Page 1

COLD ROOM CONTROLLER

USER MANUAL

www.subzero.co

INDIA

CRC-2052

Page 2

Index Index

01

CRC-2052 CRC-2052

02

Index Index

Introduction

Get to Know Your Controller

LED Indication.

5

8

Parameter List.

To set the quick freeze set point.

To set the Condenser set point.

To set cut out point of the controller for

Humidity.

QFS

CSET

HSET

9

9

10

Key Introduction

6

4

Fault Messages.

7

DESCRIPTION

PARAMETER

Pg.

No.

To set the cut-out point of the controller.

SET POINT

9

DESCRIPTION

PARAMETER

Pg.

No.

To set other parameter

10

To set allowable high temperature limit.

To set allowable low temperature limit.

To set the differential for compressor

restart.

P2

P3

P4

10

11

11

To set probe calibration.P5

12

To set time delay between relay restart

time.

P6

12-13

To set duration of defrost.P7

13

To set defrost frequency.

To set power on defrost delay.

To set type of defrost.

To set drip time for defrost.

To set defrost stop temperature.

To set type of computation for defrost

time.

P8

P9

P10

P11

P13

P12

13

13

14

14

15

14-15

To enable or disable humidity sensing. RH

15

To set allowable high humidity limit.H2

16

To set allowable low humidity limit.H3

16

To set differential (Hysterisis) for

humidity.

To set probe calibration for humidity.

To set time delay between relay restart

time for humidity.

To set quick freeze duration.

To set condenser logic.

To set condenser differential.

To set condenser probe calibration.

To set condenser on delay time.

To set condenser status at hot gas

defrost.

To set Evaporator Fan stop temperature.

To set Evaporator Restart Delay.

To set Evaporator Fan status at

compressor off.

To set Evaporator Fan differential.

To set Evaporator probe calibration.

H4

H5

H6

QFD

CND3

CND4

CND5

CND6

CND7

L1

L2

L3

L4

L5

16

17

17

18

18

18

19

19

19

20

20

20

21

21

To set Evaporator Fan status at Door

open condition.

L7

21

To enable / disable buzzer.BUZ

22

This parameter is used to set power on

delay for alarm.

AL

22

Under load limit for compressor current.C-UL

23

Over load limit for compressor current.C-OL

23

Under load limit for Heater / Solenoid.D-UL

23-24

Items Included.

5

9

To set Evap Fan status during defrost.L8

22

EXIT End of set mode

10

Page 3

Current sensing delay.

C2

24

Introduction

04

Features:

CRC-2052

Index

03

CRC-2052

Index

DESCRIPTION

PARAMETER

Pg.

No.

To enable or Disable HP sensing.

D0

24

To enable or disable LP sensing.

D1

25

Fault sensing logic.

To set LP sensing delay.

To set reset mode for HP fault.

D2

D3

D4

25

25

26

To set Compressor Relay status on

Probe Failure.

To set On cycle at room probe fail.

To set Off cycle at room probe fail.

To set Display at defrosting.

Defrost duration during Coil probe failure.

E1

TON

TOFF

E7

E8

26

26

27

27

27

To set time delay to switch off the light .

To activate Solenoid Valve relay.

To change password.

To view Compressor run Hours.

Clear Compressor Run Hours.

To set Unit ID.

LD

PDN

PW

CRH

CCRH

ID

28

28

28

29

29

29

To activate Keypad Lock.

To enable/disable Power Switch.

To set display at power OFF mode.

LP

PO

PDIS

29

30

30

To restore default settings of the

controller.

FS

31

End of programming.

EP

31

Technical Data

32-33

Caution & Warranty

34-35

Suggested Connection Diagram

The CRC-2052 is single set point cold room controller. The

Sub-Zero CRC-2052 is aesthetically superior versions of

their predecessors.

A number of parameters are displayed alphanumerically to set

up the instrument for each specific function.

The controller controls the defrost in the system based on

either an electrical heater where the compressor is stopped, or

at cycle inversion using warm gas where the compressor

keeps on working.

There are safety features which include shutting down the

system incase of a fault from a pressure control or similar

device.

A series of “safety controls” (delay at start-up, minimum disable

time, minimum time between activation) protects the

compressors from close starts. In case of probe error or

temperature alarm, the instrument signals the event through

acoustic signal and by closing the relay contact. By pressing

the mute key, the buzzer is silenced.

Computer Connectivity over RS485 and Remote

monitoring(Optional).

Single Operation Quick Freeze Mode(Press QF Key for 2 sec),

set system in quick freeze mode which is time based for that

period new set point will be lower than running set point and

system will try to achieve that set point, after time period over

set point will be normal set point.

