OPERATING MANUAL FOR SELECT EDI 60

Issue: A L300180 1

SELECT EDI 60

Part No. L300180

OPERATING MANUAL

Issue – A

10/03/17

OPERATING MANUAL FOR SELECT EDI 60

Issue: A L300180 2

CONTENTS PAGE

1 DOCUMENT HISTORY ........................................................................... 4

2 PREFACE ................................................................................................ 5

3 CONTACT DETAILS ............................................................................... 6

4 HEALTH AND SAFETY ........................................................................... 7

4.1 Explanation of symbols and references .............................................. 7

4.2 Additional safety requirements ............................................................ 7

4.3 Intended use. ...................................................................................... 7

4.4 Operating staff .................................................................................... 8

4.5 Safety information for maintenance tasks ........................................... 8

4.6 Disposing of system parts and operating materials ............................ 9

4.7 Unauthorised conversion and manufacturing replacement parts ........ 9

4.8 Warranty claims and liability ............................................................... 9

5 ABOUT YOUR WATER PURIFIER ........................................................10

5.1 The Select edi 60 range .................................................................... 10

5.2 Key components of the Select edi 60 ............................................... 10

5.2.1 Touch screen display ..................................................................... 10

5.2.2 Storage tank .................................................................................. 10

5.2.3 Removable front cover. ................................................................. 11

6 OPERATING YOUR WATER PURIFIER ................................................12

6.1 Power on screen ............................................................................. 12

6.2 Menu structure .................................................................................. 13

6.3 Clean routine menu .......................................................................... 13

6.4 Settings menu ................................................................................... 13

6.4.1 Time and date ................................................................................... 14

6.4.2 Alarms ........................................................................................... 15

6.4.3 Maintenance .................................................................................. 17

6.4.4 Systems menu ............................................................................... 18

6.4.5 Engineer menu .............................................................................. 19

6.5 Factory Default settings .................................................................... 23

6.5.1 Setting menu defaults .................................................................... 23

6.5.2 System menu defaults ................................................................... 23

6.5.3 Engineer menu defaults ................................................................. 24

7 MAINTENANCE ......................................................................................25

7.1 Replacing the media pack ................................................................. 25

7.2 Cleaning the inlet screen filter ........................................................... 26

7.3 Replace main PCB battery ................................................................ 27

8 DISINFECTION PROCEDURE ...............................................................29

9 CONSUMABLES & ACCESSORIES ......................................................30

10 TROUBLE SHOOTING ...........................................................................31

10.1 General fault conditions ................................................................. 31

10.2 Alarm/Warning messages.............................................................. 31

TECHNICAL SPECIFICATION ......................................................................33

10.3 Product outputs ............................................................................. 33

10.4 Treated water specification ............................................................ 33

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 3

10.5 Water storage ................................................................................ 33

10.6 Electrical specifications / connections ........................................... 33

10.6.1 Mains supply .............................................................................. 33

10.6.2 Fuse rating / type........................................................................ 33

10.6.3 Alarm port connection details ..................................................... 33

10.6.4 USB Mass storage device .......................................................... 34

10.6.5 Main PCB Battery Specification ................................................. 34

10.7 Feed water specification ................................................................ 34

10.7.1 Feed water quality ...................................................................... 34

10.7.2 Feed water pressures ................................................................. 34

10.8 Water services connections ........................................................... 35

10.9 Weights and dimensions ............................................................... 36

10.10 Environmental ................................................................................ 36

10.11 Cartridge outputs ........................................................................... 36

11 INSTALLATION ......................................................................................37

11.1 Unpacking...................................................................................... 37

11.2 Installation Kit ................................................................................ 37

11.3 Cartridge media pack .................................................................... 39

11.4 Unit positioning .............................................................................. 39

11.4.1 Bench mounted .......................................................................... 39

11.4.2 Wall mounted ............................................................................. 40

11.5 Drain connection ............................................................................ 42

12 APPENDIX ..............................................................................................43

12.1 MSDS ............................................................................................ 43

12.2 Pushfit water connections .............................................................. 44

12.3 Process.......................................................................................... 45

12.4 CE declaration ............................................................................... 47

12.5 WEEE declaration ......................................................................... 48

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 4

1 DOCUMENT HISTORY

Issue

Date of

Change

Description of Change

Approved by

A First Issue: 10/03/2017

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 5

2 PREFACE

This Operating Manual provides all of the information and instructions

needed to install, operate and maintain your SELECT edi 60 water purification

unit.

Please read the instructions carefully and make sure that you fully understand

the information given before operating the unit.

Details on how to install & commission your unit can be found in Section 12.

Details on how to operate your unit can be found in Section 6.

Details on how to maintain your unit can be found in Section 7.

Warning:

Before operating the unit always check to see that the water and electrical connections are

secure and not likely to cause a trip hazard. If you have concerns about the unit or are unsure

of its operation contact SUEZ Water Purification Systems limited or supplier for assistance.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 6

3 CONTACT DETAILS

Should you require any additional information relating to the servicing,

maintenance, spares and consumables, simply contact SUEZ using the

details below:-

Water Purification Systems Ltd

Bandet Way

Thame

Oxfordshire

OX9 3SJ

United Kingdom

(Or your local distributor; (see www.suezwater.co.uk for details)

For all spares, consumable and general sales enquiries contact:

Customer Services Department: Tel No. +44(0)1844 217141

For all service enquiries contact:

Service Department: Tel No. +44(0)1844 211555

E-mail :

mail.waterpurificationsystems.uk@suez.com

Website:

