Page 1

subzero.com 800.222.7820

CT Induction Cooktop

Service Manual

General Information 2

Installation Information 5

Controls & Operation 9

Component Access & Removal 14

Troubleshooting Guide 18

Technical Data 20

Wiring Diagrams 21

Page 2

General Information

IInndduuccttiioonn CCooookkttoopp

1-2

INTRODUCTION

This Wolf Induction Cooktop Technical Service Manual, Part #806657, has been compiled to provide the most recent

technical service information about the Wolf Induction Cooktops. This information will enable the service technician

to troubleshoot and diagnose malfunctions, perform necessary repairs and return a Wolf Induction Cooktop to proper

operational condition.

The service technician should read the complete instructions contained in this Service Manual before initiating any

repairs on a Wolf Appliance.

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this manual. The "Signal Words" used are WARNING and

CAUTION.

Please note that these safety labels are placed in areas

where awareness of personal safety and product safety

should be taken and lists the precautions to be taken

when the signal word is observed.

TECHNICAL ASSISTANCE

If you should have any questions regarding a Wolf

appliance and/or this manual, please contact:

Wolf Appliance, Inc.

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744-4988

Customer Service

Phone #: (800) 332 - 9513

Technical Assistance

Phone #: (800) 919 - 8324

Parts / Warranty Claims

Phone #: (800) 332 - 9513

Customer Service E-Mail Address

customerservice@wolfappliance.com

Customer Service & Technical Assistance

Facsimile #: (608) 441 - 5887

Parts / Warranty Claims

Facsimile #: (608) 441 - 5886

Office Hours:

7:00 AM to 7:00 PM Central Standard Time

Monday through Friday

This manual is designed to be used by Authorized Service Personnel only. Wolf Appliance, Inc. assumes

no responsibility for any repairs made to Wolf appliances by anyone other than Authorized Service

Technicians.

INDICATES THAT HAZARDOUS OR UNSAFE PRACTICES COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH

Indicates that hazardous or unsafe practices could

result in minor personal injury or product and/or

property damage

In addition, please pay attention to the signal word

“NOTE”, which highlights especially important information within each section.

The information and images are the copyright property of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. Neither

this manual nor any information or images contained herein may be copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. © Wolf Appliance, Inc., all rights

reserved.

Page 3

General Information

IInndduuccttiioonn CCooookkttoopp

1-4

WARRANTY INFORMATION

This page contains a summary of the 2 & 5 Year Warranty that is supplied with every Wolf product, followed by

details and notes about the warranties.

TWO & FIVE YEAR Warranty Summary

• Two year TOTAL PRODUCT warranty, *parts and labor.

• Limited Parts Only Warranty for the 3rd through 5th year on the following parts only:

Electric heating elements

Electronic Control Boards

Warranty Details:

The warranty applies only to products installed for normal residential use. The warranty applies only to product

installed in the United States or Canada.

Warranty Notes:

• All warranties begin at the time of the unit’s initial installation.

• All Warranty and Service information collected by Wolf Appliance, Inc., is arranged and

stored under the unit serial number and/or the customer’s name. Please note that Wolf Appliance, Inc.,

requests that you have the model serial number available whenever contacting the

factory or parts distributor.

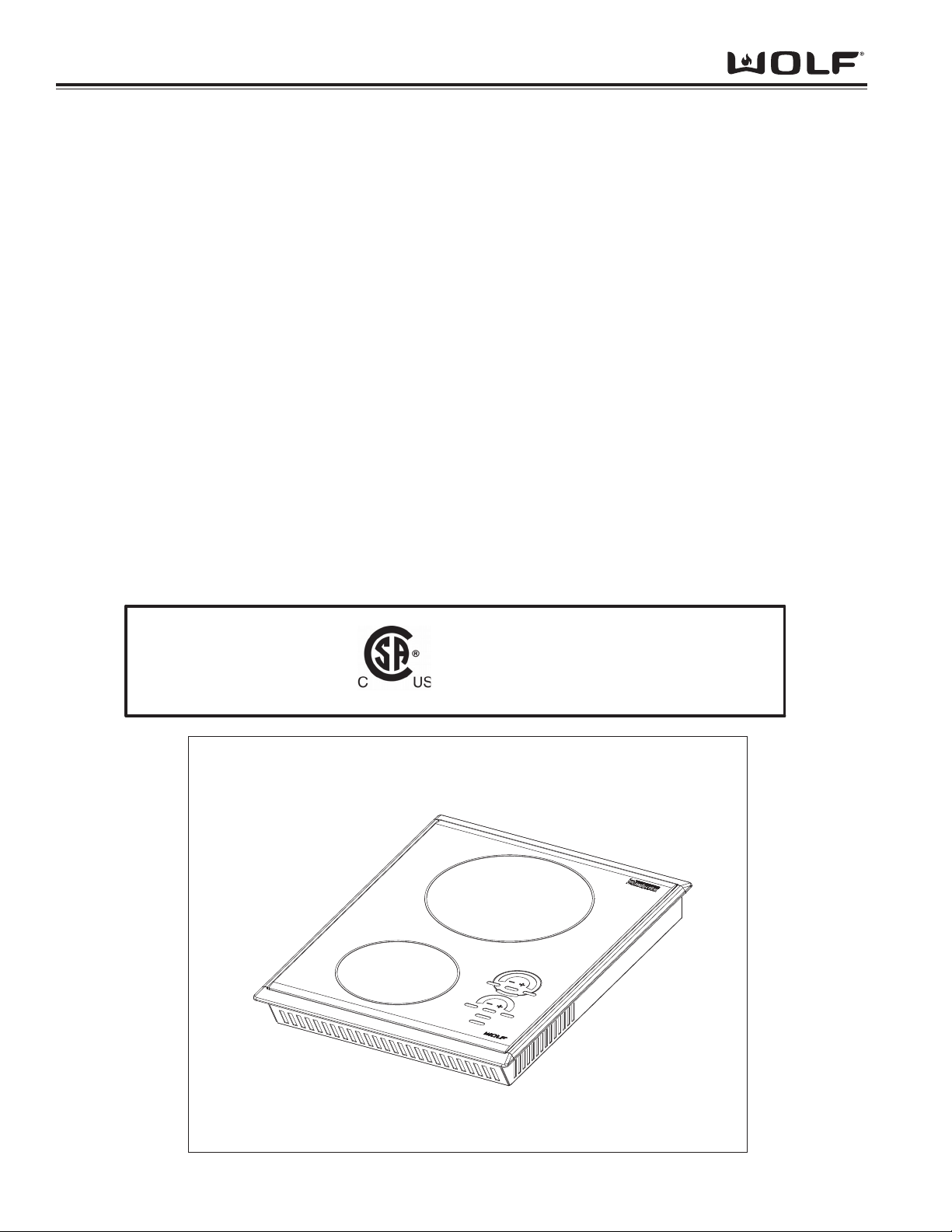

• See Figure 1-1 for serial tag layout.

