Page 1

INSTALLATION GUIDE

Undercounter Ice Machine

Page 2

Contents

Important Note

Undercounter Ice Machine 3

Ice Machine Specications 4

Ice Machine Installation 8

Installation Checklist 14

Service Information 15

Features and specications are subject to change at any time

without notice. Visit subzero.com/specs for the most up‑to‑

date information.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

To ensure the safe and efcient installation of Sub‑Zero

equipment, please take note of the following types of

highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

relevant to a problem-free installation.

CAUTION signals a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

Page 3

Undercounter Ice Machine 3

subzero.com/specs

Sub‑Zero Undercounter Ice Machine

IMPORTANT NOTE: The importance of the installation

of the Sub‑Zero ice machine cannot be overemphasized.

Installation must be completed by a qualied installer.

Read this entire installation guide prior to installation.

There are key details that you should observe during the

installation to make the process easier, problem‑free and,

most importantly, safe. The homeowner should keep this

installation guide for future reference.

Any questions or problems regarding the installation

should be directed to your authorized Sub‑Zero dealer

or Sub‑Zero customer care at 800‑222‑7820. You may

also check the contact & support section of our website,

subzero.com.

Important product information, including the model and

serial number of your unit are listed on the product rating

plate, located in the upper left corner of the ice bin and on

the back of the unit. Refer to the illustration below.

Proper installation requires connection to the water

supply, a drain and a dedicated electrical circuit. These

connections are the responsibilities of the installer.

Improper connections can result in personal injury,

property damage and improper operation.

RATING PLATE

Location of rating plate.

