Page 1

subzero.com 800.222.7820

V Series Cooktop Ventilation

Service Manual

General Information 2

Installation Information 5

Component Access & Removal 15

Troubleshooting Guide 19

Technical Data 27

Wiring Diagrams 28

Page 2

General Information

V-Series Cooktop Hoods

V-Series Cooktop Hoods

1-2

#825309 - Revision A - August, 2014

GENERAL INFORMATION

The V-Series Cooktop Hood allows for elimination of fumes and cooking odors from the kitchen through use of dedicated exhaust piping and blower motor. This Wolf Appliance Service Manual has been compiled with the latest service information from Faber S.p.A. Company.

TECHNICAL ASSISTANCE

If you should have any questions regarding the appliance and/or this manual, please contact:

Wolf Appliance, Inc.

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744 - 4988

Customer Assistance

Phone #: (800) 332 - 9513

Facsimile #: (608) 441 - 5887

Technical Assistance

(For Technicians in Customer’s Homes Only)

Phone #: (800) 919 - 8324

Warranty Claims

Phone #: (800) 404 - 7820

Facsimile #: (608) 441 - 5886

Service Department e-mail Address:

customerservice@wolfappliance.com

Main Office Hours:

8:00 AM to 5:00 PM Central Time

Monday through Friday

(24/7 Phone Coverage)

Page 3

General Information

V-Series Cooktop Hoods

V-Series Cooktop Hoods

1-4

#825309 - Revision A - August, 2014

This page contains a summary of the Warranty supplied with every Domestic Wolf V-Series Cooktop Hood.

NOTE: “ICB” warranties vary by Country and Distributor. Contact selling Distributor for warranty coverage.

2 & 5 Year Warranty Summary

2 Year Total Product Warranty, Parts and Labor.•

3-5 Limited Parts Only Warranty.•

Details:

Warranty applies to products installed in United States or Canada, for residential use only.•

Warranty begins at time of unit’s initial installation.•

This Warranty does not cover Wolf Appliances installed in a demonstration kitchen, test kitchen, culinary school•

kitchen, or similar installations. (See Special Warranty below)

Warranty and Service information collected by Wolf Appliance, Inc. is arranged and stored under unit serial num-•

ber and/or customer’s name. Please note that Wolf Appliance, Inc requests that you have model and serial number available whenever contacting factory or parts distributor.

Special Warranty Summary

2 Year Total Product Warranty, Part and Labor. •

Details:

This Warranty applies to products installed in United States or Canada, for use in a demonstration kitchen, test•

kitchen, culinary school kitchen, and similar installations that will help promote Wolf Appliance brand and its

products.

Warranty begins at time of unit’s initial installation.•

Warranty and Service information collected by Wolf Appliance, Inc. is arranged and stored under unit serial num-•

ber and/or customer’s name. Please note that Wolf Appliance, Inc. requests that you have model and serial

number available whenever contacting factory or parts distributor.

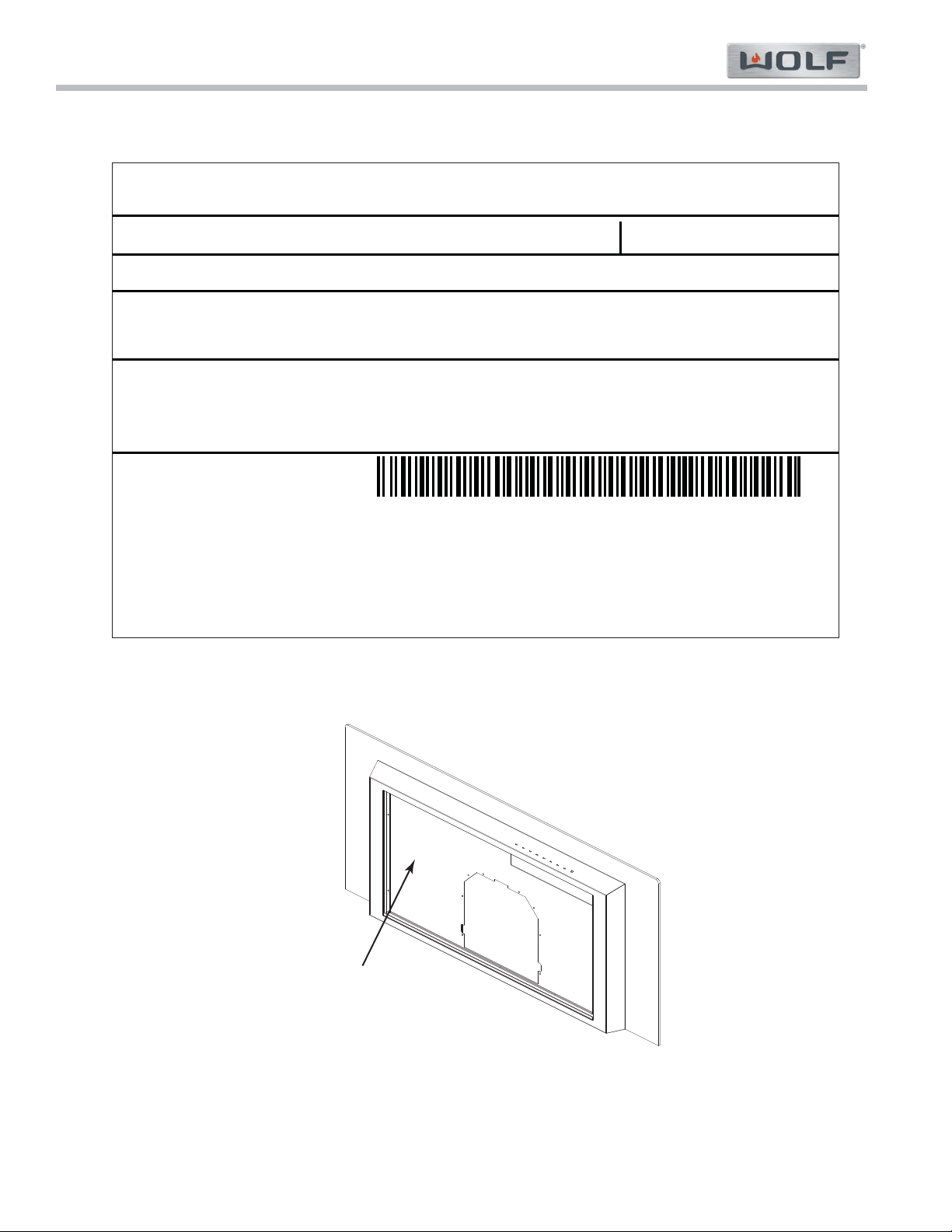

Information Plate and Serial Number

See Figure 1-1 for typical Information Plate layout. •

See Figures 1-2 for Information Plate location. •

WARRANTY INFORMATION

Page 4

V-Series Cooktop Hoods

V-Series Cooktop Hoods

General Information

1-5

#825309 - Revision A - August, 2014

MODEL: VW36S

5610315

120 Vac 60 Hz 2x1 W LED LAMPS

THERMALLY PROTECTED

FB Serial: 15508176 403

Serial: 15508176

TO PROTECT FINISH, WASH WITH MILD SOAP OR DETERGENT ONLY.TO PROTECT FINISH, WASH WITH MILD SOAP OR DETERGENT ONLY.

COMBINED RATING:

2.6A 300W with BLOWER-VENILATION 600CFM Internal Blower Unit

3.0A Maximum Recommended Remote Blower

110.0298.934

00000295500310278923

Wolf Appliance, Inc

Fitchburg, WI 53719

800-222-7820

991.0298.932

www.wolfappliance.com

Figure 1-2. Information Plate Location

Information Plate

(behind Filters)

Figure 1-1. Information Plate

Page 5

General Information

V-Series Cooktop Hoods

V-Series Cooktop Hoods

1-6

#825309 - Revision A - August, 2014

Model Number Key

Model: ICB V W 36 G

International

Product

Type

Size

Style

Product

V V-Series Hoods

Type

W Wall Hood

I Island Hood

Size

30,” 36,” 42,” and 45.”

Style

G Glass

S Stainless Steal

B Black

Page 6

2-2

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

INSTALLATION INFORMATION

This section of the manual covers some of the installation issues that a service technician may need to know

when servicing a Wolf V-Series Cooktop Hood. All dimensions are in inches.

Maximum of three 90 degree elbows.

Hood should not be installed on GFI receptacle.

Hood should be installed on 15 amp dedicated circuit.

Ducting should be 6” ridged ducting and not flexible ducting.

Maximum amp draw of any Blower Motor used is 3.0 amps.

Notes:

For Electrical, Placement, and Ducting Installation Requirements see Page 8.•

It is possible to use 10” ducting but you would have to transition to the 10” ducting after the Support Frame•

on Island Hoods, or after the Easy Cube on Wall Hoods.

