Page 1

SZ-7512-P

OPERATING

INSTRUCTIONS

4

To set other

parameters.

Display will show ‘P5’ & flash

to go other parameters, use

UP / DOWN keys.

Press and

DOWN(prg)

key for

2 seconds.

hold

prg

Introduction: SZ-7512-P(Antifreeze thermostat)

Operating Instructions

The SZ-7512-P is a digital antifreeze thermostat with manual reset

O

facility and alarm (Buzzer) facility, this has a fixed differential of 2 C

The SZ-7512-P can be used as a direct replacement to the

following mechanical antifreeze thermostats :-

(a) Honeywell T675-B, (b) Danfoss-KP61, (c) Ranco-6953,

(d) Johnson A19ACA-15C,(e) White Rodgers 16A60-9.

The alarm is automatically set equal to the set point and can be

muted with the ‘RST’ key.

The controller functions similar to the above mentioned

mechanical thermostats i.e. relay will go off when the set point is

achieved and the same can be restarted only if the differential is

reached and the ‘RST’ key is pressed.

1

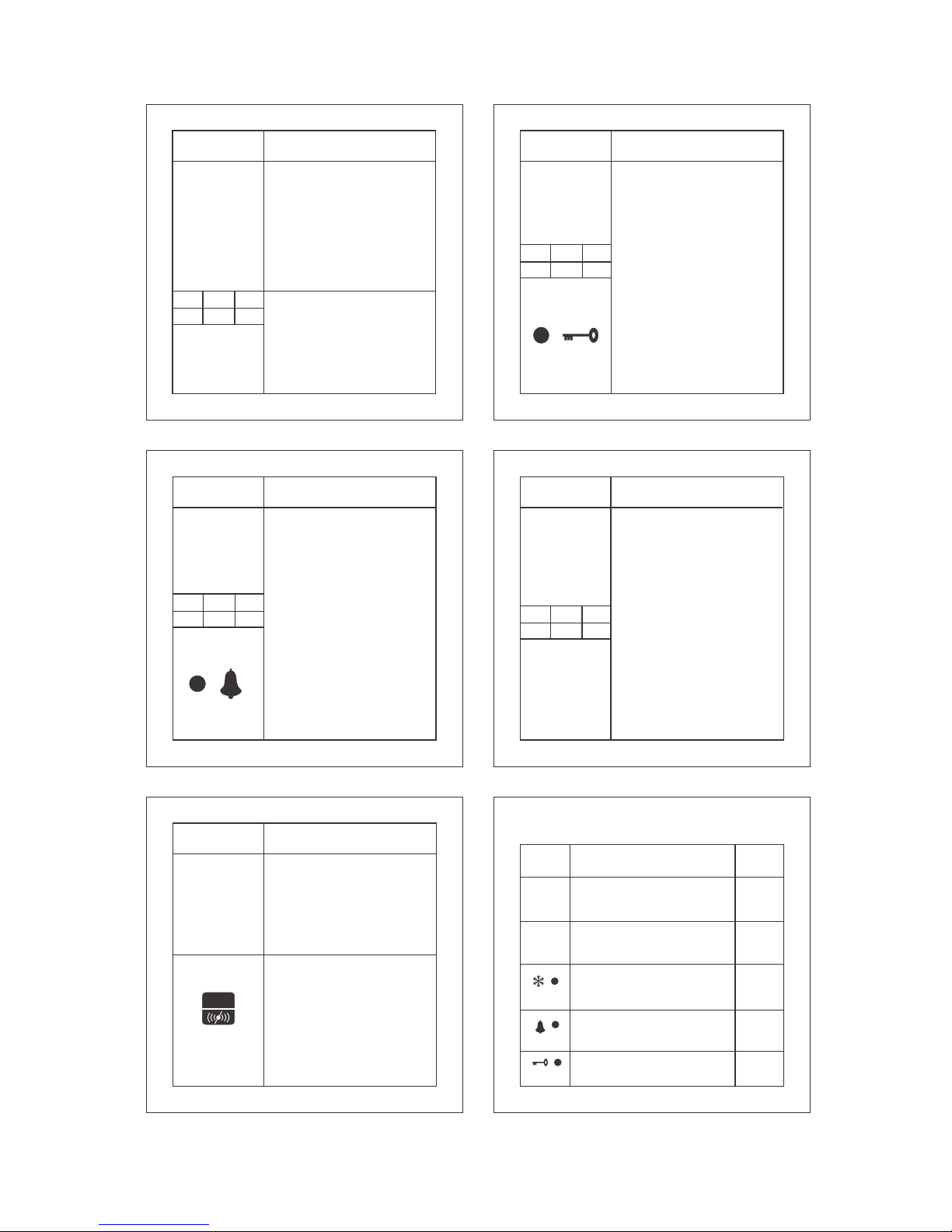

INDEX

2

Para. Page

Description

P5

LP

AL

FS

EP

3

4

5

6

7

8

9

10

12

13-14

To set the Set Point of the controller.

How to set other parameters.

Probe calibration.

Keypad lock.

Alarm - to activate buzzer.

Restore factory defaults.

End Programming & keypad functions.

Operating messages.

Wiring Diagram.

Panel cutout & dimensions.

3

Function: T

point of the controller.

o set the cut out

Display will change to set range

flash. The set point range can now

be changed by using the

UP/DOWN keys. After setting the

desired range, press the SET key

and you will see“_ _ _" which

confirms that the set point has

been stored in memory.

Set point

Press and

the SET

key for

2 seconds.

hold

-50

O

C

50

O

C

3

O

C

Min

Max

Fac.

www.ascontrols.com

INDIA

Page 2

P5

parameter

Function: To set probe

calibration.

To change

the P5

parameter,

press the

SET key.

Use UP/DOWN keys to set desired

range.

In time it may be possible that the

