Page 1

UNDERCOUNTER ICE MAKER

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

Page 2

UNDERCOUNTER ICE MAKER

Contents

3 Undercounter Ice Maker

4 Opening Dimensions

5 Electrical

6 Plumbing

7 Installation

10 Custom Panel

11 Completion

Features and specications are subject to change at any

time without notice. Visit subzero.com/specs for the most

up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Sub-Zero Customer Care 800.222.7820

Page 3

UNDERCOUNTER ICE MAKER

Product Information

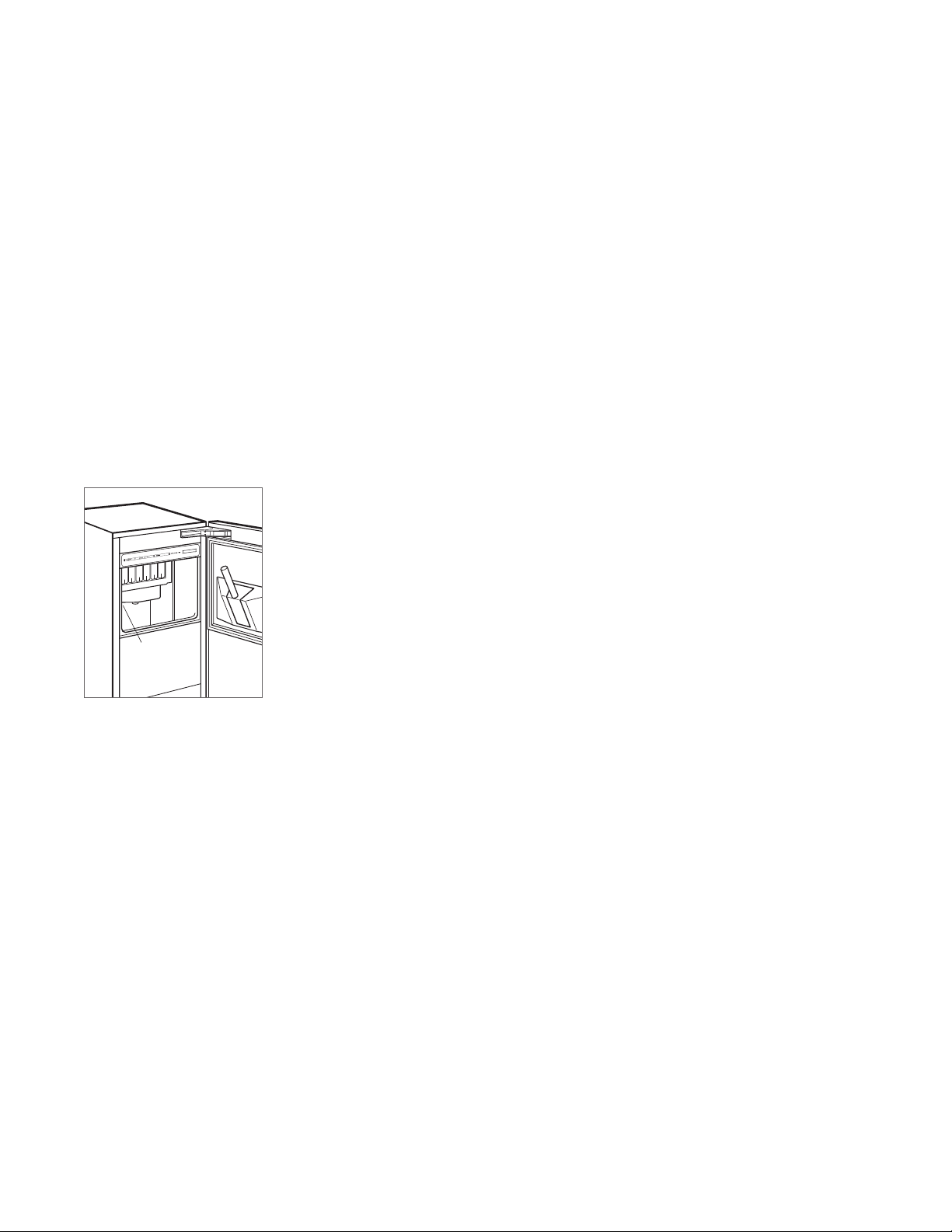

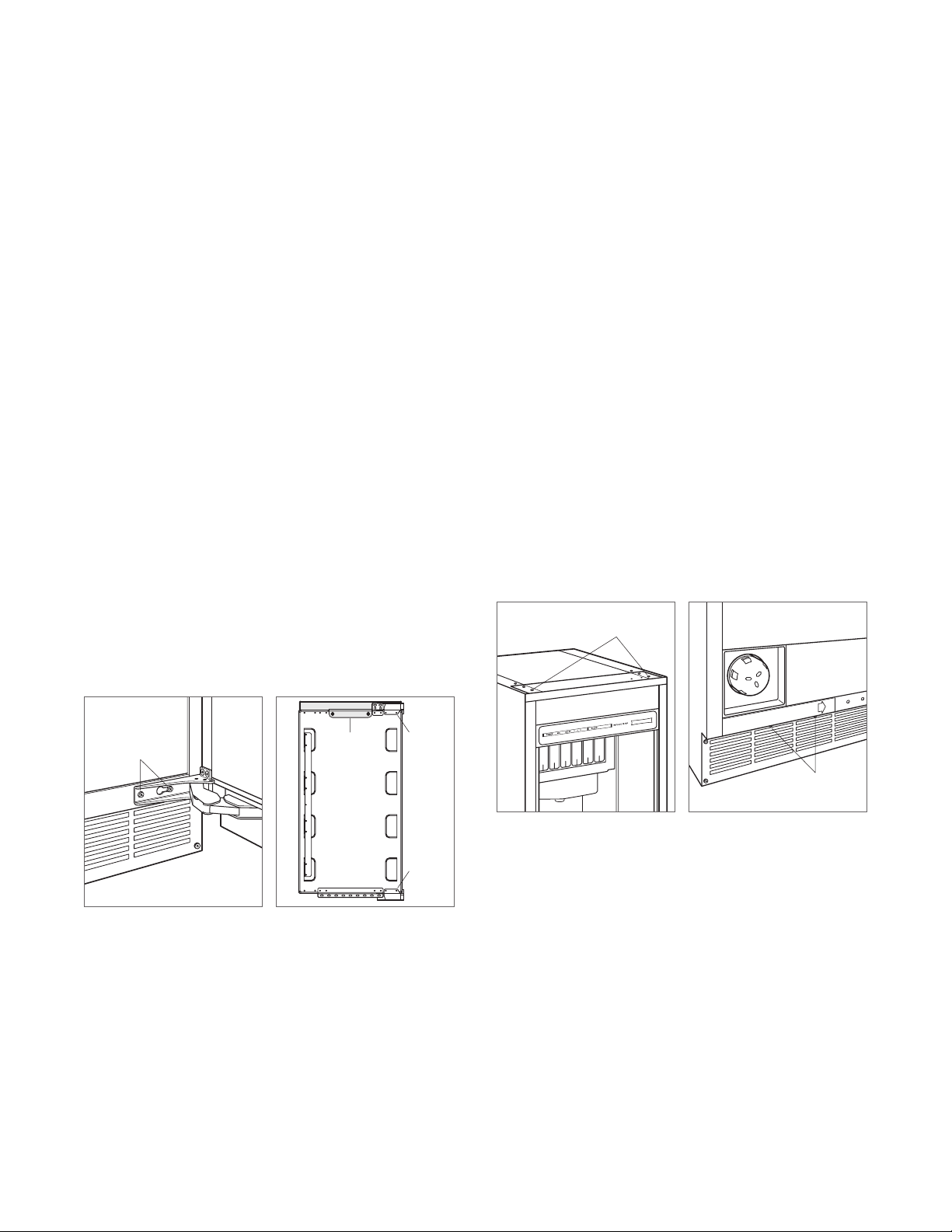

Important product information, including the model and

serial number, are listed on the product rating plate. The

rating plate is located in the upper left corner of the ice

storage bin, on the back of the unit. Refer to the illustration

below.

If service is necessary, contact Sub-Zero Factory Certied

Service with the model and serial number. For the name

of the nearest Sub-Zero Factory Certied Service or for

questions regarding the installation, visit the Support &

Service section of our website, subzero.com, or call

Sub-Zero Customer Care at 800-222-7820.

Tools and Materials

• Screwdrivers—standard, Phillips, and Torx.

• Power drill.

• Standard socket and wrench set.

• 2' level.

• Tubing cutter.

(.9 m) of

• 3'

or PEX tubing.

• Saddle valve.

• Material to protect home, ooring, and cabinetry

during installation.

1

/4" OD copper, braided stainless steel,

RATING

PLATE

Rating plate location

subzero.com | 3

Page 4

SITE PREPARATION

.