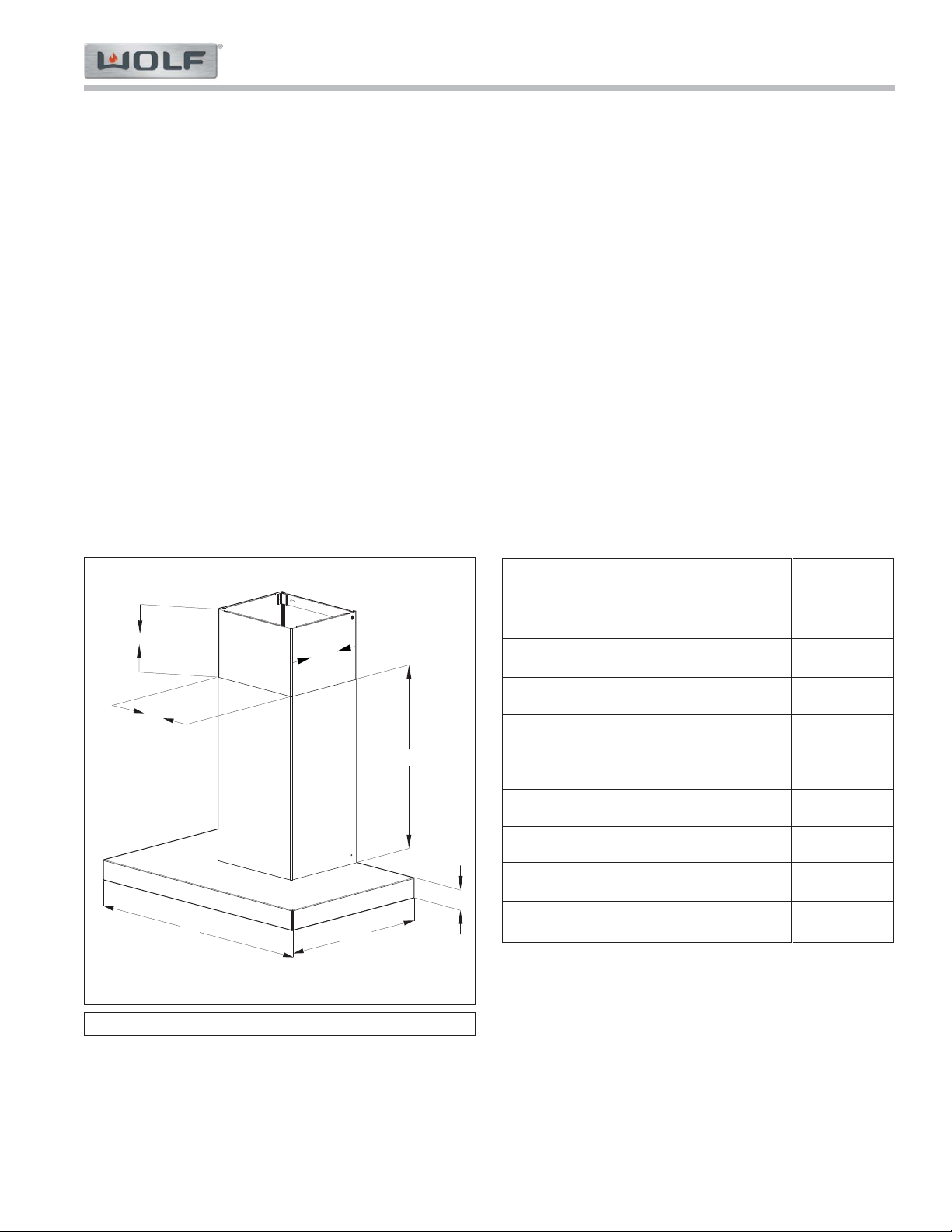

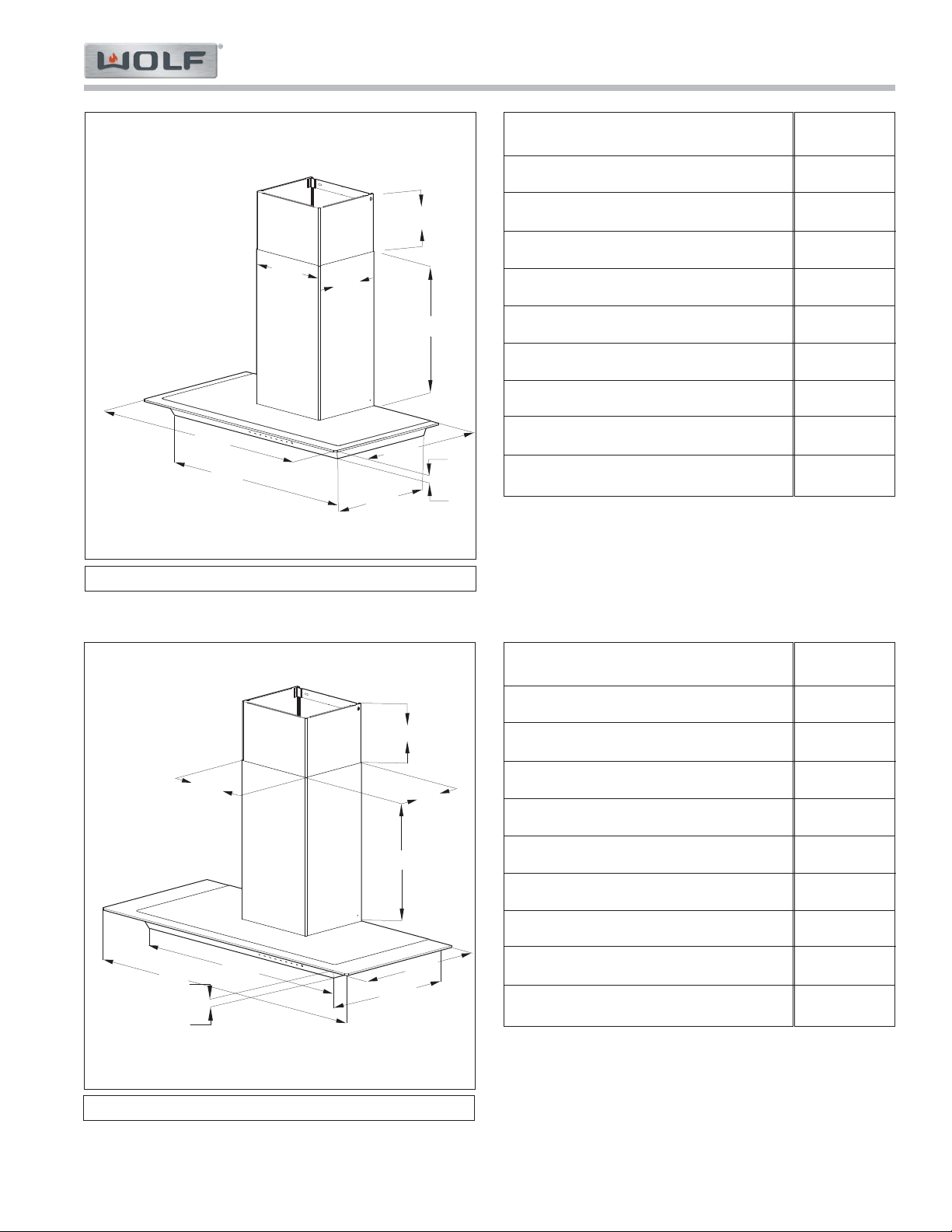

10.25”10.25”

2.25”2.25”

19.25”19.25”

30.00”30.00”

11.75”11.75”

21.25”21.25”

7.88” to 18.00”7.88” to 18.00”

VW30B

VW30B

Overall Width

Hood Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

30”

2.25”

31.38”

41.5”

19.25”

300, 600 cfm

600 cfm

600 cfm

6”

Dimensions may vary +/- 1/8”