Over load limit for Heater/Solenoid.D-OL

24

Page 4

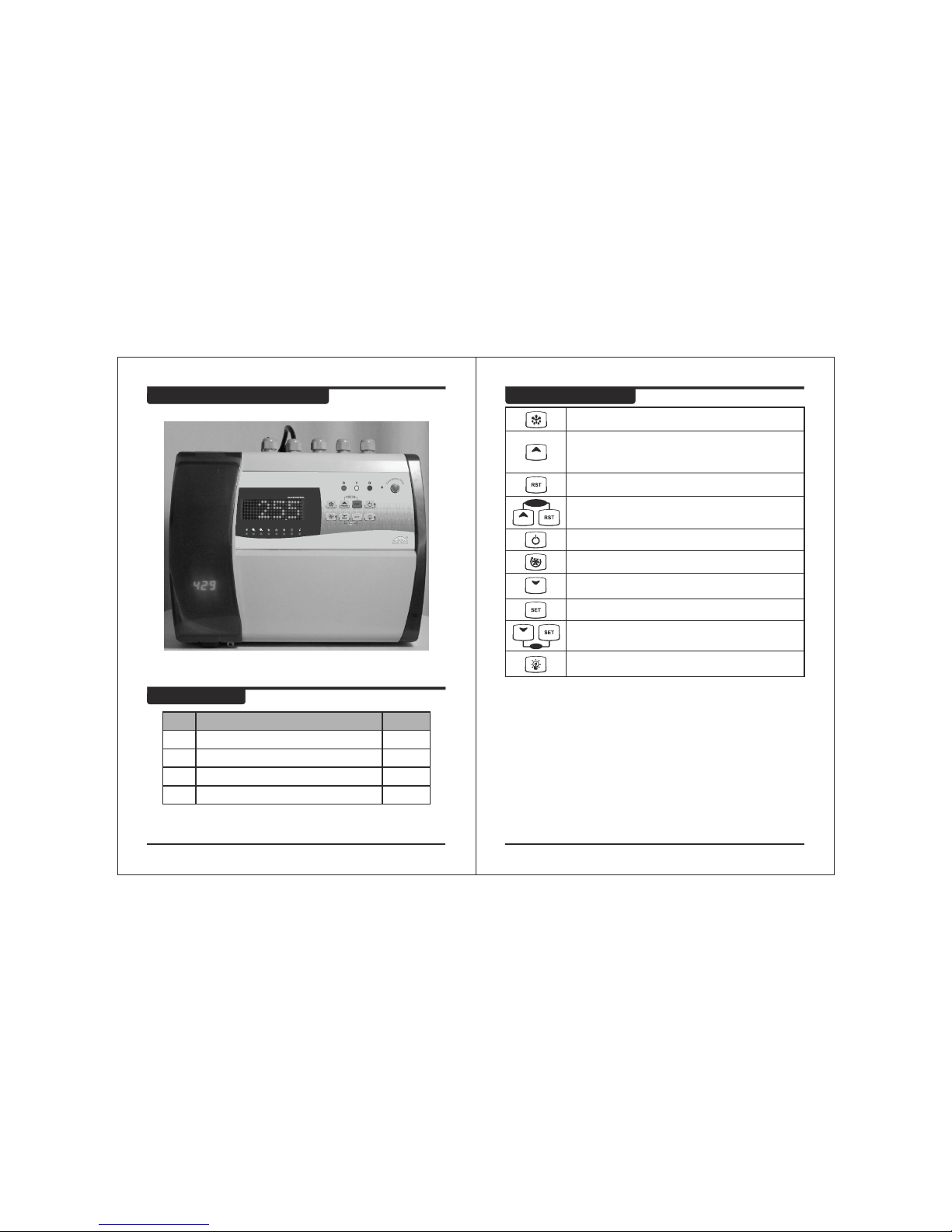

Key Introduction

06

PRG

Amp

PROBE

Used to switch OFF/ON the controller.

Used to come mute the buzzer/Alarm & to exit any mode.

Used to increment/scroll in Program Mode.

When not in any mode if this key is pressed for 2 secs controller will

enter in display Probe mode where Condenser/Evap temperature &

RH can be viewed.

PRG

PROBE

Fault Log

Used to enter into the Set mode. Also used as enter key if controller

is in Set mode/program mode.

Used to enter in manual defrost and to stop defrost if

defrosting is ON.

Used to enter in fault log mode.

Used to enter in quick freeze mode.

Used to decrement/scroll in Program mode.

Used to enter into the program mode.

Used to enter in display Amp. mode where compressor and

defrost current can be viewed.

Used to switch OFF/ON the light.

CRC-2052

05

Get to Know Your Controller

Items included

NO.

1.

2.

3.

4.

QTY

ITEMS

CONTROLLER

CATALOGUE

NTC SENSOR 5 METER

1

3

1

4

8 X 38 SCREW WITH RAWL PLUG

CRC-2052

Page 5

08

LED Indication

Messages Mode Discription

Comp. Relay On.

Comp. Relay Off.

Comp. Relay Timedelay.

Cond. Relay On.

Cond. Relay Off.

C

E

Evap. Relay On.

Evap. Relay Off.

Evap. Relay Timedelay.

Defrost Relay On.

Defrost Relay Off.

Defrost Relay Timedelay.

LSV Relay On.

LSV Relay Off.

Alarm Relay On.

Alarm Relay Off.

Controller is in drip time.

Humidifier On.

Humidifier Off.

Humidifier is in Timedelay.

Controller is in .

Controller is not in quick freeze mode.

quick freeze mode

Power Off.

Power On.

Light Relay On.

Light Relay Off.

R-phase present.

R-phase absent.

R

Y-phase present.

Y-phase absent.

Y

B-phase present.

B-phase absent.

B

Flashing

On

Off

Flashing

On

Off

On

Off

Flashing

On

Off

Flashing

On

Off

On

Off

On

Off

Flashing

On

Off

Off

On

On

Off

On

Off

On

Off

On

Off

On

Off

Controller is in emergency stop mode.

Controller is not in emergency stop

mode.

Emergency

Stop

07

High temperature alarm for Room means, room temperature is

equal or above the set value of P2 parameter.

Low temperature alarm for Room means, room temperature is

equal or below the set value of P3 parameter.