• See Figure 1-2 for serial tag location.

Wolf Appliance Company, Inc.

VOLTS :

Hz :

MODEL# : XXXXXX-X

INDUCTION COOKTOP

FOR HOUSEHOLD USE ONLY

120/208

60

"DO NOT IMMERSE IN WATER" "NE PAS PLONGE DANS L'EAU"

FITCHBURG, WI

SERIAL# : XXXXXXXX

KW :

-2

120/240

X.X

X.X

3 WIRE

Page 4

General Information

IInndduuccttiioonn CCooookkttoopp

1-5

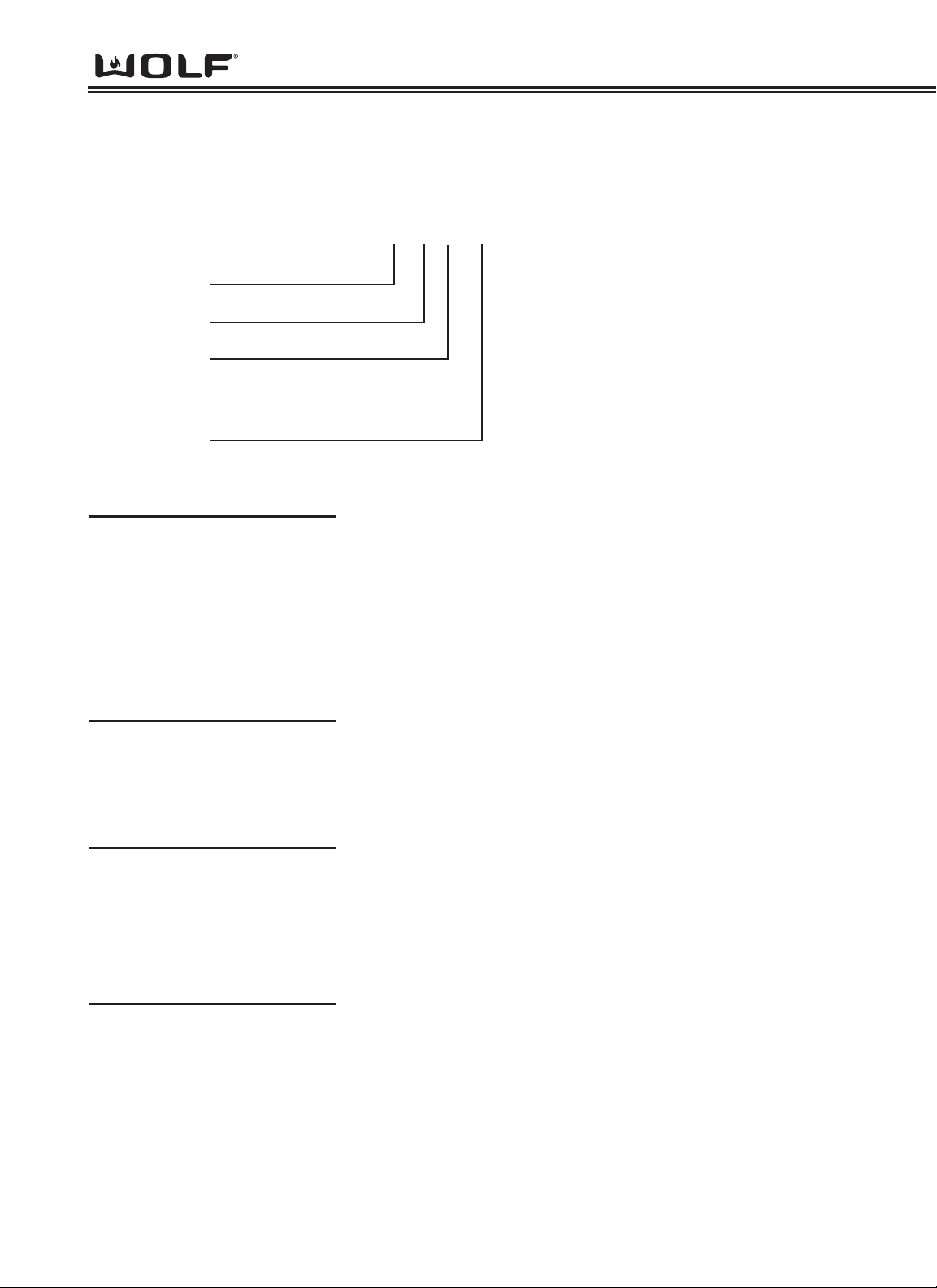

MODEL NUMBER KEY

Refer to this key for an example of the model numbers.

Model: CT 15 I / S

Product Type

Size

Fuel

Feature (If Applicable)

Finish

Product T

ype

CT Cooktop

IM Integrated Gas

Multifunction Cooktop

IG Integrated Grill Cooktop

IS Integrated Steamer Cooktop

IF Integrated Fryer Cooktop

Size

15 15 - inch wide unit

30 30 - inch wide unit

36 36 - inch wide unit

Fuel

E Electric

I Induction

G Natural Gas

LP Propane Gas (Propane Gas will be indicated by -LP at the end of the model number. Example: CT36G/S-LP)

Finish

S Classic Stainless Steel

P Platinum Stainless Steel (Not Available for IM, IG, IS and IF)

B Carbon Stainless Steel (Not available for gas models. Not available for IM, IG, IS and IF)

Page 5

General Information

IInndduuccttiioonn CCooookkttoopp

1-6

MODEL CONFIGURATIONS

Model Numbers Descriptions

CT15I/S Cooktop 15” Induction, Stainless Steel Trim

15” Electric

MODEL FEATURES

• Illuminated control lighting.

