be aligned to the front border.

1.6.1 Pinch roller positioning

Proper movement of the media will only occur if the media is driven by the two outer pinch

rollers, which are correctly located over two drive sleeves.

The pinch rollers are lowered or raised simultaneously by means of the pinch roller lever

arm, located on the right-hand side of the cutter. The pinch rollers must be lifted to allow

vinyl loading, during which the media is fed from the rear of the cutter to the front. When

raised, the pinch rollers can be moved manually to the left or the right along the pinch roller

shaft.

CAUTION: Always make sure that the pinch rollers are fully raised before sliding

them to the left or right.

Always hold the assembly at the side of the pinch roller to move it from left to

right. Do not reposition the

pinch roller by holding the assembly at the rear of

the machine.

The pinch rollers MUST be positioned correctly and lowered onto the media before an

automatic load sequence is initiated. Make sure that all the pinch rollers are positioned

above a drive sleeve. The outer left pinch roller should be positioned in one of the detents

(click position), just underneath a white triangular label. The outer right pinch roller should

be positioned somewhere over the long drive sleeve. Click positions are located at the

edges of the sleeve (area marked with a white triangular label).

FIG 1-15

1-15 POSITION PINCH ROLLERS

CAUTION: Always leave the pinch rollers in the “up” position when the cutter is

not in use. Leaving the pinch rollers in the “down”

position for a long time will

result in a flat spot in the pinch rollers, which will seriously [negatively] affect

tracking performance and cutting quality.

NOTE:

When the pinch rollers are raised

during a job, the cutter will

immediately stop and move the carriage to the right side.

S CLASS™ 2 cutter User’s Manual

Setup 1-19

1.6.2 Pinch roller pressure setting

The S CLASS 2 cutters are equipped with selectable pinch roller pressure. The pressure can

be set to “standard” or “low.” The change in pressure should only be done when the pinch

rollers are in the down position. When reduced pressure is needed, it is advised to set

autoload to ‘ASK’. Then the cutter will not start to load the vinyl when the pinch rollers are

set down or when the cutter is switched on. A message will appear on the touch screen,

giving the user time to change the pressure on the pinch rollers.

NOTE: Each time the pinch rollers are raised, the pressure is automatically reset

to full pressure.

FIG 1-16

1-16 REDUCING PRESSURE

To work with reduced pressure, do the following:

1. Set AUTOLOAD to ASK (see the section on Autoload:).

2. Load the media in the cutter (see the section on Media load procedure).

3. Push the lever of the two outer pinch rollers upwards and inwards (toward the machine)

– see figure above.

S CLASS™ 2 cutter User’s Manual

Setup 1-20

1.6.3 Loading media

1. Raise the pinch rollers by means of the pinch-roller-lever arm, which is located on the

right-hand side of the cutter, next to the touch panel.

FIG 1-17

1-17 PINCH ROLLER LEVER

2. Loosen the knobs on the two media flanges. The following illustration shows a loosened

flange (1) and a tightened flange (2).

FIG 1-18

1-18 MEDIA FLANGES

3. Insert a loosened flange into one end of the media roll and tighten the knob. Verify that

the flange is secure. Then do the same on the other side of the roll.

4. Place the flange-equipped roll on the media supply rollers. Set the flanges inside the

groove of the flange guide. The flange guides can be moved laterally on the roller.

FIG 1-19

1-19 POSITIONING THE MEDIA FLANGE ON THE CUTTER

NOTE: If the flanges are not used (not recommended – tracking is not

guaranteed), then make sure that the roll is situated

between the two flange

guides.

S CLASS™ 2 cutter User’s Manual

Setup 1-21

FIG 1-20

1-20 FEEDING ROLL MEDIA WITHOUT USING MEDIA FLANGES

5. Start feeding the media from the rear of the machine. Pass the media underneath the

pinch rollers towards the front of the machine.

6. Position the left media edge on the left-most drive sleeve and check whether the right

media edge is positioned over the long drive sleeve. Then position the left and right

pinch rollers.

The pinch rollers should be positioned over the drive sleeves about 3 to 15 mm (0.1” to

0.6”) away from the media’s outer edges (1). Then pull the media while holding the

flange at the back so the media is tight. Make sure the front media sensor is covered (2).

