Page 1

INFORMATION

MANUAL

SUB-ZERO

r

Page 2

TABLE

OF CONTENTS

Sub .Zero 500 Series

• Models532, 542 and561 ..... b

• Models511 and 550 .......... 4

• Models 501F and 501R ....... 5

• Model 590 .................. 6

III

WARRANTY

iI

_®

Product Operation

• TemperatureControls ........ 7

• Crisper Drawers ............. 7

• HumidityControl ............ 8

• Adjustable Shelves .......... 8

• Roll-Out Refrigerator Basket.. 8

• Door Shelves and Dairy

Compartment ............... 9

• Freezer Drawer Removal ..... 9

• Door Closing ............... 10

• Fan Motor Operation ....... 10

• Ice Maker Operation ....... 10

• Automatic Defrost ......... 13

• Master Power Sw_tch ...... 13

• Sounds ................... 13

Product Care

• Maintenance and

Cleaning ............... 13-14

•• Lighting Information .. 15-16

• Vacation Tame ............. 16

• Vacant House !............. 16

Food Storage Suggestions

• Suggested Storage ...... 17-18

• Product Loading Suggestions•. 17

Service Information ...... 18-19

LOG YOUR MODEL"

AND SERIAL NUMBER

Have this information ready when

calling for service.

MODEL NUMBER

SERIAL NUMBER

INSTALLATION DATE

"PROT ! L AN ''

Full 5 Year Warranty'iind lilmit_Jd6th Through

12th Year Warranty on the Sealed System

Full 2 Year Warrantyon theTotal Product

For five years from the date of original inst_lation, your Sub-Zero warranty covers all

parts and labor to repair or replace any components that prove to be defective in

materials or workmanship in the sealed Systef--n;The sealed system consists of the

• compressor, condenser evapora!gr; drier-_-d_ co_ecting tubing

For two years from the date of original installation.,your Sub-Zero warranty covers all

o parts and labor to repair or replace an_ypaJ'tof the product which proves to be de-

fective in materialsor workmanship.

LIMITED 6TH THRqUGH,!2_ _.._R WARRANTY

From the 6th through the 12th year fron'_tfi_ d_te"of'_dginal installation, your Sub-

Zero warranty covers all parts that prove to be defective in matenals or workman-

ship in the sealed system (parts only). The sealed system consists of the compres-

sor, condenser, evaporator, drier and allconnecting tubing.

TERMSAPPLICABLE TOEACH WARRANTY

All service provided by Sub-Zero under the above warranty must be performed b_

author_edSub-Zero service repros ,t_,_u_e_iotherwise specified by Sub

_Zero.Servl_:e will be provided ir_._ ___ " i'_ormal busness hours " "

; arra_.ty apphes only to produ_..It _l_l_.;f._'_ residential use. A separate

;q_.lq.Ee_identialwarranty is available _J _ rJ_lq_J_ _ '"

i_ w_'ranty applies Only to prod_ _f_•,_y. one of the fifty states of th_

!U_i_States, the District of C01_, _."_ _._inces of Caneda. This war_arl_

:d..,Qes_0t cover any p_'rtsor lal_r tQ! }_._e_._used by negligence,

;oent _ Improper use, maintenance; __k_ br repair, including b_u_trl_

_-,l!'_tad'to improper removal a_ r_h _Wt_ bi_ m"the unit"or at a remote"J_

_ ..oq_"0f,thecondensing uniL_:'_-o_- __ _'i--' " :;'-_:'

:THE REMEDIES DESCRIBED ABOVE FOR EACH WARRANTY ARE THE ONL*i

ONES WHICH SUB-ZERO WILl;'PRO VlDE_ EITHER UNDER THESE WARRAN.

TIES OR UNDER ANY WARRANTY*_t_ING!BY. OPERATION OF LAW. MJ_

ZEROWILL NOT BE RESPON_, !B'LEF,O_Y CONSEQUENTIAL OR INOIDE_I

TAL DAMAGES ARISING FROM'THE _C_°OF THESE WARRANTIES oR

ANY OTHER WARRANTIES. WHETHER F.XPRESS, /MPL/ED OR STATUTORY. _'';

Some states do not allow the ex'_si_ o_.'_'t.ati_)rl" Ofincidental or consequ;n_

damages, so the above !imitation_j" e.xcl_ ma.y,_notapply to you. This wart .a_'ty

gives you specific legal rights and you rnayalso ha.ve Other legal rights which _'

from state to state. '- ="

To-rece.._yep.arts and/or servicel at)d tSe'_. 0f-.{be Sub-Zero authorized service.; -

representative nearest you, contact yoLir Sub.Zero-dealer or distributor or contact

Sub-Zero Freezer Company, Service Department, NO. Box 44130, Madison,

Wisconsin, 53744-4130 or call: (800) 222-7820.

FULLFIVE YEI_Z,WARRANTY

FULL TWO YEAR WARRANTY

J

FAC TONYAU THORIZED SENVICEA GEN T

(PHONE NUMBER)