www.suezwater.co.uk

Or follow us on:-

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 7

4 HEALTH AND SAFETY

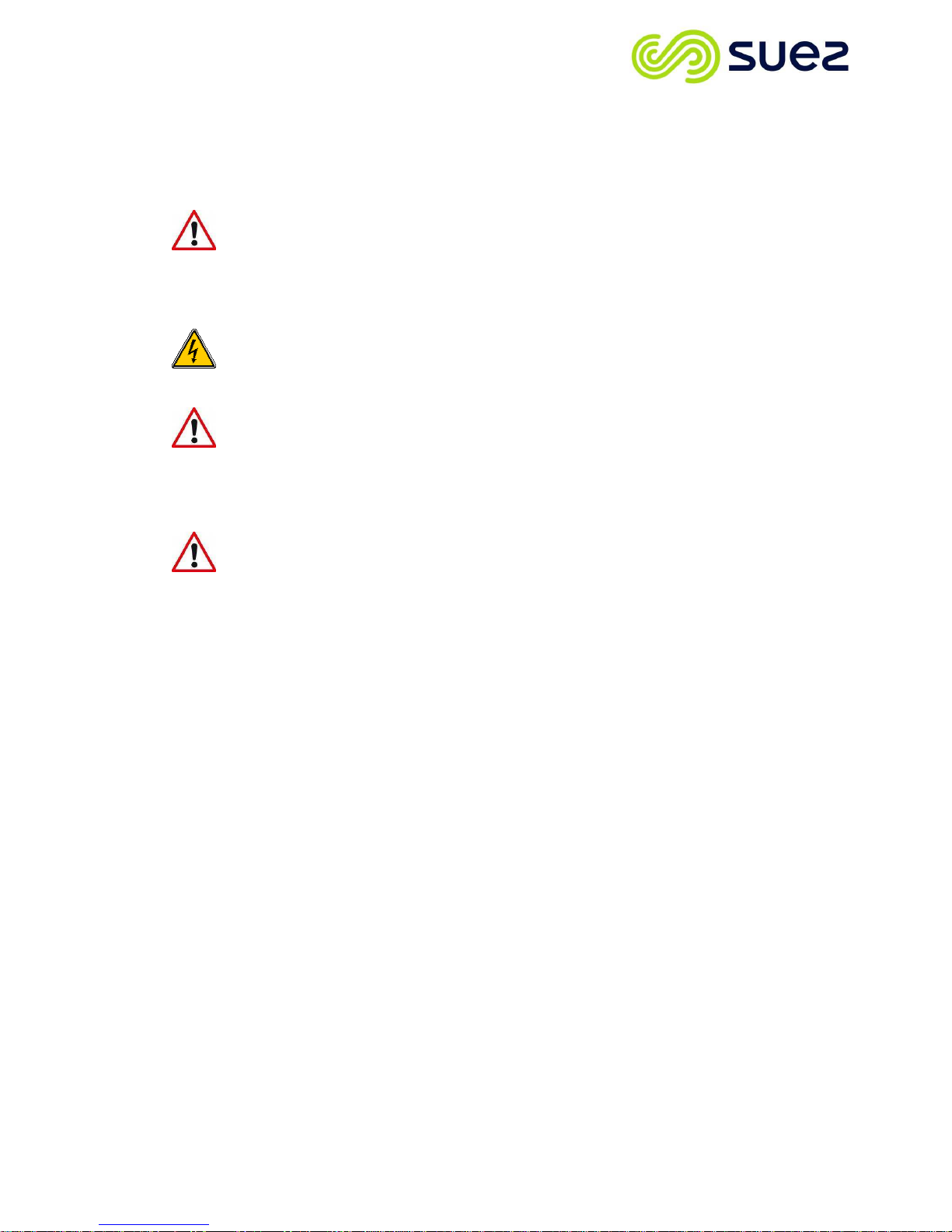

4.1 Explanation of symbols and references

This symbol refers to any immediate dangers. Failure to

follow the specified procedure could result in serious

personal Injury. Extreme caution should be observed when

conducting any activity where this symbol is shown. Work

should be completed by a trained competent person.

Electrical shock. Do not touch electrical components. Before

performing tasks on parts of the electrical system, disconnect the

system from the power supply.

This symbol refers to a possible danger. Failure to follow the

specified procedure could result in personal injury. Caution

should be observed when conducting any activity where this

symbol is shown. It is recommended work should be completed

by a trained competent person.

This symbol refers to a possibly hazardous situation.

Failure to observe these references may result in minor injuries

and/or damage to property.

I

This symbol points out important information for working with the

system in the proper manner. Failure to observe these references

may result in malfunctions in the system or impact on the

environment.

4.2 Additional safety requirements

Country-specific requirements standards and regulations must be

observed.

4.3 Intended use.

The Select edi 60 unit has been specifically designed for indoor use only

to purify potable drinking water for use in laboratory applications or similar

applications requiring highly purified deionised water. Refer to Section

11.5 for details of feed water limitations and Section 11.2 for treated water

specification. For more details relating to the intended use of the

equipment refer to the following notes.

Danger

Warning

Caution

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 8

Warning

The unit is not for use in explosive of oxygen rich atmospheres.

The unit is for indoor use only and must not be washed down.

The unit must not be allowed to freeze or be stored at temperatures below 5ºC.

Always operate in a well ventilated area and ensure the cooling vents are not covered.

DO NOT sit on the unit, place items on top of it, or use it as a step.

Always operate the unit on a firm and level surface.

DO NOT drink the purified water produced by the unit/system. It should only be used

for the purposes intended to provide purified water for laboratory use.

If the unit develops a water leak follow the procedure in Section 4.4, DO NOT continue

to operate the equipment.

Always isolate the mains electrical power supply before working on the unit.

If the unit’s performance becomes impaired and any remedial work appears to be

outside the scope of this manual, do not operate the unit and seek advice from SUEZ.

The unit must only be serviced and maintained by SUEZ Service personnel or SUEZ

approved and trained technicians.

Failure to observe the instructions contained in this manual may compromise the

safety, performance and reliability of the unit and may void any warranties.

Under no circumstances try to service or repair the system yourself if you have not

been trained and approved to do so.

4.4 Operating staff

Only persons who have read and understood this Operating Manual

should be permitted to operate the unit. When operating the units, it is

important to observe all safety information.

Bringing the system to an immediate stop in the event of an emergency

• Press “STOP” on the display two times, (Fast stop).

• Turn off the electrical supply.

• Shut off the water supply.

After remedying the damage and checking that it is safe to use:-

• Open the water supply.

• Turn on the electrical supply.

• Restart the unit via the main display.

4.5 Safety information for maintenance tasks

The operator must take care to ensure that all maintenance, inspection

and assembly tasks are performed by authorised and qualified personnel

who have been sufficiently trained regarding the task at hand (via use of

Operating Manual).

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 9

The system must be shut down and be protected from further use until all

repair and maintenance tasks have been completed. It is essential to

observe the shutdown procedure as described in this Operating Manual.

Before beginning tasks relating to electrical equipment/components of this

system, a check must confirm that power has been disconnected from the

corresponding section of the system. In addition, the system must be

secured to prevent it from being turned on again unintentionally.

4.6 Disposing of system parts and operating materials

When they need to be discarded, consumables and spares must be

disposed of according to local and National requirements. Refer to

Section 13.5 regarding disposal.

4.7 Unauthorised conversion and manufacturing

replacement parts

Modification of the unit is only permitted with the approval of the

manufacturer. The same applies to the uploading of new software for the

control system. Original replacement parts and accessories authorised by

the manufacturer enhance safety, the use of other non-approved parts will

void the warranty and could affect the safety and or performance of the

unit.

4.8 Warranty claims and liability

This product has been manufactured in accordance with our ISO

9001:2008 quality control process. If, however, you are unsatisfied with

the unit, please contact SUEZ Ltd. Any warranties guaranteed by SUEZ

with respect to the Select edi 60 will be void if the equipment is not used

in accordance with the written instructions provided within this Operating

Manual.

Please visit our website (www.suezwater.co.uk) for a copy of our terms

and conditions which contains further details on warranties.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 10

5 ABOUT YOUR WATER PURIFIER

The SUEZ Select edi 60 purifies potable water. The water is purified by a

combination of processing including; activated carbon, double pass reverse

osmosis, membrane degassing and electro-deionisation.

The Purified water produced by the unit complies with the latest standards for

laboratory grade water. Refer to Section 11.2 Treated Water Specification

for details.

5.1 The Select edi 60 range

The Select edi 60 is only as one model producing a makeup flowrate of 10

litres/hour.

The above output is based on a typical 8 hour working day at 60psi (4 bar)

inlet pressure, 25oC and maximum of 400 ppm total dissolved solids.

Note: At water temperatures below 25oC the output will decrease by as

much as 3% per Degree C. Refer to Section 11.1 for more details.

The Select edi 60 is supplied with an integral 20 litre tank or if larger

storage is required additional 50 and 100 litre tanks are available. Contact

SUEZ sales department for details.

The unit type is detailed on its serial plate which can be found on the

reverse side of the front cover.

The Select edi 60 is provided with an installation kit for quick installation.

The unit is also supplied with one complete set of consumables. Refer to

Section 9 for details

5.2 Key components of the Select edi 60

5.2.1 Touch screen display

Operation of the Select edi 60 is controlled solely through the touch

screen display. System schematics are displayed for easy

understanding of the unit’s process.

