Cyclo® 6000

Speed Reducers, Gearmotors

and Brakemotors

Operation and

Maintenance

Manual

Manual 04.601.60.002

APPENDIX

Grease Quantities for Units Having Optional Grease Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Food-Grade Lubricants ......................................................................... D-3

Maintenance Free Type:

Single (6060 to 6125)

Double Reduction (6065DA to 6125DB)

Non- Maintenance Free Type

Those units designated as maintenance free in Tables A-3 ~ A-6 do

not require replenishment when supplied with standard greases.

Certain optional greases do require replenishment. Those units will

have a Zerk fitting either on the high speed endshield or near the

input shaft bearing housing.

Replenish grease to the reduction mechanism with 1/3 to 1/2 of the

quantity listed in Table A-9 or A-10 at the interval recommended

in Table A-8. Remove the drain plug from gearbox output section.

Replenish grease through the Zerk fitting. After inserting the recommended amount of grease run the unit for five or 10 minutes to

circulate the grease and purge any excess. Replace the drain plug

and return to service.

When the unit is disassembled for overhauling, refill with the grease

quantities indicated in Table A-9 or A-10. Or alternatively, 80% of

the space around the reduction mechanism and slow speed shaft

bearings of single reduction units, and 50% around the reduction

mechanism of both the first and second stage of double reduction

units.

Apply grease liberally to the central part (i.e., around the eccentric

bearings) of the mechanism. Apply grease to both the slow speed

and high speed shaft bearings as you would to ordinary bearings at

the time or re-assembly.

If excessive grease is added, agitation heating of the grease will

raise the operating temperature of the unit. Avoid excessive greasing, but do not supply an insufficient amount of grease. When the

grease is insufficient, it will raise the unit’s operating temperature

due to breakdown of the lubrication films on the eccentric bearing.

In this case, if the operating temperature rises, supply grease immediately.

