Page 1

WINE STORAGE

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIONSANWEISUNGEN

Page 2

SUB-ZERO®is a registered trademark of Sub-Zero, Inc.

As you follow these instruc tions, you will

notice WARNING and CAUTION symbols.

This blocked information is impor tant for

the safe and efficient installation of Sub-Zero

equipment. There are two types of potential

hazards that may occur during installation.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

SUB-ZERO

WINE STORAGE

The importance of the installation of the

Sub-Zero Wine Storage unit cannot be

overemphasized. Installation should be

done by a qualified installer.

Before you begin the installation process,

it is recommended that you read this entire

Installation Instructions book. There are key

details that you should take special care to

observe during the installation. By reading

these instructions carefully, you will make

the installation process easier, problem-free

and, most importantly, safe.

Any questions or problems about the installation should be directed to your Sub-Zero

dealer. You can also visit our website at

subzero.com.

CONTENTS

Models ICB424 and ICB424FS Installation 3

Models ICB427 and ICB427R Installation 12

Model ICB430 Installation 24

Installation Checklist 34

Service Information 35

Features and specifications indicated herein and

on the website are subject to change at any time

without notice. Check our website, subzero.com,

for the most up-to-date specifications.

Page 3

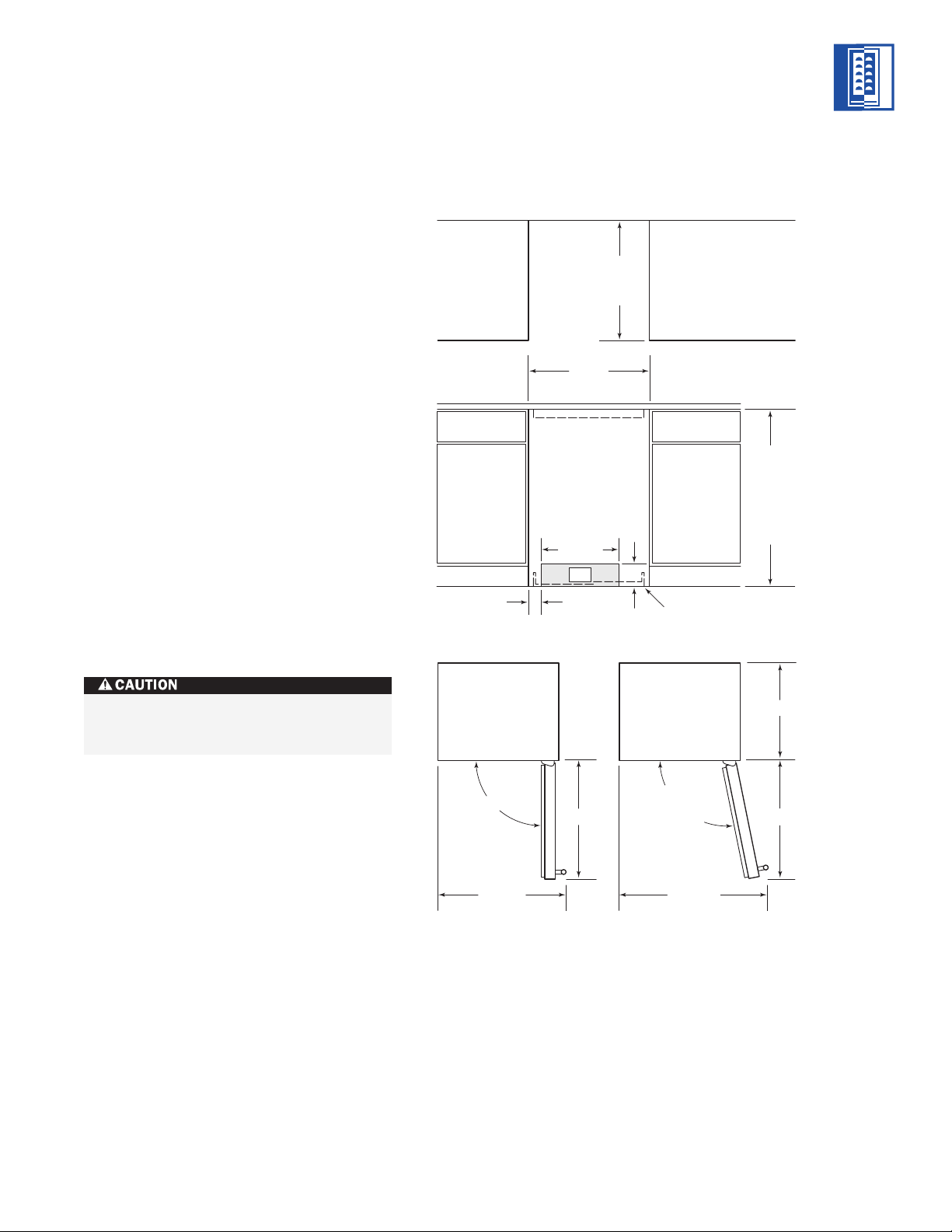

MODELS ICB424 AND ICB424FS

SITE PREPARATION

The Sub-Zero Model ICB424FS wine storage

unit is designed to be attractive in a stand

alone setting. It can also be slid into surrounding cabinetry with clearance dimensions

slightly different than the standard built-in

Model ICB424.

Make sure that the finished rough opening

where the Wine Storage unit is to be installed

is properly prepared. Refer to the Installation

Specifications illustration for rough opening

dimensions, door swing clearance and electrical placement for Models ICB424 and

ICB424FS.

IMPORTANT NOTE:

To operate properly,

the door must open a minimum of 90 degrees.

Use a minimum 76 mm filler in corner installations to assure a 90-degree door opening.

Allow enough clearance in front of the unit

for full door swing.

IMPORTANT NOTE:

Make sure the floor under

the unit is level with the surrounding finished

floor.

3

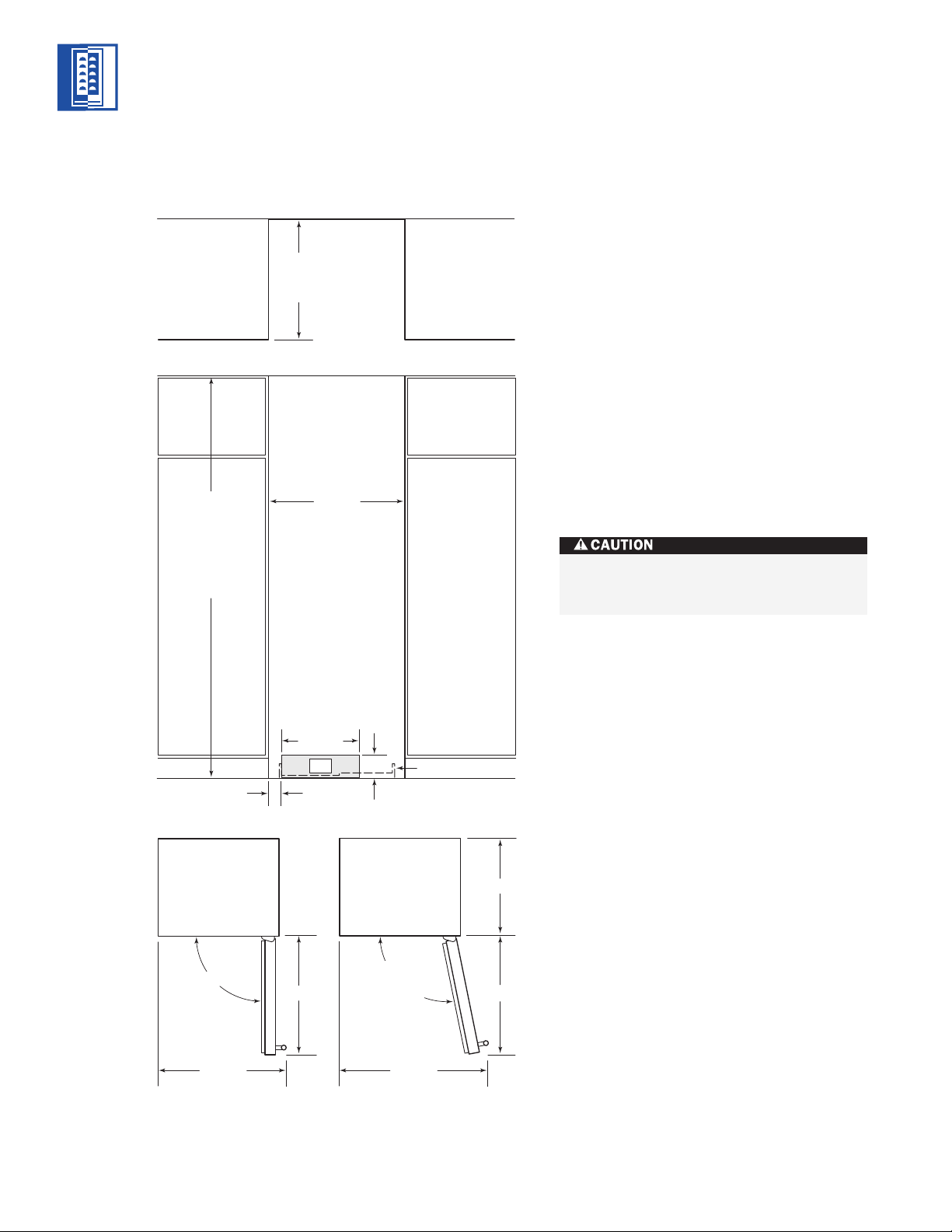

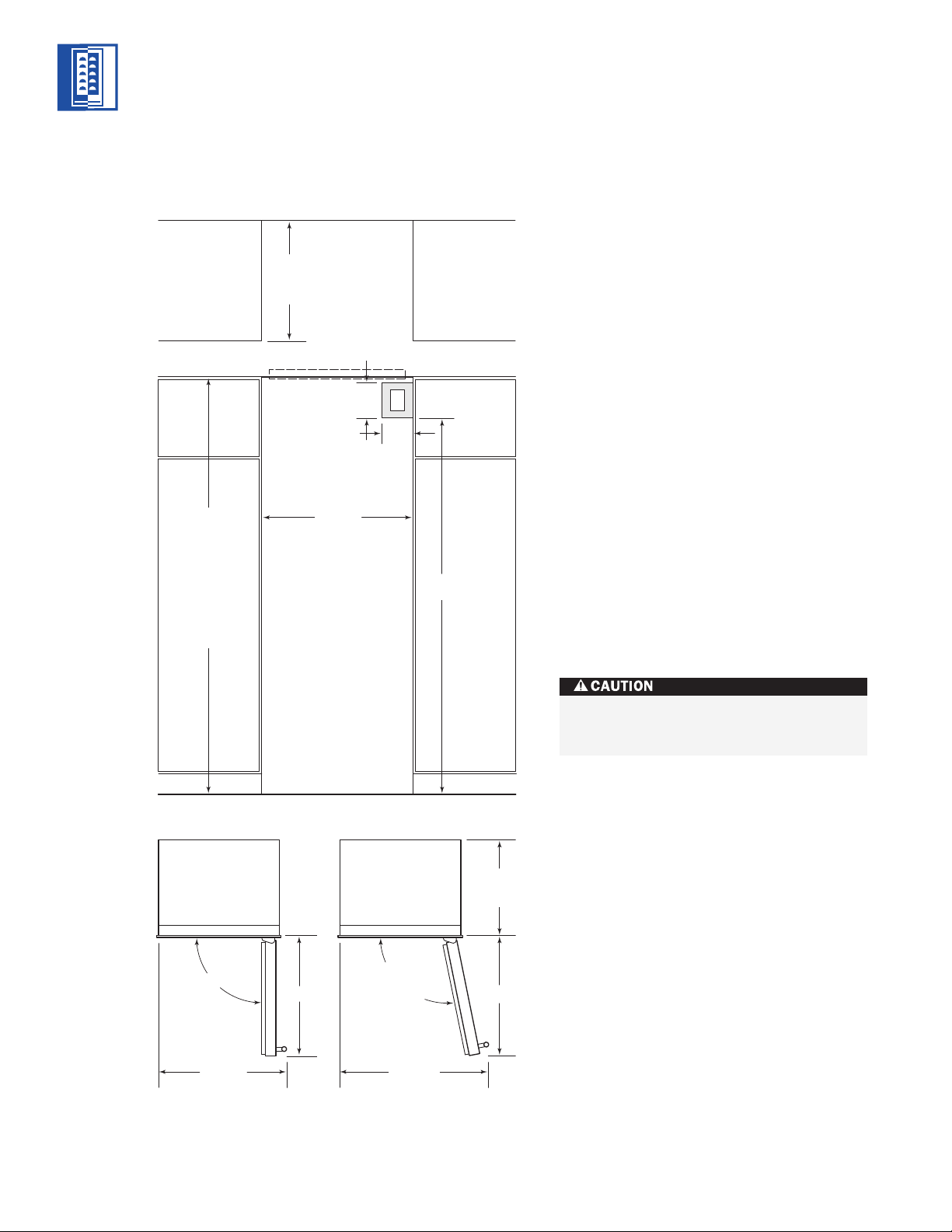

MODELS ICB424 AND ICB424FS INSTALLATION

Do not load wine into the Wine Storage

unit until the installation is complete.

INSTALLATION SPECIFICATIONS

NOTE: Door swing clearances are based on stainless

steel door and handle dimensions.

MODELS

ICB424

ICB424FS

876 mm

ROUGH

OPENING

HEIGHT

870 mm

MINIMUM

HEIGHT

REQUIRED

ROUGH OPENING

WIDTH

610 mm MODEL ICB424

619 mm MODEL ICB424FS

394 mm

610 mm

ROUGH

OPENING

DEPTH

LOCATE ELECTRICAL

WITHIN SHADED AREA

E

114

mm

64 mm

606 mm

MODEL ICB424

ANTI-TIP BRACKET

MODEL ICB424FS

ANTI-TIP BRACKET

90˚

145˚

MAXIMUM

DOOR SWING

1118 mm

DOOR CLEARANCE

660 mm

DOOR CLEARANCE

644 mm 645 mm

FRONT VIEW

TOP VIEW

Page 4

4

ELECTRICAL REQUIREMENTS

A 220-240 V AC, 50/60 Hz, 10 amp circuit

breaker and electrical supply are required. A

separate circuit, servicing only this appliance,

is required.

The power supply cord has a grounding plug,

which must be plugged into a mating ground ing-type wall recep tacle. Follow all National

Electrical codes and local codes and ordinances

when installing the receptacle. For location of

the electrical supply, refer to the Installation

Specifications illustration on page 3.

IMPORTANT NOTE:

For Models ICB424 and

ICB424FS, the outlet must be flush with the

back wall.

IMPORTANT NOTE:

A ground fault circuit

interrupter (GFCI) is not recommended and

may cause interruption of operation.

HOME ALARM SYSTEM

If a home alarm system is to be used, refer to

Home Alarm Connections on page 8. In addition

to operating power, the installer may also be

required to supply a home automation system

lead to the unit. This is for a low-voltage, lowcurrent signal similar to door and window

sensor signals. Common, normally open and

normally closed contact configurations are

provided.

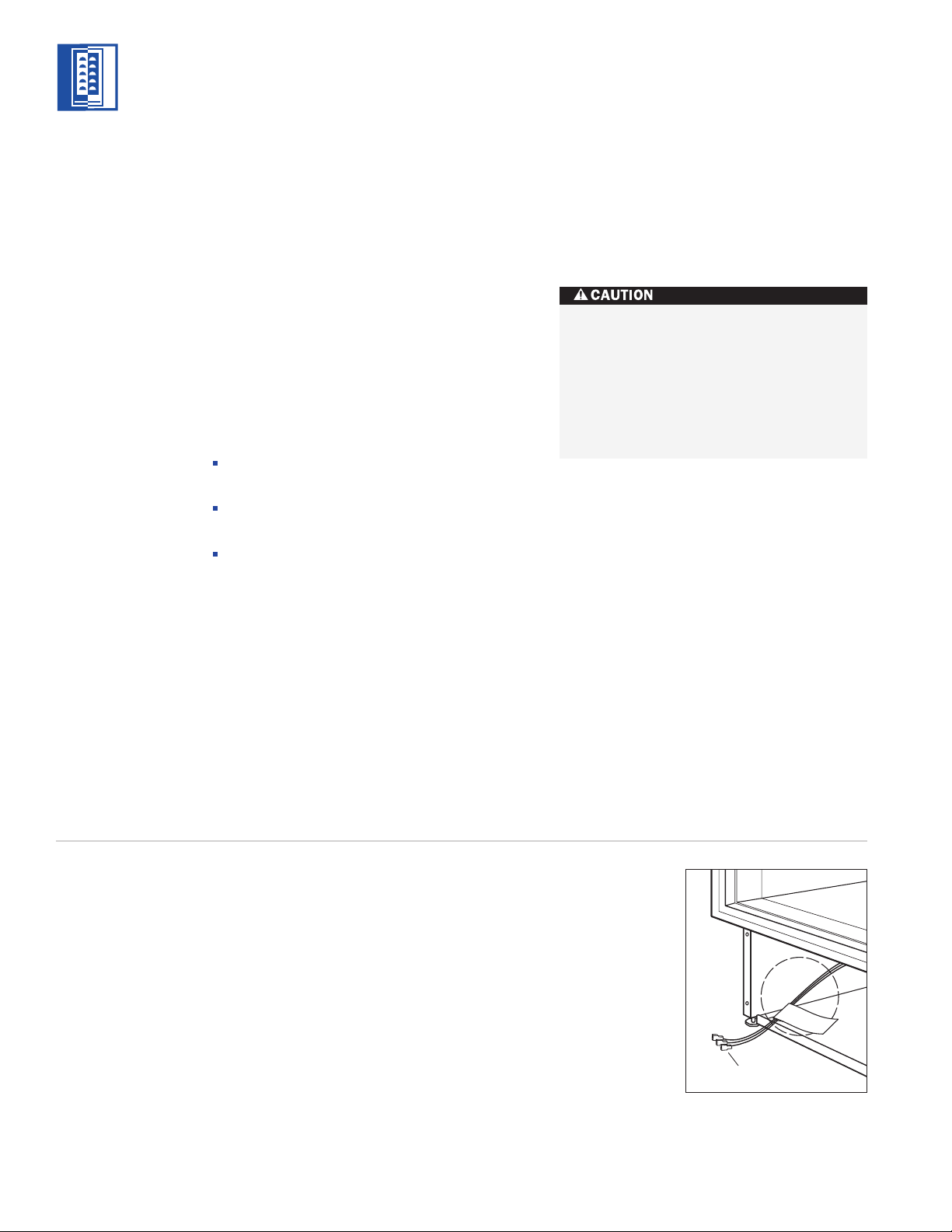

Three 6 mm female spade connectors are

located in the compressor compartment and

are accessible behind the kickplate on Models

ICB424 and ICB424FS. A minimum of 914 mm

of lead wire should be provided for each

contact, exiting the back wall near the

electrical outlet.

