Page 1

PRO 48 Refrigeration Installation Guide

Page 2

PRO 48 REFRIGERATION

Contents

3 PRO 48 Refrigeration

4 Opening Dimensions

5 Electrical

5 Plumbing

6 Preparation

6 Anti-Tip Bracket

8 Placement

8 Water Line

8 Alignment

10 Completion

Features and specications are subject to change at any

time without notice. Visit subzero.com/specs for the most

up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

Page 3

PRO 48 REFRIGERATION

Product Information

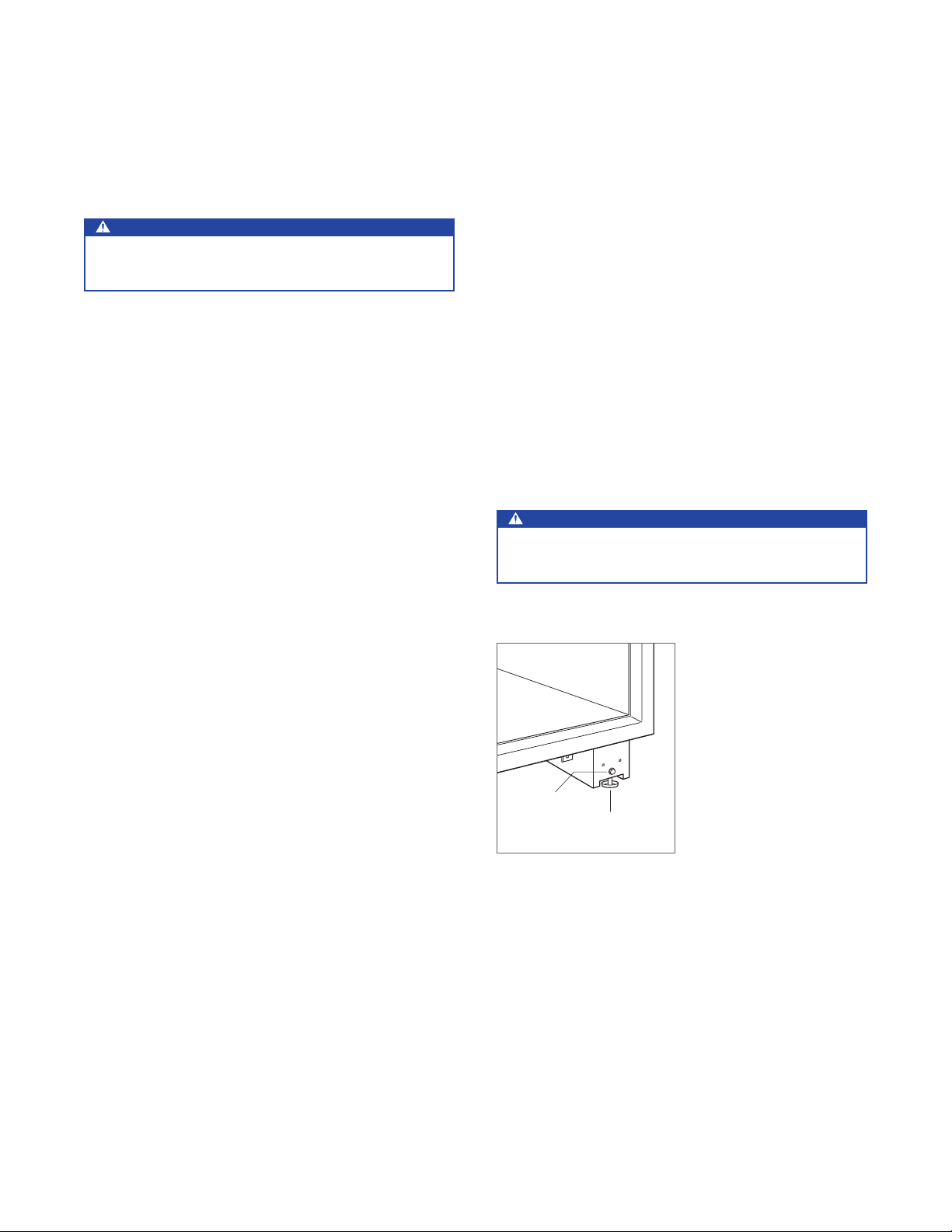

Important product information including the model and

serial number are listed on the product rating plate. The

rating plate is located inside the cabinet, to the left of the

upper freezer drawer. Refer to the illustration below.

If service is necessary, contact Sub-Zero factory certied

service with the model and serial number. For the name

of the nearest Sub-Zero factory certied service or for

questions regarding the installation, visit the contact & support section of our website, subzero.com or call Sub-Zero

customer care at 800-222-7820.

RATING

PLATE

Tools and Materials

• Screwdrivers—standard, Phillips and Torx.

• Power drill.

• Drill bits (masonry bits required for concrete installation).

• Standard Allen wrench set.

• Standard socket and wrench set.

• 2' and 4' levels.

• Tubing cutter.

1

• 3' of

• Saddle valve.

• Material to protect home, ooring and cabinetry during

/4" OD copper, braided stainless steel or PEX

tubing.

installation.

Rating plate location (inside

drawer).

subzero.com | 3

Page 4

SITE PREPARATION

SIDE

Opening Dimensions

STANDARD AND FLUSH BUILT-IN INSTALLATIONS

TOP VIEW

D

OPENING

DEPTH

W

OPENING WIDTH

FRONT VIEW

VIEW

H

OPENING

HEIGHT

OPENING W H D

Standard 471/2" (1206) 833/4" (2127) 24" (610)

Flush 48" (1219) 841/8" (2137) 26" (660)

For standard built-in installations, the face frame will extend

(51) beyond cabinetry. In ush installations, the face frame

2"

will be ush with surrounding cabinetry.

4 | Sub-Zero Customer Care 800.222.7820

Page 5

SITE PREPARATION

Electrical

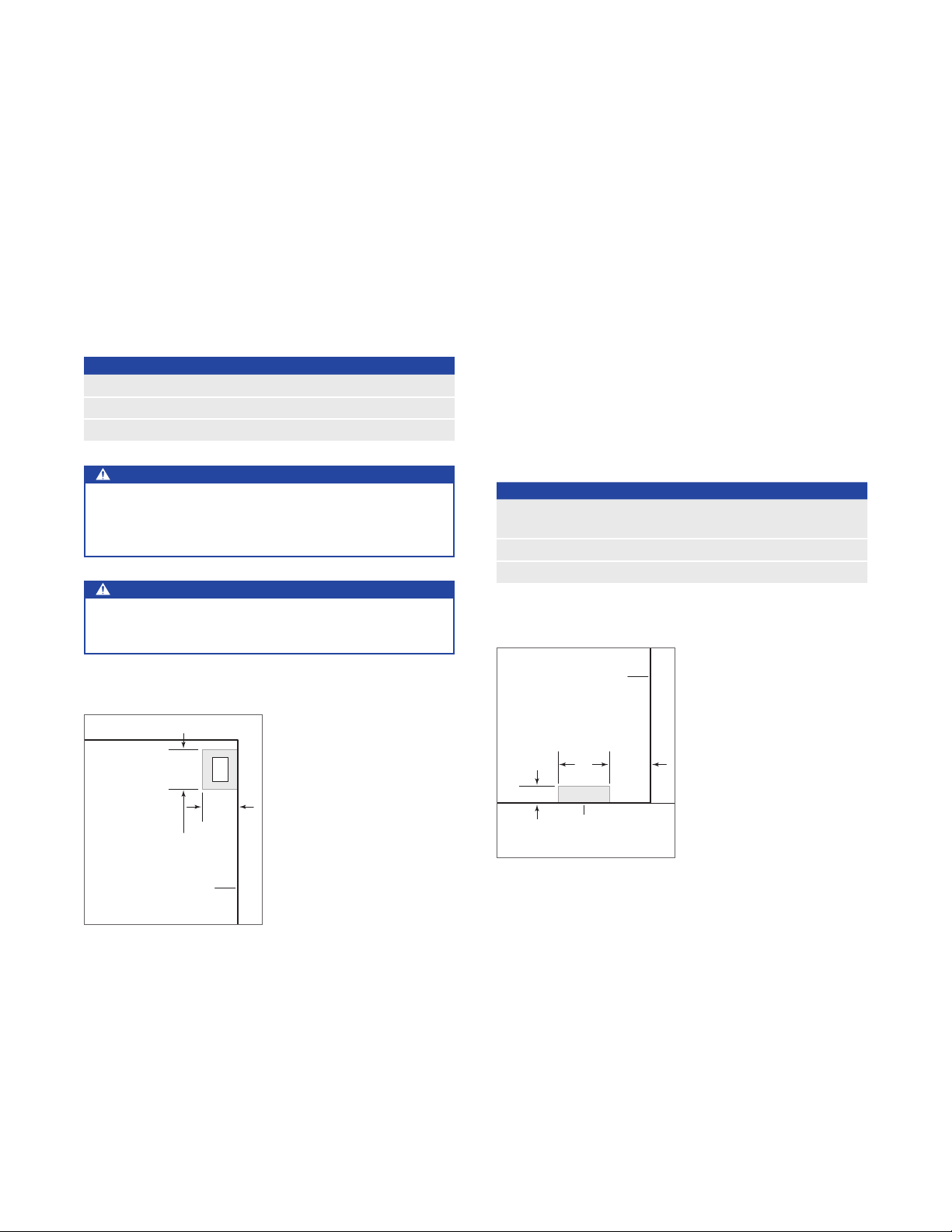

Installation must comply with all applicable electrical codes.