Page 7

2-3

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

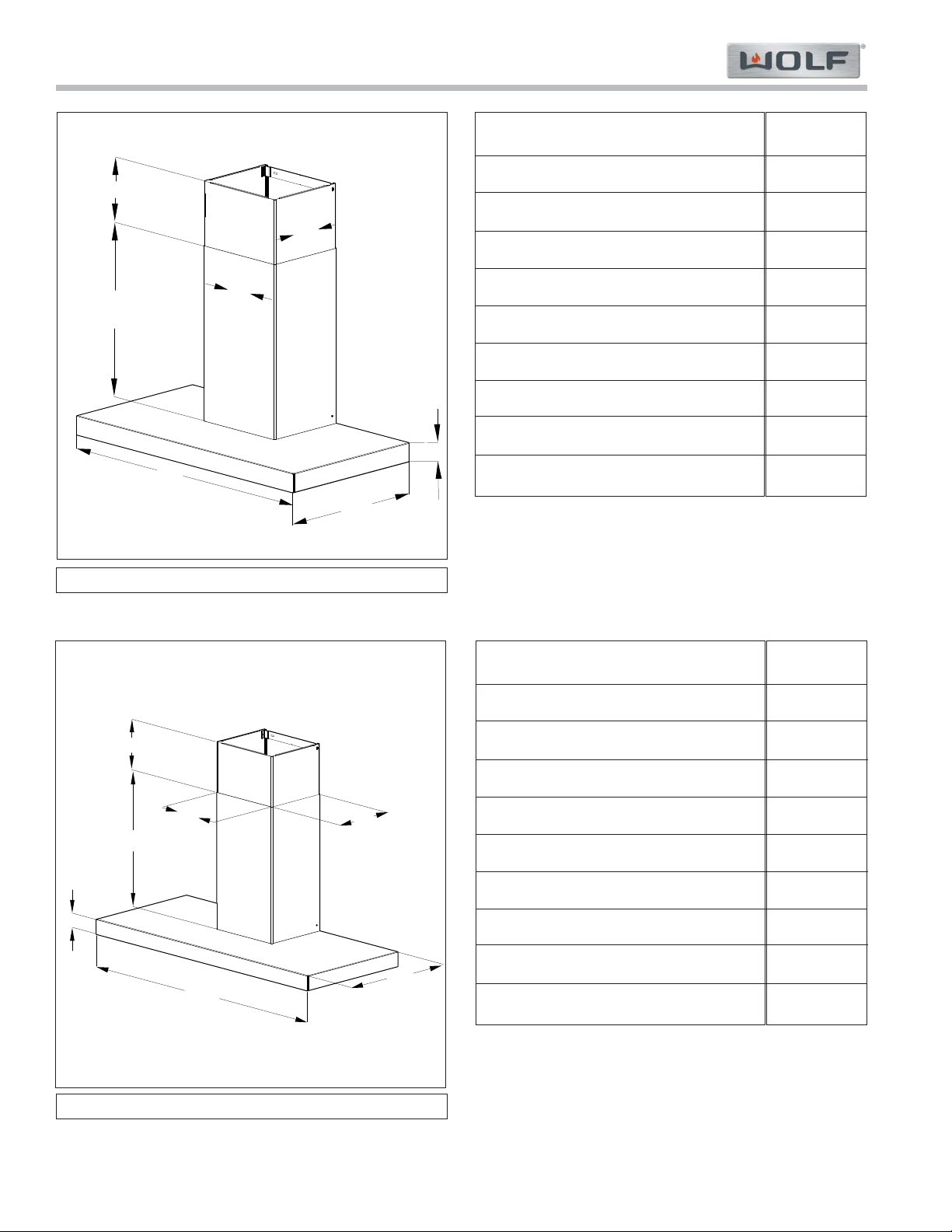

10.25”10.25”

2.25”2.25”

19.25”19.25”

21.25”21.25”

7.88” to 18.00”7.88” to 18.00”

36.00”36.00”

11.75”11.75”

45.00”45.00”

19.25”19.25”

2.25”2.25”

11.75”11.75”

10.25”10.25”

21.25”21.25”

7.88” to 18.00”7.88” to 18.00”

VW36B

VW45B

VW36B

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

36”

2.25”

31.38”

41.5”

19.25”

300, 600 cfm

600 cfm

600 cfm

6”

VW45B

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

45”

2.25”

31.38”

41.5

19.25”

300, 600 cfm

600 cfm

600 cfm

6”

Dimensions may vary +/- 1/8”

Page 8

2-4

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

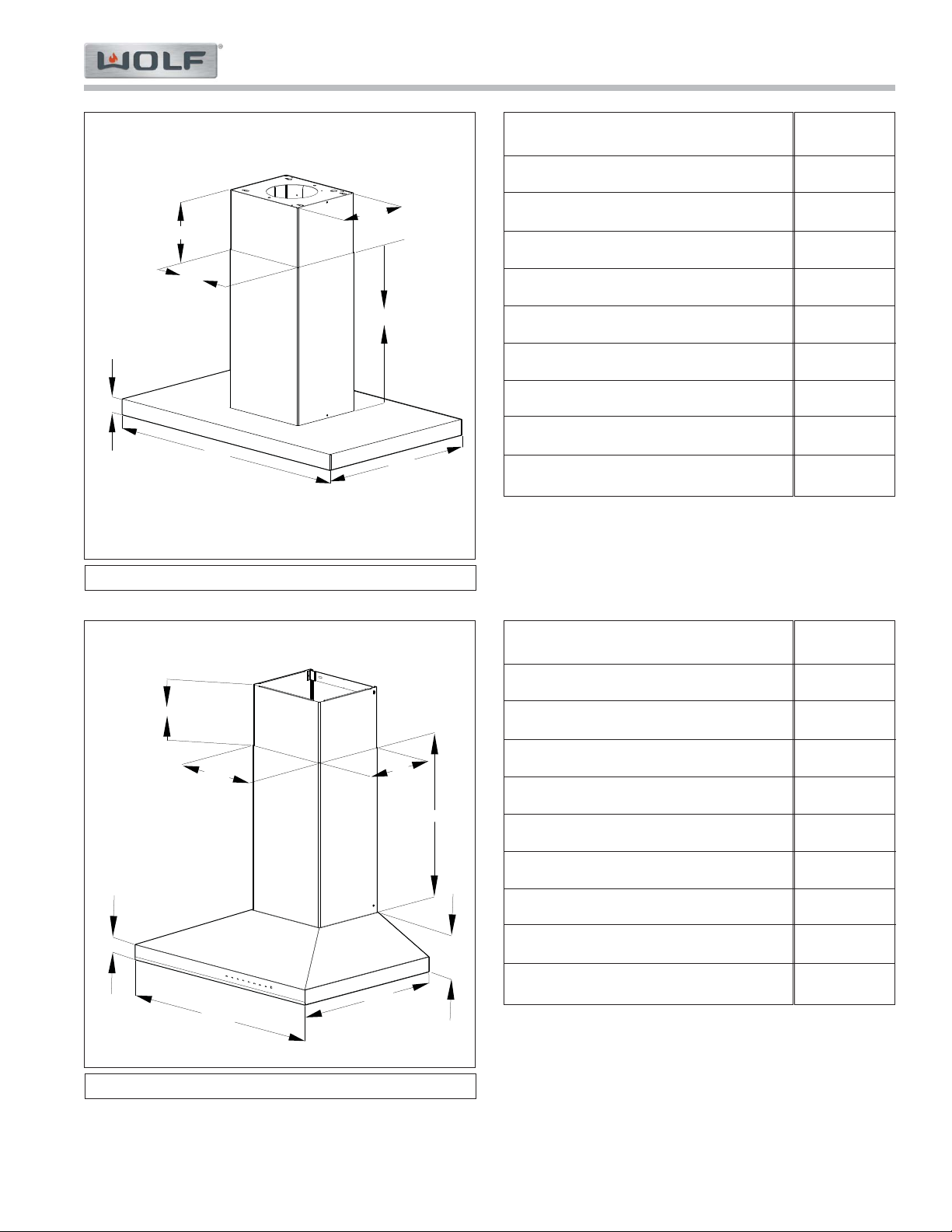

2.25”2.25”

42.00”42.00”

26.25”26.25”

11.25”11.25”

13.75”13.75”

23.63”23.63”

0.0” to 8.37”0.0” to 8.37”

VI42B

10.25”10.25”

11.75”11.75”

22.00”22.00”

30.00”30.00”

2.00”2.00”

21.25”21.25”

7.50” to 18.13”7.50” to 18.13”

6.00”6.00”

VW30S

VI42B

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

42”

2.25”

25.5”

34.25”

26.25”

300, 600 cfm

600 cfm

600 cfm

6”

VW30S

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

30”

6.00”

34.75”

45.38

22”

300, 600 cfm

600 cfm

600, 1200 cfm

6”

Dimensions may vary +/- 1/8”

