Page 1

OPERATING

INSTRUCTIONS

SZ-7510-P-DI

www.subzero.co

1

4

GENERAL DESCRIPTION

The Sub-Zero Series SZ-7510-P-DI are aesthetically superior

versions of their predecessors. The SZ-7510-P-DI is a single

set point controller. with digital input. They are specifically

des ign ed for ref riger ati on app lic ation s wh erein the

compressor cuts off at set point and is restarted at a

temperature of set point plus differential.

Additionally these controllers offer several protection features

that are easily understood by the examples in the instructions

below. The controller can be used for heating applications,

when the P1 parameter is set to “1” .

A number of parameters are displayed alphanumerically to set

up the instrument for each specific application.

The SZ-7510-P-DI controller can be used for several

O O

applications with a measuring range from -50 C to 99 C.

Instructions :

Function: To set the cut out

point of the controller.

Display will change to set range.

The set point range can now be

changed by using the UP/DOWN

key. After setting the desired

range, press the set key and you

will see “- - -” which confirms that

the set point has been stored in

memory.

Set point

Press and hold

the SET

key for

2 Seconds.

O

-50

C

O

99

C

O

10 C

Min

Max

Fac.

3

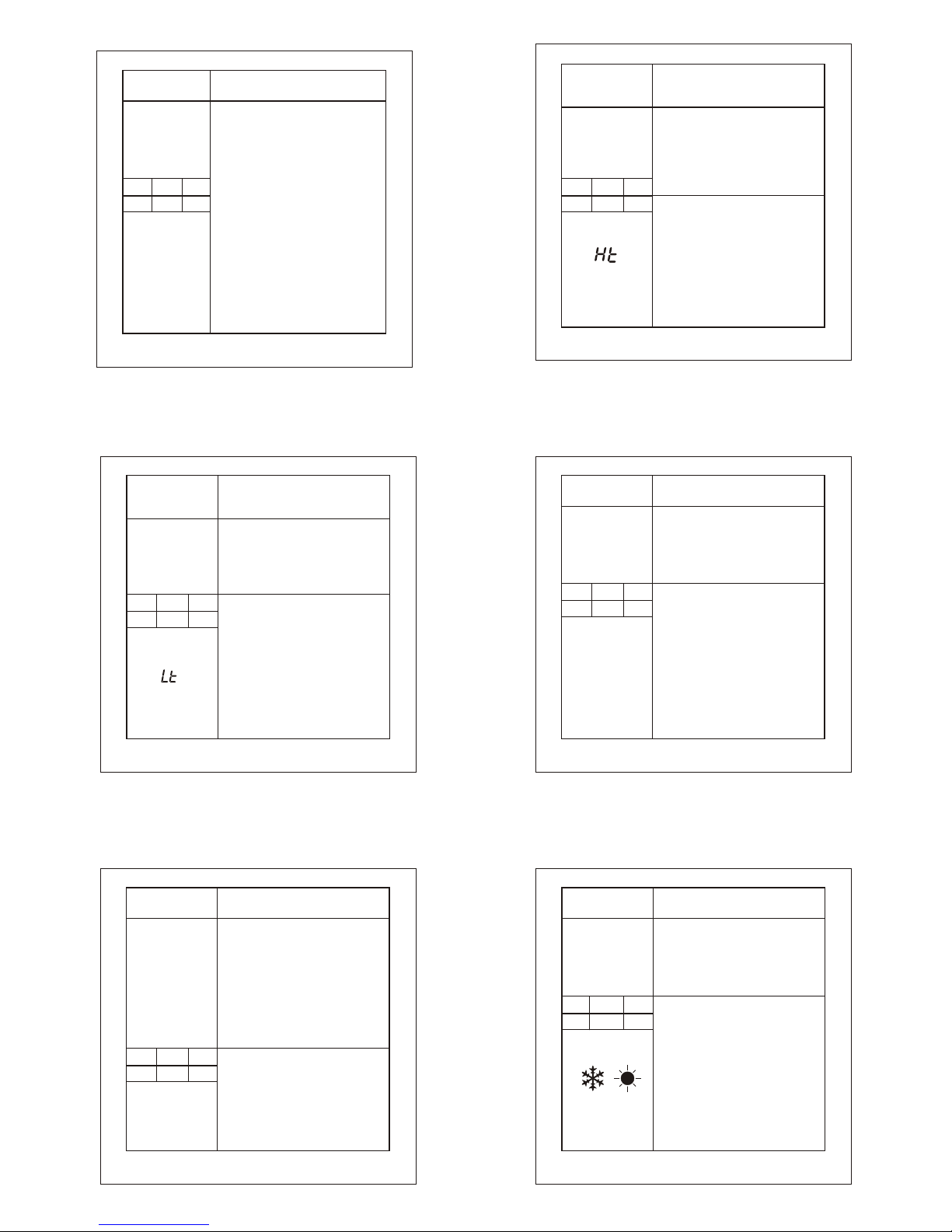

INDEX

Para. Page

Description

P1

P2

P3

P4

P5

P6

d0

d1

d2

d3

LP

E1

FS

EP

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

2

INDIA

To set other

Parameters.

Display will show P1 & flash.

To go to other parameters,

use UP/DOWN keys.

Press & hold

the DOWN(prg)

key for

2 seconds.

prg

SET

To set the SET Point of the controller.

How to set other parameters.

To set Heating or Cooling function.

Max High Temp limit & alarm.

Min Low Temp limit & alarm.

To set Differential (Hysterisis).

Probe calibration.

Time Delay (relay restart after cutoff)

Keypad lock.

Relay status on probe failure.

Restore factory defaults.

End Programming.

Operating messages.

Technical Data.

Wiring diagram.

Panel cutout & dimensions.

Activate or deactive digital input function.

Set reset mode for digital input

Set the count mode for CCF

Set the number of count for CCF

Page 2

5

P1 Parameter

Function: To set controller for heating

or cooling.

0 1 0

To change

the P1

parameter,

press the

SET key.

Use UP/DOWN keys to get

desired range & press set

to confirm.

0: Cooling mode and

1: Heating mode.

Min Max

Fac.

6

7

8

P4 Parameter

Function: To set the differential.

To change