High humidity alarm means, humidity is above the set

value of H2 parameter.

equal or

Ht

Lt

Low humidity alarm Means humidity is above the set

value of H3 parameter.

equal or

HH

LH

Room temperature fail means, Room sensor not connected or

out of range.

PP

Condenser temperature fail means, condenser sensor not

connected or out of range.

C-PP

Evaporator temperature fail means, Evaporator sensor not

connected or out of range.

Humidity fail means, Humidity sensor not connected or out of

value.

SPPR Fault.

E-PP

H-PP

Compressor over load fault.

SPPR

C-OL

Compressor under load fault.

C-UL

Defrost over load fault.

D-OL

Fault Messages :

HP fault.

HP

Auxiliary fault.

LP fault.

LP

AUX

Defrost under load fault.

D-UL

CRC-2052 CRC-2052

Page 6

10

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

HSET Function :

controller for Humidity.

To set cut out point of the

Use UP/DOWN keys to set desired value.

Example : If this parameter is set to 70

then humidifier will be off at this

humidity .

04

To change EXIT parameter,

press the set key.

H3+1%

H2-1%

70%

Range

Min Max

Fact. Set

01

P2

Parameter

Function : To set allowable high

temperature limit.

To change P2 parameter,

press the set key.

Use UP/DOWN key to set desired value.

Example : Setting this parameter

0

at 30.0 C will not allow the set point to go

0

above 30.0 C also if the temperature

0

reaches 30.0 C, the display will show HT

(High Temperature). The alarm will be

ON. But at power on till the AL delay is

over controller will not generate HT Alarm.

Once set at a particular value, this will

not allow the set point to go above this

value and below P3 setting.

To set other parameter

Press & hold PRG key for

2 seconds

Display will show ‘P2’ and scroll the

description of the parameter.

To go to other parameters ,

use up / down keys.

SP+0.5ºC

50.0ºC 50.0ºC

Range

Min Max

Fact. Set

PRG

(Message on Display)

Min: MINIMUM Max : MAXIMUM

Fact. Set : FACTORY SETTING(DEFAULT)

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

To set other parameter

Press & hold SET key for

2 seconds

Display will show ‘SET’ and scroll the

description of the parameter.

To go to other parameters,

use up / down keys.

09

SP To set the cut-out point of the controller.

Display will change to set value.

The set point value can now be changed

by using the UP/DOWN key. After

desired value, press the SET key & you

will see “-- ” which confirms that the set

point has been stored in memory.

01

To change Set Point parameter,

press the set key.

QFS

P2-0.5ºC

0ºC

Range

Min Max

Fact. Set

QFS To set the quick freeze set point.

Use UP/DOWN keys to set desired value.

If controller is in quick freeze mode then

compressor will cut in/ cut out as per this

set point till the quick freeze duration is

over.

SP : Set Point.

02

To change QFS parameter,

press the set key.

-50.0ºC

SP

-5.0ºC

Range

Min Max

Fact. Set

CSET To set the Condenser set point.

Use UP/DOWN keys to set desired value.

If condenser logic is set to SP then

condenser will switch off at this set point.

03

To change CSET parameter,

press the set key.

0.0ºC

99.9ºC

20.0ºC

Range

Min Max

Fact. Set

CRC-2052 CRC-2052

EXIT

End of set mode

05

HT

Page 7

12

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

P6

Parameter

Use UP/DOWN keys to set desired value.

Example :

This parameter is used to protect the fan

from restarting in a short period of time

and can be set between 0 to 20 minutes.

If this parameter is set at 3

minutes, the compressor will cut off at

the set temperature, but will not restart

for a minimum of 3 minutes, even if the

differential is achieved earlier. This

To change P6

press the set key.

parameter,

05

Function : To set time delay between

relay restart time.

1 Min 20 Min 3 Min

Range

Min Max

Fact. Set

P5

Parameter

Use UP/DOWN keys to set desired

value.

Example :

In time it may be possible that the

display may be offset by a degree or so.

To compensate for this error, you may

need to add or minus the degrees

required to achieve the correct

temperature.

The temperature on the

O

display is 28.0 C, whereas the actual

O

temperature is 30.0 C. You will need to

O

set this parameter to 2.0 C, which

means that once out of the programming

parameter, the display will show the

O O O

temperature 30.0 C (28.0 C + 2.0 C).

To change P5

press the set key.

parameter,

04

Function : To set probe calibration.

-10.0ºC 10.0ºC 0.0ºC

Range

Min Max

Fact. Set

11

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

02

P3

Parameter

Function : To set allowable low

temperature limit.

Use UP/DOWN key to set desired value.

Example : Setting this parameter at

0

-30.0 C will not allow the set point to go

0

below -30.0 C also if the temperature

0

reaches -30.0 C, the display will show

LT (Low Temperature). The alarm will be

ON.

Once set at a particular value, this will

not allow the set point to go below this

value and above P2 setting.

To change parameter,

press the set key.

P3

-50.0ºC

SP-0.5ºC

-50.0ºC

Range

Min Max

Fact. Set

(Message on Display)

Use UP/DOWN keys to set desired value.

Example(Cooling Mode) : If the set

0

point is set at 10.0 C and differential is

0

set at 2.0 C, then when the system

0

reaches 10.0 C, the comp. relay will

0

cutout. Since the differential is 2.0 C, the

0

comp. Relay will cutin at 12.0 C

0 0

(10.0 C + 2.0 C).

03

P4

Parameter

Function : To set the differential for

compressor restart.