display may be offset by a degree

or so.

To compensate for this error, you

may need to add or minus the

degrees required to achieve the

correct temperature. Setting range

O O

is from -10 C to + 10 C

O

-10 C

Min Max

Fac.

O

+10 C

O

0 C

Example: The temperature on

O

the display is 28 C, whereas the

O

actual temperature is 30 C. You will

need to set the P5 mode to 2,

which means that once out of the

programming mode, the display will

show the temperature

O O O

30 C (28 C + 2 C).

5 6

LP

parameter

Function : To lock keypad.

0 1 0

Min Max

Fac.

To change

the LP

parameter,

press the

SET key.

Use UP/DOWN keys to set desired

range.

This Parameter can lock the

keypad so that tampering is not

possible by by-standers.

When set to

0= keypad unlocked

1= keypad locked

When locked all parameters can

only be viewed, but not modified.

7

AL

parameter

0 1 1

Function: To activate / deactivate

alarm.

To change

the AL

parameter,

press the

SET key.

Use the UP/DOWN keys to set

alarm on or off. Once set to on, the

buzzer will come on incase the

temperature is equal to the set

point.

1 = Activates Buzzer.

0 = Deactivates Buzzer.

Note=Alarm will be ON in probe

fail condition irrespective of

AL parameter

Min Max

Fac.

FS

Parameter

Function : To restores default

settings of the controller.

To change

the FS

parameter,

press the

SET key.

When set to 1 all parameters

are programmed to default

values.

Useful to debug setting related

problems.

0 1 0

Min Max

Fac.

8

9

EP

Parameter

Function : To end programming.

To end

programming

press the

SET key

Once the SET key is pressed,

the controller goes into the

normal mode and displays the

temperature and all settings are

recorded.

This key will reset the relay and

mute the buzzer alarm.

Reset key

RST

10

Operating messages and Icon status

Parameter

Set Point

AL , P3

Message Description

Lt

Temperature is equal to the set point.