Page 9

2-5

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

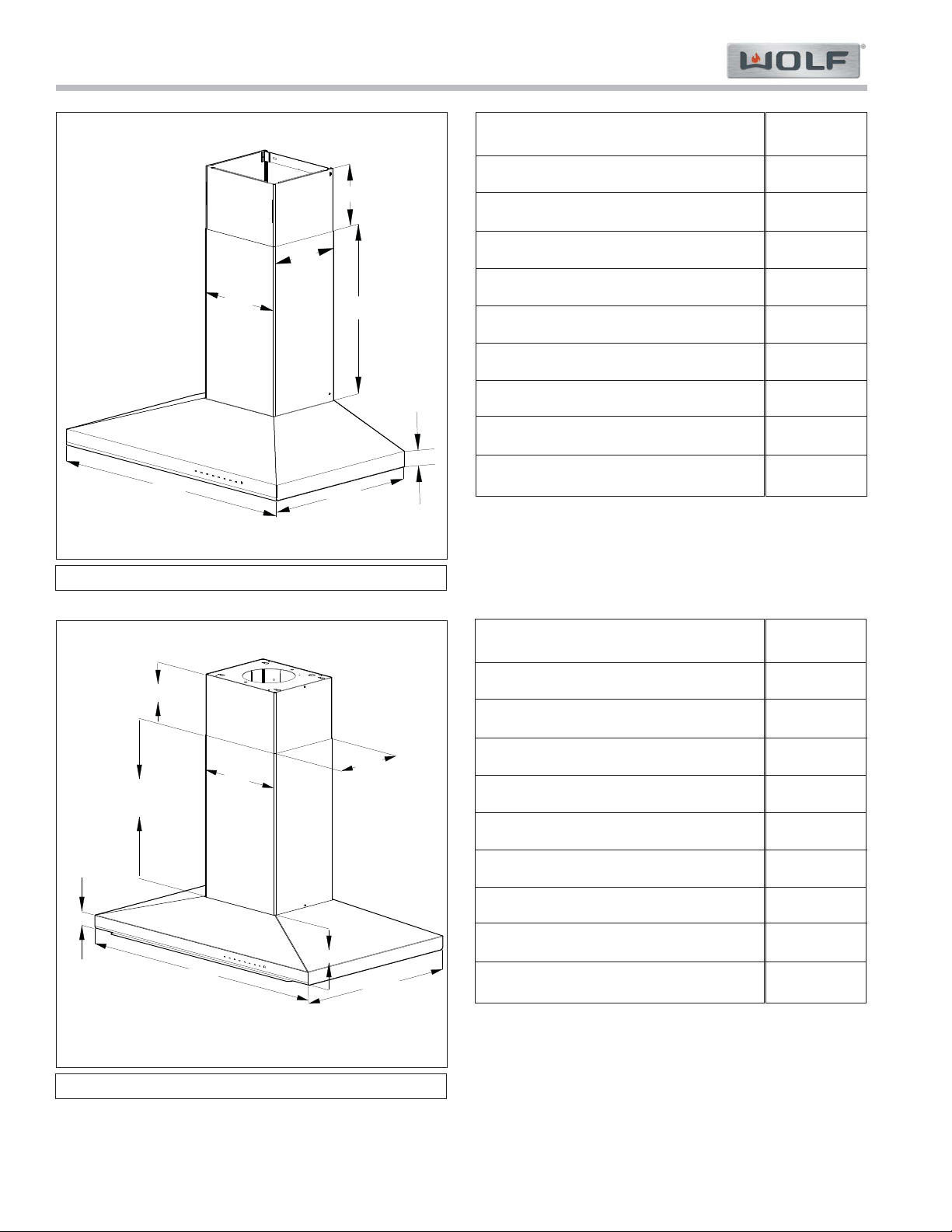

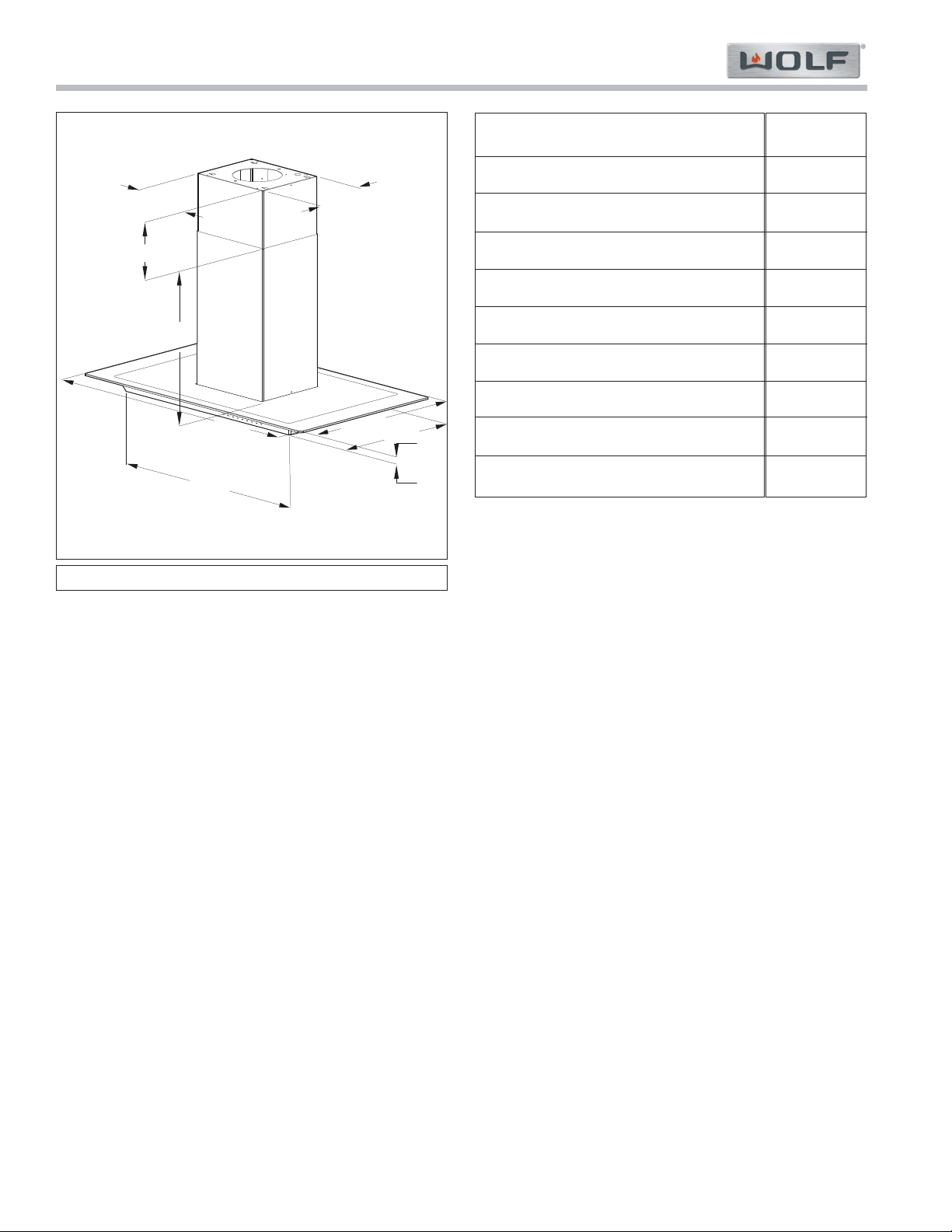

36.00”36.00”

2.00”2.00”

21.25”21.25”

7.50” to 18.13”7.50” to 18.13”

11.75”11.75”

10.25”10.25”

22.00”22.00”

VW36S

42.00”42.00”

26.50”26.50”

2.00”2.00”

13.75”13.75”

11.25”11.25”

0.00” to 7.87”0.00” to 7.87”

23.63”23.63”

6.00”6.00”

VI42S

VW36S

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

36”

6.0”

34.75”

45.38

22”

300, 600 cfm

600 cfm

600, 1200 cfm

6”

VI42S

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

Remote Blower(s)

Duct Size

42”

6.0”

29.63”

37.5”

26.25”

300, 600 cfm

600 cfm

600, 1200 cfm

6”

Dimensions may vary +/- 1/8”

Page 10

2-6

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

19.25”19.25”

45.00”45.00”

34.00”34.00”

21.25”21.25”

7.88” to 18.00”7.88” to 18.00”

11.75”11.75”

10.25”10.25”

16.00”16.00”

2.25”2.25”

VW45G

30.50”30.50”

36.00”36.00”

16.00”16.00”

19.25”19.25”

11.75”11.75”

21.25”21.25”

10.25”10.25”

7.88” to 18.00”7.88” to 18.00”

2.25”2.25”

VW36G

VW36G

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

External Blower(s)

Duct Size

36”

2.25”

31.38”

41.50”

19.25”

300, 600 cfm

600 cfm

600 cfm

6”

VW45G

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

External Blower(s)

Duct Size

45”

2.25”

31.38”

41.50”

19.25”

300, 600 cfm

600 cfm

600 cfm

6”

Dimensions may vary +/- 1/8”

Page 11

2-7

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

13.75”13.75”

11.25”11.25”

26.25”26.25”

45.00”45.00”

34.00”34.00”

20.00”20.00”

23.63”23.63”

2.25”2.25”

0.00” to 8.37”0.00” to 8.37”

VI45G

VI45G

Overall Width

Overall Height (excluding chimney)

Minimum Height (chimney contracted)

Maximum Height (chimney extended)

Overall Depth

Internal Blower(s)

Inline Blower(s)

External Blower(s)

Duct Size

45”

2.25”

25.5”

34.25

26.25”

300, 600 cfm

600 cfm

600 cfm

6”

Dimensions may vary +/- 1/8”

Page 12

2-8

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Installation Requirements

Hood Placement:

Both the Island Hood and Wall Hood should be

installed so that the bottom of the hood is 30” to 36”

above countertop. (See Figure 1)

Hood

Countertop

30” to 36”

Figure 1. Countertop to Hood Placement

Electrical:

Installation must be electrically grounded in accordance with local codes or, in the absence of local

codes, with National Electrical Code, ANSI/NFPA70.