The electrical supply should be located within the shaded

area shown in the illustration below. A separate circuit, servicing only this appliance is required. A ground fault circuit

interrupter (GFCI) is not recommended and may cause interruption of operation.

ELECTRICAL REQUIREMENTS

Electrical Supply 115 VAC, 60 Hz

Service 15 amp

Receptacle 3-prong grounding-type

CAUTION

The outlet must be checked by a qualied electrician to

be sure that it is wired with the correct polarity. Verify

that the outlet is properly grounded.

WARNING

Do not use an extension cord, two-prong adapter or

remove the power cord ground prong.

Plumbing

Installation must comply with all applicable plumbing codes.

The water supply line should be located within the shaded

area shown in the illustration below. The water supply line

should be connected to the house supply with an easily

accessible shut-off valve. Do not use self-piercing valves.

The water supply line must not interfere with installation of

the anti-tip bracket.

A reverse osmosis system can be used provided there is

constant water pressure of 35–120 psi

to the unit at all times. In this application, the water ltration

system must be bypassed by removing the lter. A copper

line is not recommended for this application.

PLUMBING REQUIREMENTS

Water Supply

Pressure 35–120 psi

Excess Line for Connection 36" (914)

(2.4–8.3 bar) supplied

1

/4" OD copper, braided

stainless steel or PEX tubing

(2.4–8.3 bar)

7"

E

(178)

6"

(152)

751/2" (1918)

FROM FLOOR

RIGHT SIDE

OF OPENING

Electrical supply location.

RIGHT SIDE

OF OPENING

53/16"

6"

(132)

(152)

3" (76)

1

AREA EXTENDS

FORWARD ON FLOOR

/2" (13)

Water supply location.

subzero.com | 5

Page 6

SITE PREPARATION

Preparation

Uncrate the unit and inspect for damage. Remove the wood

base and discard shipping bolts and brackets. Remove and

recycle packing materials. Do not discard the kickplate, antitip bracket and hardware.

Completely retract the front leveling legs to allow the unit to

be moved into position. The front and rear leveling legs can

be adjusted from the front once the unit is in position.

Remove the drain pan from the base of the unit to avoid

damage, and allow for proper appliance dolly placement.

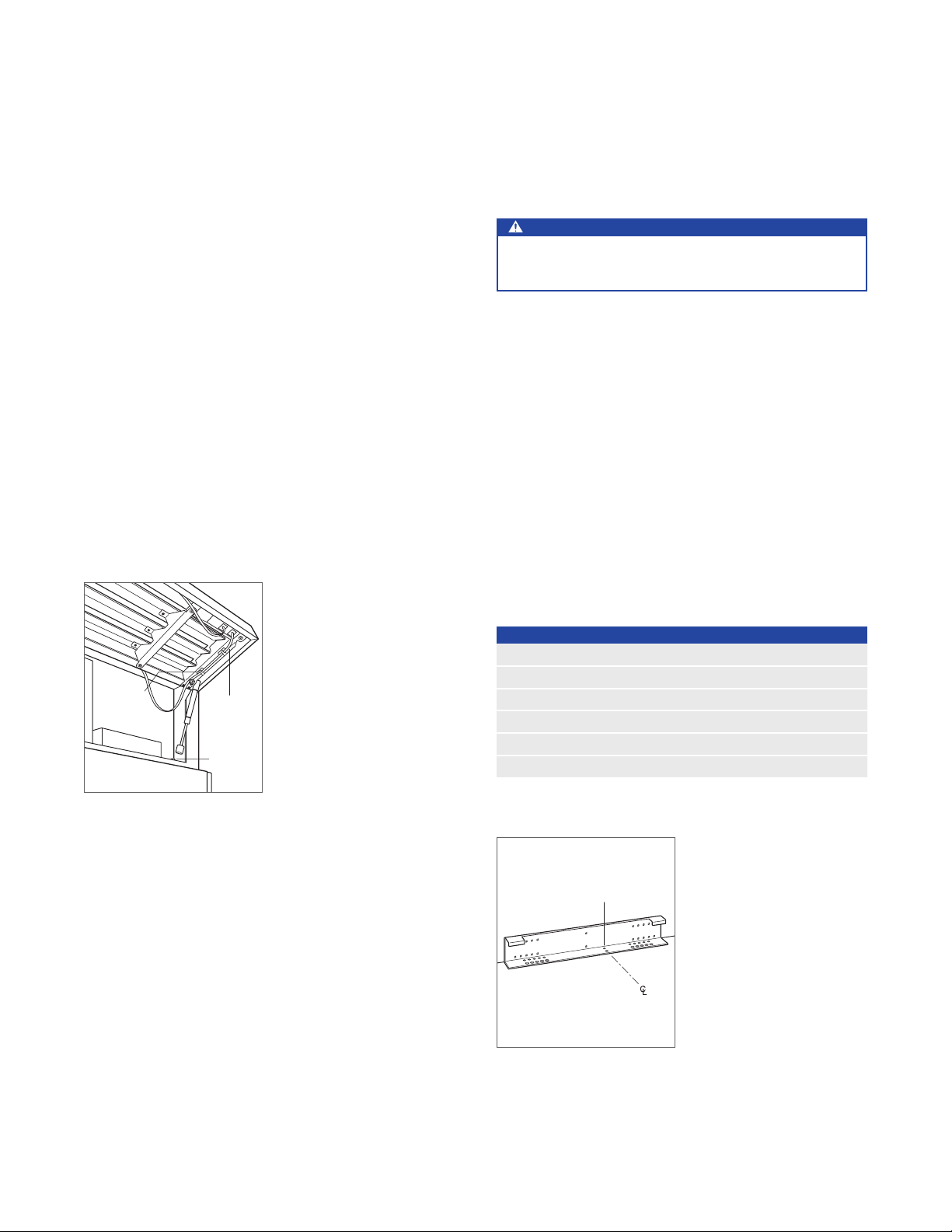

The grille assembly should be removed prior to moving the

unit. To remove, pull out on the bottom edge of the grille and

rotate upward. Cut cable ties that attach the network cable

to the grille, then disconnect the network cable. Remove

three grille bolts from the grille, then pull grille forward to

remove. Refer to the illustration below.

CABLE TIE

NETWORK

CABLE

GRILLE

BOLT

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

bracket must be installed.

Use the centerline locating holes to position the anti-tip

bracket in the center of the opening. The bracket must be

positioned 24"

back of the bracket. This depth will increase to 26"

a ush installation. Failure to properly position the anti-tip

bracket will prevent proper engagement.

Use all anti-tip bracket hardware as instructed for wood or

concrete oors.

IMPORTANT NOTE: For wood or concrete oor applications,

if the #12 screws do not hit a wall stud or wall plate, use the

#8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subooring or

nished oor may necessitate angling the screws used to

fasten the anti-tip bracket to the back wall.

ANTI-TIP HARDWARE

1 Anti-tip bracket

12 #12 x 2

3

12 #12 at washers

3 #8–18 x 1

3 Nylon Zip-it

(610) from the front of the opening to the

1

/2" pan head screws

3

/8"–16 x 33/4" wedge anchors

1

/4" truss head screws

®

wall anchors

(660) for

Grille removal.

6 | Sub-Zero Customer Care 800.222.7820

CENTERLINE

LOCATING HOLES

Anti-tip bracket.