Page 4

Ice Machine Specications 4

Ice Machine Specications

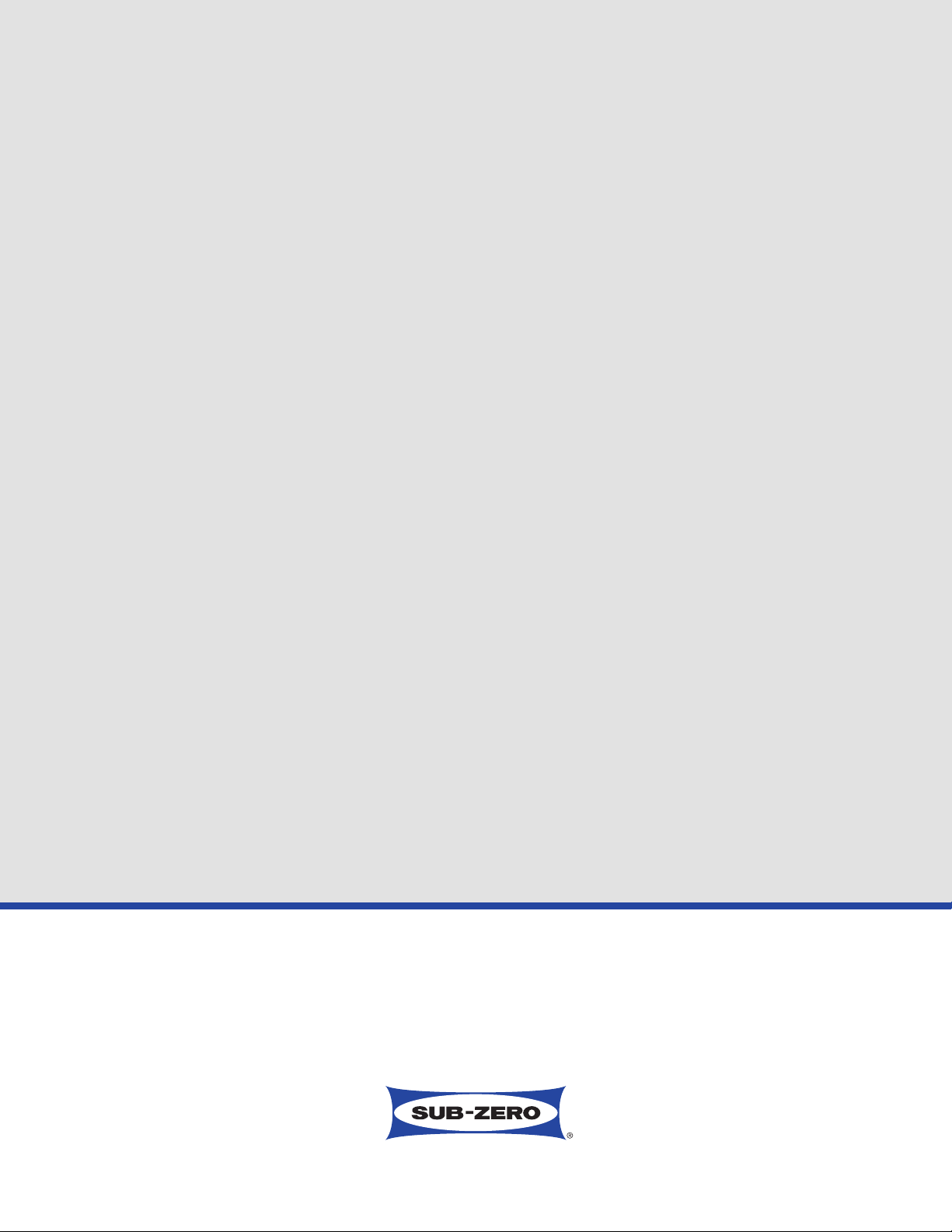

OVERALL DIMENSIONS

143/4" (375) 23" (584)

335/8"

(854)

4" (102)

18"

(457)

6"

(152)

INSTALLATION

24" (610)

OPENING DEPTH

24" (610)

OPENING

DEPTH

341/2" (876)

OPENING

HEIGHT

TOP VIEW

151/4"

(387)

OPENING

WIDTH

FRONT VIEWSIDE VIEW

Overall dimensions do not include panels or handles.

IMPORTANT NOTE:

and water supply be placed in an adjacent cabinet. If they

are placed within the opening, additional cabinet depth

Specications

Ice Storage Capacity 26 lbs (12 kg)

Shipping Weight 117 lbs (53 kg)

may be required.