Electrical supply for Wall Hoods and Island Hoods

should be located in shaded area in Figure 2.

From where Electrical Supply wires enter the hood

area:

Allow a minimum of 12” (inches) wire for connection to

Wall Hood junction box.

Allow a minimum of 6’ (feet) of wire for connection to

Island Hood junction box.

A separate circuit, servicing only this appliance is

required.

Notes:

Required Electrical Supply: Grounded, 110/120•

VAC, 60 Hz, 15 amp dedicated circuit.

No GFI Circuit.•

18”

E

Figure 2. Electrical Supply Area

Installing hood at less then 30” can damage hood•

Touch Control, LED Assemblies, or wiring.

Placing hood above 36” will reduce efficiency of•

the hood’s performance.

Page 13

2-9

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Installation Requirements

Ducting:

6” (inch) round, rigid metal duct is recommended for

V- Series cooktop ventilation.

Wall Hoods and Island Hoods include a Backdraft

Damper. Local codes may require use of addition

backdraft damper or make up air.

A straight, short run is most effective and will improve

performance and reduce noise. Elbows, transitions,

and air boxes all reduce performance of hood.

Reducing the duct size less then 6” (inches) for even

a short span reduces air flow for the entire duct run.

Duct run should not exceed 50 feet Equivalent

Ducting Length. (See Figure 3).

Internal and In-Line blowers require a Roof or Wall

Cap the same duct size as duct run. (See Figure 4).

Contact your local HVAC professional for specific

codes and requirements.

1’ of 6” Ducting = 4’ of

Equivalent Ducting Length

6” Roof/Wall Cap with Damper

is 30’ of Equivalent Ducting Length

6” 90 degree Elbow = 24’

of Equivalent Ducting Length

Figure 3. Equivalent Duct Feet

Ductwork Installation

Through the roof

Ductwork Installation

Through the eave

Ductwork Installation

Through the wall

6” Wall Cap

6” Roof Cap

6” Elbow

6” Duct

6” Duct

Eave Vent

Figure 4. Duct Run Examples

Page 14

2-10

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Wall Hood Mounting

If an Internal Blower is being installed, install Internal

Blower prior to mounting the Hood.

1. Mark center line of hood installation. Using the

information in Figure 5 and the Chart below, mark

hole locations for mounting brackets. Additional

wall framing is recommended in this area.

a. Position two mounting brackets for chimney

flue, then install using two mounting screws

per bracket.

b. Install the Easy Cube mounting screws so

there is approximately 1/4” gap between the

screw head and wall.

Note: If wall framing is not available, use of wall

anchors is recommended.

9

1

/8

"

(232)

A

(433)

(19)

17

1

/16

"

3

/4

"

BOTTOM OF HOOD

CEILING

B

Figure 5. Bracket Mounting Location

Hood

Black

Glass

Stainless

Dimension “A”

12-3/4”

12-9/16”

16-3/8”

Dimension “B”

31-3/8” to 41-1/2”

31-3/8” to 41-1/2”

34-3/4” to 45-3/8”

MountingMounting

TabTab

LevelingLeveling

ScrewScrew

Figure 6. Easy Cube Mounting.

2. Place the mounting tabs of the Easy Cube over the

mounting screws. Use leveling adjustment screws

to ensure hood is level. (See Figure 6)

3. Install Upper Chimney to Chimney Bracket.

4. Place Lower Chimney over Upper Chimney and

rest the Lower Chimney on the Hood Body. Fasten

two screw to the Easy Cube.

Page 15

2-11

#825309 - Revision A - August, 2014

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Installation Information

Island Hood Mounting

Island Hoods have a Support Frame that is adjustable

in height. The Support Frame is attached to ceiling,

the Upper and Lower Chimney is attached, then Hood

Body.

Note: If an Internal Blower is being installed, mount

Hood Body to Easy Cube/Support Frame prior

to installing Internal Blower. The two pin molex

connector for Hood Lights must be connected

prior to Internal Blower being installed.

1. Use template provided with Island Hood to mark

location of electrical supply and mounting holes for

Support Frame. Actual Template has a 6” diameter

circle for ducting. (See Figure 7)

a. Use 1-1/4” drill to create a hole for electrical

power supply.

b. Place four mounting screws in ceiling in indi-

cated location. Do not tighten screws.

2. Place Support Frame on mounting screws and

tighten mounting screws.

3. Adjust height of Support Frame by loosening four

screws on each arm of Support Frame. This

adjustment can be made prior to mounting Support

Frame if desired. (See Figure 8)

8

5/8”

(219)

Electrical

Location

11"

(279)

Figure 7. Template Example

Support

Arm

Screws

Figure 8. Support Frame

4. Install Damper on top of Easy Cube. Install

Ducting. Connect electrical supply to junction

box. Connect remote/inline blower in electrical

box.

5. Install Upper Chimney.

6. Install Lower Chimney.

7. Install Hood Body to Support Frame.

8. Install Internal Blower.

Page 16

3-2

#825309 - Revision A - August, 2014

V-Series Cooktop Hood

V-Series Cooktop Hood

Component Access

COMPONENT ACCESS AND REMOVAL

This section explains how to access and remove components from a Wolf V-Series Hood.

An attempt has been made to arrange these procedures in such a way as to simulate which components would

need to be removed first in order to gain access to the other components. When following a component removal

procedure, it may be necessary to reference another component removal procedure listed earlier in this section.

Note: Before continuing, please take note of the WARNINGS and CAUTIONS below.

• When working on the Hood and components, be careful when handling sheet metal parts. There may be sharp

edges present.

• Chimney should only be secured at the locations provided for by the Hood. Do Not cement, grout, or silicone the

chimney in any manner. Warranty does not cover removing or reinstalling chimneys attached in this manner.

• TO AVOID ELECTRIC SHOCK. POWER TO HOOD MUST BE DISCONNECTED WHEN EVER SERVICING

AND/OR ACCESSING COMPONENTS AND/OR REMOVING COMPONENTS POWERED BY ELECTRICITY OR

COMPONENTS NEAR OTHER ELECTRICAL COMPONENTS.

• IF IT IS NECESSARY TO REMOVE A HOOD FROM ITS INSTALLATION REMEMBER THAT THE UNITS ARE

HEAVY AND MUST BE LOWERED FROM THE INSTALLATION. MAY REQUIRE TWO MEN.

• REMOVING A UNIT FROM ITS INSTALLATION SHOULD ONLY BE PERFORMED BY AN AUTHORIZED SERVICE TECHNICIAN OR INSTALLER.

Page 17

3-3

#825309 - Revision A - August 2014

Component Access

V-Series Cooktop Hood

V-Series Cooktop Hood

Figure 3-1. Filter Cover Hinge

Filter Covers - Black Hoods

Black hoods have a Filter Cover. Filter Cover has a pin

that snaps into a receptacle on hood side. Pull on Filter

Cover to open. Press Filter Cover in to close.

To Remove Filter Cover:

1. Open Filter cover to 90 degrees. Press Hinge

Release Pin toward center of hood. Disengage

Filter Cover from the hinge. (See Figure 3-1)

2. Slide Filter Cover to right and disengage pin from

other hinge.

Hinge Release

Pin

Push

Figure 3-2. Filter Removal

Filter

Filter

Bottom of Hood

Filters

All V-Series Hoods have aluminum mesh filters. Glass

and Stainless Steel models are same filter. All filters

are removed in the same manner.

To Remove Filter:

1. Push plastic tab on front end of Filter toward rear of

Hood and gentlely pull down. (See Figure 3-2)

2. Pull Filter forward and remove.

Page 18

3-4

#825309 - Revision A - August, 2014

V-Series Cooktop Hood

V-Series Cooktop Hood

Component Access

Figure 3-5. Internal Blower in Easy Cube

Figure 3-4. LED Light Assembly

Figure 3-3. Light Assembly Support Removal

LED Light Assembly

Hood lights are LED fixtures that must be replaced as

assemblies. Lights are 12 VDC.

To Remove LED Light Assembly:

1. Extract screws holding Light Assembly Support to

hood. Lower front part of Light Assembly Support

and pull toward center of hood. (See Figure 3-3)

2. Align spring clips to square notches in Light

Assembly Support. Depress spring clips on side of

LED Light Assembly and push through Light

Assembly Support. (See Figure 3-4)

Square

Notches

Spring Clips

Spring Clips

Square

Notches

Internal Blower Removal

The 600 cfm Internal Blower is mounted in Easy Cube

portion of hood. Once Filter Covers (Black Hoods) and

Filters are removed Internal Blower can be extracted.