Page 7

SITE PREPARATION

Anti-Tip Bracket

WOOD FLOOR APPLICATION

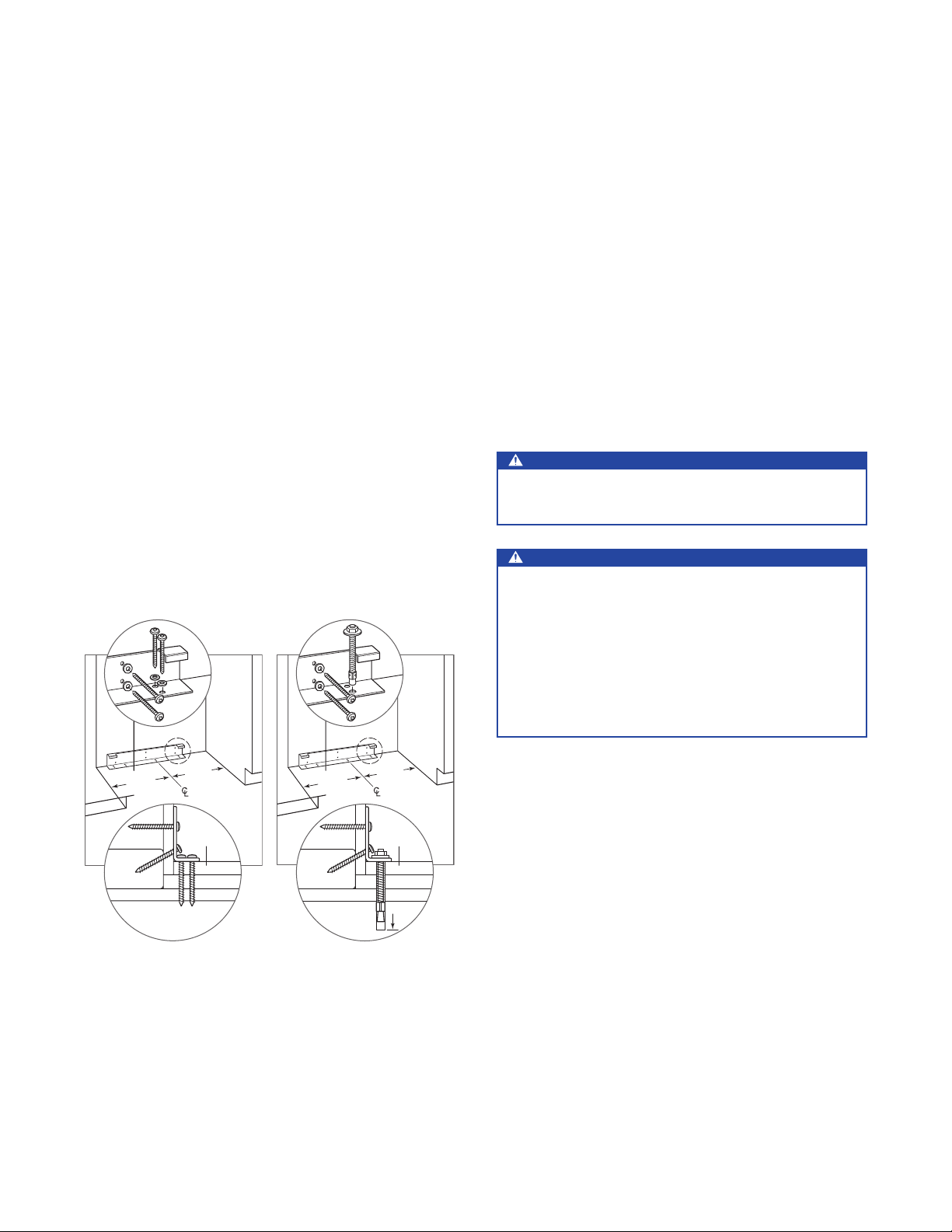

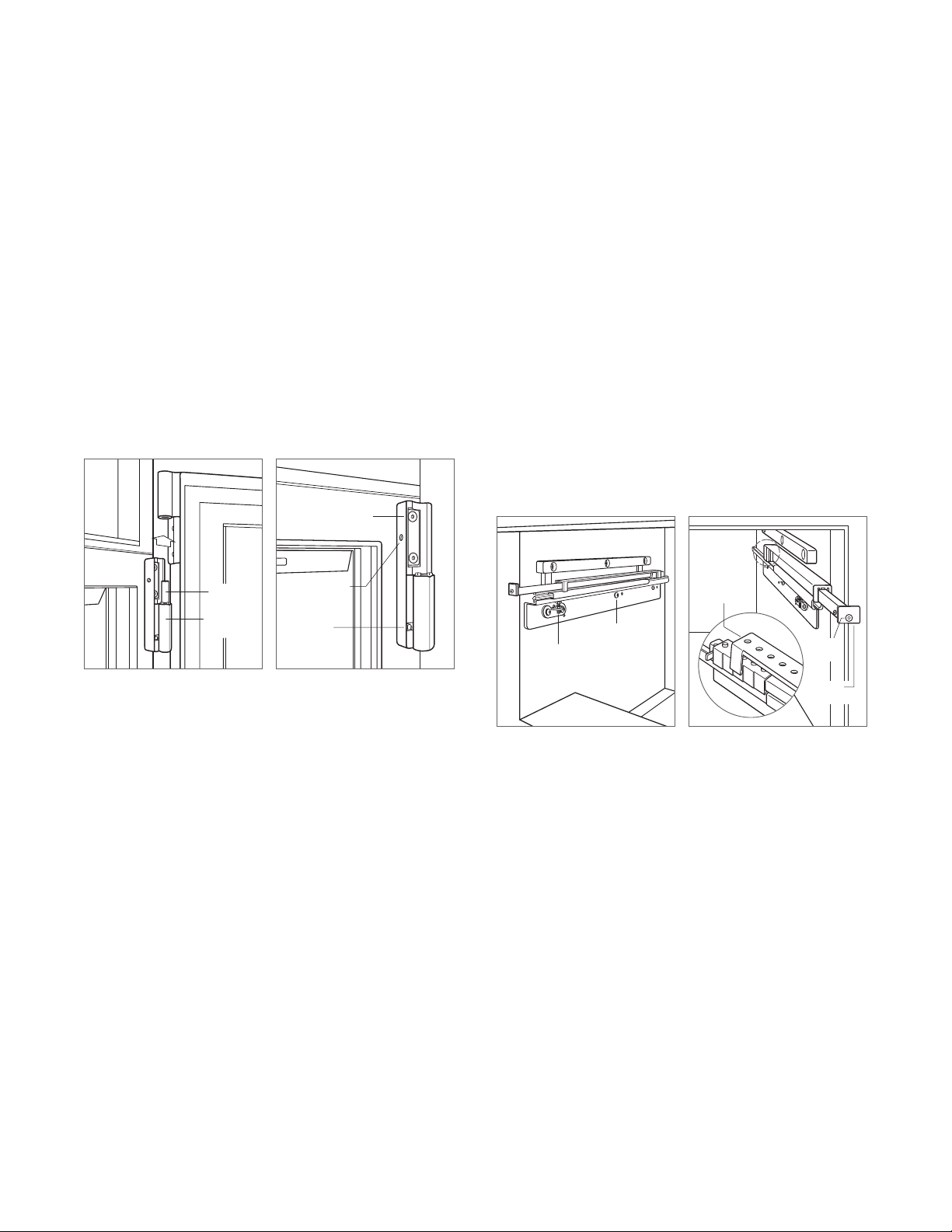

After properly locating the anti-tip bracket in the opening,

3

drill pilot holes

/16" (5) diameter maximum in the wall studs

or wall plate. Use the #12 screws and washers to secure

the bracket. Verify the screws penetrate through the ooring

3

material and into wall studs or wall plate a minimum of

(19)

. Refer to the illustration below.

/4"

CONCRETE FLOOR APPLICATION

After properly locating the anti-tip bracket in the opening,

3

drill pilot holes

or wall plate. Drill

a minimum of 1

washers to secure the bracket to the wall, and use the

/16" (5) diameter maximum in the wall studs

3

/8" (10) diameter holes into the concrete

1

/2" (38) deep. Use the #12 screws and

3

/8"

wedge anchors to secure the bracket to the oor. Verify the

3

screws penetrate wall studs or wall plate a minimum of

(19)

. Refer to the illustration below.

/4"

CONCRETE WEDGE ANCHOR INSTALLATION:

1 Drill a

3

/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or drill additional

depth to accommodate drill nes.

2 Assemble the washer and nut ush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is ush with the

surface material.

3 Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 25 foot-pounds of torque.

WARNING

Verify there are no electrical wires or plumbing in the

area which the screws could penetrate.

CAUTION

Always wear safety glasses and use other necessary protective devices or apparel when installing or

working with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use in

new concrete which has not had sufcient time to cure.

The use of core drills is not recommended to drill holes

for the anchors.

233/4"

(603)

WALL PLATE

SUBFLOORING

Wood oor.

233/4"

(603)

FINISHED

FLOORING

WOOD FLOOR

233/4"

(603)

WALL PLATE

SUBFLOORING

CONCRETE

FLOOR

Concrete oor.

233/4"

(603)

FINISHED

FLOORING

11/2"(38)

min

subzero.com | 7

Page 8

INSTALLATION

Placement

CAUTION

Before moving the unit into position, secure doors and

drawers closed and protect any nished ooring.

Use an appliance dolly to move the unit near the opening.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

Plug the power cord into the grounded outlet and roll the

unit into position. Verify the anti-tip bracket is properly

engaged.

Water Line

Approximately 3' (.9 m) of 1/4" plastic tubing is connected to

the unit with a preassembled

under the unit. The water line tting connection kit, provided

with the unit, contains a

connection to the household water line.

Purge the water line prior to nal connection to the unit. This

will remove any debris that may be present in the tubing

from installing the new water line.

1

/4" compression connection

1

/4" compression union tting for

Alignment

LEVELING

Once the unit is in position, turn the front leveling legs

clockwise to adjust the height. The rear height adjustment

can be made from the front of the roller base. Using a

3

socket, turn the

/8" hex bolt clockwise to raise the unit or

counterclockwise to lower. Use the lowest torque setting

when using a power drill. Do not turn the rear leveling legs

by hand. Refer to the illustration below.

When the unit is properly leveled, door and drawer adjustments are less likely to be necessary.

IMPORTANT NOTE: Level the unit to the oor, not sur-

rounding cabinetry. This could affect the operation of the

unit, such as door closing.

WARNING

To reduce the possibility of the unit tipping forward, the

front leveling legs must be in contact with the oor.

3

/8"

Place the sleeve and nut on the water line and fasten

to the connection at the end of the tubing. Do not over

tighten. Check all water line ttings for leaks. Verify the

drain pan can be installed and removed without water line

interference.

IMPORTANT NOTE: If a reverse osmosis system used, it is

recommended that the water ltration system be bypassed

by removing the lter.

IMPORTANT NOTE: Water lines can not be exposed to

freezing temperatures.

REAR

ADJUSTMENT

Leveling.

FRONT

LEVELING LEG

8 | Sub-Zero Customer Care 800.222.7820

Page 9

INSTALLATION

Alignment

DOOR ADJUSTMENT

To make adjustments, remove door and door stop, then

slightly loosen the two upper hinge screws. Use the Allen

wrench provided to turn adjustment screw to adjust hinge.

Refer to the illustration below. Reinstall door and check

alignment. Repeat until door is properly aligned.

IMPORTANT NOTE: When adjusting doors, verify the hinge

tab continues to engage the door light switch. Refer to the

illustration below.

HINGE

SCREW

ADJUSTMENT

SCREW

LIGHT

SWITCH

Hinge adjustment.

Door removal.

HINGE

PIN

CABINET

HINGE

DRAWER ADJUSTMENT

Vertical adjustment | Loosen the three mounting screws.