2

Page 3

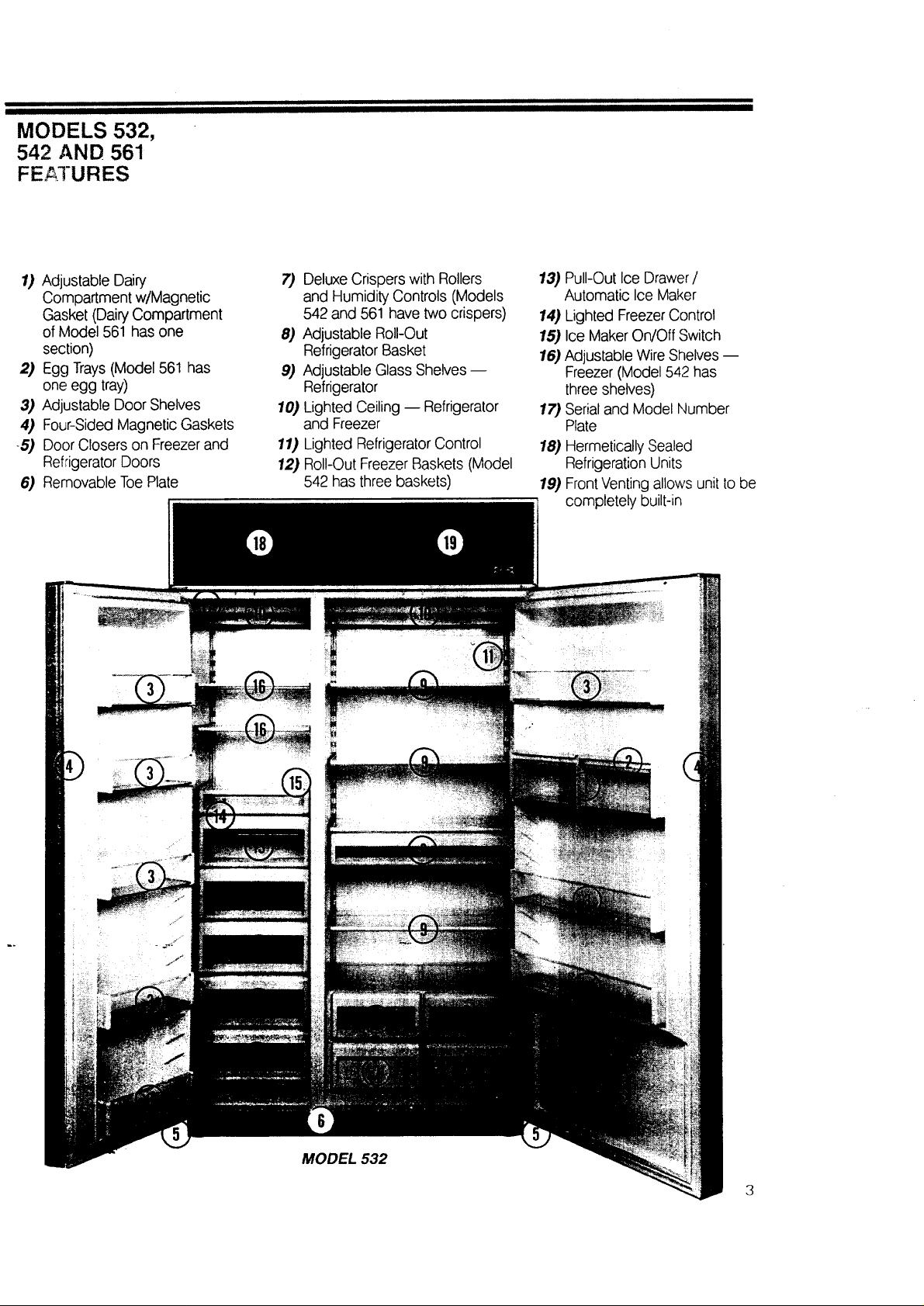

MODELS 532,

542 AND 561

FEATURES

I) Adjustable Dairy

Compartment w/Magnetic

Gasket (Dairy Compartment

of Model 561 has one

section)

2) Egg Trays (Model 561 has

one egg tray)

3) Adjustable Door Shelves

4) Four-Sided Magnetic Gaskets

5) Door Closers on Freezerand

Refrigerator Doors

6) Removable Toe Plate

7) Deluxe Crispers with Rollers

and Humidity Controls (Models

542 and 561 have two crispers)

8,) Adjustable Roll-Out

Refrigerator Basket

9) Adjustable Glass Shelves --

Refrigerator

10,)Lighted Ceiling -- Refrigerator

and Freezer

11) Lighted Refrigerator Control

12) Roll-Out Freezer Baskets (Model

542 has three baskets)

13) Pull-Out Ice Drawer/

Automatic Ice Maker

14`)Lighted Freezer Control

15`)Ice Maker On/Off Switch

16) Adjustable Wire Shelves--

Freezer (Model 542 has

three shelves)