5.2.2 Storage tank

The integral storage tank holds 20 litres of purified water. To dispense

water a bib tap has been provided at the front of the tank.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 11

5.2.3 Removable front cover.

The front cover is easily removed and provides access to the

consumable cartridge media pack.

Use the two grab slots

to gently pull away the

front cover to gain

access to the

purification packs

Bib Tap & integral 20

litre tank

Touch screen display

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 12

6 OPERATING YOUR WATER PURIFIER

Your Select edi 60 is operated via the touch screen display. Buttons are

provided on the display to access start menus, set up functions and

dispense water. The display also provides a mimic of the system when in

operation.

6.1 Power on screen

To switch the unit on press the START button from the power on screen.

POWER-ON 24/10/16 10:04

WELCOME

MENU

START

Select edi 60

When connected to an electrical supply the unit goes through an

initialisation process, followed after 10 seconds by the Power-On screen

as shown above.

When the unit is started the RO Screen is displayed showing the condition

of the permeate feed to the EDI module.

Pressing the NEXT button toggles between two further screens detailing

the parameters around the EDI module and a general information screen

showing the status of the valves and pumps within the flow path.

Pressing the MENU button at any time allows access to the set-up and

control pages.

Pressing the red STOP button will initiate a shutdown routine lasting 15

seconds to allow the RO’s to flush prior to stopping.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 13

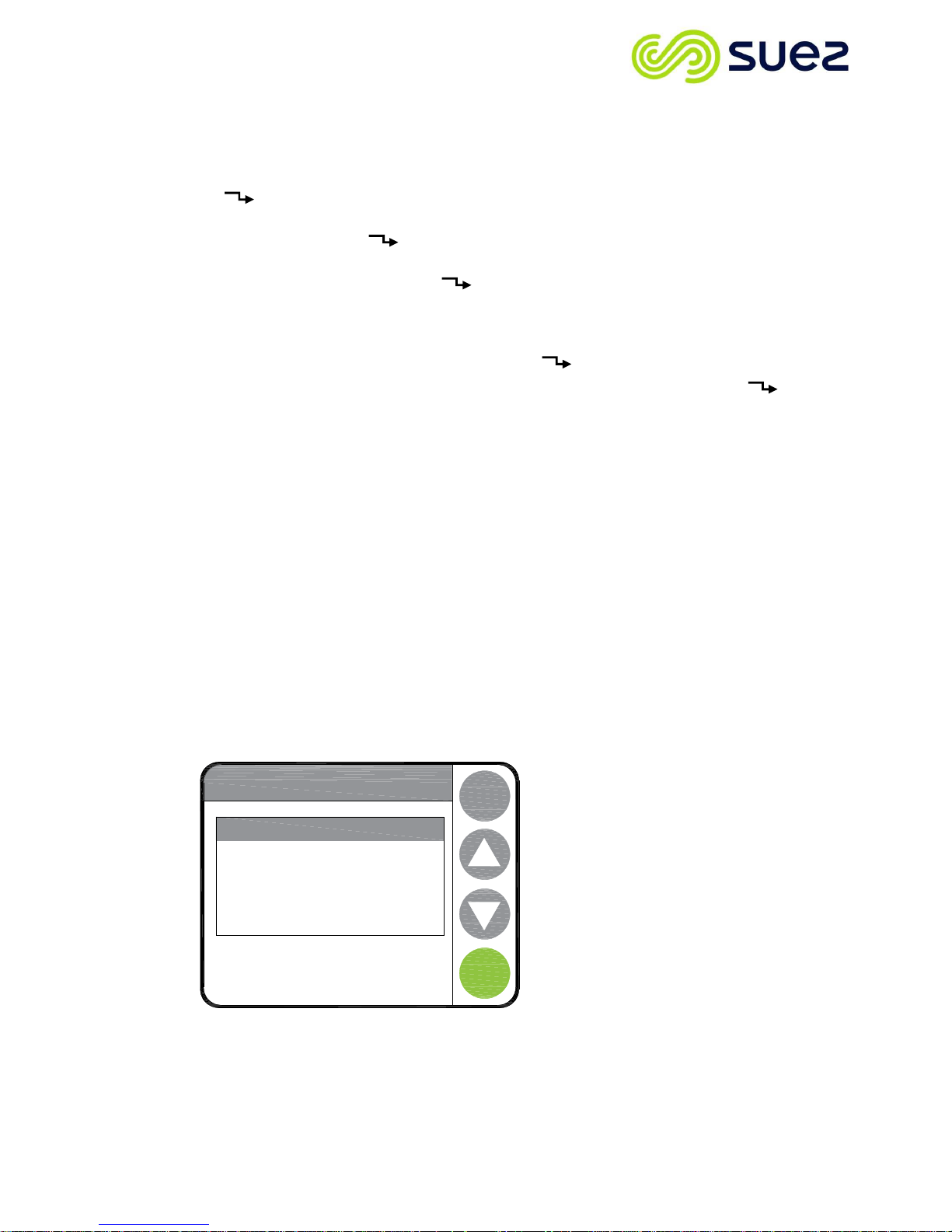

Setting Menu

BACK

ENTER

Time & Date

Alarms

Maintenance

System Menu

6.2 Menu structure

Power-On Screen

Start

User Menu

Clean routine

Setting Menu

Time & Date

Alarms

Maintenance

System Menu

Product Information

Engineering menu

Set Unit ID

Auto Restart

Set Log Frequency

Data Logging

6.3 Clean routine menu

Refer to Section 8 for details of disinfection procedure. Selecting the

Clean Routine from the menu begins the disinfection process. Prompts

are provided to guide you through the various stages of the disinfection

process.