FIG 1-21

1-21 MEDIA POSITION

In circumstances where the above procedure does not work, because the media is too

narrow to reach the long drive sleeve, try positioning the left media edge over the

second left drive sleeve and position the right media edge somewhere over the long

drive sleeve. Continue moving the left pinch roller toward the long drive sleeve until

both pinch rollers click in their designated position and directly over the edges of the

vinyl.

In all cases, both edges of the media must cover a drive sleeve. If this is not the case,

reposition the roll of material to cover the drive sleeve.

7. Make sure that the media follows a straight path from the roll of material. To accomplish

this, slide the media roll and flange guides from the left to the right along the media

support rollers.

S CLASS™ 2 cutter User’s Manual

Setup 1-22

WARNING: Keep fingers and other body parts away from the cutting area.

There are hazardous moving parts.

8. Lower the pinch roller lever to press the media firmly against the drive sleeves. The tool

carriage will move automatically from the right to the left to sense the usable media

width.

FIG 1-22

1-22 PINCH ROLLER LEVER

NOTE:

It is not recommended to unroll the media manually from the roll. The

cutter will unroll the media automatically during the load sequence.

9. The positioning and routing of sheet material is identical to that of roll media.

10. The cutter is now ready.

S CLASS™ 2 cutter User’s Manual

Setup 1-23

1.6.4 Media load procedure

CAUTION: Do not place any objects in front of, or behind, the cutter that could

interfere with cutter operation. Make sure the media is free to move forward

and back. Keep hands, hair, clothing and jewelry away from moving parts.

While the cutter is activated, it will automatically start executing a minimal loading

procedure as soon as the pinch rollers are lowered. The load procedure will also start when

the cutter is switched on while the media is already in the machine and the pinch rollers are

in the “down” position (this is not recommended). Always keep the pinch rollers in the up

position while the cutter is not in use.

The minimal loading procedure consists of:

A media-width measurement.

The media is unwound over a length, equal to the width measured between the

outer two pinch rollers.

A simultaneous 45° axial move of the drive drum (sleeves) and cutting head.

The cutter is now ready to receive files from the computer.

When receiving a job from the computer, the cutter will automatically pull the required

media from the roll. This happens gradually and the length of the used vinyl is equal to

several measured widths of the media.

IMPORTANT:

Tracking of longer signs can only be guaranteed when the full

load procedure is performed!

Full media load procedure:

WARNING: Each keystroke can initiate an internal test or movement of the

head or media. Keep fingers and other body parts away from the cutting area.

There are hazardous moving parts.

S CLASS™ 2 cutter User’s Manual

Setup 1-24

Loading a sheet.

1. Press on Media size

2. Press on Sheet

The cutter will immediately start to load the sheet. It measures the width and loads a certain

length of media, or until the end of the media is reached. The user will then be prompted to

accept the length or not.

3. Press to accept the length or go to step 4.

The cutter will now complete the loading sequence, come online and will be ready to receive

data. The loading sequence conditions the edges of the vinyl for a given length.

4. Press .

5. Press or until the required media-length appears. Then press .

The cutter will now complete the loading sequence. The cutter will come online and will be

ready. The length of the job is limited to the loaded length.

NOTE: If the rear media sensor detects the end of the media, the cutter will

complete the loading sequence without any input from the user.

Knif e pres sure 95 gr

Velocity 800 mm /s

Tool Tangential knife

Media size 50000 x 718 mm

Acti ons

Settings

Configur ation 1

Pause

Origin

Summa USB port 1Summa USB port 1

Velocity 800 mm/s

Load

Back

Home

Roll

Sheet

Extended

Media alignment

Accept

Abort

Apply

S CLASS™ 2 cutter User’s Manual

Setup 1-25

Y: 7 17X: 0

Set origin

Action | Load

Apply

Cance l

Loading a roll.

1. Press on Media size

2. Press on Roll

Four arrows will appear, together

with an “apply” button. The status is

visible in the middle of the righthand side of the screen.

3. Use , , or to reposition the origin, if necessary. Then press

.

Two arrows will stay on the screen in order to load the necessary length.

4. The media length needed for the task can be entered by pressing or . Or

the needed length for the job can be entered by pressing and then by pressing

or to change the value of the default length to load.

Depending on the manner chosen for entering the needed length of the job, the cutter will

either load the length or display the chosen length on screen.