PP

Probe short circuit, circuit open or without

0 0

probe, or temperature >50 C or < -50 C

Alarm (Lt or PP)

LP

Keypad locked/unlocked.

O

SP + 2 C

Compressor Relay On/Off.

On/Off

On/Off

Flashing

Page 3

9

12

+

-

BUZZER

To SZ-B75

(10Vdc, 10mA max)

Low TempTrip Lamp

or Other Load (5A max)

Compressor or

Contactor

or Heater

8(3)A max)

Caution : Wiring Shown for 230Vac Loads Only.

12

11

15 16

Installation : Fixing and dimensions of panel models:

To fix the unit, slide the fastener 1 through the guides 2

as per the position shown in the figure. Move the fastener in

the direction of the arrow, pressing tab 3 it permits to move

the fastener in the opposite direction of the arrow. Once the

controller has been connected, they should be covered with

the lid 4 Silicon sealant should be applied along the

perimeter of the panel cut out or a rubber ‘O’ ring supplied

before the unit is fitted to obtain IP65 grade.

Alarm (Buzzer) : Only use SZ-B75 buzzer with SZ7512-P series controller. Use of any other type of result

in permanent damage to the controller and may cause

personal injury.

Controller :Controller should be installed in a place

protected by vibration, water and corrosive gasses and

where ambient temperature does not exceed the

values specified in the technical data.

Probe :To give a correct reading, the probe must be

installed in a place protected from thermal influences,

which may affect the temperature to be controlled.

CAUTION

WIRING: The probe and its corresponding wires should never

be installed in a conduit next to control or power supply lines.

The electrical wiring should be done as shown in the diagram.

The power supply circuit should be connected to a protection

switch. The terminals admit wires of upto 2.5sq mm.

WARNING: Improper wiring may cause irreparable damage

and personal injury. Kindly ensure that wiring

is done by qualified personnel only.

Maintenance: Cleaning: Clean the surface of the controller

with a soft moist cloth. Do not use abrasive detergents, petrol,

alcohol or solvents.

Notice: The information in this document is subject to change

in order to improve reliability , design or function without prior

notice and does not represent a commitment on the part of the

company. In no event will the company be liable for direct,

indirect, special, incidental or consequential damage arising out

of the use or inability to use the product or documentation, even

if advised of the possibility of such damages. No part of this

manual may be reproduced or transmitted in any form or by any

means without the prior written permission of the company.

13

GASKET

PANEL

Side Lock

CONTROLLER

14

SZ-7512-P

prg

SET

O

C

RST

3

1

4

2

34.5mm

71mm

19mm

10mm

MAX

71mm

29mm

Panel cutout

PANEL

Suggested Wiring Diagram

PROBE

230VNCCNO

RELAY

11

10

Technical data :

≤

Display : 14.2 mm (0.56") LED.

Data storage : Non-volatile EEPROM memory

Power input : 230Vac,+/-10%, 50Hz/60Hz. Others on

request.

O O

Operating temp. : 5 C to 50 C(non-condensing).

O O

Storage temp : -20 C to 70 C(non-condensing).

Output : 1 SPDT relay 8(3)A, 250Vac

Input : NTC probe, SZ-N75

O O

Range : -50 C to 50 C

O

Resolution : 1 C

O

Accuracy : +/-1 C

O O

Probe tolerance at 25 C : +/-0.3 C

Alarm (buzzer) : SZ-B75, 10Vdc, 10mA

Housing : Black ABS plastic.

Front cover : Polycarbonate plastic.

Dimensions : Front - 75 x 34.5 mm,

Depth 71 mm (w/o back lid).

Panel Cutout : 29mm x 71mm

Mounting : Flush panel mounting with fasteners.

Protection : Front panel is water proof & IP 65 rated .

Connections : Screw terminal blocks.