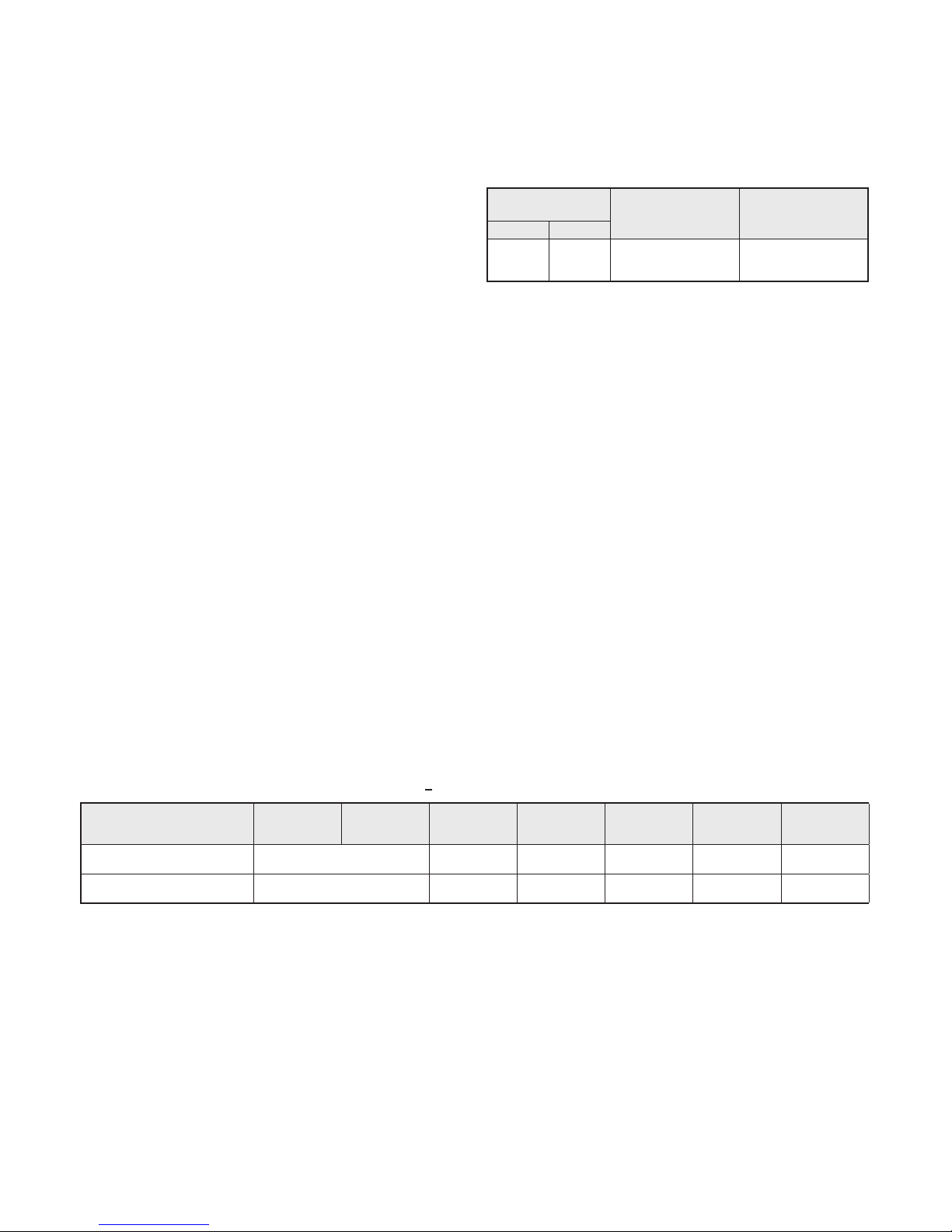

Ambient

Temperature

[2]

Cyclo®

Disc-Type

Cyclo®

Planetary-Type

°F

°C

14 to 122 -10 to 50

Exxon Unirex N2

Grease

Shell Gadus S2 V220

0 Grease

[5]

[5] For non-standard grease units, refer to page Appendix D-2 for grease quantities

[1] Avoid the use of grease other than shown in Table A-7. For Food-Grade Lubricants, see Appendix D-3.

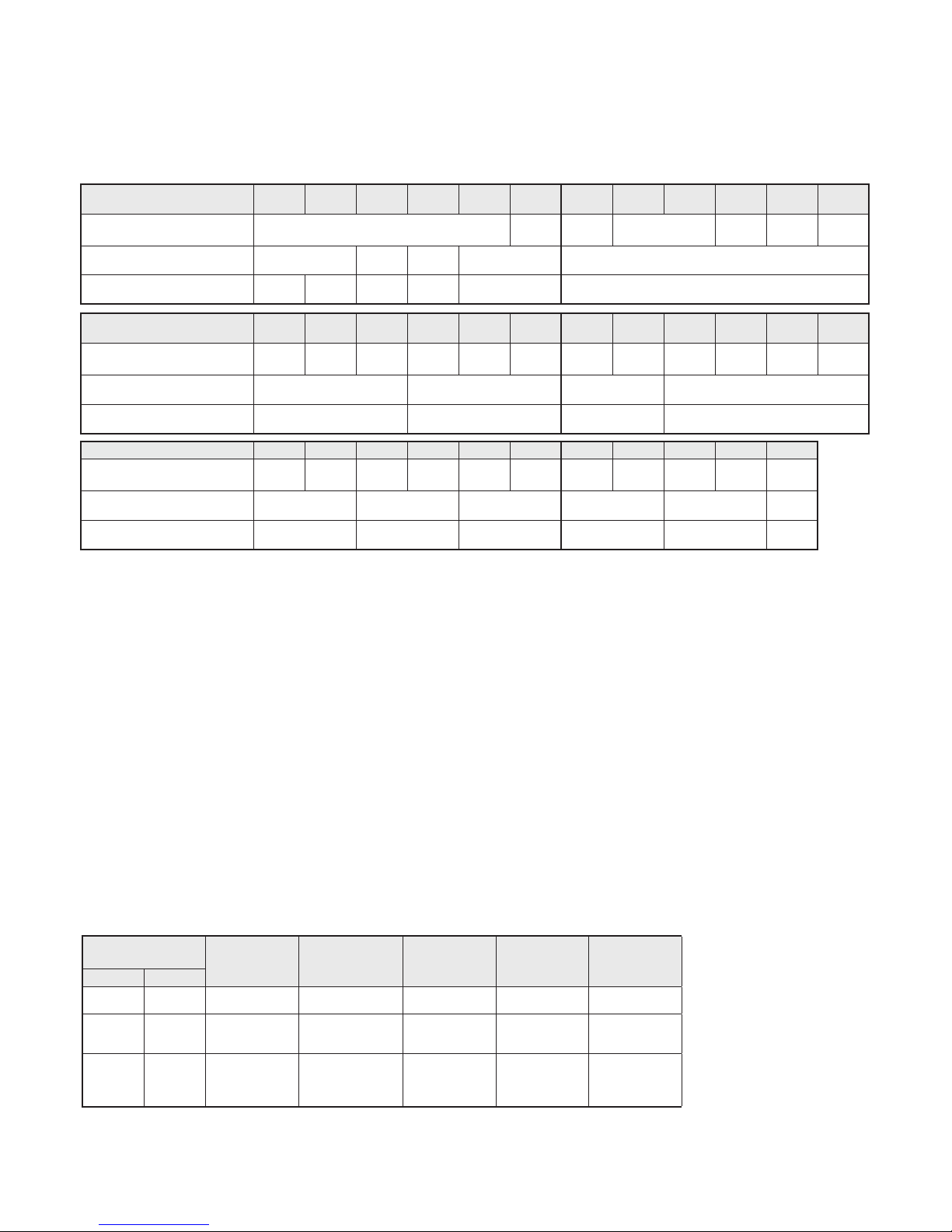

Frame Size

6060

6065

6070

6075

6080

6085

6090

6095

6100

6105

610H

6110

6115

6120

6125

612H

Speed Reduction Mechanism

0.9

(25)