5. Press

.

The cutter will now complete the loading sequence. The cutter will come online and will be

ready. The length of the job is limited to the actual length of the media, left on the roll. The

cutter will always assume a full roll, which means it will use 50000mm (1982 inches) on the

status screen.

NOTE: If the rear media sensor detects the end of the media, the cutter will

complete the loading sequence without any input from the user.

Knif e pres sure 95 gr

Velocity 800 mm /s

Tool Tangential knife

Media size 50000 x 718 mm

Acti ons

Settings

Configur ation 1

Pause

Origin

Summa USB port 1Summa USB port 1

Velocity 800 mm/s

Load

Back

Home

Roll

Sheet

Extended

Media alignment

Apply

Apply

Apply

S CLASS™ 2 cutter User’s Manual

Setup 1-26

Extended load.

The function extended load makes it possible to define the limits of the Y axis so that the

cutter can cut outside the pinch rollers. The media needs to be loaded before this function

can be used.

1. Press on Media size

2. Press on Extended

Two arrows will appear, together with an “apply” button.

3. Use or to reposition the right Y-axis limit (origin). Then press .

Two arrows will stay on the screen. The tool carriage will move to the left Y-axis limit.

4. Use or to reposition the left Y-axis limit (define size). Then press .

The cutting area in the Y-axis has now been redefined.

NOTE: Tracking is not guaranteed when using this mode.

Knif e pres sure 95 gr

Velocity 800 mm /s

Tool Tangential knife

Media size 50000 x 718 mm

Acti ons

Settings

Configur ation 1

PauseOrigin

Summa USB port 1Summa USB port 1

Velocity 800 mm/s

Load

Back

Home

Roll

Sheet

Extended

Media alignment

S CLASS™ 2 cutter User’s Manual

Setup 1-27

1.7 Tool Installation

WARNING: The S CLASS 2 cutters use razor-sharp knives. To avoid serious

injury, be careful when installing, removing or handling the knife!

1.7.1 Cutters with drag head

1.7.1.1 Knife installation

A knife is pre-installed in the cutter.

For safety reasons, the knife depth has been set to zero. Simply turn out the knife (see FIG

1-21 yellow arrow clockwise) to start cutting. Please find the complete description of the

knife removal and knife installation below.

Removing the drag knife

1. Loosen the head clamp screw (1), swing the clamp arm back and remove the knife

holder from the clamp (2).

FIG 1-23

1-23 REMOVING THE DRAG KNIFE HOLDER FROM THE CLAMP

2. Turn the knurled adjustment knob (3) clockwise to push the knife (4) out of the holder

(5).

FIG 1-24

1-24 REMOVING THE KNIFE FROM THE STANDARD DRAG KNIFE HOLDER

3. Carefully pull the knife from the holder.

S CLASS™ 2 cutter User’s Manual

Setup 1-28

Installing the drag knife

1. Remove the aluminum part from the plastic knife holder (5) by turning the knurled

adjustment knob (3) counterclockwise until the aluminum part comes out of the holder.

2. Insert the conical, non-cutting end of the knife into the opening in the narrow end of

the holder. Gently push the knife all the way in.

3. Turn the holder upside down and tap it lightly on a solid surface to ensure that the knife

is completely inserted.

4. Slowly turn the knurled knob clockwise until the tip of the blade extends the distance

required for the desired cutting media (t), as shown in the figure below.

FIG 1-25

1-25 KNIFE LENGTH ADJUSTMENT

5. Insert the knife holder into the rear (1) of the dual head clamp, seating it firmly.

FIG 1-26

1-26 DUAL CLAMP DRAG HEAD

6. Close the clamp and tighten the clamp screw.

1 is the position for knife and pen.

2 is the position for a pouncing tool (see section 1.7.1.3).

S CLASS™ 2 cutter User’s Manual

Setup 1-29

Setting the knife depth and pressure:

WARNING:

Each keystroke can initiate an internal test or movement of the

head or media. Keep fingers and other body parts away from the cutting area.

There are hazardous moving parts.

1. Power on the cutter and load the media.

2. Press on pressure

4. Or fill in the new value

after pressing Numpad.