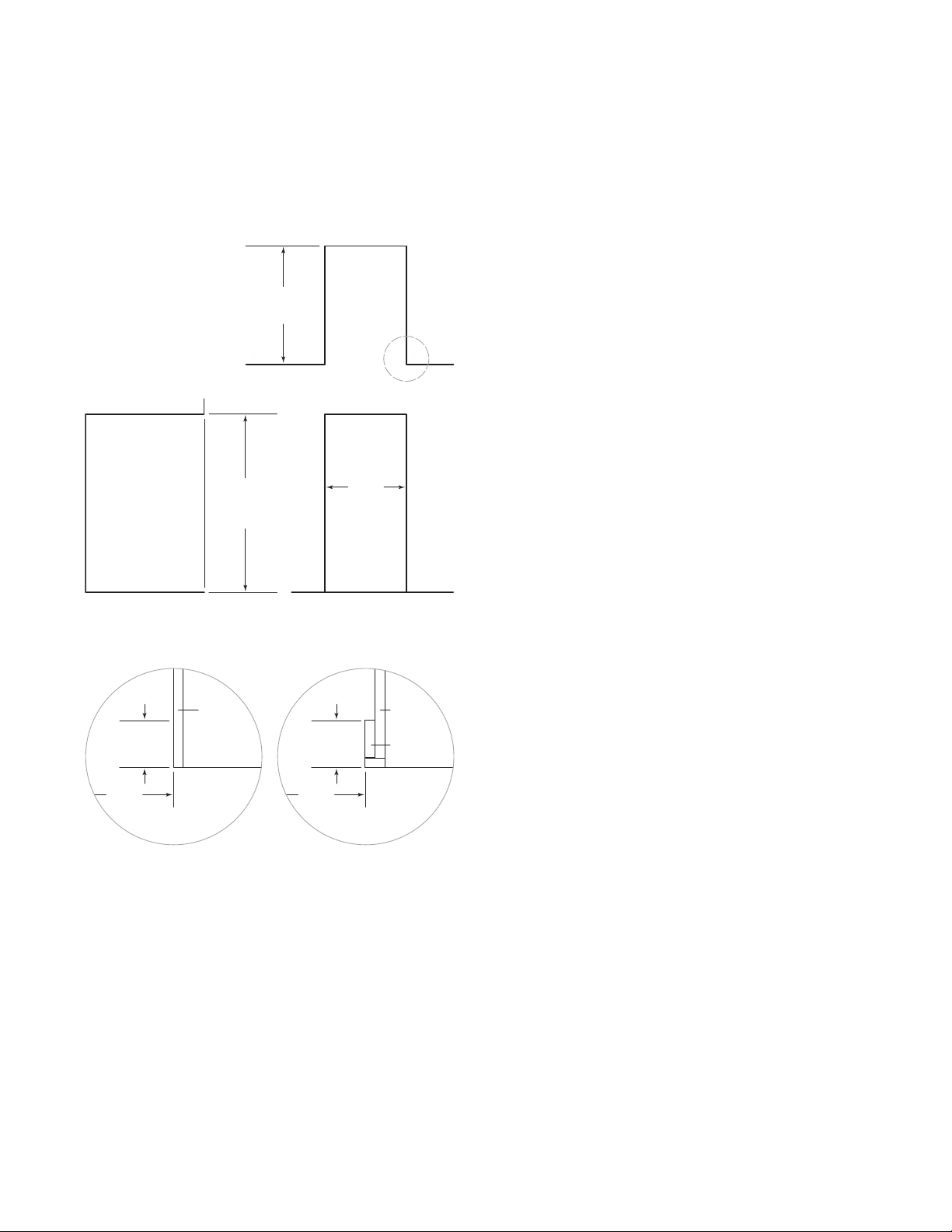

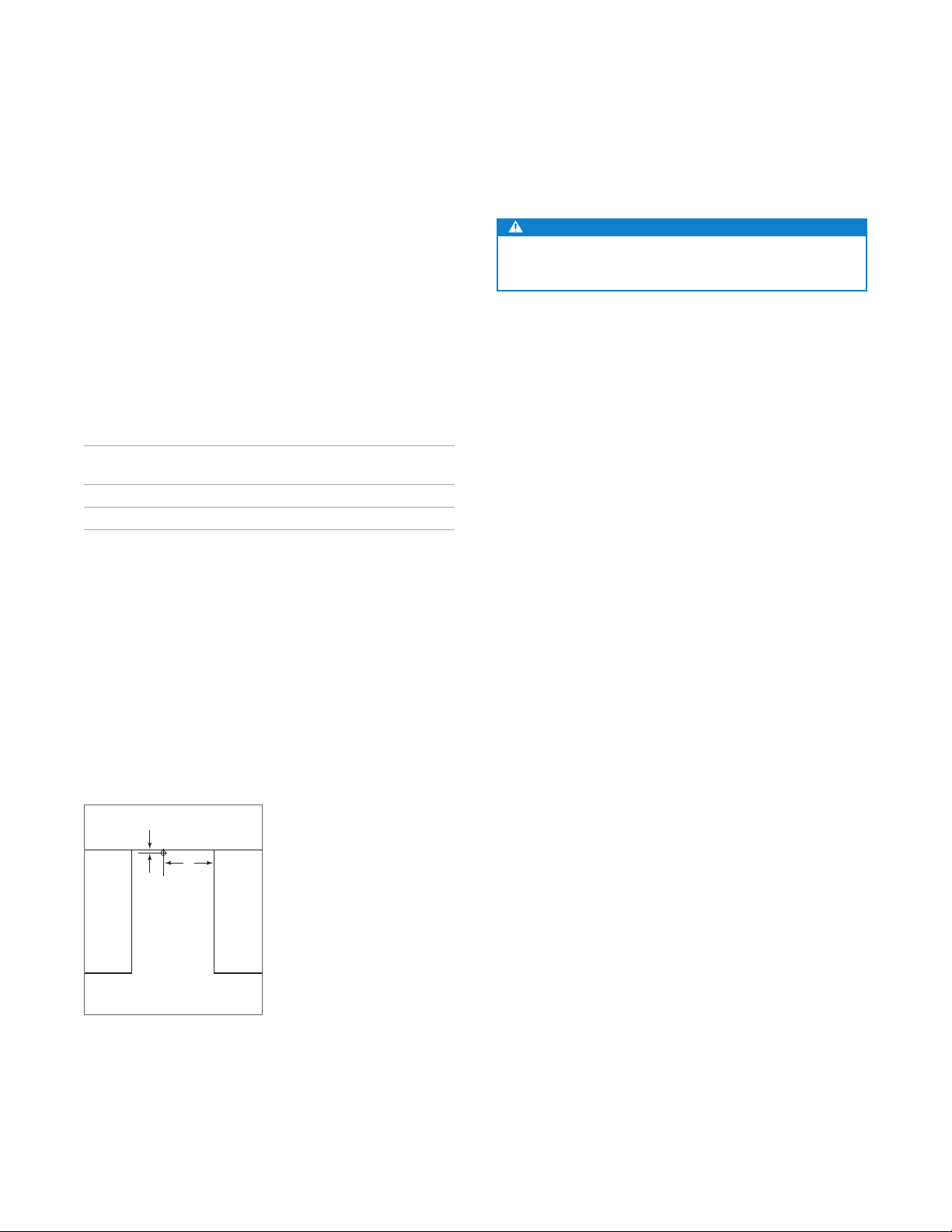

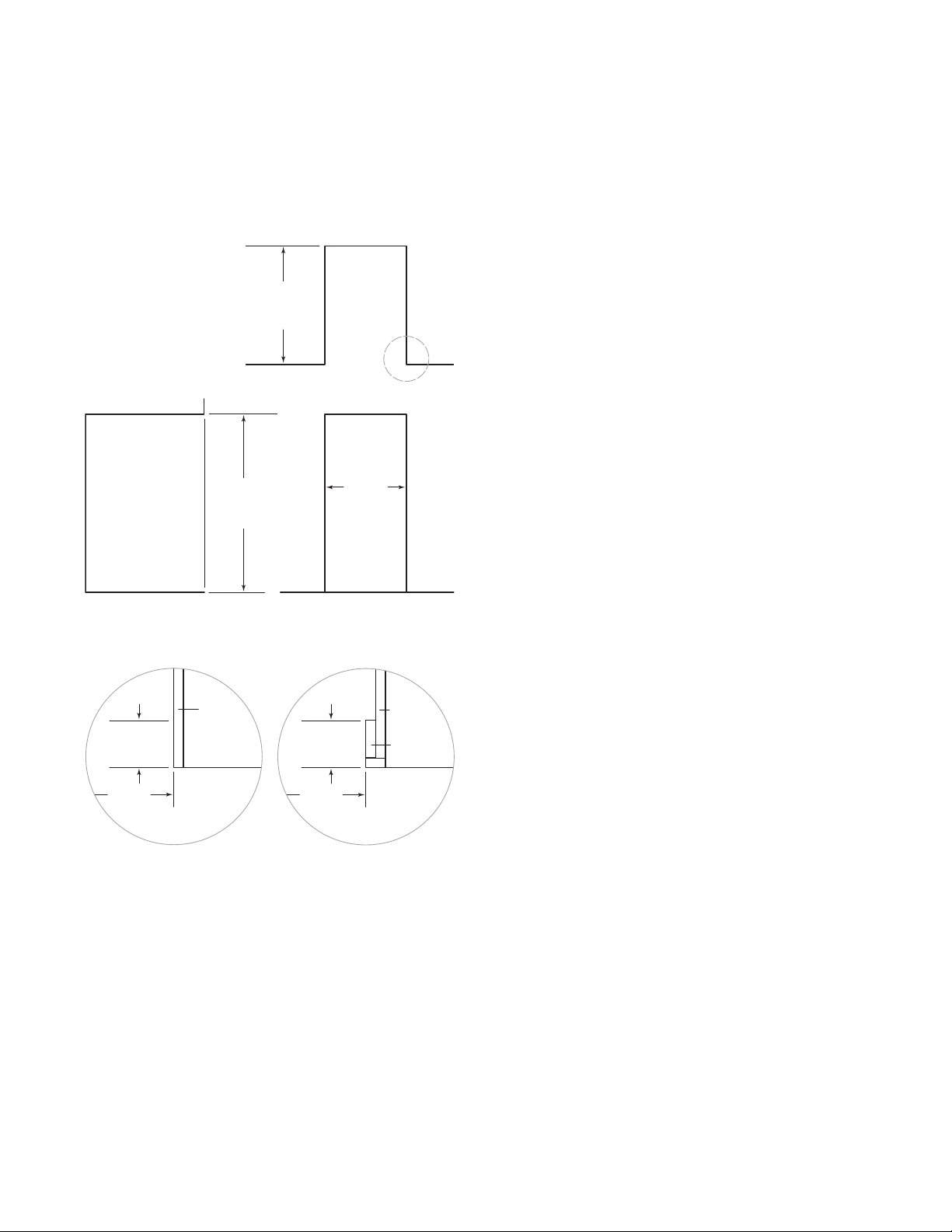

Opening Dimensions

ICE MAKER

24" (610)

OPENING

DEPTH

TOP VIEW

341/2"

(876)

OPENING

HEIGHT

SIDE VIEW FRONT VIEW

NOTE: 31/2" (89) finished returns will be visible and should be finished to match cabinetry

151/4"

(387)

OPENING

WIDTH

IMPORTANT NOTE:

It is recommended that the electrical

and water supply be placed in an adjacent cabinet. If they

are placed within the opening, additional cabinet depth may

be required.