the P4

parameter,

press the

SET key.

Use UP/DOWN keys to set

desired range.

Differential between cut out and

cut in temperature can be set

O O

between 1 C to 20 C.

O

1 C

Min Max

Fac.

O

20 C

O

2 C

Example (in cooling mode): If the

O

set point is set at 10 C and

O

differential is set at 2 C, then when

O

the system reaches 10 C, the relay

will cut out. Since the differential is

2, the relay will cut in (restart) at

O O O

12 C (10 C+2 C).

9

P5 Parameter

Function: To set probe calibration.

To change

the P5

parameter,

press the

SET key.

Use UP/DOWN keys to set desired

range.

In time it may be possible that the

display may be offset by a degree

or so.

To compensate for this error, you

may need to add or minus the

degrees required to achieve the

correct temperature. Setting range

O O

is from -10 C to +10 C.

O

-10 C

Min Max

Fac.

O

10 C

O

0 C

Example: The temperature on

O

the display is 28 C, whereas the

O

actual temperature is 30 C. You will

need to set the P5 mode to 2,

which means that once out of the

programming mode, the

temperature will show

O O O

30 C (28 C + 2 C).

10

Function: To set minimum allowable

low temperature set point.

Use UP/DOWN keys to set desired

range. Once set at a particular

range, this will not allow the set

point to go below this range.

Example: Setting this parameter at

O

-30 C will not allow the set point to

O

go below -30 C. Also, if the

O

temperature reaches -30 C, the

display will show Lt (LowTemp.)

indicating that the temperature has

gone below the range in this

parameter.

P3 Parameter

O

-50 C

Max

Fac.

O

XX CO-50 C

To change

the P3

parameter,

press the

SET key.

Min

(Message on display)

P6 Parameter

0 Min

99 Min

3 Min

Function: To set time delay

between relay restart time.

To change

the P6

parameter,

press the

SET key.

Min

Max

Fac.

Use UP/DOWN keys to set desired

range.

This parameter is used to protect

the compressor from restarting in a

short period of time and can be set

between 0 to 99 minutes.

Example: If this parameter is set at

3 minutes, the relay will cut off at

the set temperature, but will not

restart for a minimum of 3 minutes,

even if the differential is achieved

earlier. This parameter is good to

protect the life of the compressor

when there are power fluctuations

and the compressor is switched off

and on within a few seconds.

P2 Parameter

Function: To set maximum allowable

high temperature limit.

O

XX C

To change

the P2

parameter,

press the

SET key.

Max

Fac.