• Graduated control lighting.

• Lock key and universal off.

• True simmer setting on all elements.

• Melt setting on all elements.

• Hot surface indicators on all elements.

• Finish available in classic stainless steel.

• Temperature limiter to ensure that safe operating temperature of glass ceramic is never exceeded.

Page 6

IInndduuccttiioonn CCooookkttoopp

Installation Information

2-2

INDUCTION COOKTOP

INSTALLATION INFORMATION

This section of the manual covers some of the installation issues a service technician may need to know when servicing a Wolf Induction Cooktop. If additional information is needed after reviewing this section of the manual, please

refer to the Installation Guide or contact the Wolf Appliance Customer Service Department.

Electrical Requirements - Induction

Nominal Voltage

CT15I – 240V/15amp /60Hz - (20 Amp Service)

NOTE:208VACinstallation is not recommended.

Maximum Connected Load

CT15I – 3.6Kw (240V)

The Wolf Induction Cooktops require a separate, grounded three-wire service with their own circuit breaker. These

appliances must be installed in accordance with National Electrical Codes, as well as all state, municipal and local

codes. The correct voltage, frequency and amperage must be supplied to the appliance from a dedicated, grounded

circuit which is protected by a properly sized circuit breaker or time delay fuse. The proper voltage, frequency and

amperage ratings are listed on the product rating plate. The cooktops are provided with a 48" (1219 mm) conduit

consisting of two insulated hot lead conductors (copper) and one insulated ground conductor (copper).

THIS APPLIANCE MUST BE PROPERLYGROUNDED AT ALLTIMES WHEN ELECTRICALPOWER IS APPLIED.

DO NOT GROUND THE APPLIANCE WITH THE NEUTRAL(WHITE) HOUSE SUPPLYWIRE. ASEPARATE

GROUND WIRE MUST BE UTILIZED.

IF ALUMINUM HOUSE SUPPLYWIRING IS UTILIZED, SPLICE THE APPLIANCE COPPER WIRE TO THE ALUMINUM HOUSE WIRING USING SPECIALCONNECTORS DESIGNED AND CERTIFIED FOR JOINING COPPER

AND ALUMINUM. FOLLOW THE CONNECTOR MANUFACTURES RECOMMENDED PROCEDURE CAREFULLY. IMPROPER CONNECTION CAN RESULT IN AFIRE HAZARD.

TO ELIMINATE THE RISK OF BURNS OR FIRE BYREACHING OVER HEATED SURFACE UNITS, CABINET

STORAGE SPACE LOCATED ABOVE THE SURFACE UNITS SHOULD BE AVOIDED. IF CABINET STORAGE IS

TO BE PROVIDED, THE RISK CAN BE REDUCED BYINSTALLING ARANGE HOOD THAT PROTECTS HORIZONTALLYAMINIMUM OF 5" (127 MM) BEYOND THE BOTTOM OF THE CABINETS.