MODELS ICB424 AND ICB424FS INSTALLATION

UNPACKING AND MOVING

Uncrate the unit, remove its wood base and

discard the shipping bolts that hold the wood

base to the bottom of the unit. Remove all

packing materials and tape.

IMPORTANT NOTE:

Do not discard the kickplate, anti-tip bracket and hardware. These

items will be needed for the installation.

All roller-assembly wine shelves should be

removed to reduce weight and prevent them

from rolling. To remove, pull the shelf out to

its full extension, gently and evenly lift up on

both sides of the front of the shelf and remove.

Reverse the procedure to reinstall the shelf.

Use an appliance dolly to move the Wine

Storage unit. Position the dolly at the back

of the unit to prevent damage to finished

surfaces.

Do not use an extension cord. Electrical

ground is required on this appliance.

Before moving the Wine Storage unit in

to position, protect any finished flooring

with appropriate materials and secure

the door closed.

MODELS

ICB424

ICB424FS

Page 5

5

MODELS ICB424 AND ICB424FS INSTALLATION

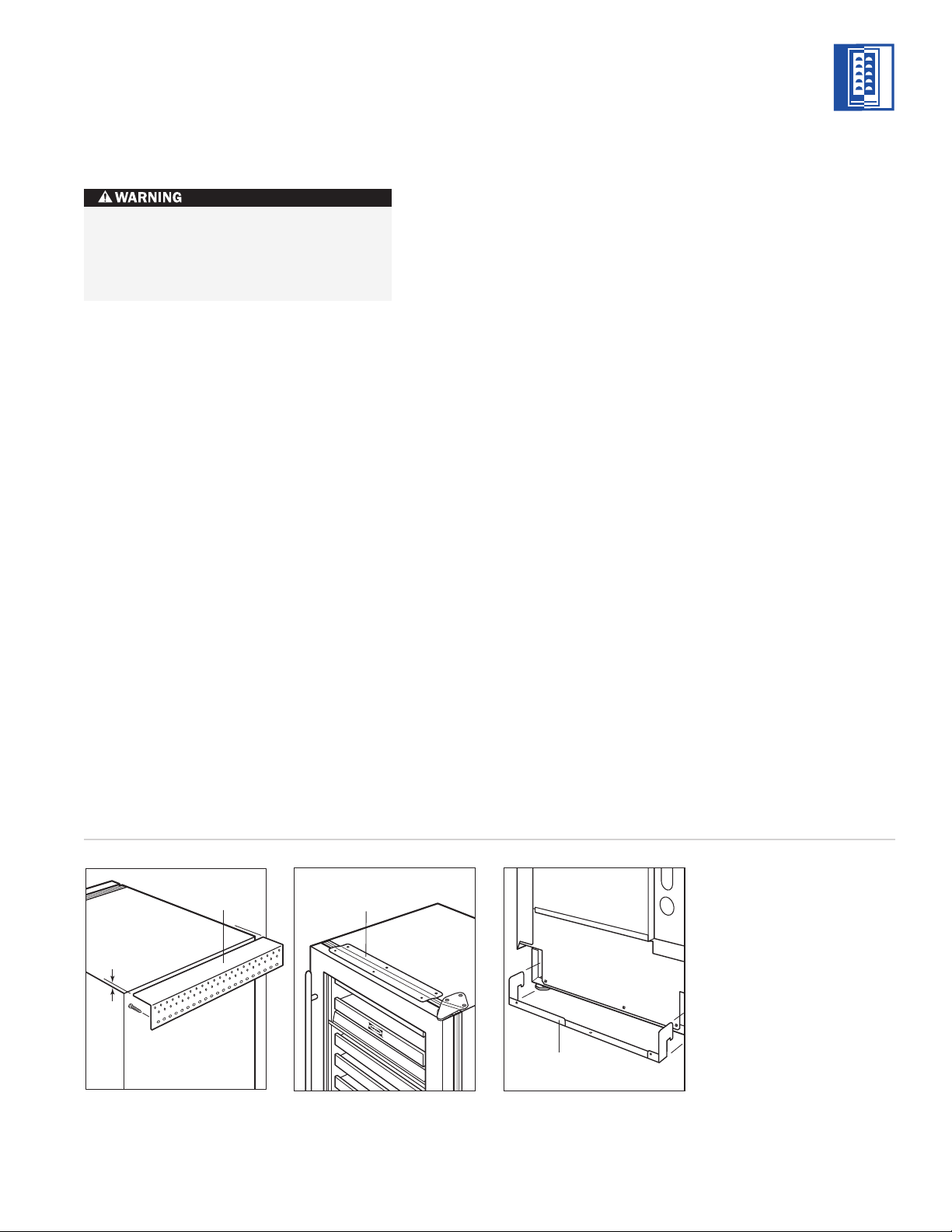

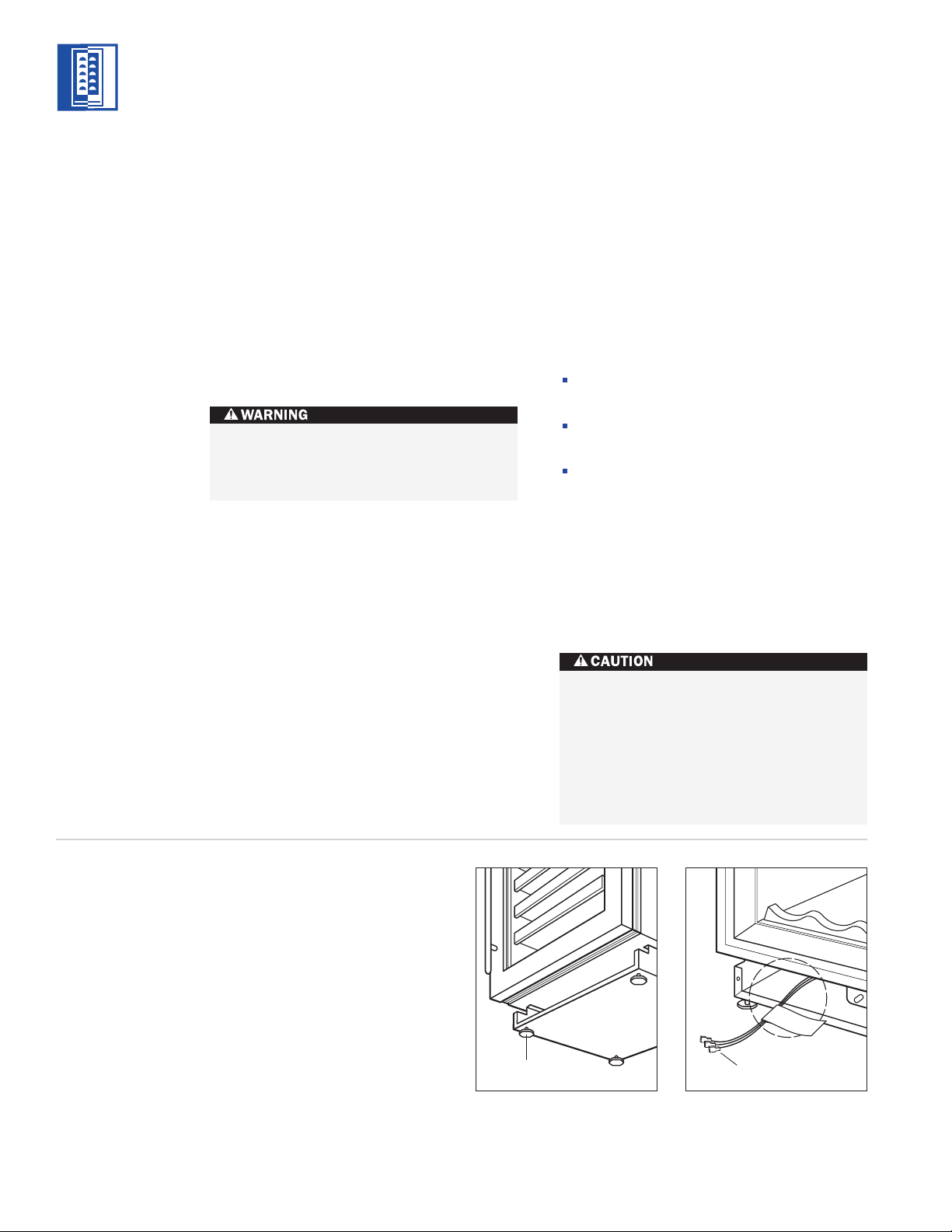

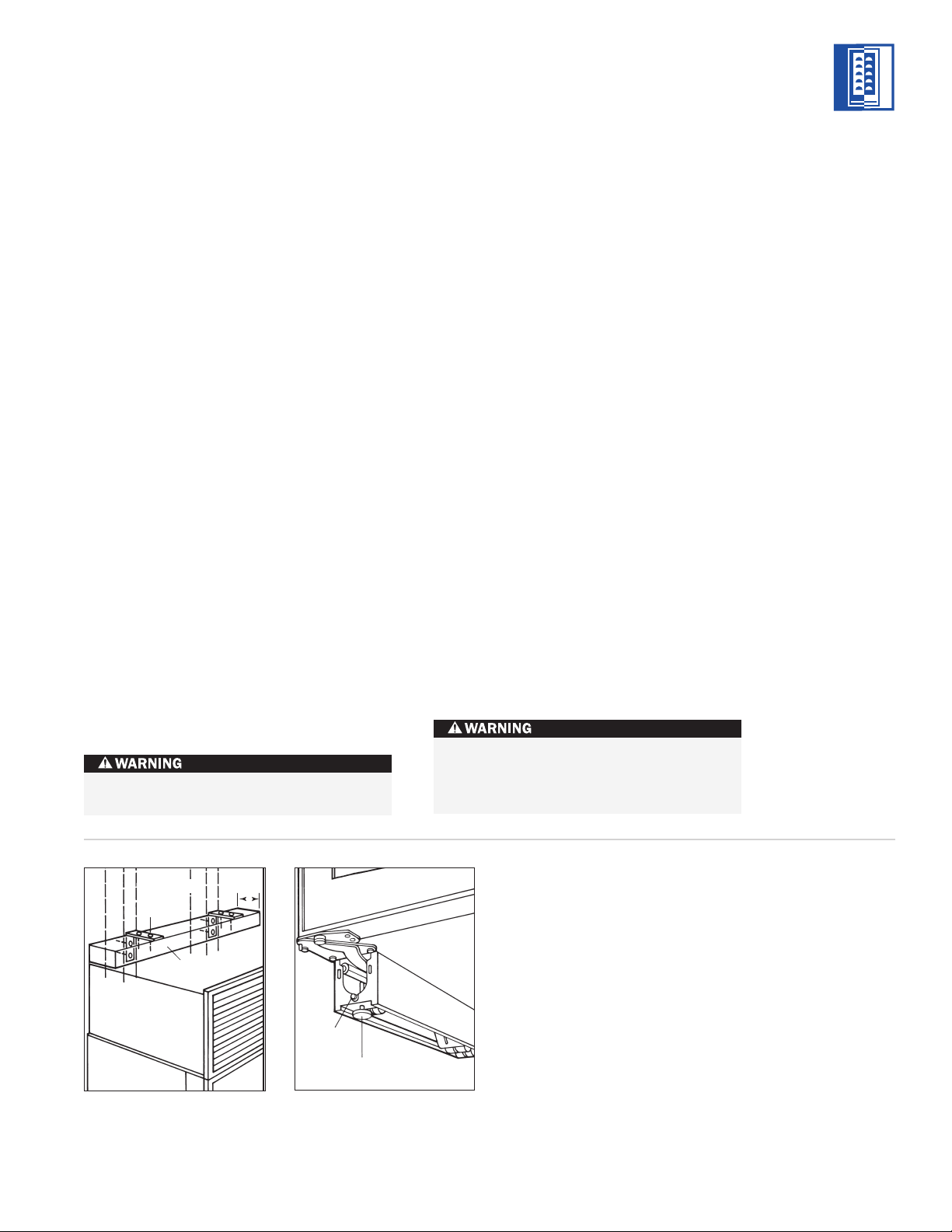

ANTI-TIP BRACKET

INSTALLATION

An anti-tip bracket and hardware is provided

with the Wine Storage unit. The anti-tip

bracket must be installed on a solid base to

prevent tipover in case several loaded wine

shelves are extended at the same time.

MODEL ICB424

The anti-tip bracket should be attached to the

wall behind the unit with the bracket flange

located immediately above the top of the unit.

Refer to illustration 1 below.

A smaller metal ‘countertop’ bracket is also

provided with the Model ICB424, for installations that need to be modified to provide a

secure surface for attaching the bracket. This

bracket will secure the front of the unit to the

underside of the countertop, above the unit.

Refer to illustration 2.

MODEL ICB424FS

If you are installing the Model ICB424FS in a

space deeper than 625 mm, the anti-tip bracket

must be installed no more than 625 mm deep,

so it engages the unit properly. It is important

that this measurement be made from the front

surface of the door, to the back of the anti-tip

bracket. Refer to illustration 3 below.

To prevent the unit from tipping forward

and provide a stable installation, the unit

must be secured in place with the anti-tip

bracket.

6 mm

Anti-Tip

Bracket

Countertop

Bracket

Anti-Tip Bracket

Illus. 1 Illus. 2 Illus. 3

MODELS

ICB424

ICB424FS

Page 6

Installation for Concrete Wedge Anchors:

1)

Drill a 10 mm diameter hole any depth

exceeding the minimum embedment.

Clean the hole or continue drilling additional depth to accommodate drill fines.

Use a carbide drill bit.

2)

Assemble the washer and nut flush with the

end of anchor to protect threads. Drive the

anchor through the material to be fastened

until the washer is flush with the surface

material.

3)

Expand the anchor by tightening the nut

3–5 turns past hand-tight position or to

34 newtons of torque.