It is recommended that the electrical

Page 5

Ice Machine Specications 5

E

E

E

subzero.com/specs

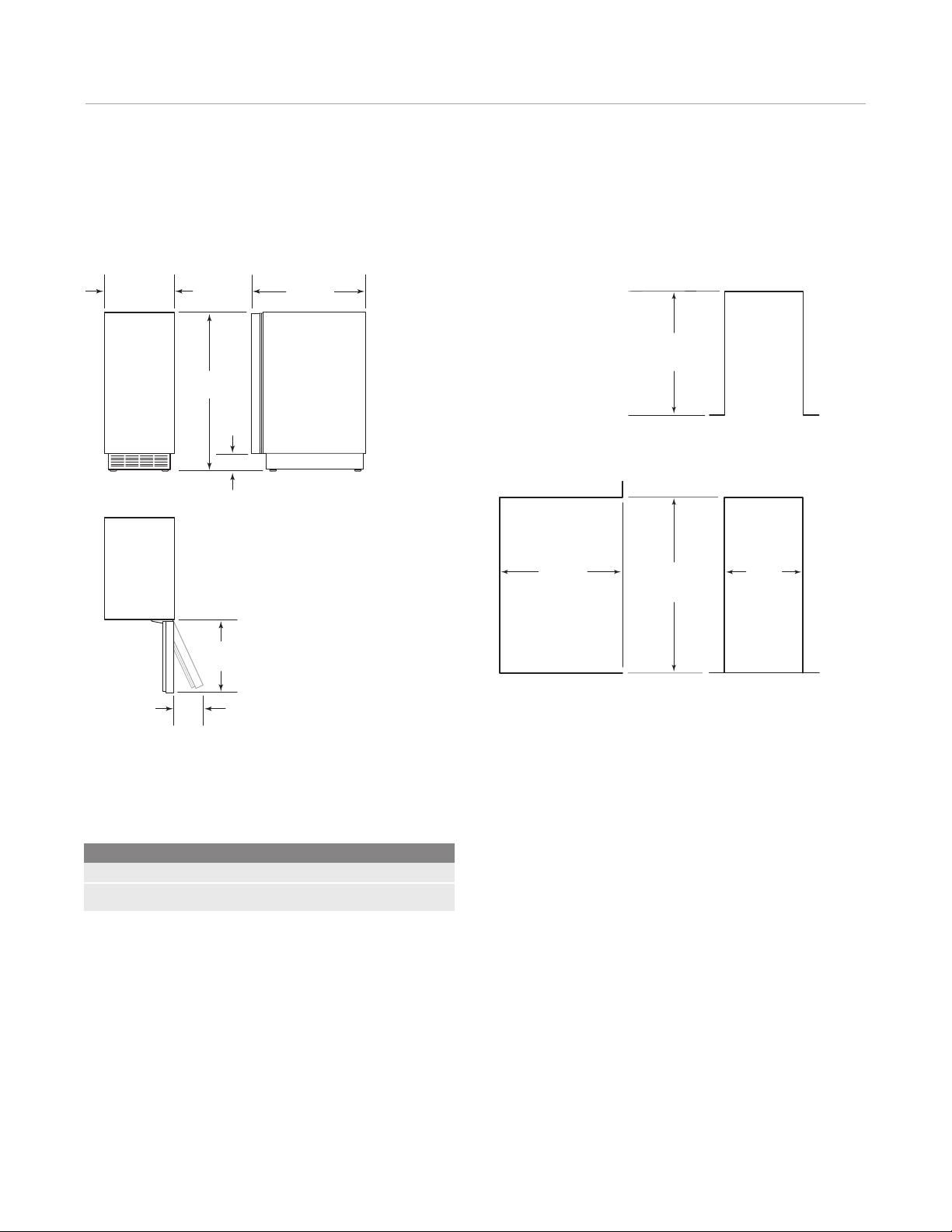

Electrical Requirements

The ice machine must be installed with adequate clear‑

ance for electrical connection at the rear of the unit. The

electrical supply for the ice machine requires installation of

a grounded receptacle on a separate circuit, servicing only

this appliance. Follow the National Electrical Code and

local codes and ordinances when installing the receptacle.

IMPORTANT NOTE: Although it can be located anywhere

on the back wall, it is recommended that the receptacle

be placed in an adjacent cabinet or in the lower right of

the opening. If it is placed within the opening, additional

cabinet depth may be required. Refer to the illustration

below.

Models UC15IO and UC‑15IPO are designed and safe for

use in outdoor applications. When installed outdoors, a

ground fault circuit interrupter (GFCI) is required to reduce

the risk of electrical shock. For outdoor models, or if a

ground fault circuit interrupter (GFCI) is required by local

codes, it must be a breaker type, not an outlet type.

Electrical Requirements

Power Supply 115 V AC, 60 Hz

Receptacle 3‑prong grounding‑type

Circuit Breaker 15 amp

Minimum Circuit 4.1 amp

The electrical supply for the ice machine must be installed

by a qualied electrician in accordance with all applicable

national and local electrical codes. Observe the following:

• The ice machine must be grounded in accordance with

national and local electrical codes.

• A separate fuse or circuit breaker must be provided for

each ice machine.

• The maximum allowable voltage variation is ±10% of

the rated voltage at ice machine start‑up, when the

electrical load is highest.

• The minimum wire size is #14 for less than 100'

or #12 for more than 100'

(31 m) to 200' (61 m), use solid

(31 m)

copper conductor only. The recommended breaker is

15 amp. Local or state electrical code, length of run or

materials used, can increase the minimum wire gauge

required. A qualied electrician must determine the

proper wire size, although #14 is the minimum size

allowed.

• The minimum circuit requirement is used to help select

the wire size of the electrical supply. Minimum circuit

requirement is not the ice machine’s running amp load.

• Observe correct polarity of incoming line voltage.

Incorrect polarity can lead to erratic ice machine oper‑

ation and a safety issue.

Do not use an extension cord or two-prong adapter.

Electrical ground is required on this appliance.

Location of electrical supply.

Page 6

Ice Machine Specications 6

Plumbing Requirements

The ice machine must be installed with adequate clear‑

ance for water and drain connections at the rear of the

unit. Prepare the water supply line and drain connection

before installing the ice machine.

Improper water supply and drain connections can

result in personal injury and property damage.

