Page 1

BUILT-IN DESIGN GUIDE

Page 2

Contents

Built-In Design Options 4

Model Specifications 6

Planning Information 9

Framed Panels 12

Overlay Panels 18

Flush Inset Panels 22

Dispenser Specifications 28

Side Panels 29

Dual Installations 30

Accessories 37

Full-Scale Templates 38

Sub-Zero Warranty 42

Features and specifications indicated herein and on our

website are subject to change at any time without notice.

Check our website, subzero.com, for the most up-to-date

specifications.

SUB-ZERO®is a registered trademark of Sub-Zero, Inc.

Page 3

Built-In Refrigeration 3

subzerotrade.com

Introducing New Built-In Refrigeration. Beginning in Fall, 2008, you will have a new line of built-in refrigeration

to offer your clients. We have re-engineered—exterior and interior —our built-in product line to offer you the best in design

options, and your clients the best in food preservation. The 600 series as you understand it now will be gone and the new

offering will take its place. We will have new panel sizes, model numbers and many new features. Review this design

guide for general specification information and keep coming back to the trade section of our website, subzerotrade.com,

for new information during the coming months.

Model Numbers. The cross-reference chart below

provides a listing of the new built-in model numbers and

the existing 600 series model numbers they are replacing.

New Built-In Model 600 Series

ALL REFRIGERATOR / ALL FREEZER

BI-36R 601R

BI-36RG 601RG

BI-36F 601F

OVER-AND-UNDER

BI-30U 611

BI-30UG 611G

BI-36U 650

BI-36UG 650G

SIDE-BY-SIDE

BI-36S 661

BI-42S 642

BI-42SD 685

BI-48S 632

BI-48SD 695

EXAMPLES

BI-30UG/O-RH 611G/O-RH

BI-48SD/F 695/F

Model Number Key

MODEL BI-36UG/S/PH-RH

PRODUCT TYPE

WIDTH

STYLE

FEATURE

DESIGN

HANDLE

DOOR SWING

PRODUCT TYPE

Built-In Refrigeration BI

WIDTH

30" (762) 30

36" (914) 36

42" (1067) 42

48" (1219) 48

STYLE

All Refrigerator R

All Freezer F

Over-and-Under U

Side-by-Side S

FEATURE

Glass Door G

High Altitude Glass A

Ice and Water Dispenser D

DESIGN

Framed /F

Overlay or Flush Inset /O

Classic Stainless Steel /S

HANDLE (classic stainless steel models)

Tubular Handle /TH

Curved Handle /CH

Pro Handle /PH

DOOR SWING

Right-Hand Swing -RH

Left-Hand Swing -LH

Page 4

Built-In Design Options 4

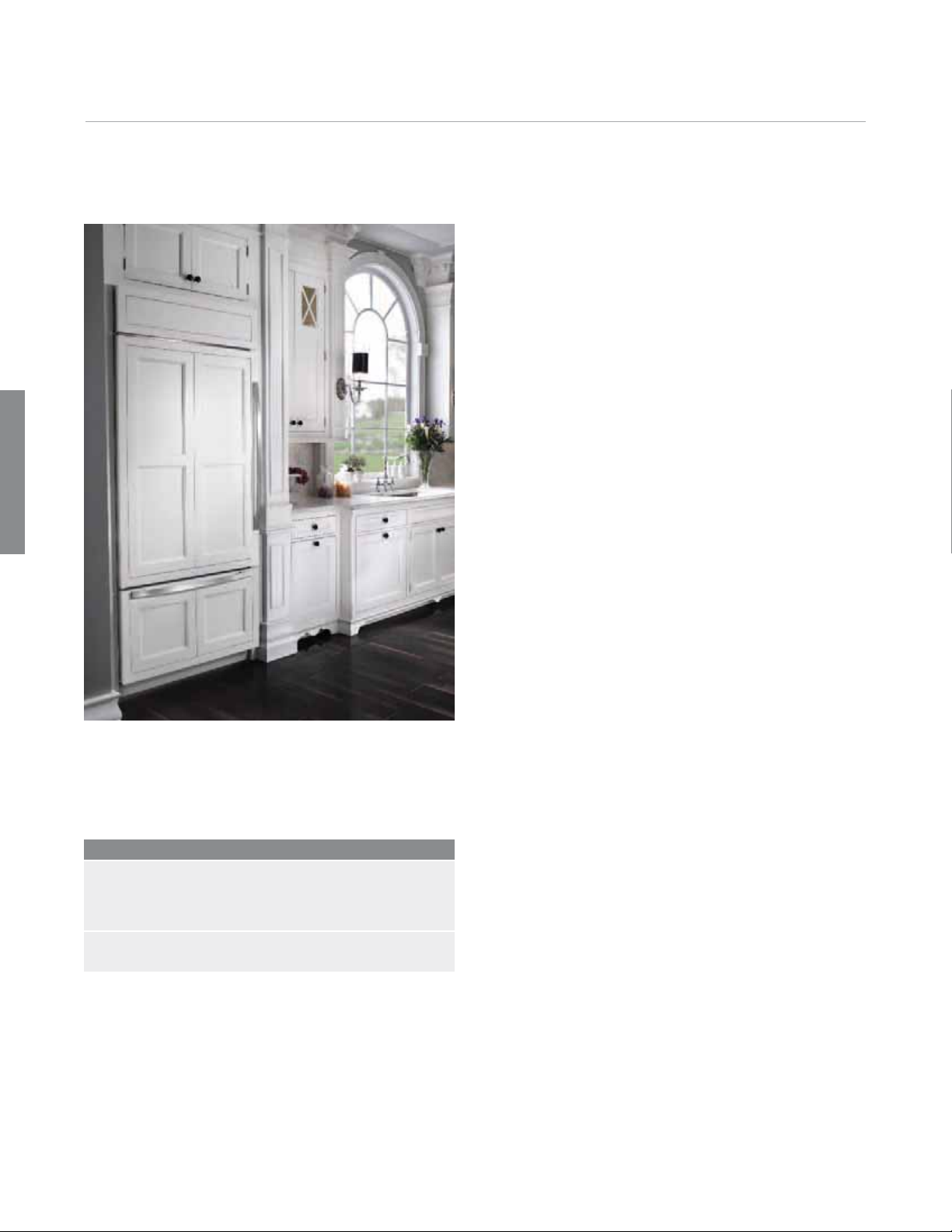

Built-In Design Options. A design classic is now even better. Four distinct design approaches provide limitless

flexibility for creating a beautiful kitchen. New lower profile hinges enable the new built-in units to merge more seamlessly

with surrounding cabinetry. Three handle options coordinate with Wolf cooking products.

Framed. Custom cabinetry

panels slide into the framed

door to blend into the kitchen

design. The framed design

comes with a standard

louvered grille and extruded

handles.

Overlay. Custom cabinet

overlay panels can be

combined with unique hardware for design flexibility.

Shown with curved handle

option to compliment Wolf

E Series ovens.

Page 5

Built-In Design Options 5

subzerotrade.com

Flush Inset. This brand new

design option allows for a flush

door and grille. Classic,

platinum and carbon stainless

steel panels are available as

sales accessories. Shown with

tubular handle option to mirror

Wolf L Series ovens.

Stainless Steel. For a

professional look, classic

stainless is standard and

requires no customization.

To compliment the look of Wolf

ranges, choose the Pro handle

option shown here.

Page 6

Model Specifications 6

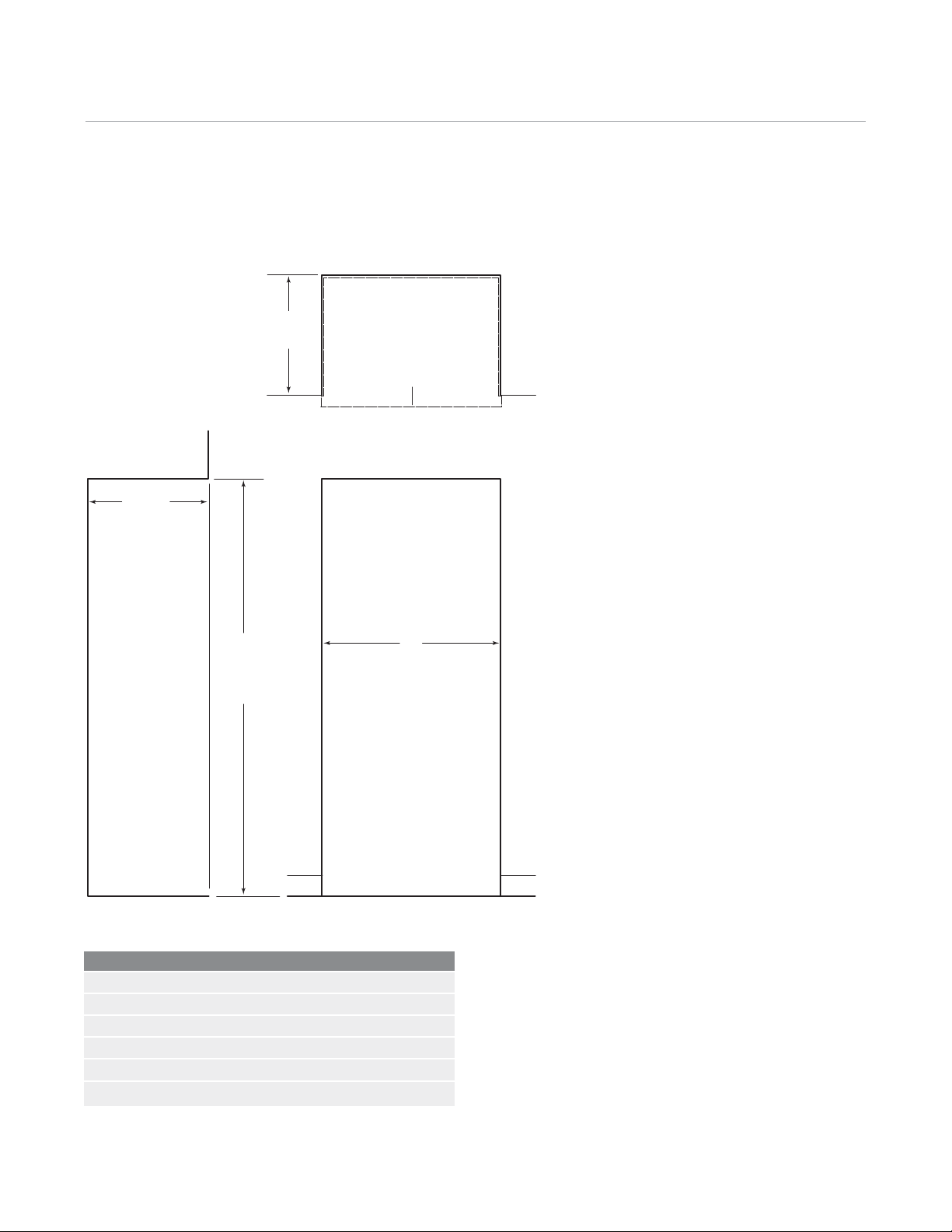

All Refrigerator / All Freezer Models

IMPORTANT NOTE:

The heights of the All

Refrigerator / All Freezer

Models have increased

from 73" (1854) to 84"

(2134).

84"

(2134)

36"

(914)

Model BI-36R

ALL REFRIGERATOR

Model BI-36RG

ALL REFRIGERATOR

GLASS DOOR

Over-and-Under Models

30"

(762)

(914)

30"

(762)

36"

36"

(914)

Model BI-36F

ALL FREEZER

36"

(914)

24"

(610)

SIDE VIEW

36"

(914)

84"

(2134)

24"

(610)

Model BI-30U Model BI-36UG

Model BI-30UG

WITH GLASS DOOR

Model BI-36U

WITH GLASS DOOR

SIDE VIEW

Page 7

Model Specifications 7

subzerotrade.com

Side-by-Side Models

84"

(2134)

36"

(914)

48"

(1219)

42"

(1067)

Model BI-42SModel BI-36S

Model BI-42SD

WITH DISPENSER

42"

(1067)

24"

(610)

SIDE VIEW

Models are shown in the stainless

steel design.

IMPORTANT NOTE: Throughout this

guide, dimensions in parentheses

are millimeters unless otherwise

specified.

84"

(2134)

48"

(1219)

24"

(610)

Model BI-48S

Model BI-48SD

WITH DISPENSER

SIDE VIEW

Page 8

Model Specifications 8

Door Clearance

237/8"

(606)

BEHIND

FRAME

A

C

23/8"

(60)

237/8"

(606)

BEHIND

FRAME

237/8"

(606)

BEHIND

C

BA

23/8"

(60)

FRAME

A

23/8"

(60)

All Refrigerator / All Freezer Models Over-and-Under Models Side-by-Side Models

Door Clearance

ALL REFRIGERATOR / ALL FREEZER A C

BI-36R, BI-36RG and BI-36F 371/4" (946) 17" (432)

OVER-AND-UNDER A B C

BI-30U and BI-30UG 311/4" (796) 235/8" (600) 141/2" (368)

BI-36U and BI-36UG 371/4" (946) 235/8" (600) 17" (432)

SIDE-BY-SIDE A C D

BI-36S 221/4" (565) 101/4" (260) 81/2" (216)

The doors of all built-in models open to a maximum of 110°.

A 90° door stop is shipped with all units. For additional

information, refer to the full-scale templates at the end of this

guide. The handle depth reflects the tubular, curved and pro

handles. For framed handle profile, refer to the full-scale

template on page 38.

IMPORTANT NOTE: For flush inset applications, add

to dimension (A).

BI-42S and BI-42SD 261/4" (668) 121/2" (318) 83/4" (222)

BI-48S and BI-48SD 30" (762) 14" (356) 93/4" (248)

CD

23/8"

(60)

1

/2"(13)

Interior Capacity / Weight

Capacity / Weight R F W

BI-36R 23.3 (660) 420 (191)

BI-36RG 23.5 (665) 430 (195)

BI-36F 22.8 (646) 406 (184)

BI-30U 12.7 (361) 4.1 (116) 462 (210)

BI-30UG 12.9 (367) 4.1 (116) 476 (216)

BI-36U 15.9 (450) 5.2 (148) 515 (234)

BI-36UG 16.1 (447) 5.2 (142) 529 (240)

Capacity / Weight R F W

BI-36S 12.2 (346) 8.0 (227) 538 (244)

BI-42S 16.0 (455) 8.0 (227) 582 (264)

BI-42SD 15.9 (452) 8.1 (230) 608 (276)

BI-48S 18.8 (532) 9.5 (269) 630 (286)

BI-48SD 18.7 (530) 9.6 (272) 656 (298)

Refrigerator (R) and freezer (F) interior capacities are listed in

cubic feet and (liters). Shipping weights (W) are listed in

pounds and (kilograms) and are based on stainless steel

models.