Use UP/DOWN keys to set

desired range.

Once set at a particular

range, this will not allow the

set point to go above this

range.

O

99 CO99 C

Example: Setting this parameter

O

at 25 C will not allow the

O

set point to go above 25 C. Also,

O

if the temperature reaches 25 C,

the display will show Ht (High Temp.)

indicating that the temperature.

has gone above the range in this

parameter.

Min

(Message on display)

Flashing

Time delay in progress

Page 3

15

LP Parameter.

0 1 0

Function: To lock keypad.

To change

the LP

parameter

press the

SET key.

Use UP/DOWN keys to set

desired range.

This parameter can lock the

keypad so that tampering is not

possible by by-standers.

0 = keypad unlocked

1 = keypad locked

When locked all parameters can

only be viewed, but not modified.

Min Max

Fac.

16

E1 Parameter

0 2

2

Function : Relay status on

Probe Failure.

Min Max

Fac.

To change

the E1

parameter

press the

SET key.

Use UP/DOWN keys to set

desired range.

When set to

0 = Relay status is ON.

1 = Relay performs a duty cycle

10 minutes ON and 4minutes

OFF.

2 = Relay status is OFF.

11

d0 Parameter

0 2 1

Function : To activate or deactive

digital input function.

To change

the d0

parameter

press the

SET key

Use UP/DOWN keys to set

desired range.

0: Digital input disable.

1: DI with 230VAC present

2: DI with 0VAC present.

Min Max

Fac.

Example :

If this parameter is set to 0,

controller will not sense any digital

input.

If set to 1, when 230VAC is

present, controller will treat it as a

fault and turn off the compressor

and DI ( )will flash.

If set to 2, when 0VAC is present,

controller will treat it as a fault and

turn off the compressor and

DI ( )will flash.

12

d1 Parameter

Function : To set reset mode for

digital input.

0 1 0

Min Max

Fac.

To change

the d1

parameter

press the

SET key

Use UP/DOWN keys to set desired

range.

0: Auto reset.

1: Manual reset.

Example :

If this parameter is set to 0, then

incase of a fault in d0 parameter,

unit will auto reset after fault is

cleared.

If this parameter is set to 1, then

incase of a fault in d0 parameter,

unit will allow reset after pressing

AUTO/MAN button. (after d0 fault is

cleared).

14

13

Use UP/DOWN keys to set desired

range.

This parameter sets the permissible

number of reset cycles of

compressor.

When number of compressor reset

cycles within 1 Hr. goes above the

d3 parameter, controller switch to

manual reset mode and “CCF”

led will be ON.

NOTE: This parameter saves the

compressor from multiple (more

than max.10 nos.) reset within 1 Hr.

Use RST key to reset this CCF

fault.

Use UP/DOWN keys to set desired

range.

0: CCF count increment with each

Comp. OFF and DI fault.

1: CCF count increment only with

DI fault.

d3 Parameter

d2 Parameter

0

0

1015

0

Min

Min

Max

Max

Fac.

Fac.

To change

the d2

parameter

press the

SET key

To change

the d2

parameter

press the

SET key

Function : To set the number of reset

cycles of compressor.

Function : To set the count mode for CCF .

CCF- compressor count fault.

RST

AUTO

MAN

Page 4

20

Technical data:

Dimensions: Front : 75 X 34.5 MM,

Depth 7 MM (w/o back lid)

: 1

Mounting: Flush panel mounting with fasteners

Frontal protection : I.P65

Connections: Screw terminal blocks. 2.5sqmm one

wire/ terminal only

Display: 2 X14.2 mm (0.56") LED

Data storage: Non-volatile EEPROM memory

Power input: 230Vac +/-10%,50-60Hz.

Other on request

O O

Operating temp.: 5 C to 50 C(non-condensing)

O O

Storage temp: -20 C to 70 C(non-condensing)

Output:1 SPDT relay 8 (3)A, 250Vac.

Input: NTC probe, SZ-N75

O O

Range: -50 C to 99 C

O

Resolution: 1 C

O

Accuracy: +/- 1 C

O O

Probe tolerance: +/- 0.3 C at 25 C

Housing : Black, ABS Plastic

Front Cover : Red Polycarbonate plastic.

18

EP Parameter.

To end

programming

press the

SET key

Once the SET key is pressed, the

control goes into the normal mode

and displays the temperature and

all settings are recorded.

Function: To end programming.