6

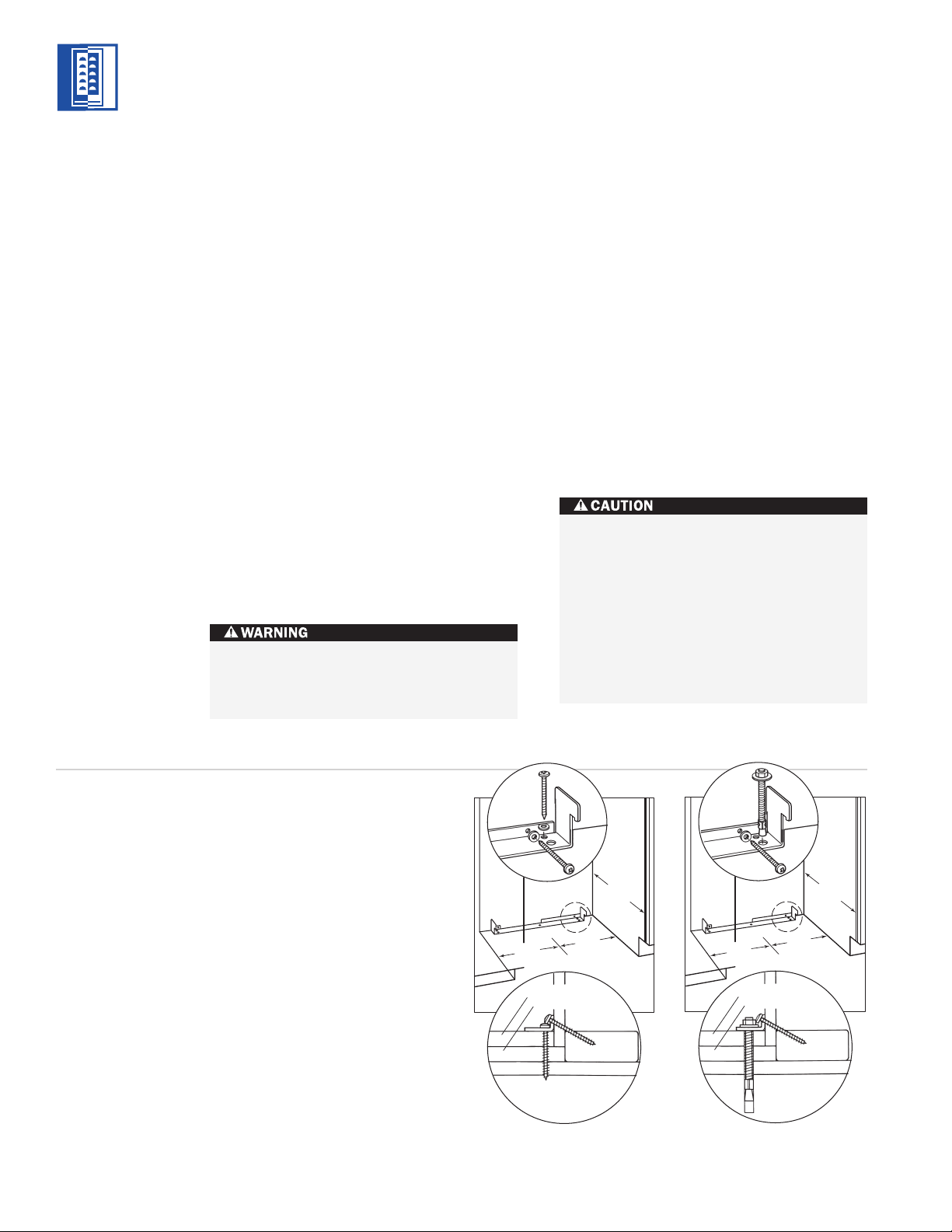

MODELS ICB424 AND ICB424FS INSTALLATION

ANTI-TIP BRACKET

INSTALLATION

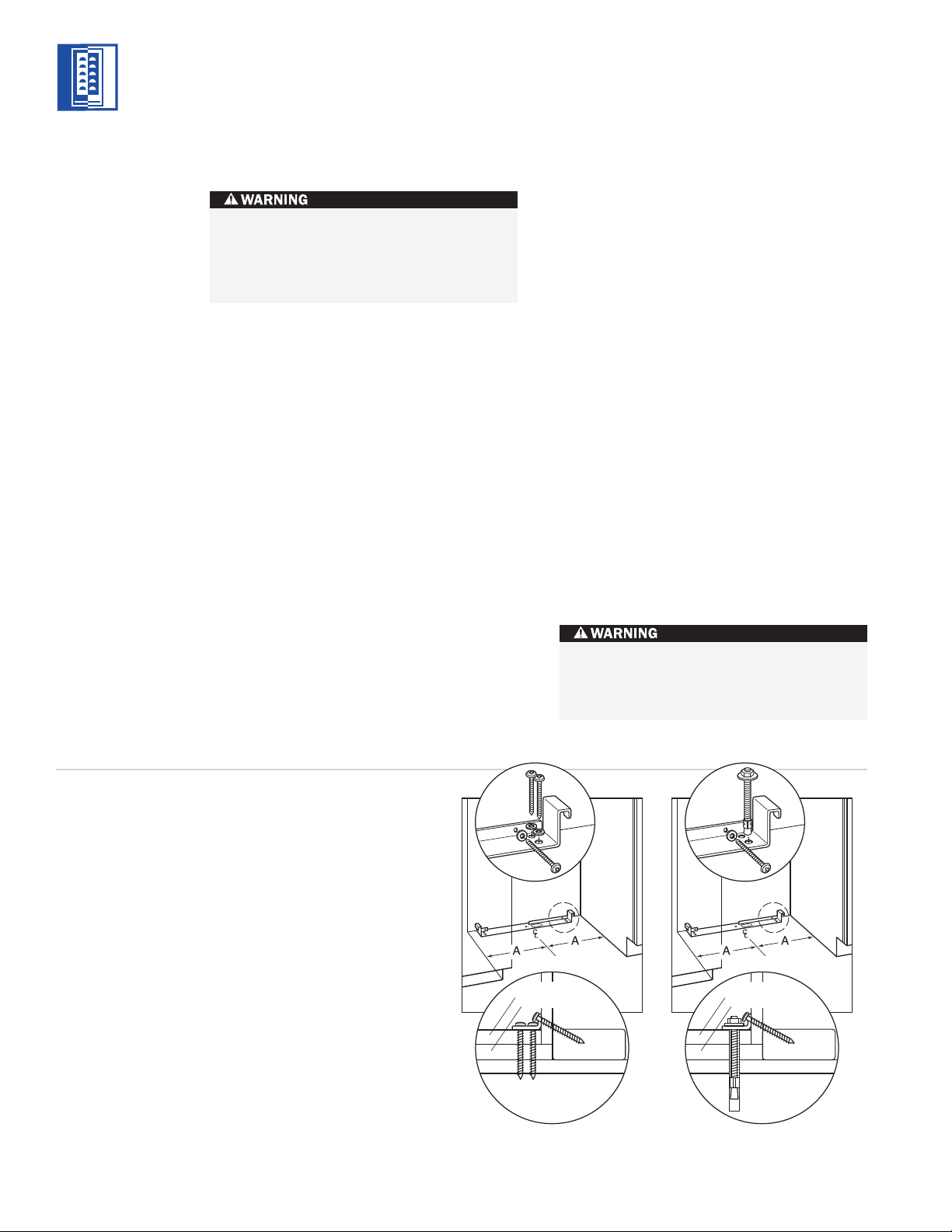

WOOD FLOOR APPLICATIONS

Use the four #12 x 64 mm wood screws and

the four 6 mm flat washers provided. Drill pilot

holes 5 mm diameter maximum, and be sure

that the screws penetrate through the flooring

material and into the wall plate a minimum of

19 mm. Be sure that the screws hold tight.

Refer to illustration 4 below.

CONCRETE FLOOR APPLICATIONS

Use the two 10 mm x 95 mm concrete wedge

anchors, two #12 x 64 mm wood screws and

two 6 mm flat washers provided. Be sure that

the anchors and screws hold tight. Refer to

illustration 5 below.

IMPORTANT NOTE:

In some installations

the subflooring or finished floor may require

angling the wood screws used to fasten the

anti-tip bracket to the back wall. Refer to

illustrations 4 and 5.

310

mm

310

mm

610

mm

C

L

WOOD FLOOR

Finished Flooring

Underlayment

Sub Flooring

Wall Plate

Illus. 4 Illus. 5

Make sure that there are no electrical

wires in the area which the screws could

penetrate.

Always wear safety glasses and use other

necessary protective devices or apparel

when installing or working with anchors.

Anchors are not recommended for use in

lightweight masonry material such as

block or brick, or for use in new concrete

which has not had sufficient time to cure.

The use of core drills is not recommended

to drill holes for the anchors.

MODELS

ICB424

ICB424FS

C

L

310

mm

Finished Flooring

Underlayment

38

mm

CONCRETE

min

FLOOR

310

mm

Wall Plate

Sub Flooring

610

mm

Page 7

7

MODELS ICB424 AND ICB424FS INSTALLATION

LOCK INSTALLATION

IMPORTANT NOTE:

If you are adding an

accessory lock kit to your Wine Storage unit,

it should be installed before you position the

unit. Installation instructions are included with

the lock kit.

For Model ICB424, the lock is attached to the

bottom of the metal door frame. The decorative door panel is not involved in the installation or operation of the lock. The catch portion

of the lock is attached to the bottom of the

appliance cabinet in pre-punched holes. When

installing the lock kit, it may be helpful to tip

the unit on its back for easier access.

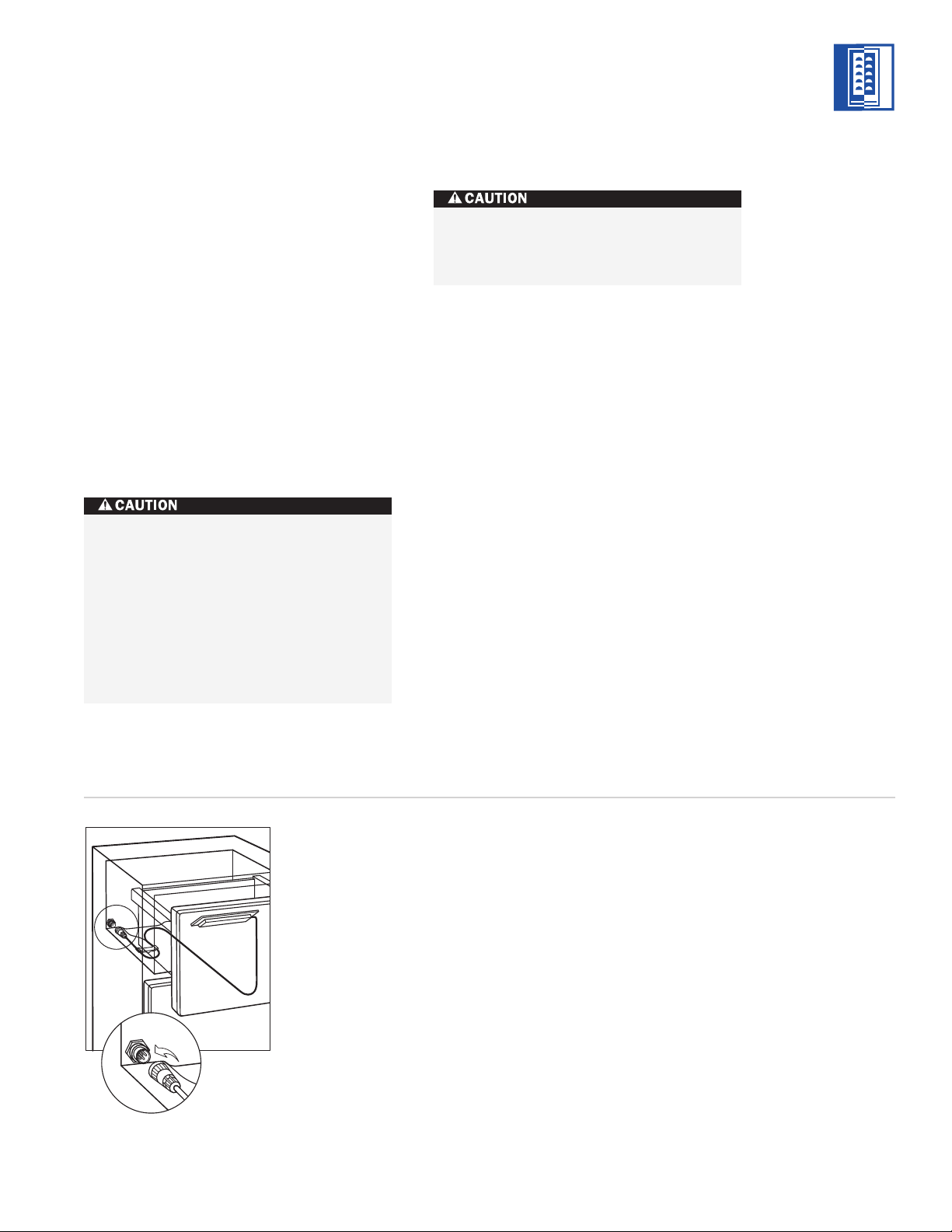

POSITION THE UNIT

IMPORTANT NOTE:

If for any reason the Wine

Storage unit has been laid on its back or side,

you must allow the unit to stand upright for

a minimum of 24 hours before connecting

power.

Plug the power supply cord into the 10 amp

grounded electrical outlet. With power applied

to the appliance, check for lighting and cooling

before going any further. Once you are satisfied that the unit is operating properly, shut

off power to the electrical outlet at the circuit

breaker and proceed.

If a home alarm system is to be used with the

Wine Storage unit, the lead wires should be

threaded into the compressor compartment

before you position the unit. See Home Alarm

Connections on page 8, for the location of

these lead wires. After the unit is in position,

the alarm wiring can be completed from the

front.

Pre-level the Wine Storage unit before sliding

it into position. Leveling cannot be completed

with the unit pushed back in the installation

opening.

For Model ICB424FS, adust the leveling legs

so the top of the unit is no more than 879 mm

above the floor. This is to allow the unit to

engage the anti-tip bracket properly. Center the

Model ICB424FS in front of the anti-tip bracket.

Slide the unit into position, making sure the

anti-tip bracket is engaged properly.

IMPORTANT NOTE:

When the Wine Storage

unit is installed, the anti-tip bracket will be

positioned just below the engaging bracket

on the unit. It is not necessary to raise the

unit up so that it locks into the anti-tip bracket,

but the unit must be in alignment with the

anti-tip bracket.

The Wine Storage unit provides the best

access to its contents when the front surface

of the door panel extends out from surrounding cabinets approximately 6 mm. For Model

ICB424FS, if there are no surrounding cabinet

surfaces to gauge depth, slide the unit back

until it engages the anti-tip bracket.

IMPORTANT NOTE:

The floor under the Wine

Storage unit must be at the same level as the

surrounding finished floor to allow for removal

of the unit for servicing.

Shut off the power to the electrical outlet.