Page 9

Planning Information 9

subzerotrade.com

Standard Installation Opening Dimensions

Framed, Overlay and Classic Stainless Steel Models

TOP VIEW

24" (610)

OPENING

24" (610)

OPENING DEPTH

DEPTH

OUTLINE

OF UNIT WITH

3

/4" (19) PANEL

SIDE VIEW

833/4"

(2127)

OPENING

HEIGHT

83" min

(2108)

A

OPENING WIDTH

FRONT VIEW

Opening Width A

BI-36R, BI-36RG and BI-36F 351/2" (902)

BI-30U and BI-30UG 291/2" (746)

BI-36U and BI-36UG 351/2" (902)

BI-36S 351/2" (902)

BI-42S and BI-42SD 411/2" (1054)

BI-48S and BI-48SD 471/2" (1206)

IMPORTANT NOTE: If two units are installed side by side,

refer to pages 30–31 for dual standard installations.

Classic stainless steel models are ready to install out of the

box.

Page 10

Planning Information 10

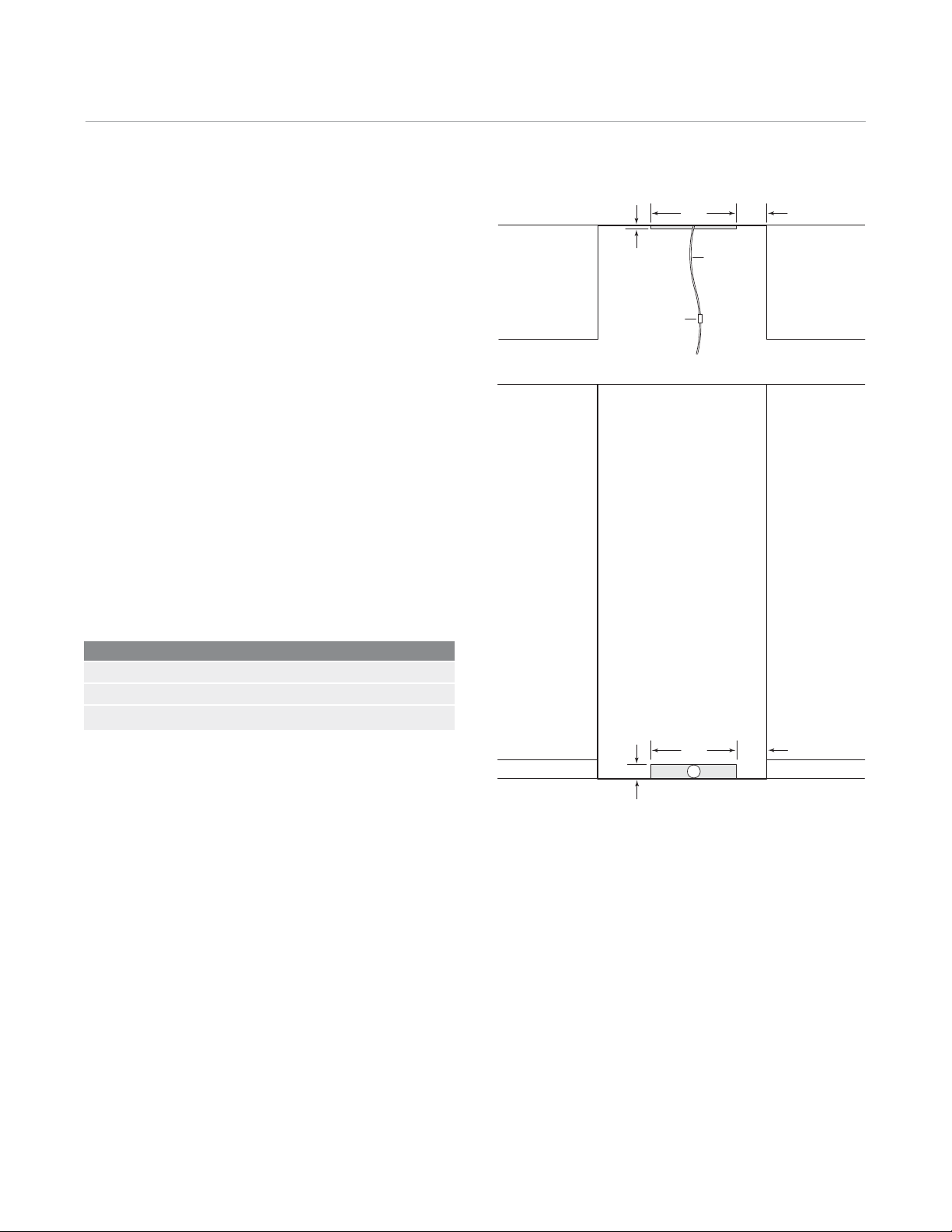

Electrical Requirements. For all built-in models, the

electrical supply should be located within the shaded area

shown in the illustration. Follow the National Electrical

Code and local codes and ordinances when installing

the receptacle. A separate circuit, servicing only this

appliance is required.

IMPORTANT NOTE: A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

Electrical Requirements

Power Supply 115 V AC, 60 Hz

Circuit Breaker 15 amp

Receptacle 3-prong grounding-type

FRONT VIEW

Location of electrical supply.

7"

(178)

E

6"

(152)

751/2"

(1918)

Page 11

Planning Information 11

subzerotrade.com

Plumbing Requirements. All built-in models with an

automatic ice maker come with a microbiological water

filtration system. The water supply line should be located

within the shaded area shown in the illustration. The

water supply line should be connected to the house

supply with an easily accessible shut-off valve between

the supply and the unit. Do not use self-piercing valves.

A saddle valve kit (4200880) is available from your

Sub-Zero dealer. The water line must not interfere with

installation of the anti-tip brackets.

IMPORTANT NOTE: A reverse osmosis system can be

used provided there is constant water pressure of 30 psi

(2.1 bar) to 100 psi (6.9 bar) supplied to the unit at all

times. In this application, the microbiological water filtration system should be set to bypass mode by removing

the water filter cartridge and inserting the bypass plug

(7005018) available from your Sub-Zero dealer. Installation

instructions packed with the unit will outline this

procedure.

Plumbing Requirements

Water Supply Line

Water Pressure 30–100 psi (2.1–6.9 bar)

Excess Water Line for Connection 36" (914)

1

/4" OD copper line

1

/2"

(13)

3" (76)

SHUT-OFF

VALV E

TOP VIEW

FRONT VIEW

18"

(457)

18"

(457)

W

(152)

WATER LINE

(152)

6"

6"

Location of water supply.

Page 12

Framed

Framed Panels 12

Framed Panels. If you and your client have ordered a

framed model, you will be adding panels to give the unit

the traditional Sub-Zero look. The framed panel design

option is available for all built-in framed models. For exact

door panel dimensions for built-in framed models, refer to

framed panel specifications on the following pages. Also

refer to the full-scale templates at the end of this guide

for additional panel and handle considerations.

The traditional framed models come with an elegant,

smooth, full-length handle. Optional extended full-length

handles that provide additional finger clearance for raised

panels are available through your Sub-Zero dealer.

Custom cabinetry panels slide into the framed door to

blend into the kitchen design. The framed design comes

with a standard louvered grille and extruded handles.

Framed Panel Requirements

MAX WEIGHT PER PANEL

BI-36R, BI-36RG and BI-36F 75 lbs (34 kg)

All Other Framed Models 50 lbs (23 kg)

MIN PANEL THICKNESS

All Framed Panels

1

/4" (6)

Page 13

Framed Panels 13

subzerotrade.com

Framed Panels. If the thickness of the custom panels

is less than

of shim material to build the total thickness to

the panel is thicker than

1

/4" (6), they must be backed up with a sheet

1

/4" (6). If

1

/4" (6), a routed edge must be

provided around the panel to ensure a proper fit. Refer to

the illustrations.

IMPORTANT NOTE: On all framed models, routing,

recessing or optional extended handles may be required

on raised panels for finger clearance under the handle.

Refer to the full-scale templates at the end of this guide.

TRIM

REVEAL

1

/4" (6) min

1

/4" (6)

PANEL

MAIN FRAME

DOOR

TRIM

REVEAL

1

/4" (6) min

ROUT TO

1

/4" (6)

MAIN FRAME

DOOR

Framed

IMPORTANT NOTE: On glass door models, the edges of

the window cut-out will need to be finished, as they will

be exposed.

IMPORTANT NOTE: When installing two units in a side by

side application, refer to pages 30–31 for dual standard

installations. Be aware that rough opening dimensions are

different for this application.

Do not exceed the framed decorative panel dimensions. Exceeding dimensions could cause damage

to the panels and the Sub-Zero unit.

Panels1/4" (6) thick or less. Panels thicker than1/4" (6).

Page 14

Framed Panels 14

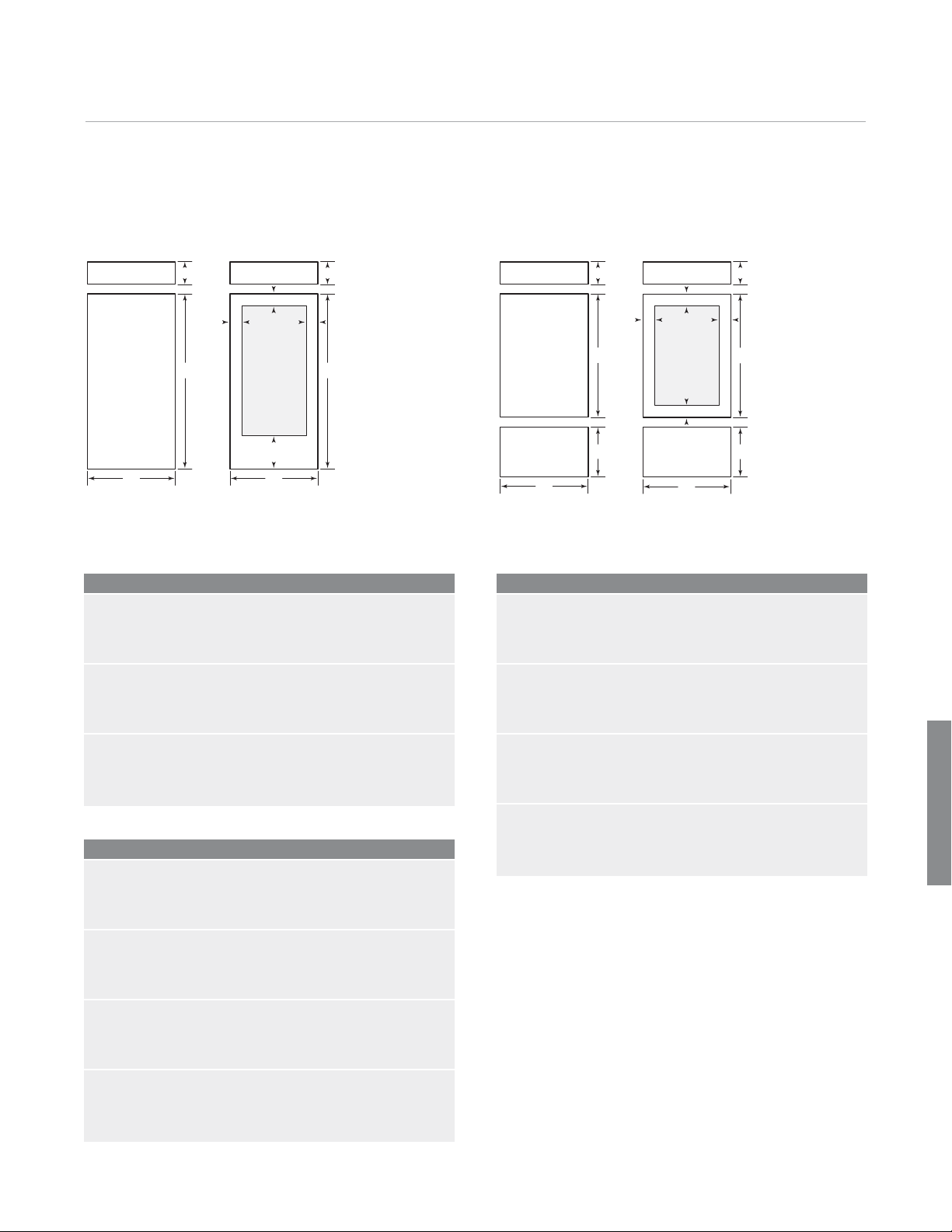

Framed Panel Specifications

Framed

A

A A

H

B

W

W

H

BI-36R / BI-36F BI-36RG

Models BI-36R, BI-36RG and BI-36F

REFRIGERATOR/FREEZER W H

Door Panel 353/4" (908) 699/16" (1767)

BI-36RG W H

Window Cut-Out 251/2" (648) 541/16" (1373)

AB

Cut-Out Location 53/16" (132) 105/16" (262)

A

A A

H

A

H

W

W

H

H

BI-30U / BI-36U BI-30UG / BI-36UG

Models BI-30U and BI-30UG

REFRIGERATOR W H

Door Panel 293/4" (756) 4915/16" (1268)

FREEZER W H

Drawer Panel 293/4" (756) 1811/16" (475)

BI-30UG W H

Window Cut-Out 191/2" (495) 3911/16" (1008)

Cut-Out Location 53/16" (132)

A

Models BI-36U and BI-36UG

REFRIGERATOR W H

Door Panel 353/4" (908) 4915/16" (1268)

FREEZER W H

Drawer Panel 353/4" (908) 1811/16" (475)

BI-36UG W H

Window Cut-Out 251/2" (648) 3911/16" (1008)

Cut-Out Location 53/16" (132)

A

Page 15

Framed Panels 15

subzerotrade.com

Framed Panel Specifications

A

H

H

B

Framed

WW

WW

BI-36S / BI-42S / BI-48S BI-42SD / BI-48SD

Model BI-36S

REFRIGERATOR W H

Door Panel 1913/16" (503) 699/16" (1767)

FREEZER W H

Door Panel 157/16" (392) 699/16" (1767)

Models BI-42S and BI-42SD

REFRIGERATOR W H

Door Panel 2413/16" (630) 699/16" (1767)

FREEZER W H

Door Panel 167/16" (418) 699/16" (1767)

BI-42SD W H

Dispenser Cut-Out 57/8" (149) 127/16" (316)

AB

Cut-Out Location 17/8" (48) 283/4" (730)

Models BI-48S and BI-48SD

REFRIGERATOR W H

Door Panel 281/2" (724) 699/16" (1767)

FREEZER W H

Door Panel 183/4" (418) 699/16" (1767)

BI-48SD W H

Dispenser Cut-Out 57/8" (149) 127/16" (316)

AB

Cut-Out Location 17/8" (48) 283/4" (730)

For Models BI-42SD and BI-48SD, panel thickness in the

1

dispenser area can range from

1

/8" (29). If the panel is thicker, you must rout out a mini-

1

1

/4" (6) flat landing area to accommodate the glasswell

mum

/4" (6) to a maximum of

bezel.