17) Serial and Model Number

Plate

18) Hermetically Sealed

Refrigeration Units

19,)Front Venting allows unit to be

, completely built-in

MODEL 532

Page 4

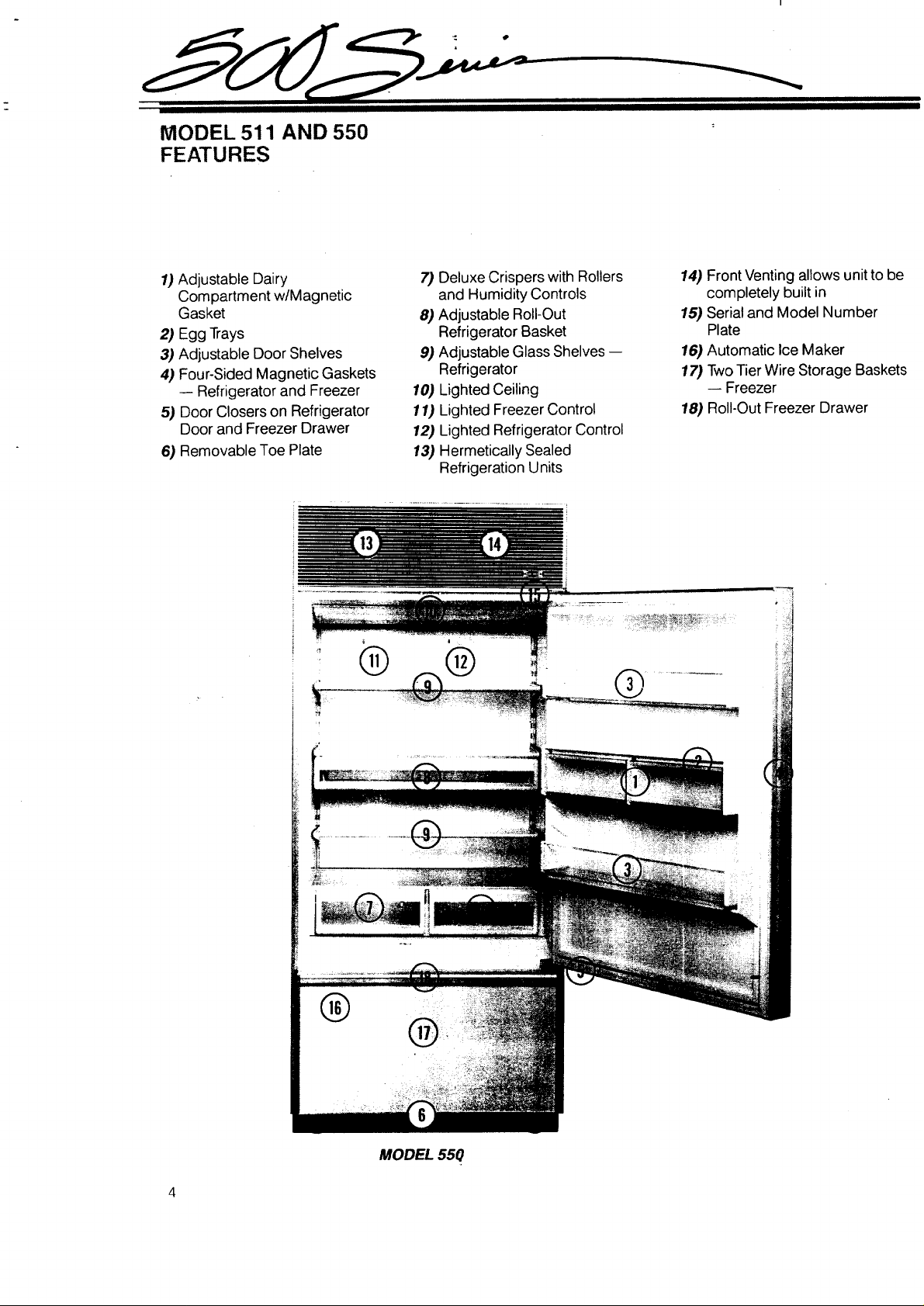

MODEL 511 AND 550

FEATURES

1) Adjustable Dairy

Compartment w/Magnetic

Gasket

2) Egg Trays

3) Adjustable Door Shelves

4) Four-Sided Magnetic Gaskets

Refrigerator and Freezer

5) Door Closers on Refrigerator

Door and Freezer Drawer

6) Removable Toe Plate

®

7) Deluxe Crispers with Rollers

and Humidity Controls

8) Adjustable Roll-Out

Refrigerator Basket

9) Adjustable Glass Shelves --

Refrigerator

10) Lighted Ceiling

1I) Lighted Freezer Control

12) Lighted Refrigerator Control

13) Hermetically Sealed

Refrigeration Units

14) Front Venting allows unit to be

completely built in

15) Serial and Model Number

Plate

16) Automatic Ice Maker

17) TwoTier Wire Storage Baskets

-- Freezer

18) Roll-Out Freezer Drawer

®

MODEL 550

Page 5

'"'"i '