To change P4

press the set key.

parameter,

0.5ºC 20.0ºC 2.0ºC

Range

Min Max

Fact. Set

parameter is good to protect the life of

the compressor when there are power

fluctuations and the compressor is

switched off and on within a few seconds.

LT

Page 8

13

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

P7

Parameter

06

Function : To set duration of defrost.

To change the P7 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

0 Min 99 Min 30 Min

Range

Min Max

Fact. Set

This is maximum amount of time allowed

for defrost. If set to 0, there will be no

defrost cycle.

Example : If P7 is set to 15 Mins and

P8 parameter is set to 1 Hr. then after

every 1 Hr defrosting will take place for

15 mins.

P8

Parameter

07

Function : To set defrost frequency.

To change the P8 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

1 Hr 31 Hrs 6 Hr

Range

Min Max

Fact. Set

This is the amount of time between two

defrost cycles.

Example : same as P7 parameter.

P9

Parameter

08

Function : To set power on defrost delay.

To change the P9 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

0 Min 99 Min 30 Min

Range

Min Max

Fact. Set

This is the amount of time at power on

after which defrosting will take place

once.

Example : If P9 parameter is 30 mins

then at power after 30 mins defrosting

will take place once.

14

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

P10

Parameter

09

Function : To set type of defrost.

To change the P10 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

HTR HTG HTR

Range

Min Max

Fact. Set

HTR : Heater defrost where compressor

is OFF.

HTG : Hot Gas defrost where compressor

is ON.

P11

Parameter

10

Function : To set drip time for defrost.

To change the P11 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

0 Min 30 Min 1 Min

Range

Min Max

Fact. Set

During this period Compressor,

Evaporator Fan, LSV relay and Heater

will stay off so that the defrost water can

drain out.

P12

Parameter

11

Function : To set type of computation for

defrost time..

To change the P9 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

REAL CRH REAL

Range

Min Max

Fact. Set

REAL = Total of real time.

Example : This means that the time

calculation for defrost frequency will be

for the total hours the unit has been

running.

CRH - Sum of total compressor

operating times. This means that for

time calculation, the unit will add the

total time the compressor has been in

an ON mode.

It keeps a record of the hours worked

+/-½ Hour incase of a power failure.

CRC-2052 CRC-2052

Page 9

15 16

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

Example : If Defrost frequency is set to

6hrs. and 3.45 hrs have passed after

unit has started and power fails, then

defrost cycle will stat after 3½ hours

when power resumes.

P13

Parameter

12

Function : To set defrost stop

temperature

To change the P13 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

-50.0ºC 50.0ºC 4.0ºC

Range

Min Max

Fact. Set

If coil/Evap temperature is reached upto

this temperature defrost will stop.

Example : If this parameter is set to

7.0ºC,then if defrosting is in progress then

when temperature reaches 7.0ºC, the

defrost process will stop.

RH

Parameter

13

Function : To enable or disable humidity

sensing.

To change the RH Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

DIS ENB DIS

Range

Min Max

Fact. Set

DISABLE : Humidity sensing disable.

ENABLE : Humidity sensing enable.

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

H2

Parameter

14

Function : To set allowable high humidity

limit.

To change the H2 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

Hset+1 100% 100%

Range

Min Max

Fact. Set

Once set at a particular value, this will not

allow the set point for Humidity to go

above this value and below H3 Set value.

Example : Setting this parameter at 70%

will not allow the set point of Humidity to

go above 70% .

Also, if the humidity reaches 70% or

above. the display will show HH(High

Humidity) indicating that the humidity has

gone above the value in this parameter

H3

Parameter

15

Function : To set allowable low humidity

limit.

To change the H3 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

0% Hset-1 0%

Range

Min Max

Fact. Set

Once set at a particular value, this will not

allow the set point for Humidity to go

below this value and above H2 Set value.

Example : Setting this parameter at 40%

will not allow the set point of Humidity to

go below 40% .

Also, if the humidity reaches 40%. the

display will show LH(Low Humidity)

indicating that the humidity has gone

below the value in this parameter.

H4

Parameter

16

Function : To set differential (Hysterisis)

for humidity.

To change the H4 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

Example : If the set point is set at 60%

and differential is set at 3, then when the

system reaches 60%, the Relay will cut

out. Since the differential is 3, the relay will

cut in (restart) at 63% (60% -3%).

1% 10% 2%

Range

Min Max

Fact. Set

(Message on Display)

HH

(Message on Display)

LH

CRC-2052 CRC-2052

Page 10

17

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

H5

Parameter

17

Function : To set probe calibration for

humidity.

To change the H5 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired

value.

In time it may be possible that the

display for Humidity may be offset by a

% or so. To compensate for this error,

you may need to add or minus the %

required to achieve the correct Humidity.

Example : The Humidity on the display

is 40%, whereas the actual Humidity is

42%. You will need to set the H5

parameter to 2, which means that once

out of the programming mode, the

Humidity will show 42%(40% + 2%).

-10% 10% 0%

Range

Min Max

Fact. Set

H6

Parameter

18

Function : To set time delay between

relay restart time for humidity.

To change the H6 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

This parameter is used to protect the

Humidifier from restarting in a short period

of time.

Example : If H6 set at 3 minutes, the

relay for Humidifier will cut off at the set

Humidity, but will not restart for a

minimum of 3 minutes, even if the

differential is achieved earlier. This

parameter is good to protect the life of

the Humidifier or even in applications

where the probe is placed at places

where there are sudden & short changes

in humidity like above a cold room door.