31/2" (89)

FINISHED

RETURN

151/4"

(387)

FRAMELESS

CABINETRY

3

/4" (19)

TYPICAL

31/2" (89)

FINISHED

RETURN

151/4"

(387)

FRAMED

CABINETRY

3

/4" (19)

TYPICAL

FILLER

4 | Sub-Zero Customer Care 800.222.7820

Page 5

SITE PREPARATION

E

E

E

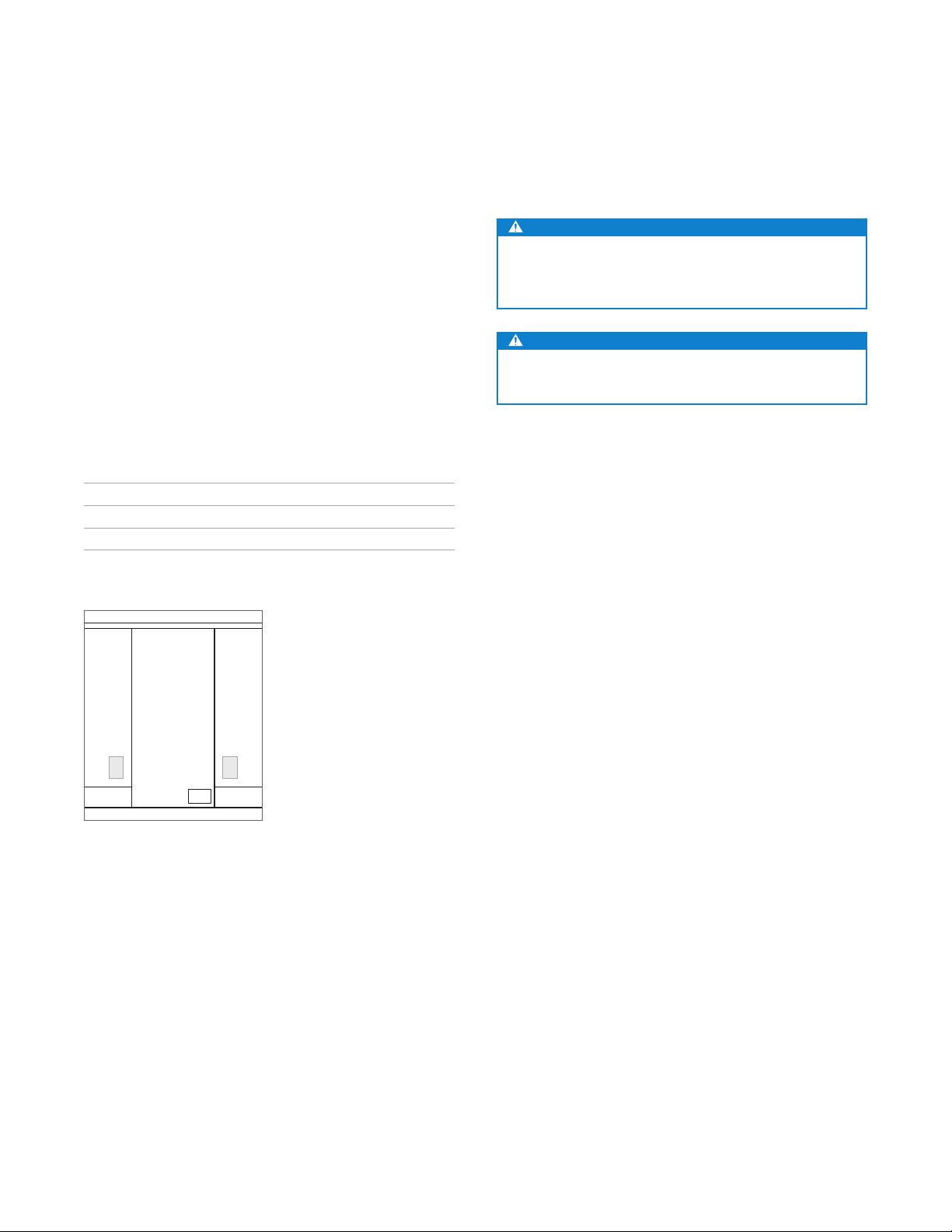

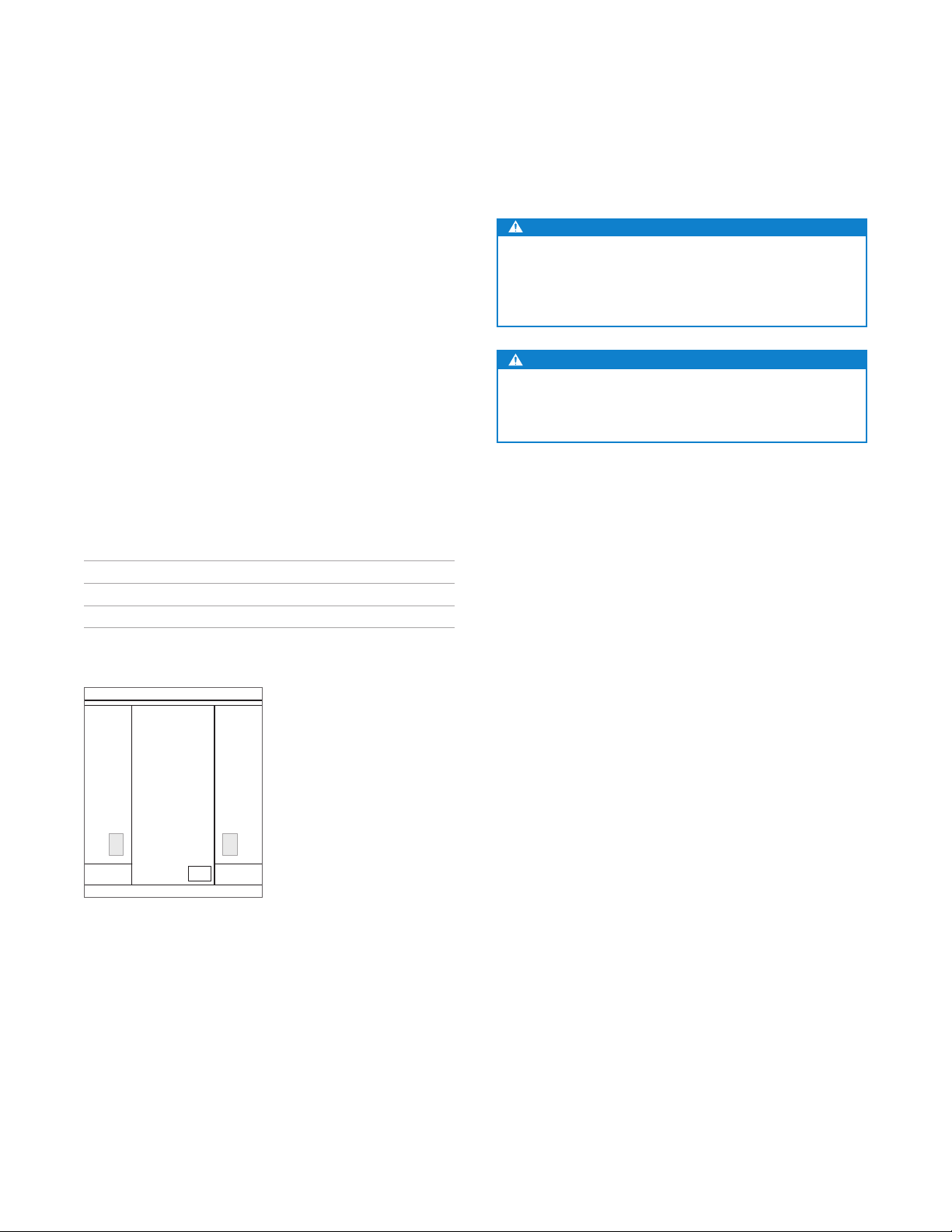

Electrical Requirements

Installation must comply with all applicable electrical codes.

Although it can be located anywhere on the back wall, it

is recommended that the electrical supply be placed in an

adjacent cabinet or in the lower right of the opening. Refer

to the illustration below. A separate circuit servicing only this

appliance is required.

Model UC-15I(P)O is designed and safe for use in outdoor

applications. When installed outdoors, a ground fault circuit

interrupter (GFCI) is required to reduce the risk of electrical

shock. A GFCI is not recommended for use with the indoor

model and may cause interruption of operation.

ELECTRICAL REQUIREMENTS

Electrical Supply 115 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

CAUTION

The outlet must be checked by a qualied electrician

to be sure it is wired with the correct polarity. Verify the

outlet is properly grounded.

WARNING

Do not use an extension cord, two-prong adapter, or

remove the power cord ground prong.

Electrical supply location

subzero.com | 5

Page 6

SITE PREPARATION

24" (610)

ROUGH

OPENING

DEPTH

Plumbing Requirements

Installation must comply with all applicable plumbing codes.

The water supply line should be located as shown in the

illustration below. The water supply line should be connected to the house supply with an easily accessible shutoff valve. Do not use self-piercing valves.

A reverse osmosis system can be used provided there is

constant water pressure of 20–80 psi

the unit at all times. A copper line is not recommended for

this application.

PLUMBING REQUIREMENTS

Water Supply Line

Water Pressure 20–80 psi

Excess Water Line for Connection 36" (914)

ICE MAKER DRAIN

The ice maker can be ordered with or without a drain pump.

Models without a pump will drain water by gravity.

A drain must be installed.

(1.4–5.5 bar) supplied to

1

/4" OD copper, braided stain-

less steel, or PEX tubing

(1.4–5.5 bar)

Preparation

CAUTION

Before moving the unit into position, secure the door

closed and protect any nished ooring.

Uncrate the unit and inspect for damage. Remove the wood

base and discard shipping bolts and brackets. Remove and

recycle packing materials. Do not discard the kickplate and

hardware.

Use an appliance dolly to move the unit near the opening.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

The drain and inlet water tubes must be plumbed before

connection to the ice maker. For the gravity drain, horizontal

1

drain lines must have a

/4" (6) per 12" (305) fall. An air gap

will likely be required between the unit and drain. A stand

pipe with a trap below is acceptable for the drain.

