Page 1

Lock Kit Installation

subzero.com 800.222.7820

Contents

Qty Description

1 Washer, Anti-Rotation

1 Plate, Catch

1 Screw, #10 x ¾"

2 Screw, #10 x ¾" machine

1 Lock, Door

1 Key

1 Washer, Finish

1 Nut, Extension

1 Cam

3 Spacers

1 Trim, Header

1

1 Template,

/8" Drilling

1 Instructions

Installation

1 For ease of installation, install the lock when the unit is

approximately 6" from being fully installed. For stainless

steel panels, skip to step 3.

2 Use the drilling template provided to drill a

pilot hole through the back of the panel. Then use a

(Forstner) bit to drill the lock assembly hole.

3 Insert the lock through the finish washer, anti-rotation

washer (not required for stainless panel) then into the

hole. For custom panels, secure the lock to the panel

using the ½" barrel extension nut. For stainless steel

panels, secure the lock with the ¾" barrel extension nut.

1

∕8" diameter

7

∕8"

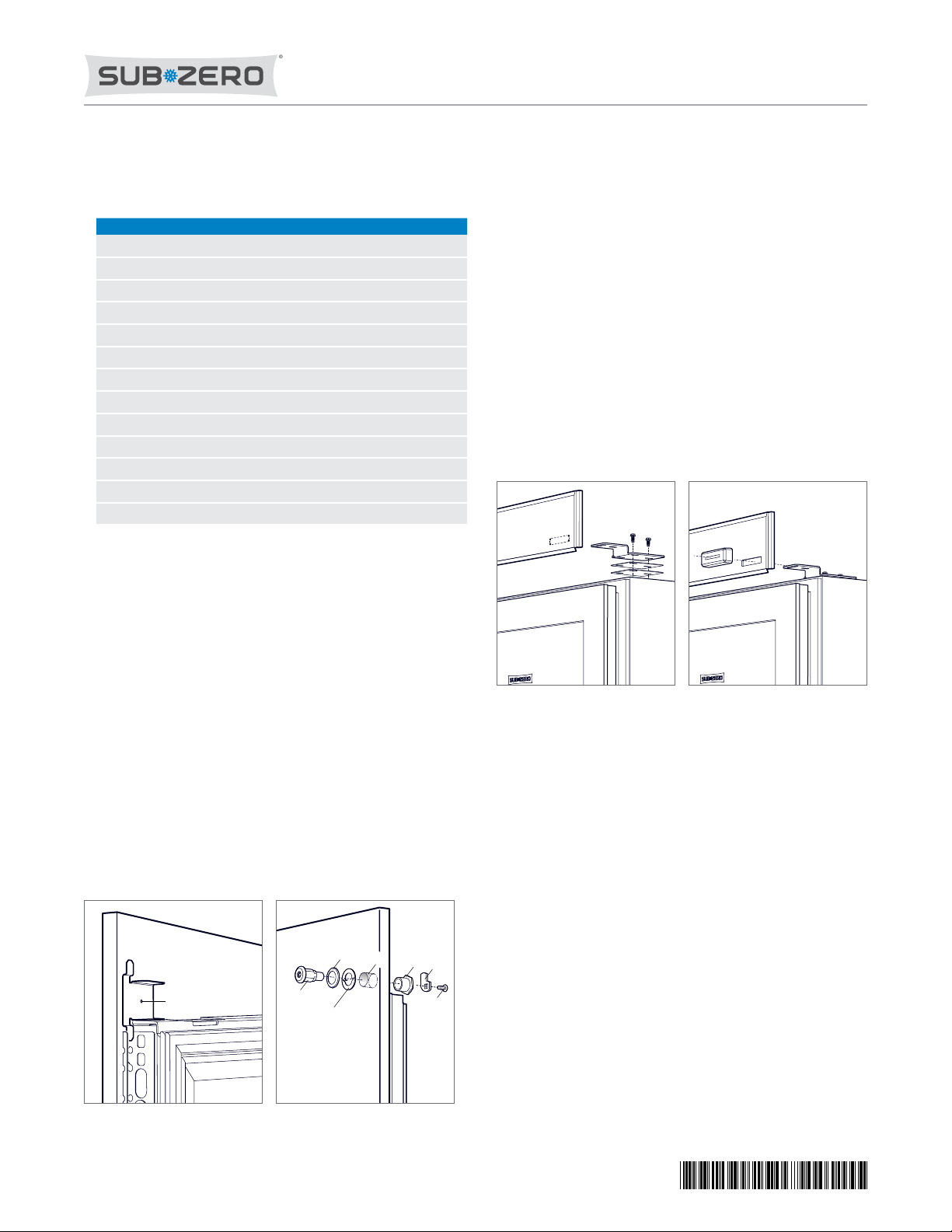

5 Install the catch plate by removing the two top cabinet

hinge screws on the handle side of the unit. Place two

spacers under the catch plate. Use the two #10 x ¾"

machine screws provided to install but do not tighten.

6 Verify the lock for proper operation. If catch plate needs

adjusting, add or remove spacer(s) to achieve proper

alignment, then tighten the hinge screws.

7 To create the opening for the catch plate in the header,

drill four

1

∕8" diameter holes. The four locations are

recessed on the back of the header. Once the four

holes have been drilled, use a utility knife to remove the

remaining material.

8 Install the header and header trim.

Install catch plate Install header and trim

4 Install the cam to the lock using the #10 screw. Verify

the lock turns clockwise (right hinge) or counter clockwise (left hinge).

TEMPLATE FOR

1

∕8" PILOT HOLE

Drilling template

7028772 REV-B 06/2014

FINISH

WASHER

LOCK

ANTI-ROTATION

WASHER

Install lock

HOLE

EXTENSION

NUT

SCREW

CAM

page 1 of 1

Loading...

Loading...