1 Min 20 Min 2 Min

Range

Min Max

Fact. Set

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

18

QFD

Parameter

19

Function : To set quick freeze duration.

To change the QFD Parameter,

press the set key.

Use UP/DOWN keys to set desired value.

This is the maximum amount of time

allowed for Quick Freeze. If set to “0”,

there will be no quick freeze.

Example : If QFS is set to -20.0 C, and

quick freeze duration is set to 1 hr ,then

when it is in quick freeze mode, then the

Comp. will work on -20.0C set point for

1hr.

0 Hr 12 Hrs 2 Hr

Range

Min Max

Fact. Set

CND3

Parameter

20

Function : To set condenser logic.

To change the CND3

parameter, press the set key.

Use UP/DOWN keys to set desired value.

This function is used to set condenser

logic as per compressor or condenser Set

point

COMP = As per compressor.

SP = As per condenser SP.

If this parameter is set to Compressor

then condenser will switch ON / OFF as

per compressor. But if set to SP then

Condenser will be OFF when condenser

temperature reaches condenser SP.

COMP SP COMP

Range

Min Max

Fact. Set

CND4

Parameter

21

Function : To set condenser differential.

To change the CND4

parameter, press the set key.

Use UP/DOWN keys to set desired value.

Example : If this parameter is set to SP

and CSET (Condenser set point ) is 20.0

deg & CND4 to 2.0 deg then at 20.0

degree condenser relay will be off and

restart at (20.0 +2.0) 22.0 deg

0.5ºC 20.0ºC 2.0ºC

Range

Min Max

Fact. Set

CRC-2052 CRC-2052

Page 11

19

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

CND5

Parameter

22

Function : To set condenser probe

calibration.

To change the CND5

parameter, press the set key.

Use UP/DOWN keys to set desired

value.

In time it may be possible that the

display for condenser may be offset by a

deg or so. To compensate for this error,

you may need to add or minus the offset

required to achieve the correct

condenser temperature.

Example : The temperature on the

display is 28.0ºC, whereas the actual

temperature is 30.0ºC. You will need to

set the CND5 parameter to 2.0ºC, which

means that once out of the programming

mode, the temperature will show 30.0ºC

(28.0ºC+ 2.0ºC).

-10.0ºC 10.0ºC 0.0ºC

Range

Min Max

Fact. Set

CND6

Parameter

23

Function : To set condenser on delay

timings.

To change the CND6

parameter, press the set key.

Use UP/DOWN keys to set desired value.

When Compressor delay over Condenser

Fan will come ON first, after cond. On

delay over Comp will come ON.

0 Sec 30 Sec 15 Sec

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired value.

This function is used to decide the

condenser status when hot gas defrost is

on. This parameter is not applicable for

Heater defrost.

At hot gas defrost,

OFF : Condenser will be OFF

ON : Condenser will be ON

CND7

Parameter

24

Function : To set condenser status at hot

gas defrost.

To change the CND7

parameter, press the set key.

OFF ON OFF

Range

Min Max

Fact. Set

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

20

Use UP/DOWN keys to set desired value.

This setting is used to limit the max.

temperature beyond which the Evap.Fan

will cut off.

Example : If this parameter is set to

2.0ºC, then Evap. Fan will cut off at 2.0ºC.

L1

Parameter

25

Function : To set Evaporator Fan stop

temperature.

To change the L1 parameter,

press the set key.

-50.0ºC 50.0ºC 2.0ºC

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired

value.

Example : If this is set at 3 minutes,

Evap. Fan relay will cut off at the set by

Evap. Fan Stop TC. Parameter but the

Fan will not come on for a minimum of 3

minutes even if it’s differential is

achieved earlier.

L2

Parameter

26

Function : To set Evaporator Restart

Delay.

To change the L2 parameter,

press the set key.

0 Min 20 Min 1 Min

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired value.

OFF : Evaporator Fan will be Off at

compressor OFF.

ON : Evaporator Fan will be On at

compressor OFF.

L3

Parameter

27

Function : To set Evaporator Fan status

at compressor off.

To change the L3 parameter,

press the set key.

OFF ON

ON

Range

Min Max

Fact. Set

CRC-2052 CRC-2052

Page 12

21

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

L4

Parameter

28

Function : To set Evaporator Fan

differential.

To change the L4 parameter,

press the set key.

Use UP/DOWN keys to set desired

value.

Example : If Evaporator Fan Stop Tc

parameteris set to 2.0ºC, and if EVAP

DIFFERENTIAL parameter is set to

2.0ºC,then Evap. Fan will cut off at 2.0ºC

and restart only at 0.0ºC.

(2.0ºC-2.0ºC = 0.0ºC).

0.5ºC 20.0ºC 2.0ºC

Range

Min Max

Fact. Set

L5

Parameter

29

Function : To set Evaporator probe

calibration.

To change the L5 parameter,

press the set key.

Use UP/DOWN keys to set desired value.

In time it may be possible that the display

may be offset by a degree or so. To

compensate for this error, you may need

to add or minus the degrees required to

achieve the correct temperature. Setting

value is from -10ºC to + 10ºC.

-10.0ºC 10.0ºC 0.0ºC

Range

Min Max

Fact. Set

L7

Parameter

30

Function : To set CompressorEvaporator Fan status at Door open

condition.

To change the L7 parameter,

press the set key.

Use UP/DOWN keys to set desired value.