2.5 sq.mm wire terminal only

Page 4

INDIA

Ball Valves

Globe Valves

Hand Valves

Flow Switches

Solenoid Valves

OUR OTHER PRODUCTS

Cold Room Controller

Chiller Controller

Two Compressors Controller

Heating Controller

Humidity Controller

Pressure Controller

TM

00 / 25.11.09

18

LIMITATION OF LIABILITY : ASCPL's total liability for any and

all losses and damages arising out of any cause whatsoever

shall in no event exceed the purchase price of the products or

parts in respects of which such cause arises, whether such

cause be based on theories of contract, negligence, strict liability,

tort or otherwise.

In no event is ASCPL responsible for any consequential or

punitive damages or losses of any nature whatsoever. ASCPL

shall not be liable for, and buyer assumes any liability for, all

personal injury and property damage connected with the

17

Warranty : All Subzero products manufactured by A.S.Controls

Pvt. Ltd (thereafter reffered to as ASCPL) are under warranty

against defects in workmanship and materials for a period of one

year from date of shipment from factory. This warranty is in force

only when products are properly installed,maintained and

operated in use and service as specifically stated in Subzero

catalogues.

Defective products, or parts there of returned to the factory with

transporatation charges prepaid and found to be defective by

factory inspection, will be replaced or repaired at ASCPL's

option, free of charge, Ex-factory. Warranty does not cover

products that have been altered, or repaired in the field, or

damaged in transit, or have suffered accidents, misuse, or abuse.

Products disabled by dirt or other foreign substances will not be

considered defective. This warranty does not cover any cosmetic

issues, such as product damaged by accident, abuse and misuse

as a result of service or modification other than company. Repair

or change in parts or replacement of parts or products does not

extend the warranty.

The express warranty set forth above constitutes the only

warranty applicable to ASCPL products, and is in lieu of all other

warranties, expressed or implied. No employee, agent, dealer or

any other person is authorised to give any warranties on behalf of

ASCPL, nor to assume for ASCPL, any other liability in

connection with any of its products.

19

handling, transporatation, possession, further manufacture, other

use or resale of the products, whether used alone or in

combination with any other products or materials. ASCPL makes

NO other warranty, expressed or implied, and makes no warranty

of merchantibility or fitness for any particular purpose.

From time to time buyers might call to ask ASCPL for technical

advice based upon limited facts disclosed to ASCPL. If ASCPL

furnishes technical advice to the buyer, whether or not at buyer's

request, with respect to application, further manufacture or use of

the products or parts, ASCPL shall not be liable for such technical

advice or any such advice provided to buyer by any third party

and buyer assumes all risks of such advice and results thereof.

NOTICE TO USERS OF PRODUCTS : The Limited Warranty

stated above is a factory warranty to the first purchasers of

ASCPL products. Since many users have purchased these

products from ASCPL distributors, the user must within thirty (30)

days after user's discovery of what the user believes is a defect,

notify in writing and return the product to the distributor from

whom he purchased the product/part. The distributor may or may

not at the distributor's option choose to submit the products/parts

to ASCPL pursuant to this limited warranty. Failure by the buyer

to give such written notice within 30 (thirty) days shall be deemed

an absolute and unconditional waiver of buyers claim for such

20

defects. Acceptance of any alleged defective product/parts by

ASCPL's distributor for replacement or repairs under the terms

of ASCPL's limited warranty in no way determines ASCPL's

obligations under this Limited Warranty.

Because of a policy of continous product improvement, ASCPL

reserves the right to change designs, materials or specifications

without notice.

Disclaimer: This manual & its contents remain the sole property

of A.S. CONTROLS Pvt. Ltd, India and shall not be reproduced

or distributed without authorisation. Although great care has

been taken in the prepartion of this document, the company or

its vendors in no event will be liable for direct, indirect, special,

incidental or consequential damage arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages. No part of this manual may be

reproduced or transmitted in any form or by any means without

the prior written permission of the company. A.S. CONTROLS

Pvt. Ltd, reserves the right to make and changes or

improvements without prior notice.

Loading...

Loading...