To Remove Internal Blower:

1. Support Internal Blower and extract two screws at

bottom of mounting plate. (See Figure 3-5)

2. Lower Internal Blower from hood. Disconnect

Internal Blower Harness from Internal Blower.

Touch Control

Screw

Touch Control

Screw

Ribbon Cable

Screws

Internal Blower

Connector

Blower Mounting

Screws

Touch Control Board

The touch control board is removed differently for black

h

oods and stainless steel/glass hoods. Once the light

assembly support is removed, the touch control

assembly case, which contains the board, is accessible.

Remove the Touch Control Board - Black Hoods:

1. Open the case.

2. Remove the two ribbon c

disconnect the ribbon cable.

3. Remove the two touch control board screws, and

remove the touch control board.

able screws, and

Figure 3-6. Black Hood Touch Control Board

Page 19

3-5

#825309 - Revision A - August 2014

Component Access

V-Series Cooktop Hood

V-Series Cooktop Hood

Easy Cube Access

The Easy Cube is located directly above the hood body.

If their is an Internal Blower it is located inside the Easy

Cube. The Power Board Assembly, Light Transformer,

and Hood Electricals are mounted on top of the Easy

Cube.

To Access Area Above Easy Cube:

Note: The Lower Chimney should not be secured to

the wall in any manner. In instances where the

Lower Chimney has been secured, it is the customer’s responsibility to have the Lower

Chimney removed.

1. Extract two screws at bottom of Lower Chimney.

Raise and block Lower Chimney up on Island

Hoods, and remove Lower Chimney on Wall Hoods.

2. The Easy Cube has the control board mounted on

front edge, and unit electricals mounted on back

edge. (See Figure 3-7)

Touch Control Assembly - continued

To Remove Touch Control Assembly - Glass and

Stainless Steel Hoods:

1. Extract two Ribbon Cable screws and disconnect

Ribbon Cable. (See Figure 3-6)

2. Release six tabs retaining Touch Control Assembly

to Hood.

Figure 3-8. Power Board Assembly

Figure 3-7. Wall Hood Easy Cube - Side View

Power Board

Assembly

Unit Electrical

Box

Screws to

Easy Cube

Case Screws

Case Screws

Ribbon Cable

Cover

Power Board Assembly Removal

The Power Board Assembly is located in a black case

attached by two screws to front of Easy Cube.

To Remove Power Board Assembly:

1. Open Ribbon Cable cover with a flat blade screwdriver and disconnect Ribbon Cable.

(See Figure 3-8)

2. Extract two screws holding Power Board Assembly

case to Easy Cube.

3. Extract four screws holding Power Board Assembly

case together.

4. Disconnect harnesses from Power Board Assembly.

5. Remove three black screws holding Power Board to

Power Board Assembly case.

(See Figure 3-9 - Red Circles)

Primary

Power

12 VDC to

Lighting

12 VDC to

Touch Control

Figure 3-9. Power Board and Transformer

Transformer:

Transformer is located in top cover of Power Board

Assembly case. It is held in with two screws. Orange

wires are 120 VAC to Primary side of Transformer.

Harness in wire sheath is 12 VDC to hood lights.

Connector with gray, black, and white wires is 12 VDC

to Touch Control.

Page 20

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Troubleshooting

4-2

#825309 - Revision A - August, 2014

TROUBLESHOOTING

This section explains how to troubleshoot various components in Wolf V-Series Cooktop Hood.

An attempt has been made to arrange these procedures in such a way as to trace the issue from component to

component.

Note: Before continuing, please take note of the WARNINGS and CAUTIONS below.

• TO AVOID ELECTRIC SHOCK. POWER TO HOOD MUST BE DISCONNECTED WHEN PREPARING FOR A

SPECIFIC TEST. CARE SHOULD BE USED WHILE PERFORMING ANY TEST WITH THE HOOD ENERGIZED.

• IF IT IS NECESSARY TO REMOVE A HOOD FROM ITS INSTALLATION REMEMBER THAT THE UNITS ARE

HEAVY AND MUST BE LOWERED FROM THE INSTALLATION.

• When working on the Hood and components, be careful when handling sheet metal parts. There may be

sharp edges present.

Page 21

Troubleshooting

V-Series Cooktop Hoods

V-Series Cooktop Hoods

4-3

#825309 - Revision A - August, 2014

Troubleshooting and Test Procedures

Troubleshooting table ............................................... 4-3

1. Hood Lights and Blower do not energize ............. 4-3

2. Blower Motor Runs only at High Speed ............... 4-4

3. Hood Lights do not work ....................................... 4-4

4. Blower Motor does not run at any speed ............. 4-5

a. Checks for Internal Blowers ............................ 4-5

b. Checks for External/Inline Blowers

................ 4-6

5. Blower Motor runs but not at all four speeds ... 4-6

6. Hood does not move enough Air ...................... 4-6

DIAGNOSTIC TEST RESOLUTION MANUAL PAGE

Check Voltage at Power

Cable to Easy Cube:

L1 to Ground = 115 VAC

N to Ground = 0 VAC

L1 to N = 115 VAC

Replace or repair Power

Cable.

Test Procedure #2.

Check Voltage at three

pin connector in Easy

Cube Electrical Box.

Pin 1 to Pin 2 =115 VAC

Pin 2 to Pin 3 =0 VAC

Pin 1 to Pin 3 =115 VAC

Replace/Repair

Electrical Connector or

wires.

Test Procedure #3.

Check Voltage at Power

Board:

Pin 1 to Pin 2 =115 VAC

Replace/Repair connector from Electrical Box

on Easy Cube to Power

Board.

Section 3, Page 5.

Test Procedure #4.

SYMPTOM

Hood Lights and Blower

do not energize. No GFI

Circuit.

Check house circuit is

115 VAC, 15 amp, dedicated circuit.

Breaker is closed.

Bring circuit into specification.

Close Breaker.

Installation Guide.

Service Manual Section

2.

Check Voltage at J-Box:

L1 to Ground = 115 VAC

N to Ground = O VAC

L1 to N = 115 VAC

Correct circuit.

Correct Polarity.

Correct Ground.

Assure connections are

tight.

Installation Guide.

Test Procedure #1.

Test Procedures

Test Procedures ......................................................... 4-7

1. Testing Line Voltage at J-Box ............................... 4-7

2. Testing Line Voltage at Power Cable .................... 4-7

3. Testing Line Voltage at 3 Pin Connector inside

Electrical Box ....................................................... 4-7

4. Testing Line voltage at 7 Pin Connector on Power

Board .................................................................... 4-7

5. Testing Line Voltage to Transformer and Blower

Motor ..................................................................... 4-8

6. Testing Line Voltage to Transformer on Power

Board ................................................................... 4-8

7. Testing 12 VDC at Transformer Secondary........... 4-8

8. Testing Lighting Voltage at Easy Cube ................. 4-8

9. Testing Lighting Voltage at Light Support ............. 4-9

10. Testing LED Assembly for a Short ........................ 4-9

11. Testing Blower Voltage at Easy Cube

Connection ............................................................ 4-9

12. Testing Blower voltage at Blower Connection ...... 4-9

13. Testing Internal Blower for Open or Short ............ 4-9

14. Testing External/Internal Blower for Open

or Short ................................................................. 4-9

Page 22

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Troubleshooting

4-4

#825309 - Revision A - August, 2014

SYMPTOM

Hood Lights and Blower do

not energize - continued.

Blower motor runs only at

High Speed.

Power Board fault. Replace Power Board. Section 3, Page 5.

Hood Lights do not work.

DIAGNOSTIC TEST

RESOLUTION MANUAL PAGE

If one LED is out in the

LED Light Assembly.

Replace LED Light

Assembly.

Section 3, Page 4.

With Blower and Lights

energized:

Check 115 VAC L to N

on connector (orange) to

Transformer.

Check 115 VAC Blue to

Brown on terminal block

in Electrical Box on Easy

Cube.

With power Off check

that ribbon cable from

Power Board to Touch

Control is seated correctly:

Ribbon Cable connector

on Power Board.

Locking connector in

Easy Cube.

Connector on Touch

Pad.

If Ribbon Cable is seated correctly at all points,

and no voltage out of

Power Board then the

Power Board or Touch

Control is bad. Try

replacing the Power

Board first.

Section 3, Page 4.

Section 3, Page 5.

Test Procedure #5.

Remove connector from

Secondary side of

Transformer and check

for 12 VDC between

pins on Transformer.

If no voltage replace the

Transformer.

Section 3, Page 5.

Test Procedure #7.

Unplug two pin connector in Easy Cube and

check for 12 VDC.