Page 7

IInndduuccttiioonn CCooookkttoopp

Installation Information

2-3

INDUCTION COOKTOP

PRE-INSTALLATION SPECIFICATIONS

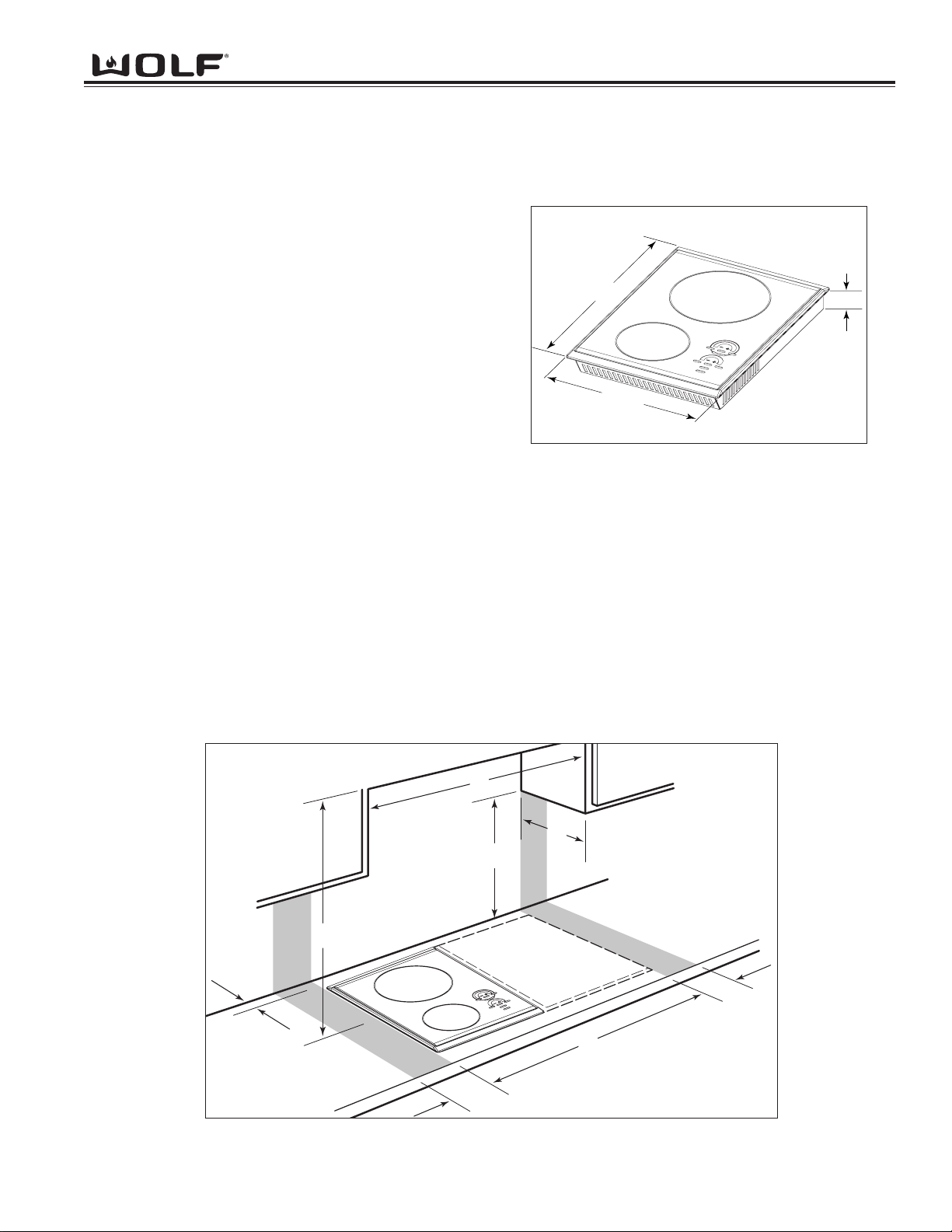

Countertop Location

Dimension Description

A Minimum flat countertop surface. Must be equal to

or greater than cooktop width.

B Minimum 2-inches (152mm) wide clearance from

the cooktop side edge to any combustible surface

up to 18 inches (457mm) above the cooktop

(noted by shaded area).

C Minimum 2-inches (152mm) wide clearance from

the cooktop side edge to any combustible surface

up to 18 inches (457mm) above the cooktop

(noted by shaded area).

Overhead Cabinet Dimensions

Dimension Description

D Minimum spacing between cabinets directly over cooktop, must be greater than or equal to the nomi-

nal width of the cooktop unit.

E Minimum 18 inches (457mm) vertical distance from the countertop surface to the bottom of cabinets

adjacent to the cabinet directly above the cooktop unit.

F Minimum 24-inches (610mm) clearance between the top of the cooking surface and the bottom of

wood or metal cabinet which is protected by not less than 1/4-inch (6mm) flame retardant millboard

covered with not less than No. 28 MSG sheet steel, 0.015-inch (.4mm) stainless steel or 0.024-inch

(.5mm) copper. Minimum 30” (762mm) clearance between the top of the cooking surface and the bottom of an unprotected wood or metal cabinet.

G Minimum 1-1/2-inches (38mm) from rear wall.

H Maximum 13-inch (330mm) depth of overhead cabinets.

Figure 2-2. Pre-Installation Specifications

Figure 2-1. Overall Dimensions

NOTE:Dimension may vary by ± 1/8” (3mm).

21”

(533mm)

15”

(381mm)

3 1/4”

(83mm)

D

H

E

F

G

C

A

B

Page 8

INDUCTION COOKTOP

Countertop Cut-out Dimensions

This cooktop is designed to fit a standard 24" (610 mm) deep base

cabinet with a 25" (635 mm) deep countertop. Before making the

countertop cut-out, verify that the cooktop will clear the side walls of

the base cabinet below. There should be at least 5-1/2" (140 mm) to

7" (178 mm) clearance between the top countertop surface and any

combustible surface directly below the unit. This includes upper

edges of drawers located directly below unit. Refer to the following

illustrations for cut-out dimensions.

NOTE:Locate the junction box within reach of the 48" (1219 mm)

conduit, and so as to be accessible when the cooktop unit is

installed.

NOTE:Plastic or other utensils with low melting temperatures should

not be located in drawers directly below unit.

IInndduuccttiioonn CCooookkttoopp

Installation Information

2-4

Figure 2-4. Cut-out Dimensions

Figure 2-3. Overhead View of Countertop

NOTE:Dimension may vary by ± 1/8” (3mm).

NOTE: Dimensions in

parentheses are in millimeters.

(356)

14"

CUT-OUT

WIDTH

(489)

191/4"

CUT-OUT

21/2"min

(64)

FRONT OF COUNTERTO

NOTE: Dimensions in parentheses are in millimeters.

DEPTH

P

30"

(762)

13"

(330)

191/4" (489)

COOKTOP CUT-OUT

DEPTH

21/2"min

(64)

24" OR 30"*

(610 or 762)

TO COOKING

SURFACE

18"

(457)

3"

(76)

14" (356)

CUT-OUT

33" (838)

RECOMMENDED

CABINET WIDTH

WIDTH

61/4"

(159)

36"(914)

STANDARD

FLOOR TO

COUNTER

HEIGHT

E

15"

(381)

15"

(381)

RIGHT SIDE

CABINET VIEW

NOTE: Application shown allows for installation of two 15" (381 mm) modules side-by-side.

* Minimum 24" (610 mm) from protected cabinet or 30" (762 mm) from unprotected cabinet to cooking surface.

18"

(457)

3"

(76)

Page 9

INDUCTION COOKTOP

INSTALLATION PROCEDURE

Install

• Insert cooktop into countertop opening and center cooktop. Check that the front edge of the cooktop is

parallel to the front edge of the countertop. Check that all

required clearances are met.

• To attach hold down brackets to the sides of the unit, insert

holddown clip into the rectangular punch-out in the pan and

push down.

• Install the clamping screws into the bracket and tighten until

screw contacts the underside of the countertop.

(See Figure 2-5).

NOTE: Do not over tighten screws.

NOTE: Do not use caulk or silicon to secure the unit to the countertop.

Installation of Multiple Cooktops

If this cooktop is to be used with any combination of additional cooktop units or modules with a filler strip, the cut-out

width is calculated by adding the corresponding units' cut-out dimensions plus 1-1/4" (32 mm) for each additional

unit. (See Figure 2-6).

IInndduuccttiioonn CCooookkttoopp

Installation Information

2-5

Figure 2-5. Attaching Hold Down Clamp

Figure 2-6. Multiple Cooktop Installation

COOKTOP

COUNTERTOP

BRACKET

CLIP

31/2" (89 mm)

CLAMPING

SCREW

593/4" (1518) FOUR MODULES CUT-OUT WIDTH

(See Design Guide)

441/2" (1130) THREE MODULES WIDTH

(See Design Guide)

291/4" (743)

TWO MODULES WIDTH

21/2"min

(64)

14"

(356)

CUT-OUT

WIDTH

191/4"

(489)

CUT-OUT

DEPTH

FRONT OF COUNTERTOP

NOTE: Dimensions in parentheses are in millimeters.