MODELS

ICB424

ICB424FS

Page 8

8

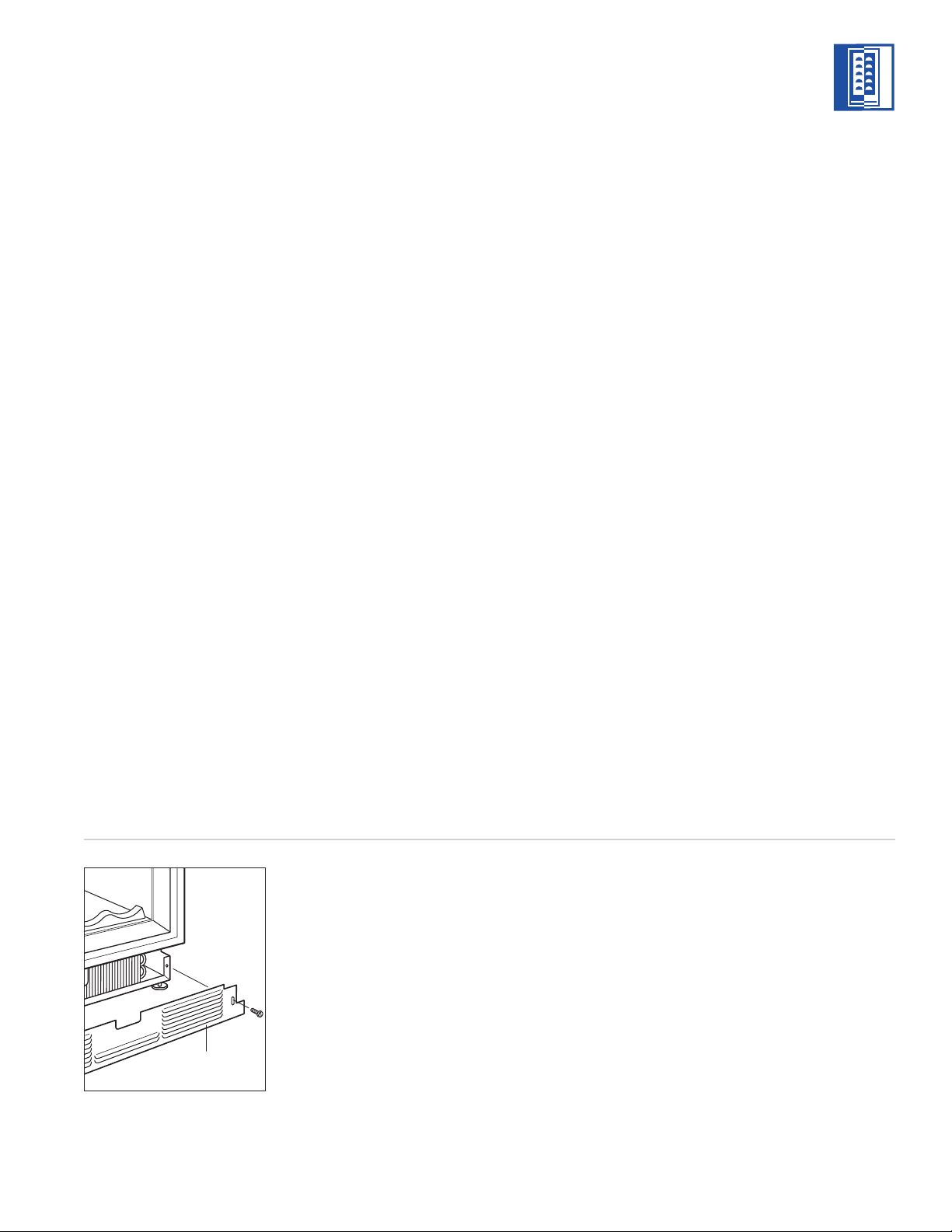

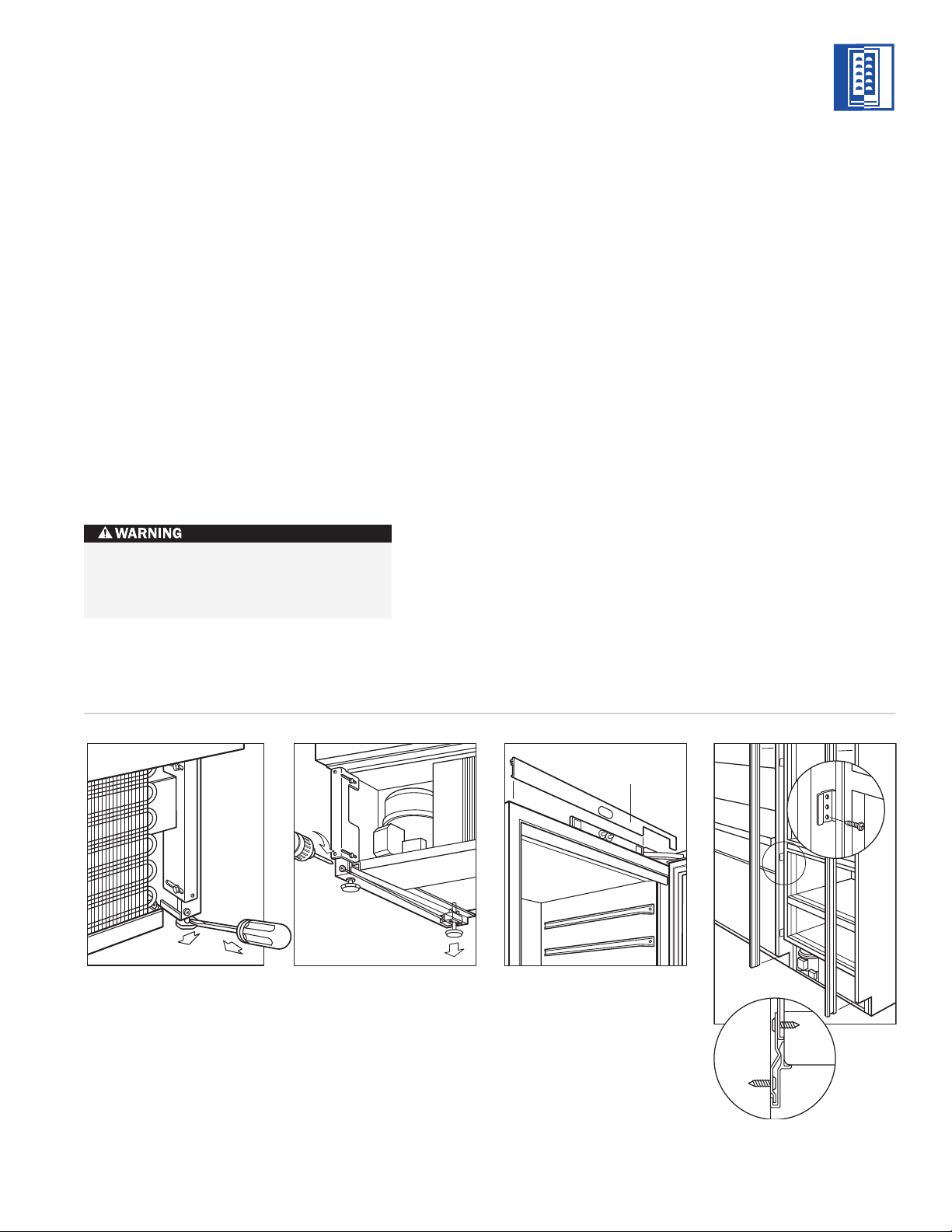

LEVEL THE UNIT

Using an adjustable wrench or pliers, turn

each of the four leveling legs clockwise to raise

the unit and counterclockwise to lower the

unit. For the location of the leveling legs, see

illustration 6 below.

For Model ICB424, the countertop bracket

should be used to make a solid installation.

Refer to illustration 2 on page 5. If this is not

possible, wedge shims along the sides and

top.

MODELS ICB424 AND ICB424FS INSTALLATION

Leveling Legs

Home Alarm

Connections

Illus. 6 Illus. 7

HOME ALARM CONNECTIONS

Before the kickplate is installed, all necessary

wiring connections in the compressor compartment should be completed.

If a home alarm system is to be installed on

the Wine Storage unit, the connections should

be made using the logic supplied with the

alarm specifications. See illustration 7 below

for the appliance lead locations, and refer to

the following for color codes:

Normally open contacts – white with red

stripe wire

Normally closed contacts – white with blue

stripe wire

Common – gray with white stripe wire

Use the 6 mm spade terminals or wire nuts

provided to make the proper wiring connections.

IMPORTANT NOTE:

If you are not responsible

for alarm system connection, this information

should be supplied to the home security

system contractor.

To reduce the possibility of the unit

tipping forward, the front leveling legs

must be in contact with the floor.

The alarm circuit in the unit is intended as

a low-voltage, low-current device only. It

should not be used to switch line power.

Any unused terminals should be

completely insulated and all wires should

be secured away from conductive or

moving components.

MODELS

ICB424

ICB424FS

Page 9

9

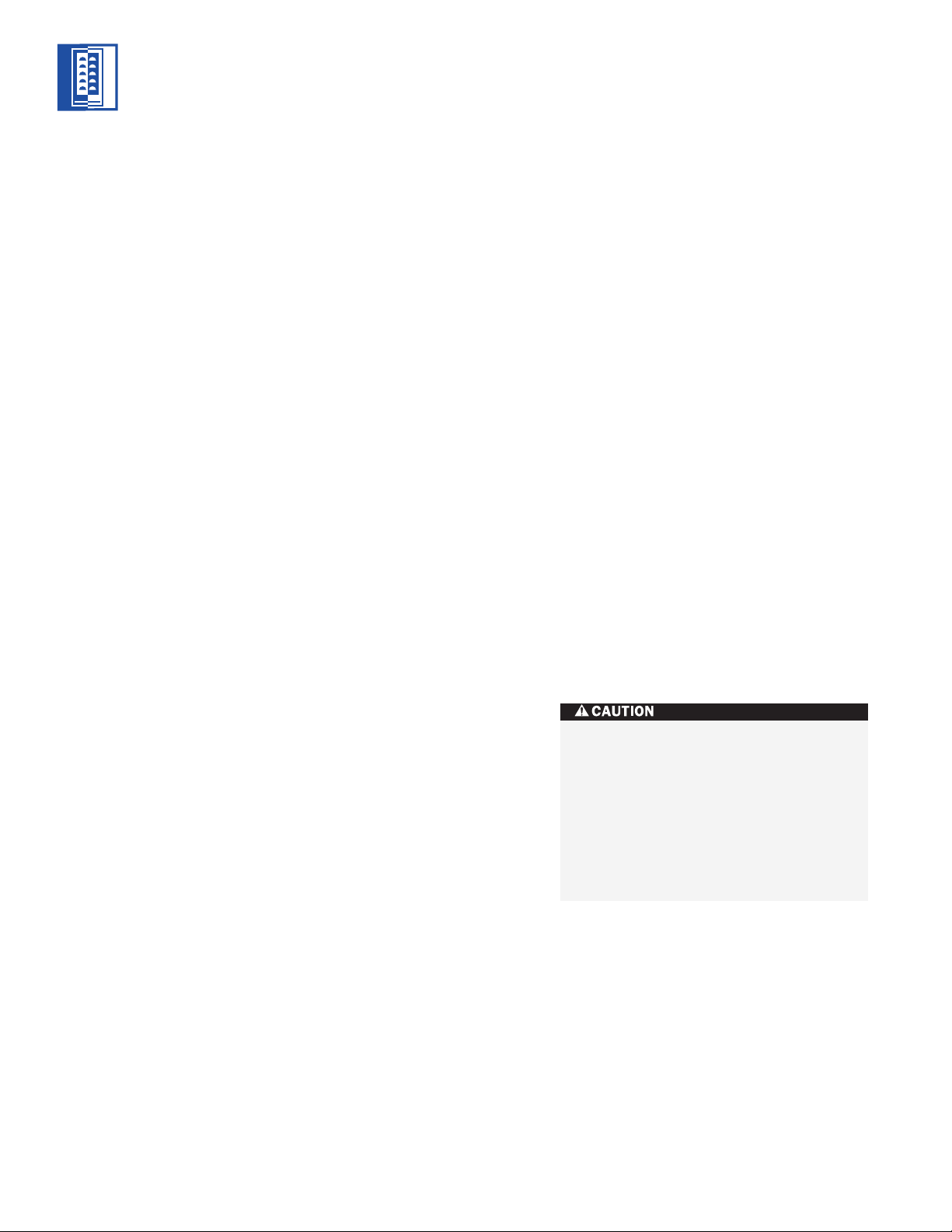

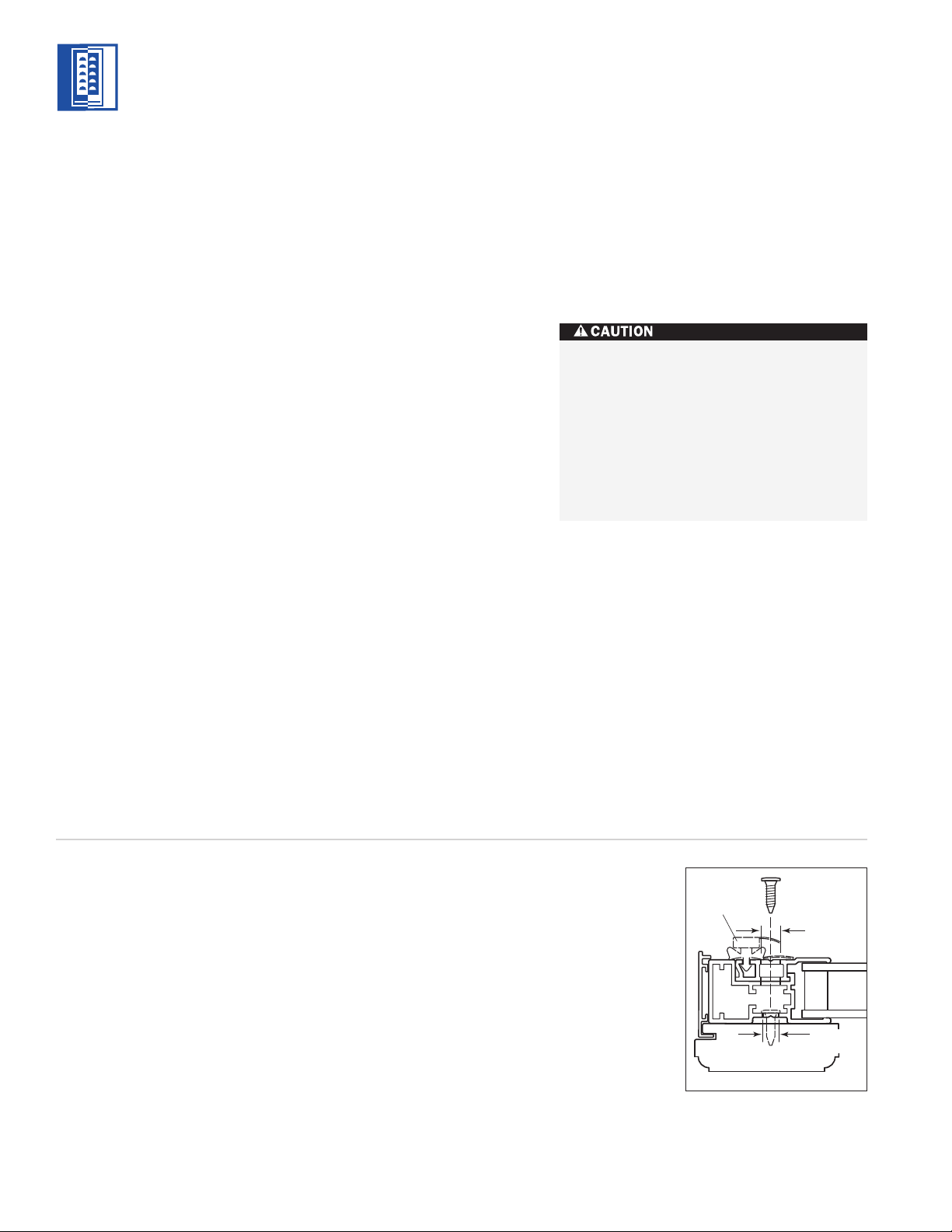

KICKPLATE INSTALLATION

Once the unit is leveled and wiring connections

made, the kickplate can be installed. Use the

two #10 x 13 mm stainless steel screws that

are provided with the kickplate. Refer to illustration 8 below.

IMPORTANT NOTE:

The kickplate must be

removed for servicing. The floor cannot interfere with removal. The louvered section of the

kickplate must not be covered so as to prevent

air circulation.

Turn power back on to the electrical outlet.

MODELS ICB424 AND ICB424FS INSTALLATION

Kickplate

Illus. 8

DOOR PANELS – MODEL ICB424

Model ICB424 is offered in two design applications; stainless steel (/S) and overlay (/O). Each

of these designs are available as a glass door

(G) model.

The stainless steel Model ICB424 is available in

the classic finish only and is shipped from the

factory with the decorative stainless steel door

panel and matching handle in place.

The overlay Model ICB424/O is designed to

accept a decorative door panel to match

surrounding cabinetry. The door panel and

the handle will be provided by the customer.

The solid door Model ICB424S—with no glass

window—requires a different door panel than

the glass door design.

Before beginning installation, check for the

correct components for the fit and finish

desired. All overlay doors require a decorative

panel 603 mm by 764 mm and a minimum

16 mm thick.

If you have questions, contact your Sub-Zero

dealer or cabinet supplier. Additional panel

information can be found in the Sub-Zero

Design Guide.

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

MODELS

ICB424

ICB424FS

Page 10

10

MODELS ICB424 AND ICB424FS INSTALLATION

MODELS

ICB424

ICB424FS

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

IMPORTANT NOTE:

After the first three or

four mounting screws are in place, but not

completely tightened, close the door and check

your panel fit. This is the time to make small

adjustments. Once you are satisfied with the

appearance, open the door and apply the

remainder of the screws. Check all screws for

tightness.

The metal frame on the glass door has

numerous mounting holes on each side of the

door. This is to accommodate the Sub-Zero

accessory handles and provide for easy attachment of the handle through the door frame.

If you choose not to use the pre-drilled handle

mounting holes, it will be necessary to fasten

the handle from the rear of the door panel

only, or drill one or more additional holes

through the metal frame of the glass door.

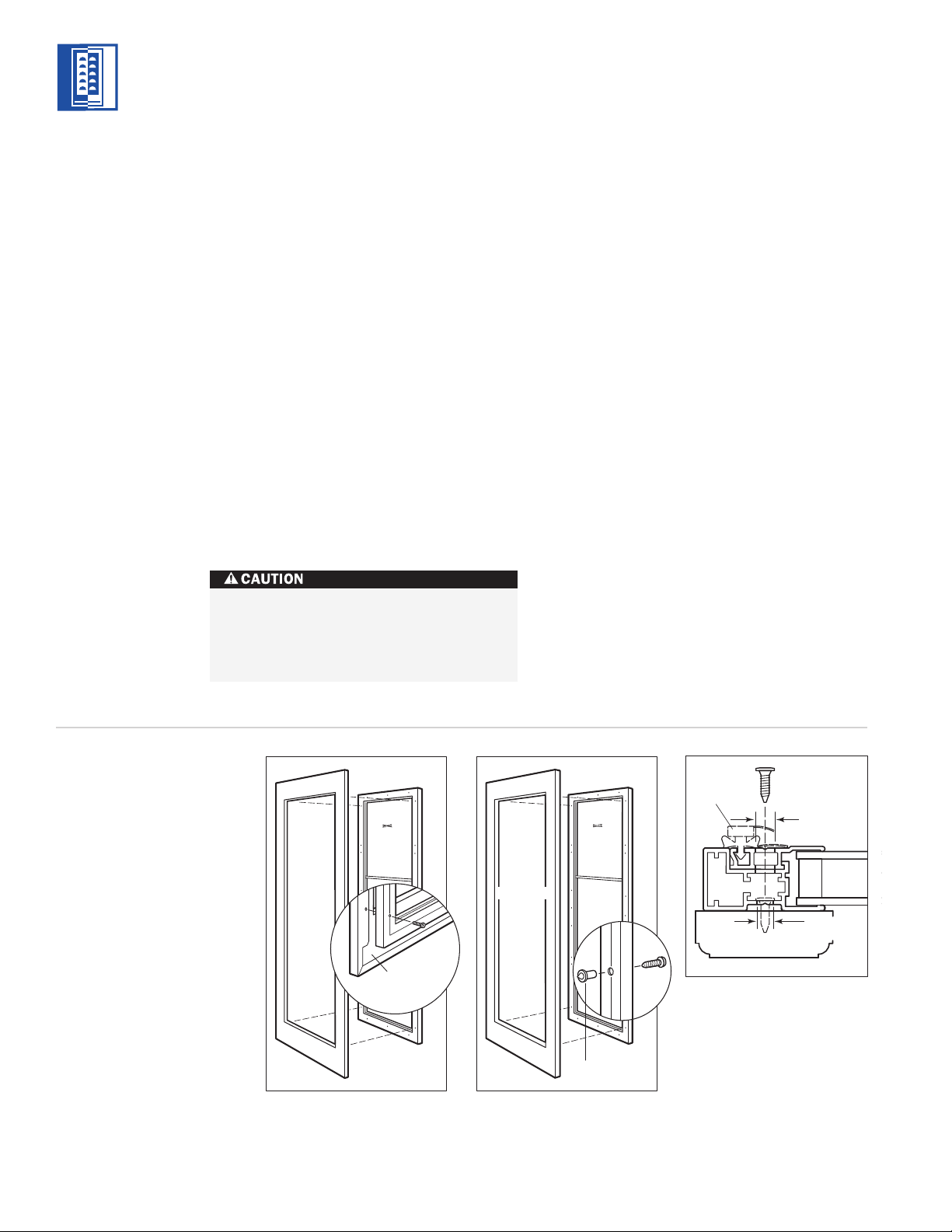

Illustration 10 on page 11 shows how this

hole passes through the door frame. The hole

center is on the small locator groove in the

front of the frame. A 6 mm diameter hole is

made in the front wall of the extrusion and

an 11 mm diameter hole through the rest

of the frame.