1. Press to perform the internal knife pressure test.

2. Press to confirm the chosen knife pressure and exit the menu.

3. Press to leave the pressure unchanged.

Once is pressed, the current knife pressure value will be set automatically to the

new value and the cutter will cut the knife pressure test pattern.

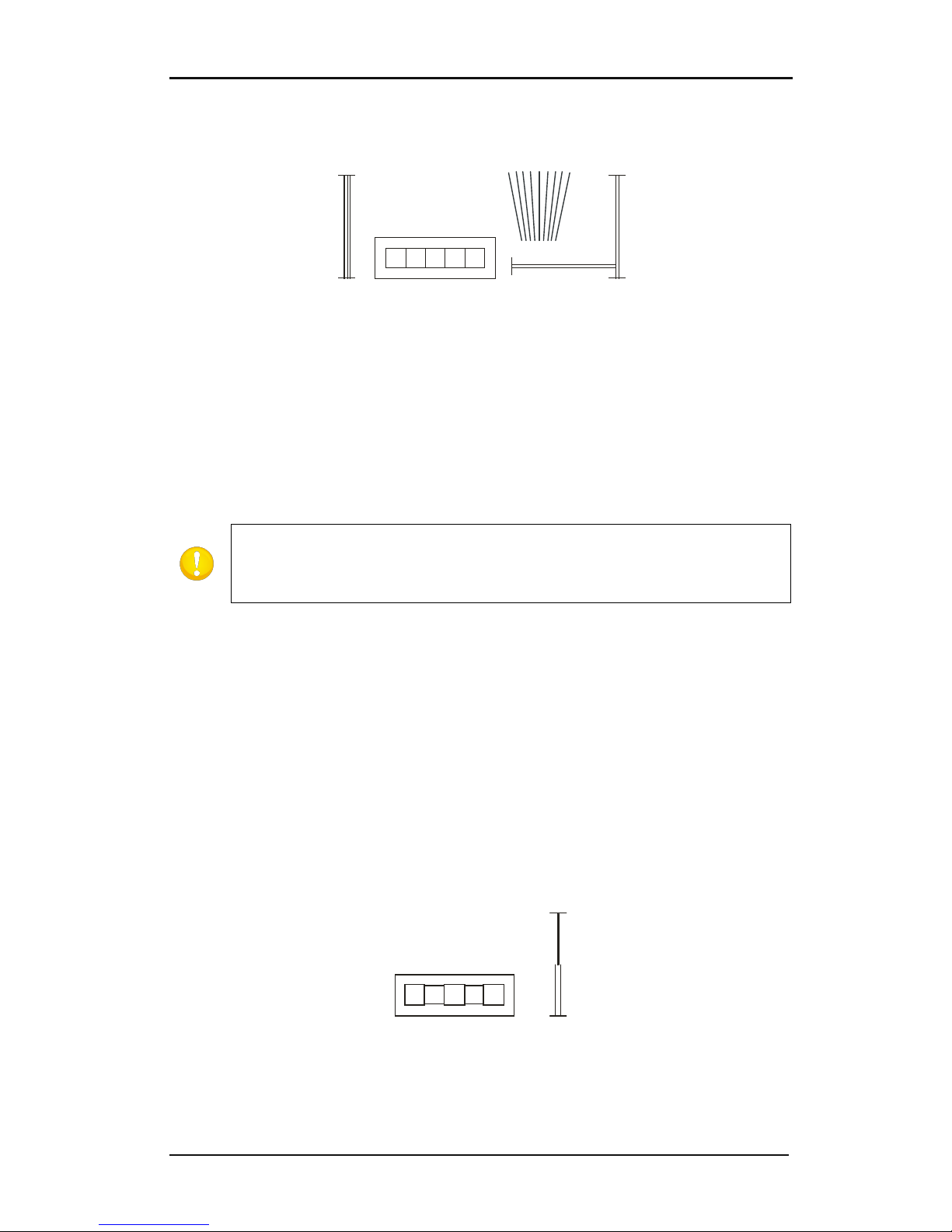

FIG 1-27

1-27 KNIFE PRESSURE TEST PATTERN

Peel out the rectangle and inspect the media backing.

The knife depth is set correctly when the test pattern cuts completely through the vinyl.

and the blade tip visibly scratched the front side of the media backing when the vinyl is

removed. The blade should never cut in the backing but should only slightly scratch the