Page 16

Framed

Framed Panels 16

Optional Panel Grille. A louvered grille, providing an

4" (2134) overall unit height, is standard on framed

8

applications. You may choose to use Sub-Zero’s optional

panel grille for your application. The panel grilles can be

used with all built-in models and are available for 83"

(2108), 84" (2134) and 88" (2235) overall unit heights.

Grille panel dimensions listed are for a standard 84"

(2134) overall height of the unit. For an 83" (2108) overall

height, subtract 1" (25) from grille panel height dimensions. For an 88" (2235) overall height, add 4" (102) to

height dimensions.

Optional Grille Panel W H

30" (762) Models 293/4" (756) 815/16" (227)

36" (914) Models 353/4" (908) 815/16" (227)

42" (1067) Models 413/4" (1060) 815/16" (227)

48" (1219) Models 473/4" (1213) 815/16" (227)

Optional panel grille.

Grille Panel Requirements

MAX WEIGHT

Grille Panel 13 lbs (6 kg)

MIN PANEL THICKNESS

Grille Panel

1

/4" (6)

Page 17

Framed Panels 17

subzerotrade.com

Partial Framed Option. If you choose not to use

custom panels above and below the glasswell for

dispenser Model BI-42SD or BI-48SD, a stainless steel

insert panel is available as a sales accessory. This

accessory kit includes partial framed molding and classic

stainless steel panel to provide a spill-resistant finish

above and below the glasswell on the refrigerator door

only. The partial framed accessory kit (7004855) is

available through your Sub-Zero dealer. Refer to panel

dimensions for the partial framed option below.

H

WW

Framed

IMPORTANT NOTE: When using raised panels with the

partial framed kit, a

1

/2" (13) trim reveal down to1/4"(6)

thickness is necessary at the bezel for the panels to fit

properly.

Optional Partial Framed Panels

MODEL BI-42SD W H

Refrigerator Panel 151/16" (383) 699/16" (1767)

Freezer Panel 151/16" (383) 699/16" (1767)

MODEL BI-48SD W H

Refrigerator Panel 163/4" (425) 699/16" (1767)

Freezer Panel 163/4" (425) 699/16" (1767)

Partial Framed Kit

BI-42SD / BI-48SD

Partial Framed Option

Page 18

Overlay Panels 18

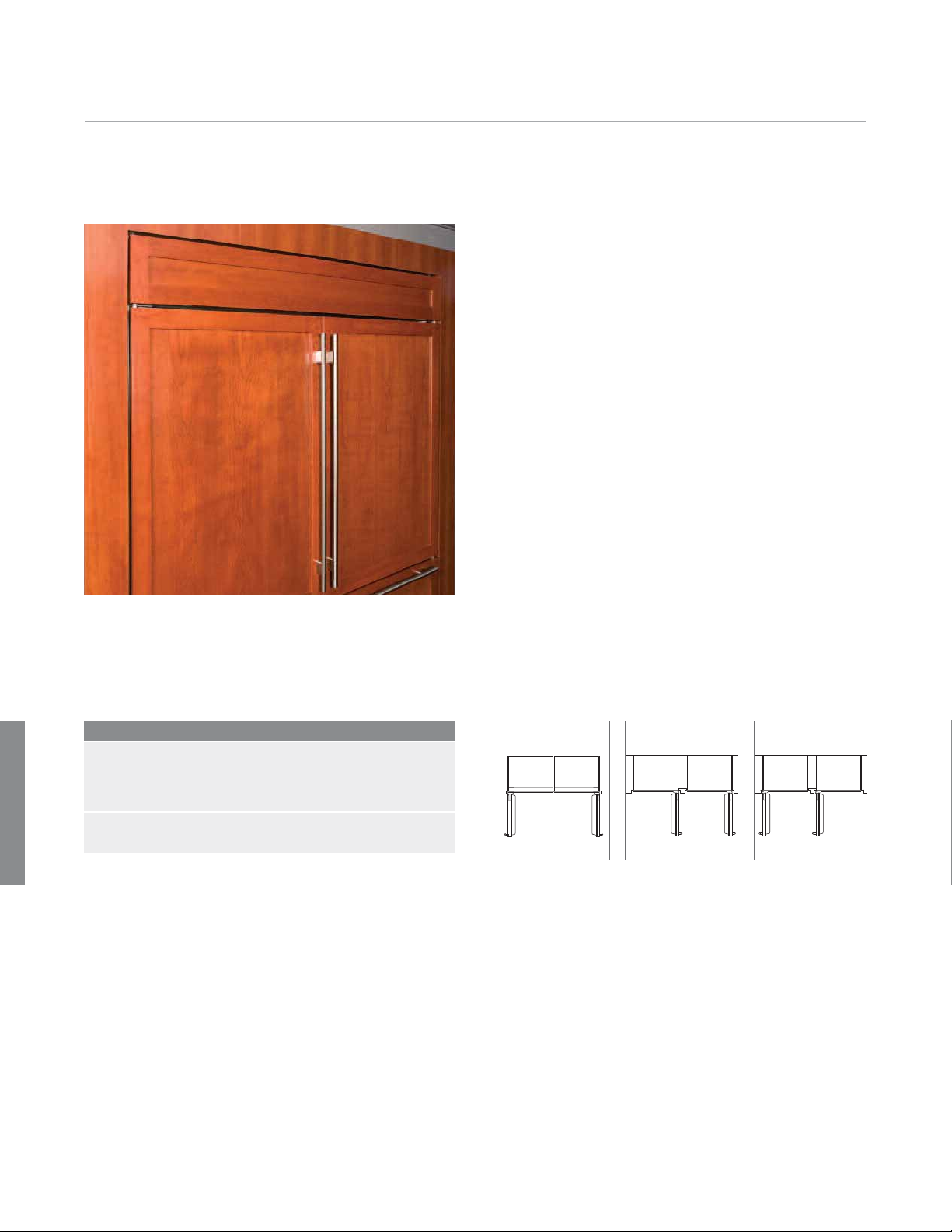

Overlay Panels. If you and your client have ordered

an overlay model, you will be adding panels and handles

to give the unit a more custom look. The overlay panel

design option is available for all built-in overlay models.

For exact door panel dimensions, refer to overlay panel

specifications on the following pages.

IMPORTANT NOTE: Overlay models can be used in a

overlay or a flush inset application. Be aware that the

application specified will affect panel sizes, rough opening dimensions and installation.

Overlay

Custom cabinet overlay panels can be combined with

unique hardware for design flexibility. Shown with curved

handle option to compliment Wolf E Series ovens.

Overlay Panel Requirements

MAX WEIGHT PER PANEL

BI-36R, BI-36RG and BI-36F 75 lbs (34 kg)

All Other Overlay Models 50 lbs (23 kg)

Grille Panel 13 lbs (6 kg)

MIN PANEL THICKNESS

All Overlay Panels

5

/8" (16)

The overlay design allows decorative panels to cover the

door trim for a more seamless appearance that blends

with the design of the room. The most common way to

achieve this look is to work with three panels—the decorative overlay panel which is typically

spacer panel and a

1

/4" (6) backer panel. Depending on

3

/4" (19), a .10" (3)

your cabinet manufacturer, this could also be one panel

routed for different dimensions.

Regardless of the physical construction of the panels

(three-panel assembly or routed panel), you will need to

follow the overlay panel specifications on the following

pages for exact sizing and panel placement to ensure a

proper fit.

Page 19

Overlay Panels 19

subzerotrade.com

Overlay Panels. The illustrations provide a cross

section view of the three-panel assembly showing placement of the trim and a rear view of the three-panel

assembly with critical dimensions, standard for all built-in

models.

Overlay grille panels for the panel grille match the design

of the overlay door panels. Dimensions for the grille panel

are listed in the overlay panel specifications on the following pages.

IMPORTANT NOTE: On glass door models, the edges of

the window cut-out will need to be finished, as they will

be exposed.

IMPORTANT NOTE: When installing two units in a side by

side application, refer to pages 30–31 for dual standard

installations. Be aware that rough opening dimensions are

different for this application.

Do not exceed the overlay decorative panel dimensions. Exceeding dimensions could cause damage

to the panels and the Sub-Zero unit.

SPACER PANEL

OVERLAY PANEL

BACKER PANEL

TRIM

5

/16" (8) min

1

/8"

(3)

Panel assembly cross

section.

OVERLAY

PANEL

3

/4"

(19)

typical

.10" (3)

1

/4" (6)

SPACER

PANEL

BACKER

PANEL

Panel assembly rear view.

Overlay

Page 20

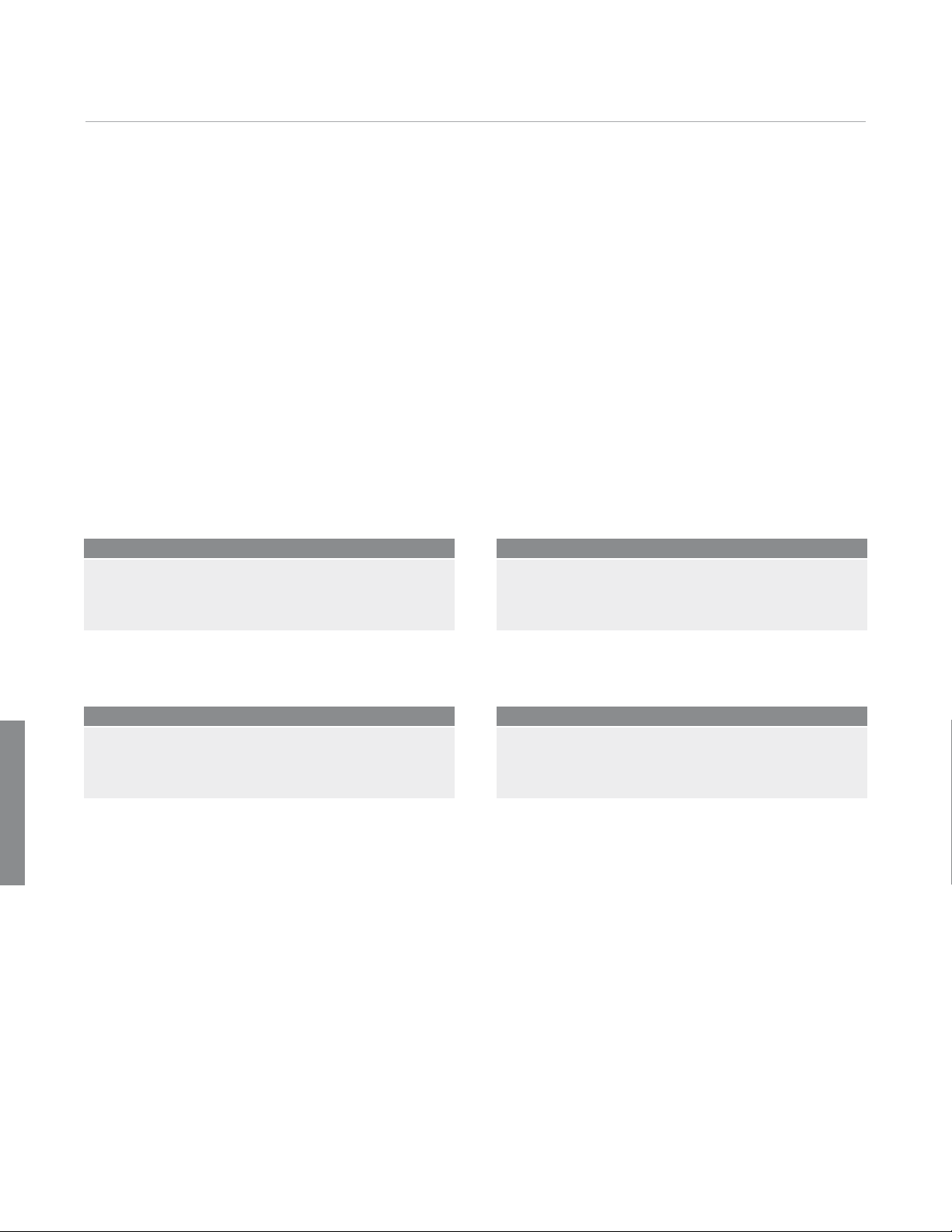

Overlay Panels 20

Overlay Panel Specifications

Overlay

HH

A

A A

H

B

W

W

H

W

H H

A

A A

H

A

H

W

H

H

BI-36R / BI-36F BI-36RG BI-30U / BI-36U BI-30UG / BI-36UG

Models BI-36R, BI-36RG and BI-36F

REFRIGERATOR/FREEZER W H

Overlay Panel 36" (914) 693/4" (1772)

Spacer Panel 351/8" (892) 6815/16" (1751)

Backer Panel 353/4" (908) 699/16" (1767)

GRILLE W H

Overlay Panel 36" (914) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

BI-36RG W H

Window Cut-Out 251/2" (648) 541/8" (1375)

AB

Cut-Out Location 51/4" (133) 103/8" (264)

Models BI-30U and BI-30UG

REFRIGERATOR W H

Models BI-36U and BI-36UG

REFRIGERATOR W H

Overlay Panel 36" (914) 501/8" (1273)

Spacer Panel 351/8" (892) 495/16" (1253)

Backer Panel 353/4" (908) 4915/16" (1268)

FREEZER W H

Overlay Panel 36" (914) 19" (483)

Spacer Panel 351/8" (892) 181/16" (459)

Backer Panel 353/4" (908) 1811/16" (475)

GRILLE W H

Overlay Panel 36" (914) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

BI-36UG W H

Window Cut-Out 251/2" (648) 395/8" (1006)

Cut-Out Location 51/4" (133)

Overlay Panel 30" (762) 501/8" (1273)

Spacer Panel 291/8" (740) 495/16" (1253)

Backer Panel 293/4" (756) 4915/16" (1268)

FREEZER W H

Overlay Panel 30" (762) 19" (483)

Spacer Panel 291/8" (740) 181/16" (459)

Backer Panel 293/4" (756) 1811/16" (475)

GRILLE WH

Grille panel dimensions listed are for a standard 84" (2134)

overall height of the unit. For an 83" (2108) overall height,

subtract 1" (25) from grille panel height dimensions. For an

88" (2235) overall height, add 4" (102) to height dimensions.