At Door Open,

NORM : Normal.

FAN : Evaporator Fan Off.

COMP : Compressor Off.

F-C : Compressor and Evaporator Fan

Off.

NORM F-C NORM

Range

Min Max

Fact. Set

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

L8

Parameter

31

Function : EvaporatorTo set Fan status

during defrost.

To change the L8 Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

OFF ON OFF

Range

Min Max

Fact. Set

OFF : Fan Off during

defrost.

ON : Fan On during

defrost.

Evaporator

Evaporator

22

BUZ

Parameter

32

Function : To enable / disable buzzer.

To change the BUZ Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

DIS ENB ENB

Range

Min Max

Fact. Set

Example:

ENB : Buzzer enabled.

DIS : Buzzer disabled.

AL

Parameter

33

Function : This parameter is used to set

power on delay for alarm.

To change the AL Parameter

parameter, press the set key.

Use UP/DOWN keys to set desired value.

0 Min 99 Min 30 Min

Range

Min Max

Fact. Set

Example : If you set this parameter to

20, once the power is switched on, the

alarm will not activate for 20 minutes

after the power is switched on. This

is most useful to avoid the nuisance

alarms when the ambients are high

when the machine is switched on after

a long time.

CRC-2052 CRC-2052

Page 13

23

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

C-UL

Parameter

34

Function : Under load limit for

compressor current.

To change the C-UL parameter,

press the set key.

Use UP/DOWN keys to set desired

value.

Example : If C-UL= 1.0A and

compressor current is less than 1.0A

then and exists till C2 current sensing

delay then it is registered as UL fault.

Compressor will get OFF on this fault. If

after 3 retries within 1 Hour current

drawn is still less than 1.0Amp the

controller will trip the compressor on

fault and activate respective alarm relay.

Also display will flash ‘C-UL’. Controller

will go in manual reset mode.

0.0A (C-OL

-1.0)A

1.0A

Range

Min Max

Fact. Set

C-OL

Parameter

35

Function : Over load limit for compressor

current.

To change the C-OL parameter,

press the set key.

Use UP/DOWN keys to set desired value.

Example : If C-OL= 10 A and compressor

current is greater than 10 A then and exist

till C2 current sensing delay then C-OL

fau lt e xists and fla sh o n di splay.

Compressor will be tripped on this fault.

(C-UL

+1.0) A

18.0A 10.0A

Range

Min Max

Fact. Set

24

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

D-UL

Parameter

36

Function : Under load limit for Heater /

Solenoid.

To change the D-UL parameter,

press the set key.

0.0A (D-OL

-1.0) A

1.0A

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired value.

Example : If C2 = 5 sec then, any

current fault will be valid only when it

exists for more than 5 sec.

To change the C2 parameter,

press the set key.

C2

Parameter

38

Function : Current sensing delay.

5 Sec

60 Sec

5 Sec

Range

Min Max

Fact. Set

D-OL

Parameter

37

Function : Over load limit for

Heater/Solenoid.

To change the D-OL parameter,

press the set key.

Use UP/DOWN keys to set desired

value.

Example : If D-OL= 10 A and Heater /

Solenoid current is greater than 10 A

then and exist till C2 current sensing

delay then D-OL fault exists and flash on

display. Heater / Solenoid will be tripped

on this fault.

(D-UL

+1.0) A

18.0A 10.0A

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired value.

If this parameter is set to

Setting this parameter to disable will

ignore HP fault for compressor. If this

parameter is set to Enable then controller

will detect HP trip.

Example :

ENB : HP sensing is enabled.

DIS : HP sensing is disabled

To change the D0 parameter,

press the set key.

D0

Parameter

39

Function : To enable or Disable HP

sensing.

DIS

ENB

ENB

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired

value.

Example : If D-UL= 1.0A and Heater /

Solenoid current is less than 1.0A then

and exists till C2 current sensing delay

then it is registered as UL fault. Heater /

Solenoid will get OFF on this fault. If

after 3 retries within 1 Hour current

drawn is still less than 1.0Amp the

controller will trip the Heater/Solenoid on

fault and activate respective alarm relay.

Also display will flash ‘D-UL’. Controller

will go in manual reset mode.

CRC-2052 CRC-2052

Page 14

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

26

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

25

Use UP/DOWN keys to set desired

value.

Setting this parameter to disable will

ignore LP fault for compressor. If this

parameter is set to Enable then controller

will detect LP trip.

Example:

If this parameter is set to

ENB : LP sensing is enabled.

DIS : LP sensing is disabled.

To change D1

parameter, press the set key.

DIS

ENB

D1

Parameter

40

ENB

Function : To enable or disable LP

sensing.

Range

Min

Max

Fact. Set

D2

Parameter

41

To change D2 parameter,

press the set key.

0V

230V

Function : Fault sensing logic.

230V

Use UP/DOWN keys to set desired

value.

0v : 0V at HP/LP/AUX input will be

sensed as fault and trip the

compressor.

230V : 230V at HP/LP/AUX input will be

sensed as fault and trip the

compressor.

Range

Min

Max

Fact. Set

To change D3 parameter,

press the set key.

0 Sec

42

MinMin

Use UP/DOWN keys to set desired value.

Example : If this parameter is set to 5

sec,then LP fault will be sensed only

when it present continuously for 5 Secs.

180 Sec

30 Sec

D3

Parameter

Function : To set LP sensing delay.

Range

Max

Fact. Set

Range

Max

Fact. Set

To change D4 parameter,

press the set key.