OVERLAY DOOR PANELS

OVERLAY GLASS DOOR – MODEL ICB424

Inspect the door panel for the minimum 16 mm

thickness, the finished inside edge and the 5 kg

weight limit. See the Wine Storage section of

the Sub-Zero Design Guide for additional panel

information.

Decide if the handle will be attached through

the glass door frame or just through the decorative door panel. If it is just through the door

panel, the handle must be attached first.

Decorative panels are attached to the Model

ICB424 door using #8 x 16 mm square drive

screws passing through the door frame from

the rear, behind the gasket into the panel. The

door panel is marked for screw locations by

the use of ‘tenon centers’, which are temporarily inserted into the 6 mm diameter holes in

the front of the glass door frame. Refer to illustration 9 on page 11.

With the Wine Storage unit secured in position

and the door closed, the panel is held in the

desired position on the door and rapped by

hand from the front, putting center marks on

the rear surface of the panel. If the door panel

is made of such a material that pre-drilling is

needed, all of the mounting holes should be

marked. If not, only enough holes to hold the

panel in place temporarily, are necessary.

The door panel is then lowered from the door

frame, tenon centers removed, the door

opened and the screws driven into the panel

through the black tape on the door frame,

using the center marks to locate the screws.

The screw holes inside the door are hidden

under a cover flap on the door gasket. It is

necessary to lift the flap to insert the screws.

Use as many screws as necessary to hold the

door panel in place properly.

The wine storage unit door is made with

a sealed double wall tempered glass core.

The drill must not contact this core when

drilling. Be sure the hole is centered on

the small groove in the front of the door

frame and the drill passes squarely

through the frame. If you are inexperienced with drilling, fasten the handle

from the rear of the door panel only.

Page 11

Door

Frame

Overlay

Panel

Tenon Center

6 mm

Diameter

11 mm

Diameter

Glass

Gasket

Illus. 9 Illus. 10

IMPORTANT NOTE:

Install screws in all the

mounting holes in the door frame. The nature

of the door panel with a narrow outer rim and

no connecting center member requires the

support provided by the glass door.

After the door panel installation is complete,

apply the cover patches or plugs provided over

the holes on the inside surface of the door.

OVERLAY SOLID DOOR – MODEL ICB424

IMPORTANT NOTE:

The solid door panel for

the Model ICB424 must be a minimum of 16

mm thick and cannot exceed 9 kg.

Installation of the solid door panel is the same

as the door panel for a glass door model.

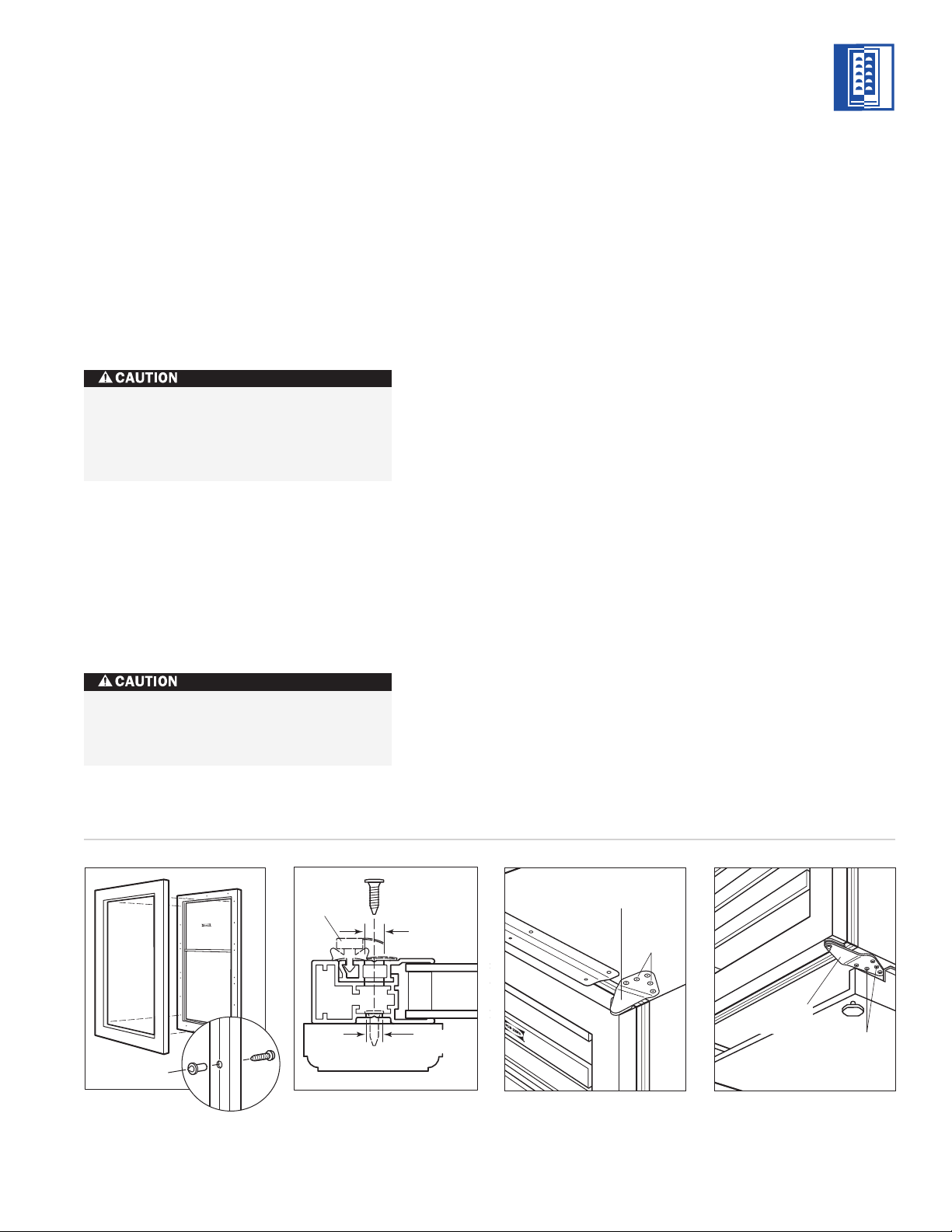

HINGE ADJUSTMENT

IMPORTANT NOTE:

The Wine Storage unit

must be installed and leveled before door

hinge adjustments can be made.

The top and bottom cabinet hinges on Models

ICB424 and ICB424FS are held in place with

three permanent adjustment screws and two

shipping screws. Refer to illustrations 11 and

12 below. The shipping screws must be

removed and discarded to adjust the door

alignment and fit. If no adjustments are necessary, it is recommended that all five screws

remain in place.

On the Model ICB424FS, only the bottom door

hinge can be adjusted. Remove and discard

the two shipping screws and loosen the three

hinge screws to adjust the door. Refer to

illustration 12.

COMPLETING THE INSTALLATION

IMPORTANT NOTE:

When you have

completed the installation of the Model ICB424

or ICB424FS Wine Storage unit, refer to pages

34–35 for the Installation Checklist and Service

Information.

A solid panel must not be installed on a

glass door unit, as this may cause

moisture to form behind the panel.

The cover patches or plugs are part of the

insulation system on the door of the Wine

Storage unit. Be sure to cover all the

holes in the door that were used.

11

MODELS ICB424 AND ICB424FS INSTALLATION

MODELS

ICB424

ICB424FS

Top Door Hinge

Shipping

Screws

Shipping

Screws

Bottom

Door Hinge

Illus. 11 Illus. 12

Page 12

12

SITE PREPARATION

Make sure that the finished rough opening

where the Wine Storage unit is to be installed

is properly prepared. Refer to the Installation

Specifications illustration for rough opening

dimensions, door swing clearance and electrical placement for Models ICB427 and ICB427R.

IMPORTANT NOTE:

To operate properly, the

door must open a minimum of 90 degrees.

Use a minimum 51 mm filler in corner installations to assure a 90-degree door opening.

Allow enough clearance in front of the unit for

full door swing.

IMPORTANT NOTE:

Make sure the floor under

the unit is level with the surrounding finished

floor.

MODELS ICB427 AND ICB427R INSTALLATION

686 mm

ROUGH OPENING WIDTH

635 mm

ROUGH

OPENING

DEPTH

606 mm

90˚

105˚

MAXIMUM

DOOR SWING

889 mm

DOOR CLEARANCE

711 mm

DOOR CLEARANCE

648 mm 648 mm

394 mm

LOCATE ELECTRICAL

WITHIN SHADED AREA

E

114

mm

64 mm

ANTI-TIP BRACKET

FRONT VIEW

TOP VIEW

2032 mm

ROUGH OPENING

HEIGHT

TO FINISHED

FLOORING

2019 mm

MIN HEIGHT

REQUIRED

Do not load wine into the Wine Storage

unit until the installation is complete.

MODELS ICB427 AND ICB427R

INSTALLATION SPECIFICATIONS

NOTE: Door swing clearances are based on stainless

steel door and handle dimensions.

MODELS

ICB427

ICB427R

Page 13

13

ELECTRICAL REQUIREMENTS

A 220-240 V AC, 50/60 Hz, 10 amp circuit

breaker and electrical supply are required. A

separate circuit, servicing only this appliance,

is required.

The power supply cord has a grounding plug,

which must be plugged into a mating ground ing-type wall recep tacle. Follow all National

Electrical codes and local codes and ordinances when installing the receptacle. For

location of the electrical supply, refer to

the Installation Specifications illustration on

page 12.

IMPORTANT NOTE:

A ground fault circuit

interrupter (GFCI) is not recommended and

may cause interruption of operation.

HOME ALARM SYSTEM

If a home alarm system is to be used, refer to

Other Wiring Connections on page 18. In

addition to operating power, the installer may

also be required to supply a home automation

system lead to the unit. This is for a lowvoltage, low-current signal similar to door and

window sensor signals. Common, normally

open and normally closed contact configurations are provided.

Three 6 mm female spade connectors are

located in the compressor compartment and

are accessible behind the kickplate/grille on

Models ICB427 and ICB427R. A minimum of

914 mm of lead wire should be provided for

each contact, exiting the back wall near the

electrical outlet.

UNPACKING AND MOVING

Uncrate the unit, remove its wood base and

discard the shipping bolts that hold the wood

base to the bottom of the unit. Remove all

packing materials and tape.

IMPORTANT NOTE:

Do not discard the

kickplate/grille, anti-tip bracket and hardware.

These items will be needed for the installation.

All roller-assembly wine shelves should be

removed to reduce weight and prevent them

from rolling. To remove, pull the shelf out to

its full extension, gently and evenly lift up on

both sides of the front of the shelf and remove.

Reverse the procedure to reinstall the shelf.

Retract the front leveling legs to allow you to

move the unit more easily during installation.

You will extend the leveling legs when the unit

is in its final position to reduce the possibility

of the unit tipping forward.

Use an appliance dolly to move the Wine

Storage unit. Position the dolly at the side of

the unit to prevent damage to finished

surfaces.

MODELS ICB427 AND ICB427R INSTALLATION

Before moving the Wine Storage unit into

position, protect any finished flooring

with appropriate materials.

Do not use an extension cord. Electrical

ground is required on this appliance.

MODELS

ICB427

ICB427R

Page 14

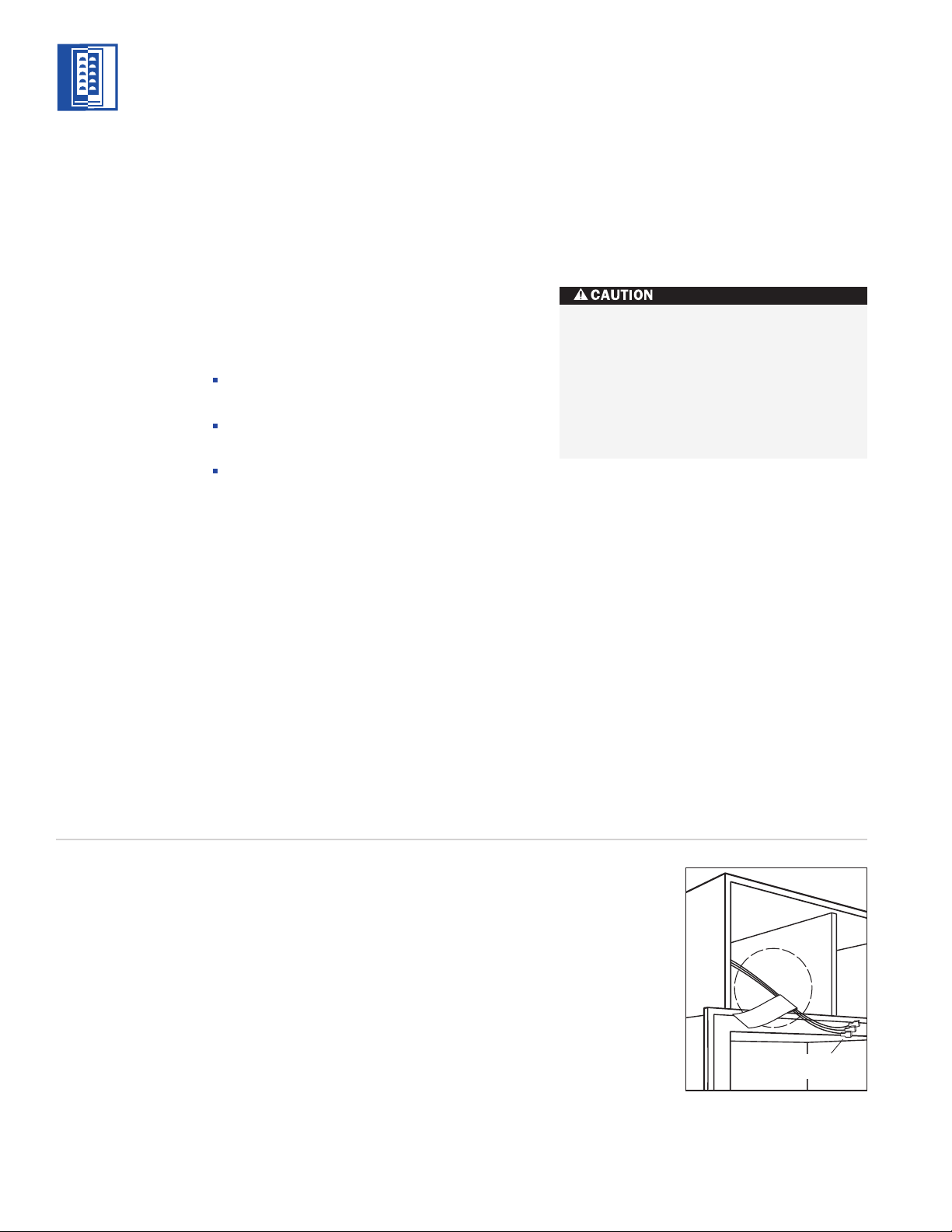

WOOD FLOOR APPLICATIONS

Use the six #12 x 64 mm wood screws and the

six 6 mm flat washers provided. Drill pilot

holes 5 mm diameter maximum, and be sure

that the screws penetrate through the flooring

material and into the wall plate a minimum of

19 mm. Be sure that the screws hold tight.

Refer to illustration 1 below.

CONCRETE FLOOR APPLICATIONS

Use the two 10 mm x 95 mm concrete wedge

anchors, two #12 x 64 mm wood screws and

two 6 mm flat washers provided. Be sure that

the anchors and screws hold tight. Refer to

illustration 2 below.

IMPORTANT NOTE:

In some installations the

subflooring or finished floor may require

angling the wood screws used to fasten the

anti-tip bracket to the back wall. Refer to illustrations 1 and 2 below.

14

MODELS ICB427 AND ICB427R INSTALLATION

ANTI-TIP BRACKET

INSTALLATION

An anti-tip bracket and hardware is provided

with the Wine Storage unit. The anti-tip

bracket must be installed on a solid base to

prevent tipover in case several loaded wine

shelves are extended at the same time.

If you are installing the Model ICB427 or

ICB427R in a space deeper than 610 mm, the

anti-tip bracket must be installed no more than

610 mm deep, so it engages the unit properly.

It is important that this measurement be made

from the front of the unit without panels, to

the back of the anti-tip bracket.

To prevent the unit from tipping forward

and provide a stable installation, install

the anti-tip bracket and extend the front

leveling legs to the floor.

Make sure that there are no electrical

wires in the area which the screws could

penetrate.

MODELS

ICB427

ICB427R

Illus. 1 Illus. 2

SPECIFICATIONS

Dimension A 343 mm

Finished Flooring

Underlayment

Wall Plate

Subflooring

WOOD FLOOR

Finished Flooring

Underlayment

38

mm

CONCRETE

min

FLOOR

Wall Plate

Subflooring

Page 15

15

MODELS ICB427 AND ICB427R INSTALLATION

POSITION THE UNIT

IMPORTANT NOTE:

For Model ICB427R, the

top drawer has a control cable that needs to be

disconnected before removing this drawer.