7

Refer to the illustration below. Using a

/16" wrench, turn the

adjustment bolt clockwise to raise and counterclockwise to

lower. Tighten screws, then reinstall drawer and check alignment. Repeat until drawer is properly aligned.

Horizontal adjustment | Loosen the front drawer slide

screw. Refer to the illustration below. Adjust the front

retainer right or left, then tighten screw. Next, lift up on

the rear retainer and shift forward or backward to maintain

alignment with front retainer. Each set of holes will adjust

1

BOLT

/32" (.8).

MOUNTING

SCREW

REAR

RETAINER

SLIDE

SCREW

FRONT

RETAINER

alignment by

ADJUSTMENT

Vertical adjustment.

Horizontal adjustment.

subzero.com | 9

Page 10

INSTALLATION

Completion

Install the grille assembly and check for proper t. Reconnect the network cable. Refer to page 6. Attach the network

cable to the grille using cable ties provided.

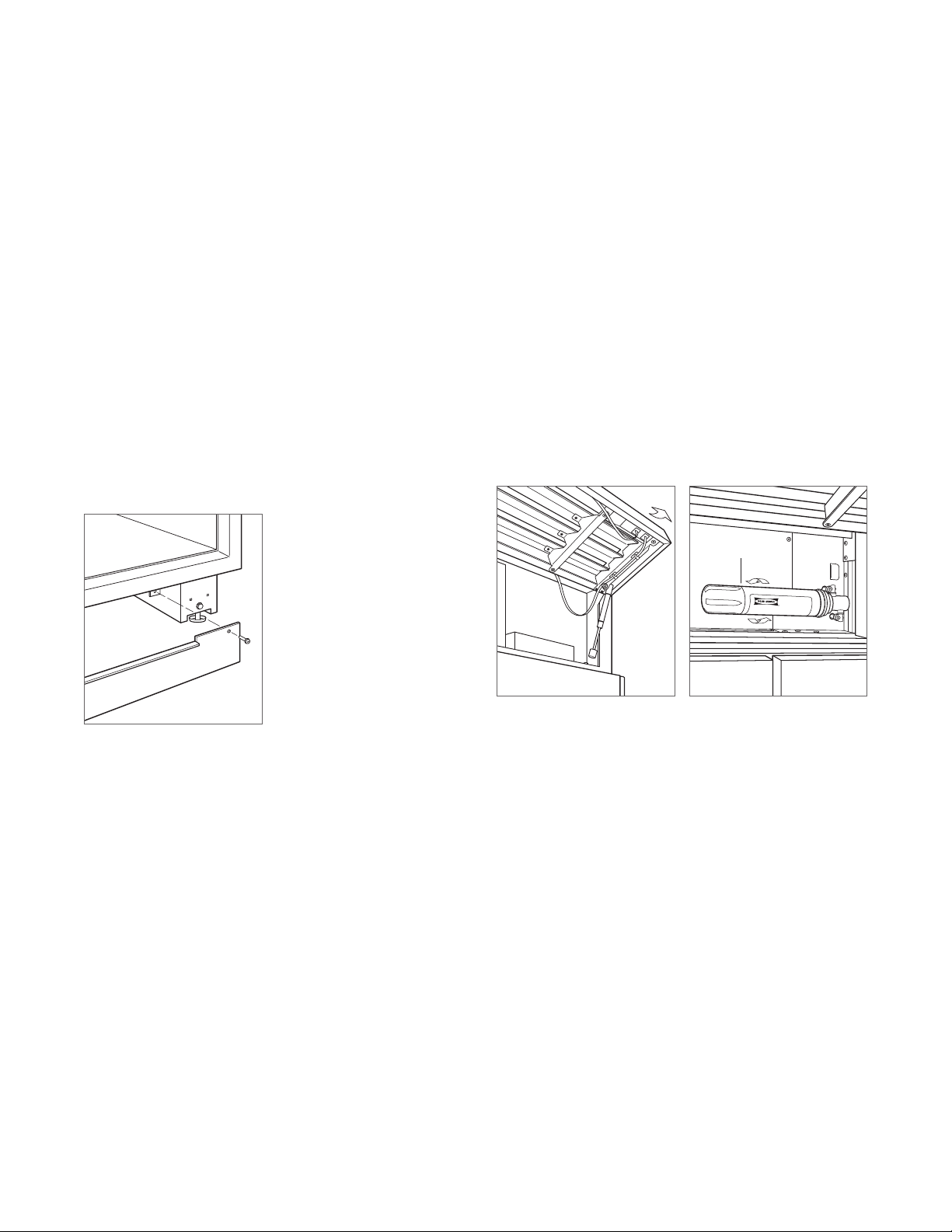

Reinstall the drain pan and verify it is in the proper position.

Install the kickplate using screws to attach it to brackets on

the inside of each roller base. Refer to the illustration below.

The kickplate must be removable for service. The oor

cannot interfere with removal.

Install leg covers. Remove paper backing and press into

position.

Turn power on by touching POWER on the control panel.

WATER FILTER BYPASS

If the water ltration system will not be utilized, it can be

placed in water lter bypass mode by removing the water

lter. Refer to the illustration below. Follow these steps to

remove the water lter:

1 Pull out on the bottom edge of the grille assembly and

tilt the grille frame upward.

2 To remove the cartridge, rotate the cartridge counter-

clockwise one-quarter turn and pull out. Refer to the

illustration below.

WATER FILTER

Kickplate installation.

Open grille.

Water lter removal.

10 | Sub-Zero Customer Care 800.222.7820

Page 11

INSTALLATION

Completion

90° DOOR STOP

The doors of all models open to 135°. For installations

where the door opening must be limited, an optional 90°

door stop kit is available through an authorized Sub-Zero

dealer. For local dealer information, visit the nd a showroom section of our website, subzero.com.

WARNING

Follow all city and state laws when storing, recycling or

discarding unused refrigerators and freezers.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, and Ingredients are registered trademarks and service marks of Sub-Zero, Inc. Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf

Appliance, Inc. (collectively, the “Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

subzero.com | 11

Page 12

UNIDAD DE REFRIGERACIÓN PRO 48

Contenido

3 Unidad de refrigeración PRO 48

4 Dimensiones de abertura

5 Instalación eléctrica

5 Plomería

6 Preparación

6 Soporte antivuelco

8 Colocación

8 Línea de agua

8 Alineación

10 Finalización

Aviso importante

Para garantizar que este producto sea instalado y operado

de la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en esta guía:

AVISO IMPORTANTE resalta la información que es especial-

mente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: En toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique

lo contrario.

2 | Atención al cliente de Sub-Zero 800.222.7820

Page 13

UNIDAD DE REFRIGERACIÓN PRO 48

Información del producto

La información importante del producto, incluido el modelo

y número de serie de la unidad, se encuentran en la placa

de datos del producto. La placa de datos se encuentra

dentro del gabinete, a la izquierda del cajón superior del

refrigerador. Consulte la siguiente ilustración.

Si necesita servicio, póngase en contacto con el centro

de servicio autorizado de Sub-Zero y tenga a la mano el

modelo y número de serie de la unidad. Para obtener los

datos del centro de servicio autorizado de Sub-Zero más

cercano o si tiene preguntas acerca de la instalación, visite

la sección de contacto y soporte técnico en nuestra página

de Internet, subzero.com o llame a la línea de atención al

cliente de Sub-Zero al 800-222-7820.

Herramientas y materiales

• Destornilladores: estándar, Phillips y Torx.

• Taladro eléctrico.

• Brocas (se requieren brocas de mampostería para

instalación en concreto).

• Juego de llaves Allen estándar.

• Juego de llaves estándar y de vaso.

• Niveles 2' y 4'.

• Cortador de tubos.

• 3' de tubería de cobre, trenzada de acero inoxidable o

PEX de

• Válvula de asiento.

• Material para proteger la casa, el piso y los gabinetes

durante la instalación.

1

/4"de diámetro exterior.

PLACA DE

DATOS

Ubicación de la placa de datos

(dentro del cajón).

subzero.com | 3

Page 14

PREPARACIÓN DEL SITIO

SIDE

Dimensiones de abertura

INSTALACIONES INTEGRADAS ESTÁNDAR Y EMPOTRABLES

TOP VIEW

VISTA

SUPERIOR

OPENING

PROFUNDIDAD

DEPTH

DE LA ABERTURA

OPENING

PROFUNDIDAD

DE LA ABERTURA

DEPTH

VIEW

VISTA LATERAL VISTA FRONTAL

OPENING

ALTURA DE

HEIGHT

LA ABERTURA

OPENING

ANCHURA DE

WIDTH

ABERTURA

FRONT VIEW

APERTURA ESTÁNDAR EMPOTRABLE

1

Ancho 47

/2"(1206) 48"(1219)

Altura 833/4"(2127) 841/8"(2137)

Profundidad* 24"(610) 26"(660)

*En las instalaciones estándar, el marco frontal se extenderá

(51) más allá de los gabinetes. En las instalaciones empo-

2"

trables, el marco frontal se instalará con los gabinetes que

lo rodean.

4 | Atención al cliente de Sub-Zero 800.222.7820

Page 15

PREPARACIÓN DEL SITIO

TOP VIEW

BACK WALL

1

/2"

(13)

53/16"

(132)

6"

(152)

Instalación eléctrica

La instalación debe cumplir con todos los códigos eléctricos vigentes.

El suministro eléctrico debe colocarse dentro del área

sombreada que se muestra en la siguiente ilustración.

Es necesario un circuito independiente, que dé servicio

únicamente a este aparato. No es recomendable utilizar un

circuito de fallos de conexión a tierra (GFCI, por sus siglas

en inglés) ya que puede interrumpir el funcionamiento de la

unidad.