Plumbing Requirements

Water Supply Line

or PEX tubing

Water Pressure 20–80 psi

Water Temperature 50°F (10°C) – 80°F (27°C)

Water Outlet (gravity drain)

Water Outlet (drain pump)

1

/4" OD copper, braided stainless steel

(1.4–5.5 bar)

3

/4" (19) ID hose

3

/8" (10) ID hose

WATER SUPPLY LINE

For all ice machine models, locate the water supply line as

shown in the illustration below.

IMPORTANT NOTE: It is recommended that the water

supply be placed in an adjacent cabinet within the shaded

area shown in the illustration. If placed within the opening,

additional cabinet depth may be required.

The water supply line should be connected to the house

supply with an easily accessible shut‑off valve between

the water supply and the ice machine. A reverse osmosis

system can be used, provided there is constant water

pressure of 20 psi

(1.4 bar) to 80 psi (5.5 bar) supplied to the

unit at all times. A copper line is not recommended for this

application.

• A cold water supply line must be supplied to the

ice machine. Use

1

/4" (6) OD copper, braided stain‑

less steel or PEX tubing and compression tting (not

included). The incoming water temperature must

remain between 50°F

(10°C) and 80°F (27°C).

• Do not connect the ice machine to a hot water supply.

Be sure all hot water restrictors installed for other

equipment are working, such as check valves on sink

faucets, dishwashers, etc.

• If water pressure exceeds the maximum recommended,

install a water pressure regulator.

• Insulate the water supply line to prevent condensation.

12"

(305)

3"(76)

3"(76)

12"

(305)

1

/2"

(13)

LOCATION OF

WATER LINE

TOP VIEW

Location of water supply line.

8"

(203)

Page 7

Ice Machine Specications 7

subzero.com/specs

Plumbing Requirements

DRAIN CONNECTION

Models UC‑15I and UC‑15IO are gravity drain models that

require a drain tube that is pitched down from the outlet

at the back of the unit to the sanitary sewer connection.

Models UC‑15IP and UC‑15IPO have a built in drain pump

that will pump water up to a drain point, such as a sink.

Gravity drain models are supplied with a drain hose for

gravity draining. A pump model must be used if a gravity

drain is not possible. Both drain methods require routing

to an open site drain. Do not connect directly to a drain

line as bacteria from the drain line may contaminate the

ice machine. Locate the drain in an adjacent cabinet.

Refer to the illustrations below. For installations that will

not allow the drain to be placed in an adjacent cabinet, the

drain must be located within

1

/2" (13) of the back wall.

Improper drainage can lead to water owing back into

ice machine and poor performance.

AIR GAP

DRAIN TUBE

SHUT-OFF

VALVE

WATER

SUPPLY

DRAIN

TUBE

SHUT-OFF

VALVE

WATER

SUPPLY

• The ice machine drain connection is approximately

5"

(127) from the oor.

• For the gravity drain, all horizontal runs of drain lines

must have a

• Drain pump models have a maximum rise of 12'

and a maximum run of 100'

1

/4" (6) per 12" (305) fall.

(31 m).

(4 m)

• Drain pump models will likely require an air gap

between the unit and the drain receptacle.

• The oor drain must be large enough to accommodate

drainage from all drain lines.

• The drain pump discharge line must terminate at an

open site drain.

• If there is not adequate room behind the ice machine

for the drain or waste water receptacle, the drain can

be located below the oor.

WATER FILTER

The water lter provided with the ice machine is designed

to inhibit scale formation, lter sediment, and remove

chlorine odor and taste. The life expectancy of the water

lter is approximately six months during normal usage.

The ice machine control board will monitor water usage

and indicate when replacement is required.

Replacement water lters are avail able through your

authorized Sub‑Zero dealer. For local dealer information,

visit the nd a showroom section of our website, subzero.

com.

Gravity drain models.

Drain pump models.

Page 8

Ice Machine Installation 8

Installation Requirements

• Installation must allow removal of the ice machine for

cleaning and service. Service diagnostics are per‑

formed from the top of the ice machine.

• If the ice machine is installed in a corner, the door

swing may be limited due to handle contact with the

adjacent wall or cabinet. A 90° door stop is provided.

• Do not install the ice machine within 18"

container, compactor or recycling container.