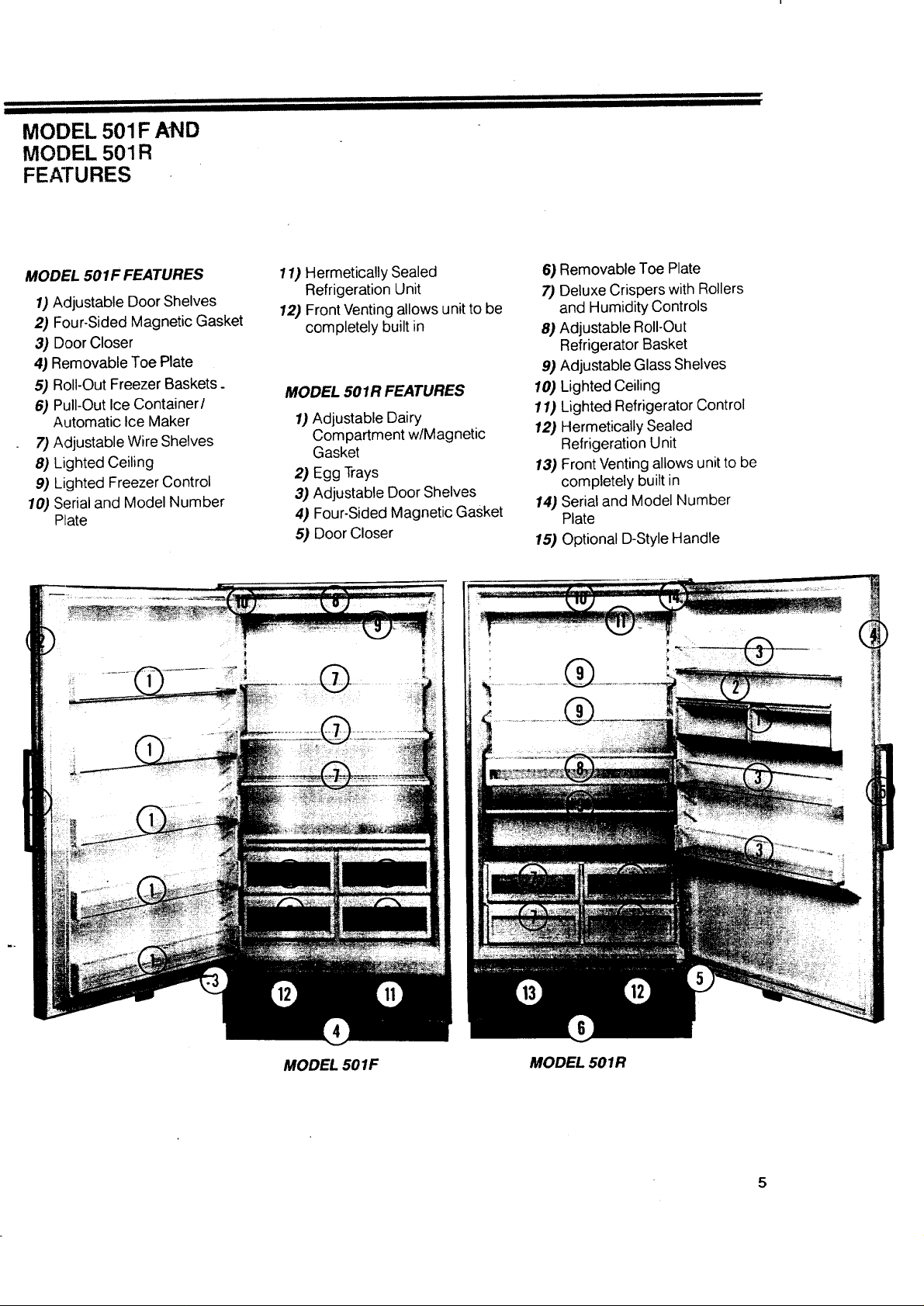

MODEL 501F AND

MODEL 501R

FEATURES

III II

MODEL 501F FEATURES

1) Adjustable Door Shelves

2) Four-Sided Magnetic Gasket

3) Door Closer

4) Removable Toe Plate

5) Roll-Out Freezer Baskets.

6) Pull-Out Ice Container/

Automatic Ice Maker

7) Adjustable Wire Shelves

8) Lighted Ceiling

9) Lighted Freezer Control

10) Serial and Model Number

Plate

11) Hermetically Sealed

Refrigeration Unit

12) Front Venting allows unit to be

completely built in

MODEL 501R FEATURES

1) Adjustable Dairy

Compartment w/Magnetic

Gasket

2) Egg Trays

3) Adjustable Door Shelves

4) Four-Sided Magnetic Gasket

5) Door Closer

6) Removable Toe Plate

7) Deluxe Crispers with Rollers

and Humidity Controls

8) Adjustable Roll-Out

Refrigerator Basket

9) Adjustable Glass Shelves

10) Lighted Ceiling

11) Lighted Refrigerator Control

12) Hermetically Sealed

Refrigeration Unit

13) Front Venting allows unit to be

completely built in

14) Serial and Model Number

Plate

15) Optional D-Style Handle

MODEL 501F

MODEL 501R

5

Page 6

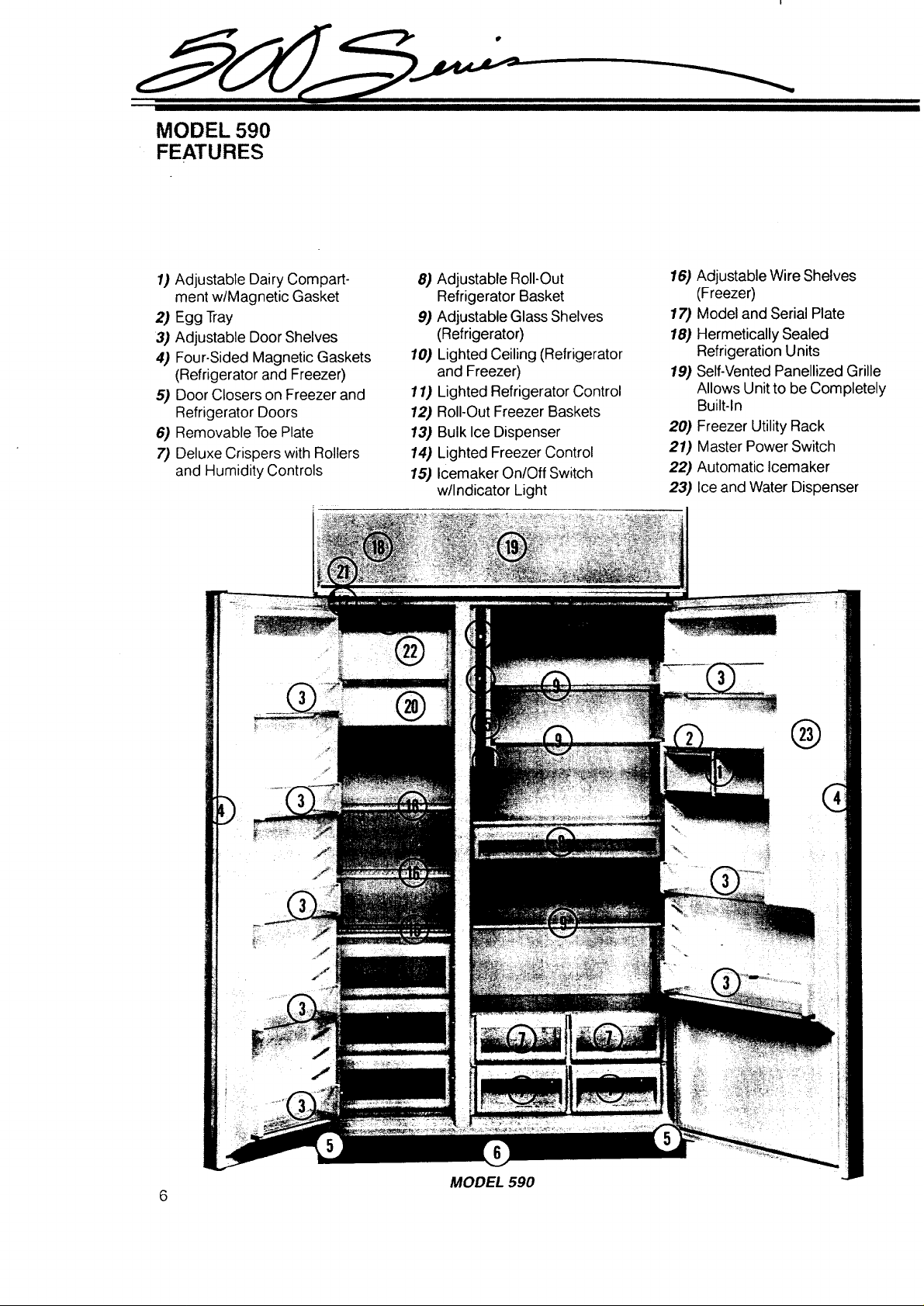

MODEL 590

FEATURES

1) Adjustable Dairy Compart-

ment w/Magnetic Gasket

2) Egg Tray

3) Adjustable Door Shelves

4) Four-Sided Magnetic Gaskets

(Refrigerator and Freezer)