6.4 Settings menu

The settings menu enables

system parameters to be

entered and stored

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 14

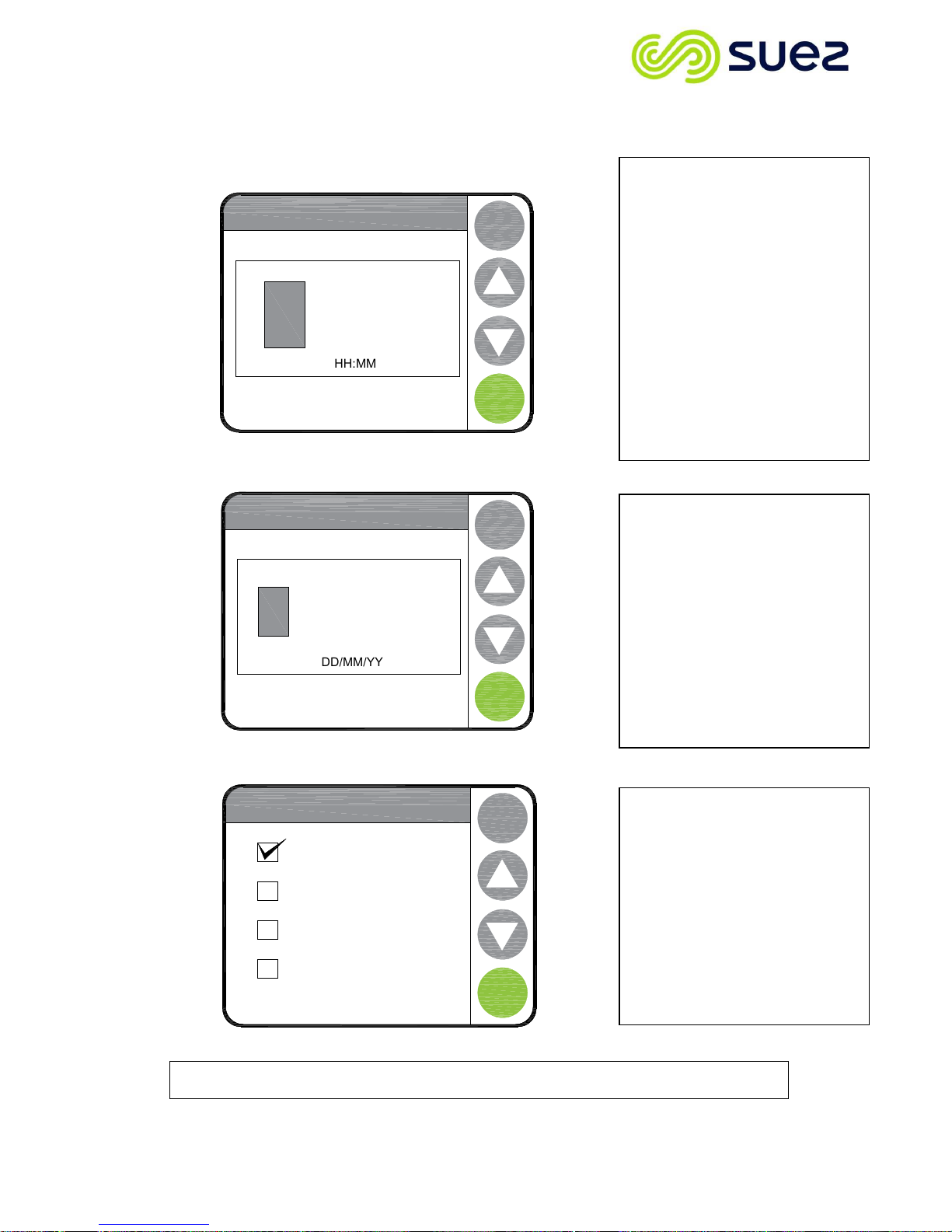

Set Time

BACK

ENTER

16:03

HH:MM

Set Date

BACK

ENTER

17/01/17

DD/MM/Y

Y

Set Format

BACK

ENTER

DD/MM/YY

DD/MM/YYYY

MM/DD/YY

MM/DD/YYYY

6.4.1 Time and date

Note: Pressing the “BACK” button prior to pressing the “ENTER” button will cancel changes

currently being made and return you to the “Setting MENU”.

If you select “Set Time” the

screen opposite will be displayed.

The flashing cursor identifies which

digit you can adjust.

By using the ▲/▼buttons you can

either increase or decrease the

number value. Once the correct

number has been selected, press

“NEXT” to move to the next

number. On pressing “NEXT” on

the final number a confirmation

screen will pop up, stating “Done”

and after a few seconds the screen

will revert back to the “Time Date

Menu”

To select “

Set Date

” from the

menu use the ▲/▼ buttons and

press “ENTER”. The date will be

displayed and the cursor will flash

on the first number.

Use the ▲/▼ buttons to change

the number to the correct value,

then press “NEXT” to move to the

next one. On pressing “NEXT” on

the final number a confirmation

screen will pop up and after a few

seconds the screen will revert back

to the “Time Date Menu”

Should the format of the date be

wrong, by selecting the “Set

Format” menu and by pressing

“ENTER” the “Set Format” menu

will be displayed. Touch the box

that matches the correct format. A

tick will appear to confirm your

selection. Press “ENTER” a

confirmation screen will pop up

and after a few seconds the screen

will revert back to the “Time Date

Menu”

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 15

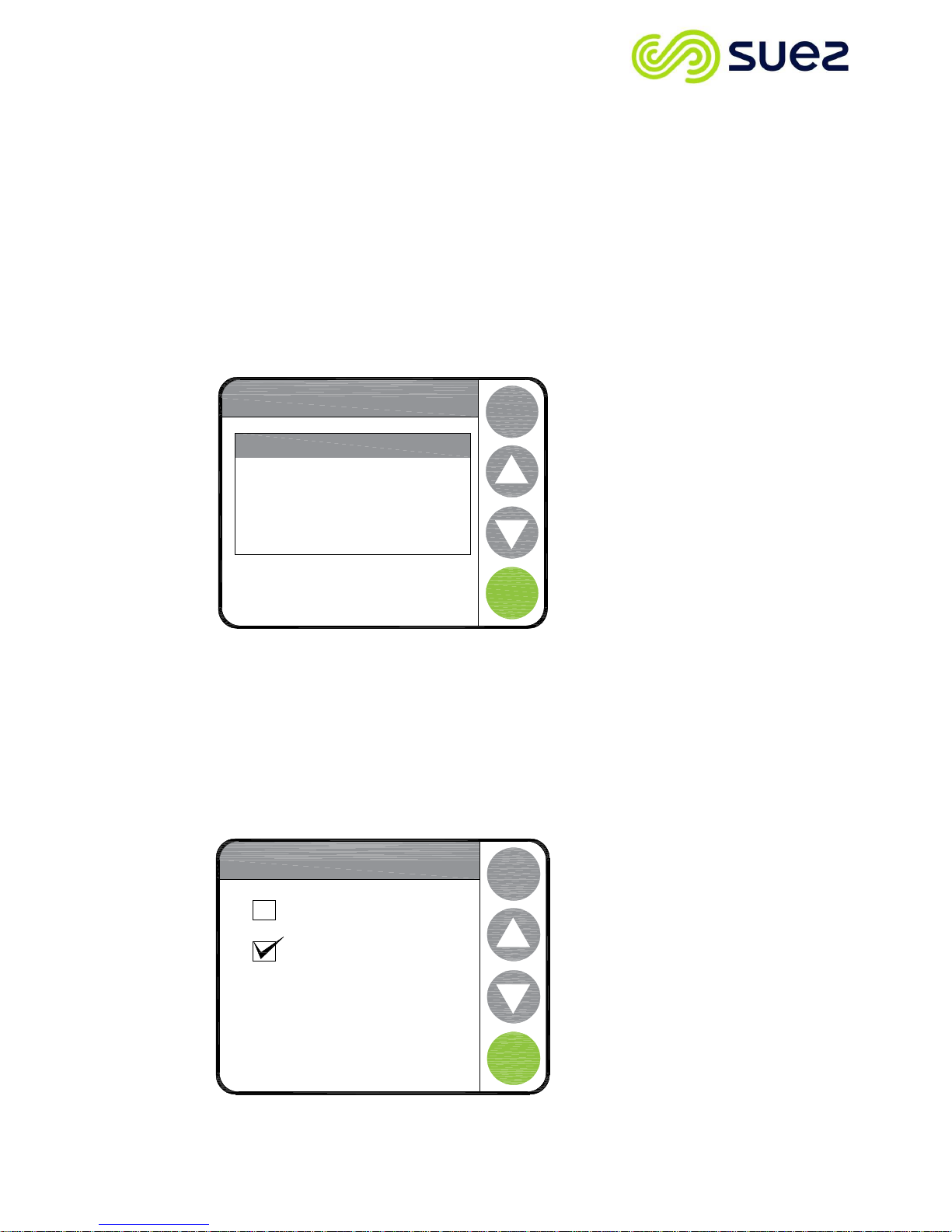

Alarms

BACK

ENTER

Audio Alarm Enable

Set Perm Quality Alarm

Set Perm Temp Alarm

Set Rinse Temp

Audio Alarm Enable

BACK

ENTER

Disable

Enable

6.4.2 Alarms

The

Select edi 60

unit can be programmed to sound an alarm buzzer if

certain performance limits are exceeded or if the unit has detected a

serious fault.