21

NEUTRAL

To

SZ-N75

Compressor, Contactor

or Heater 8(3)A max

PHASE

Caution:Wiring for 230Vac load only

230V

NO NC C

7

11 12

8

5

3 4

1

6

PROBE

COMP.

Phase from

Digital Input

trip contact

Neutral

3

1

4

2

35mm

71mm

19mm

15mm

MAX

71

29

Panel cutout

22

RST

SZ-7510-P-DI

prg

SET

-

DI

CCF

AUTO

MAN

RST

19

Operating messages and Icon status

Parameter

Message

Description

P2

Ht

Temperature above the maximum

limit of the set point.

P3

Lt

Temperature below the minimum limit

of the set point.

PP

Probe short circuit, circuit open or without

0 0

probe, or temperature > 99 C or <-50 C

SP, P4

Comp. Relay on/off

On/Off

P6

Time delay in progress

Flashing

LP

Keypad locked/unlocked

d0,d1

d2,d3

Digital input fault ON

Compressor count fault : CCF

On

On/Off

DI

On

CCF

17

FS Parameter

Function : To restore default

settings of the controller.

0

1 0

Min Max

Fac.

To change

the FS

parameter

press the

SET key.

When set to 1 all parameters

are programmed to factory

values.

Useful to debug setting

related problems.

Page 5

25

Disclaimer: This manual & its contents remain the sole property

of A.S. CONTROLS Pvt. Ltd, India and shall not be reproduced or

distributed without authorisation. Although great care has been

taken in the prepartion of this document, the company or its

vendors in no event will be liable for direct, indirect, special,

incidental or consequential damage arising out of the use or

inability to use the product or documentation, even if advised of the

possibility of such damages. No part of this manual may be

reproduced or transmitted in any form or by any means without the

prior written permission of the company. A.S. CONTROLS Pvt. Ltd,

reserves the right to make and changes or improvements without

prior notice.

Warranty: This product is warranted against defects in

materials and workmanship for a period of one year from

the date of purchase. During the warranty period, product

determined by us to be defective in form or function will be

repaired or, at our option, replaced at no charge. This

warranty does not apply if the product has been damaged

by accident, abuse, and misuse or as a result of service or

modification other than by the company. This warranty is in

lieu of any other warranty expressed or implied. In no event

shall the company be held liable for incidental or

consequential damages, including lost revenue or lost

business opportunity arising from the purchase of this

product..

INDIA

Ball Valves

Globe Valves

Hand Valves

Flow Switches

Solenoid Valves

OUR OTHER PRODUCTS

Cold Room Controller

Chiller Controller

Two Compressors Controller

Heating Controller

Humidity Controller

Pressure Controller

TM

24

CAUTION

WIRING: The probe and its corresponding wires should never

be installed in a conduit next to control or power supply lines.

The electrical wiring should be done as shown in the diagram.

The power supply circuit should be connected to a protection

switch. The terminals admit wires of upto 2.5sq mm.

WARNING: Improper wiring may cause irreparable damage

and personal injury. Kindly ensure that wiring is done by

qualified personnel only.

Maintenance: Cleaning: Clean the surface of the controller

with a soft moist cloth. Do not use abrasive detergents, petrol,

alcohol or solvents.

Notice: The information in this document is subject to

change in order to improve reliability , design or function

without prior notice and does not represent a commitment

on the part of the company. In no event will the company

be liable for direct, indirect, special, incidental or

consequential damage arising out of the use or inability to

use the product or documentation, even if advised of the

possibility of such damages. No part of this manual may

be reproduced or transmitted in any form or by any means

without the prior written permission of the company.

23

Installation : Fixing and dimensions of panel models:

To fix the unit, slide the fastener 1 through the guides 2

as per the position shown in the figure. Move the fastener in

the direction of the arrow, pressing tab 3 it permits to move

the fastener in the opposite direction of the arrow. Once the

controller has been connected, they should be covered with

the lid 4 .

Silicon sealant should be applied along the perimeter of the

panel cut out or a rubber ‘O’ ring supplied before the unit is

fitted to obtain IP65 grade.

Controller :Controller should be installed in a place

protected by vibration, water and corrosive gasses and

where ambient temperature does not exceed the

values specified in the technical data.

Probe :To give a correct reading, the probe must be

installed in a place protected from thermal influences,

which may affect the temperature to be controlled.

Loading...

Loading...