5) Door Closers on Freezer and

Refrigerator Doors

6) Removable Toe Plate

7) Deluxe Crispers with Rollers

and Humidity Controls

8) Adjustable Roll-Out

Refrigerator Basket

9) Adjustable Glass Shelves

(Refrigerator)

10) Lighted Ceiling (Refrigerator

and Freezer)

11) Lighted Refrigerator Control

12) Roll-Out Freezer Baskets

13) Bulk Ice Dispenser

14) Lighted Freezer Control

15) Icemaker On/Off Switch

w/Indicator Light

16) Adjustable Wire Shelves

(Freezer)

17) Model and Serial Plate

18) Hermetically Sealed

Refrigeration Units

19) Self-Vented Panellized Grille

Allows Unit to be Completely

Built-In

20) Freezer Utility Rack

21) Master Power Switch

22) Automatic Icemaker

23) Ice and Water Dispenser

®

\

6

MODEL 590

Page 7

PRODUCT

OPERATION

The importance of the installation

ofyour Sub-Zero cannot be over-

emphasized. The proper in-

stallation of your unit is the

responsibility of the selling dealer

or installer. Any questions or

problems pertaining to the installation

should be directed to the selling

dealer.

TEM; ERATURE

CONTROLS

Your new refrigerator/freezer was

thoroughly inspected and tested

before it was shipped from the

Sub-Zero factory. During these

procedures, the temperatures

were preset to maintain approxi-

mately 38 degrees in the refrigera-

tor section and approximately 0

degrees in the freezer section. If

you wish to adjust the temperature,

simply turn the control dial. The

illuminated dial indicates the

control setting, #1 warmest to #10

coldest. See Figures 1,2, and 3.

You should be aware it is normal

for temperatures to fluctuate

slightly depending on external

influences, such as: an open door

for extended periods, the degree

of humidity present and room

temperature.

NOTE: Always allow 24 hours

for the refrigerator to reach the

temperature you set.

MODELS 532, 542 AND 561

The refrigerator control islocated

on the back wall of the refrigerator

near the top right. See Figure 1.

The freezer control is located on

the freezer panel just above the ice

drawer. Toadjust, pull the drawer

out, on the left side of the panel

turn the control dial until the

desired setting appears on the

panel. See Figure 2.

Figure 2

MODEL 590

The refrigerator and freezer con-

trols are both located inside the

refrigerator section on the left hand

side at a convenient level. See

Figure 3.

Figure 3

CRISPER DRAWERS

To remove your crisper drawer,

pull open until drawer stops. Raise

front of crisper and pull out as

shown in Figure 4. To reinstall:

With the front of the crisper raised,

insert crisper into the tracks. See

Figure 4.

Figure 1

•MODELS 511 AND 550

The refrigerator and freezer

controls are both located on the

back wall of the refrigerator near

the top. The refrigerator control is

on the right and the freezer

control is on the left. See Figure 1.

MODELS 501F AND 501R

The temperature control for each

model is located on the back wall

of the unit near the top right. See

Figure 1.

Figure 4

Page 8

PRODUCT

OPERATION

HUMIDITY CONTROL

The humidity level in each crisper

may be controlled for the storage

of meats, fruits or vegetables, (See

"Food Storage Suggestions," (See

pages 17 and 18). Adjust the slide

on the front, to the left for higher

humidity, or to the right for lower

humidity. See Figure 5.

Figure 6

Figure 5

ADJUSTABLE

SHELVES

To remove or adjust shelves,

tiltthe shelf up at the front, then lift

up and out of tracks on rear wall of

refrigerator or freezer as shown in

Figure 6. Note: If door is only

allowed to open 90 °, in order to

clear door shelves, lift and tilt right

end of shelf up and left end down,

_and lift out clearing door shelves ....

Caution should be exercised

whe_:handling refrigerator

glass shelves to prevent

breakage or scratching of

interior. To replace shelves:

Select desired shelf height. With

shelf front raised slightly, insert

shelf in tracks at rear of unit. Then

lower front of shelf until it locks into

position.

ROLL-OUT

REFRIGERATOR

BASKET

This basket rolls in and out for easy

access to small containers and

food items.

To remove: Pull basket out, lift up

on the front and then out as shown

in Figure 7 below. Note: If door is

only allowed to open 90 °,then

entire basket and shelf must be

removed as one unit in order to

clear door shelves. Todo this, place

one hand palm up under the roll out

refrigerator basket and lift out of the

support track. Tilt right end upward

and remove clearing door shelves.

Toreplace: With the front of the

basket raised, insert the basket

roller into tracks and push in.

Page 9

PRODUCT

OPERATION

DOOR SHELVES

AND DAIRY

COMPARTMENT

The door shelves and dairy

assembly are adjustable within the

guides of the door liner.See

Figure 8.

Toremove: Lift straight up and out

-from the bottom. Toreinstall:

Select desired position and push

down into guides.

FREEZER DRAWER

REMOVAL

MODELS 511 AND 550

The freezer drawer will stop before

coming all the way out of the unit.