8"

(203)

1

/2"

(13)

LOCATION OF

WATER LINE

TOP VIEW

Water supply location

6 | Sub-Zero Customer Care 800.222.7820

Page 7

INSTALLATION

Installation

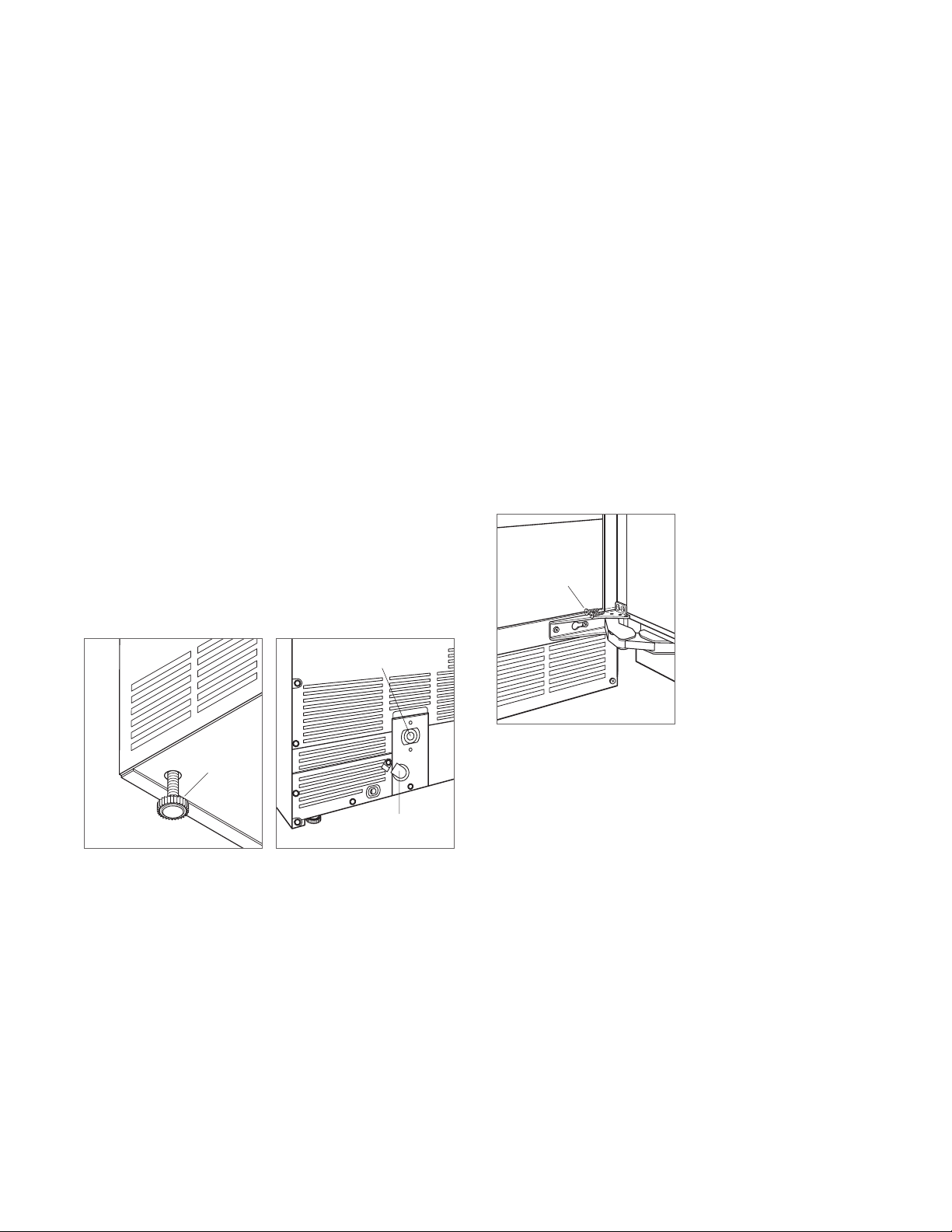

INSTALL ICE MAKER

1 Adjust the leveling legs close to the desired height. Refer

to the illustration below.

2 Reverse the door swing if needed. Refer to steps out-

lined on page 9.

3 Gravity Drain Model: Install the drain hose provided onto

the drain tting on the back of unit and route to the open

site drain. Refer to the illustration below and plumbing

requirements on the previous page.

Drain Pump Model: Route the drain tubing through the

drain tting on the back of the unit and install the drain

hose provided on the drain pump. Route the other end of

the drain tubing to the drain site. Refer to the illustration

below and plumbing requirements on the previous page.

4 Use a compression tting to connect the water inlet on

the back of ice maker to the prepared

1

/4" (6) OD cold

water line. Refer to the illustration below.

DRAIN FITTING

5 Open the shut-off valve on the water line. Check all

plumbing connections for leaks. Failure to do so could

result in ooding.

6 Plug the power cord into the grounded receptacle.

7 Level the ice maker to assure the door closes and seals

properly. Place a level on the top of the unit and turn

each leveling leg to raise or lower as needed.

8 Move the ice maker into its nal position.

9 Anchor the ice maker by installing the two at head

screws provided through each hinge. Refer to the illustration below.

ANCHORING

SCREWS

Leveling

LEVELING

LEG

Drain connection

WATER INLET

Anchoring

subzero.com | 7

Page 8

INSTALLATION

Installation

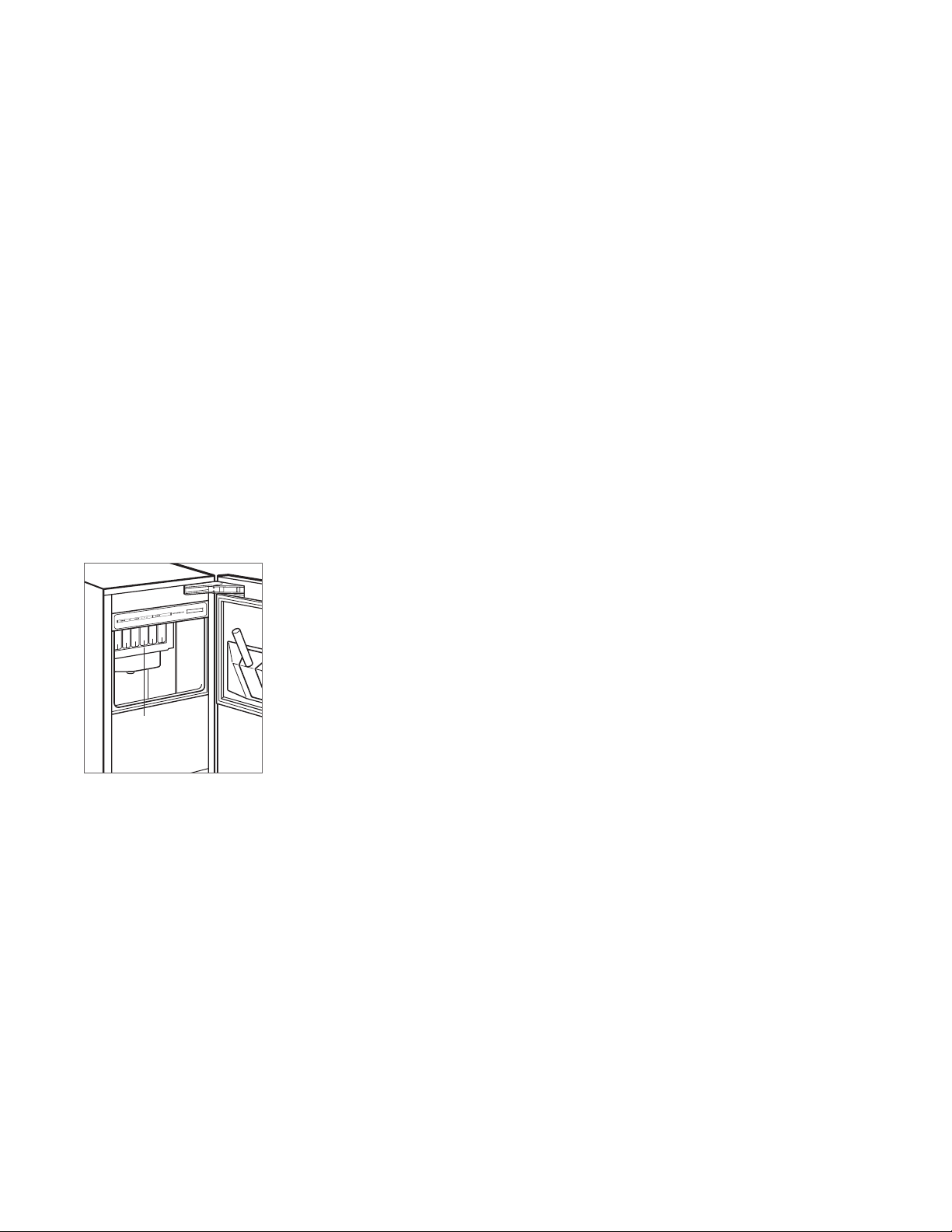

VERIFY ICE PRODUCTION

1 Press “POWER” to turn the ice maker on.

2 Add one gallon (3.8 L) of cold water to the ice bin. Verify

the water completely drains from the ice bin and there

are no leaks. If the water has not drained within 60 seconds, there may be a kink in the drain tube or the drain

installation is incorrect.

3 Press “CLEAN”. Wait three minutes until the CLEAN light

ashes, then add 1 tablespoon

(15 ml) of undiluted ice

maker sanitizer directly into the spray area. Refer to the

illustration below. Use only the sanitizer made for the

Sub-Zero ice maker available at subzerowolfstore.com.

For questions, contact Sub-Zero Customer Care at

800-222-7820.

4 A 10-minute sanitizing cycle begins, followed by eight

rinse cycles. When the process is complete, the CLEAN

light will no longer be illuminated. The entire cycle takes

approximately 30 minutes.

5 At initial start-up, the ice maker will need approximately

30 minutes to freeze ice cubes and up to ve minutes to

harvest. Verify completion of the rst cycle ice production to conrm proper installation.

WATER

SHUTTERS

Water shutters location

8 | Sub-Zero Customer Care 800.222.7820

Page 9

INSTALLATION

Installation

REVERSE DOOR SWING

The door hinges are designed to be placed on either the

right or left side of the ice maker. The unit is shipped with

the door hinged on the right. Moving the hinges to the left

using the pre-drilled holes allows for a left-hand door swing.

To Reverse the Door Swing:

1 Detach the hinges from the ice maker by removing two

screws per hinge, then remove the door. Remove the

shim located between the cabinet and bottom hinge, this

shim will transfer to the left side bottom hinge.

2 Detach the hinges from the door by removing two

screws per hinge.

3 Detach the right-hand upper trim (shaded area) from the

door by removing the two screws. Refer to the illustration below. Replace it with the left-hand upper trim.

4 Transfer the hinges to the left side of the door and

reinstall. The upper hinge will now be in the lower hinge

position and the lower hinge in the upper hinge position.

5 Remove the top cover of the ice maker by removing the

two screws at the top rear of the unit.

6 Remove the four screws from the front top rail, then pivot

the top rail end for end to expose the two left-hand top

hinge mounting holes and reinstall. Refer to the illustration below.