Page 10

IInndduuccttiioonn CCooookkttoopp

Operation Information

3-2

IF A CRACK APPEARS IN THE GLASS SURFACE, DISCONNECT THE APPLIANCE IMMEDIATELY TO AVOID

ANY RISK OF ELECTRICAL SHOCK.

NEVER USE COOKING SURFACE AS A STORAGE SPACE OR CUTTING BOARD.

NEVER ALLOW POWER CABLES FOR OTHER ELECTRICAL APPLIANCES TO TRAIL ACROSS THE COOKING SURFACE.

DO NOT LEAVE EMPTY PANS ON THE COOKING SURFACE IN CASE OF RESIDUAL HEAT OR IF THE UNIT

IS TURNED ON BY MISTAKE.

PRINCIPLES OF INDUCTION

Introduction

There are two techniques of glass-ceramic heating:

• Infrared.

• Induction.

The difference is only obvious once the cooking zones are

turned on. The Infrared one glows red while the the induction doesn’t seem to operate.

The Infrared is provided with radiant or halogen sources

that transmit heat by radiation or conduction. Induction

Cooktops produce a magnetic field which passes through

the glass ceramic to the pan. When ferro magnetic cookware is used, this magnetic field excites the molecules in

the pan, causing them to vibrate at a very high frequencies,

producing heat.

The principles of heating by induction is a natural phenomenon discovered in the 19th century by several physicists,

among whom a certain Leön Foucault. He highlighted the development of currents facing the magnetic field in a

moving metallic mass or a fixed metallic mass run though by a variable magnetic flux. These eddy currents comparable to short-circuits cause a heating effect (Joule effect) in the mass.

The operating principle is innovating. Contrary to other cooking modes, it is the container itself, which heats and not

the cooking surface. This results in a very responsive method of cooking.

You put a saucepan on the cooking zone that is sufficient to initiate the heat while the cooking surface remains cool.

the heating element is nothing but the container metal, which transforms the magnetic energy into thermal energy.

Induction qualities are flexibility, low inertia, easy cleaning, good efficiency and thermal safety. Induction efficiency

may reach up to 90% according to the types of cooking. With such a technique, the container only heats. Inertia is

therefore low, and above all, the plate stepping from the mildest temperature to the strongest power, in an instant

and while diffusing heating a homogeneous way, attracts more and more consumers.

Induced currents

Electronic circuit

Induction coil

Figure 3.1. Principles of Induction

Induced currents

Induction coil

Electronic circuit

+

-

Page 11

IInndduuccttiioonn CCooookkttoopp

Operation Information

3-3

PRINCIPLES OF INDUCTION

Operational Principles

An induction cooktop operates thanks to the electromagnetic properties of most containers used on the traditional

cooktop.

At a first approximation, you can compare this cooktop with a transformer of which the secondary winding would

have been shorted. A significant internal current arises therein and causes quick heating.

The saucepan can be compared with a shorted set of concentric whose internal resistance is not

zero.

From the function keys, you can control the electrical power supply to the transformer primary

winding that generates a magnetic field. This field induces currents at the bottom of the container placed on the cooking zone. These induced currents heat immediately the container, which

transmits the produced heat to the food contained inside. Cooking is performed practically without any loss of energy. The appliance heating power is pushed to its maximum.

Figure 3.2. Operation Principles

TRANSFORMER

INDUCTION UNIT

Magnetic Conductor 1 Saucepan

Secondary Winding 2 Saucepan

Gap 3 Glass-Ceramic Plate

Primary Winding 4 Inductor (Element)

Magnetic Conductor 5 Ferrite

Magnetic Field 6 Magnetic Field

1

2

3

4

5

6

Page 12

IInndduuccttiioonn CCooookkttoopp

Operation Information

3-4

INDUCTION COOKTOP OPERATION

Control Operation

The Wolf Induction cooktop operates by automatically cycling the heating elements between zero power and full

power. As the heat is increased on the control panel, the element will stay on at full power for longer periods and

the element will have shorter periods of zero power.

Residual Heat Indicators

As an added safety precaution, residual heat indicator lights will illuminate when the surface temperature of the

glass is above 150°F. Each heating element has an independently controlled light located to the right of that element. Even if the cooktop controls are turned off, the indicator light(s) will illuminate to show the user that the cooktop surface remains hot.

Modes of Operation

Lock Mode: All keypad operation on the control panel is disabled and all of the heating elements are

de-energized. A steady glowing light within the "key" symbol indicates the unit is locked.

• To unlock the control, touch and hold the "key" symbol for 3 seconds. The unit will beep twice and the light

with-in the "key" symbol will go out. The control unit is now in the idle mode. (See Figure 3-4).

• To lock the control, touch and hold the "key" symbol for three seconds. The unit will beep three times

and the light within the "key" symbol will illuminate. (See Figure 3-4).

NOTE: When the unit is powered up for the first time or if there was a power outage, the unit will default to this

mode.

Idle Mode: After unlocking the control panel as described in Lock Mode, the unit enters the idle mode of operation.

The only valid keypad operations are the "OFF /ON" for each element and the "key" symbol.

Figure 3-3. Control Panel Figure 3-4. Lock Key

-

OFF/ON

H

I

-

+

HIGH

R

P

E

O

W

+

MELT

-

OFF/ON

H

I

-

+

HIGH

R

P

E

O

W

MELT

+

MELT

OFF/ON

OFF

HIGH

MELT

OFF/ON

OFF

HIGH

Page 13

IInndduuccttiioonn CCooookkttoopp

Operation Information

3-5

Front Element Operation

To activate a heating element, you must first touch the corresponding "OFF/ON" area of the desired element. The

power indicator bar graph will begin to blink and show a half power status. To complete the activation of heating element, you must do one of the following while the bar graph is still blinking:

• Touch "+" symbol of the element control to complete the activation and set the power output one

indicator light above half mark.