• Do not install the ice machine near heat‑generating

equipment.

• The installation location must not obstruct airow

through the kickplate.

• The installation location must be free of airborne and

other contaminants.

• The ambient air temperature must be between 50°F

(10°C) and 100°F (38°C) for indoor models and between

50°F

(10°C) and 110°F (43°C) for outdoor models.

IMPORTANT NOTE: Failure to follow installation require‑

ments of the ice machine may affect warranty coverage.

(457) of a trash

Installation

Before moving the ice machine into position, make sure

all opening dimensions, electrical and plumbing require‑

ments are complete and accurate. The oor under the ice

machine must be at the same level as the surrounding

nished oor.

Move the ice maker into position near the installation

opening. Remove and discard all packing materials.

Remove the literature packet and drain hose from inside

the ice machine. The bin thermostat clip is shipped with

tape holding it in position. Remove the tape. Also, remove

the tape securing the water shutters.

Although the ice machine has been designed to be

serviced in place, in some cases it may be necessary to

slide the unit out for service or cleaning. The installation

must allow for removal of the unit.

Before moving the ice machine into position, protect

any nished ooring to avoid damage.

The ice machine must be protected if it will be

exposed to ambient temperatures below 32°F

Component failure caused by exposure to freezing

temperatures is not covered by the warranty.

(0°C).

Page 9

Ice Machine Installation 9

subzero.com/specs

Installation

INSTALL THE ICE MACHINE

1) Adjust the leveling legs close to the desired height.

Refer to the illustration below.

2) Reverse the door swing if needed. Refer to steps

outlined on the following pages.

3) Gravity drain models: Install the drain hose (provided)

onto the drain tting on the back of unit and route to

the open site drain. Refer to the illustration below and

plumbing requirements on pages 6–7.

Pump models: Route drain tubing through the drain

tting on the back of the unit and install the drain hose

(provided) on the drain pump. Route the other end of

the drain tubing to the drain site. Refer to the illustra‑

tion below and plumbing requirements on pages 6–7.

4) Use a compression tting to connect the water inlet on

back of ice machine to the prepared

1

/4" (6) OD cold

water line. Refer to the illustration below.

5) Open the shut‑off valve on the water line. Check all

plumbing connections for leaks. Failure to do so could

result in ooding.

6) Plug the power cord into the grounded receptacle.

7) Level the ice machine to assure that the door closes

and seals properly. Place a level on top of the unit and

turn each leveling leg to raise or lower as needed.

8) Move the ice machine into its nal position.

9) Secure the ice machine by installing two #8 x

1

/2" at

head screws through each hinge. Refer to the illustra‑

tion below.

10) Add 1 tablespoon

(15 ml) of undiluted ice machine

sanitizer to a container that will t under the lifted

water shutters. Refer to the illustration below for

location of the water shuttters.

11) Press the CLEAN key pad. Wait three minutes until

the CLEAN light ashes, then add the prepared sani‑

tizer by lifting the water shutters and pouring directly

into the spray area. The ice machine will automatically

time out a ten‑minute sanitizing cycle, followed by

eight rinse cycles, and stop. The CLEAN light will turn

off to indicate that the sanitizing cycle is complete.

This entire cycle lasts approximately 30 minutes.

12) Add one gallon

(3.8 L) of cold water to a container that

will easily t under the lifted water shutters. Lift the

water shutters and pour the water directly into the

spray area. Watch for proper drainage.

13) Press the POWER button.

14) At initial start‑up, the ice machine will need approxi‑

mately 30 minutes to freeze ice and up to ve minutes

to harvest the ice. Wait for rst cycle of cubes to drop

to ensure proper installation.

Leveling.

LEVELING

LEG

DRAIN FITTING

WATER INLET

Drain connection.

HINGE

SCREWS

Secure ice machine.

WATER

SHUTTERS

Location of water shutters.

Page 10

Ice Machine Installation 10

Reverse Door Swing

The hinged side of the door may be reversed to the other

side if needed.

The ice machine is shipped with the door hinged at the

right. The door and hinges are designed for placing

the hinges on either the right or the left side of the unit.

Moving the hinges to the left in the pre‑drilled holes,

allows the door to pivot from the left side.