REQUISITOS ELÉCTRICOS

Suministro eléctrico 115 V CA, 60 Hz

Interruptor de circuito 15 amperes

Receptáculo Conexión a tierra de 3 clavijas

PRECAUCIÓN

Un electricista calicado debe revisar el tomacorriente

para asegurarse de que la conexión se haya realizado

con la polaridad correcta. Verique que el tomacorriente esté debidamente conectado a tierra.

ADVERTENCIA

No utilice un cable de extensión, adaptador de dos

clavijas ni retire la clavija con conexión a tierra del

cable de alimentación.

Plomería

La instalación debe cumplir con todos los códigos de

plomería vigentes.

La línea del suministro de agua debe colocarse dentro del

área sombreada que se muestra en la siguiente ilustración.

La línea del suministro de agua debe conectarse al suministro doméstico con una válvula de cierre de fácil acceso.

Evite utilizar válvulas autoperforantes. La línea del suministro de agua no debe interferir en la instalación del soporte

antivuelco.

Se puede utilizar un sistema de ósmosis inversa siempre

y cuando la presión del agua que llegue a la unidad se

mantenga de forma constante entre 35 y 120 psi

8.3bares)

en todo momento. En esta aplicación, se debe

desviar el sistema de ltrado de agua mediante la extracción del ltro. No es recomendable utilizar una línea de

cobre para esta aplicación.

REQUISITOS DE PLOMERÍA

Línea de suministro de agua Tubería de cobre, trenzada

de acero inoxidable o PEX de

1

/4"de diámetro exterior.

Presión del agua De 35 a 120 psi

Línea de exceso de agua para la

conexión

(de 2.4 a

(de 2.4 a

8.3bares)

36"(914)

VISTA FRONTAL

FRONT VIEW

7"

7"

E

(178)

(178)

6"

6"

(152)

(152)

751/2"

751/2"

(1918)

(1918)

DESDE EL

FROM

SUELO

FLOOR

Ubicación del suministro

eléctrico.

6"

6"

(152)

(152)

53/16"

53/16"

(132)

SUELO

FLOOR

(132)

3" (76)

3" (76)

VISTA FRONTAL

FRONT VIEW

Ubicación del suministro de

agua (parte posterior).

1

1

/2"

53/16"

53/16"

(132)

(132)

(13)

(13)

/2"

PARED POSTERIOR

BACK WALL

6"

6"

(152)

(152)

TOP VIEW

VISTA SUPERIOR

Ubicación del suministro de

agua (parte inferior).

subzero.com | 5

Page 16

PREPARACIÓN DEL SITIO

Preparación

Desembale la unidad e inspeccione si tiene algún daño.

Retire la base de madera y deseche los pernos y soportes

de transporte. Retire y recicle los materiales de embalaje.

No deseche el zócalo, el soporte antivuelco ni las piezas de

montaje.

Repliegue completamente las patas niveladoras delanteras

para que pueda mover la unidad a su posición. Las patas

niveladoras delanteras y traseras se pueden ajustar desde

el frente de la unidad una vez que la misma está en su

posición.

Retire la bandeja de drenaje de la base de la unidad para

evitar que se dañe y permitir que se pueda colocar bien la

plataforma rodante.

Debe quitar el conjunto de la rejilla antes de mover la

unidad. Para quitarlo, jale el borde inferior de la rejilla hacia

fuera y gire hacia arriba. Corte los amarracables que unen

el cable de red con la rejilla y desconecte el cable de red.

Quite los tres pernos de la rejilla y jálela para extraerla. Consulte la siguiente ilustración.

Soporte antivuelco

ADVERTENCIA

Para evitar que la unidad se incline hacia delante y proporcionar una instalación estable, la unidad debe estar

asegurada en su lugar con el soporte antivuelco.

Utilice los oricios de ubicación de la línea central para

colocar el soporte antivuelco en el centro de la abertura.

El soporte se debe colocar a 24"

abertura hasta la parte posterior del soporte. Esta profundidad aumentará a 26"

(660) en una instalación empotrable.

No colocar correctamente el soporte antivuelco impedirá

que la unidad quede bien enganchada.

Utilice todas las piezas de montaje de los soportes antivuelco de acuerdo con las instrucciones para suelos de

madera o de concreto.

AVISO IMPORTANTE: Para aplicaciones en suelo de madera

o de concreto, si los tornillos del # 12 no alcanzan un

travesaño o la placa de pared, utilice tornillos del # 8 y arandelas del # 12 con los anclajes de pared.

AVISO IMPORTANTE: En algunas instalaciones el contrapiso

o el suelo terminado pueden necesitar que se inclinen los

tornillos utilizados para sujetar el soporte antivuelco a la pared

del fondo.

(610) desde el frente de la

CABLE TIE

AMARRACABLES

Extracción de la rejilla.

6 | Atención al cliente de Sub-Zero 800.222.7820

NETWORK

CABLE

DE RED

CABLE

PERNO

GRILLE

DE LA

BOLT

REJILLA

PIEZAS DE MONTAJE ANTIVUELCO

1 Soporte antivuelco

1

12 Tornillos de cabeza plana de #12 x 2

3

3 Anclas de cuña de

12 Arandelas planas del #12

3 Tornillos de cabeza segmentada de #8–18 x 1

3 Anclajes Nylon Zip-it® para pared

CENTERLINE

ORIFICIOS DE UBICACIÓN

LOCATING HOLES

DE LA LÍNEA CENTRAL

Soporte antivuelco.

/8"–16 x 33/4"

/2"

1

/4"

Page 17

PREPARACIÓN DEL SITIO

Soporte antivuelco

APLICACIÓN EN SUELO DE MADERA

Después de ubicar apropiadamente el soporte antivuelco

en la abertura, taladre los oricios guía con un diámetro

3

máximo de

/16"(5) en los travesaños o en la placa de la

pared. Utilice los tornillos #12 y las arandelas para sujetar

el soporte. Compruebe que los tornillos penetren a través

del material del suelo y los travesaños o la placa de la pared

3

/4"(19) como mínimo. Consulte la siguiente ilustración.

APLICACIÓN EN PISO DE CONCRETO

Después de ubicar apropiadamente el soporte antivuelco

en la abertura, taladre los oricios guía con un diámetro

3

máximo de

pared. Taladre oricios con un diámetro de

concreto con una profundidad de 1

/16"(5) en los travesaños o en la placa de la

3

1

/2"(38) como mínimo.

/8"(10) en el

Utilice los tornillos #12 y las arandelas para sujetar el

3

soporte a la pared, y utilice las anclas de cuña de

/8"para

sujetar el soporte al suelo. Compruebe que los tornillos

penetren a través de los travesaños o la placa de la pared

3

/4"(19) como mínimo. Consulte la siguiente ilustración.

INSTALACIÓN DE LAS ANCLAS DE CUÑA PARA CONCRETO:

1 Haga un oricio de

3

/8"(10) de diámetro con una profundidad superior al empotrado mínimo. Limpie el oricio o

continúe taladrando para hacer el oricio más profundo

y que quepan los residuos en él.

2 Coloque la arandela y la tuerca al ras del extremo del

ancla para proteger las roscas. Inserte el ancla a través

del material que va a jar hasta que la arandela quede

al ras del material de la supercie.

3 Para expandir el ancla gire la tuerca de 3 a 5 vueltas

para ajustarla hasta que quede bien apretada o a

25libras-pie de torsión.

ADVERTENCIA

Verique que no haya cables eléctricos o tuberías en la

zona donde va a introducir los tornillos.

PRECAUCIÓN

Utilice siempre gafas de seguridad y otros dispositivos o prendas de protección que sean necesarios al

instalar o trabajar con anclas.

No se recomienda el uso de anclas en material de

mampostería poco pesado, como son los bloques o

ladrillos; tampoco se recomienda utilizarlos en concreto fresco que no haya tenido tiempo suciente para

curar. No se recomienda el uso de brocas huecas para

hacer los oricios para el ancla.

233/4"

233/4"

233/4"

(603)

(603)

PLACA DE PARED PLACA DE PARED

WALL PLATE

SUBFLOORING

CONTRAPISO

SUELO DE MADERA

233/4"

(603)

(603)

SUELO

FINISHED

TERMINADO

FLOORING

WOOD FLOOR

Suelo de madera.

233/4"

233/4"

(603)

(603)

WALL PLATE

CONTRAPISO

SUBFLOORING

PISO DE

CONCRETE

CONCRETO

FLOOR

Piso de concreto.

233/4"

233/4"

(603)

(603)

SUELO

FINISHED

TERMINADO

FLOORING

11/2"

11/2"(38)

(38)

min

min

subzero.com | 7

Page 18

INSTALACIÓN

Colocación

PRECAUCIÓN

Antes de mover la unidad a su posición, asegúrese

de que las puertas y cajones estén cerrados y proteja

cualquier suelo con acabado.

Utilice una plataforma rodante para mover la unidad cerca

de la abertura.

Si la unidad ha estado o está acostada o de lado, debe

ponerla de pie y dejarla así durante un mínimo de 24 horas

antes de conectarla al suministro eléctrico.

Conecte el cable de alimentación a la conexión a tierra y

coloque la unidad en su sitio. Compruebe que el soporte

antivuelco esté bien enganchado.

Línea de agua

Debe conectar un tubo de plástico de aproximadamente 3'

(0.9 m)

de 1/4"a la unidad con una conexión de compresión

1

/4"previamente ensamblada debajo de la unidad. El kit

de

para instalar la conexión de la tubería de agua, que viene

con la unidad, contiene un accesorio para unión de compresión de

1

/4"para conectarlo a la toma de agua doméstica.