1.4

(40)

2.1

(60)

4.2

(120)

6.7

(190)

8.8

(250)

Slow Speed Shaft Bearing

0.5

(15)

0.9

(25)

1.1

(30)

1.1

(30)

1.6

(45)

1.9

(55)

Planetary-type units use the same oil as that of a Disc-type unit.

The grease type diers between Planetary-type units and Disc-type

units. Planetary units use Gadus S2 V220 0 grease, while Disc units

use standard Unirex N2 grease.

Frame Size

6060DA

6065DA

6070DA

6075DA

6090DA

6095DA

6100DA

6105DA

6120DA

6125DA

6120DB

6125DB

6130DA

6135DA

6130DB

6135DB

6130DC

6135DC

6140DA

6145DA

6140DB

6145DB

6140DC

6145DC

Speed Reduction Mechanism

(1st stage)

0.9

(25)

2.1

(60)

0.9

(25)

2.1

(60)

0.9

(25)

2.1

(60)

4.2

(120)

Speed Reduction Mechanism

(2nd stage)

0.9

(25)

2.1

(60)

4.2

(120)

8.8

(250)

15.9

(450)

Slow Speed Shaft Bearing (2nd

stage)

0.5

(15)

0.5

(15)

1.1

(30)

1.1

(30)

1.9

(55)

10.6

(300)

Frame Size

6160DA

6165DA

6160DB

6165DB

6160DC

6165DC

6170DA

6175DA

6170DB

6175DB

6170DC

6175DC

6180DA

6185DA

6180DB

6185DB

6190DA

6195DA

6190DB

6195DB

6205DA 6205DB

Speed Reduction Mechanism

(1st stage)

2.1

(60)

4.2

(120)

8.8

(250)

2.1

(60)

4.2

(120)

8.8

(250)

4.2

(120)

15.9

(450)

11.6

(330)

15.9

(450)

11.6

(330)

15.9

(450)

Speed Reduction Mechanism

(2nd stage)

26.5

(750)

35.3

(1000)

38.8

(1100)

52.9

(1500)

Slow Speed Shaft Bearing (2nd

stage)

10.6

(300)

17.6

(500)

21.2

(600)

24.7

(700)

Frame Size

6215DA 6215DB 6225DA 6225DB 6235DA 6235DB 6245DA 6245DB 6255DA 6255DB 6265DA

Speed Reduction Mechanism

(1st stage)

15.9

(450)

26.5

(750)

15.9

(450)

35.3

(1000)

26.5

(750)

35.3

(1000)

26.5

(750)

38.8

(1100)

35.3

(1000)

52.9

(1500)

52.9

(1500)

Speed Reduction Mechanism

(2nd stage)

70.5

(2000)

88.2

(2500)

141.1

(4000)

158.7

(4500)

211.6

(6000)

282.2

(8000)

Slow Speed Shaft Bearing (2nd

stage)

28.2

(800)

31.7

(900)

35.3

(1000)

38.8

(1100)

42.3

(1200)

45.9

(1300)

Ambient

Temperature

[1,2]

Exxon Oil Mobil Oil Shell Oil BP Oil Idemitsu

°F

°C

14 to 41 -10 to 5 Spartan® EP 68

Mobilgear® 600 XP 68Omala

®

S2 G Oil 68Energol® GR-XP

68

Daphne Super

Gear Oil 68

32 to 95 0 to 35

Spartan®

EP 100

EP 150

Mobilgear® 600 XP

100,150

Omala

®

S2 G Oil

100, 150

Energol®

GR-XP 100

GR-XP 150

Daphne Super

Gear Oil

100, 150

86 to 122 30 to 50

Spartan®

EP 220

EP 320

EP 460

Mobilgear® 600 XP

220, 320, 460

Omala

®

S2 G Oil

220, 320, 460

Energol®

GR-XP 220

GR-XP 320

GR-XP 460

Daphne

Versatileforce

220, 320

[3] For Food-Grade Lubricants, see Appendix D-3.

[3]

Loading...

Loading...