Width dimensions do not vary.

Overlay Panel 30" (762) 91/4" (235)

Spacer Panel 291/8" (740) 85/16" (211)

Backer Panel 293/4" (756) 815/16" (227)

BI-30UG W H

Window Cut-Out 191/2" (495) 395/8" (1006)

A

Cut-Out Location 51/4" (133)

A

Page 21

Overlay Panels 21

subzerotrade.com

Overlay Panel Specifications

H H

A

H

WW

BI-36S / BI-42S / BI-48S BI-42SD / BI-48SD

H

B

WW

Overlay

Model BI-36S

REFRIGERATOR W H

Overlay Panel 201/16" (510) 693/4" (1772)

Spacer Panel 193/16" (487) 6815/16" (1751)

Backer Panel 1913/16" (503) 699/16" (1767)

FREEZER W H

Overlay Panel 1511/16" (398) 693/4" (1772)

Spacer Panel 1413/16" (376) 6815/16" (1751)

Backer Panel 157/16" (392) 699/16" (1767)

GRILLE W H

Overlay Panel 36" (914) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

Models BI-42S and BI-42SD

REFRIGERATOR W H

Overlay Panel 251/16" (637) 693/4" (1772)

Spacer Panel 243/16" (614) 6815/16" (1751)

Backer Panel 2413/16" (630) 699/16" (1767)

FREEZER W H

Overlay Panel 1611/16" (424) 693/4" (1772)

Spacer Panel 1513/16" (402) 6815/16" (1751)

Backer Panel 167/16" (418) 699/16" (1767)

GRILLE W H

Overlay Panel 42" (1067) 91/4" (235)

Spacer Panel 411/8" (1045) 85/16" (211)

Backer Panel 413/4" (1060) 815/16" (227)

BI-42SD W H

Dispenser Cut-Out 57/8" (149) 127/16" (316)

AB

Cut-Out Location 2" (51) 2813/16" (732)

Models BI-48S and BI-48SD

REFRIGERATOR W H

Overlay Panel 283/4" (730) 693/4" (1772)

Spacer Panel 277/8" (708) 6815/16" (1751)

Backer Panel 281/2" (724) 699/16" (1767)

FREEZER W H

Overlay Panel 19" (483) 693/4" (1772)

Spacer Panel 181/8" (460) 6815/16" (1751)

Backer Panel 183/4" (476) 699/16" (1767)

GRILLE W H

Overlay Panel 48" (1219) 91/4" (235)

Spacer Panel 471/8" (1197) 85/16" (211)

Backer Panel 473/4" (1213) 815/16" (227)

BI-48SD W H

Dispenser Cut-Out 57/8" (149) 127/16" (316)

AB

Cut-Out Location 2" (51) 2813/16" (732)

Grille panel dimensions listed are for a standard 84" (2134)

overall height of the unit. For an 83" (2108) overall height,

subtract 1" (25) from grille panel height dimensions. For an

88" (2235) overall height, add 4" (102) to height dimensions.

Width dimensions do not vary.

Page 22

Flush Inset

Flush Inset Application 22

Flush Inset Application. It is necessary to consider

the following points when planning for a flush inset

application:

• The flush inset depth is 2

standard opening.

• The flush inset width is 2

standard opening.

• The flush inset height is1/4" (6) higher than the

standard opening.

• Panel widths increase to achieve the flush inset look.

• You must allow a

1

of the unit and grille to allow for proper door swing

and airflow.

IMPORTANT NOTE: Do not confuse the flush inset application as being a separate model. This is an overlay unit in a

flush installation. The same model is used in an overlay or

flush inset application.

Rough opening dimensions for the new flush inset application assume the use of a

illustrations below show the difference between standard

and flush inset installations.

3

/16" (56) deeper than the

1

/2" (64) wider than the

/2" (13) reveal around the perimeter

3

/4" (19) decorative panel. The

This brand new design option allows for a flush door and

grille. Classic, platinum and carbon stainless steel panels

are available as sales accessories. Shown with tubular

handle option to mirror Wolf L Series ovens.

FLUSH INSET INSTALLATION

3

/4" (19) PANEL

STANDARD INSTALLATION

24" (610)

OPENING

DEPTH

TOP VIEW

WITH

24" (610)

OPENING

DEPTH

23/16"

(56)

TOP VIEW

263/16"

(665)

FLUSH

INSET

DEPTH

Standard installation. Flush inset installation.

11/4"

(32)

Page 23

Flush Inset Application 23

11/4"

(32)

24"

(610)

OPENING

DEPTH

TO CLEAT

CLEAT

TOP VIEW

263/16"

(665)

FLUSH

INSET

DEPTH

23/16"

(56)

3"

(76)

typical

24"

(610)

OPENING

DEPTH TO

CLEAT

11/4"

(32)

23/16"

(56)

CLEAT

SHADED

AREA

MUST BE

FINISHED

3"

typical

(76)

4"

(102)

subzerotrade.com

Flush Inset Installation Opening Dimensions

TOP VIEW

24" (610)

CLEAT

1

(6)

263/16"

/4"

(665)

FLUSH

INSET

DEPTH

DEPTH

TO CLEAT

23/16"

(56)

11/4"

(32)

OUTLINE

OF UNIT WITH

3

/4" (19) PANEL

CLEAT

DETAIL A

24" (610)

DEPTH TO CLEAT

263/16" (665)

FLUSH INSET DEPTH

SIDE VIEW

23/16"

(56)

833/4"

(2127)

HEIGHT

TO CLEAT

83" min

(2108)

84"

(2134)

FLUSH

INSET

HEIGHT

11/4"

(32)

A

WIDTH TO CLEAT

B

FLUSH INSET WIDTH

DETAIL B

FRONT VIEW

11/4"

(32)

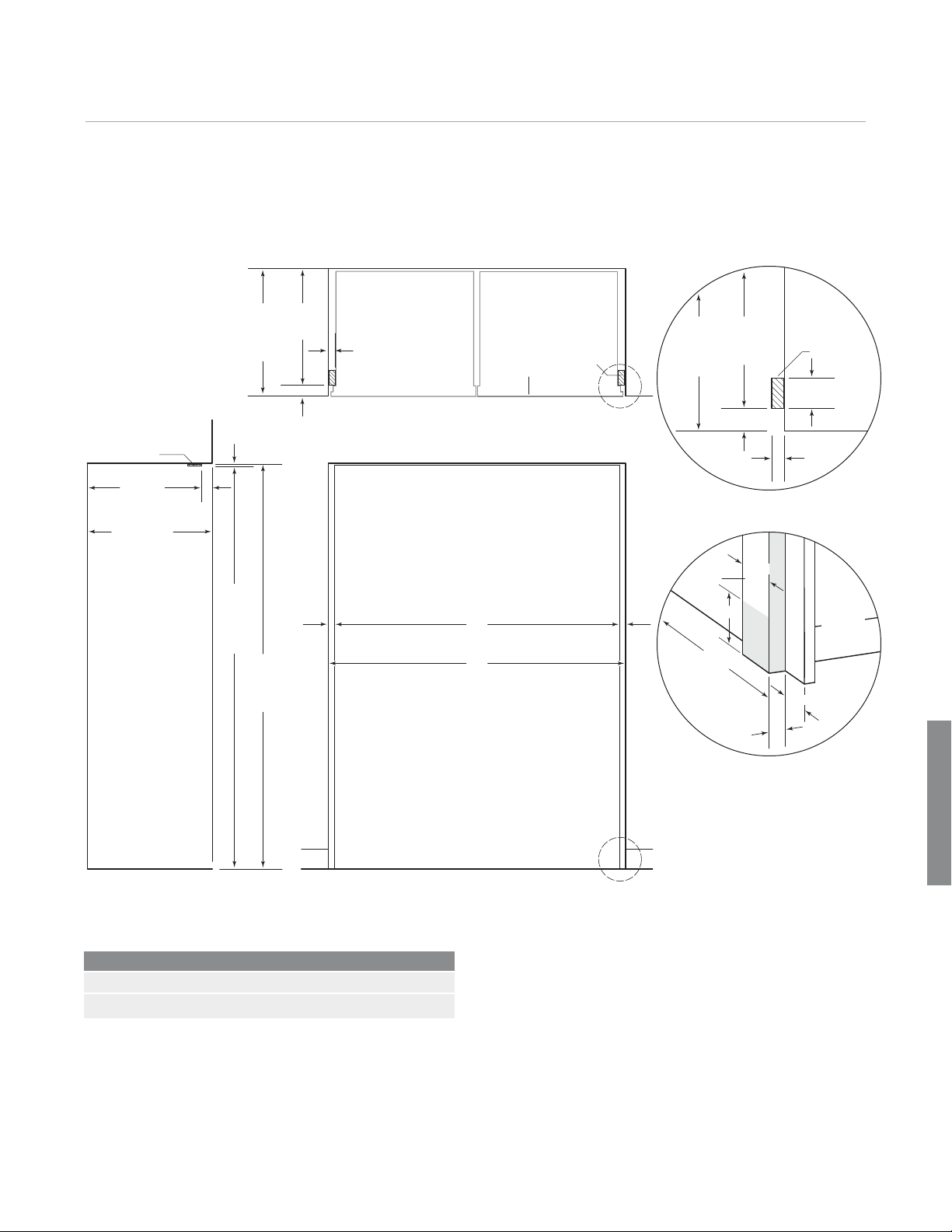

Detail A

Flush Inset

Detail B

Flush Inset Opening Widths A B

BI-36R, BI-36RG and BI-36F 351/2" (902) 38" (965)

BI-30U and BI-30UG 291/2" (746) 32" (813)

BI-36U and BI-36UG 351/2" (902) 38" (965)

BI-36S 351/2" (902) 38" (965)

BI-42S and BI-42SD 411/2" (1054) 44" (1118)

BI-48S and BI-48SD 471/2" (1206) 50" (1270)

IMPORTANT NOTE: Dimensions assume a3/4" (19) panel

thickness.

IMPORTANT NOTE: If two units are installed side by side,

refer to pages 32–33 for dual flush inset installations.

Page 24

Flush Inset

Flush Inset Panels 24

Flush Inset Panels. The flush inset application allows

decorative panels on the front of the unit to be flush with

surrounding cabinetry and is available for all built-in

overlay models. For exact panel dimensions, refer to flush

inset panel specifications on the following pages.

The flush inset design allows decorative panels to cover

the door trim for a seamless appearance that blends with

the design of the room. The most common way to

achieve this look is to work with three panels—the decorative flush inset panel which is typically

(3) spacer panel and a

1

/4" (6) backer panel. Depending

3

/4" (19), a .10"

on your cabinet manufacturer, this could also be one

panel routed for different dimensions.

Regardless of the physical construction of the panels

(three-panel assembly or routed panel), you will need to

follow the flush inset panel specifications on the following

pages for exact sizing and panel placement to ensure a

proper fit.

The illustration to the right provides a rear view of the

three-panel assembly with critical dimensions, standard

for all built-in models.

Do not exceed the flush inset decorative panel

dimensions. Exceeding dimensions could cause

damage to the panels and the Sub-Zero unit.

Flush Inset Panel Requirements

MAX WEIGHT PER PANEL

BI-36R, BI-36RG and BI-36F 75 lbs (34 kg)

All Other Flush Inset Models 50 lbs (23 kg)

Grille Panel 13 lbs (6 kg)

MIN PANEL THICKNESS

All Flush Inset Panels

FLUSH INSET

PANEL

5

/8" (16)

SPACER

PANEL

BACKER

PANEL

IMPORTANT NOTE: The inside edges of the rough open-

ing as well as the sides and a portion of the back side of

the decorative panels will need to be finished, as they will

be exposed when the doors are open.

IMPORTANT NOTE: On glass door models, the edges of

the window cut-out will need to be finished, as they will

be exposed.

IMPORTANT NOTE: For flush inset panels thicker than

3

/4"

(19), a 90˚ door stop may be needed to avoid interference

with adjacent cabinets. Refer to the full-scale templates

at the end of this guide.

IMPORTANT NOTE: When installing two units side by side

in a flush inset application, refer to pages 32–35 for dual

flush inset installations. Be aware that rough opening

dimensions, panel sizes and offsets are different for this

application.