Lift up evenly on each side of the

drawer, while holding the top

basket in place and pull out. The

drawer and basket will come out

together as in Figure 9.

I_CAUTION I

IMPORTANT."Unload the drawer

before removing. CAUTION

should be taken when

removing the drawer, keeping

your feet clear from under the

drawer.

MODELS 532, 542, 561 AND 590

To remove: Pull open until drawer

stops. Raise front of drawer and

pull out. Note: If door is only

allowed to open 90 o, in order to

clear door shelves, we

recommend the following

procedure. Pull ice drawer out until

itstops. Lift back of ice drawer up,

clearing carrier assembly. Pivoting

the right side of ice drawer toward

you, lift ice drawer out. Remove

the remaining drawers in

sequence by lifting up and out in

the Same manner, tilting up

sharply as soon as the rollers leave

the tracks. (If drawer sticks during

removal, lifting up will disengage

the rollers). To reinstall: Reverse

procedure. Note: To replace the

ice drawer, make sure the white

carrier assembly is pulled

completely forward and hang the

back lip of the drawer on the top of

the carrier assembly.

MODEL 501F

Toremove: Pullopen until drawer

stops, raise front of drawer and

pull up and out.

Toreinstall: Reverse procedure.

Figure 8

Figure 9

Page 10

PRODUCT

OPERATION

DOOR CLOSING

MODELS 532, 542, 561, 501F,

501R AND 590

Refrigerator and freezer doors are

both equipped with a spring

loaded door closure-mechanism.

As the doors are closed, the door

closure engages to assist in the

closing and sealing ofthe doors.

MODEL 550 AND 511

Refrigerator door: Your

refrigerator door isequipped with

a door closing cam to assist inthe

closing of the door.With the door

opened to approximately 120° the

cam will hold in the open position

ifthe door isstopped. Ifthe door

continues to swing open, have the

unit checked for proper leveling

by your installer or dealer.

As you close the door, the cam will

take over at approximately the 15°

position and assist inthe door

closing.

Freezer drawer: The freezer

drawer is equipped with a self-

closing mechanism. The incline,

built into the roller assemblies on

the basket, uses gravity to assist in

the drawer closing.

FAN MOTOR

OPERATION

ICEMAKER

OPERATION

The icemaker in your Sub-Zero is

fully automatic and has been fac-

tory pre-tested. Toput into opera-

tion it requires only a connection to

the house water supply.

MODELS 501F, 511 AND 550

The icemaker is shut off when the

container is removed from the

freezer basket. Replace the ice

container and ice production is

restored. For Models 511 and 550

see Figure 10 and for Model 501F

see Figure 11.

Figure 10

MODELS 532, 542 AND 561

The icemaker may be turned off

and on by the switch on the front of

the freezer control panel. See

Figure 12.

Figure 12

To remove the ice drawer for

Models 532, 542 and 561: Pull

it out until it stops and lift back of

ice drawer up clearing carrier

assembly, and lift ice drawer out.

Note: Ifdoor isonly allowed to open

90 °, repeat above procedure, but

when lifting ice drawer out, pivot

right side of ice drawer toward you

and out. This will allow drawer to

clear the door.

All units have one fan behind the

grille to cool the compressor

area. l"Bis fan runs with either

compressor.

10

Figure 11

Page 11

PRODUCT

CARE

MODEL 590

WATER DISPENSER

This automatic water and ice dis-

pensing product offers the conve-

nience of dispensing both chilled

water and ice from the product

without having to open the doors.

See Figure 13.

Figure 13

The water dispenser operates

as follows: To operate the water

dispenser, the water dispenser

switch must be depressed

continuously for the required

amount. This switch is located on

the refrigerator door glasswell. See

Figure 13. The very first time the

water dispenser isoperated, itwill

be necessary to flush and purge

the water system and water

storage tank for three minutes.

This procedure will clear out any

air in the system a_swell as any

foreign material that occl,Lr.switha

new plumbing connection in the

home.

The chilled water container is

mounted inside the refrigerator

section. It will take several hours to

chill the water to the refrigerator

temperature upon the original fill or

ifa significant amount of water is

I_t,CAUTION J

Do not run the water dispenser

switch any longer than 8 min-

utes continuously as this will

damage the equipmenL

MODEL 590

ICE DISPENSER

The ice dispenser operates as

follows: Tooperate the ice dis-

penser, the ice dispenser switch

must be depressed continuously

for the required amount. This

switch is located on the refrigerator

door glasswell. See Figure 13.

After original start-up of the ice-

maker operation, itwillbe neces-

sary to discard the first few batches

of ice as they may be discolored

due to the new plumbing connec-

tion to the home.

The ice dispenser feature can

deliver ice in two different ways:

(1) By inserting a glass into the

glasswell and then depressing the

ice dispenser switch as in Figure

13, ice cubes will automatically

dispense into the glass. (2) If a

larger quantity of ice is required,

open up the refrigerator door, posi-

tion an ice container underneath

the ice dispenser chute and then

depress the button for bulk ice

dispensing. See Figure 14.

I_,CAUTION J

Do not run the-ice dispenser

switch any longer than 8 min-

utes continuously as this will

damage the equipment.

IACAUTION I

Do not use a fragile glass as the

ice crescents dropping into the

glass from the ice dispenser

may break this type of glass.

Figure 14

MODEL 590

ICE DISPENSER

OPERATING TIPS

1) If no ice, is the ice system

switch on? See Figure 18.

2) Make sure there isa supply of

iceinstorage container. See

"Ice Storage Container"

page 12.

3) Make sure storage container is

alltheway into insureproper

engagement of auger motorto

back ofcontainer. If icecon-

tainer is notall theway back,

push oncontainer and ice

dispenserswitch at the same

time to properly engage.