Note: Internal Blower

may need to be

removed.

Replace harness from

Easy Cube to

Transformer.

Section 3, Page 5.

Test Procedure #8.

Unplug two pin connector behind Light Support

and check for 12 VDC

Replace harness from

Easy Cube to Hood

Body.

Section 3, Page 4.

Test Procedure #9.

Ohm LED Light

Assembly connector.

Assure there is no short.

Replace LED Light

Assemblies.

Section 3, Page 4.

Test Procedure #10.

Page 23

Troubleshooting

V-Series Cooktop Hoods

V-Series Cooktop Hoods

4-5

#825309 - Revision A - August, 2014

Remove connector

LUX1 from Power Board

and check for 115 VAC

from Pin 1 to Pin 2.

If Blower Motor is working, replace Power

Board.

Section 3, Page 4.

Test Procedure #6.

On motor Side of connector Ohm out:

Pin 4 to Pin 5.

Pin 4 to motor case.

Pin 5 to motor case.

If reading Open Pin 4 to

Pin 5, or Continuity Pin

4 or Pin 5 to motor case,

confirm it is not Blower

Motor Harness, then

replace Blower Motor.

Section 3, Page 4.

Test Procedure #13.

Remove connector from

Primary side of

Transformer and check

for 115 VAC between

Orange wires.

Replace/Repair harness

from Power Board to

Transformer.

Section 3, Page 5.

Test Procedure #5.

SYMPTOM

DIAGNOSTIC TEST

RESOLUTION MANUAL PAGE

Hood Lights do not work continued.

Check Voltage at Power

Cable to Easy Cube:

L1 to Ground = 115 VAC

N to Ground = 0 VAC

L1 to N = 115 VAC

Replace/Repair

Electrical Connector or

wires

Installation Guide.

Test Procedure #2.

Blower Motor does not run

at any speed.

Note: Perform Checks for

Internal Blower Motor or

Checks for External/Inline

Blower Motor Prior to these

checks.

Check Voltage at J-Box:

L1 to Ground = 115 VAC

N to Ground = O VAC

L1 to N = 115 VAC

If Lights are working,

likely this is a short or

loose connection.

Installation Guide.

Test Procedure #1.

Check for 115 VAC at

terminal block in

Electrical Box on Easy

Cube.

Replace/Repair connector from Power Board to

Electrical Box.

Test Procedure #5b.

Unplug three pin connector and check for 115

VAC Pin 1 to Pin 3

inside Easy Cube.

Disconnect Internal

Blower connector from

Blower, check for 115

VAC Pin 4 to Pin 5 on

Hood side of connector.

Replace harness from

terminal block to Easy

Cube Connector.

Replace Blower Motor

Harness.

Test Procedure #11.

Section 3, Page 4.

Test Procedure #12.

Check Voltage at three

pin connector in Easy

Cube Electrical Box.

Pin 1 to Pin 2 =115 VAC

Pin 2 to Pin 3 =0 VAC

Pin 1 to Pin 3 =115 VAC

Replace/Repair

Electrical Connector or

wires.

Test Procedure #3.

Check Voltage at Power

Board:

Pin 1 to Pin 2 =115 VAC

Replace/Repair connector from Electrical Box

on Easy Cube to Power

Board.

Section 3, Page 5.

Test Procedure #4.

Checks for Internal Blower

Motor.

Notes:

Perform “Blower Motor does

not run at any speed”

checks after these checks if

needed.

Internal Blower will need to

be removed.

Page 24

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Troubleshooting

4-6

#825309 - Revision A - August, 2014

This failure can be

caused by failure of the

Triac on the Power

Board or by a Touch

Control Failure. At this

time there is no test to

determine where the failure is.

Replace Power Board or

Touch Control.

Section 3, Page 4

Section 3, Page 5

On motor side of terminal block disconnect

External/Inline Blower

Motor wires:

Ohm out between wires.

Ohm each wire to

ground.

If reading Open between

Blower wires, or

Continuity from either

Blower Wire to Ground:

Check that the wiring

between terminal block

and Blower Motor is

good. If wiring is good,

replace External/Inline

Blower.

Installation Guide.

Test Procedure 14.

Check for External/Inline

Blower Motor.

Note: Perform “Blower

Motor does not run at any

speed” checks after these

checks if needed.

Blower Motor runs, but not

at all four Speeds.

Hood does not move

enough Air.

Correct ducting installed.

Verify the duct run is the

correct size including:

Wall/Roof Cap is correct.

No reduction is size at

any point.

Damper is installed correctly.

No excessive elbows.

No excessive length.

No air box used.

Correct Duct issue. Installation Guide.

Service Manual Section

Two.

Blower Motor is not

changing speeds.

On Internal Blowers

remove ducting above

Easy Cube.

On Inline blowers

remove ducting on inlet

and outlet.

On External Blowers

Remove inlet ducting.

Note: With ducting

attached a possible

restriction will prevent

hearing the speed

change.

If no speed change

noticed see “Blower

Motor runs, but not at

all four speeds.”

If there is a speed

change review ducting

again for restriction.

Installation Guide.

Service Manual Section

Two.

Filters are Dirty. Remove Filters to test,

then clean Filters.

Use and Care.

Insufficient Make Up Air Open outside door or

window to test.

Contact HVAC company.

Page 25

Troubleshooting

V-Series Cooktop Hoods

V-Series Cooktop Hoods

4-7

#825309 - Revision A - August, 2014

Test Procedures

1. Testing Line Voltage at J-Box.

J-Box is mounted to the Support Frame on Island

Hoods and is mounted by Installer on wall behind

Upper Chimney on Wall Hoods. (See Figure 4-1)

a. Disconnect wires between Electrical Supply and

Hood.

b. Measure voltage from Electrical Supply L1 (typi-

cally Black) to Ground. Voltage should be 115

VAC.

c. Measure voltage from Electrical Supply Neutral

(typically white) to ground. Voltage should be 0

VAC.

d. Measure voltage from Electrical Supply L1 to

Neutral. Voltage should be 115 VAC.

e. Confirm both ground screw connections are

tight.

Neutral (White)

Ground (Green)

Power Cable

L1 (Black)

3. Testing Line Voltage at 3 Pin Connector in

Electrical Box - continued

Disconnect 3 Pin Connector and test on Power

Cable Receptacle side of connector.

(See Figure 4-2)

a. Measure voltage from Pin 1 to Pin 2. Voltage

should be 115 VAC.

b. Measure voltage from Pin 2 to Pin 3. Voltage

should be 0 VAC.

c. Measure voltage from Pin 1 to Pin 3. Voltage

should be 115 VAC.

2. Testing Line Voltage at the Power Cable.

Power Cable plugs into the top of the Electrical Box

on Easy Cube. (See Figure 4-1)

a. Inside Power Cable measure voltage from L1 to

Ground. Voltage should be 115 VAC.

b. Inside Power Cable measure voltage from

Neutral to Ground. Voltage should be 0 VAC.

c. Inside Power Cable measure voltage from L1 to

Neutral. Voltage should be 115 VAC.

d. Check resistance (ohms) between Ground on

Power Cable and another Ground terminal on a

near by outlet. You should read Continuity.

Figure 4-1. Hood J-Box

3 Pin Connector

Power Cable

Receptacle

Figure 4-2. 3 Pin Connector in Electrical Box

4. Testing Line Voltage at 7 Pin Connector on Power

Board.

On Power Board disconnect 7 Pin Connector from

Power Board. Test on Wire side of connector.

(See Figure 4-3)

a. Measure voltage from Pin 1 to Pin 2. Voltage

should be 115 VAC.

7 Pin Connector

3. Testing Line Voltage at 3 Pin Connector in

Electrical Box.

Inside Electrical Box on top of Easy Cube is a 3 pin

connector that connects the Power Cable receptacle to Power Board connector.

Figure 4-3. 7 Pin Connector in Power Board

Page 26

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Troubleshooting

4-8

#825309 - Revision A - August, 2014

Voltage to

Transformer

Figure 4-4. Light Transformer

Power to Blower

Terminals

Figure 4-5. Terminal Block

8. Testing Lighting Voltage at Easy Cube

a. If Hood has an Internal Blower it will need to be

removed to perform this check.

b. Disconnect two pin Lighting Harness from Easy

Cube connection. (See Figure 4-8).

c. Measure voltage between pins of connector

inside Easy Cube. Voltage should be 12 VDC.

5. Testing Line Voltage to Transformer and Blower

Motor.

Perform both of these tests with the Blower Motor

and Lights Energized.

a. Disconnect two pin connector or screws with

two orange wires to Transformer. Measure volt

age between two pins or wires on Power Board

side of connector. Voltage should be 115 VAC.

(See Figure 4-4)

b. Measure voltage between terminal posts on the

Terminal Block inside Electrical Box. Voltage

should be 115 VAC. (See Figure 4-5)

6. Testing Line Voltage to Transformer on Power

Board.