7 Remove the two screws from the lower edge of the

bottom trim plate and slide it to the right to cover

the right hinge mounting holes. Refer to the illustration below. The left hinge mounting holes will now be

exposed.

8 Reinstall the shim removed in step 1, between the

cabinet and the left side bottom hinge. Reinstall the door

by mounting the hinges using the left hinge mounting

holes. Verify operation of the door.

TOP RAIL

SCREWS

HINGE

SCREWS

Remove door

UPPER

TRIM (RH)

Detach hinges and trim

HINGE

HINGE

Front top rail

Bottom trim plate

TRIM PLATE

SCREWS

subzero.com | 9

Page 10

INSTALLATION

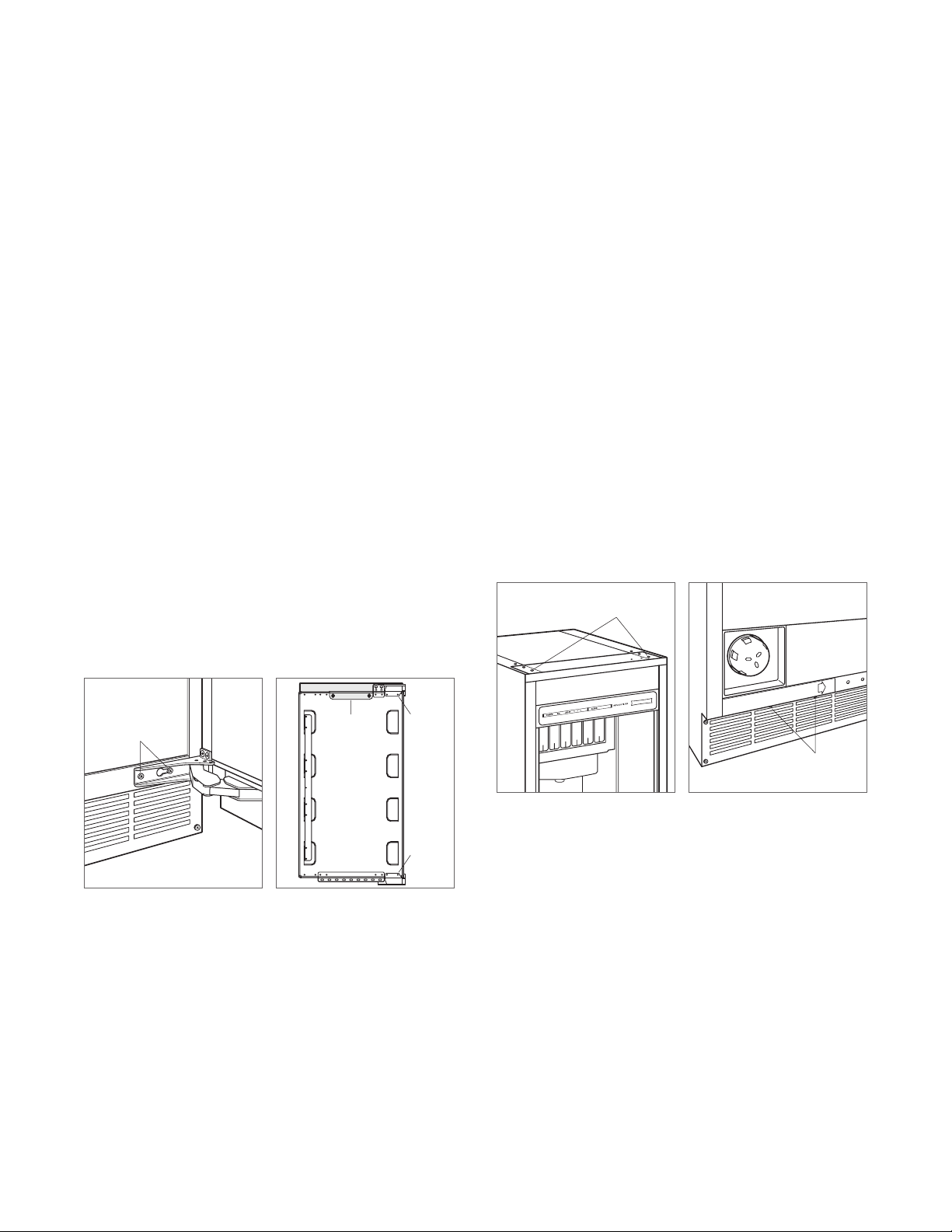

Custom Panel

OVERLAY PANEL

For overlay applications, a custom door panel must be

installed. The panel size is critical for a proper t. To verify

panel requirements and dimensions, refer to the Sub-Zero

Design Guide at subzero.com/specs.

Finish all sides of the custom panel. They will be visible

when the door is open.

A D-style handle is recommended. The door handle must be

located near the edge of the panel opposite the hinge, centered top to bottom. Stainless steel tubular and pro handles

are avail able through an authorized Sub-Zero dealer. For

local dealer information, visit the nd a showroom section

of our website, subzero.com.

PANEL INSTALLATION

Remove the handle side bracket attached to the front of

the door. Place the custom door panel face down on a

protected work surface. Place the template on the back of

the door panel, then mark and drill the holes. Secure the

1

mounting bracket to the panel with the #8 x

/2" screws

provided. Refer to the illustration below.

Install the door panel by engaging the tabbed bracket to

the door. Once the door panel is in place, use the remaining

1

/2" screws to secure the panel to the upper and lower

#8 x

mounting brackets. Once secure, install the hinge covers.

Refer to page 11.

UPPER

BRACKET

Template position

LOWER

BRACKET

Mounting brackets

10 | Sub-Zero Customer Care 800.222.7820

Page 11

INSTALLATION

Completion

KICKPLATE INSTALLATION

Install the kickplate using the two screws provided. Refer to

the illustration below. The kickplate must be removable

for service. The oor cannot interfere with removal. Do not

cover the louvered section of the kickplate.

90° DOOR STOP

The door stop pins provided with the ice maker will limit the

door swing to 90°.

To install, open the door to approximately 80°. Insert one

stop pin into the top door hinge (pin enters from the bottom)

and the other stop pin into the bottom door hinge (pin

enters from the top). Refer to the illustration below. Check

for proper operation.

DOOR STOP PIN

HINGE COVERS

Install the hinge covers once installation of the ice maker

is complete and the door stop pins have been installed

(if applicable). The knock-out in the hinge cover must be

removed if the 90° door stop is used.

Verify the hinges are free of dirt or grease before applying

the covers. To install, remove paper backing and apply the

hinge covers to each hinge. Attach the magnetic center

covers. Refer to the illustration below.

WARNING

Follow all city and state laws when storing, recycling,

or discarding unused refrigerators and freezers.

KNOCK-OUT

90° door stop

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

Hinge covers

subzero.com | 11

Page 12

FABRICADOR DE HIELO EMPOTRADA

Contenido

3 Fabricador de hielo empotrada

4 Dimensiones de la abertura

5 Instalación eléctrica

6 Instalación de plomería

7 Instalación

10 Panel personalizado

11 Finalización

Las características y especicaciones están sujetas a

cambios sin previo aviso. Visite subzero.com/specs para

obtener la información más actualizada.

Aviso importante

Para garantizar que este producto se instale y opere de

la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en esta guía:

AVISO IMPORTANTE señala la información que es especial-

mente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: en toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique lo contrario.

AVISO IMPORTANTE: guarde estas instrucciones para el

inspector eléctrico local.

2 | Atención al cliente de Sub-Zero 800.222.7820

Page 13

FABRICADOR DE HIELO EMPOTRADA

Información del producto

La información importante del producto, incluido el modelo

y número de serie de la unidad, se encuentra en la placa

de datos del producto. La placa de datos se encuentra en

la esquina superior izquierda del recipiente de almacenamiento de hielo, en la parte posterior de la unidad. Consulte

la siguiente ilustración.

Si necesita servicio, póngase en contacto con el centro

de servicio autorizado de Sub-Zero y tenga a la mano el

modelo y número de serie de la máquina. Para obtener

los datos del centro de servicio autorizado de Sub-Zero

más cercano o si tiene preguntas acerca de la instalación,

visite la sección de Soporte y Servicio de nuestro sitio web,

subzero.com o llame a la línea de atención al cliente de

Sub-Zero al 800-222-7820.

Herramientas | Materiales

• Destornilladores: estándar, Phillips y Torx.

• Taladro eléctrico.

• Juego de llaves de cubo e inglesas estándar.

• Nivel de 2'.

• Cortador de tubos.

(.9 m) de tubería de cobre, trenzada de acero inoxi-

• 3'

dable o PEX de

• Válvula de asiento.

• Material para proteger la casa, el piso y los gabinetes

durante la instalación.

1

/4" de diámetro exterior.

PLACA DE

DATOS

Ubicación de la placa de datos

subzero.com | 3

Page 14

PREPARACIÓN DEL SITIO

Dimensiones de abertura

FABRICADOR DE HIELO

(610)

24"

PROFUNDIDAD

DE LA

ABERTURA

VISTA SUPERIOR

341/2"

(876)

ALTURA DE

LA ABERTURA

VISTA LATERAL VISTA FRONTAL

NOTA: Los tubos de retorno de 31/2" (89) con acabados se podrán ver y se deben

terminar para que se ajusten a los gabinetes.

151/4"

(387)

ANCHURA DE

ABERTURA

AVISO IMPORTANTE:

Se recomienda que el suministro

eléctrico y de agua se encuentren en un gabinete adyacente. Si se encuentra dentro de la abertura, posiblemente

el gabinete deba ser más profundo.

TUBO DE

RETORNO DE

31/2" (89) CON

ACABADOS

151/4"

(387)

GABINETE SIN

MARCO

TÍPICO

3

DE

/4" (19)

TUBO DE

RETORNO DE

31/2" (89) CON

ACABADOS

151/4"

(387)

GABINETE CON

MARCO

TÍPICO

3

/4" (19)

DE

RELLENO

4 | Atención al cliente de Sub-Zero 800.222.7820

Page 15

PREPARACIÓN DEL SITIO

E

E

E

Instalación eléctrica

La instalación debe cumplir con todos los códigos eléctricos vigentes.

Aunque puede estar ubicado en cualquier lugar de la pared

posterior, se recomienda instalar el suministro eléctrico en

un gabinete adyacente o en la esquina inferior derecha de

la abertura. Consulte la siguiente ilustración. Se necesita un

circuito independiente que le suministre electricidad únicamente a este electrodoméstico.