• Touch "-" symbol of the element control to complete the activation and set the power output one indicator light

below half mark.

• Touch "HIGH" symbol of the element control to complete the activation and set the power output to full power.

• Touch "MELT" symbol of the element control to complete the activation and set the power output to the lowest

power.

NOTE: Power indicator bar graph continues to blink until cookware is placed on the corresponding element or if

cookware is removed from the element. If no cookware is placed on the heating element for 30 seconds, the element will automatically shut off.

To change power level setting, once the unit is activated and the bar graph lights remain steady on:

• Touch “+” to increase the power level by one light on the bar graph.

• Touch “-” to decrease the power level directly to full power.

• Touch "HIGH" to increase power level directly to full power.

• Touch“MELT” to decrease power level directly to minimum.

• Touch “OFF/ON” to turn the element off.

Rear Element Operation

• Turn on and activate element as described above.

• Touch “HI POWER” to boost the rear element wattage

output from 1800W maximum to 2200W maximum.

Indicator light under “HI POWER” touch pad will be

illuminated.

NOTE: When “HI POWER” is active, the front element will

be limited to 600W maximum output.

• Touch “HI POWER” again to de-activate “HI POWER”

mode. The light under “HI POWER” touch pad will go

out.

Universal OFF Key

In an emergency situation where there is a need to turn

off all heating elements, use the universal “OFF” touch

pad to turn the entire unit off. (See Figure 3-5).

Figure 3-5. Universal OFF

MELT

MELT

-

OFF/ON

H

I

-

OFF/ON

+

HIGH

R

P

E

O

W

+

HIGH

OFF

Page 14

IInndduuccttiioonn CCooookkttoopp

Operation Information

3-6

COOKWARE SELECTION:

Glass, Aluminum, Copper, Non-Magnetic Stainless Steel

NOTE: Refer to “USE & CARE INFORMATION” booklet supplied with the product for further information on cook-

ware selection.

Pan Test:

Place your pan on a zone. With the selected zone turned on the display will not flash if the pan is compatible. If the

display flashes then you cannot use the pan for Induction Cooking.

NOTE: You can also test the pans compatibility with a magnet. If the magnet sticks to the bottom of the pan it is

compatible for Induction cooking.

Pan Compatible with Induction:

• Pans made of enamel coated steel with or without a non-stick coating.

• Cast iron pans with or without enamel coated base.

NOTE: Enamel coated base will prevent the glass top of your cooking surface from scratches.

• Stainless steel pans designed for induction cooking.

NOTE: Stainless steel pans are suitable for induction cooking if they pass the pan test.

• Aluminum pans with special base.

NOTE: Pans which do not have a flat base may be suitable, however they must not be deformed too badly.

• Choose a pan marked with the logo on its base or

packaging to be sure that it is perfectly suitable for use

on your induction cooktop under normal conditions of

use. (See Photo 3-1)

Photo 3-1. Induction Logo

SPECIAL CONSIDERATIONS:

• Glass, ceramic, earthenware pans, aluminum pans (Without special base) and copper pans, and some non-magnetic stainless steel pans are incompatible with induction cooking. You will be informed by the flashing display.

• For uniform cooking, use of a pan that has a thick flat base is best due to it distribution of heat.

Page 15

IInndduuccttiioonn CCooookkttoopp

Component Access and Removal

4-2

COMPONENT ACCESS AND REMOVAL

This section explains how to access and remove components from a Wolf Induction cooktop. Depending on which

component you are going to access or remove in the following sections, you may have to remove some components

first. Refer to the appropriate section in this manual that explains how to access and remove those various components. When reassembling, just reverse the steps that were used to access and remove the components.

NOTE: Before attempting to access or remove any components from a Wolf appliance, take note of the

WARNINGS and CAUTIONS below.

TO AVOID ELECTRIC SHOCK, POWER TO THE UNIT MUST BE DISCONNECTED WHENEVER SERVICING

AND/OR ACCESSING COMPONENTS.

KEEPIN MIND THAT GLASS TOPSURFACES AND COMPONENTS GET HOT DURING USE OF THE APPLIANCE.

IF IT IS NECESSARYTO REMOVE AUNIT FROM ITS INSTALLATION, REMEMBER THAT THE UNITS ELECTRICALPOWER CORD IS HARD WIRED AND COMPLETE REMOVALWILLBE LIMITED. PULLING AUNIT

FROM ITS INSTALLATION SHOULD ONLYBE PERFORMED BYAN AUTHORIZED SERVICE TECHNICIAN OR

INSTALLER.

When working on the cooktop and components, be careful when handling sheet metal parts. There may be

sharp edges present.

Major Serviceable Components

• Glass Ceran top includes Keypad

• Control Board

• Front Element includes Temperature Sensor

• Rear Element includes Temperature Sensor

• HSI (Hot Surface Indicator) includes bracket

• Generator Assembly includes Power Board, Fan & Front and Rear Element (Inducers) with Temperature Sensors.

Page 16

IInndduuccttiioonn CCooookkttoopp

Component Access and Removal

4-3

Glass Top Assembly Removal

The cooktop will have to be removed from its installation in order to remove the glass top assembly.

NOTE: Refer to the installation section of this manual or

the Installation Guide included with the cooktop for

additional information needed.

Extract screws that secure the glass top and trim to

burner box. (See Figure 4.1).

Next, carefully lift glass top up until access to control

board connections are obtained.

Locate ribbon cable connector on glass top, gently disconnect from control board. (See Figure 4.2).

Next, lift tabs located on bottom center portion of molex

connector and disconnect cable. (See Figure 4.3).

Now remove glass top assembly.

Control Board Removal

Lay glass top down so the control board points upward.

NOTE: Care must be taken to protect glass surface

from scratches or damage. Place on protective surface.

Now, push in the tabs which mount control board to

keypad board. (See Figure 4.4).

Next, lift control board straight up and off of tabs and

remove. (See Figure 4-5).

NOTE: Care must be taken to ensure connector pins

are not bent.

Figure 4.1. Glass Top Removal.

4

Figure 4.2. Control Board Ribbon Cable Removal.