On Power Board LUX1 is the voltage to

Transformer.

a. Disconnect LUX1 from Power Board and meas-

ure voltage between the pins on the board.

Voltage should be 115 VAC. (See Figure 4-6)

LUX 1

Figure 4-6. LUX1 Connector on Power Board

7. Testing 12 VDC from Transformer Secondary.

Wires in sheath are 12 VDC to LED Assemblies.

The three pin connector is the Lighting Command

Harness. (See Figure 4-7)

a. Disconnect two pin connector from secondary

side of Transformer. Measure voltage on pins

of Transformer. Voltage should be 12 VDC.

b. Disconnect three pin connector from secondary

side of Transformer. Measure voltage between

pins that correspond with black and white wire

on the connector. Voltage should be 12 VDC.

c. Disconnect three pin connector from second-

ary side of Transformer and Power Board.

Check Continuity from each wire in Lighting

Command Harness.

Voltage to

LEDs

Voltage for

Lighting

Commands

Figure 4-7. Transformer Secondary

Light Harness

Connection

Figure 4-8. Lighting Connection in Easy Cube

Page 27

Troubleshooting

V-Series Cooktop Hoods

V-Series Cooktop Hoods

4-9

#825309 - Revision A - August, 2014

9. Testing Lighting Voltage at Light Support

a. Disconnect two pin Lighting Harness from LED

Assembly connection. (See Figure 4-9).

b. Measure voltage between pins of connector on

Easy Cube side of connection. Measure voltage at each Lighting Harness connection.

Voltage should be 12 VDC.

Light Support Assembly

LED Assembly

Connection

LED Assembly

Connection

Light Harness

to Easy Cube

Figure 4-9. Lighting Connection on Light Support

10. Testing LED Assembly for a Short.

a. Disconnect two pin Lighting Harness from LED

Assembly connection. (See Figure 4-9).

b. Measure resistance from each pin of LED

Assembly connector to LED Assembly case.

There should be no Continuity.

Blower Motor

Connection

Figure 4-10. Blower Connection in Easy Cube

11. Testing Blower Voltage Easy Cube Connection.

a. Remove Internal Blower.

b. Disconnect three pin Internal Blower Harness

from Easy Cube connection. (See Figure 4-10)

c. Check for 115 VAC between Pin 1 and Pin 3

inside Easy Cube.

12. Testing Blower Voltage at Blower Connection

a. Disconnect Internal Blower Cable connection

from Internal Blower. (See Figure 4-11).

b. Measure voltage between pins 4 and 5 on the

Easy Cube side of connector.

Internal Blower

Cable Connection

Figure 4-11. Internal Blower Cable Connector

13. Testing Internal Blower for Open or Short

a. Disconnect Internal Blower Cable connection

from Internal Blower. (See Figure 4-12).

b. Measure resistance Pin 4 to Pin 5. If it is open,

replace Blower Motor.

c. Measure resistance Pin 4 to Blower Motor

case, and Pin 5 to Blower Motor case. If there

is Continuity, replace Blower Motor.

Internal Blower

Motor Connection

Figure 4-12. Internal Blower Motor Connection

14. Testing External/Inline Blower for Open or Short

a. Disconnect External/Inline Blower Motor wires

from Terminal Block. (See Figure 4-13).

b. Measure resistance wire to wire.

Measure resistance each wire to ground.

c. If step 14a reads Open or 14b reads Continuity,

then confirm the wiring from the Terminal Block

to the Blower Motor is good. If the wiring is

good, replace the Blower Motor.

Blower Motor

Wires

Figure 4-13. Terminal Block

Page 28

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Technical Data

5-2

#825309 - Revision A - August, 2014

Technical Data

This Technical Data Section has been compiled with the latest information from Faber S.p.A. Company.

600 cfm Internal Blower

414 WATTS

115 VAC

3.6 AMPS

Note: All measurements in Watts, Voltage, or amps are approximate. Actual readings can very plus or minus 10

percent.

General Hood Information:

Light System is 12 VDC.•

Three wire harness from Power Board Assembly to Transformer is Light Control Circuit and is 12 VDC.•

Blower speed is controlled by a Triac on the Power Board Assembly.•

General Use and Care Information:

Delay mode lasts for 10 minutes.•

Activate Boost by holding Hi for 3 seconds. Boost is on for 10 minutes, then returns to prior speed. •

Boost increase air flow by approximately 20%.•

Approximately 100 hour to activate Filter Alarm.•

LED Assembly is S1000 LED Natural White 4000k.•

Remote Control takes 2 AAA batteries.•

Black Hood Use and Care Information:

Hood flashes FC for Recirculation Filter alarm and FG for Mesh Filter alarm. No matter which filter system is•

being used the hood will flash both FC and FG.

Hold Delay for 5 seconds to reset Filter Alarm. Hood will flash FF when reset.•

Hi is displayed for Boost.•

Activate or Deactivate Remote Control by holding On/Off for 5 seconds.•

Hood flashes IR when Remote Control is activated or deactivated.•

Stainless Steel and Glass Hood Use and Care Information:

Hold Filter for 5 seconds to reset Filter Alarm.•

High Blinks when in Boost.•

Activate or Deactivate the Remote Control by holding Delay for 5 seconds with Lights and Blower Motor off.•

On/Off and Low flash twice when Remote Control is activated or deactivated.•

Page 29

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Wiring Diagrams

6-2

#825309 - Revision A - August, 2014

Basic Wiring

115 VAC comes in through the junction box then plugs into the Electrical Box. It is wired to the Power Board with a

three wire harness.

From the Power Board 115 VAC is sent back to the Electrical Box to the Terminal Block where the Internal, Remote

or Inline Blower is connected.

Voltage goes through the Ribbon Cable Harness from the Power Board through the Easy Cube and connects to the

Ribbon Cable from the Hood Body to provide power to the Touch Control. A signal back to the Power Board returns

through the same ribbon cable.

115 VAC is provided to the Light Transformer on the primary side of the Transformer. The Transformer converts the

115 VAC to 12 VDC and provides power to the LED Assemblies through a two wire harness that has a connector in

the Easy Cube. The Hood Body has a two wire harness from the LED Assemblies that connects to the harness in

the Easy Cube.

Page 30

Wiring Diagrams

V-Series Cooktop Hoods

V-Series Cooktop Hoods

6-3

#825309 - Revision A - August, 2014

7 Pin Connector

Electrical Supply to Hood

to Power

Board

3 Pin Connector

in Electrical

Box

White

Black

3

2

1

3

2

1

Connector

Brown

Green

Blue

J-Box

Electrical

Power

Cable

Ground

Yellow-Green

Blower

Terminal Block

Electrical Box

Page 31

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Wiring Diagrams

6-4

#825309 - Revision A - August, 2014

Blower Motor Connection

M

Green

Internal Blower

Harness

Electrical Box

115 VAC is provided to terminals #1 and #2.

Connect Blower Black wire to terminal A and

White wire to terminal B.

For Internal Blower connector, move Black wire

to terminal A and White wire to terminal B.

Blue

Brown

Black

White

A

B

1

2

Internal Blower

Remote

Blower

J-Box

Power

Cable

Electrical

Connector

Ground

Blue

Brown

Page 32

Wiring Diagrams

V-Series Cooktop Hoods

V-Series Cooktop Hoods

6-5

#825309 - Revision A - August, 2014

Power Board and Touch Control

Power Board

Touch Control

(in Hood Body)

Ribbon Cable

(Passes through

Easy Cube)

Ribbon Cable

(From Hood Body

connects in Easy Cube)

Ferromagnetic

Device

Page 33

V-Series Cooktop Hoods

V-Series Cooktop Hoods

Wiring Diagrams

6-6

#825309 - Revision A - August, 2014

LED Assemblies and Transformer

Additional LED Assemblies in Island Hoods

LED Assembly with Two Pin

Connector behind Light Support

Electrical Box

Connector passes through

Electrical Box and connects

in Easy Cube.

Connector from

Hood Body.

Light Control

Circuit - 12 VDC

12 VDC

to LED

Assembly

115 VAC

from

Power Board

Transformer

Page 34

Wiring Diagrams

V-Series Cooktop Hoods

V-Series Cooktop Hoods

6-7

#825309 - Revision A - August, 2014

V-Series Wiring Diagram

Internal

Blower

Motor

Remote

Blower

Motor

Electrical Box

J-Box

Power

Cable

Electrical

Connector

3 Pin Connector

Electrical Box

Ground

Blower

Terminal

Block

Internal

Blower

Harness

Touch Control

Power Board

Ribbon

Cable

Additional LED Assemblies in Island Hoods

LED Assemblies

Light Control

Circuit

Transformer

12 VDC

to LED

Assemblies

Ferromagnetic

Device

Loading...

Loading...