El Modelo UC-15I(P)O está diseñado y es seguro para su

uso en aplicaciones al aire libre. Cuando se instala al aire

libre, es necesario instalar un circuito de fallos de conexión

a tierra (GFCI, por sus siglas en inglés) para reducir el riesgo

de descarga eléctrica. No es recomendable usar un GFCI

con el modelo interior, ya que puede interrumpir el funcionamiento de la unidad.

REQUISITOS ELÉCTRICOS

Suministro eléctrico 115 V CA, 60 Hz

Servicio Circuito dedicado de 15 amperes

Receptáculo Conexión a tierra de 3 clavijas

PRECAUCIÓN

Un electricista calicado debe revisar el tomacorriente

para asegurarse de que la conexión se haya realizado

con la polaridad correcta. Verique que el tomacorriente esté debidamente conectado a tierra.

ADVERTENCIA

No use un cable de extensión, adaptador de dos clavijas ni retire la clavija con conexión a tierra del cable

de corriente.

Ubicación del suministro

eléctrico

subzero.com | 5

Page 16

PREPARACIÓN DEL SITIO

24" (610)

ROUGH

OPENING

DEPTH

Plomería

La instalación debe cumplir con todos los códigos de plomería vigentes.

La tubería del suministro de agua debe colocarse como se

muestra en la siguiente ilustración. La tubería del suministro de agua debe conectarse al suministro doméstico

con una válvula de cierre de fácil acceso. No use válvulas

autoperforantes.

Se puede usar un sistema de ósmosis inversa siempre

y cuando la presión del agua que llegue a la unidad se

mantenga de forma constante entre 20 a 80 psi

5.5bares)

en todo momento. No es recomendable usar tube-

rías de cobre para esta aplicación.

REQUISITOS DE PLOMERÍA

Tuberías de suministro

de agua

Presión del agua De 20 a 80 psi

Tubería de exceso de

agua para la conexión

Tubería de cobre, trenzada de acero inoxi-

dable o PEX de 1/4" de diámetro exterior

(de 1.4 a

(de 1.4 a 5.5 bares)

36" (914)

Preparación

PRECAUCIÓN

Antes de mover la unidad a su posición, verique que

la puerta esté cerrada y proteja el suelo con acabado.

Desembale la unidad e inspeccione si tiene algún daño.

Retire la base de madera y deseche los pernos y soportes

de transporte. Retire y recicle los materiales de embalaje.

No deseche el zócalo ni las piezas de montaje.

Use una plataforma rodante para mover la unidad cerca de

la abertura.

Si la unidad ha estado o está acostada o de lado, debe

ponerla de pie y dejarla así durante un mínimo de 24 horas

antes de conectarla al suministro eléctrico.

DRENAJE DE LA FABRICADOR DE HIELO

Puede ordenar la fabricador de hielo con o sin una bomba

de drenaje. Los modelos sin bomba drenarán el agua por

gravedad. Se debe instalar un drenaje.

Los tubos de agua de entrada y drenaje deben instalarse

antes de conectarlos a la fabricador de hielo. Para el drenaje

por gravedad, las tuberías de drenaje horizontales deben

1

tener una caída de

/4" (6) cada 12" (305). Es probable que

se requiera un entrehierro entre la máquina y el drenaje. Se

puede utilizar un tubo vertical con un colector abajo para el

drenaje.

8"

(203)

1

/2"

(13)

UBICACIÓN DE

LA LÍNEA

DE AGUA

VISTA SUPERIOR

Ubicación del suministro de agua

6 | Atención al cliente de Sub-Zero 800.222.7820

Page 17

INSTALACIÓN

Instalación

INSTALE LA FABRICADOR DE HIELO

1 Ajuste las patas niveladoras cerca de la altura deseada.

Consulte la siguiente ilustración.

2 Si es necesario, invierta el giro de la puerta. Consulte los

pasos indicados en la página 9.

3 Modelo de drenaje por gravedad: Instale la manguera

de drenaje provista en el accesorio de drenaje ubicado

en la parte posterior de la unidad y guíela hacia el drenaje abierto. Consulte la ilustración a continuación y los

requisitos de plomería en la página anterior.

Modelo de bomba de drenaje: Guíe los tubos de

drenaje a través del accesorio de drenaje en la parte

posterior de la unidad e instale la manguera de drenaje

provista en la bomba de drenaje. Guíe el otro extremo de

los tubos de drenaje hacia el lugar de drenaje. Consulte

la ilustración a continuación y los requisitos de plomería

en la página anterior.

4 Use un accesorio de compresión para conectar la

entrada de agua en la parte posterior de la fabricador

1

de hielo a la tubería de agua fría de

/4" (6) de diámetro

exterior. Consulte la siguiente ilustración.

5 Abra la llave de paso en la tubería de agua. Revise

todas las conexiones de plomería para comprobar que

no haya fugas. Si no lo hace, se puede ocasionar una

inundación.

6 Enchufe el cable de corriente eléctrica en un tomaco-

rriente con conexión a tierra.

7 Nivele la fabricador de hielo para asegurar que la puerta

se cierre y selle correctamente. Coloque un nivel en la

parte superior de la unidad y gire cada pata niveladora

para levantarla o bajarla, según sea necesario.

8 Mueva la fabricador de hielo a su posición nal.

9 Ancle la fabricador de hielo mediante la instalación de

los dos tornillos de cabeza plana provistos a través de

cada bisagra. Consulte la siguiente ilustración.

TORNILLOS

DE ANCLAJE

Nivelación

PATA

NIVELADORA

ACCESORIO DE DRENAJE

ENTRADA DE AGUA

Conexión de drenaje

Anclaje

subzero.com | 7

Page 18

INSTALACIÓN

Instalación

VERIFIQUE LA PRODUCCIÓN DE HIELO

1 Presione “POWER” (Potencia) para encender la fabri-

cador de hielo.

2 Agregue un galón (3.8 l) de agua fría al recipiente de

hielo. Verique que el agua se drene completamente del

recipiente de hielo y que no haya fugas. Si el agua no se

ha drenado dentro de 60 segundos, el tubo de drenaje

puede estar doblado o el drenaje puede estar instalado

incorrectamente.

3 Presione “CLEAN” (Limpiar). Espere tres minutos hasta

que la luz CLEAN parpadee, luego, agregue 1 cucha-

(15 ml) de desinfectante para generadores de hielo

rada

sin diluir directamente en la zona de rocío. Consulte la

siguiente ilustración. Solo use un desinfectante elaborado para la

fabricador de hielo Sub-Zero disponible en

subzerowolfstore.com. Si tiene alguna pregunta, comuníquese con la línea de atención al cliente de Sub-Zero

al 800-222-7820.

4 Comienza un ciclo de desinfección de 10 minutos,

seguido de ocho ciclos de enjuague. Una vez que el proceso haya nalizado, la luz CLEAN dejará de estar iluminada. Todo el ciclo dura aproximadamente 30minutos.

5 En la puesta en marcha inicial, la fabricador de hielo

necesitará aproximadamente 30 minutos para congelar

los cubos de hielo y hasta cinco minutos para recogerlos. Verique la nalización de la producción de hielo

del primer ciclo para conrmar que la instalación esté

correcta.

OBTURADORES

DE AGUA

Ubicación de los obturadores

de agua

8 | Atención al cliente de Sub-Zero 800.222.7820

Page 19

INSTALACIÓN

Instalación

INVIERTA EL GIRO DE LA PUERTA

Las bisagras de la puerta están diseñadas para colocarse

en el lado derecho o izquierdo de la fabricador de hielo. La

máquina se envía con la bisagra de la puerta a la derecha.

Si mueve las bisagras a la izquierda en los oricios previamente perforados, podrá girar la puerta a la izquierda.

Para invertir el giro de la puerta:

1 Retire las bisagras de la fabricador de hielo sacando dos

tornillos por bisagra, luego quite la puerta. Retire la cuña

ubicada entre el gabinete y la bisagra inferior; esta cuña

se cambiará a la bisagra inferior izquierda.

2 Retire las bisagras de la puerta sacando dos tornillos por

bisagra.

3 Quite el ribete superior derecho (área sombreada) de

la puerta sacando dos tornillos. Consulte la siguiente

ilustración. Reemplácelo con el ribete superior izquierdo.

4 Cambie las bisagras al lado izquierdo de la puerta y

vuelva a instalarlas. Ahora la bisagra superior estará en

la posición de la bisagra inferior y viceversa.

5 Quite la tapa superior de la fabricador de hielo sacando

dos tornillos de la parte posterior de la unidad.

6 Quite cuatro tornillos del riel superior delantero, luego

gire el extremo del riel superior para exponer los dos

oricios de montaje de la bisagra superior izquierda y

vuelva a instalar. Consulte la siguiente ilustración.

7 Quite dos tornillos del borde inferior de la placa de la

placa decorativa inferior y deslícela hacia la derecha

para tapar los oricios de montaje de la bisagra derecha.

Consulte la siguiente ilustración. Ahora los oricios de

montaje de la bisagra izquierda estarán expuestos.

8 Vuelva a instalar la cuña que retiró en el paso 1, entre el

gabinete y la bisagra inferior del lado izquierdo. Vuelva a

instalar la puerta colocando las bisagras en los oricios

de montaje de la bisagra izquierda. Verique que la

puerta funcione.

TORNILLOS DEL

RIEL SUPERIOR

TORNILLOS DE

LA BISAGRA

Retire la puerta

RIBETE

SUPERIOR

(RH)

BISAGRA

BISAGRA

Retire las bisagras y el ribete

Riel superior delantero

TORNILLOS DE LA

PLACA DECORATIVA

Placa del ribete inferior

subzero.com | 9

Page 20

INSTALACIÓN

Panel personalizado

PANEL REVESTIBLE

Para aplicaciones revestibles, es necesario instalar un panel

de puerta personalizado. El tamaño del panel es fundamental para un buen ajuste. Para vericar los requisitos y

dimensiones del panel, consulte la guía de diseño de SubZero en subzero.com/specs.

Aplique el acabado a todos los lados de los paneles personalizados. Estos serán visibles con la puerta abierta.

Se recomienda usar manijas estilo D. Las manijas de las

puertas deben colocarse cerca del borde del panel opuesto

a la bisagra, centradas entre los extremos superior e inferior.

Están disponibles manijas tubulares y pro de acero inoxidable con los distribuidores autorizados Sub-Zero. Para

obtener más información de los distribuidores locales, visite

la sección para encontrar una sala de exhibición de nuestro

sitio web, subzero.com.