Refer to illustration 3 below for placement and

how to disconnect this fitting.

For Model ICB427R, the drawers should be

placed aside until you are ready for installation

of the door and drawer panels.

IMPORTANT NOTE:

When two Model ICB427,

ICB427R or Integrated units are installed closer

than 51 mm to one another, it is necessary to

use the Sub-Zero dual installation heater kit.

Contact your Sub-Zero dealer for the proper

components and additional instructions. The

heater plate from this dual installation heater

kit must be attached to the left side exterior of

the right hand unit before the unit is slid into

position.

Illus. 3

Always wear safety glasses and use other

necessary protective devices or apparel

when installing or working with anchors.

Anchors are not recommended for use in

lightweight masonry material such as

block or brick, or for use in new concrete

which has not had sufficient time to cure.

The use of core drills is not recommended

to drill holes for the anchors.

Installation for Concrete Wedge Anchors:

1)

Drill a 10 mm diameter hole any depth

exceeding the minimum embedment. Clean

the hole or continue drilling additional

depth to accommodate drill fines. Use a

carbide drill bit.

2)

Assemble the washer and nut flush with the

end of anchor to protect threads. Drive the

anchor through the material to be fastened

until the washer is flush with the surface

material.

3)

Expand the anchor by tightening the nut

3–5 turns past hand-tight position or to 34

newtons of torque.

Before moving the Wine Storage unit into

position, secure the door closed. Remove

the drawers of the Model ICB427R.

MODELS

ICB427

ICB427R

OPTIONAL

COMPONENTS

Optional installation components

are available

through your

Sub-Zero dealer.

You can also visit

our website at

subzero.com.

Page 16

16

POSITION THE UNIT

IMPORTANT NOTE:

If you are adding an

accessory lock kit to your Model ICB427 or

ICB427R, the catch should be installed at the

top of appliance cabinet before you position

the unit. See Lock Installation on page 23.

Installation instructions are included with the

lock kit.

Remove the decorative top and side moldings

and the kickplate/grille of the Wine Storage

unit.

IMPORTANT NOTE:

If for any reason the Wine

Storage unit has been laid on its back or side,

you must allow the unit to stand upright for a

minimum of 24 hours before connecting

power.

Plug the power supply cord into the 10 amp

grounded electrical outlet. With power applied

to the appliance, check for lighting and cooling

before going any further. Once you are satisfied that the unit is operating properly, shut off

power to the electrical outlet at the circuit

breaker and proceed.

If a home alarm system is to be used with the

Wine Storage unit, the lead wires should be

threaded into the compressor compartment

before you position the unit. See Other Wiring

Connections on page 18 for the location of

these lead wires. After the unit is in position,

the alarm wiring can be completed from the

front.

Pre-level the Wine Storage unit before rolling

into position. This is to allow the unit to

engage the anti-tip bracket properly.

Roll the unit into position, making sure the

anti-tip bracket is engaged properly. Screw the

front leveling legs out approximately 5 mm to

make any future adjustments easier.

IMPORTANT NOTE:

When the Wine Storage

unit is installed, the anti-tip bracket will be

positioned just below the engaging bracket on

the unit. It is not necessary to raise the unit up

so that it locks into the anti-tip bracket, but the

unit must be in alignment with the anti-tip

bracket.

IMPORTANT NOTE:

The floor under the Wine

Storage unit must be at the same level as the

surrounding finished floor to allow for removal

of the unit for servicing.

MODELS ICB427 AND ICB427R INSTALLATION

Shut off the power to the electrical outlet.

MODELS

ICB427

ICB427R

Page 17

17

MODELS ICB427 AND ICB427R INSTALLATION

LEVEL THE UNIT

Level the unit by turning the front leveling legs

clockwise to raise the unit, or counterclockwise

to lower it. To assist you in adjusting the front

leveling legs up or down, use a standard

screwdriver blade and place it in the front

leveling leg as shown in illustration 4 below.

The rear leveling legs are adjusted from the

front of the base by turning the Phillips head

screw. Refer to illustration 5.

IMPORTANT NOTE:

The rear leveling legs will

only move 2 mm for every 18 revolutions on

the Phillips head screw. Do not over torque.

Use the lowest torque setting on any power

screwdriver. Do not turn the rear leveling legs

by hand. Damage will occur if you turn these

legs.

To reduce the possibility of the unit

tipping forward, the front leveling legs

must be in contact with the floor.

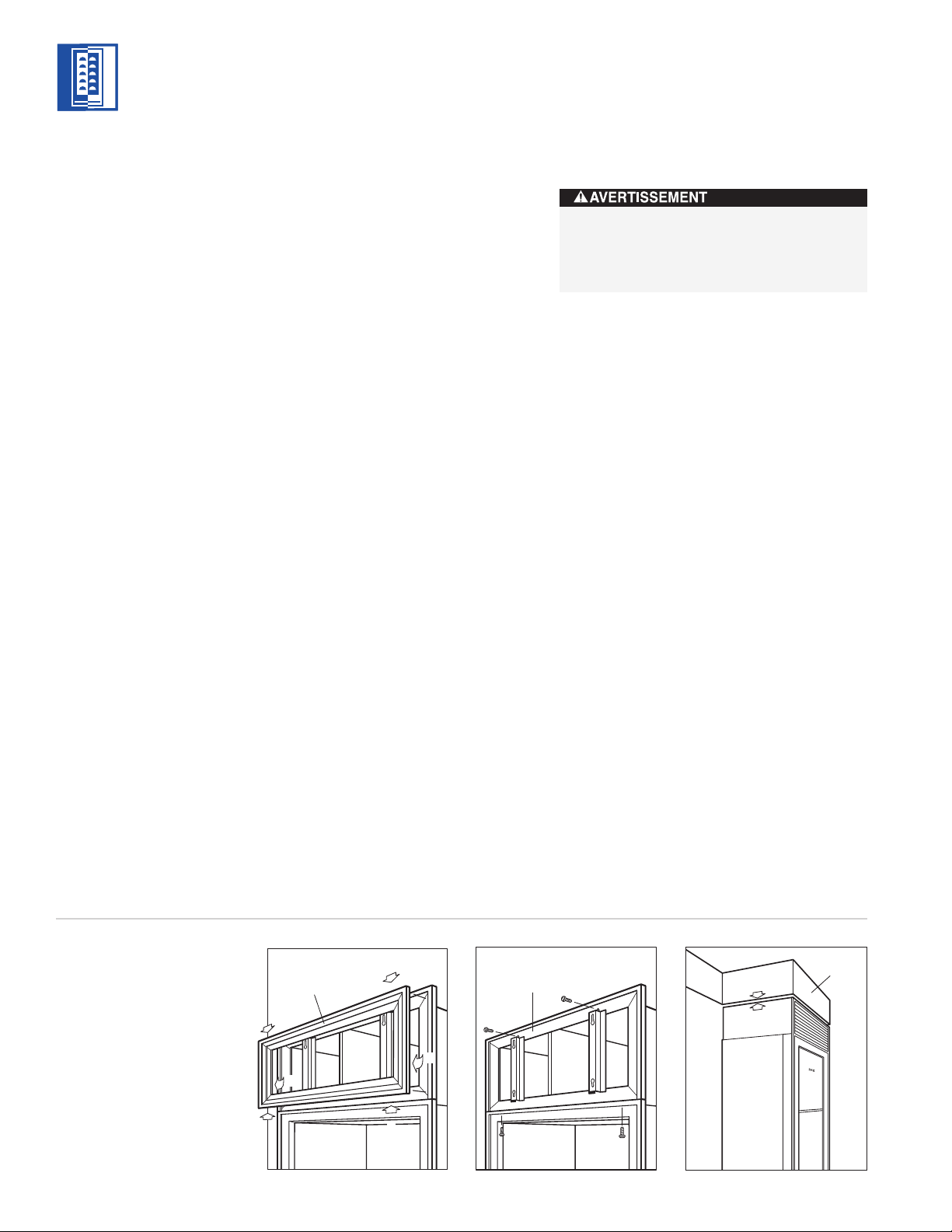

MOLDING INSTALLATION

The decorative white molding strips for the

side and top of Models ICB427 and ICB427R

can be snapped into place. The top molding

piece must be installed before the side

molding can be attached. For installation of the

top molding, refer to illustration 6 below. Refer

to illustration 7 for side molding installation.

For installations where units are side by side,

see Finished Wood Side Panels on page 23.

Illus. 4 Illus. 5 Illus. 6

Illus. 7

MODELS

ICB427

ICB427R

Top Molding

Page 18

IMPORTANT NOTE:

If you are not responsible

for alarm system connection, this information

should be supplied to the home security

system contractor.

18

OTHER WIRING CONNECTIONS

Before the kickplate/grille is installed, all

necessary wiring connections in the compressor compartment should be completed.

If the dual installation heater kit (#7007529) is

used with Model ICB427 or ICB427R, the power

supply leads should be connected according to

instructions included with the kit.

If a home alarm system is to be installed on

the Wine Storage unit, the connections should

be made using the logic supplied with the

alarm specifications. See illustration 8 below

for the appliance lead locations, and refer to

the following for color codes:

Normally open contacts – white with red

stripe wire

Normally closed contacts – white with blue

stripe wire

Common – gray with white stripe wire

Use the 6 mm spade terminals or wire nuts

provided to make the proper wiring connections.

MODELS ICB427 AND ICB427R INSTALLATION

The alarm circuit in the unit is intended as

a low-voltage, low-current device only. It

should not be used to switch line power.

Any unused terminals should be

completely insulated and all wires should

be secured away from conductive or

moving components.

Home Alarm

Connections

Illus. 8

MODELS

ICB427

ICB427R

OPTIONAL

COMPONENTS

Optional installation components

are available

through your

Sub-Zero dealer.

You can also visit

our website at

subzero.com.

Page 19

19

KICKPLATE / GRILLE INSTALLATION

Once the unit is leveled and wiring connections made, the kickplate/grille can be

installed.

IMPORTANT NOTE:

The kickplate/grille must

be removed for servicing. The floor cannot

interfere with removal. The louvered section of

the kickplate/grille must not be covered so as

to prevent air circulation.

For Models ICB427 and ICB427R, there is some

adjustment to the mounting assembly so that

the kickplate/grille can fit flush with the

surrounding area. Refer to illustration 9 below.

IMPORTANT NOTE:

The unit must be allowed

to have ventilation through the fins of the kickplate/grille. You may cover the solid area, but

do not block the fins. For Model ICB427R, the

lower drawer panel may hang in front of the

fins, but your baseboard molding must not

cover them.

Turn power back on to the electrical outlet.

DOOR PANELS

Models ICB427 and ICB427R are available as a

glass door (G) or solid door (S) model. Each of

these Wine Storage units are set up at the job

site as either the stainless steel or integrated

design.

Classic stainless steel panels—available as

sales accessories—may be configured several

ways and are shipped separately. Stainless

steel panels are shipped with matching

handles in place.

The integrated design uses custom wood or

other decorative panels and handles provided

by the customer.

Model ICB427R requires solid panels on the

drawers that may match the door panel, or be

complementary. The Model ICB427R stainless

steel drawer panel set and stainless steel door

panel are ordered and shipped as two items.

The solid door Model ICB427S or ICB427RS—

with no glass window—requires a different

door panel than the glass door design.

Before beginning installation, check for the

correct components for the fit and finish

desired. The door and drawers (Model

ICB427R) require a decorative panel that is a

minimum 16 mm thick.

If you have questions, contact your Sub-Zero

dealer or cabinet supplier. Additional panel

information can be found in the Sub-Zero

Design Guide.

MODELS ICB427 AND ICB427R INSTALLATION

Illus. 9

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

MODELS

ICB427

ICB427R

Page 20

20

STAINLESS STEEL DOOR PANEL

Before installing the stainless steel door panel,

check the panel carefully. Options are available

for kickplate/grille height, overall height, door

swing and door lock.

The stainless steel panel is mounted to the

door by passing the #8–32 x 16 mm screws

provided, through holes in the door frame

from the rear, and into the threaded holes in

the door panel. Refer to illustration 10 below.

The screw holes inside the door are hidden

under a cover flap on the door gasket. It is

necessary to lift the flap to insert the screws.

After the door panel installation is complete,

apply the cover patches or plugs provided over

the holes on the inside surface of the door.

For installation of stainless steel panels on

Model ICB427R drawers, see Model ICB427R

Drawer Panels on page 22.

OVERLAY GLASS DOOR PANEL

Inspect the door panel for the minimum 16

mm thickness, the greater width requirements

for the stiles (to cover the door hinges), and

the finished inside edge. The door panel has a

weight limit of 9 kg. See the Wine Storage

section of the Sub-Zero Design Guide for additional panel information.

Decide if the handle will be attached through

the glass door frame or just through the decorative door panel. If it is just through the door

panel, the handle must be attached first.

If a lock is to be used, the body of the lock

should be installed on the door panel after the

panel is mounted.

Decorative panels are attached to the Model

ICB427 and ICB427R door using #8 x 16 mm

square drive screws passing through the door

frame from the rear, behind the gasket into the

panel. The door panel is marked for screw

locations by the use of ‘tenon centers’, which

are temporarily inserted into the 6 mm

diameter holes in the front of the glass door

frame. Refer to illustration 11 below.

Door

Frame

Stainless

Steel

Panel

Back of

Stainless Steel

Panel

Door

Frame

Integrated

Panel

Tenon Center

6 mm

Diameter

11 mm

Diameter

Glass

Gasket

Illus. 10 Illus. 11

Illus. 12

MODELS ICB427 AND ICB427R INSTALLATION

The cover patches or plugs are part of the

insulation system on the door of the Wine

Storage unit. Be sure to cover all the

holes in the door that were used.

MODELS

ICB427

ICB427R

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

Page 21

21

With the Wine Storage unit secured in position

and the door closed, the panel is held in the

desired position on the door and rapped by

hand from the front, putting center marks on

the rear surface of the panel. If the door panel

is made of such a material that pre-drilling is

needed, all of the mounting holes should be

marked. If not, only enough holes to hold the

panel in place temporarily, are necessary.

The door panel is then lowered from the door

frame, tenon centers removed, the door

opened and the screws driven into the panel

through the black tape on the door frame,

using the center marks to locate the screws.

The screw holes inside the door are hidden

under a cover flap on the door gasket. It is

necessary to lift the flap to insert the screws.

Use as many screws as necessary to hold the

door panel in place properly.

IMPORTANT NOTE:

After the first three or

four mounting screws are in place, but not

completely tightened, close the door and check

your panel fit. This is the time to make small

adjustments. Once you are satisfied with the

appearance, open the door and apply the

remainder of the screws. Check all screws for

tightness.

The metal frame on the glass door has

numerous mounting holes on each side of the

door. This is to accommodate the Sub-Zero

accessory handles and provide for easy attachment of the handle through the door frame.

If you choose not to use the pre-drilled handle

mounting holes, it will be necessary to fasten

the handle from the rear of the door panel

only, or drill one or more additional holes

through the metal frame of the glass door.

Illustration 12 on page 20 shows how this hole

passes through the door frame. The hole

center is on the small locator groove in the

front of the frame. A 6 mm diameter hole is

made in the front wall of the extrusion and a

11 mm diameter hole through the rest of the

frame.

IMPORTANT NOTE:

Install screws in all the

mounting holes in the door frame. The nature

of the door panel with a narrow outer rim and

no connecting center member requires the

support provided by the glass door.

After the door panel installation is complete,

apply the cover patches or plugs provided over

the holes on the inside surface of the door.

MODELS ICB427 AND ICB427R INSTALLATION

The cover patches or plugs are part of the

insulation system on the door of the Wine

Storage unit. Be sure to cover all the

holes in the door that were used.

The wine storage unit door is made with

a sealed double wall tempered glass core.

The drill must not contact this core when

drilling. Be sure the hole is centered on

the small groove in the front of the door

frame and the drill passes squarely

through the frame. If you are inexperienced with drilling, fasten the handle from

the rear of the door panel only.

