SU LEE MACHINE

ST-260.4

MODEL

®

ST-360.4

INSTRUCTION BOOK AND PARTS BOOK

SU LEE MACHINE .CO.,LTD.

IMPORTANT SAFETY INSTRUCTIONS

When using your cutting machine,basic safety precautions should always be followed,including

the following

1. Read all instructions.

2. Use machine only for its intended use a portable cutting machine

3. Turn machine to “OFF” before connecting or disconnecing power cord.

4. Do not install or store this machine in a wet location.

5. Keep area around machine free from the accumulation of lint.

6. Always disonnect machine from electrical connector when not in use, before

servicing, and when changing blades

7. Do not operate machine with a damaged cordor if machine has been dropped .Do not

disassemble; take to qualified serviceman for repairs. Incorrect reassemble can cause

electric shock when the nachine is used.

8. Keep visitors away. Do not leave machine unattended while it is connected.

9. Keep hands away from blade.

10. Be sure machine is properly grounded while in use to protect the operator from

electrical shock.

11. Keep machine clean and blaed sharp for best and safest performance.

12. The knife key and other wrenches must be removed from machine before starting

motor.

13. Keep guards in place and in working order.

Save These Instructions

重要安全指導

當你使用斷布機時,必須遵守以下的安全警告指示

1.閱讀所有的指示說明。

2.由經訓練的專人使用操作。

3.接上或取下電源時,機器開關必須先關閉。

4.勿將機器安裝或存放於潮濕的地方。

5.機器周圍地區保持乾淨,遠離棉,毛絮堆積。

6.當機器不使用或保養、維修、更換砂輪、刀片等零件時,必須先拔下電源。

7.請勿自行分解拆裝,應交由合格的技師進行維修,不正確的拆裝將造成電機的損毀和故障

8.非操作人員請勿靠近,操作人員不在時請拔掉電源。

9.保持注意手遠離刀片。

10.確定電源接地。

11.保持機器清潔和刀片鋒利,以備最佳使用狀態。

12.更換刀片務必確定鎖緊並移除相關工具。

13.安全護蓋裝置使用前必須裝好固定。

謹記以上說明

- 1 -

INSTRUTION MANUAL