IMPORTANT NOTE: The plastic molding which covers the

top area of the door, packaged with the ice machine, is

required for this procedure.

1) To begin, remove the four screws that secure the door

hinges to the ice machine. Refer to the illustration

below. Remove the door. Remove the shim located

between the cabinet and bottom hinge, this shim will

transfer to the left side bottom hinge.

HINGE

SCREWS

2) Remove the hinges from the door by removing the four

screws (two per hinge) that secure the hinges to the

door. Refer to the illustration below.

3) Remove the right‑hand upper trim (shaded area) from

the door by removing the two screws that secure it to

the door. Refer to the illustration below. Replace it with

the left‑hand upper trim.

4) Transfer the hinges to the left side of the door and

reinstall. The upper hinge will now be in the lower hinge

position and the lower hinge will now be in the upper

hinge position. Refer to the illustration below.

UPPER

TRIM (RH)

HINGE

HINGE

UPPER

TRIM (LH)

Remove door.

HINGE

Remove hinges and trim.

Transfer hinges.

HINGE

Page 11

Ice Machine Installation 11

TRIM PLATE

SCREWS

subzero.com/specs

Reverse Door Swing

5) Remove the ice machine top cover by removing the

two screws along the back of the unit. Refer to the

illustration below.

6) Remove four screws from the front top rail. Refer to the

illustration below.

7) Pivot the top rail end for end to expose the two left‑

hand top hinge screw holes and reinstall.

TOP COVER

SCREWS

Remove top cover.

Remove front top rail.

TOP RAIL

SCREWS

8) Remove two screws from the lower edge of the bottom

trim plate and slide the trim plate to the right, to cover

the right‑hinge mounting screw holes. The left‑hinge

mounting screw holes will now be exposed. Refer to

the illustration below.

9) Reinstall the door by mounting hinges using the left‑

hinge mounting holes. Reinstall the shim removed in

step 1, between the cabinet and bottom hinge. Check

operation of the door by opening it.

Bottom trim plate.