MODELS

ICB427

ICB427R

Page 22

22

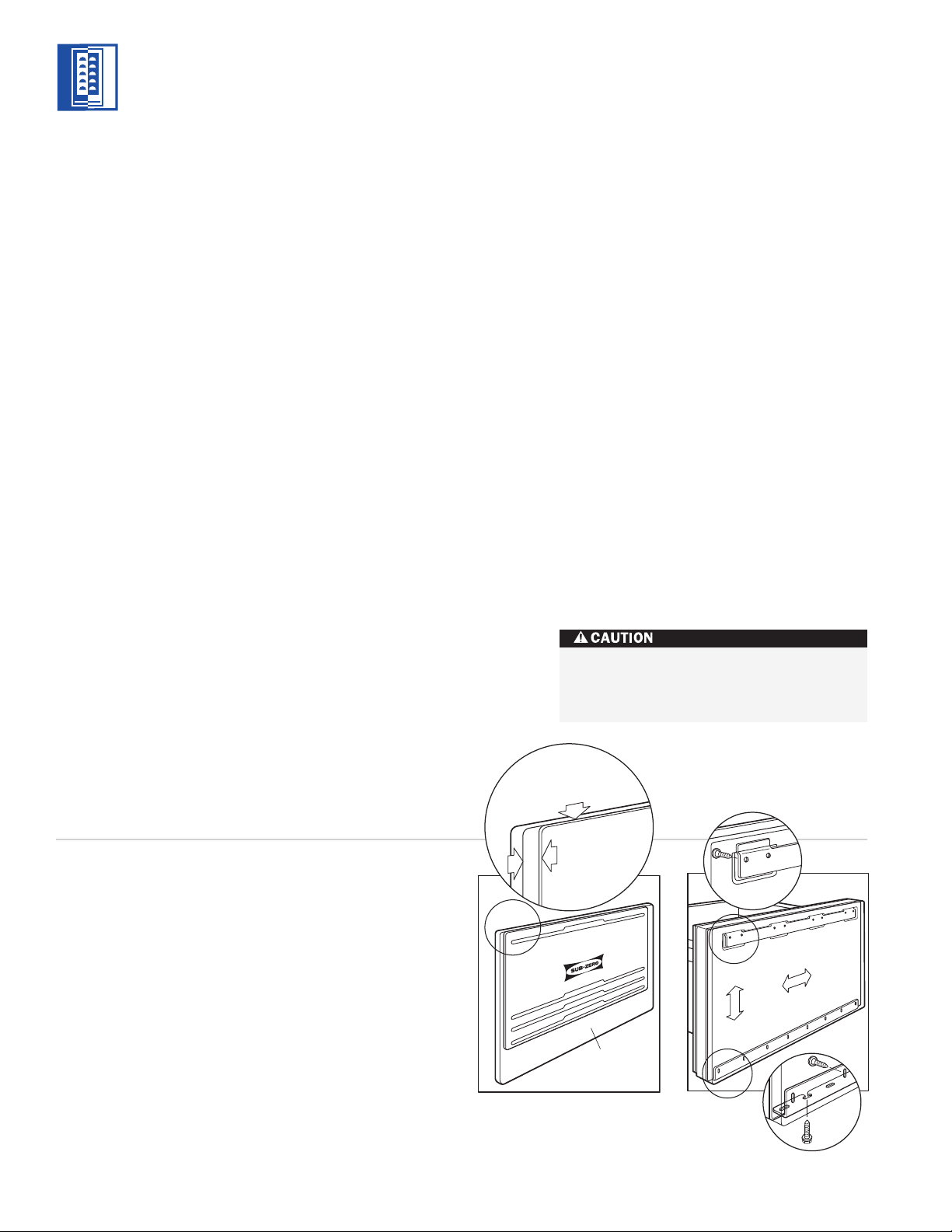

MODEL ICB427R DRAWER PANELS

IMPORTANT NOTE:

Drawer panels for Model

ICB427R must be a minimum of 16 mm thick

and cannot exceed 5 kg for each panel.

Remove the mounting hardware provided and

set aside. You should work on the back side of

each drawer panel and you should protect the

fronts of these panels.

Position the top edge of the drawer template

flush with the top edge of each drawer. For the

top drawer, there is only one place for the

lower mounting bracket to be placed. However,

depending on the depth of the lower drawer

panel, you have two options for placement of

the bracket. Refer to illustration 13 below.

Secure the template in place with tape or small

clamps and mark positions for your pilot holes.

Remove template. Drill pilot holes and place

the hardware in the proper place (dog-ear

bracket on top) and fasten securely with the #8

x 13 mm screws provided. See illustration 14.

To help with proper placement of drawer

panels, examine the lower panel mounting

bracket and determine which slotted holes to

use. Position screws into the lower portion of

the drawer that correspond with these slotted

holes. Leave these screws out a small distance

so they can help when you mount the drawer

panels to the drawer.

With the two brackets in place on the drawer

panel, engage the top dog-ear bracket first and

then the lower bracket onto the protruding

screws. You will have a 6 mm adjustment up

and down and side to side in each drawer

panel. Fasten all screws to the lower bracket to

secure the drawer panel.

IMPORTANT NOTE:

Once drawer panels have

been adjusted for proper spacing, be sure to

reconnect the control cable on the upper

drawer after you have installed the drawer.

Refer to illustration 3 on page 15.

SOLID DOOR PANE LS

IMPORTANT NOTE:

The solid door panel for

Models ICB427 and ICB427R must be a minimum

of 16 mm thick and cannot exceed 18 kg.

Installation of the solid door panel is the same

as the door panel for a glass door model.

MODELS ICB427 AND ICB427R INSTALLATION

A solid panel must not be installed on a

glass door unit, as this may cause

moisture to form behind the panel.

MODELS

ICB427

ICB427R

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

Illus. 13 Illus. 14

Top Of Template

Flush With Top Of

Drawer Panel

Gap On Side

Edges Will Vary

According To

Design

Back Of

Drawer Panel

Page 23

23

FINISHED WOOD SIDE PANELS

Side panels for Models ICB427 and ICB427R

are not attached to the unit. You must securely

fasten the panels to adjacent cabinets and

floor.

Panels should be fastened to the floor and

walls using ‘L’ brackets (hardware not

provided). To help you move the unit into

place, rout out an area in the floor so the ‘L’

bracket will sit flush with the floor level.

Brackets and screws are provided for

mounting the unit to adjoining cabinets and

side panels. Each unit has four side-mounting

clips on each side.

IMPORTANT NOTE:

For installations where

you are not attaching to a side wall, or you are

installing two Model ICB427, ICB427R or Integrated units together, you must remove the

side-mounting clips before moving the unit

into position. After removing the clips, replace

the screws into the appliance.

A dual installation heater kit (#7007529) is

necessary for anchoring two Model ICB427,

ICB427R or Integrated units together. Contact

your Sub-Zero dealer for details.

LOCK INSTALLATION

For Models ICB427 and ICB427R, the accessory

lock is attached to the decorative door panel

through a field-drilled hole in the panel. The

catch should be installed on the top of appliance cabinet before the unit was moved into

position. Installation instructions are included

with the lock kit.

IMPORTANT NOTE:

For accessory stainless

steel panels requiring a lock, panels must be

ordered with the lock mounting hole predrilled.

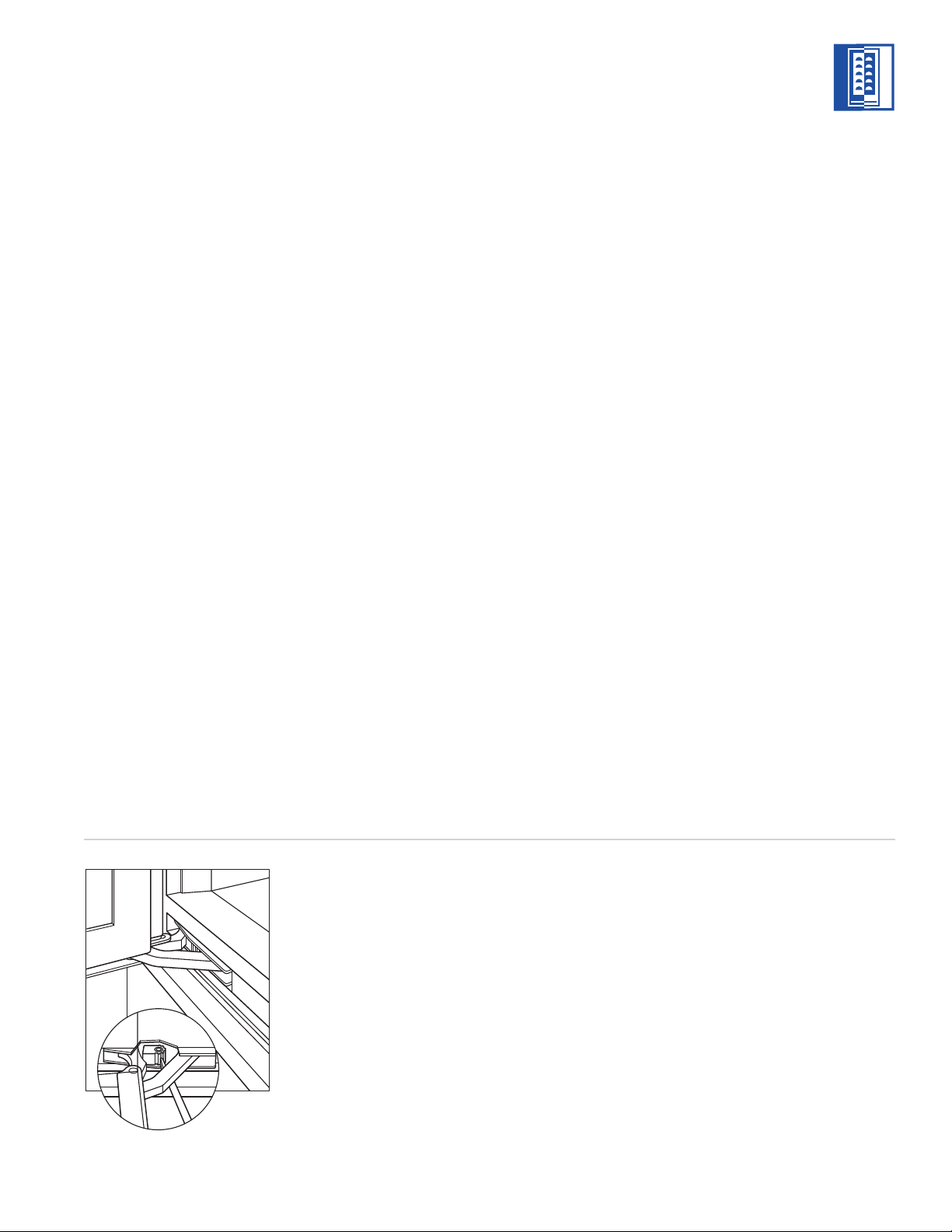

90-DEGREE

DOOR STOP

Models ICB427 and ICB427R have a 90-degree

door stop built into the hinge system. Use the

blade edge of a standard screwdriver and

rotate the brass cam in the center portion of

the hinge until you reach the stop. You must

make this adjustment to both the bottom and

top hinge. Refer to illustration 15 below.

COMPLETING THE INSTALLATION

IMPORTANT NOTE:

When you have

completed the installation of the Model ICB427

or ICB427R Wine Storage unit, refer to pages

34–35 for the Installation Checklist and Service

Information.

MODELS ICB427 AND ICB427R INSTALLATION

Illus. 15

MODELS

ICB427

ICB427R

OPTIONAL

COMPONENTS

Optional installation components

are available

through your

Sub-Zero dealer.

You can also visit

our website at

subzero.com.

Page 24

24

SITE PREPARATION

Make sure that the finished rough opening

where the Wine Storage unit is to be installed

is properly prepared. Refer to the Installation

Specifications illustration for rough opening

dimensions, door swing clearance and electrical placement for Model ICB430.

If you are installing two Model ICB430 units

side by side, or a Model ICB430 and a Built-In

model, a separating filler strip is recommended. Add the filler strip width to the

finished rough opening dimension. Complete

the installation with the Anchoring Kit (part

#4200900), see page 33.

IMPORTANT NOTE:

To operate properly,

the door must open a minimum of 90 degrees.

Use a minimum 76 mm filler strip in corner

installations to assure a 90-degree door

opening. Allow enough clearance in front of

the unit for full door swing.

IMPORTANT NOTE:

Make sure the floor under

the unit is level with the surrounding finished

floor.

MODEL ICB430 INSTALLATION INSTRUCTIONS

Do not load wine into the Wine Storage

unit until the installation is complete.

1918

mm

178

mm

152

mm

749 mm

ROUGH OPENING WIDTH

610 mm

ROUGH

OPENING

DEPTH

E

LOCATE ELECTRICAL

WITHIN SHADED AREA

ANTI-TIP BLOCK

90˚

130˚

MAXIMUM

DOOR SWING

1270 mm

DOOR CLEARANCE

838 mm

DOOR CLEARANCE

765 mm 765 mm

606 mm

BEHIND

FRAME

FRONT VIEW

TOP VIEW

2127 mm

ROUGH OPENING

HEIGHT

TO FINISHED

FLOORING WITH

STANDARD

279 mm GRILLE

2108 mm

MIN HEIGHT

REQUIRED

(LEVELERS IN)

MODEL ICB430 INSTALLATION

INSTALLATION SPECIFICATIONS

NOTE: Door swing clearances are based on stainless

steel door and handle dimensions.

MODEL

ICB430

Page 25

25

UNPACKING AND MOVING

Uncrate the unit, remove its wood base and

discard the shipping bolts that hold the wood

base to the bottom of the unit. Remove all

packing materials and tape.

IMPORTANT NOTE:

Do not discard the

kickplate, anti-tip blocking kit and hardware.

These items will be needed for the installation.

All roller-assembly wine shelves should be

removed to reduce weight and prevent them

from rolling. To remove, pull the shelf out to

its full extension, gently and evenly lift up on

both sides of the front of the shelf and remove.

Reverse the procedure to reinstall the shelf.

Retract the front leveling legs to allow you to

move the unit more easily during installation.

You will extend the leveling legs when the unit

is in its final position to reduce the possibility

of the unit tipping forward.

Use an appliance dolly to move the unit.

Remove the drain pan from the base of the

unit to avoid damage to the drain pan, and

allow for proper placement of the appliance

dolly.

ELECTRICAL REQUIREMENTS

A 220-240 V AC, 50/60 Hz, 10 amp circuit

breaker and electrical supply are required. A

separate circuit, servicing only this appliance,

is required.

The power supply cord has a grounding plug,

which must be plugged into a mating ground ing-type wall recep tacle. Follow all National

Electrical codes and local codes and ordinances when installing the receptacle. For

location of the electrical supply, refer to the

Installation Specifications illustration.

IMPORTANT NOTE:

A ground fault circuit

interrupter (GFCI) is not recommended and

may cause interruption of operation.

HOME ALARM SYSTEM

If a home alarm system is to be used, refer to

Home Alarm Connections on page 28. In

addition to operating power, the installer may

also be required to supply a home automation

system lead to the unit. This is for a lowvoltage, low-current signal similar to door and

window sensor signals. Common, normally

open and normally closed contact configurations are provided.

Three 6 mm female spade connectors are

located in the compressor compartment and

are accessible behind the grille on Model

ICB430. A minimum of 914 mm of lead wire

should be provided for each contact, exiting

the back wall near the electrical outlet.

MODEL ICB430 INSTALLATION INSTRUCTIONS

Before moving the Wine Storage unit in

to position, protect any finished flooring

with appropriate materials, secure the

door closed and remove the grille.

Do not use an extension cord. Electrical

ground is required on this appliance.

MODEL

ICB430

Page 26

26

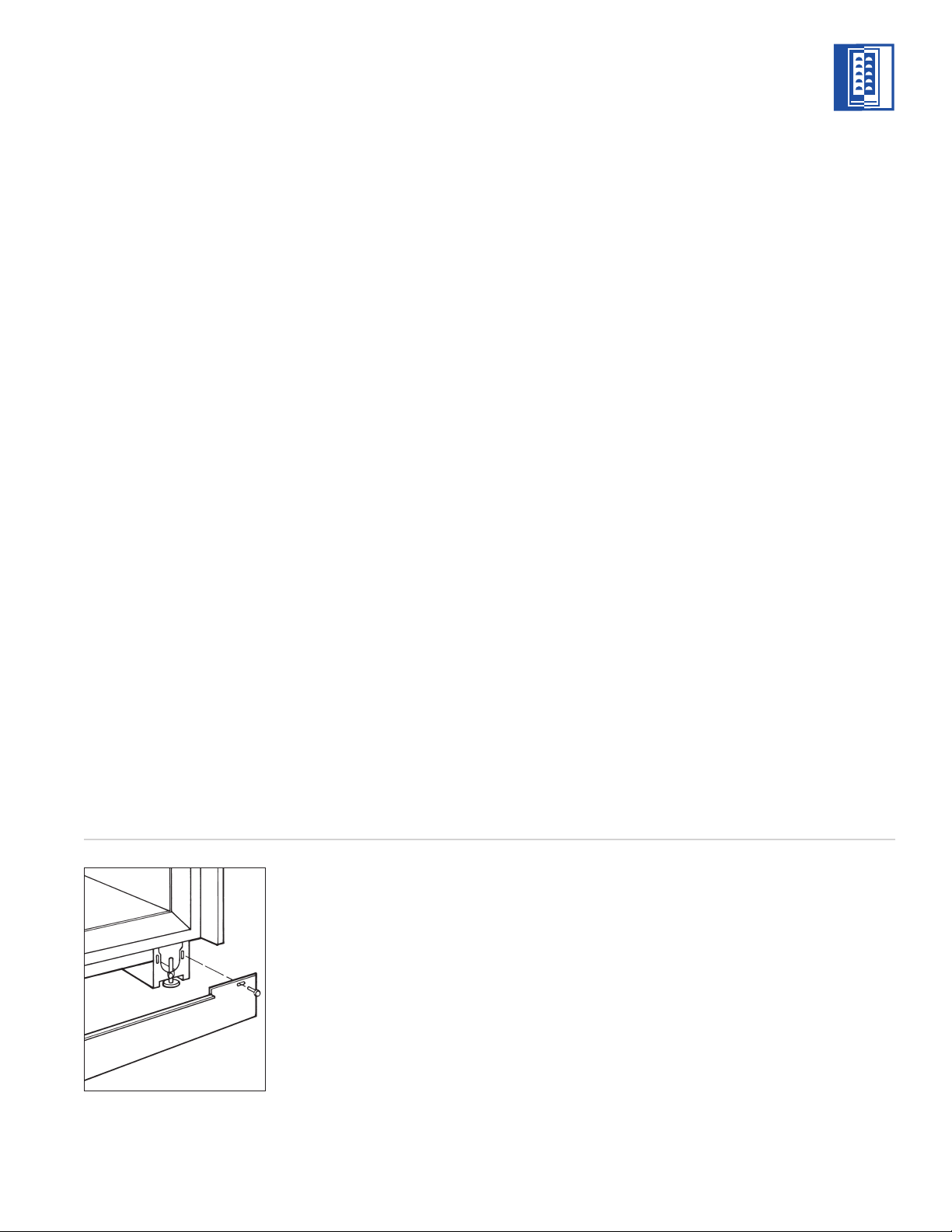

MODEL ICB430 INSTALLATION INSTRUCTIONS

GRILLE REMOVAL

In order to prevent damage to the grille and to

access the power cord, the top grille assembly

should be removed prior to moving the unit.