3

/4"

(19)

typical

.10" (3)

1

/4" (6)

Three-panel assembly

Page 25

Flush Inset Panels 25

subzerotrade.com

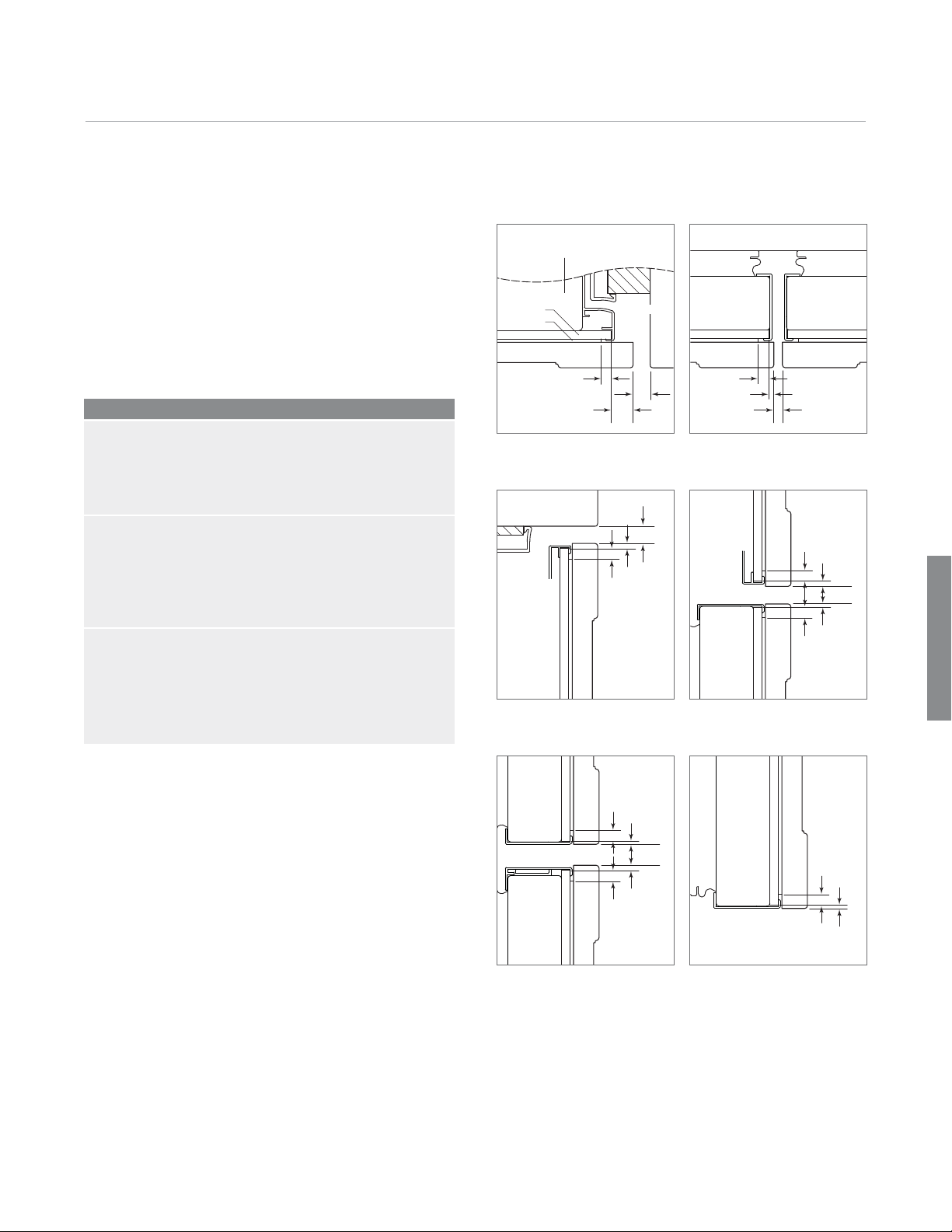

Flush Inset Panels. Illustrations A–F provide panel

offsets and reveals for all built-in models in a flush inset

application. Refer to the chart below for reference to the

illustrations relating to your specific model.

For additional information on model specific panel

reveals, visit the Specification Library section of our

website, subzerotrade.com.

Panel Offsets Illus.

ALL REFRIGERATOR / ALL FREEZER

Door / Grille Sides A

Grille Top C

Grille Bottom / Door Top D

Door Bottom F

OVER-AND-UNDER

Door / Drawer / Grille Sides A

Grille Top C

Grille Bottom / Door Top D

Door Bottom / Drawer Top E

Drawer Bottom F

SIDE-BY-SIDE

Doors (hinge) / Grille Sides A

Doors (handle) Sides B

Grille Top C

Grille Bottom / Door Top D

Door Bottom F

5

/16" (8)

TOP VIEW

CABINETRY

1

/2"

(13)

5

/8"

(16)

DOOR DOOR

5

/16" (8)

1

DOOR / DRAWER / GRILLE

BACKER

SPACER

FLUSH INSET PANEL

Illus. A Illus. B

CABINETRY

1

GRILLE

1

5

/16"

(8)

SIDE VIEW

/8"

(3)

/2"(13)

GRILLE

DOOR

Illus. C Illus. D

/8" (3)

TOP VIEW

1

/4" (6)

REVEAL

5

/16"

5

(8)

3

5

/16"

(8)

SIDE VIEW

/32"

(4)

/32"

(2)

1

/2"(13)

Flush Inset

5

/16"

3

(8)

/32"

5

/16"

(8)

SIDE VIEW

(2)

5

/8"(16)

5

/32"

(4)

DOOR

DRAWER

Illus. E Illus. F

DOOR /

DRAWER

SIDE VIEW

5

/16"

(8)

3

/32"

(2)

Page 26

Flush Inset Panels 26

Flush Inset Panel Specifications

Flush Inset

HH

A

A A

H

B

W

W

H

W

H H

B

A A

H

B

H

W

H

H

BI-36R / BI-36F BI-36RG BI-30U / BI-36U BI-30UG / BI-36UG

Models BI-36R, BI-36RG and BI-36F

REFRIGERATOR/FREEZER W H

Flush Inset Panel 37" (940) 693/4" (1772)

Spacer Panel 351/8" (892) 6815/16" (1751)

Backer Panel 353/4" (908) 699/16" (1767)

GRILLE W H

Flush Inset Panel 37" (940) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

BI-36RG W H

Window Cut-Out 251/2" (648) 541/8" (1375)

AB

Cut-Out Location 53/4" (146) 103/8" (264)

Models BI-36U and BI-36UG

REFRIGERATOR W H

Flush Inset Panel 37" (940) 501/8" (1273)

Spacer Panel 351/8" (892) 495/16" (1253)

Backer Panel 353/4" (908) 4915/16" (1268)

FREEZER W H

Flush Inset Panel 37" (940) 19" (483)

Spacer Panel 351/8" (892) 181/16" (459)

Backer Panel 353/4" (908) 1811/16" (475)

GRILLE W H

Flush Inset Panel 37" (940) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

BI-36UG W H

Window Cut-Out 251/2" (648) 395/8" (1006)

Models BI-30U and BI-30UG

REFRIGERATOR W H

Cut-Out Location 53/4" (146) 51/4" (133)

Flush Inset Panel 31" (787) 501/8" (1273)

Spacer Panel 291/8" (740) 495/16" (1253)

Backer Panel 293/4" (756) 4915/16" (1268)

FREEZER W H

Flush Inset Panel 31" (787) 19" (483)

Spacer Panel 291/8" (740) 181/16" (459)

Backer Panel 293/4" (756) 1811/16" (475)

GRILLE WH

Grille panel dimensions listed are for a standard 84" (2134)

overall height of the unit. For an 83" (2108) overall height,

subtract 1" (25) from grille panel height dimensions. For an

88" (2235) overall height, add 4" (102) to height dimensions.

Width dimensions do not vary.

Flush Inset Panel 31" (787) 91/4" (235)

Spacer Panel 291/8" (740) 85/16" (211)

Backer Panel 293/4" (756) 815/16" (227)

BI-30UG W H

Window Cut-Out 191/2" (495) 395/8" (1006)

AB

Cut-Out Location 53/4" (146) 51/4" (133)

AB

Page 27

Flush Inset Panels 27

subzerotrade.com

Flush Inset Panel Specifications

H H

A

H

H

B

WW

WW

BI-36S / BI-42S / BI-48S BI-42SD / BI-48SD

Model BI-36S

REFRIGERATOR W H

Flush Inset Panel 209/16" (522) 693/4" (1772)

Spacer Panel 193/16" (487) 6815/16" (1751)

Backer Panel 1913/16" (503) 699/16" (1767)

FREEZER W H

Flush Inset Panel 163/16" (411) 693/4" (1772)

Spacer Panel 1413/16" (376) 6815/16" (1751)

Backer Panel 157/16" (392) 699/16" (1767)

GRILLE W H

Flush Inset Panel 37" (940) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

Models BI-42S and BI-42SD

REFRIGERATOR W H

Flush Inset Panel 259/16" (649) 693/4" (1772)

Spacer Panel 243/16" (614) 6815/16" (1751)

Backer Panel 2413/16" (630) 699/16" (1767)

FREEZER W H

Flush Inset Panel 173/16" (437) 693/4" (1772)

Spacer Panel 1513/16" (402) 6815/16" (1751)

Backer Panel 167/16" (418) 699/16" (1767)

GRILLE W H

Flush Inset Panel 43" (1092) 91/4" (235)

Spacer Panel 411/8" (1045) 85/16" (211)

Backer Panel 413/4" (1060) 815/16" (227)

DISPENSER (BI-42SD) W H

Dispenser Cut-Out 57/8" (149) 127/16" (316)

AB

Cut-Out Location 2" (51) 2813/16" (732)

Models BI-48S and BI-48SD

REFRIGERATOR W H

Flush Inset Panel 291/4" (743) 693/4" (1772)

Spacer Panel 277/8" (708) 6815/16" (1751)

Backer Panel 281/2" (724) 699/16" (1767)

FREEZER W H

Flush Inset Panel 191/2" (495) 693/4" (1772)

Spacer Panel 181/8" (460) 6815/16" (1751)

Backer Panel 183/4" (476) 699/16" (1767)

GRILLE W H

Flush Inset Panel 49" (1245) 91/4" (235)

Spacer Panel 471/8" (1197) 85/16" (211)

Backer Panel 473/4" (1213) 815/16" (227)

DISPENSER (BI-48SD) W H

Cut-Out 57/8" (149) 127/16" (316)

AB

Cut-Out Location 2" (51) 2813/16" (732)

Grille panel dimensions listed are for a standard 84" (2134)

overall height of the unit. For an 83" (2108) overall height,

subtract 1" (25) from grille panel height dimensions. For an

88" (2235) overall height, add 4" (102) to height dimensions.

Width dimensions do not vary.

Flush Inset

Page 28

Dispenser Specifications 28

Dispenser Area. For Models BI-42SD and BI-48SD,

the refrigerator door panel must include a cut-out to

accommodate the dispenser glasswell and bezel. The

thickness of the panel in this area can range from

to a maximum of 1

1

/8" (29).

IMPORTANT NOTE: Regardless of the thickness of the

panel for Model BI-42SD or BI-48SD, you must plan for a

flat landing area for the decorative bezel surrounding the

glasswell area. The illustration to the right provides exact

bezel dimensions. Refer to the appropriate panel specifications page for exact cut-out location. This landing area

can be accomplished in a number of different ways.

These photos show two options.

One option (flush) is to rout the panel so the bezel will be

flush with rails and stiles. You must rout a space to

accommodate the height and width of the bezel. The

width of the stile immediately adjacent to the bezel must

7

be 1

/16" (37). Do not cut the entire stile to this dimen-

sion.

The other option (proud) shows a boxed out landing area

for the bezel using stiles and rails to create this space. In

this application, the bezel will sit proud of the stiles and

rails. The total thickness of the panels at this level must

not exceed 1

1

/8" (29).

For overlay and flush inset Models BI-42SD and BI-48SD,

mounting placement of the refrigerator door handle must

assure proper access to the glasswell and adequate

clearance under the handle. The handle placement illustration shows the relation of the refrigerator door handle

to the glasswell bezel on stainless steel models.

1

/4"(6)

Flush option.

5

/8"

(16)

65/16" (160)

127/8"

(327)

Dispenser dimensions.

Proud option.

3

/32"

(2)

1"

(25)

1

/8" (3)

radius

Handle placement.

2"

(51)