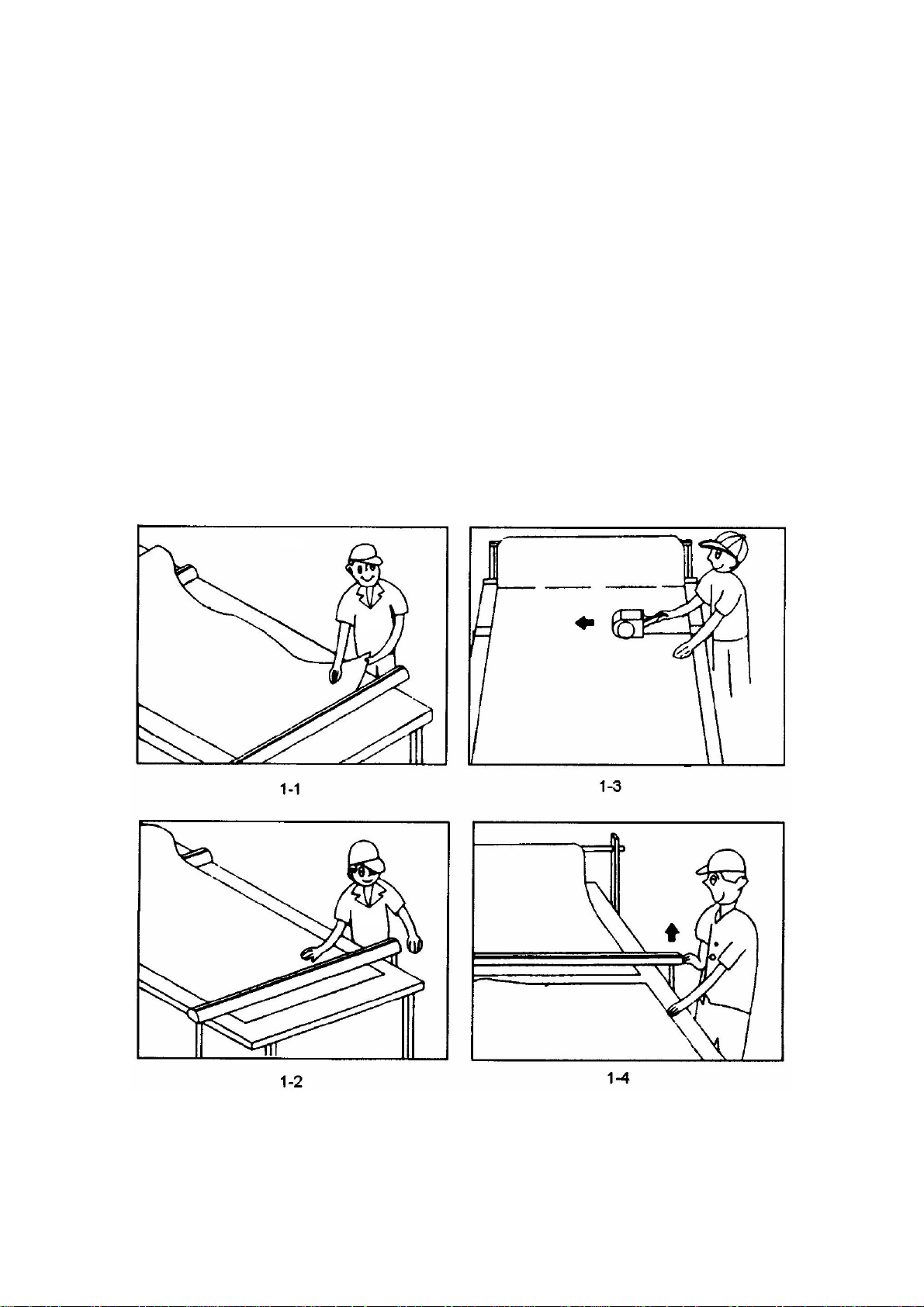

1.1 Connect the terminal,grind the knife 2~3times,reser the counter to 0000,counter switch is

turn ON.

1.2 See pictuer 1-1,pall cloth to end rail.

1.3 See pictuer 1-2,Lift rail to press clothe.

1.4 See pictuer 1-3,Push button switch on,and pull cutter cut off cloth in a straight line.

1.5 See pictuer 1-4,Lift end rail then put down.

操作說明

操作說明

操作說明操作說明

1.1 接

1.2 依圖 1-1 所示,將布拉至尾壓布器.

1.3 依圖 1-2 所示,將布壓夾於裁床.

1.4 依圖 1-3 所示,按切布開關,起動切刀向前推,將布切斷.

1.5 依圖 1-4 所示,抬起軌道,使布料自行落下,並放下軌道,將布料壓固於裁床.

通電源,磨刀 2~3 次,將計數器歸零,計數器開關置於零 ON.

•

1-1

1-2

1-3

1-4

- 2 -

INSRUCTION AND PROCESS OF INSTALLATION

2.1 Align the right foot rest 263946N-R and the left foot rest 263946N-L and secure both on the

cutter.

2.2 Place the right hoist rod 264749N from top to bottom into the pulley groove of the right rest

263946N-R and the left hoist rod 264750N from top to bottom into the pulley groove of the

left rest 263946N-L.

2.3 As shown in Fig.2-2, secureone end of the hoist belt 2662 onto the right rest 263946N-R

and the other end onto the pulley on top to of the left hoist rod 264750N through thepulley

2649 on top of the pulley of pulley set 2650.(Note:the hoist belt must be tightened and the

right hoist rod 264749N and the left hoist rod 264750N shall be kept at the same level)

2.4 Place the track 265359 at equal distance on top of the right rod 264749N and the left hoist

rod 264750N,while securing both using the track cecuring screw 2660.

2.5 Place the left end of the track into the track end lid 2655N and lock it using screw PRM0510.

2.6 Place in the fabric-cutting machine 260138 and drop in some sewing machine oil into the

track.