Page 12

Ice Machine Installation 12

Panel Installation

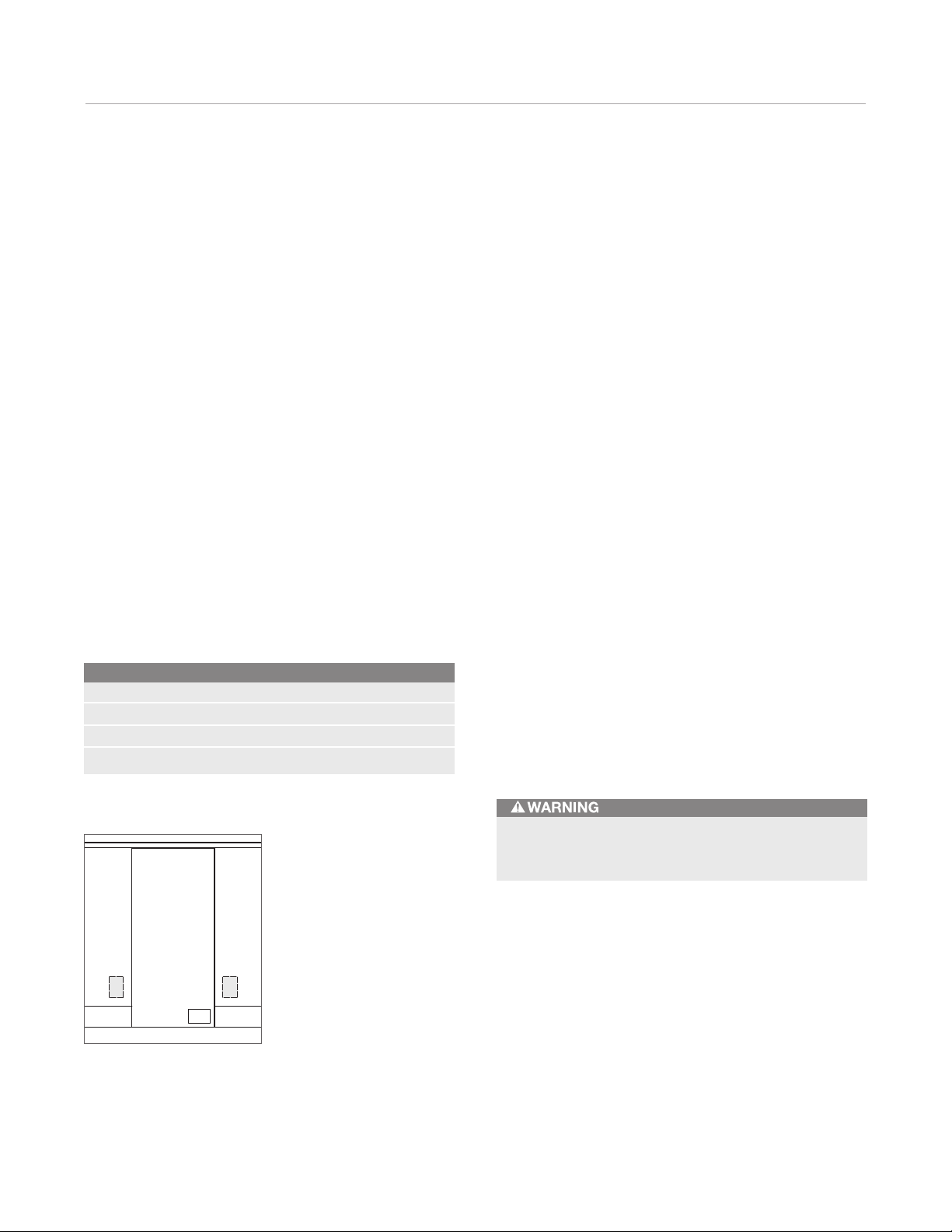

DOOR PANEL INSTALLATION

You should be sure of the door panel size and placement

before proceeding with the installation. Refer to the chart

for panel specications. If you have questions, contact

your authorized Sub‑Zero dealer or cabinet supplier.

For door handle hardware, a D‑style pull, centered on

the edge opposite the door hinge side is recommended.

Screw heads may need to be countersunk to ensure that

the hardware does not interfere with the panel tting ush

with the door.

Remove the handle side bracket attached to the front of

the door and set aside. Place the door panel lying face

down on a protected surface to ensure that the front will

not be scratched or damaged.

On the back of the panel, position the plastic template

(provided) ush with the top and side edges. Be sure you

are following the exact position for right‑hand or left‑hand

door swing. Refer to the illustration below.

Door Panel Specications

Panel Width 15" (381)

Panel Height 303/8" (772)

Minimum Thickness

Maximum Weight 15 lbs (7 kg)

Dimensions based on 1/8" (3) reveal.

5

/8" (16)

Panel dimensions in the chart are the minimum necessary

to cover the door. The exact dimensions of your door

panel may vary depending on your particular installation.

Once you have located the proper position for the

hardware, mark the holes, remove template, and drill

pilot holes for mounting the hardware. It is best to start

the rst few holes, position the hardware and then drill the

remaining pilot holes. Secure the mounting brackets with

1

#8 x

/2" screws. Refer to the illustrations below.

Install the door panel by engaging the tabbed bracket to

the door rst and then sliding the hinge side hardware

over the positioning screws. You will have a

1

/4" (6) adjust‑

ment, up and down, and side to side.

Template position.

Once you have the door in place, attach the remaining

1

#8 x

/2" screws to the hinge side mounting bracket and

install the hinge covers. Refer to page 14.

Right-hand door panel.

Left-hand door panel.

Page 13

Ice Machine Installation 13

subzero.com/specs

Panel Installation

Exercise caution when drilling holes for mounting

hardware. This is especially critical with inset panels.

If the reveal on the hinge side of the door panel is less

1

than

/4", and the panel has a square corner, severe

nger pinching or damage to the unit may occur.

SIDE PANEL INSTALLATION

With the ice machine, you must securely fasten side

panels to adjacent cabinets and oor. Brackets and

screws are provided for mounting the unit to adjoining

cabinets and side panels.

Side panels should be fastened to the oor and walls

using L‑shaped brackets (not included). To help move the

unit into place, rout out an area in the oor so the bracket

will sit ush with the oor.