Within the “Alarms” menu alarm set points can be set for the final

purified water quality and for the temperature of the purified water. If

exceeded the unit will sound a buzzer.

There is also an option to “Enable or Disable” the alarm buzzer. The

unit will be supplied with the alarm buzzer “Enabled”.

The device can be

programmed to activate

alarms in the event that

defined parameters are

exceeded. The alarms can

be “enabled” to sound as

an audible buzzer.

Audio alarm

This is enabled / disabled by first selecting the “Audio alarm” from the

menu listing, and then by simply touching the relevant box next to

either “Disabled” or “Enabled” you can change the alarm status. Then

press “Enter” to save. Confirmation of your selection is given by a tick

appearing in the selected box.

The audible alarm will also

sound after any fatal alarm

condition, refer to Section

10.2 for list of alarms and

warning messages. The

alarm can be muted by

pressing any part of the

screen.

The alarm buzzer can be

enabled / disabled by

selecting from the audio

alarm menu above.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 16

Set Perm Quality Alarm

BACK

ENTER

015

µ

S

Set quality alarm

A minimum water quality is required to protect the EDI Cell from

fouling. An alarm can be set that will warn if the water quality exceeds

the set value (5-10us nom). Enter the desired water quality alarm limit

in the set quality alarm menu. During “Processing” should water quality

fall below this level the navigation bar on the mimic screen will display

“Poor Water Quality” alarm message. If the audible alarm is enabled a

buzzer will sound. If the water quality improves to below the set point

the alarm message will be removed from the screen and the buzzer will

stop sounding

The range of the alarm set point is between 15 – 25uS. The unit will be

set on delivery to 15uS. Setting a value lower than 15uS will disable

this alarm.

To change the displayed value simply use the ▲,

,

up/down buttons

to either increase or decrease the value, pressing the “NEXT” button

will move the cursor to the next digit. Then press “NEXT” to save the

setting and return you to the “Settings Menu”.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 17

Set Perm Temp Alarm

BACK

ENTER

30.0

°C

Maintenance

BACK

ENTER

Pre-treat(PT) pack date

Set temperature alarm

If dispensed water must be supplied below a certain temperature an

alarm can be set. Enter the maximum water temperature in the “”Set

Perm Temp alarm” menu. During “Processing” should the water

temperature rise above this, the navigation bar will display

“Temperature High” alarm message. If the audible alarm is enabled a

buzzer will sound.

The range of the alarm set point is between 20.0 – 35.0 oC. The unit

will be set on delivery to 35.0 oC

To change the displayed value simply use the ▲,

,

up/down buttons

to either increase or decrease the value, pressing the “NEXT” button

will move the cursor to the next digit. Then press “NEXT” to save the

setting and return you to the “Settings Menu”.

To disable this function enter a value of 0.0 oC

6.4.3 Maintenance

The maintenance menu can be accessed via the settings menu.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 18

System Menu

BACK

ENTER

Product Information

Engineering Menu

Set Unit ID

Auto Restart

Set Log Frequency

Data Logging

Product Information

BACK

ENTER

TYPE:

SERIAL NUMBER:

Unit ID:

UNIT VERSION:

POD VERSION:

COMMISSION DATE:

UNIT CHECKSUM:

POD CHECKSUM:

DATA MEMORY FULL:

ADDRESS:

Select EDI 60

00000000

B.0.12/1069

B.0.12/1067

20/10/16

0xCA8B

0xA619

1%

02

The maintenance menu provides the capability to set defined dates for

replacement of consumable items in the device. These dates, when

expired, will trigger an alarm which will be displayed on the mimic

screen

6.4.4 Systems menu

The systems menu provides information about your device and enables

identifcation of the unit.

Product information

Displays data about your device.

This option will display details of the unit’s configuration and current

version of software being used

The data displayed cannot be edited via this screen.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 19

ENGINEER MENU

BACK

ENTER

Serial Number

Unit Type

Maintenance

Setup

Commission date

Software Update

Restore Defaults

6.4.5 Engineer menu

Access to the Engineer menu is limited to SUEZ Service personnel of

approved/authorised technicians. The menu contains data relating to

the factory settings of the unit. A PIN no. password is required to enter.

This option is password protected and for use by SUEZ Ltd service

personnel only. Changes to settings within this menu should only be

carried out by SUEZ Service personnel or those trained and approved

by SUEZ.

“Serial No.”

Displays a six digit number; the number can be changed within this

menu.

“Unit Type”

Can be set to

“Select edi 60”

or

“Select edi 60 + PP”.

“Maintenance”

Is used to quantify the number of EDI operations and water volume

produced since commissioning.

Set Up menu.

This sub menu is split into 4 further lower level menus

Line cell constants

Flow calibration

Transit Mode

Touchscreen calibration

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 20

“Line Cell Constants”

There are three line cells within the unit, each cell constant can be set

independently and are displayed. The accepted input range will be 0.05

– 1.99. If a value outside of this range is entered, the value will be

ignored, and the previous value retained.

“Transit Mode”

When the unit is first delivered it will be set in “Transit mode”, When the

unit is first powered up the user will be prompted to set the time & date

and reset the consumable dates. After the time & date options have

been entered the Transit mode option will automatically go to

“Disabled”

“Touchscreen Calibration”

The calibration of the touch screen will be able to be carried out within

this menu option. A number of identified calibration points will be

highlighted on the touch screen. Pressing the highlighted

points/markers will cause the resulting values to be stored and used in

place of the default values. Default values will be entered/used for

Touch screen calibration whenever

Commission Date

This feature when selected will display the date on which the unit was

commissioned. The date is automatically entered following the setting

of the time and date after Transit Mode. If the unit is re-commissioned

at any point in the future the date can be changed within this menu.

The default date is set as 01/01/09

Software Update

This menu option will provide a means of uploading/replacing software

on the unit’s control and display boards. Files will be able to be

uploaded direct from a USB memory device, which can be plugged into

the display board/pod. Three sub menus will be displayed on selecting

this feature.

“Update Display”

“Update Controller”

“Update GUI”

When any one of these options is selected, an “Are You Sure”

message will be displayed. If “Yes” is selected the unit will upload the

appropriate files from the USB memory device. The unit’s software will

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 21

Set Unit ID

BACK

ENTER

00

Auto Restart

BACK

ENTER

Disabled

Enabled

detect if a USB memory device is connected. If no device is detected, a

message “Memory Stick Not Detected” shall appear for a few seconds

on the screen. The stages of data transfer and programming sequence

will be displayed. The programme upload, and transfer for the Control

board will likely take several minutes. A “%” indicator bar will be

displayed providing an indication of rate of transfer.

“Restore Defaults”

When this option is selected, all the adjustable/selectable options will

revert back to their default settings. Refer to Section 6.5 for a complete

listing of factory default settings.

Set unit ID

A discrete device identifier can be stored here should multiple units be

used in one location.

Auto restart

If “Enabled” the unit will automatically return to operation following an

interruption in the power supply.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 22

Set Log Frequency

BACK

ENTER

030

MINUTES

Data Logger

BACK

ENTER

Upload Files

Clear Logger

Set log frequency

The device has an inbuilt data logger that record status of the unit and

any alarm events and performance data. Data is written to the memory.