2.7 Place the right end of the track into the track lid 2655N and the lock it using screw

PRM0510.

2.8 Hang the lift aid spring 2644-A on the right rest umder the right hoist rod 264749N(as shown

in Fig.2-1)

2.9 Mount the fabric rack 2651 as shown on the cutting bed.

2.10 Plug in the power cord 523C1 to finish the process.

安裝說明

2.1 將右腳架組 263946N-R 與左腳架組 263946-L 對齊,緊固於裁床兩旁.

2.2 右升降組 264749N 由上而下放入右腳架組 263946N-R 之內,左升降桿組 264750N 由上而下

放入左腳架組 263946N-L 之滑槽內.

2.3 如圖2-2 所示,將升降帶2662一端緊固於右腳架組263946N-R,另一端經右升降桿組 264749N

上端之滑輪 2649 到對面左升降桿組 264750N 上方之滑輪,再穿過滑輪組 2650 之滑輪往上,

最後緊固於左腳架組.

(注意:升降帶必須拉緊,並使右升降桿組 264749N 與左升降桿組 264750N 同等高度)

2.4 軌道 265359 等距置放於右升降桿組 264749N 及左升降桿組 264750N 上方以軌道固定螺絲

2660 固定.

2.5 軌道左端置入軌道端蓋 2655N,用螺絲 PRM0510 鎖上.

2.6 放入切布主機 260138,並於軌道內滴入少許針車油潤滑.

2.7 軌道右端置入軌道端蓋 2655N,用螺絲 PRM0510 鎖上.

2.8 將右腳架組上之提升輔助彈簧 2644-A 掛於右升降桿組 264749N 之下方(如圖 2-1 所示).

2.9 撐布架組 2651 依圖於組裝於裁床.

2.10 插上電源插頭線 523C1 即可.

- 3 -

~~655N-Bl-2

~fl'

'

'

4 7 49N

'

'

'

'

'

✓

-~~f

✓

-~~~i~t1/

...-:%~

035

~

MODEL:ER-109

CLOTH

(CHOICE

PRESS

l!ll-t!i

EQUIPMENT)

:ff

(~ffliflft'.11:f:)

- 4 -

CHECKING (Release connecting plugs)

3.1 Every 24 hours, Clean the Rail bar.

3.2 Every 200 hours, Give oil to roller 2611-BN

3.3 Adjustment of Re-sharpener:

While the grinding wheel wears ,loosen stop nut of collar holder and rectify the re-sharpener

position so as to the grinding wheel keeps proper contact with the knife edge.

3.4 Replacement of Grinding wheel,See Grinding wheel Replacement Guide.

3.5 Replacement of knife:

1. Remove the knife guard 2633 and knife cover 2633C.

2. Lock the knife to the Standard 2609,insetting 2.5mm spanner 2666 to hole in the knife.

The corresponding hole for locking knife is also provided in the standard ,Remove knife

lock hut 2630N

by turning it left Use the wrench 2666 attached.

3. Remove knife.

4. Be sure the front face of the knife when re-setting the knife “SU LEE ST-260”markde face

is the front face.

5. Adjust the position of re-sharpener 2626 after each replacement of knife.

3.6 Replacement of Carbon Brush

1. Too much weaving of carbon brush will cause motor troubles. Carbon brush must be

replaced when it wears to 5-6mm.

2. Carbon brush cap S105 is replaced by turning it left by attached wrench.

3. Always replace right and lift carbon brushes simultaneously.

4. Be sure to hold metallic part of the brush , keep fingers away from carbon.

保養與檢修(注意:將插頭拔掉)

3.1 每使用 24 小時,清理軌道內部之棉布絮.

3.2 每使用 200 小時,請於滑輪 2611-BN 處加少許潤滑油.

3.3 磨刀石的調整:

當刀片磨損時,將磨刀石螺絲放鬆,調整磨刀石位置,使砂輪與刀片的邊緣保持正確的接觸面,在

將螺絲旋緊即可.

3.4 砂輪的更換請看圖解所示.