D4

Parameter

43

Function : To set reset mode for HP fault.

MAN

AUTO

AUTO

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

Use UP/DOWN keys to set desired

value.

MAN : Manual Mode.

AUTO : Auto mode.

If this parameter set to “MAN” mode HP

fault will be cleared only after pressing

reset key for 2 seconds.

If this parameter is set to “AUTO” mode

HP fault will be cleared automatically

when it is healthy.

To change E1 parameter,

press the set key.

E1

Parameter

44

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

When set to

ON : Relay will stay ON.

CYC : Relay performs a duty cycle of

as per TON & TOFF .

OFF : Relay will stay OFF.

ON OFF CYC

Function : To set Compressor Relay

status on Probe Failure.

Use UP/DOWN keys to set desired

value.

To change TON parameter,

press the set key.

TON

Parameter

45

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

At room probe fail condition when E1

parameter is selected as 'CYC' then the

on cycle is specified by Ton parameter.

1 Min 30 Min 10 Min

Function : To set On cycle at room

probe fail.

Use UP/DOWN keys to set desired

value.

CRC-2052 CRC-2052

Page 15

27

28

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

To change TON parameter,

press the set key.

TOFF

Parameter

46

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

At room probe fail condition when E1

parameter is selected as 'CYC' then the

Off cycle is specified by Ton parameter.

1 Min 30 Min 4 Min

Function : To set Off cycle at room probe

fail.

Use UP/DOWN keys to set desired

value.

To change PDN parameter,

press the set key.

PDN

Parameter

49

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

DIS : SV relay will not activate.

ENB : SV relay will get activated and

will cut out and cut-in according

to set temperature.

DIS ENB DIS

Function : To activate Solenoid Valve

relay.

Use UP/DOWN keys to set desired

value.

E7

Parameter

Use UP/DOWN keys to set desired

value.

TEMP : At defrosting temperature

will be dispalyed.

DEFR : At Defrosting 'Defrost ON'

will scroll.

47

Function : To set Display at defrosting.

To change E7 parameter,

press the SET key.

TEMP DEFR

TEMP

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

Example : If this parameter is set to 7

mins then, when light is switched on after

7 mins it will be switch off automatically.

LD

Parameter

Use UP/DOWN keys to set desired

value.

This parameter is used set the time

delay to automatically switch off the light.

If LD is set to 0 then this parameter is

disabled.

48

Function : To set time delay to switch off

the light .

To change LD parameter,

press the SET key.

0 Min 30 Min 7 Min

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

0

9999

0

To change the PW parameter,

press the set key.

PW

Parameter

50

Function : To change password.

Use U P/DOWN key to change the

password.

User can enter into program mode

only if correct password is entered. If the

password is wrong it will show ‘INVALID

PASSWORD’.

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

E8

Parameter

Use UP/DOWN keys to set desired

value.

Example: If this is set to 10 min,

then manual defrost for 10 min

will take place during Coil probe fail.

47

Function : Defrost duration during Coil

probe failure.

To change E8 parameter,

press the SET key.

1 Min 10 Min

5 Min

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

CRC-2052 CRC-2052

Page 16

29

30

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

ID

Parameter

This parameter is used to set the Unit ID

of the device.

53

Function : To set Unit ID.

To change Unit ID

parameter, press the SET key.

1 240

1

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

CRH

Parameter

51

Function : To view Compressor run

Hours.

It will display compressor run hours. It's

a read only parameter.

NO

YES

NO

CCRH

52

Function : Clear Compressor Run

Hours.

If this parameter is set to ‘YES’

compressor run hours (CRH) are

cleared.

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

LP

54

To change Keypad Lock

parameter, press the set key.

NO YES NO

Function: To activate Keypad Lock.

This parameter can lock the keypad so

that tempering is not possible by bystanders.

NO : deactivates keypad lock.

YES : activates keypad lock.

On activation, all the parameters can only

be viewed, but not modified.

If the keypad is locked “LOCK” message

will be displayed..

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

DIS

ENB

DIS

To change PO parameter,

press the SET key.

PO

Parameter

Function : To enable/disable Power

Switch.

Use UP/DOWN keys to get desired

value & press SET key to confirm.

DIS : Disable power switch

ENB : Enables power switch

Controller has power switch, which

if enable puts controller in active or

stand by state.

If press for 2 seconds controller will

go in stand by mode, display will

be as per “PDIS” parameter.

To again switch to ACTIVE WORKING

MODE, press power switch again for 2

seconds. All leds and display will flash

and enter into NORMAL WORKING

MODE.

23

55

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

LED

TEMP

LED

To change PDIS parameter,

press the SET key.

PDIS

Parameter

Function : To set display at power OFF

mode.

Use UP/DOWN keys to set desired value.

At power OFF mode power OFF LED

will glow & display will be as below,

LED : Display Will be Blank.

OFF : Display will show OFF.

TEMP : Display will show Temperature.

23

56

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

CRC-2052 CRC-2052

Page 17

31

Sr.

No.

Parameter setting method

Description of parameters and functions.

Parameter

EP

Parameter

Once the set key is pressed, the

controller goes into the normal mode

and displays the Room Temperature and

all settings are recorded.

58

Function: To exit programming.

To exit programming

parameter, press the SET key.

NO

YES

NO

To change FS parameter,

press the SET key.

FS

Parameter

Function : To restore default settings of

the controller.

Use UP/DOWN keys to set desired value.

When set to YES all parameters

are programmed to factory

values.