Glasswell

Profile

Handle

Profile

Page 29

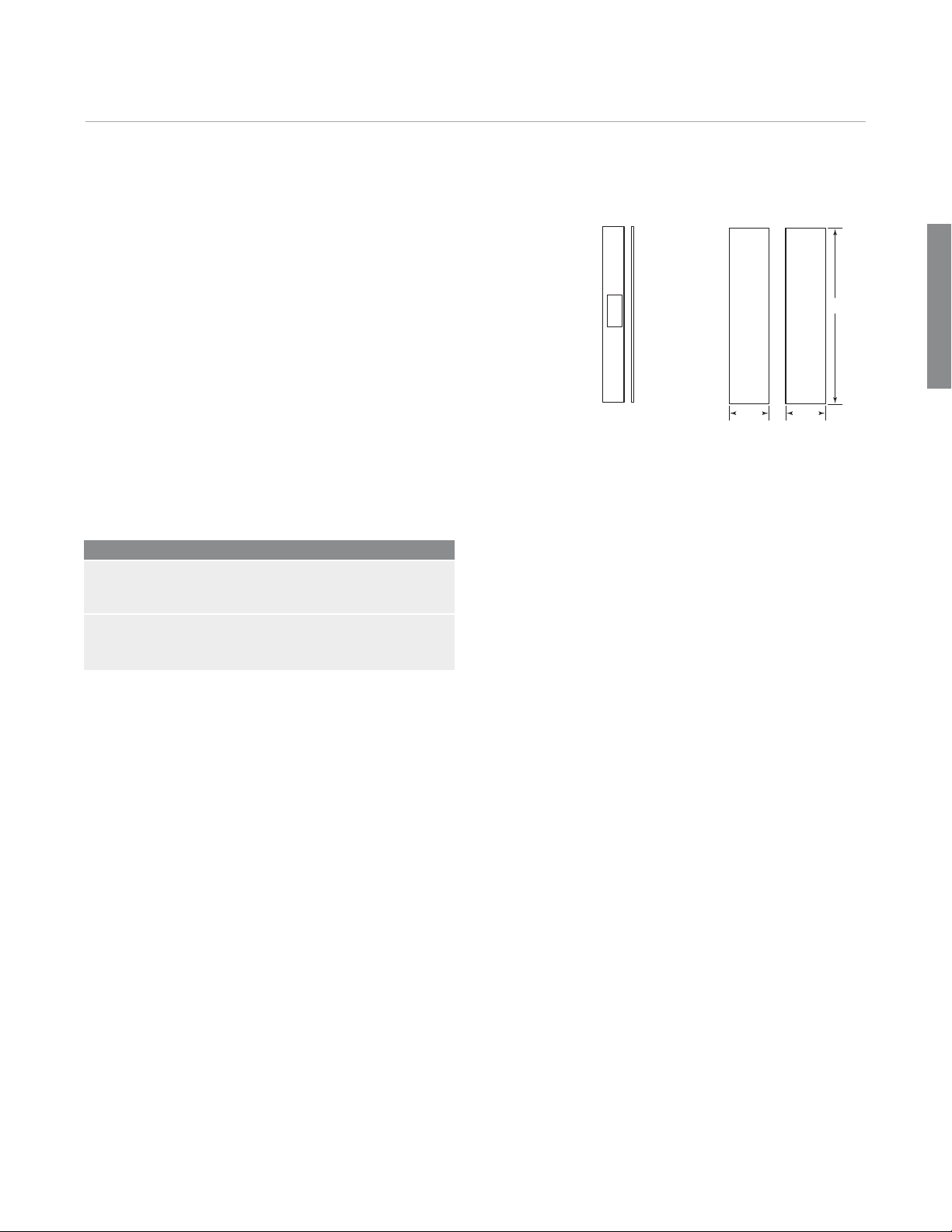

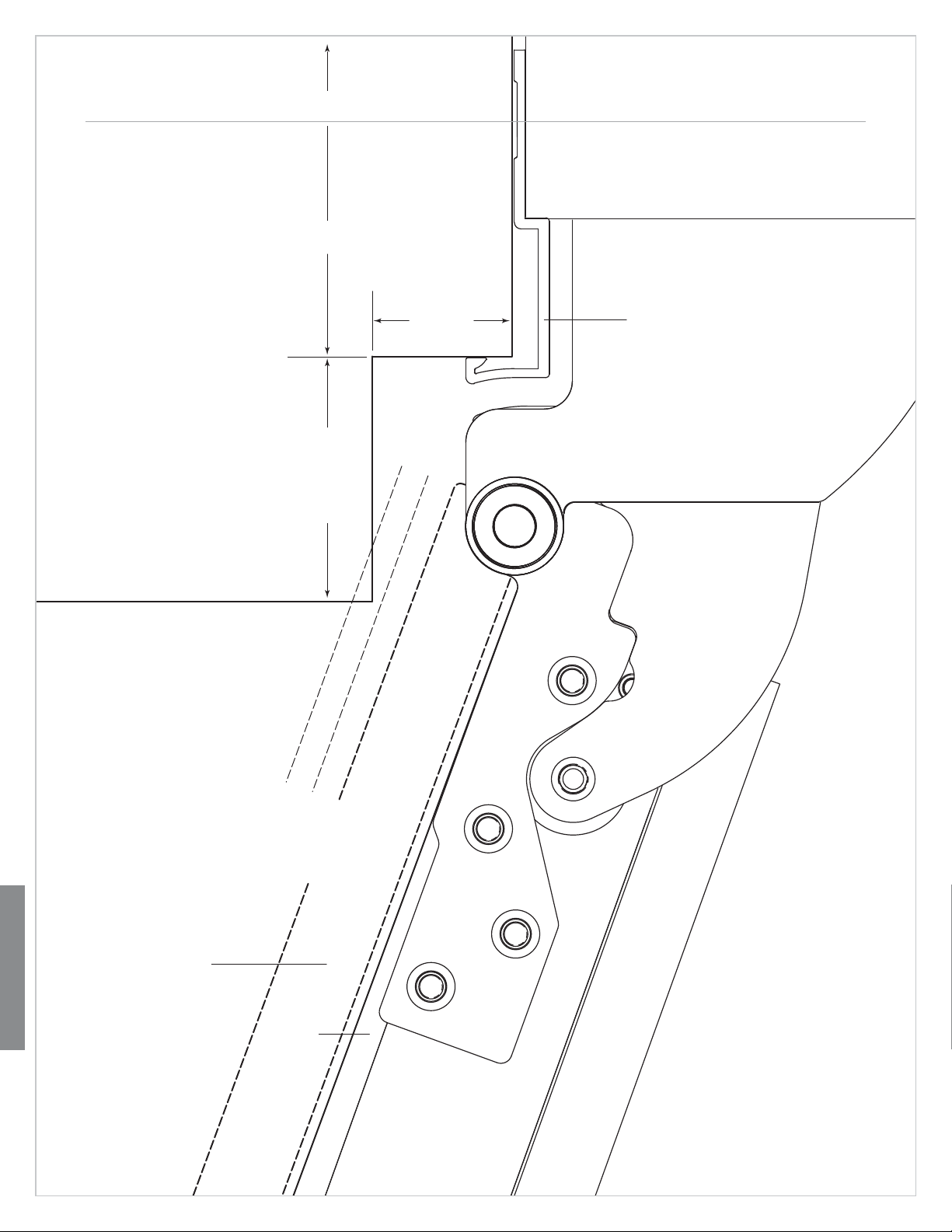

Side Panels 29

subzerotrade.com

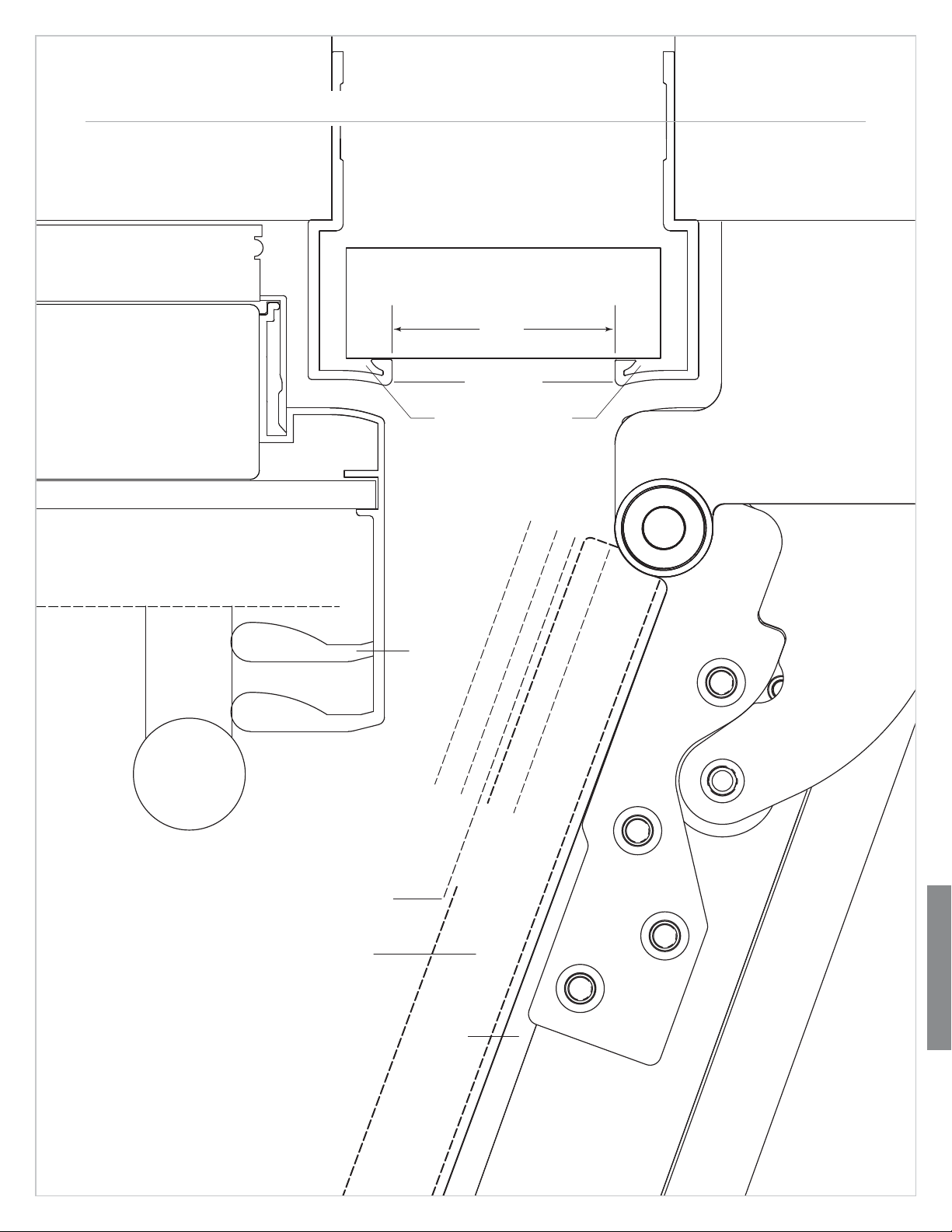

Side Panels. Side panels can be used with all framed,

overlay, flush inset and stainless steel design applications. When planning for side panels with the installation

of a built-in model, you need to be aware of the space

configuration to achieve a pleasing fit. Depending on the

exact panel you are using with your unit, the height of the

panel may vary.

IMPORTANT NOTE: The use of side panels may change

the width of your rough opening.

When installing a built-in unit with a custom side panel,

an accessory kit (7003407) is required. Classic stainless

steel and white enamel side panels are also available

through your Sub-Zero dealer.

The side panel will need to be a minimum of 24" (610)

deep and

sions illustration for additional specifications. Routing will

be necessary in order for the side panel to fit flush

against the side of the unit. Refer also to the routing

detail illustration.

IMPORTANT NOTE: If you have a Model BI-30U, BI-30UG,

BI-36U or BI-36UG, extra routing will be necessary to

avoid having the panel hit the refrigerator lower hinge

plate.

1

/2" (13) thick. Refer to the side panel dimen-

24" (610)

FRONT

OF SIDE

PANEL

1

ROUT TO

/8" (3)

17/8"(48)

1" (25)

41/4" (108)

ROUT TO

3

/16" (5)

(OVER-AND-UNDER

MODELS)

4" (102)

OPTIONAL

TOE KICK

CUT-OUT

53/4"

(146)

201/2"

(521)

Side panel dimensions.

(2134)

25/8"

(67)

84"

1" (25)

1

/8" (3)

1

/2" (13)

MAIN

FRAME

Routing Detail.

17/8" (48)

SIDE PANEL

ROUTING

Page 30

Dual Installations 30

Dual Standard Installations. Two framed, overlay

or stainless steel units may be placed side by side in a

dual installation. Some dual standard installations will

require a dual installation kit, available through your

Sub-Zero dealer. If you are installing two units side by

side in a flush inset application refer to page 33.

A custom filler strip can be used in between two units in a

framed, overlay or stainless steel design application. It is

recommended that the filler strip be at least 2" (51) wide,

to prevent condensation between the units. Be sure to

add the filler strip width to your rough opening width.

Refer to the full-scale template on page 41.

Dual installations without a filler strip can only be accomplished using two units with opposite hinges as shown in

illustration A below. The dual installations shown in illustrations B and C require a filler strip.

Dual Installations

Dual Standard Installation

Dual Installation Panel Requirements

MAX WEIGHT PER PANEL

BI-36R, BI-36RG and BI-36F 75 lbs (34 kg)

All Other Models 50 lbs (23 kg)

Dual Wide Grille Panel 26 lbs (12 kg)

MIN PANEL THICKNESS

Framed Panels

Overlay and Flush Inset Panels

1

/4" (6)

5

/8" (16)

IMPORTANT NOTE: For the application shown in illustra-

tion A, a dual installation accessory kit is required. Refer

to page 36 for information on dual installation accessory

kits.

WITHOUT FILLER STRIP

Illus. A

FILLER STRIP REQUIRED

FILLER STRIP REQUIRED

Illus. B Illus. C

Page 31

Dual Installations 31

subzerotrade.com

Dual Standard Installation Opening Dimensions

Framed, Overlay and Classic Stainless Steel Models

TOP VIEW

24" (610)

OPENING

24" (610)

OPENING DEPTH

DEPTH

OUTLINE

OF TWO UNITS WITH

3

/4" (19) PANEL

833/4"

(2127)

OPENING

HEIGHT

83" min

(2108)

Opening Widths A

Two 30" (762) Models 593/4" (1518)

Two 36" (914) Models 713/4" (1822)

A

OPENING WIDTH

FRONT VIEWSIDE VIEW

IMPORTANT NOTE: A dual installation kit will be required for

this installation.

Classic stainless steel models are ready to install out of the

box.

Dual Installations

Page 32

Dual Installations 32

Dual Flush Inset Installation. Installing two built-in

models side by side in a flush inset application will require

adjustments to the dimensions of your finished rough

opening, panel sizes and panel offsets. It will also require

a dual installation kit, available through your Sub-Zero

dealer.

Dual installations without a filler strip can only be accomplished using two units with opposite hinges as shown in

illustration A below. The dual installations shown in illustrations B and C require a filler strip. Illustration A is the

only application that will accommodate the dual wide grille.

IMPORTANT NOTE: The application shown in illustration A

can only be achieved by installing dual flush inset panels.

Failure to install dual flush inset panels will cause the

handle side of the panels to collide when closing. In this

application a dual installation accessory kit is also

required.

Dual Installations

Dual Flush Inset Installation

Dual Installation Panel Requirements

MAX WEIGHT PER PANEL

BI-36R, BI-36RG and BI-36F 75 lbs (34 kg)

All Other Models 50 lbs (23 kg)

Dual Wide Grille Panel 26 lbs (12 kg)

MIN PANEL THICKNESS

Flush Inset Panels

5

/8" (16)

Dual flush inset panels and dual installation kits are available through your Sub-Zero dealer. Refer to pages 34–35

for dual flush inset panel specifications and page 36 for

information on dual installation accessory kits.

WITHOUT FILLER STRIP

Illus. A

FILLER STRIP REQUIRED FILLER STRIP REQUIRED

Illus. B Illus. C

Page 33

Dual Installations 33

11/4"

(32)

24"

(610)

OPENING

DEPTH

TO CLEAT

CLEAT

TOP VIEW

263/16"

(665)

FLUSH

INSET

DEPTH

23/16"

(56)

3"

(76)

typical

24"

(610)

OPENING

DEPTH TO

CLEAT

11/4"

(32)

23/16"

(56)

CLEAT

SHADED

AREA

MUST BE

FINISHED

3"

typical

(76)

4"

(102)

subzerotrade.com

Dual Flush Inset Installation Opening Dimensions

TOP VIEW

610)

24" (

263/16"

DEPTH

(665)

TO CLEAT

FLUSH

CLEAT

24" (610)

DEPTH TO CLEAT

263/16" (665)

FLUSH INSET DEPTH

23/16"

(56)

INSET

DEPTH

1

/4"

(6)

23/16"

(56)

11/4"

(32)

OUTLINE OF

TWO UNITS WITH

3

/4" (19) PANEL

CLEAT

DETAIL A

Detail A

833/4"

(2127)

HEIGHT

TO CLEAT

83" min

(2108)

(2134)

FLUSH

INSET

HEIGHT

84"

11/4"

(32)

SIDE VIEW

Opening Widths A B

Two 30" (762) Models 593/4" (1518) 621/4" (1581)

Two 36" (914) Models 713/4" (1822) 741/4" (1886)

A

WIDTH TO CLEAT

B

FLUSH INSET WIDTH

FRONT VIEW

IMPORTANT NOTE: Dimensions assume a3/4" (19) panel

thickness. A dual installation kit will be required for this

installation.