Alineación

NIVELACIÓN

Una vez que la unidad está en posición, gire las patas

niveladoras delanteras en sentido de las manecillas del

reloj para ajustar la altura. El ajuste de la altura de la parte

trasera se puede realizar desde la parte delantera de la base

rodante. Con un vaso de

sentido de las manecillas del reloj para levantar la unidad o

en sentido opuesto a las manecillas del reloj para bajarla.

Utilice la velocidad más baja para el par de torsión cuando

utilice un taladro eléctrico. No ajuste las patas niveladoras

traseras con la mano. Consulte la siguiente ilustración.

Cuando la unidad está bien nivelada, no es tan necesario

ajustar de las puertas y los cajones.

AVISO IMPORTANTE: Nivele la unidad con el suelo, no con

los gabinetes que la rodean. Esto podría afectar el funcionamiento de la unidad, por ejemplo el cerrado de la puerta.

ADVERTENCIA

Para reducir la posibilidad de que la unidad se vuelque

hacia adelante, las patas niveladoras delanteras deben

estar en contacto con el suelo.

3

/8"gire 3/8"el perno hexagonal en

Purgue la línea de agua antes de hacer la conexión nal a la

unidad. Esto eliminará cualquier residuo que pueda haber

quedado en la tubería al instalar la nueva línea de agua.

Coloque la manga y la tuerca en la toma de agua y sujételos a la conexión en el extremo de la tubería. No apriete

demasiado. Revise todos los accesorios de la línea de agua

para detectar fugas. Compruebe si puede instalar y quitar la

bandeja de drenaje sin interferir en la línea de agua.

AVISO IMPORTANTE: Si utiliza un sistema de ósmosis

inversa, se recomienda desviar el sistema de ltración de

agua mediante la extracción del ltro.

AVISO IMPORTANTE: Las líneas de agua no pueden quedar

expuestas a temperaturas de congelación.

REAR

AJUSTE DE

ADJUSTMENT

LA PARTE

TRASERA

Nivelación.

FRONT

PATA NIVELADORA

DELANTERA

LEVELING LEG

8 | Atención al cliente de Sub-Zero 800.222.7820

Page 19

INSTALACIÓN

Alineación

AJUSTE DE LA PUERTA

Para realizar cualquier ajuste, retire la puerta y el tope de la

puerta y aoje ligeramente los dos tornillos de la bisagra

superior. Con la llave Allen incluida gire el tornillo para

ajustar la bisagra. Consulte la siguiente ilustración. Vuelva

a instalar la puerta y verique la alienación. Repita los pasos

hasta que la puerta esté alineada correctamente.

AVISO IMPORTANTE: Al momento de ajustar las puertas,

compruebe que la pestaña de la bisagra siga conectada

con el interruptor de la luz de la puerta. Consulte la

siguiente ilustración.

TORNILLO DE

HINGE

LA BISAGRA

SCREW

PASADOR

CABINET

GABINETE

Extracción de la puerta.

HINGE

DE LA

PIN

BISAGRA

BISAGRA

DEL

HINGE

TORNILLO

ADJUSTMENT

DE AJUSTE

SCREW

INTERRUPTOR

LIGHT

DE LUZ

SWITCH

Ajuste de bisagra.

AJUSTE DE LOS CAJONES

Ajuste vertical | Aoje los tres tornillos de montaje. Con-

7

sulte la siguiente ilustración. Con una llave de

/16", gire el

perno de ajuste en el sentido de las manecillas del reloj para

levantar la unidad, y en sentido opuesto a las manecillas

del reloj para bajarla. Apriete los tornillos, vuelva a instalar

el cajón y revise la alineación. Repita los pasos hasta que el

cajón esté alineado correctamente.

Ajuste horizontal | Aoje el tornillo de las correderas del

cajón frontal. Consulte la siguiente ilustración. Ajuste el

retenedor frontal a la derecha o a la izquierda y apriete

el tornillo. Luego, levante el retenedor frontal y desplace

hacia delante y hacia atrás para mantener la alineación con

el retenedor frontal. Cada conjunto de oricios ajustará la

1

BOLT

/32"(0.8).

TORNILLO

MOUNTING

DE MONTAJE

SCREW

REAR

RETENEDOR

RETAINER

POSTERIOR

TORNILLO

SLIDE

DE LA

SCREW

CORREDERA

FRONT

RETENEDOR

FRONTAL

RETAINER

alineación en

PERNO DE

ADJUSTMENT

AJUSTE

Ajuste vertical.

Ajuste horizontal.

subzero.com | 9

Page 20

INSTALACIÓN

Finalización

Instale el conjunto de la rejilla y verique que se ajuste

adecuadamente. Vuelva a conectar el cable de red. Consulte la página 6. Una el cable de red a la rejilla con los

amarracables que vienen incluidos.

Vuelva a instalar la bandeja de drenaje y compruebe que

esté bien puesta.

Instale el zócalo y sujételo a los soportes con los tornillos

dentro de cada una de las bases rodantes. Consulte la

siguiente ilustración. El zócalo debe ser desmontable para

sacarlo cuando sea necesario dar servicio a la unidad. El

suelo no debe interferir al desmontarlo.

Instale las cubiertas de las patas. Retire el refuerzo de papel

y fuércelo en su posición.

Para encender la unidad pulse el botón de ENCENDIDO en

el panel de control.

DESVIACIÓN DEL FILTRO DE AGUA

Si no va a utilizar el sistema de ltrado, puede colocarlo en

el modo de desvío del ltro de agua mediante la extracción

del ltro de agua. Consulte la siguiente ilustración. Siga

estos pasos para extraer el ltro de agua:

1 Jale el borde inferior de la rejilla hacia fuera e incline el

marco de la rejilla hacia arriba.

2 Para retirar el cartucho, gírelo un cuarto en sentido

opuesto a las manecillas del reloj y jálelo. Consulte la

siguiente ilustración.

FILTRO DE AGUA

WATER FILTER

Instalación del zócalo.

Apertura de la rejilla.

Extracción del ltro de agua.

10 | Atención al cliente de Sub-Zero 800.222.7820

Page 21

INSTALACIÓN

Finalización

TOPE PARA PUERTA A 90°

Las puertas de todos los modelos abren a 135°. Las instalaciones en las que se debe limitar la abertura de la puerta

disponen de un juego de topes de 90° para puertas a través

de un distribuidor autorizado de Sub-Zero. Para obtener

más información acerca de los distribuidores locales, visite

la sección para encontrar una sala de exhibición de nuestro

sitio web, subzero.com.

ADVERTENCIA

Siga todas las leyes estatales y locales para almacenar,

reciclar o desechar los refrigeradores y congeladores

no utilizados.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design e Ingredients

son marcas comerciales registradas y marcas de servicio de Sub-Zero, Inc. Wolf, Wolf & Design, Wolf Gourmet, W & Design y el color rojo aplicado

a las perillas son marcas comerciales registradas y marcas de servicio de Wolf Appliance, Inc. (en conjunto las “Marcas de la Compañía".) Todas las

demás marcas comerciales o marcas comerciales registradas son propiedad de sus respectivos propietarios en los Estados Unidos y otros países.

subzero.com | 11

Page 22

RÉFRIGÉRATION PRO 48

Table des matières

3 Réfrigération PRO 48

4 Dimensions de l’ouverture

5 Électricité

5 Plomberie

6 Préparation

6 Support antibasculement

8 Mise en place

8 Tuyau d’alimentation en eau

8 Alignement

10 Achèvement

Remarque importante

Pour s’assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note des

types de renseignement mis en évidence tout au long de ce

guide :

REMARQUE IMPORTANTE met en évidence des renseigne-

ments qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d’indication contraire.

2 | Service à la clientèle de Sub-Zero 800.222.7820

Page 23

RÉFRIGÉRATION PRO 48

Renseignements sur le produit

Des renseignements importants sur le produit, y compris les

numéros de modèle et de série de votre unité, se trouvent

sur la plaque signalétique du produit. La plaque signalétique est située à l’intérieur de l’armoire à la gauche du

tiroir supérieur du congélateur. Reportez-vous à l’illustration

ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Sub-Zero certié par l’usine et ayez les numéros de

modèle et de série de l’unité à la portée de la main. Pour

obtenir le nom du centre de service Sub-Zero certié par

l’usine près de chez vous ou si vous avez des questions

concernant l’installation, consultez la section Contact et

assistance de notre site Web, subzero.com ou appelez le

service à la clientèle de Sub-Zero au 800-222-7820.

Outils et matériaux

• Tournevis—standard, cruciforme et Torx.

• Perceuse électrique.

• Mèches (des mèches à maçonnerie sont requises pour

l’installation dans le béton).

• Ensemble de clés Allen standard.

• Ensemble de clés et douilles standard.

• Niveaux de 2pi

• Coupe-tube.

(914) de tube PEX ou en acier inoxydable tressée en

• 3pi

cuivre de

• Vanne à étrier.

• Des matériaux pour protéger la résidence, le plancher et

les armoires pendant l’installation.

(601) et 4pi (1 219).

1

/4po (6) de diamètre extérieur.