Installation

INSTALL KICKPLATE

Once the ice machine is in position, install the kick‑

plate using the screws provided. The kickplate must be

removed for servicing. The oor cannot interfere with

removal. Do not cover the vents of the kickplate to allow

proper airow. The door panel may hang in front of the

vents, but a decorative kickplate must not cover the vents.

If you choose, the kickplate may be painted another color.

Follow these steps: Rough up the surface to be painted

with ne grit sandpaper. Wipe with alcohol to ensure that

the surface is clean and dry. Use an appliance or industrial

grade, oil base, high gloss enamel paint.

Page 14

Ice Machine Installation 14

Installation

90° DOOR STOP

Door stop pins provided with the ice machine will limit the

door swing to 90°. Follow these steps to install:

1) Open the door to approximately 80°.

2) Insert the stop pin into the bottom door hinge (pin

enters from the top). Refer to the illustration below. The

pin must be inserted until the head has made contact

with the hinge body.

3) Insert the stop pin into the top door hinge (pin enters

from the bottom).

4) Check for proper operation.

HINGE COVER INSTALLATION

Install the hinge covers after installation of the ice machine

is complete. The 90° door stop must be installed prior to

installing the hinge covers. It will be necessary to remove

the knock‑out in the hinge cover when the 90° door stop

is used.

Make sure hinges are free of dirt or grease before applying

covers. To install, remove backing paper from the

adhesive pads and bond to the hinge. Attach the magnetic

center covers. Refer to the illustration below.

Installation Checklist

To ensure a safe and proper installation, the following

checklist should be completed by the installer to ensure

that no part of the installation has been overlooked.

INSTALLATION CHECKLIST

Have all electrical and water connections been made?

Is the power cord plugged into a properly grounded

3‑prong outlet, which has been installed in accordance

with all applicable electrical codes?

Is the water supply turned on? Have water supply and

drain connections been examined for leaks?

Is the ice machine drain line routed to an open site

drain for gravity drains and according to instructions

for drain pump models?

Has all packing materials and tape been removed?

Is the ice machine level? Are all leveling legs making

contact with the oor?

Has the kickplate been installed properly? Is there

proper clearance in front of the kickplate for airow?

If applicable, is the door panel installed properly?

If applicable, has the 90° door stop been installed?

Have hinge covers been installed?

DOOR STOP PIN

90° door stop.

KNOCK-OUT

Hinge cover installation.

Has the ice machine and bin been sanitized?

Does the customer understand the unit's operation

and maintenance? Have you given the customer the

warranty package?

Have any installation or service problems been noted

on the product registration card? Has the registration

card been mailed in?

If applicable, has the stainless steel door panel been

inspected for any imperfections? This is to be done

by the dealer or installer with the customer upon com‑

pletion of the installation. Stainless steel panels are

covered by a limited 60‑day parts and labor warranty

for cosmetic defects.

Page 15

Service Information 15

subzero.com/specs

Service Information

If service is necessary, maintain the quality built into your

ice machine by calling Sub‑Zero factory certied service.

For the name and number of Sub‑Zero factory certied

service nearest you, check the contact & support section

of our website, subzero.com or call Sub‑Zero customer

care at 800‑222‑7820.

When calling for service, you will need the model and

serial numbers of your unit. Both numbers are listed on the

product rating plate, located in the upper left corner of the

ice bin and on the back of the unit. Refer to the illustration

below.

If you are storing or disposing of your old refrigerator

or freezer, please do it

safely. Remove the

doors or tightly secure

the doors closed.

Child entrapment

accidents can be tragic.

RATING PLATE

Location of rating plate.

The information and images in this guide are the copyright property of Sub‑Zero, Inc. Neither this guide nor any information or images contained herein may be

copied or used in whole or in part without the express written permission of Sub‑Zero, Inc. ©Sub‑Zero, Inc. all rights reserved.

Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf Appliance, Inc.

Sub‑Zero, Sub‑Zero & Design, Dual Refrigeration, Constant Care and The Living Kitchen are registered trademarks and service marks of Sub‑Zero, Inc.

(collectively, the “Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

Page 16

SUB-ZERO, INC. P. O. BOX 44848 MADISON, WI 53744 SUBZERO.COM 800.222.7820

7024818 REV‑B 10 / 2013

Loading...

Loading...