3.5 刀片的更換:

1.將前護片 2633 及刀片護蓋 2633C 取下.

2.使用內六角扳手 2667 插入刀片孔內,使刀片卡鎖在馬達座 2609 上,不會轉動,再使用鎖刀扳

手 2666 將鎖刀螺帽 2630N 依反時針方向轉開.

3.取下刀片.

4.裝刀片時請確定刀片上印有“SU LEE ST-260”字樣的一面,即正面朝向外面,人可看到.

5.每次更換刀片後,須將磨刀石 2626 重新調整至適當位置.

3.6 碳刷的更換:

1.碳刷磨損太多時,可能損壞馬達,當碳刷磨損到長度剩下 5~6MM 即可更換.

2.只須將碳刷蓋 S105 轉開即可取出舊碳刷,再將新碳刷置入,將碳刷蓋旋上即可.

3.通常更換碳刷時,請將左右兩個同時更換.

4.裝入時,請確認碳刷有接觸在金屬整流子上,勿用手碰碳刷.

- 5 -

26070

SlO

2631

LOOSEN(~)

"-

~

2630-:?-

666

"-

633[

SPECIFICATIONS:

Knife Size :108mm(4 ¼inches)

Knife Shape :Round

Cutting Capacity :10mm

Voltage :Single Phase 1

Cycle

Power :130W

:50~60Hz

OOV~120V

or

220V~240V

m~:

7JJ=r

R-t

]J

J=r%)jjt

~llrntjJ

~

le@,

~j

$uul±\J)J$

l!

$

'

:108mm(4 ¼~o-1)

:

[;]]J

:10mm

: ]i[:ffl 1

:50~60Hz

:130W

DOV~

E!X:

220V~240V

120V

26013

1

~0

8

=1

1§1

DOUBLE

INSULATE

1§1

~Jitfg~

CE

CE

- 6 -

S\vM

NTM

618

~-3

I

I

I

I

I

I

I >

I

'------36 - / S\,IM5

' /

~

DR

601N-AD

~3

ST-260

,\

,)

/

/,,,,

✓~

/

"'

61922N I

I

~,,/

2635-•o

RM040

/

,,,

,,/

SM053

-22~~

l1LJ

I I

NT

~/

/ 0 '-

,;;:,

(

2611

2611-

-102

I ' '

l

636

I

634

/'.'-

'-

,/.

7

/

/ /

/

/

'- '- '-

S~3

·

Sl

S17

261

/

66

'~

TM6

'-

S\vM6<

~;;;

'-

'-

' '

1/2627~

<·

SM052

~~MS

'-

~~M0508/

" /

✓617 < ~

'

~

15

616

>

'-1/

'-e61416

26232\

J

PRMO

~,.in~-/"-,/

'

,, ,,

//

.

~.

I 631

::;

~

~

•

~;

/

'-2614-3

6

633C

i~::~,

)

)

I

I

2034-7'

8'

9'

10'

12'

- 7 -

652-7'

10'

8'

9'

12'

<

/

2658-7'

~

2662-7'

~

8'

9'

10'

12'

8'

9'

10'

12'

655N-Bl-

2

~

~

/65359-7'

~

~

~

" I •

266[]-__

8'

9'

10'

~

12'

657

'----l

,.655N-B2-2

I

I ,

~I

I o /

1" / /

"'

I

,ti"::_"

¢ I

~

~

~

~

655N-A

/ •

~

~

~

~

"SHSC

65~"

'""I

_I,,,

i

I

I

I

I

I

I

I

fM0510

'-

640

'----

'~

-------

I

I

I

M0630

-------

641

7

I

I

I

I

I

v63946N-L

I

P\./MJ

S\./M-

NTM::;

I

I

I

I

I

l

~

®.•

@

~

~/

I

-------

SM0510

• I

I

I

J

/

/ / "

'-

'-..