PLAQUE

SIGNALÉ-

TIQUE

Emplacement de la plaque

signalétique (dans le tiroir).

subzero.com | 3

Page 24

PRÉPARATION DU SITE

SIDE

Dimensions de l’ouverture

INSTALLATIONS INTÉGRÉES STANDARDS ET À AFFLEUREMENT

VUE DE

TOP VIEW

DESSUS

PROFONDEUR DE

OPENING

DEPTH

L’OUVERTURE

PROFONDEUR DE

OPENING

DEPTH

L’OUVERTURE

VIEW

VUE DE PROFIL VUE DE FACE

HAUTEUR DE

OPENING

HEIGHT

L’OUVERTURE

LARGEUR DE

OPENING

WIDTH

L’OUVERTURE

FRONT VIEW

OUVERTURE STANDARD À AFFLEUREMENT

1

Largeur 47

/2po (1 206) 48po (1 219)

Hauteur 833/4po (2 127) 841/8po (2 137)

Profondeur* 24po (610) 26po (660)

*Pour les installations standards, le cadre de la façade se

prolongera de 2po

(51) au-delà des armoires. Dans les

installations à afeurement, le cadre de la façade sera à

égalité avec les armoires.

4 | Service à la clientèle de Sub-Zero 800.222.7820

Page 25

PRÉPARATION DU SITE

TOP VIEW

BACK WALL

1

/2"

(13)

53/16"

(132)

6"

(152)

Électricité

L’installation doit se conformer à tous les codes électriques

applicables.

L’alimentation électrique doit se trouver à l’intérieur de la

zone ombragée indiquée dans l’illustration ci-dessous.

Un circuit séparé servant uniquement cet appareil est

requis. Un disjoncteur de fuite de terre (GFCI) n’est pas

recommandé et peut interrompre le fonctionnement.

EXIGENCES ÉLECTRIQUES

Alimentation électrique 115 volts CA, 60 Hz

Disjoncteur 15 ampères

Prise mise à la terre à trois broches

MISE EN GARDE

Cette prise doit être vériée par un électricien qualié pour s’assurer qu’elle est câblée avec la polarité

appropriée. Assurez-vous que la prise est correctement

mise à la terre.

AVERTISSEMENT

N’utilisez pas une rallonge ou un adaptateur à deux

broches et ne retirez pas la broche de mise à la terre

du cordon d’alimentation.

Plomberie

L’installation doit se conformer à tous les codes de plomberie applicables.

Le tuyau d’alimentation en eau doit se trouver à l’intérieur

de la zone ombragée indiquée dans l’illustration ci-dessous.

Le tuyau d’alimentation en eau doit être relié à l’alimentation

de la maison avec un robinet d’arrêt facilement accessible.

N’utilisez pas des vannes à auto-perçage. Le tuyau d’alimentation en eau ne doit pas nuire à l’installation du support

antibasculement.

Un système à osmose inverse peut être utilisé à condition

qu’il y ait une pression d’eau constante de 35 à 120 psi

(2,4 à 8,3 bars)

vers l’unité en tout temps. Dans cette application, le système de ltration doit être dérivé en retirant le

ltre. Une conduite en cuivre n’est pas recommandée pour

cette application.

EXIGENCES DE PLOMBERIE

Tuyau d’alimentation en eau tube PEX ou en acier inoxy-

dable tressé en cuivre de

1

/4po (6) de diamètre extérieur

Pression d’eau 35-120 psi

Tuyau d’alimentation en eau

supplémentaire pour connexion

(2,4-8,3 bars)

36po (914)

VUE DE FACE

FRONT VIEW

7po

7"

E

(178)

(178)

6po

6"

(152)

(152)

751/2po

751/2"

(1 918) DU

(1918)

PLANCHER

FROM

FLOOR

Emplacement de l’alimentation

électrique.

1

/2po

1

(13)

MUR ARRIÈRE

BACK WALL

6po

6"

(152)

(152)

6po

6"

(152)

(152)

53/16po

FLOOR

53/16"

(132)

(132)

VUE DE

TOP VIEW

DESSUS

Emplacement de l’alimentation

en eau (au fond).

3po (76)

3" (76)

PLANCHER

FRONT VIEW

VUE DE FACE

Emplacement de l’alimentation

en eau (à l’arrière).

/2"

(13)

53/16po

53/16"

(132)

(132)

subzero.com | 5

Page 26

PRÉPARATION DU SITE

Préparation

Sortez l’unité de la boîte et examinez-la pour vous assurer

qu’elle n’est pas endommagée. Retirez la base en bois et

jetez les boulons et les supports d’expédition. Retirez et

recyclez les matériaux d’emballage. Ne jetez pas la plaque

de protection, le support antibasculement et la quincaillerie.

Rentrez complètement les pieds de nivellement avant an

de pouvoir déplacer l’unité jusqu’à son emplacement. Les

pieds de nivellement avant et arrière peuvent être réglés à

partir de l’avant lorsque l’unité est en place.

Retirez la cuvette d’égouttement de la base de l’unité pour

éviter de l’endommager et permettre de bien placer le chariot à appareil.

L’assemblage de la grille doit être retiré avant de déplacer

l’unité. Pour retirer, tirez le rebord inférieur de la grille vers

l’extérieur et tournez-le vers le haut. Coupez les attaches de

câble qui xent le câble de réseau à la grille, puis débranchez le câble de réseau. Retirez les trois boulons de la grille,

puis tirez cette dernière vers l’avant pour l’enlever. Reportez-vous à l’illustration ci-dessous.

Support antibasculement

AVERTISSEMENT

Pour empêcher l’unité de basculer vers l’avant et

obtenir une installation stable, elle doit être xée en

place au moyen du support antibasculement.

Utilisez les trous de localisation de la ligne centrale pour

placer le support antibasculement au centre de l’ouverture. Le support doit être placé à une distance de 24po

(610) de l’avant de l’ouverture jusqu’à l’arrière du support.

Cette profondeur passe à 26po

afeurement. Si le support antibasculement n’est pas aligné

adéquatement, il ne s’enclenchera pas correctement.

Utilisez toute la quincaillerie pour support antibasculement

selon les directives pour les planchers en bois ou en béton.

REMARQUE IMPORTANTE : pour les applications sur des

planchers en bois ou en béton, si les vis n° 12 ne touchent

pas un poteau mural ou une plaque murale, utilisez les vis

n° 8 et les rondelles n° 12 avec les cales d’ancrage.

REMARQUE IMPORTANTE : dans certaines installations,

le sous-plancher ou le plancher ni peuvent nécessiter

l’inclinaison des vis utilisées pour xer le support antibasculement au mur arrière.

(660) pour une installation à

ATTACHE

CABLE TIE

DE CÂBLE

Retrait de la grille.

CÂBLE DE

NETWORK

RÉSEAU

CABLE

BOULON

GRILLE

DE LA

BOLT

GRILLE

QUINCAILLERIE ANTIBASCULEMENT

1 Support antibasculement

1

12 Vis à tête cylindrique bombée n°12 x 2

3

3 Cales d’ancrage de

12 Rondelles plates n°12

3 Vis à tête bombée n°8–18 x 1

3 Cales d’ancrage au mur à glissière en nylon Zip-it

TROUS D’EMPLACEMENT

CENTERLINE

DE LA LIGNE CENTRALE

LOCATING HOLES

Support antibasculement

/8 po–16 x 33/4 po

1

/4po

/2 po

®

6 | Service à la clientèle de Sub-Zero 800.222.7820

Page 27

PRÉPARATION DU SITE

Support antibasculement

APPLICATION SUR UN PLANCHER EN BOIS

Après avoir correctement repéré les supports antibasculement dans l’ouverture préliminaire, percez des avant-trous

3

/16po (5) de diamètre au maximum dans les poteaux

de

muraux ou la plaque murale. Utilisez les vis et les rondelles

n° 12 pour xer les supports. Vériez que les vis pénètrent

dans le matériau du plancher et dans les poteaux muraux

3

ou la plaque murale d’une distance d’au moins

/4po (19).

Reportez-vous à l’illustration ci-dessous.

APPLICATION SUR UN PLANCHER EN BÉTON

Après avoir correctement repéré les supports antibasculement dans l’ouverture préliminaire, percez des avant-trous

3

/16po (5) de diamètre au maximum dans les poteaux

de

muraux ou la plaque murale. Percez des trous de

3

/8po (10)

de diamètre dans le béton d’une profondeur d’au moins

1

/2po (38). Utilisez les vis et les rondelles n° 12 pour xer

1

le support au mur et utilisez les cales d’ancrage de

3

/8po

(10) pour xer le support au plancher. Vériez que les vis

pénètrent dans les poteaux muraux ou la plaque murale

3

d’une distance d’au moins

/4po (19). Reportez-vous à

l’illustration ci-dessous.

INSTALLATION DE LA CALE D’ANCRAGE POUR BÉTON :

1) Percez un trou de

3

/16po (10) diamètre de toute profondeur excédant le noyage minimal. Nettoyez le trou

ou continuez à percer plus profondément pour accommoder les nes de perçage.

2) Assemblez la rondelle et l’écrou à égalité avec l’extrémité

de la cale d’ancrage pour protéger les lets. Enfoncez la

cale d’ancrage dans le matériau à xer jusqu’à ce que la

rondelle soit à égalité avec la surface du matériau.

3) Ouvrez la cale d’ancrage en serrant l’écrou de trois à

cinq tours au-delà de la position serrée à la main ou un

couple de 25 pi-lb

(3,4 kg-m).

AVERTISSEMENT

Vériez qu’il n’y ait pas de ls électriques ou de plomberie dans la zone qui pourraient être pénétrés par les vis.

MISE EN GARDE

Portez toujours des lunettes de sécurité et utilisez

d’autres dispositifs ou vêtements de protection

nécessaires lors de l’installation ou du travail avec des

dispositifs d’ancrage.