The frequency of sending data to the memory can be set via this menu

option.

Data Logger

Data can be downloaded and saved on a memory stick device and

transferred to a PC computer. Refer to Section for details of suitable

memory devices.

“Upload files”

Follow the displayed commands to download data from the unit

memory.

Insert data stick into the USB port on the underside of the pod. This

may take some time depending upon the amount of stored data.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 23

Data is stored to the data stick as a .CSV file which may be viewed

using Microsoft Excel.

“Clear data logger”

After downloading data it is recommended to clear the data logger

memory as it has a limited capacity which when exceeded

historical data will be over written

Selecting and accepting clear data logger clears the data file log.

6.5 Factory Default settings

6.5.1 Setting menu defaults

SETTINGS MENU

Default settings

Date and Time

Set Time

-

Set Date

-

Set Format

DD/MM/YY

Alarms

Audio Alarm

Enable

Enable

Permeate

Quality Alarm

15 uS

Permeate

Temperature Alarm

35oC

Rinse Temperature

30°C

Maintenance

Pre-treat (PT) Pack date

-

6.5.2 System menu defaults

SYSTEM MENU

Default settings

Product Information

-

Engineer menu

-

Set Unit ID

00

Auto Restart

Disabled

Log Frequency

30 Minutes

Data Transfer

-

Upload Files

-

Clear Logger

-

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A 24

6.5.3 Engineer menu defaults

ENGINEER MENU

Default settings

Serial Number

000000

Unit Type

-

Select edi 60

Select edi 60

+ PP

-

Maintenance

EDI Run Hours

-

EDI On / Offs

-

Total Volume

-

S

etup

Line Cell Constants

-

Outlet Line Cell

0.12

Product Line Cell

0.13

RO Line Cell

0.55

Flow Calibration

16000

Transit Mode

Disabled

Touchscreen Calibration

-

Commission Date

-

Software Update

-

Update Display

-

Update Controller

-

Update GU

I

-

Restore Defaults

OPERATING MANUAL FOR SELECT EDI 60

Issue: 1 R041180

7 MAINTENANCE

7.1 Replacing the media pack

Scan QR code for video clip on how to replace the media pack

•

Switch the unit off by pressing the STOP button.

•

Leave the unit to stand for 30 seconds to relieve any internal pressure.

•

Pull away the front door cover to expose the media packs.

•

Press down the lever on top of the cartridge to be replaced and pull it

away from its retainer block.

•

Discard the media pack and remove the new pack from its packaging

ensuring that the two plugs are removed from the inlet/outlet ports.

•

Slide the media pack into the retaining block, push it home until it clicks

into position and retaining mechanism clicks up and locks. Check by

trying to pull the cartridge, it should not slide back out.

•

Press “START” and follow the instructions on screen for setting new

pack replacement date.

•

After resetting pack date the unit can be started from the power on

screen.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

26

7.2 Cleaning the inlet screen filter

It is recommended that this filter is cleaned at least once per year. The

inlet screen filter is located in the rear of the unit and can be cleaned as

follows:

•

Switch off the water supply at source

•

To relieve any residual water pressure, momentarily switch the unit on

then off.

•

Remove the right hand side panel of the unit.

o

To do so first remove the front cover by pulling it gently from the

unit using the hand holds provided.

o

Pull the pod assembly gently forward to disengage the top cover

retaining pin.

o

Remove the top cover by lifting up the front and sliding gently

backwards.

o

Remove the four retaining screws holding the side panel in place

and slide gently backwards.

o

Remove the rear panel retaining screws and move the panel

aside.

Screen filter

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

27

•

To obtain access to the filter screen unscrew the black knurled top anti-

clockwise. The screen will then be exposed. Pull the screen away

from the housing and clean away any debris.

•

Once cleaned, replace the screen and black top.

•

Replace the rear, side, top and front cover using the reverse procedure

and switch on the water supply. Start the unit from the power on

screen

7.3 Replace main PCB battery

(Ref to Section 9 for re-order part no. of replacement battery)

Note: Replacement of the battery should only be carried out by trained

and/or SUEZ approved technicians.

1. Ensure unit is in “Power On” mode.

2. Turn the unit off by using the rear isolation rocker switch, ensure switch

is in the “O” position and then isolate the unit from the electrical mains

supply by removing the power cord from the wall socket or from the

connection on the rear of the unit.

3. Turn off the incoming water supply to the unit.

4. The battery is located within the main PCB which is accessed via

removal of the top cover.

5. Pull the Pod forward to disengage from the top cover. The top cover can

then be lifted away from the unit. Once removed the battery can be clearly

seen on the main PCB, prise the battery out of its holder. (Refer to

“location Lithium battery on main PCB diagram”

)

7. Refit the new battery ensuring the,

(+)

positive side is facing upwards,

the battery should be pressed gently until the four clamps in the retainer

“snap” over the battery fully. Refer to Section 11.4.5 to check details of

battery before fitting.

8. Dispose of the old battery according to guidelines in Section 13.5.

9. Refit the top cover and push the Pod back ensuring it engages with the

cover.

10. Reinstate the mains power supply and check the operation of unit.

11. You may be requested to reset the Time & Date, refer to Section 6.4.1

Warning:

Incorrect fitting of the battery could cause irreversible damage to the main PCB. Ensure

the

(+) positive

side of the battery is facing upwards. Always use the recommended

battery, Part No. R083349. The battery has a five year in-service life, but we recommend

that it is replaced every three years. However, if the unit has been switched off and

disconnected from the mains supply for more than 1 year we would recommend that

the battery is replaced.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

28

Location of lithium battery on main PCB

Main PCB

Lithium PCB

battery

Part No.

(R083349) Ref

Section 11.4.5

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

29

8 DISINFECTION PROCEDURE

Sanitisation of the unit should be carried out at least once every 6 months.

•

Switch the unit off by pressing the STOP button.

•

The unit will now have reverted to the POWER ON screen.

•

Turn off the water supply to the unit.

•

Leave the unit to stand for 60 seconds to relieve the pack water

pressure.

•

Pull away the front door cover to reveal the media cartridge packs.

•

Remove the left hand Pre-Treatment pack and discard.

o

To sanitise the unit insert a cleaning pack adaptor (Suez part

number L998549) into the left hand media pack location.

•

Turn on the water supply and press the menu button.

•

Select ‘Clean Routine’ from the menu and follow the ‘on screen’

instructions.

•

When the clean routine has completed, isolate the water supply and

allow the unit to stand for 60 seconds to depressurise.

•

Remove the cleaning / descale pack and dispose of according to local

regulations.

•

Fit a new ‘Pre-Treatment pack and follow the ‘on screen’ instructions.

The unit will revert to the ‘Power On’ screen and be ready for operation

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

30

9 CONSUMABLES & ACCESSORIES

CONSUMABLE

PART No. DESCRIPTION

MEMBRANE PACK M996057 Select edi 60 RO membrane pack

CONSUMABLE PACK M996006 2 x PT 8 cartridges

DEGASSING CONTACTOR R090331 Select edi 60 membrane degasser

ELECTRO-DEIONISATION CELL R090330 Select edi 60 cell

INSTALLATION & WALL MOUNTS

L300901 wall mount kit

PM00901 Installation kit

L991110 Feed water pressure regulator

L998405 External Tank Wall mount Kit

EXTERNAL FILTRATION

L991276 10" filter housing

R011044 10” 5µm filter element

OTHERS

L998549 Disinfection pack

R041180 Operator’s Manual (extra copies)

R083349 Main PCB Battery

R083352 Tank interface cable

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

31

10 TROUBLE SHOOTING

The touch screen communicates faults with the system via both the mimic

screen and text lines.