'- >

7'

649

,

.✓

TM5

\./M6

I

I

I

L

I

I

I

J

- 8 -

FOR ST-260C & ST-360C & ST-288C MODEL:ER-109

P\.IM

S\.IM

NTM

649

~64750N

'i

i

I

I

I

L - - - -

/~/650

/ '

/ '

/ '

/ '

(///

TM508

!l

! :

'

,,~~~6

_1

----~:___~_M06151

648N :

650-A)

i - j

,---

I

~osii4o

i

------7

646

I I

I " I

:

,~

1

-~-,

647-BR

I

v63946N-L

I

I

I

I

L

__________

\.IM6

11~~~11

TM610

I

I

I

I

J

- 9 -

PART NO. PART NAME

零件名稱

PART NO. PART NAME

零件名稱

260110-110 110V Motor

260110-220 220V Motor

260138-110 110V Cutter Head

260138-220 220V Cutter Head

2601-110 110V Stator

2601-220 220V Stator

2602-110 110V Armature

2602-220 220V Armature

2606 O Ring

2607 Motor Cover

2608 Screw For Stator

2609 Motor Plate

2611N Standard

2611-BN Roller

2611-C Roller Shaft

2613 Screw For Pressure Spring

261416 4th Lower Blade

2614 4th Lower Blade Arm

2614-3 3rd Lower Blade

2615

2616

2617 Screw for 4th Lower Blade

2617-3 Screw for 3rd Lower Blade

2618 Balance Iron

261922N Drive Handle Set

2619N Handle Cover

2620 Switch

262327 Sharpener

2623 Grinder Collar

2624 Spring for Collar

Lower Blade

Screw for Lower Blade

110V馬達組

220V馬達組

110V 切刀主機

220V 切刀主機

110V 定子

220V 定子

110V 轉子

220V 轉子

O型環

馬達殼

定子固定螺絲

馬達座

L型基座

滑輪

滑輪軸

底刀彈片固定螺絲

4代底刀組

4代底刀架

3代底刀組

底刀片

底刀片固定螺絲

4代底刀組固定螺絲

3代底刀組固定螺絲

平衡塊

新短手把組

新短手把蓋

手把開關

磨刀石組

磨石套管

磨石套管彈簧

265359-9' 9feet Rail Set

-10'

2655N Rail Guard

2655N-B1-2 Long Spring

2655N-B2-2 Short Spring

2657-7' 7feet Rail Steel Belt

-8'

-9'

-10' 10feet Rail Steel Belt

2658-7' 7feet Rail Rubber belt

-8'

-9'

-10'

2660 Screw for Rail

2662-8' 8feet Lifter Belt

-10'