4) Make sure freezer utility rack

isproperly installed asthis

insuresproper ice storage

containerpositioning. See

"Freezer Utility Rack"page 12.

5) Press ice dispenser switc,-h.If

no auger motor noise is heard,

wait 5 minutes and try again.

On second try ifno auger

motor noise isheard, call

your local Factory Authorized

Service Agency.

6) If the icedispenser isnot used

for an extended period, the ice

will tend to fuse together. It will

be necessary to discard old

ice.

11

Page 12

PRODUCT

CARE

MODEL 590

FREEZER UTILITY RACK

The freezer utility rack is specifi-

cally designed to accommodate

and hold freezer juice containers.

For the removal of the freezer utility

rack, lift up and pull out atthe bot-

tom with one hand and then sup-

port the top with the other hand as

in Figure 15.

I

!

Figure 15

MODEL 590

ICE STORAGE CONTAINER

The ice storage container holds

an ample supply of ice for

the average family's daily

consumption.

The ice storage container can be

removed for discarding unused ice

or for general cleaning purposes.

Toaccess theice storage con-

tainer, the freezer utility rack must

be first removed. See Figure 15. To

remove t_e ice storage container,

lift up on the ice container handle

and pull out having the bottom of

the ice storage container sup-

ported with the other hand as

shown in Figure 16.

Figure16

MODEL 590

LIGHT BULB AND LIGHT

SWITCH IN DISPENSER UNIT

The door dispenser light switch is

located inthe upper left hand

portion of the water and ice

dispenser glasswell. Depress the

light switch to turn the dispensing

light on and off. NOTE: Inthe off

mode the light will activate when

either the water or ice switch is

depressed. The light bulb can

easily be replaced with a 7 watt

appliance bulb. See Figure 17.

NO TE: Dispenser light will re.

main on for 5 seconds after

dispenser switch is released.

IAWARNINGI

Shut off circuit breaker to

refrigerator or master power

switch before attempting this

.maintenance. See Figure 19.

Figure 17

MODEL 590

DISPENSER SPILL TRAY

At the bottom of the water and ice

dispenser, there is aspill tray as-

sembly. This tray will catch and

evaporate small spills. NOTE:

There is no drain in this area;

therefore do not pour water

into the spill tray. See Figure 17.

To clean this area, depress the

front left corner of the spill plate and

it can easily be removed.

MODEL 590

ICEMAKER SWITCH

This switch is located in the refrig-

erator section on the right hand

side of the Control Panel As-

sembly. See Figure 18. NOTE:

When the switch ison, the ice-

maker system light will be illumi-

nated. See Figure 18. The design

of this sw_ch isto allow the icema-

ker and ice dispenser to be shut off

for extended _cation periods.

During these vacation periods, we

recommend the icemaker switch be

turned off. Then the ice storage

container can be removed, emptied

and returned to its location. See

Figure 16. This prevents the unused

ice, over a period of time, from

shrinking and sticking together,

possibly causing a'no ice"situation.

12

Page 13

illllllll ii iii i

iiii iii I iiiii

III

PRODUCT ....

OPERATION

II

Figure 18

ICE PRODUCTION

ALL MODELS

The level of ice in the ice containers

is controlled by an ice level arm.

When the containers are filled with

ice the ice level arm senses the

level and shuts down the icemaker.

As ice is used, the level drops and

the level arm signals the icemaker

to restore ice production.

These icemakers are designed

to produce an adequate

supply of ice for normal family

consumption. The length of time

between ice harvest cycles will

vary depending on load condi-

tions, door openings and ambient

room temperatures. On the

average, you can expect a harvest

of ice every 2 hours.

If ice is not used regularly it will

tend to fuse together. Te..avoidthis,

empty the ice container'periodically.

AUTOMATIC

DEFROST

For your convenience your Sub-

Zero unit is equipped with an auto-

matic defrost system. The

refrigerator section will defrost

during each off cycle of the refrig-

erator. The freezer section is con-

trolled by a timer which defrosts as

needed.

MASTER POWER

SWITCH

MODEL 590

The Model 590 features a Master

Power Switch. This switch, which is

located behind the top grille, will

turn off all electrical power to the

equipment. See Figure 19. This

eliminates having to shut power off

at the circuit breaker or having to

pull the power plug from the wall

receptacle. This switch can be

used for either shutting down the

equipment for servicing or during

extended vacations.

Inorder to access this switch, the

front inner grille panel assembly

must be first removed (refer to

panellized grille removal instruc-

tions on Page 14, Figure 23).

Figure 19

SOUNDS

Certain noises may be evident with

the normal operation of the unit.

Surrounding acoustics like walls,

floors and cabinets may affect the

sound level of your unit.

A gurgling sound or running water

sound may be evident as the refri-

gerant circulates through the

tubing.

In Model 590, the ice dispenser

valve within the refrigerator door

snaps closed 5 seconds after

either the water or ice dispenser

switch is released.

During the icemaker cycle you may

hear the sound of ice dropping into

the container or of the solenoid

valve while refilling the icemaker

with water.

During the freezer defrost you may

hear crackling and/or sizzling as

the heat from the defrost element

clears the frost from the freezer coil

and water runs into the defrost

water pan.

While the compressors are in

operation a slight hum may be

evident. During the startup and

shutdown of the compressor,

some vibration may occur lasting .

only a few seconds.

MAINTENANCE AND

CLEANING

IACAUTION J

We recommend for main-

tenance and cleaning, that the

circuit breaker or master power

switch if applicable to the re-

frigerator be shut off and pro-

tective gloves (when cleaning

the condenser) be worn.

CONDENSER:To insurepro_e r

performance, the cleaning of your

unit's condenser is required.This

should be performed every 3 to 6

months under normal use. To

clean, remove grille. See page 14.

.o

13

Page 14

PRODUCT

CARE

STANDARD GRILLE REMOVAL

MODELS 532, 542, 561, 511

AND 550

Remove center grille screw. Tilt the

grille forward at the top and

release the spring(s) from behind

the grille and lift off. See Figure 20.