DETAIL B

11/4"

(32)

Detail B

Dual Installations

Page 34

Dual Installations 34

Dual Installations

Flush Inset Panels—Dual Installation. When

installing two built-in models side by side in a flush inset

application, you must decrease the width of the decorative flush inset panels by

offsets will also need to be made. These adjustments are

needed to achieve a proper fit and to ensure the panels

do not collide when closing. Panel dimensions in the

chart below have been adjusted to reflect the decrease in

panel dimensions.

IMPORTANT NOTE: If a filler strip is not used, dual instal-

lations can only be accomplished using two units with

opposite hinges.

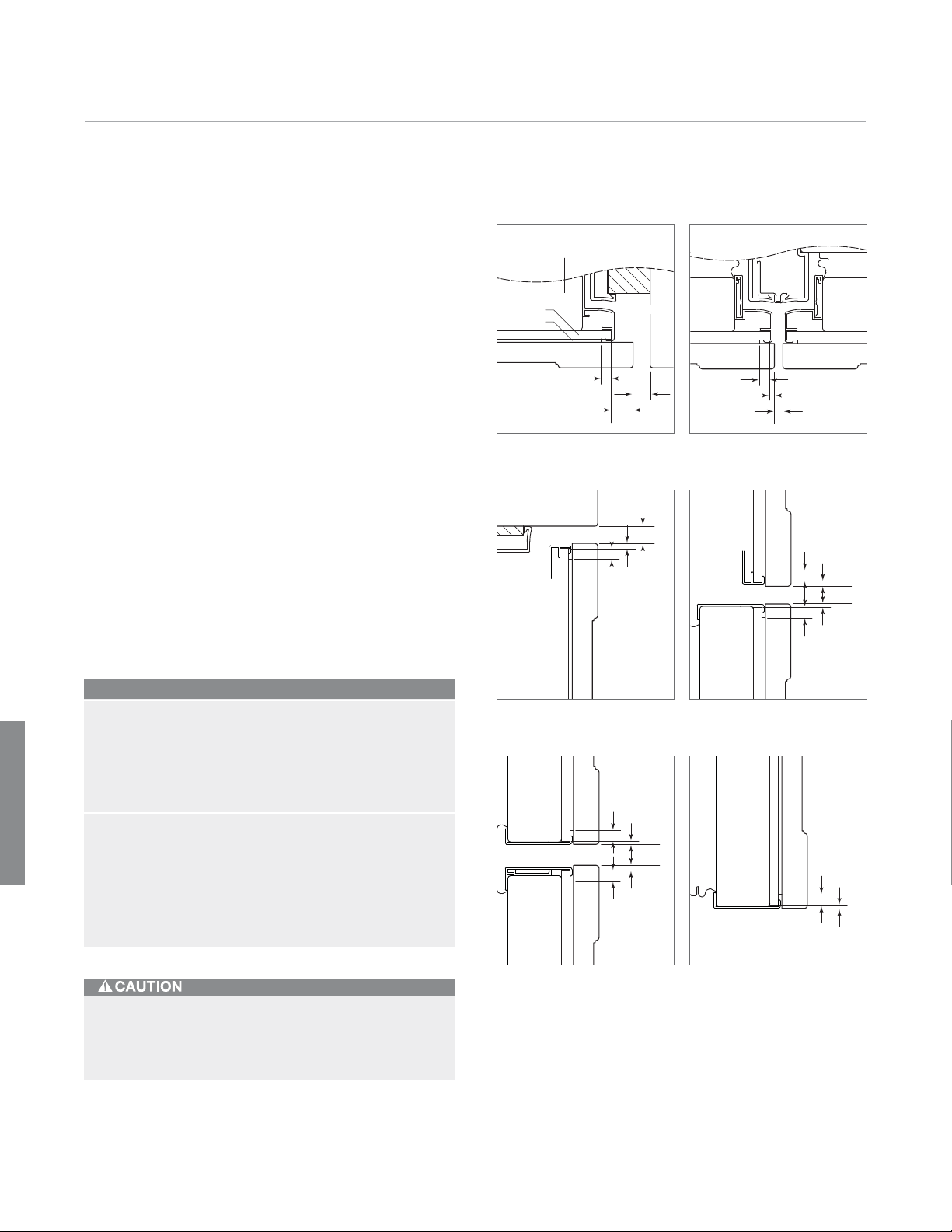

Illustrations A–F provide panel offsets and reveals for all

built-in models in a flush inset application. Refer to the

chart below for reference to the illustrations relating to

your specific model. All reveals are

wise specified.

For additional information on model specific panel

reveals, visit the Specification Library section of our

website, subzerotrade.com.

Panel Offsets Illus.

ALL REFRIGERATOR / ALL FREEZER

Doors (hinge) / Grille Sides A

Doors (handle) Sides B

Grille Top C

Grille Bottom / Door Top D

Door Bottom F

OVER-AND-UNDER

Doors (hinge) / Drawer / Grille Sides A

Doors (handle) Sides B

Grille Top C

Grille Bottom / Door Top D

Door Bottom / Drawer Top E

Drawer Bottom F

1

/2". Adjustments to the panel

1

/2" (13) unless other-

5

/16" (8)

TOP VIEW

CABINETRY

1

/2"

(13)

5

/8"

(16)

DOOR DOOR

5

/16" (8)

1

DOOR / DRAWER / GRILLE

BACKER

SPACER

FLUSH INSET PANEL

Illus. A Illus. B

CABINETRY

1

GRILLE

1

5

/16"

(8)

SIDE VIEW

/8"

(3)

/2"(13)

GRILLE

DOOR

Illus. C Illus. D

5

/16"

3

(8)

/32"

5

/16"

(8)

SIDE VIEW

(2)

5

/8"(16)

5

/32"

(4)

DOOR

DRAWER

/8" (3)

DOOR /

DRAWER

TOP VIEW

DUAL

TRIM

SIDE VIEW

1

/4" (6)

REVEAL

5

/16"

5

(8)

3

5

/16"

(8)

SIDE VIEW

5

/32"

(4)

/32"

(2)

/16"

(8)

1

/2"(13)

3

/32"

(2)

Do not exceed the flush inset decorative panel

dimensions. Exceeding dimensions could cause

damage to the panels and the Sub-Zero unit.

Illus. E Illus. F

Page 35

Dual Installations 35

subzerotrade.com

Flush Inset Panel Specifications—Dual Installation

HH

A

A A

H

B

W

W

H

W

H H

B

A A

H

B

H

W

H

H

BI-36R / BI-36F BI-36RG BI-30U / BI-36U BI-30UG / BI-36UG

Models BI-36R, BI-36RG and BI-36F

REFRIGERATOR/FREEZER W H

Flush Inset Panel 361/2" (927) 693/4" (1772)

Spacer Panel 351/8" (892) 6815/16" (1751)

Backer Panel 353/4" (908) 699/16" (1767)

GRILLE W H

Flush Inset Panel 361/2" (927) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

BI-36RG W H

Window Cut-Out 251/2" (648) 541/8" (1375)

AB

Cut-Out Location 53/4" (146) 103/8" (264)

Models BI-36U and BI-36UG

REFRIGERATOR W H

Flush Inset Panel 361/2" (927) 501/8" (1273)

Spacer Panel 351/8" (892) 495/16" (1253)

Backer Panel 353/4" (908) 4915/16" (1268)

FREEZER W H

Flush Inset Panel 361/2" (927) 19" (483)

Spacer Panel 351/8" (892) 181/16" (459)

Backer Panel 353/4" (908) 1811/16" (475)

GRILLE W H

Flush Inset Panel 361/2" (927) 91/4" (235)

Spacer Panel 351/8" (892) 85/16" (211)

Backer Panel 353/4" (908) 815/16" (227)

BI-36UG W H

Window Cut-Out 251/2" (648) 395/8" (1006)

Models BI-30U and BI-30UG

REFRIGERATOR W H

Cut-Out Location 53/4" (146) 51/4" (133)

Flush Inset Panel 301/2" (775) 501/8" (1273)

Spacer Panel 291/8" (740) 495/16" (1253)

Backer Panel 293/4" (756) 4915/16" (1268)

FREEZER W H

Flush Inset Panel 301/2" (775) 19" (483)

Spacer Panel 291/8" (740) 181/16" (459)

Backer Panel 293/4" (756) 1811/16" (475)

GRILLE WH

Grille panel dimensions listed are for a standard 84" (2134)

overall height of the unit. For an 83" (2108) overall height,

subtract 1" (25) from grille panel height dimensions. For an

88" (2235) overall height, add 4" (102) to height dimensions.

Width dimensions do not vary.

For dual wide grilles, refer to page 36.

Flush Inset Panel 301/2" (775) 91/4" (235)

Spacer Panel 291/8" (740) 85/16" (211)

Backer Panel 293/4" (756) 815/16" (227)

BI-30UG W H

Window Cut-Out 191/2" (495) 395/8" (1006)

AB

Cut-Out Location 53/4" (146) 51/4" (133)

Dual Installations

AB

Page 36

Dual Installations 36

Dual Installation Kit with Dual Wide Grille.

This kit will replace the existing grilles that ship with the

units and span the entire width of both units. The kit

1

includes a

/4" (6) center trim strip (required for proper

installation of the dual wide grille), heater, dual kickplate

and mounting hardware. Dual wide grilles are available for

all built-in models and design applications. The overlay

dual installation kit with grille will accept overlay and dual

flush inset panels. For dual wide grille panel dimensions,

refer to the panel specifications below for your design

application. Grille panel dimensions listed are for a

standard 84" (2134) overall height of the unit.

Dual Wide Grille—Overlay Panels

Two 30" (762) Models

DUAL WIDE GRILLE W H

Overlay Panel 601/4" (1530) 91/4" (235)

Spacer Panel 593/8" (1558) 85/16" (211)

Backer Panel 60" (1524) 815/16" (227)

Dual Wide Grille—Flush Inset Panels

Dual Installation Kit. This kit is available for those

who choose to utilize the individual grilles that ship with

each unit. The kit includes a

the reveal between the units and grilles), heater and

mounting hardware. This dual installation kit is not

required if a custom filler strip is used. The filler strip

should be a minimum of 2" (51) wide. Refer to full-scale

template on page 41 for more information.

Two 36" (914) Models

DUAL WIDE GRILLE W H

Overlay Panel 721/4" (1835) 91/4" (235)

Spacer Panel 713/8" (1813) 85/16" (211)

Backer Panel 72" (1829) 815/16" (227)

1

/4" (6) filler strip (which fills

Dual Installations

Two 30" (762) Models

DUAL WIDE GRILLE W H

Flush Inset Panel 611/4" (1556) 91/4" (235)

Spacer Panel 593/8" (1558) 85/16" (211)

Backer Panel 60" (1524) 815/16" (227)

Two 36" (914) Models

DUAL WIDE GRILLE W H

Flush Inset Panel 731/4" (1861) 91/4" (235)

Spacer Panel 713/8" (1813) 85/16" (211)

Backer Panel 72" (1829) 815/16" (227)

Page 37

Built-In Accessories 37

subzerotrade.com

Accessories. These optional accessories are available for built-in models. Be aware that some accessories can not be

used with every model. Accessories are available through your Sub-Zero dealer. To obtain local dealer information, visit

the Showroom Locator section of our website, subzero.com.

• Front panels for framed design in white and classic

stainless steel—not available for glass door models.

• Front panels for flush inset application in classic,

platinum and carbon stainless steel with tubular,

curved and pro handles.

• Louvered, panel and stainless steel grilles for 83"

(2108) and 88" (2235) overall heights. Built-in models

come standard with a grille for an 84" (2134) overall

height of the unit.

• Side panels in white and classic stainless steel.

• Custom side panel mounting kit.

• Extended framed handles for framed models with

raised panels.

• Decorative stainless steel handles available in tubular,

curved and pro styles in a variety of lengths. For

standard handle lengths, refer to the chart.

• Retrofit kits for use with 600 series panels. Allows for

existing 600 series panels to be used on a new built-in

model—not available for Models BI-36R, BI-36RG, BI36F, BI-30UG, BI-36UG, BI-42SD and BI-48SD.

Standard Handle Lengths

ALL REFRIGERATOR / ALL FREEZER / SIDE-BY-SIDE MODELS

Tubular Handle 637/8" (1622)

Pro Handle 451/8" (1146)

Curved Handle 575/8" (1464)

Stud Spacing 437/8" (1114)

BI-30U and BI-30UG DOOR DRAWER

Tubular Handle 441/4" (1124) 245/16" (633)

Pro Handle 371/2" (952) 21" (533)

Curved Handle 453/16" (1148) 251/4" (641)

Stud Spacing 361/4" (921) 165/16" (414)

BI-36U and BI-36UG DOOR DRAWER

Tubular Handle 441/4" (1124) 305/16" (770)

Pro Handle 371/2" (952) 231/2" (597)

Curved Handle 453/16" (1148) 311/4" (796)

Stud Spacing 361/4" (921) 225/16" (567)

• Dual installation kit for use when placing units side by

side. Kits available with or without the dual wide grille

assembly.

• Partial framed kit for dispenser Models BI-42SD and

BI-48SD. Includes a stainless steel trim piece to be

used above and below the dispenser.