2666 Wrench

2667 2.5mm Spanner

S104 Carbon Brush

S105 Cap for Carbon Brush

S105-A Seat for Carbon Brush

S169 Oilier

S178 Pressure Spring for Lower Blade

2032 Rocker

2032-B Screw for Rocker

2032-C Screw Cap

2033-B Rocker stop screw

2033-C Rocker stop screw cover

2034-7' 7feet Rocker Bar

-8' 8feet Rocker Bar

10feet Rail Set

8feet Rail Steel Belt

9feet Rail Steel Belt

8feet Rail Rubber belt

9feet Rail Rubber belt

10feet Rail Rubber belt

10feet Lifter Belt

9呎軌道組

10呎軌道組

軌道護蓋

長防撞彈簧

短防撞彈簧

7呎軌道鋼帶

8呎軌道鋼帶

9呎軌道鋼帶

10呎軌道鋼帶

7呎軌道膠條

8呎軌道膠條

9呎軌道膠條

10呎軌道膠條

軌道固定螺絲

8呎升降帶

10呎升降帶

鎖刀扳手

2.5mm 內六角扳手

碳刷

碳刷蓋

碳刷座

油壺

底刀彈簧

搖臂

搖臂螺絲

搖臂螺絲套

搖桿臂固定螺絲

搖桿臂固定螺絲套管

7呎搖桿棍

8呎搖桿棍

2625 Collar Holder

2626 Emery Wheel

2627 Grinder Arm

2630N Lock Nut for Knife

2631 Round Knife

2633 Knife Guard

2633C Knife Cover

2634 Terminal Box

2635-110 110V Counter

2635-220 220V Counter

2636 Counter Switch

2638 Cover for Terminal Box

263946N-L Left Clamp Set

263946N-R Right Clamp Set

2639N A Clamp

2640 Lift Belt Catch

2641 Bar lifter Roller

2644-A Spring for Lift

2645 Big Screw

2646 Washer for Big Screw

264749N Right Bar Lifter

264750N Left Bar Lifter

2647-A Bar Lifter Plate

2647-BL Left Bar

2647-BR Right Bar

2648N Roller for Lift Belt

2649 Roller Shaft

2650 Roller Set

2651 Sustaining Frame Unit

2652-7' 7feet Sustaining Bar

磨石套管支架

砂輪組

磨刀石架

銷刀螺帽

圓刀片

前護片

刀片護蓋

配電盒

110V 計數器

220V 計數器

計數器開關

配電盒蓋

新左腳架組

新右腳架組

A型腳架

升降帶固定片

藍輪

提升輔助彈簧

轉螺絲

碗型華司

新右升降桿組

新左升降桿組

升降桿座

左升降桿

右升降桿

升降帶滑輪

滑輪軸

滑輪組

撐布支架

7呎撐布棍

-9'

-10'

2035 Cloth Fixture

508C1-101 220V Socket

-102

523C1-101 220V Cable Set

-102

HM0825 Screw M8×25 Nut Cap

NTM508 NUT M5-0.8 Hex

NTM610 NUT M6-1.0 Hex

NTM8

PM0416

PRM0306 Screw M3×6 Plate Round Cap

PRM0510 Screw M5×10 Plate Round Cap

PWM5 Washer 5.3×10

PWM6 Washer 6.4×11.5

PWM8 Washer 8.4×15.5

RM0408 Screw M4×8 Round Cap

RM0508 Screw M5×8 Round Cap

RM0535 Screw M5×35 Round Cap

RM0615 Screw M6×15 Round Cap

RM0630 Screw M6×30 Round Cap

SM0520 Screw M5×20 Flat Cap

SM0620 Screw M6×20 Flat Cap

SM0630 Screw M6×30 Flat Cap

2661-7' 7feet Cloth Hold Bar

-8'

-9'

-10'

360138-110 110V Long handle Cutter Head

9feet Rocker Bar

10feet Rocker Bar

110V Socket

110V Cable Set

NUT M8-1.25 Hex

Screw M4×16

8feet Cloth Hold Bar

9feet Cloth Hold Bar

10feet Cloth Hold Bar

9呎搖桿棍

10呎搖桿棍

布卷固定器

220V單相插座組

110V單相插座組

220V單相插頭組

110V單相插頭組

M8×25六角螺絲

M5六角螺母

M6六角螺母

M8六角螺母

M4×16切尾螺絲

M3×6扁圓頭螺絲

M5×10扁圓頭螺絲

M5平華司

M6平華司

M8平華司

M4×8圓頭螺絲

M5×8圓頭螺絲

M5×35圓頭螺絲

M6×15圓頭螺絲

M6×30圓頭螺絲

M5×20沉頭螺絲

M6×20沉頭螺絲

M6×30沉頭螺絲

7呎壓布軌道組

8呎壓布軌道組

9呎壓布軌道組

10呎壓布軌道組

110V長把切刀主機

-8' 8feet Sustaining Bar

-9'

-10'

2652-C Sustaining Bar Ring

265359-7' 7feet Rail Set

-8'

9feet Sustaining Bar

10feet Sustaining Bar

8feet Rail Set

8呎撐布棍

9呎撐布棍

10呎撐布棍

撐布棍定位環

7呎軌道組

8呎軌道組

360138-220

3601N Long Handle

3601N-SP Spring

3601N-C1 Rear Arm

3601N-AD Front Arm

220V Long handle Cutter Head

220V長把切刀主機

長手把組

轉軸彈簧

長後段鋁頭

長把短前臂

...

...----

.....

CR)

_______

,..

SU

LEE

MACHINE

SU LEE MACHINE IND.CO.,LTD.

Loading...

Loading...