INSTALACIÓN DEL PANEL

Retire el soporte del lado de la manija unido a la parte

delantera de la puerta. Coloque el panel de puerta revestible

personalizado boca abajo sobre una supercie de trabajo

protegida. Coloque la plantilla en la parte posterior del panel

de la puerta, luego marque y taladre agujeros. Asegure el

1

soporte de montaje al panel con los tornillos # 8 x

/2" sumi-

nistrados. Consulte la siguiente ilustración.

Instale el panel de la puerta acoplando el soporte con

pestañas a la puerta. Una vez que el panel de la puerta está

1

en su lugar, utilice los tornillos # 8 x

/2" restantes para asegurar el panel a los soportes de montaje superior e inferior.

Una vez seguro, instale las cubiertas de la bisagra. Consulte

la página 11.

SOPORTE

SUPERIOR

Posición de la plantilla

SOPORTE

INFERIOR

Soportes de montaje

10 | Atención al cliente de Sub-Zero 800.222.7820

Page 21

INSTALACIÓN

Finalización

INSTALACIÓN DEL ZÓCALO

Instale el zócalo con los dos tornillos proporcionados. Consulte la siguiente ilustración. El zócalo debe ser desmontable para sacarlo cuando sea necesario hacerle servicio a

la máquina. El suelo no debe interferir al desmontarlo. No

cubra la sección tipo persiana del zócalo.

TOPE PARA PUERTA A 90°

Los pasadores del tope de la puerta proporcionados con

la fabricador de hielo limitarán el giro de la puerta a 90°.

Para instalar, abra la puerta a aproximadamente 80°. Inserte

un pasador del tope en la bisagra de la puerta superior

(el pasador entra desde la parte inferior) y el otro pasador

de tope en la bisagra de la puerta inferior (el pasador entra

desde la parte superior). Consulte la siguiente ilustración.

Compruebe que funcione correctamente.

PASADOR DEL TOPE

DE LA PUERTA

TAPAS DE LAS BISAGRAS

Instale las tapas de las bisagras una vez que haya nalizado

la instalación de la fabricador de hielo y se hayan instalado

los pasadores del tope de la puerta (si corresponde). El

prepunzonado en la tapa de la bisagra se debe eliminar si

se usa el tope de puerta de 90°.

Verique que las bisagras no estén sucias ni tengan grasa

antes de colocar las tapas. Para instalar, quite el papel

protector y coloque las tapas de las bisagras en cada una

de ellas. Instale las tapas del centro magnético. Consulte la

siguiente ilustración.

ADVERTENCIA

Siga todas las leyes estatales y locales para almacenar,

reciclar o desechar los refrigeradores y congeladores

no utilizados.

PREPUNZONADO

Tope para puerta a 90°

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design son marcas registradas y marcas de servicio de Sub-Zero Group, Inc. y sus asociados. Todas

las demás marcas registradas son propiedad de sus dueños respectivos en los Estados Unidos y otros países.

Tapas de las bisagras

subzero.com | 11

Page 22

MACHINE À GLAÇONS SOUS LE COMPTOIR

Table des matières

3 Machine à glaçons sous le comptoir

4 Dimensions de l'ouverture

5 Électricité

6 Plomberie

7 Installation

10 Panneau personnalisé

11 Achèvement

Les caractéristiques et les spécications peuvent

être modiées en tout temps sans préavis.

Visitez subzero.com/specs pour obtenir les

renseignements les plus récents.

Remarque importante

Pour s'assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note

des types de renseignement mis en évidence tout au long

de ce guide :

REMARQUE IMPORTANTE met en évidence des

renseignements qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d'indication contraire.

REMARQUE IMPORTANTE : conservez ces directives pour

l'inspecteur en électricité local.

2 | Service à la clientèle de Sub-Zero 800.222.7820

Page 23

MACHINE À GLAÇONS SOUS LE COMPTOIR

Renseignements sur le produit

Des renseignements importants sur le produit, y compris les

numéros de modèle et de série, se trouvent sur la plaque

signalétique du produit. La plaque signalétique est située

dans le coin supérieur gauche du bac de rangement, à

l'arrière de l'unité. Reportez-vous à l'illustration ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Sub-Zero certié par l'usine avec les numéros de

modèle et de série. Pour obtenir le nom du centre de service

Sub-Zero certié par l'usine le plus près de chez vous ou si

vous avez des questions concernant l'installation, visitez la

section Support et service de notre site Web, subzero.com

ou appelez le service à la clientèle de Sub-Zero au

800-222-7820.

Outils | matériaux

• Tournevis—standard, cruciforme et Torx.

• Perceuse électrique.

• Ensemble de clés et de douilles standard.

• Niveau de 2 pi.

• Coupe-tube.

(0,9m) de tube PEX ou en acier inoxydable tressé en

• 3pi

cuivre de ¼po de diamètre extérieur.

• Vanne à étrier.

• Des matériaux pour protéger la résidence, le plancher et

les armoires pendant l'installation.

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

subzero.com | 3

Page 24

PRÉPARATION DU SITE

Dimensions de l'ouverture

MACHINE À GLAÇONS

po (610)

24

PROFONDEUR

DE

D’OUVERTURE

VUE DE DESSUS

341/2 po

(876)

HAUTEUR DE

D’OUVERTURE

VUE DE PROFIL VUE DE FACE

REMARQUE : Les retours finis de 31/2 po (89) seront visibles et doivent être finis pour

s’apparier aux armoires.

151/4 po

(387)

LARGEUR DE

L’OUVERTURE

REMARQUE IMPORTANTE :

il est recommandé que

l'alimentation électrique et l'alimentation en eau soient

placées dans une armoire adjacente. Si elles sont placées

dans la même ouverture, la profondeur de l'armoire pourra

devoir être augmentée.

RETOUR

FINI DE

31/2 po (89)

151/4 po

(387)

ARMOIRE SANS

CADRE

TYPIQUE

DE

3

/4 po (19)

RETOUR

FINI DE

31/2 po (89)

151/4 po

(387)

ARMOIRE AVEC

CADRE

TYPIQUE

DE

3

/4 po (19)

MATÉRIAU DE

REMBLAYAGE

4 | Service à la clientèle de Sub-Zero 800.222.7820

Page 25

PRÉPARATION DU SITE

E

E

E

Électricité

L'installation doit se conformer à tous les codes électriques

applicables.

Bien qu'elle puisse être située n'importe où sur le mur

arrière, il est recommandé que l’alimentation électrique

soit placée dans une armoire adjacente ou dans le coin

inférieur droit de l'ouverture. Reportez-vous à l'illustration

ci-dessous. Un circuit séparé servant uniquement cet

appareil est requis.

Le modèle UC-15I(P)O est conçu pour être utilisé sans

danger dans les applications extérieures. Lors d'une

installation à l'extérieur, un disjoncteur de fuite de terre

(GFCI) est requis pour réduire le risque de choc électrique.

Un disjoncteur de fuite de terre n'est pas recommandé pour

usage avec le modèle pour l’intérieur et peut interrompre le

fonctionnement.

EXIGENCES ÉLECTRIQUES

Alimentation électrique 115 volts CA, 60 Hz

Service Circuito dedicado de 15 amperes

Prise mise à la terre à trois broches

MISE EN GARDE

Cette prise doit être vériée par un électricien qualié

pour s'assurer qu'elle est câblée avec la polarité

appropriée. Assurez-vous que la prise est correctement

mise à la terre.

AVERTISSEMENT

N'utilisez pas une rallonge ou un adaptateur à deux

broches et ne retirez pas la broche de mise à la terre

du cordon d'alimentation.

Emplacement de l'alimentation

électrique

subzero.com | 5

Page 26

PRÉPARATION DU SITE

24" (610)

ROUGH

OPENING

DEPTH

Plomberie

L'installation doit se conformer à tous les codes de

plomberie applicables.

La conduite d'alimentation en eau doit se trouver à

l'endroit indiqué dans l'illustration ci-dessous. La conduite

d'alimentation en eau doit être reliée à l'alimentation de

la maison avec un robinet d'arrêt facilement accessible.

N'utilisez pas des vannes à auto-perçage.

Un système à osmose inverse peut être utilisé à condition

qu'il y ait une pression d'eau constante de 20 à 80lb/po²

(1,4 à 5,5bars)

cuivre n'est pas recommandée pour cette application.

EXIGENCES DE PLOMBERIE

Conduite d'alimentation

en eau

Pression d'eau 20–80 lb/po²

Conduite d'alimentation en eau

supplémentaire pour connexion

ÉVACUATION DE LA MACHINE À GLAÇONS

vers l'unité en tout temps. Une conduite en

tube PEX ou en acier inoxydable tressé

en cuivre de ¼po (6) de diamètre extérieur

(1,4–5,5 bars)

36po (914)

Préparation

MISE EN GARDE

Avant de mettre l'unité en place, sécurisez la porte en

position fermée et protégez tout plancher ni.

Sortez l'unité de la boîte et examinez-la pour vous assurer

qu'elle n'est pas endommagée. Retirez la base en bois et

jetez les boulons et les supports d'expédition. Retirez et

recyclez les matériaux d'emballage. Ne jetez pas la plaque

de protection et la quincaillerie.

Utilisez un chariot à appareil pour déplacer l'unité près de

l'ouverture.

Si l'unité a été posée sur le dos ou le côté, elle doit être

mise debout pendant au moins 24 heures avant de relier

l'alimentation.

La machine à glaçons peut être commandée avec ou sans

pompe d’évacuation. Les modèles sans pompe élimineront

l’eau par gravité. Un drain doit être installé.

Les tubes d’évacuation et d’admission d’eau doivent

être reliés à la plomberie avant d’être reliés à la machine

à glaçons. Pour l’évacuation par gravité, les conduites

d’évacuation horizontales doivent avoir une inclinaison vers

le bas de ¼po

(6) par longueur de 12po (305). Un écart anti-

retour sera probablement requis entre l’unité et l’évacuation.

Une cheminée d’équilibre munie d’un siphon dans le bas

peut servir de drain.

8 po

(203)

1

/2 po

(13)

EMPLACEMENT

DE LA

CONDUITE D’EAU

VUE DE DESSUS

Emplacement de l'alimentation en eau

6 | Service à la clientèle de Sub-Zero 800.222.7820

Page 27

INSTALLATION

Installation

INSTALLATION DE LA MACHINE À GLAÇONS

1 Réglez les pieds de nivellement près de la hauteur

désirée. Reportez-vous à l'illustration ci-dessous.