Useful to debug setting related

problems.

23

57

Range

Min Max

Fact. Set

Range

Min Max

Fact. Set

Technical Data

32

Housing : ABS Plastic.

Dimensions : 400 x 300 x 135 mm

Mounting : Wall mounting.

Connection : Spring clamp terminal block.

4 sq. mm wire.

Display : 4 Digit, 1” Dot matrix Display and 14 LEDs for

indication.

Data Storage : Non-Volatile EEPROM Memory.

Power Input (Options) : 415Vac +/-10%, 50-60Hz.

3Phase Supply with Neutral

0 0

Operating Temp : 5 C to 50 C(non-condensing).

0 0

Storage temp : -20 C to 70 C(non-condensing).

Output :

Contactors Comp & Def. : 18A.

Contactor Evap. : 9A.

Condenser Relay : 10A/250Vac.

Light Relay : 10A/250Vac.

Alarm Relay : 5A/250Vac.

Humidifier Relay : 10A/250Vac.

Sensors :

1) Temperature sensor:

0

Resolution : 0.1 C.

0

Accuracy : +/-1 C.

0 0

Probe Tolerance at 25 C : +/-0.3 C.

Room & Evap Temperature :

0 0

Range : -50.0 C to 50.0 C

Condenser Temperature :

0 0

Range : 0.0 C to 99.9 C

2) Humidity sensor

Range : 0 to 100%

Resolution : 1%.

Analog I/p:

Compressor current (R,Y,B)

Defrost current(R,Y,B)

Resolution : 0.1Amp.

Accuracy : +/-1 Amp.

Sensor Type : NTC Thermistor.

Sensor Type : 4-20mA out.

CRC-2052 CRC-2052

Page 18

33

Technical Data

Digital Inputs:

HP, LP, Auxillary, Door, Sppr, R-Ph, Y-Ph, B- Ph.

Buzzer : Internal

RS485 Connectivity : Modbus RTU Protocol

Baud Rate : 9600

Device ID : 1 (By Default)

34

WIRING : The probe and its corresponding wires should never be installed

in a conduit next to control or power supply lines. The electrical wiring

should be done as shown in the diagram. The power supply circuit should

be connected to a protection switch.

WARNING : Improper wiring may cause irreparable damage and personal

injury. Kindly ensure that wiring is done by qualified personnel only.

Maintenance : Cleaning : Clean the surface of the controller with a soft

moist cloth. Do not use abrasive detergents, petrol, alcohol or solvents.

Controller

Controller should be installed in a place protected by vibration, water and

corrosive gasses and where ambient temperature does not exceed the values

specified in the technical data.

Probe

To give a correct reading, the probe must be installed in a place protected from

thermal influences, which may affect the temperature to be controlled.

Caution

CRC-2052 CRC-2052

Page 19

35

The information in this document is subject to change in order to improve

reliability, design or function without prior notice and does not represent a

commitment on the part of the company. In no event will the company be liable

for direct, indirect, special, incidental or consequential damage arising out of

the use or inability to use the product or documentation, even if advised of the

possibility of such damages. No part of this manual may be reproduced or

transmitted in any form or by any means without the prior written permission of

the company.

Notice

Disclaimer

Warranty

This manual & its contents remain the sole property of A.S.Controls Pvt.Ltd.,

India and shall not be reproduced or distributed without authorization. Although

great care has been taken in the preparations of this document, the company

or its vendors in no event will be liable for direct, indirect, special, incidental or

consequential damage arising out of the use or inability to use the product or

documentation, even if advised of the possibility of such damages. No part of

this manual may be reproduced or transmitted in any form or by any means

without the prior written permission of the company. A.S.Controls Pvt.Ltd.

reserves the right to make and changes or improvements without prior notice.

This product is warranted against defects in materials and workmanship for a

period of one year from the date of purchase. During the warranty period,

product determined by us to be defective in form or function will be repaired or,

at our option, replaced at no charge. This warranty does not apply if the product

has been damaged by accident, abuse, and misuse or as a result of service or

modification other than by the company. This warranty is in lieu of any other

warranty expressed or implied. In no event shall the company be held liable for

incidental or consequential damages, such as lost revenue or lost business

opportunity arising from the purchase of this product.

INDIA

Ball Valves

Globe Valves

Hand Valves

Flow Switches

Solenoid Valves

OUR OTHER PRODUCTS

Cold Room Controller

Chiller Controller

Two Compressors Controller

Heating Controller

Humidity Controller

Pressure Controller

TM

00 / 13.03.12

CRC-2052

Page 20

SUGGESTED CONNECTION DIAGRAM

2 1

5

4

3

6

R PHASE

LSV

COMP

DEF

EVAP

COND

2 1

4

3

LIGHT

ALARM

HUMIDIFIER

PHASE

1

4

7

6

9 8

10

2

35

LP

AUX

HP

SPPR

DOORGND

B Phase

1

4

9

8

7

6

11 1012

Y Phase

2

35

R PHAS E

NEUTRAL

1

4

9 8

111012

2

35

Cond P robe

Coil P robe

Room P robe

7

6

14 13

RH IN

GND

RS485

+

-

2 1

6

5

3

7

GND

CT6

CT5

CT4

CT3

CT2

CT1

4

8

A2 A3 A6

A7A5

1 2

A1

A4

OUTPUTS FAULT SIGNALS INPUT SUPPLYSENSOR CT INPUTOUTPUTS

EMERGENCY

STOP

Loading...

Loading...