Il n’est pas recommandé d’utiliser des dispositifs

d’ancrage dans de la maçonnerie légère comme des

blocs ou de la brique, ou dans du nouveau béton qui

n’a pas eu assez de temps pour sécher. L’utilisation de

forets-aléseurs n’est pas recommandée pour percer les

trous des cales d’ancrage.

233/4"

(603)

WOOD FLOOR

233/4po

(603)

(603)

PLANCHER

FINISHED

FINI

FLOORING

233/4po

233/4"

(603)

WALL PLATE

PLAQUE MURALE PLAQUE MURALE

SUBFLOORING

SOUS-PLANCHER

PLANCHER EN BOIS

Plancher en bois.

233/4po

233/4"

(603)

(603)

WALL PLATE

SOUS-PLANCHER

SUBFLOORING

PLANCHER

CONCRETE

EN BÉTON

FLOOR

Plancher en béton.

233/4po

233/4"

(603)

(603)

PLANCHER

FINISHED

FINI

FLOORING

11/2po

11/2"(38)

(38)

min

min

subzero.com | 7

Page 28

INSTALLATION

Mise en place

MISE EN GARDE

Avant de mettre l’unité en place, sécurisez les portes et

les tiroirs en position fermée et protégez tout plancher ni.

Utilisez un chariot à appareil pour déplacer l’unité près de

l’ouverture.

Si l’unité a été posée sur le dos ou le côté, elle doit être

mise debout pendant au moins 24 heures avant de relier

l’alimentation.

Branchez le cordon d’alimentation dans une prise mise à la

terre et roulez l’unité en place. Vériez que le support antibasculement est correctement enclenché.

Tuyau d’alimentation en eau

Approximativement 3po (0,9 m) de tube en plastique de

1

/4po (6) est relié à l’unité au moyen d’une connexion de

compression pré-assemblée de

trousse de connexion du raccord du tuyau d’alimentation

d’eau, fournie avec l’unité, comprend un raccord d’union

1

de compression de

/4po (6) pour relier jusqu’au tuyau

d’alimentation d’eau de la résidence.

1

/4po (6) sous l’unité. La

Alignement

NIVELLEMENT

Une fois l’unité en position, tournez les pieds de nivellement

avant dans le sens horaire pour régler la hauteur. Le réglage

de la hauteur arrière peut être effectué à partir de l’avant de

la base à roulettes. Au moyen d’une douille de

3

tournez le boulon hexagonal de

/8po(10) dans le sens

horaire pour relever l’unité ou dans le sens antihoraire pour

l’abaisser. Utilisez le réglage de couple le plus bas lorsque

vous utilisez une perceuse électrique. Ne tournez pas les

pieds de nivellement arrière à la main. Reportez-vous à

l’illustration ci-dessous.

Lorsque l’unité est correctement mise au niveau, des

réglages à la porte et au tiroir ne seront probablement pas

nécessaires.

REMARQUE IMPORTANTE : nivelez l’unité en fonction du

plancher, pas des armoires environnantes. Cela pourrait

affecter le fonctionnement de l’unité, comme la fermeture

de la porte.

AVERTISSEMENT

An de réduire le risque de basculement vers l’avant de

l’unité, les pieds de nivellement avant doivent être en

contact avec le sol.

3

/8po(10),

Purgez le tuyau d’alimentation en eau avant d’effectuer

la dernière connexion vers l’unité. Ceci éliminera tous les

débris qui pourraient se trouver dans le tube suite à l’installation du nouveau tuyau d’alimentation en eau.

Placez l’écrou et le manchon sur le tuyau d’alimentation en

eau et xez à la connexion à l’extrémité du tube. Ne serrez

pas trop. Vériez que tous les raccords du tuyau d’alimentation en eau n’aient pas de fuites. Vériez que la cuvette

d’égouttement puisse être installée et retirée sans interférence de la part du tuyau d’alimentation en eau.

REMARQUE IMPORTANTE : si un système à osmose inverse

est utilisé, il est recommandé que le système de ltration

d’eau soit contourné en retirant le ltre.

REMARQUE IMPORTANTE : les tuyaux d’alimentation en eau

ne doivent pas être exposés au gel.

REAR

AJUSTEMENT

ADJUSTMENT

ARRIÈRE

Nivellement.

PIED DE

FRONT

NIVELLEMENT

LEVELING LEG

AVANT

8 | Service à la clientèle de Sub-Zero 800.222.7820

Page 29

INSTALLATION

Alignement

RÉGLAGE DE LA PORTE

Pour effectuer des réglages, retirez la porte et la butée de

porte, puis desserrez légèrement les deux vis de la charnière supérieure. Utilisez la clé Allen fournie pour tourner la

vis de réglage pour ajuster la charnière. Reportez-vous à

l’illustration ci-dessous. Réinstallez la porte et vériez l’alignement. Répétez jusqu’à ce que la porte soit correctement

alignée.

REMARQUE IMPORTANTE : lors du réglage des portes,

vériez que l’onglet de la charnière continue à enclencher

l’interrupteur d’éclairage de la porte. Reportez-vous à l’illustration ci-dessous.

VIS DE

HINGE

CHARNIÈRE

SCREW

VIS DE

ADJUSTMENT

RÉGLAGE

SCREW

INTER-

RUPTEUR

LIGHT

D’ÉCLAIRAGE

SWITCH

Réglage des charnières.

Retrait de la porte.

HINGE

AXE DE

CHARNIÈRE

PIN

CHARNIÈRE

CABINET

D’ARMOIRE

HINGE

RÉGLAGE DU TIROIR

Réglage vertical | Desserrez les trois vis de montage.

Reportez-vous à l’illustration ci-dessous. Au moyen d’une

7

clé de

/16po (11), tournez le boulon de réglage dans le

sens horaire pour relever et dans le sens antihoraire pour

abaisser. Serrez les vis, puis réinstallez le tiroir et vériez

l’alignement. Répétez jusqu’à ce que le tiroir soit correctement aligné.

Réglage horizontal | Desserrez la vis coulissante du tiroir

avant. Reportez-vous à l’illustration ci-dessous. Réglez

le dispositif de retenue avant droit ou gauche, puis serrez

la vis. Ensuite, soulevez le dispositif de retenue arrière et

bougez vers l’avant ou l’arrière pour conserver l’alignement

avec le dispositif de retenue avant. Chaque ensemble de

1

trous règlera l’alignement de

VIS DE

MOUNTING

MONTAGE

BOULON DE

ADJUSTMENT

RÉGLAGE

BOLT

Réglage vertical

SCREW

/32po (0,8).

DISPOSITIF

REAR

DE RETENUE

RETAINER

ARRIÈRE

Réglage horizontal

SLIDE

VIS

COULISSANTE

SCREW

DISPOSITIF

FRONT

DE RETENUE

RETAINER

AVANT

subzero.com | 9

Page 30

INSTALLATION

Achèvement

Installez l’assemblage de la grille et vériez son ajustement.

Rebranchez le câble de réseau. Reportez-vous à la page 6.

Fixez le câble de réseau à la grille au moyen des attaches

de câble fournies.

Réinstallez la cuvette d’égouttement et vériez qu’elle se

trouve à la bonne position.

Installez la plaque de protection au moyen de vis pour la

xer aux supports situés à l’intérieur de chaque base de

roulettes. Reportez-vous à l’illustration ci-dessous. La

plaque de protection doit pouvoir être enlevée pour toute

réparation. Le plancher ne doit pas nuire à l’enlèvement.

Installez les couvercles des pieds. Retirez l’endos en papier

et appuyez en position.

Coupez le courant en appuyant sur la touche POWER sur le

panneau de commande.

DÉRIVATION DU FILTRE À EAU

Si le système de ltration d’eau ne sera pas utilisé, il peut

être mis en mode de dérivation du ltre à eau en retirant le

ltre à eau. Reportez-vous à l’illustration ci-dessous. Suivez

ces étapes pour retirer le ltre à eau :

1 Tirez le rebord inférieur de l’assemblage de la grille et

inclinez le cadre de la grille vers le haut.

2 Pour retirer la cartouche, pivotez-la dans le sens

antihoraire d’un quart de tour et tirez vers l’extérieur.

Reportez-vous à l’illustration ci-dessous.

FILTRE À EAU

WATER FILTER

Installation de la plaque de

protection.

Grille ouverte.

Retrait du ltre à eau.

10 | Service à la clientèle de Sub-Zero 800.222.7820

Page 31

INSTALLATION

Achèvement

BUTÉE DE PORTE DE 90°

Les portes de tous les modèles s’ouvrent jusqu’à 135°. Pour

les installations où l’ouverture de la porte doit être limitée,

une trousse pour butée de porte de 90° en option est offerte

par un dépositaire Sub-Zero autorisé. Pour obtenir des

renseignements sur votre dépositaire local, visitez la section

salle d’exposition de notre site Web, subzero.com

AVERTISSEMENT

Respectez toutes les lois provinciales et locales lors

de l’entreposage, le recyclage ou l’élimination des

réfrigérateurs et des congélateurs non utilisés.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design et Ingredients sont des marques déposées

et de service de Sub-Zero, Inc. Wolf, Wolf & Design, Wolf Gourmet, W & Design et la couleur rouge qui se trouve sur les boutons sont des marques déposées et de service de Wolf Appliance,

Inc. (collectivement, les « Marques d’entreprise »). Toutes les autres marques de commerce ou déposées appartiennent à leurs propriétaires respectifs aux États-Unis et dans d’autres pays.

subzero.com | 11

Page 32

SUB-ZERO, INC. P.O. BOX 44848 MADISON, WI 53744 SUBZERO.COM 800.222.7820

7028630 REV-A 5/2013

Loading...

Loading...