2 Inversez l’ouverture de la porte si nécessaire. Reportez-

vous aux étapes décrites à la page 9.

3 Modèle à évacuation par gravité: installez le tuyau

d'évacuation fourni dans le raccord d'évacuation situé à

l'arrière de l'unité et acheminez-le jusqu'au drain à site

ouvert. Reportez-vous à l'illustration ci-dessous et aux

exigences de plomberie à la page précédente.

Modèle à pompe d'évacuation: acheminez le tuyau

d'évacuation à travers le raccord d'évacuation situé à

l'arrière de l'unité et installez le tuyau d'évacuation fourni

sur la pompe d'évacuation. Acheminez l'autre extrémité

du tube d'évacuation jusqu'au site du drain. Reportezvous à l'illustration ci-dessous et aux exigences de

plomberie à la page précédente.

4 Utilisez un raccord de compression pour relier

l'admission d'eau à l'arrière de la machine à glaçons à

la conduite d'eau froide préparée à diamètre intérieur de

¼po (6). Reportez-vous à l'illustration ci-dessous.

5 Ouvrez le robinet d'arrêt de la conduite d'eau. Assurez-

vous qu'il n'y a pas de fuites dans les connexions de

plomberie. Le non-respect de cette directive pourrait

entraîner une inondation.

6 Branchez le cordon d'alimentation dans la prise mise à la

terre.

7 Nivelez la machine à glaçons pour vous assurer que

la porte se ferme et se scelle correctement. Placez un

niveau sur le dessus de l'unité et tournez chaque pied de

nivellement pour les relever ou les abaisser au besoin.

8 Placez la machine à glaçons à son emplacement nal.

9 Arrimez la machine à glaçons en installant les deux vis

à tête plate fournies dans chaque charnière. Reportezvous à l'illustration ci-dessous.

VIS D’ANCRAGE

Nivellement

PIED DE

NIVELLEMENT

RACCORD D’ÉVACUATION

ADMISSION D'EAU

Raccord d'évacuation

Ancrage

subzero.com | 7

Page 28

INSTALLATION

Installation

VÉRIFICATION DE LA PRODUCTION DE GLAÇONS

1 Appuyez sur «POWER» (mise en marche) pour mettre la

machine à glaçons en marche.

2 Ajoutez un gallon (3,8l) d’eau froide au bac à glaçons.

Vériez que l’eau est complètement évacuée du bac à

glaçons et qu’il n’y a pas de fuites. Si l’eau ne s’évacue

pas dans un délai de 60 secondes, il est possible qu’il

y ait un pli dans le tube d’évacuation ou le drain est mal

installé.

3 Appuyez sur «CLEAN» (nettoyage). Attendez trois

minutes jusqu’à ce que le voyant CLEAN (nettoyage)

clignote, puis ajoutez 1 cuiller à soupe

(15ml) de

désinfectant de machine à glaçons directement dans

la zone de pulvérisation. Reportez-vous à l'illustration

ci-dessous. Utilisez uniquement le désinfectant fabriqué

pour les machines à glaçons de Sub-Zero

offert sur

le site subzerowolfstore.com. Pour toute question,

communiquez avec le service à la clientèle de Sub-Zero

à 800-222-7820.

4 Une cycle de désinfection de 10 minutes commence,

suivi de huit cycles de rinçage. Lorsque le processus est

terminé, le voyant CLEAN (nettoyage) n’est plus illuminé.

Le cycle au complet prend environ 30 minutes.

5 Lors du démarrage initial, la machine à glaçons prendra

environ 30 minutes à congeler l’eau et jusqu'à cinq

minutes pour produire des glaçons. Vériez la n du

premier cycle de production de glaçons pour conrmer

que la machine a été installée correctement.

VOLETS D’EAU

Emplacement des volets d’eau

8 | Service à la clientèle de Sub-Zero 800.222.7820

Page 29

INSTALLATION

Installation

INVERSION DU SENS D'OUVERTURE DE LA PORTE

Les charnières sont conçues pour être placées du côté droit

ou du côté gauche de la machine à glaçons. L’unité est

expédiée avec les charnières à la droite. Le déplacement

des charnières du côté gauche dans les trous pré-perçés

permet d’ouvrir la porte du côté gauche.

Pour inverser le sens d’ouverture de la porte:

1 Retirez les charnières de la machine à glaçon en

enlevant deux vis par charnière, puis retirez la porte.

Retirez la cale située entre l'armoire et la charnière

inférieure; cette cale sera transférée à la charnière

inférieure du côté gauche.

2 Retirez les charnières de la porte en enlevant deux vis

par charnière.

3 Retirez la garniture supérieure droite (zone ombragée) de

la porte en retirant deux vis. Reportez-vous à l'illustration

ci-dessous. Remplacez-la par la garniture supérieure

gauche.

4 Transférez les charnières vers le côté gauche de la porte

et réinstallez-les. La charnière supérieure se trouvera

maintenant dans la position inférieure et la charnière

inférieure se trouvera dans la position supérieure.

5 Retirez le couvercle supérieur de la machine à glaçons

en enlevant deux vis situées dans la partie supérieure

arrière de l’unité.

6 Retirez quatre vis du rail supérieur avant, puis pivotez

le rail supérieur de bout à bout pour exposer les deux

trous de montage de la charnière gauche supérieure et

réinstallez. Reportez-vous à l'illustration ci-dessous.

7 Retirez deux vis du rebord inférieur de la plaque de

garniture inférieure et glissez-la vers la droite pour

couvrir les trous de vis de montage de la charnière

droite. Reportez-vous à l'illustration ci-dessous. Les

trous de montage de la charnière gauche seront

maintenant exposés.

8 Réinstallez la cale, retirée à l'étape 1, entre l'armoire et

la charnière inférieure gauche. Réinstallez la porte en

installant les charnières en utilisant les trous de montage

de la charnière gauche. Vériez le fonctionnement de

la porte.

VIS DU RAIL

SUPÉRIEUR

VIS DE

CHARNIÈRE

Retirez la porte

GARNITURE

SUPÉRIEURE (D)

Retirez les charnières et la

garniture

CHARNIÈRE

CHARNIÈRE

Rail supérieur avant

VIS DE LA PLAQUE

DE GARNITURE

Plaque de garniture inférieure

subzero.com | 9

Page 30

INSTALLATION

Panneau personnalisé

PANNEAU À REVÊTEMENT

Pour les applications à revêtement, un panneau de porte

personnalisé doit être installé. La taille du panneau est

critique pour obtenir un ajustement approprié. Pour vérier

les exigences et les dimensions des panneaux, reportez-vous

au guide de conception Sub-Zero à subzero.com/specs.

Finissez tous les côtés du panneau personnalisé. Ils seront

visibles lorsque la porte est ouverte.

Une poignée en forme de D est recommandée. La poignée

de porte doit se trouver près du rebord du panneau opposé

à la charnière et être centrée de haut en bas. Des poignées

tubulaires et professionnelles en acier inoxydable sont

offertes par les dépositaires Sub-Zero autorisés. Pour

obtenir des renseignements sur votre dépositaire local,

visitez la section salle d'exposition de notre site Web,

subzero.com.

INSTALLATION DU PANNEAU

Retirez le support du côté de la poignée xé à l'avant

de la porte. Placez le panneau de porte à revêtement

personnalisé vers le bas sur une surface de travail protégée.

Placez le gabarit à l'arrière du panneau de la porte, puis

marquez et percez les trous. Fixez le support de montage

1

au panneau avec les vis # 8 x

/2" fournies. Reportez-vous à

l'illustration ci-dessous.

Installez le panneau de la porte en engageant le support

à onglet sur la porte. Une fois que le panneau de la porte

1

est en place, utilisez les vis restantes # 8 x

/2" pour xer le

panneau sur les supports de xation supérieurs et inférieurs.

Une fois sécurisé, installez les couvercles des charnières.

Reportez-vous à la page 11.

SUPPORT

SUPÉRIEUR

Position du gabarit

SUPPORT

INFERIEUR

Supports de montage

10 | Service à la clientèle de Sub-Zero 800.222.7820

Page 31

INSTALLATION

Achèvement

INSTALLATION DE LA PLAQUE DE PROTECTION

Installez la plaque de protection au moyen des deux vis

fournies. Reportez-vous à l'illustration ci-dessous. La

plaque de protection doit pouvoir être enlevée pour toute

réparation. Le plancher ne doit pas nuire à l'enlèvement.

Ne couvrez pas la section à persiennes de la plaque de

protection.

BUTÉE DE PORTE DE 90°

Des goupilles de butée de porte fournies avec la machine à

glaçons limiteront l'ouverture de la porte à 90°.

Pour installer, ouvrez la porte à environ 80°. Insérez une

goupille de butée dans la charnière de porte supérieure (la

goupille s’insère à partir du bas) et l’autre goupille de butée

dans la charnière de porte inférieure (la goupille s’insère à

partir du haut). Reportez-vous à l'illustration ci-dessous.

Vériez le bon fonctionnement.

COUVERCLES DE CHARNIÈRE

Installez les couvercles de charnière lorsque l’installation de

la machine à glaçons est terminée et les goupilles de butée

de porte sont installées (le cas échéant). Le trou à défoncer

dans le couvercle de charnière doit être retiré si la butée de

porte de 90° est utilisée.

Assurez-vous que les charnières sont libres de saleté ou de

graisse avant de poser les couvercles. Pour installer, retirez

l’endos en papier et appliquez les couvercles de charnière

sur chaque charnière. Fixez les couvercles à centre

magnétique. Reportez-vous à l'illustration ci-dessous.

AVERTISSEMENT

Respectez toutes les lois provinciales et locales lors

de l'entreposage, le recyclage ou l'élimination des

réfrigérateurs et des congélateurs non utilisés.

GOUPILLE D’ARRÊT

DE PORTE

TROU À DÉFONCER

Butée de porte de 90°

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, les boutons de couleur rouge, Cove et Cove & Design sont des marques déposées et de service de Sub-Zero Group, Inc. et ses liales.

Toutes les autres marques de commerce appartiennent à leurs propriétaires respectifs aux États-Unis et dans d'autres pays.

Couvercles de charnière

subzero.com | 11

Page 32

SUB-ZERO, INC. P.O. BOX 44848 MADISON, WI 53744 SUBZERO.COM 800.222.7820

7024818 REV-D 8/2019

Loading...

Loading...