Figure 4.3. Control Board Molex Connector Removal.

er

3

Figure 4.4. Control Board Tabs.

Figure 4.5. Control Board Removal.

F103

TP5

CN4

R 10 6

1

C29

C31

TP4

C 1 03

C 1 02

R 1 08

R 10 5

1001

R 10 9

R 1 10

3R3

R 1 1 1

C104

C105

CN5

D4

OUT3

F103

TP5

CN4

C29

U4

C31

U16

R 10 6

TP4

C 1 02

C 1 03

U 12

C 19

R 1 08

C20

R 10 5

1001

R

C32

JP1

R 10 9

R 1 10

3R3

R 1 1 1

C104

C105

C33

CN5

1

D4

R 1 1

OUT3

331

K1

L1

L2

U15

TP3

B

331

R66

C30

U4

U16

U 12

C 19

C20

C32

JP1

C33

R 1 10

331

K1

C30

R36

472

R39

472

472

R37

R49

R44

412

1001

R48

TR4

U 13

1 8

DIS2

1

R57

R56

D5

331

331

331

331

R52

DE00

R47

72

4

TR3

R2

CN1

2

47

R36

472

472

R39

472

R37

R49

412

1001

R48

TR4

U 13

1 8

1

R57

D5

331

331

DE00

R

72

R102

C16

C15

U5

472

U10

C21

C18

C22

C17

U11

C24

R42

R36

R30

R20

331

331

331

331

331

331

C100

331

R-11-

R40

1 0 9

412

R23

02

C101

R50

331

331

R45

R46

U8

R4

R5

472

472

412

331

331

331

C26

XT100

1001

R41

R43

R33

R32

R27

R26

R24

R23

C25

R42

1001

1001

1001

1001

C23

U7

C27

R34

D3

1001

U9

R35

R28

412

1001

C28

R44

R56

331

R52

R207

R201

R209

1001

R20

412

R13

R15

R16

R12

1001

1001

R20

C8

1001

C12

C8

1001

412

TP1

412

R21

C11

C19

CN3

TP2

C14

Z1

R2A6

R10

R1

Page 17

IInndduuccttiioonn CCooookkttoopp

Component Access and Removal

4-4

Element Removal

First, disconnect wiring to temperature sensor. (See

Figure 4.6).

NOTE: Temperature sensor is part of element. When

reinstalling element and temperature sensor assembly,

make sure temperature sensor is tucked into tabs on

element. (See Figure 4.7).

Now, lift element straight up and off mounting brackets.

Disconnect wiring to element then remove. (See Figure

4-8).

HSI (Hot Surface Indicator) Removal

Disconnect wiring at HSI. Extract screw securing HSI

to unit and remove. (See Figure 4.9).

NOTE: To remove rear HSI, the bracket it is attached

to will need to be removed first. (See Figure 4.10)

Figure 4.6. Temperature Sensor Removal.

Figure 4.7. Position Temperature Sensor under tab.

Figure 4.8. Lift element with temperature sensor and

disconnect wiring.

Figure 4.10. Rear HSI (Heat Sensor Indicator).

1

H

S

E

Figure 4.9. Front HSI (Heat Sensor Indicator).

o

m

ro

n

M

A

D

E

I

N

M

A

L

A

Y

S

IA

9980-379

0 04 1 0 01 0

2

DI

B

BEFORE SERVICING

DISCONNECT POWER

HEAT SINK IS LIVE

RISK OF ELECTRIC

WARNING

SHOCK

SHOCK

WARNING

RISK OF ELECTRIC

HEAT SINK IS LIVE

DISCONNECT POWER

BEFORE SERVICING

R9

S28

S29

0407

32288

S14

551

Page 18

IInndduuccttiioonn CCooookkttoopp

Component Access and Removal

4-5

Figure 4.12. Left rear mounting bracket removal.

S

Figure 4.11. Baffle removal.

Generator Removal

First, extract screws securing baffle, located at the front

of generator, and remove. (See Figure 4.11).

Next, extract screws securing left front, left rear and

right rear burner mounting brackets and remove. (See

Figure 4.12 and 4.13).

NOTE:Care must be taken when removing right rear

burner mounting bracket due to wiring in this location.

Remove two rear screws that secure generator to burner box. (See Figure 4.14).

Remove ground screw located at rear left side of generator and disconnect L1 and Neutral leads. (See Figure

4.15).

Next, lift rear locking clips on generator and slide generator assembly towards front of burner box, then lift to

remove generator. (See Figure 4.16).

NOTE:Generator must be moved forward enough to

allow tabs securing generator to burner pan allowing

proper room for removal. (See Figure 4.17).

Figure 4.14. Remove rear screws securing generator.

Figure 4.13. Front left and right rear mounting bracket.

Figure 4.15. Remove gnd screw and L1& N leads.

Figure 4.16. Lift locking clips at rear of generator.

Figure 4.17. Slide generator to front until tabs release.

Ground Screw

C

D32

GND

FP1

734

LP4

S o

C2

FOHB

SITU

FAB

C6

4

S18

S

F

2

7

Locking

Clips

Page 19

DIAGNOSTIC MODE

Diagnostic mode allows the Service Technician to determine the cause of the failure. In diagnostic mode only the last error code is displayed.

To initiate diagnostic mode, the unit must to be in the “LOCK” mode. Then, press and hold the

universal “OFF” keypad for 5 seconds. The cooktop controls will now enter into diagnostic

Mode.

In diagnostics mode, zone LED bars will illuminate and display the last error code logged.

NOTE: If no errors were recorded, no LED’s will be illuminated. Unit will beep, and return to

“OFF” mode.

NOTE: If the “OFF” keypad is not released after 7 seconds, the diagnostic mode will be can-

celled and the unit will return to the “OFF” mode.

NOTE: If any other input signals are detected from the keypad, the unit will not enter diagnostic

mode.

NOTE: When in diagnostic mode all heating units are off.

NOTE: The unit will exit diagnostic mode if no

inputs are detected from the keypad in 20 seconds.

NOTE: If the “OFF” keypad is pressed again

anywhere within the diagnostic program, the

unit returns to the “LOCK” mode of operation.