Page 38

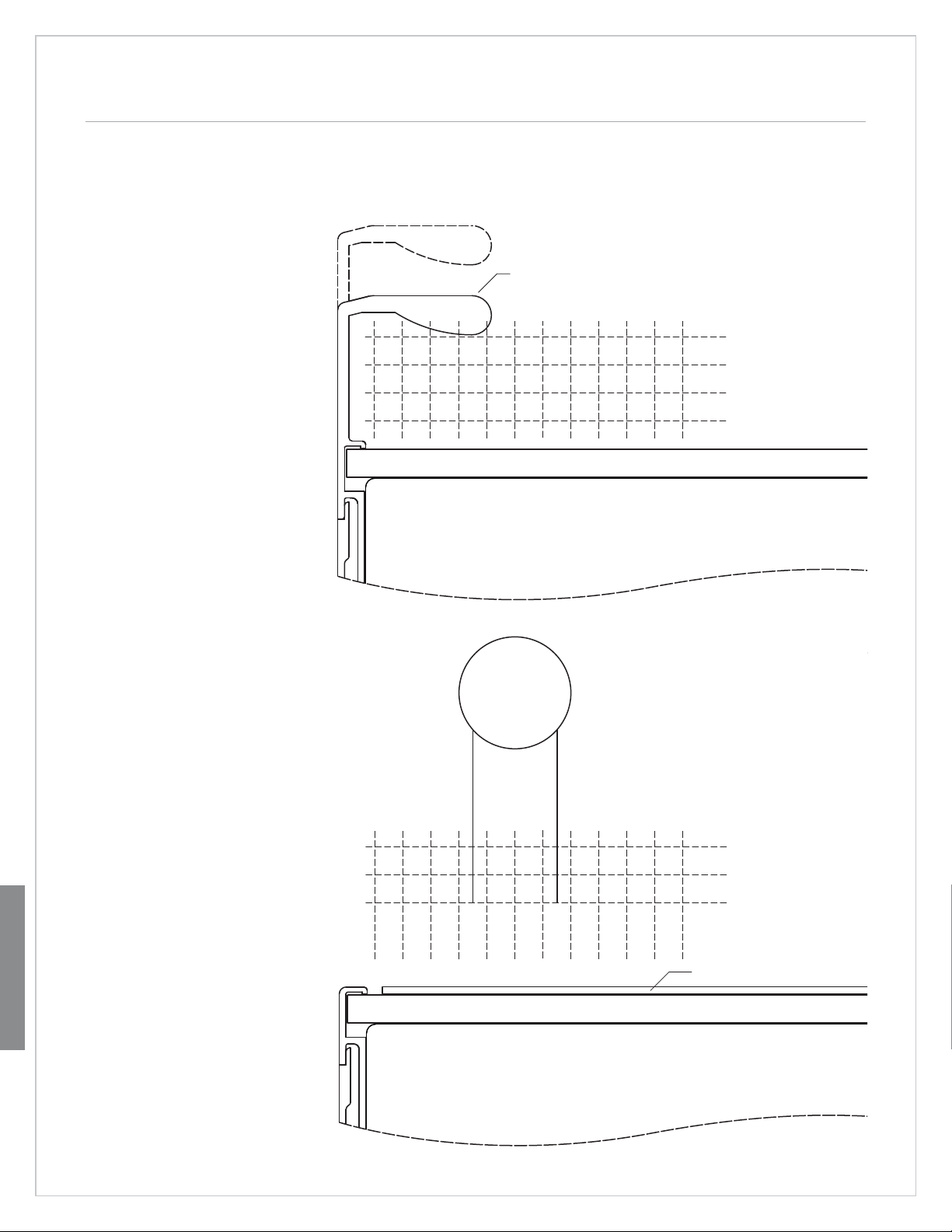

Panel Thickness and Handle Profile 38

OPTIONAL EXTENDED

FULL-LENGTH HANDLE

Framed. The top full-scale

template shows handle placement and panel thickness for

framed applications.

1"

(25)

1

/4" (6) FRAMED PANEL

STANDARD

FULL-LENGTH HANDLE

2"

(51)

DOOR

3"

(76)

11/4" (32) PANEL

1" (25) PANEL

3

/4" (19) PANEL

1

/2" (13) PANEL

Full-Scale Templates

Overlay and Flush Inset.

The bottom full-scale template

shows handle placement and

panel thickness for overlay and

flush inset applications.

IMPORTANT NOTE: Panel thickness does not include the

backer panel and .10" (3) spacer

panel.

IMPORTANT NOTE: The panel

must be a minimum of

thick to support mounting the

handle hardware.

Mount door handles close to the

opening edge of the door for

ease of opening.

1

/4"(6)

5

/8"(16)

1"

(25)

1

/4" (6) BACKER PANEL

DOOR

DEPTH OF TUBULAR, CURVED

AND PRO HANDLES

2"

(51)

3"

(76)

11/4" (32) PANEL

1" (25) PANEL

3

/4" (19) PANEL

.10" (3) SPACER PANEL

Page 39

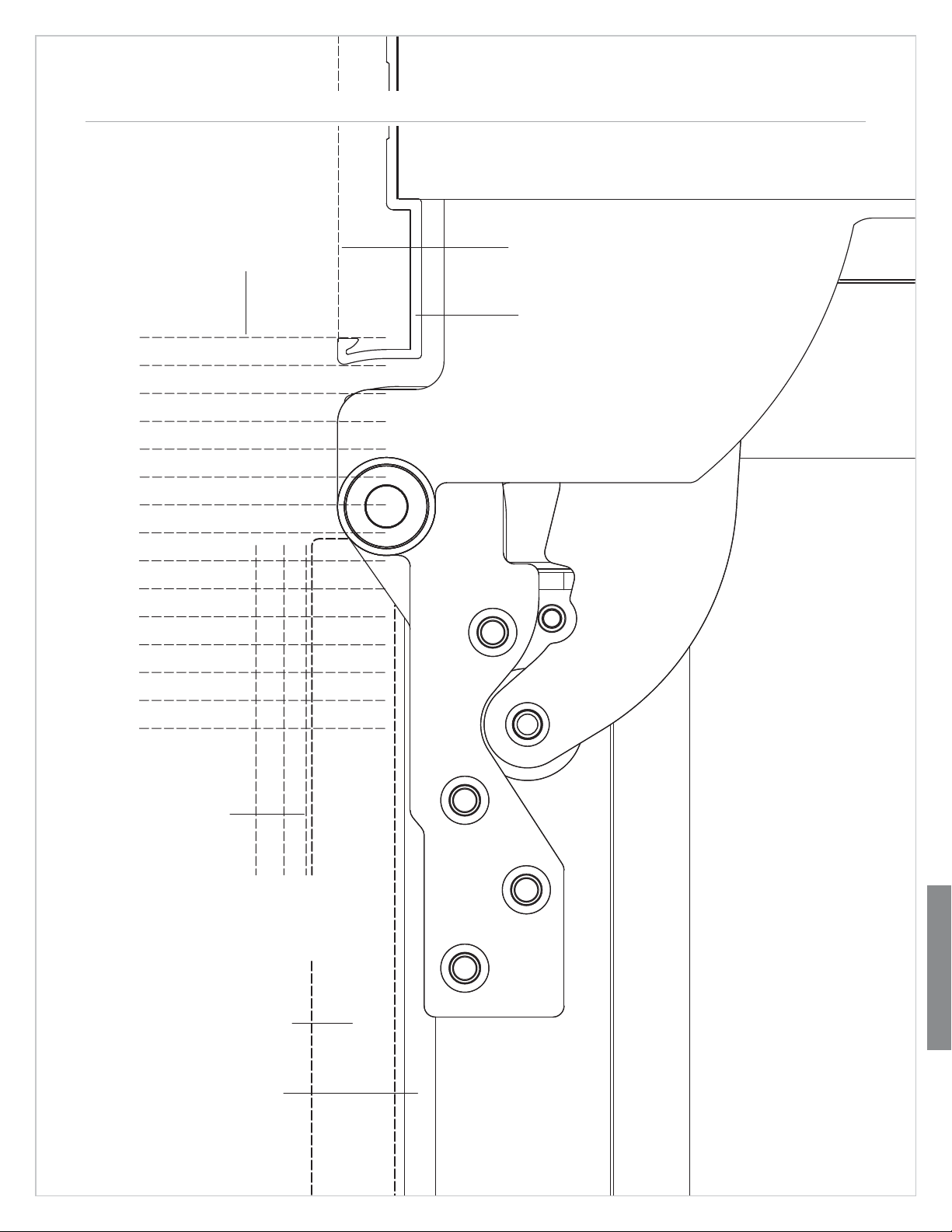

Overlay Panel Application—90° Door Opening 39

SUB-ZERO UNIT

237/8" (606)

TO REAR OF UNIT

(0)

0"

1

(6)

"

4

/

1

(13)

"

2

/

3

(19)

"

4

/

(25)

1"

1

(32)

"

4

/

1

1

(38)

"

2

/

1

3

(44)

"

4

/

1

(51)

2"

1

(57)

"

4

/

2

1

(63)

"

2

/

2

3

(70)

"

4

/

2

OVERALL WIDTH

OF UNIT

MAIN FRAME

subzerotrade.com

DOOR CLOSED

TOP VIEW

(76)

3"

1

(83)

"

4

/

3

1

(89)

"

2

/

3

APPROX THICKNESS

OF WRAPPED STAINLESS

STEEL DOOR

(32) PANEL

"

4

/

1

1

OVERLAY PANEL

3

/4" (19) THICK

(TYPICAL)

1

4"(6)

/

PA N

EL

(25) PANEL

1"

(19) PANEL

"

4

/

3

DOOR OPEN 90˚

This full-scale template

shows what considerations

you need to make for

overlay panel applications

and how they may interact

with adjacent cabinets and

countertops.

Full-Scale Templates

Page 40

Flush Inset Panel Application—110° Door Opening 40

SUB-ZERO UNITCABINETRY

This full-scale template

shows what considerations

you need to make for flush

inset panel applications and

how they may interact with

adjacent cabinets and

countertops.

IMPORTANT NOTE: For

flush inset panels thicker

3

than

/4" (19), a 90˚ door

stop may be needed to

avoid interference with

adjacent cabinets.

Dimensions in parentheses

are in millimeters unless

otherwise specified.

24" (610)

TO BACK WALL

23/16" (56)

ASSUMES

3

/4" (19)

FLUSH INSET

PANEL

THICKNESS

11/4" (32)

MAIN FRAME

Full-Scale Templates

FLUSH INSET PANEL

3

/4" (19) THICK

(TYPICAL)

4

/

1

1

(32)PANEL

"

1

PA NE L

1"

4

/

(25)PANEL

(6)

"

3

(19)PANEL

"

4

/

TOP VIEW

DOOR OPEN 110˚

Page 41

Panel and Handle Profile—110° Door Opening 41

subzerotrade.com

TOP VIEW

FILLER STRIP

2" (51)

SUB-ZERO UNITSUB-ZERO UNIT

DOOR CLOSED

APPROX PROFILE OF

STAINLESS STEE WRAPPED

DOOR AND HANDLE

This full-scale template

shows the panel and handle

profile for a dual installation

with a 2" (51) filler strip at

110˚ door opening.

Interference of door panels

with handles at maximum

door opening may require

the use of an optional 90˚

door stop available through

your Sub-Zero dealer.

Dimensions in parentheses

are in millimeters unless

otherwise specified.

OPTIONAL

FRAMED EXTENDED

FULL-LENGTH HANDLE

APPROX THICKNESS OF

WRAPPED STAINLESS

STEEL DOOR

OVERLAY PANEL

3

/4" (19) THICK

(TYPICAL)

MAIN FRAME

ALLOW FOR FILLER LAP

BEHIND FLANGE

STANDARD

FRAMED

FULL-LENGTH

HANDLE

(25) PANEL

1"

"

4

/

PA N

(19)

"

4

/

3

(6)

"

4

/

1

1

(32) PANEL

1

PA NEL

EL

(13) PANEL

"

2

/

1

Full-Scale Templates

DOOR OPEN 110˚

Page 42

Sub-Zero Products Limited Warranty

RESIDENTIAL USE ONLY

FULL FIVE YEAR SEALED SYSTEM WARRANTY

LIMITED SIXTH THROUGH TWELFTH YEAR WARRANTY ON THE SEALED SYSTEM

FULL TWO YEAR WARRANTY ON TOTAL PRODUCT*

FULL FIVE YEAR SEALED SYSTEM WARRANTY

For five years from the date of original installation, your Sub-Zero warranty covers all parts and labor to repair or

replace any components that prove to be defective in materials or workmanship in the sealed system.The sealed

system consists of the compressor, condenser, evaporator, drier and all connecting tubing.

FULL TWO YEAR WARRANTY*

For two years from the date of original installation, your Sub-Zero warranty covers all parts and labor to repair or

replace any part of the product, that proves to be defective in materials or workmanship.

LIMITED SIXTH THROUGH TWELFTH YEAR SEALED SYSTEM WARRANTY

From the 6th through the 12th year from the date of original installation, your Sub-Zero warranty covers all parts

that prove to be defective in materials or workmanship in the sealed system (parts only). The sealed system

consists of the compressor, condenser, evaporator, drier and all connecting tubing.

TERMS APPLICABLE TO EACH WARRANTY

All service provided by Sub-Zero under the above warranty must be performed by an authorized Sub-Zero service

center, unless otherwise specified by Sub-Zero. Service will be provided in the home during the normal business

hours. This warranty applies only to products installed for normal residential use. Details regarding a non-residential warranty are available upon request.

The warranty applies only to products installed in any one of the fifty states of the United States, the District of

Columbia or the ten provinces of Canada. This warranty does not cover any parts or labor to correct any defect

caused by negligence, accident or improper use, maintenance, installation, service or repair, including but not

limited to improper removal and reinstallation (whether in the unit or at a remote location) of the condensing unit.

THE REMEDIES DESCRIBED ABOVE FOR EACH WARRANTY ARE THE ONLY ONES THAT SUB-ZERO WILL

PROVIDE, EITHER UNDER THESE WARRANTIES OR UNDER ANY WARRANTY ARISING BY OPERATION OF

LAW. SUB-ZERO WILL NOT BE RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING FROM THE BREACH OF THESE WARRANTIES OR ANY OTHER WARRANTIES, WHETHER EXPRESS,

IMPLIED OR STATUTORY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other

legal rights, which vary from state to state.

To receive parts and/or service and the name of the Sub-Zero authorized service center nearest you, contact your

Sub-Zero dealer, distributor or the Sub-Zero Customer Service Department, P. O. Box 44130, Madison Wisconsin, 53744-4130; check the Contact & Support section of our website, subzero.com, or call 800-222-7820.

*Stainless Steel (classic, platinum and carbon) doors, panels, product frames and stainless interior surfaces are

covered by a limited 60 day parts and labor warranty for cosmetic defects.

*Replacement water filter and air purification cartridges are not covered by the product warranty.

Page 43

©Sub-Zero, Inc. all rights reserved. The information and images in this guide are the copyright property of Sub-Zero, Inc. Neither this guide nor

any information or images contained herein may be copied or used in whole or in part without the express written permission of Sub-Zero, Inc.

Page 44

Sub-Zero, Inc.

PO Box 44130

Madison, WI 53744-4130

800.222.7820

subzero.com

BIDG 6 /2008

Loading...

Loading...