A fault finding guide with corrective actions is shown below.

10.1 General fault conditions

Symptom/s Possible causes Actions

Unit does not power up

1. Fuse blown in mains lead

2. Fuse blown in IEC module

3. Electrical fault with the unit.

1. Check 5 amp fuse in mains lead

2. Check fuses in IEC module (refer

to Sec. 11.4.2)

3. Contact supplier

Make up rate into

integral tank declining

1. Feed water temp low.

2. Media pack needs replacing

3. (RO) membrane fouled

1. Check feed conditions. (Refer to

Sec.11.1 and 11.5.1-11.5.2)

2. Check all replacement dates and

replace where necessary.

3. Contact supplier with details.

4. Check condition of pre-filter

10.2 Alarm/Warning messages

DISPLAY POSSIBLE CAUSE OPERATOR ACTION

TEMPERATURE

SENSOR ERROR

Temperature probe lead possibly

disconnected or faulty.

Contact your local distributor or

SUEZ Service Department.

LINE CELL ERROR

Line cell lead possibly disconnected

or faulty.

Contact your local distributor or

SUEZ Service Department.

LOW PRESSURE

RO Boost Pump faulty or loss of

feed water supply.

Low pressure switch fault.

PT media pack blocked.

Check boost pump operation.

Check feed water supply pressure.

Replace pre-filter.

Contact supplier if fault persists.

HIGH PRESSURE

Increase in feed water pressure.

RO membrane may require

cleaning

Check feed water pressure must be

<30psi.

Check plugs have been removed

from new pack.

Contact supplier if problem persists.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

32

LHS PACK NOT

FITTED

PT media pack not fitted or not fully

engaged.

Check pack is fully engaged and

retainer pin locked. (ref sec 7.1)

RHS PACK NOT

FITTED

Flushing pack not fitted or not fully

engaged.

Check Pack is fully engaged and

retainer pin located. (Ref Sec 7.1)

FIT BOTH PACKS

PT media pack or Flushing pack

not fitted or both not fully engaged.

Check pack/s are fully engaged and

retainer pins located. (Ref Sec 7.1)

TIME/DATE NOT SET

On Start Up, time and date may not

be set.

Main PCB battery needs replacing.

Select Set Time and Date function

from settings menu and set.

Replace lithium PCB battery (Ref

Sec. 7.4)

POOR WATER

QUALITY

RO membranes fouled

Check membrane performance,

clean if required.

Contact supplier if new pack does

not improve water quality.

TANK LOW LEVEL

Water in process tank below low

level.

Usage exceeding make up rate.

Check feed water supply and (RO)

performance.

Check tank level (visual).

Check take off rate from any

attached equipment, eg. Washers.

COMMS ERROR

Link between keypad and main

PCB faulty

Contact your local distributor or

SUEZ service department.

TEMPERATURE

HIGH

Temperature of purified water

above set limit.

Check temp setting. (Refer to Sec

6.4.2)

Drain off water from system and

leave to refill.

Check feed water temp. (Ref Sec

11.5)

NOTE:

If remedial actions do not resolve the problem, turn off the water

supply, isolate the unit from the electrical supply and contact either your

authorised supplier or call SUEZ Service Department. DO NOT ATTEMPT

TO DISMANTLE THE UNIT AND CARRY OUT ANY REPAIRS, UNLESS

TRAINED AND APPROVED TO DO SO, WITHOUT FIRST CONTACTING

SUEZ LIMITED OR YOUR AUTHORISED SUPPLIER.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

33

TECHNICAL SPECIFICATION

10.3 Product outputs

Make-up

rate (l/hr)

@ 10°C &

60psi

6

@ 25°C &

60psi

10

10.4 Treated water specification

•

Inorganics > 1 MΩ.cm

•

pH Neutral

•

Bacteria > 99% rejection

•

Organics (TOC) <50ppb

10.5 Water storage

Pure water storage capacity: 20 litres

10.6 Electrical specifications / connections

10.6.1 Mains supply

Electrical

Supply

KW

Rating

Current

Draw (Amps)

External Fus

e

Rating

Single phase

100-230v

+10%,50/60

Hz and Earth

0.25

1.0

5

Amps

(conforming to

BS1362)

10.6.2 Fuse rating / type

IEC module fuse type: - (20x5mm), T5AH250V, conforming to IEC 127

Number per unit = 2

The mains supply is double pole/live & neutral fused.

10.6.3 Alarm port connection details

Application: BMS Volt free alarm output.

Connector type: Din 3-pin Plug (max rating 34Vdc / 24ac, 1 amp).

Maximum lead length= 10 metres.

Contact SUEZ for supply of alarm lead.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

34

10.6.4 USB Mass storage device

Specification: FAT 16 formatted USB memory stick

10.6.5 Main PCB Battery Specification

Voltage: 3V

Type: Lithium, CR2032

10.7 Feed water specification

10.7.1 Feed water quality

The unit has been designed to only operate on a potable water supply

conforming to current EC Directive “Relating to the quality of water

intended for human consumption”, but with the following additions.

Pre Filtration

Filtered to

5 Micron

*

Free Chlorine < 1 ppm as Cl2

Total Dissolved Solids (Max) 1000 ppm

Temperature 1-35oC (33.8 – 95o F)

TOC Up to 2000ppb (Typical)

* Provided by external filter assembly supplied as part of the installation

kit.

10.7.2 Feed water pressures

Feed water Pressure (Max) (90 psi)*

Feed water Pressure (Min) (20 psi)

Optimum Pressure (60 psi)**

* If your feed water pressure is greater than a pressure regulator will be

required. Refer to Section 9 for details.

** Output performances based on 60 psi, 10Deg C potable water.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

35

10.8 Water services connections

All water feed connections are found on the rear of the unit. Using the

installation kit provided attach the water feed, Low pressure drain, high

pressure drain and overflow tubing as shown below.

Unit Viewed from the rear. Electrical & hydraulic connections

‘Dry’ alarm contact

External tank connection

Main voltage supply

Overflow

Rear tank outlet

Feed water

Low pressure drain

High pressure drain

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

36

10.9 Weights and dimensions

Unit Weight kg

Height

(mm)

Width (mm) Depth (mm)

Select edi 60

35 (shipping)

55 (working)*

750 440 560

*Weight with full tank of 20 litres

10.10

Environmental

Room storage and operating

temperature range

5 to 40oC (41-104oF)

Relative Humidity 30 to 80%

Max Altitude 2000m

Transport and Storage temperature

(limited by RO membranes)

-5 to 85oC (with frost protection liquid – 40 to

85oC)

RFI/EMI Radiation

Care must be taken not to have sources of

RFI/EMI, which are liable to cause

electromagnetic disturbance to the unit. If

the unit is affected by such disturbances, the

sources should be suppressed or relocated.

10.11 Cartridge outputs

Cartridge

Exchange

Capacity

Pretreat PT 8 10,000 litres*

*Based on continuous operation for 1500 hours.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

37

11 INSTALLATION

For details on installing the unit scan the QR code below to gain access to

video clip or alternatively follow the procedure below.