NOTE: There will be no audible signals dur-

ing the diagnostic mode.

INTERPRETING HEX DECIMAL CODE

The zone bar light uses the first four LED’s

from the right (LED 16), to left (LED 1), to display the HEX DECIMAL code used to determine the error code. Each LED has a corresponding numeric value that needs to be

added together to determine the corresponding error code. (See Figure 5.1)

When the sum of the corresponding numeric

value of the illuminated LED totals 10 - 13,

then a letter is assigned in placed of that sum.

Example: 10 = A; 11 = B; 12 = C; 13 = D.

NOTE: The troubleshooting guide list the cor-

responding illuminated LED’s.

(See Figure 5.2)

NOTE: Error code may appear in either dis-

play or both simultaneously.

IInndduuccttiioonn CCooookkttoopp

Troubleshooting Guide

5-2

Figure 5.1. Example of Error Code F3.

2

4

8

MELT

2

4

8

1

1

-

OFF/ON

8

4

+

2

1

8

4

2

1

HIGH

H

I

R

P

E

O

W

1

8

2

4

8

1

2

4

8

MELT

0 = LED OFF

1 = LED ON

Example above indicates 0011. Add

cooresponding numbers together

(2 + 1 = 3). 3 means F3 (Error 3)

-

OFF/ON

OFF

4

+

2

1

8

4

2

1

HIGH

Page 20

IInndduuccttiioonn CCooookkttoopp

Troubleshooting Guide

5-3

F1 0 0 0 1 Shorted Temperature Sensor

on front Cooking Zone

Check connection.

Replace front element

F2 0 0 1 0 Open Temperature Sensor on

front Cooking Zone

Check connection.

Replace front element

F3 0 0 1 1 Shorted Temperature Sensor

on rear Cooking Zone

Check connection.

Replace rear element.

F4 0 1 0 0 Open Temperature Sensor on

rear Cooking Zone

Check connection.

Replace rear element.

F5 0 1 0 1 Shorted Temperature Sensor as

check on transistors

Check connections.

Replace generator.

F6 0 1 1 0 Open Temperature Sensor as

check on transistors

Check connections.

Replace generator.

F7 0 1 1 1

Temperature of electronics

exceeded 158°F (70 º C) during

operation.

Check installation of unit.

Check for proper ventilation.

F8 1 0 0 0 If the Temperature Sensor’s are

interchanged during the assem-

bly or after a service call.

Verify and correct Temperature

Sensor connections.

F9 1 0 0 1 Mains voltage Vrms < 180 V.

Check Line Voltage

Replace Control Board

FA 1 0 1 0 Time out communication

Replace Generator Assy.

FB 1 0 1 1 Check sum error Replace Generator Assy.

FC 1 1 0 0 Boost Led Error

Replace Control Board

FD 1 1 1 0 Lock Led Error

Replace Control Board

ERROR

CODE

LED ON

13 14 15 16

POSSIBLE CAUSE

CORRECTIVE ACTION

TROUBLESHOOTING GUIDE

Figure 5.2. Troubleshooting guide.

NOTE: If the unit is not working and no error codes are recorded, the likely cause is the control

board or Generator assembly. In this circumstance replace both control board and Generator

assembly together.

Page 21

IInndduuccttiioonn CCooookkttoopp

Technical Data

6-2

THIS APPLIANCE MUST BE PROPERLYGROUNDED AT ALLTIMES WHEN ELECTRICALPOWER IS APPLIED.

DO NOT GROUND THE APPLIANCE WITH THE NEUTRAL(WHITE) HOUSE SUPPLYWIRE. ASEPARATE

GROUND WIRE MUST BE UTILIZED.

IF ALUMINUM HOUSE SUPPLYWIRING IS UTILIZED, SPLICE THE APPLIANCE COPPER WIRE TO THE ALUMINUM HOUSE WIRING USING SPECIALCONNECTORS DESIGNED AND CERTIFIED FOR JOINING COPPER

AND ALUMINUM. FOLLOW THE CONNECTOR MANUFACTURES RECOMMENDED PROCEDURE CAREFULLY. IMPROPER CONNECTION CAN RESULT IN AFIRE HAZARD.

TO ELIMINATE THE RISK OF BURNS OR FIRE BYREACHING OVER HEATED SURFACE UNITS, CABINET

STORAGE SPACE LOCATED ABOVE THE SURFACE UNITS SHOULD BE AVOIDED. IF CABINET STORAGE IS

TO BE PROVIDED, THE RISK CAN BE REDUCED BYINSTALLING ARANGE HOOD THAT PROTECTS HORIZONTALLYAMINIMUM OF 5" (127 MM) BEYOND THE BOTTOM OF THE CABINETS.

Mode Led's On Zone On Watts Amp Draw

HI 16 Both 3600 15 ± 10%

HI-POWER 16 Both 2800 11.7 ± 10%

Figure 6.2. Amp draw take at L1.

Amperage Test:

Figure 6.1. Element Specifications.

Element Specifications:

Element Power Output Ohm Diameter

Front 1800 2 ± 10% 6”

Rear 2200 2 ± 10% 8 1/2”

Temperature Sensor: (Part of Element)

Figure 6.3. K Ohm Reading.

Temperature

Minimum

(K ohm)

Normal

(K ohm)

Maximum

(K ohm)

77°F (25°C)

97.21 117.8 142.5

86°F (30°C) 79.5 95.72 115

122°F (50°C) 37.54 44.11 51.69

158°F (70°C) 19.15 22.02 25.25

212°F (100°C) 7.87 8.8 9.81

Page 22

IInndduuccttiioonn CCooookkttoopp

Wiring Diagram

7-2

CT15I Wiring Schematic

CONTROL

Front

Element

WHITE

YELLOW

Rear

Element

RED

BLUE

J6

J4

J2

J5

FAN

WHITE

BLACK

J10

OUT1

BLUE

Rear

Temperature

Sensor

OUT2

L1

CN4

L2

PURPLE

GRAY RIBBON

Front

Temperature

Sensor

J3

BLACK

RED

GENERATOR

LN

RED

L1

L2

BLACK

Loading...

Loading...