Overlay panel grille:

First, remove the inner

grille panel assembly as shown in illustration 1

below. Lift up, then pull out at the bottom, pull

the top section down and out of the top key

slot. Remove the four mounting screws that

hold the outer grille panel assembly to the top

compartment. Refer to illustration 2.

ANTI-TIP

BLOCKING KIT

An anti-tip blocking kit (wood block and

hardware) is provided with the Model ICB430.

If there is a solid soffit above the unit with

clearance between the unit and the soffit of 25

mm or less, you won’t need to block the unit.

For installations with clearances of more than

25 mm, you must install the anti-tip blocking

kit, to prevent tipover in case several loaded

wine shelves are extended at the same time.

Locate and mark two wall studs against the

wall where the unit will be installed. Then

locate the proper height to clear the unit. The

space between the unit top and the bottom of

the wood block must not be more than 6 mm.

Position the wood block over the unit and use

the screws and ‘L‘ brackets to lock it in place.

Make sure the screws extend a minimum of 22

mm into each of the two wall studs. The wood

block must be positioned securely and must

extend at least 76 mm over the unit. Refer to

illustration 4 on page 27.

Using the front and rear leveling legs, raise the

unit until it makes contact with the wood block.

See Level the Unit on page 28.

To prevent the unit from tipping forward

and provide a stable installation, the unit

must be secured in place with an anti-tip

blocking device.

Inner Grille

Panel Assembly

1

2

3

1

2

3

Panel Grille

Frame

Soffit

25 mm

Illus. 1 Illus. 2 Illus. 3

MODEL

ICB430

Page 27

27

MODEL ICB430 INSTALLATION INSTRUCTIONS

If a home alarm system is to be used with the

Wine Storage unit, the lead wires should be

threaded into the compressor compartment

before you position the unit. See Home Alarm

Connections on page 28 for the location of these

lead wires. After the unit is in position, the

alarm wiring can be completed from the front.

Roll the unit into position under the wood block

or soffit. Model ICB430 is equipped with rollers

so you can easily move the unit into place.

Using the front and rear leveling legs, raise the

unit until it makes contact with the wood block.

LEVEL THE UNIT

Once the unit is in position, extend the front

leveling legs down to make contact with the

floor. Level the unit by turning the front leveling

legs clockwise to raise the unit, or counterclockwise to lower it. The rear height adjustment can

be made by turning the 8 mm hex bolt at the

front of the base. Refer to illustration 5 below.

IMPORTANT NOTE:

Be sure to reference

leveling of the unit to the floor and not to

surrounding cabinetry.

76

mm

WOOD BLOCK

SHROUD

WALL STUD

SCREW

Illus. 4 Illus. 5

LOCK INSTALLATION

IMPORTANT NOTE:

If you are adding an

accessory lock kit to your Wine Storage unit,

it should be installed before you position the

unit. Installation instructions are included with

the lock kit.

For Model ICB430, the lock is attached to the

bottom of the metal door frame. The decorative

door panel is not involved in the installation or

operation of the lock. The catch portion of the

lock is attached to the bottom of the appliance

cabinet in pre-punched holes. When installing

the lock kit, it may be helpful to tip the unit on

its back for easier access.

POSITION THE UNIT

IMPORTANT NOTE:

If for any reason the Wine

Storage unit has been laid on its back or side,

you must allow the unit to stand upright for a

minimum of 24 hours before connecting power.

Plug the power supply cord into the 10 amp

grounded electrical outlet. With power applied

to the appliance, check for lighting and cooling

before going any further. Once you are satisfied that the unit is operating properly, shut off

power to the electrical outlet at the circuit

breaker and proceed.

Shut off the power to the electrical outlet.

Rear

Adjustment

Front

Leveling Leg

To reduce the possibility of the unit

tipping forward, the front leveling legs

must be in contact with the floor.

MODEL

ICB430

Page 28

28

Home Alarm

Connections

Illus. 6

MODEL ICB430 INSTALLATION INSTRUCTIONS

IMPORTANT NOTE:

If you are not responsible

for alarm system connection, this information

should be supplied to the home security system

contractor.

HOME ALARM CONNECTIONS

Before the kickplate and grille are installed, all

necessary wiring connections in the compressor compartment should be completed.

If a home alarm system is to be installed on

the Wine Storage unit, the connections should

be made using the logic supplied with the

alarm specifications. See illustration 6 below

for the appliance lead locations, and refer to

the following for color codes:

Normally open contacts – white with red

stripe wire

Normally closed contacts – white with blue

stripe wire

Common – gray with white stripe wire

Use the 6 mm spade terminals or wire nuts

provided to make the proper wiring connections.

The alarm circuit in the unit is intended as

a low-voltage, low-current device only. It

should not be used to switch line power.

Any unused terminals should be

completely insulated and all wires should

be secured away from conductive or

moving components.

MODEL

ICB430

Page 29

29

KICKPLATE AND GRILLE

After the unit has been leveled, make sure the

drain pan is installed properly and install the

kickplate. Refer to illustration 7 below.

IMPORTANT NOTE:

The kickplate must be

removed for servicing. The floor cannot interfere with removal. Refer to label mounted on

the kickplate support for height clearance.

IMPORTANT NOTE:

The floor under the Wine

Storage unit must be at the same level as the

surrounding finished floor to allow for removal

of the unit for servicing.

Replace the grille by reversing the procedure

outlined on page 26. If you’re using a panel

grille, see Overlay Grille Panel on page 31.

Turn power back on to the electrical outlet.

DOOR PANELS

Model ICB430 is offered in two design applications; stainless steel (/S) and overlay (/O). Each

of these designs is available as a glass door

(G) model.

The stainless steel Model ICB430 is available in

the classic finish only and is shipped from the

factory with the decorative stainless steel door

panel and matching handle in place.

The overlay Model ICB430/O is designed to

accept a decorative door panel to match

surrounding cabinetry. This door panel and the

handle will be provided by the customer.

Before beginning installation, check for the

correct components for the fit and finish

desired. All models require a decorative panel

a minimum of 16 mm thick.

Illus. 7

MODEL ICB430 INSTALLATION INSTRUCTIONS

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

MODEL

ICB430

Page 30

30

MODEL ICB430 INSTALLATION INSTRUCTIONS

Glass

Gasket

11 mm

Diameter

6 mm

Diameter

Illus. 8

Illustration 8 shows how this hole passes

through the door frame. The hole center is on

the small locator groove in the front of the

frame. A 6 mm diameter hole is made in the

front wall of the extrusion and a 11 mm

diameter hole through the rest of the frame.

Sub-Zero allows a 6 mm space to slide the

backing material into place on the door frame.

Requirements for proper fit and appearance

are; 16 mm minimum overall thickness, 3 mm

wide groove between backer portion and

overlay portion of panel, finished inside edge

and 11 kg maximum weight. See the Wine

Storage section of the Sub-Zero Design Guide

for additional panel information.

The wine storage unit door is made with

a sealed double wall tempered glass core.

The drill must not contact this core when

drilling. Be sure the hole is centered on

the small groove in the front of the door

frame and the drill passes squarely

through the frame. If you are inexperienced with drilling, fasten the handle from

the rear of the door panel only.

OVERLAY DOOR PANEL

If your customer has chosen an overlay design

door and grille panel, the unit will be shipped

without handle and hardware. The cabinet

manufacturer or designer will provide handle

hardware at the job site to match the overall

decorating scheme. We recommend larger

D-style pulls. The use of small, one-piece

knobs is not recommended.

The metal frame on the glass door has

numerous mounting holes on each side of the

door. This is to accommodate the Sub-Zero

accessory handles and provide for easy attachment of the handle through the door frame.

If you choose not to use these pre-drilled

mounting holes, you must either drill additional holes through the metal frame of the

door, or attach the handle through the door

panel only.

If you attach through the door panel only, the

handle must be attached before the door panel

is installed and the handle screws will need to

be set into the rear surface of the door panel.

If you choose to drill through the metal door

frame, this must be done before the handle

holes are located and drilled in the panel.

MODEL

ICB430

PANEL

DESIGN

Additional panel

design information

can be found in

the Sub-Zero

Design Guide.

Check our website

at subzero.com.

Page 31

31

MODEL ICB430 INSTALLATION INSTRUCTIONS

IMPORTANT NOTE:

The size of the overlay

panel is critical. It must fit over the door frame.

To install overlay panels, first remove the

magnet backed trim molding using a piece of

tape to pull it away from the frame and expose

the frame screws. The molding will bend at the

center so that you can remove it.

Remove the frame by removing the five screws

holding it in place. The door channel is now

ready to accept the overlay panel. Slide the

panel into the frame on the door. With the

panel in position, replace the frame end. Be

sure the panel is inserted completely into the

channel for proper fit and alignment. Next,

replace the trim molding by inserting the top,

then the bottom into the frame channel.

Release the middle and set the magnets.

Install the #8 x 16 mm screws through the back

of the glass door frame into the door panel.

IMPORTANT NOTE:

Install screws in all the

mounting holes in the door frame. The nature

of the door panel with a narrow outer rim and

no connecting center member requires the

support provided by the glass door.

After the door panel installation is complete,

apply the cover patches or plugs provided over

the holes on the inside surface of the door.

OVERLAY GRILLE PAN EL

If you have not already removed the inner and

outer grille frame for moving the unit, remove

the inner grille panel assembly, see Grille

Removal on page 26. Remove the top two

corner screws and pull away the top frame.

Slide the panel into position in the grille frame.

If you are using a grille panel 6 mm or thinner,

you will need to install a filler.

Reattach the top frame by reinstalling the two

top corner screws. Install the inner grille panel

assembly onto the unit.

The cover patches or plugs are part of the

insulation system on the door of the Wine

Storage unit. Be sure to cover all the

holes in the door that were used.

A solid panel must not be installed on a

glass door unit, as this may cause

moisture to form behind the panel.

MODEL

ICB430

Page 32

SIDE PANEL INSTALLATION OPTIONS

32

SIDE PANEL INSTALLATION

If you’re installing a Model ICB430 with side

panels, check with your installer or use one of

the following Side Panel Installation Options.

Drill three holes equidistant in a vertical

section of the aluminum frame, and install pan

head screws. Do not drill through model and

serial number plate. Anchor the side panel

with decorative screws or finishing nails from

a local hardware store. Do not use adhesives.

Refer to illustration 9 below.

The dimensions given in the Side Panel

Installation Options are for typical wood side

panels. If a 6 mm thick or less panel is used

and inserted into the return channel extrusion,

then a 616 mm wide panel is necessary. In this

application, the panel must be notched for the

grille and other brackets or screws that are in

the return channel. Toe kick cut-outs will be

necessary for all side panel applications. Refer

to illustration 10 below.

IMPORTANT NOTE:

The use of side panels

may change the width of your rough opening.

IMPORTANT NOTE:

The overall height on the

side panel will vary with the height of the grille

being used. Make sure you know your finished

height before cutting any panels.

MODEL ICB430 INSTALLATION INSTRUCTIONS

610 mm

610 mm

616 mm

FRAME

6 mm THICK SIDE PANEL FITTED IN TO UNIT FRAME

3 mm THICK BATTENS

DOOR PAN HEAD SCREW

SIDE OF SUB-ZERO UNIT

6 mm SIDE PANEL MATERIAL

FRAME

10 mm THICK SIDE PANEL FITTED UP TO UNIT FRAME

3 mm THICK BATTENS

DOOR PAN HEAD SCREW

SIDE OF SUB-ZERO UNIT

10 mm SIDE PANEL MATERIAL

610 mm

FRAME

METAL SIDE PANEL FITTED UP TO UNIT FRAME

DOOR PAN HEAD SCREW

SIDE OF SUB-ZERO UNIT

METAL SIDE PANEL MATERIAL

610 mm

FRAME

13 mm THICK SIDE PANEL FITTED UP TO UNIT FRAME

3 mm ROUT

DOOR PAN HEAD SCREW

SIDE OF SUB-ZERO UNIT

13 mm SIDE PANEL MATERIAL

FRAME

6 mm

THICK BATTENS

DOOR PAN HEAD SCREW

SIDE OF SUB-ZERO UNIT

6 mm SIDE PANEL MATERIAL

6 mm THICK SIDE PANEL FITTED UP TO UNIT FRAME

3 mm THICK BACK-UP

6 mm

337 mm

6 mm

76 mm

76 mm

102 mm

DOOR

FRAME

SIDE PANEL

PAN HEAD

SCREW

29

mm

Illus. 9

Illus. 10

Top Views

MODEL

ICB430

Page 33

33

ANCHOR THE UNIT

After door and side panels have been installed,

the unit has been leveled and door adjustment

completed, anchor the unit to the opening.

This will assure a proper fit and a secure

installation. The Sub-Zero Anchoring Kit (part

#4200900), available from your Sub-Zero

dealer, includes the necessary hardware.

IMPORTANT NOTE:

Be sure to level and

square the unit before anchoring it.

TWO UNITS ANCHORED TOGETHER

Drill three 5,16 mm holes through the

middle trim of both units.

Using the Loctite on the screws, install the

three Chicago screw posts.

Recheck the units for level.

Drill three 5 mm holes through both outer

trims. Refer to illustration 11 below.

Using a 3 mm drill bit, drill into the cabinetry for a pilot hole.

Install all six Sems to the cabinetry.

UNIT ANCHORED TO CABINETRY

First, make sure units have been leveled

and aligned, and doors adjusted.

Drill three 5 mm holes through both outer

trims. Refer to illustration 12 below.

Drill a 3 mm pilot hole into the cabinetry.

Install all six Sems.

Illus. 11 Illus. 12

Do not drill through the model and serial

number plate.

MODEL ICB430 INSTALLATION INSTRUCTIONS

MODEL

ICB430

OPTIONAL

COMPONENTS

Optional installation components

are available

through your

Sub-Zero dealer.

You can also visit

our website at

subzero.com.

Page 34

34

INSTALLATION CHECKLIST

The importance of the installation of the

Sub-Zero Wine Storage unit cannot be

overemphasized. Proper installation is the

responsibility of the selling dealer or installer.

IMPORTANT NOTE:

To ensure a safe and

proper installation, the following checklist

should be completed by the installer to ensure

that no part of the installation has been overlooked.

Any questions or problems regarding the

installation should be directed to your

Sub-Zero dealer. You may also check the

Contact & Support section of our website,

subzero.com.

MODEL ICB430 INSTALLATION INSTRUCTIONS

HINGE ADJUSTMENT

IMPORTANT NOTE:

The unit must be installed

and leveled before adjusting the door hinges.

Check to make sure the door is properly

adjusted. If not, adjust the top or bottom door

hinge by first removing and discarding the two

small shipping screws. Refer to illustration 13

below. Adjust the top hinge left to right and in

or out by loosening the three allen head

screws. Adjust the bottom hinge by loosening

the four allen head screws with a 3 mm allen

wrench. Refer to illustration 14. The door will

now be able to move left to right or in and out.

90-DEGREE

DOOR STOP

An optional 90-degree door stop kit for Model

ICB430 is available through your Sub-Zero

dealer.

COMPLETING THE INSTALLATION

IMPORTANT NOTE:

When you have

completed the installation of the Model ICB430

Wine Storage unit, refer to the following

Installation Checklist and Service Information.

Illus. 13 Illus. 14

MODEL

ICB430

OPTIONAL

COMPONENTS

Optional installation components

are available

through your

Sub-Zero dealer.

You can also visit

our website at

subzero.com.

Page 35

35

If you are storing or disposing of your old

refrigerator or freezer, please do it safely.

Remove the doors or tightly secure the

doors closed. Child entrapment accidents

can be tragic.

CONTACT

INFORMATION

Website:

subzero.com

SERVICE INFORMATION

The information and images in this book are

the copyright property of Sub-Zero, Inc.

Neither this book nor any information or

images contained herein may be copied or

used in whole or in part without the express

written permission of Sub-Zero, Inc.

©Sub-Zero, Inc. all rights reserved.

INSTALLATION CHECKLIST

Has the packing material been removed?

Turn the unit on first, is the unit operating

properly? If not, is it plugged in? Is the

control turned on?

Has the unit been secured in place with an

anti-tip bracket or by a secure overhead

cabinet or structure?

Are front leveling legs extended and

making contact with the floor? Is the unit

level?

Is power cord connected directly to a

properly grounded outlet?

Has the drain pan been installed properly,

(Model ICB430)?