The unit can either be wall or bench mounted. Refer to Section 12.4.2 for

details on how to install the wall mounting kit.

11.1 Unpacking

Remove all packaging materials and ensure the following items have been

provided:

•

Select edi 60 unit

•

Installation kit

•

Select wall mount kit (optional)

•

1 off PT media pack

•

1 off Flushing pack

•

User manual

11.2 Installation Kit

The installation kit comprises of the following items:-

•

1 off security clips

•

1 off 12mm stem elbow

•

3 off 8mm stem elbow

•

3 m ½” blue braided hose

•

7 m 8mm natural, nylon tubing

•

3 m 12mm natural, nylon tubing

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

38

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

39

11.3 Cartridge media pack

Your

Select edi 60

is supplied with a Pretreat PT8 cartridge pack and a

blank ‘Flushing pack’

Note: The PT8 pack must be fitted in the left hand position in the front of

the unit and the Flushing pack should be fitted in the right hand position.

Refer to Section 9, Consumables, for part nos. of all consummable items.

11.4 Unit positioning

The

Select edi 60

can be either bench or wall mounted.

11.4.1 Bench mounted

Locate the unit on a suitable work surface, ensuring access to tank

dispense bib tap and sufficient clearance to rear of the machine for all

water and electrical connections.

All water feed connections are found on the rear of the unit. Using the

installation kit provided attach the water feed, drain and overflow tubing

as shown below.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

40

11.4.2 Wall mounted

Installation steps

Find a suitable mounting position. The wall bracket MUST be fitted to a

load bearing wall of masonry or concrete material capable of

supporting the weight of the bracket, unit, tank and full load of stored

water. For this reason the unit SHOULD NEVER BE MOUNTED TO A

STUD OR PARTITION WALL. (Refer to Section 11.7 for details of

unit working weights).

Mark the centre fixing position on the wall allowing for the height of the

unit below the ceiling level (650mm min).

Drill the centre fixing hole to the correct

size for the masonry fastener to be

used and install the first fastener.

Offer the main bracket body to the wall

and fix tightly to the wall (after levelling

the bracket) and mark the remainder of

the fixing positions.

Remove the bracket from the wall (or

rotate out of the way), drill and fit the

remaining four wall fixing positions.

Offer the main bracket body to the wall

again, level / align correctly and tighten

the bracket into position using the

correct torque for the fixings being

used.

OPERATING MANUAL FOR SELECT EDI 60

Issue: 1 R041180

If the unit is supplied with an internal

tank, fix the tank support bracket to

the bracket base plate using 3 off

washers and nylock nuts supplied.

Remove the feet from the underside

of the unit and discard the feet and

fixing screws.

Slide the base plate onto the main wall

bracket ensuring it is fully back.

Lift the unit onto the base

plate and fit the two shorter

Anulok retaining screws

through the front of the slide

plate into the unit feet

inserts.

Fit the longer Anulok

retaining screws through

the base plate rear fixing

positions (slots) and into the

water unit rear feet fixing

inserts.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

42

Tighten the front and rear retaining screws to fix the unit firmly to the

plate and bracket.

Bracket operation

Empty the storage tank of water to make the unit lighter to move.

Loosen the four slide plate fixing screws (DO NOT REMOVE). Pull the

unit and slide plate forwards.

The unit and slide plate will only move forwards to the limits of the slots

in the slide plate and will prevent the unit from falling forwards.

The returns in the slide plate trap the unit to the main bracket and stop

the unit from moving sideways.

11.5 Drain connection

Attach a suitable length of 8mm tubing to both drain connections so that

the free end may be inserted into an appropriate drain. The tubing must

not be kinked or the flow restricted in any way.

If the drain is to be run over 5 metres and/or rises above the level of the

unit then contact our Service Department for advice.

Attach a suitable length of 12mm hose to the overflow connection on the

unit and run to a suitable drain point. If the drain is to be run over 5 metres

of the unit then contact our Services Dept. for advice.

The overflow tubing should never be allowed to rise higher than the unit.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

43

12 APPENDIX

12.1 MSDS

Material Safety Data Sheets for the following accessories are available upon

request or can be downloaded from the SUEZ web site, see Section 3 for

details.

•

PT 8 Media Pack

OPERATING MANUAL FOR SELECT EDI 60

Issue: 1 R041180

12.2 Pushfit water connections

To make a connection, the

tube is simply pushed in by hand;

an

integral

collet locking system then holds the tube firmly in place without

deforming it or restricting flow.

Cut the tube square and push in until

the tube stops.

Fitting grips before it seals. Ensure

tube is pushed into tube stop, securing

tube in position.

To remove tubing push collet against

body and slide tube out of fitting.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

45

12.3 Process

Refer to flow diagram on following page.

All external hydraulic and electrical connections are positioned at the rear

of the unit to protect them from accidental damage.

On entering the Select Analyst an internal feed water strainer removes any

large debris remaining in the feed water supply.

When operated, an inlet solenoid opens and allows water to pass through

the pre-treatment cartridge to remove chlorine from the water and then on

to the reverse osmosis boost pump.

The boost pump increases the feed water pressure to a level to enable the

reverse osmosis (RO) membranes to operate efficiently.

The Pre-filtered water enters the first reverse osmosis module. Purified

water passes through the membrane and is termed ‘permeate’ (85-95% of

salts removed). The water containing the rejected salts passes across the

membrane and out of the RO module to drain and is termed ‘concentrate’.

The concentrate is pumped at high velocity across the RO membrane to

lessen the risk of fouling or scaling.

The concentrate flow rate is controlled by a fixed orifice restrictor located in

the drain line. The permeate is further purified by the second reverse

osmosis membrane with the ‘concentrate’ returning to the pump inlet for

recirculation.

The second stage ‘permeate’ then flows through the degasser where

excess CO2 is removed prior to polishing with the Electro deioniser (EDI).

An optional NCP media cartridge containing high grade mixed ionexchange resin performs a final polishing if fitted.

The deionised water then feeds directly into the integral 20 litre storage

tank. Water can be dispensed from this tank via the front mounted bib tap.

When the tank is full, the unit feeds a small amount of water back through

the EDI to ‘turn over’ the stored water to keep it fresh and to ‘refresh’ the

EDI Cell.

If the unit performs 3 ‘refresh’ cycles within 20 minutes, the unit will go into

standby mode to conserve power. Drawing water from the tank to the mid

position will awake the unit and place it back into ‘Processing’ mode.

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

46

L300180 PID

11 1

0.4Bar @ 15l/h

3 bar @ 18L/h

7 bar @ 0.5 Bar inlet

& 80L/h

(pump)

0.3 ID, 40lg

0.9 ID,

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

47

12.4 CE declaration

A copy of Declaration of Conformity can be obtained from SUEZ upon

request or from our website at

www.suezwater.co.uk

OPERATING MANUAL FOR SELECT EDI 60

L300180 Iss:A

48

12.5 WEEE declaration

Users in the United Kingdom who wish to discard electrical and electronic

equipment that was supplied by SUEZ should contact:-

Tel: No: 0844 873 1034

E-mail: info@complydirect.com

Fax No: 0844 873 1035

SUEZ Registration No. WEE/EGO267RW

Users in other European Countries should contact their producer, who will

be the organisation in their country that supplied the product.

For users outside of the European Union, if you wish to discard this

product then please contact your local authorities or dealer and ask for the

correct method of disposal.

Loading...

Loading...