Toreinstall: reverse procedure.

Figure 20

PANELLIZED GRILLE REMOVAL

The optional panellized grille which

is removed by lifting up (1) and

then pulling out at the bottom (2)

and then down to release from the

grille mounting bracket (3).See

Figure 22.

I'_CAUTION I

Failure to properly clean

this area could result in

temperature loss, or possible

mechanical failure in both

refrigerator and freezer.

Figure23

GRILLE REMOVAL

MODELS 501F AND 501R

Toremove grille, remove two black

screws located in the lowest louver

in the grille. Tilt the bottom of the

grille out and away, itwill release

from the top of the grille. See

Figure 21. To reinstall: reverse

procedure.

F/gum 21

14

Figure 22

CLEANING PROCEDURE

Use "soft" bristle brush and

vacuum hose to remove the

accumulation of dust and lint

particles on the condenser

(radiators). See Figure 23 for

Models 511,532, 542, 561,550

and 590. See Figure 24 for

Models 501F and 501R

i

Figure 24

INTERIOR: For cleaning of interior

surfaces and removable parts of

your refrigerator/freezer,wash with

a mild solution of soap and

lukewarm water towhich a small

amount of baking soda has been

added. Use of vinegar isnot

recommended. Rinseand dry

thoroughly.Avoid getting water on

lightsor controldials.

Page 15

PRODUCT "

CARE

590 Exterior Surfaces: Same as

interior for all Factory Supptied

Exterior Surfaces.

590 Glasswell cleaning: Wipe up

spills after removing dispenser spill

tray. See Figure 17. Clean with a

mild solution of soap and water to

which a small amount of baking

soda has been added.

I_wARNING I

Shut off electrical power to

equipment before cleaning

product with soap and water

solution.

I_'cAU'I]ON I

Do not submerge or pour hot

water over cold glass shelves.

CLEANING OUT THE ICE

CHUTE MODEL 590

On occasion, ice crescents may

become lodged in the ice chute.

The ice chute is aclear plastic

housing that directs ice from the

freezer section's ice storage con-

tainer to the refrigerator door ice

dispenser. This may prevent the

icemaker from supplying ice to

either the ice dispenser or the bulk

ice dispenser. We have made avail-

able access to the ice chute to

allow a convenient way to unblock

any obstructions.

The ice chute is located behind the

freezer control panel, mounted to

the left hand side of-refrigerator.

The side panel is removed by

holding the bottom of the"_ide

panel and pushing rearward, then

pulling out as in Figure 25. Once

the panel is removed, the clear

plastic ice chute will be visible as

well as any obstruction.

Figure 25

To remove the side cover of the ice

chute, depress the two side

locking tabs, then pull up and out.

See Figure 26.

Toreinstall, make sure the bottom

section of the ice chute is installed

first; the outside front cover lip fits

inside the stationary portion. Then

push the two assemblies together

and secure the self-locking tabs

closed.

LIGHTING

INFORMATION

IMPORTANT." When the

refrigerator doors (all models)

or freezer doors (501F, 532, 542,

561 and 590) are left open for

an extended period of time, the

lights may go off. This design

protects the internal parts from

overheating. To reset the light

switch, close the door(s)

for approximately 15 to 30

minutes.

[,_CAUTION ]

For your safety, the circuit

breaker to the refrigerator

should be shut off (or on Model

590, the master power switch is

turned off, see page 13) before

replacing bulbs. Protective

gloves should be worn when

handling light bulbs (40 watt

maximum).

REFRIGERATOR LIGHTING

The light shield in the top of the

refrigerator must be removed

to replace the light bulbs. Todo

so: Place your hands on the back

edge of the shield and pull towards

you to release (this shield may have

a snug fit). Drop the front edge

of the shield out of the channel and

remove. The light bulbs are now

accessible. Toreinstall: Engage

front edge of shield into channel

and snap the back edge up into

position. See Figure 27 on

page 16.

Figure 26

15

Page 16

PRODUCT

CARE

Figure 27

FREEZER LIGHTING MODELS

532, 542, 561 AND 501F

The overhead lighting is accessed

the same as described for

"Refrigerator Lighting," on

page 15.

FREEZER CONTROL LIGHTING

MODELS 532, 542 AND 561

Additional freezer lighting is

located behind the control panel.

To replace: Remove ice

container, reach behind the

control panel and unscrew bulb.

See Figure 28.

FREEZER BASKET LIGHTING

MODELS 532, 542 AND 561

Below the icemaker, mounted on

the back wall of the freezer, is the

lower freezer lighting. To remove

the light shield and access the

bulb, gently compress the shield

to release the top and then the

bottom.'TSeeFigure 28. To rein-

stall: Engage the bottom first and

then compress and insert thetop.

Figure 28

FREEZER LIGHTING

MODELS 511 AND 550

The freezer lighting is supplied by

bulbs in the top ofthe freezer

(Model 511 has one bulb, Model

550 hastwo bulbs), mounted to

the front of the evaporator cover.

The bulbs are accessible by open-

ing the freezer drawer and un-

screwing the bulb from the top of

the freezer.

FREEZER LIGHTING

MODEL 590

The overhead lighting is accessed

the same as described for

"Refrigerator Lighting."

See Figure 29.

..

VACATION TIME

For extended vacations: The

control(s)to your refrigerator or

freezer should be turned off or the

circuit breaker can be shut off (on

Model 590, the master power

switch, Se_ page 13.) Empty all

contents in the refrigerator/freezer.

BLOCK THE DOORS OPEN

SLIGHTLY WHEN THE

UNIT IS NOT IN USE. About

one inch space will let fresh air in to

keep the interior dry.

For short vacations: Remove all

perishable items. Shut off the ice-

maker switch (see Icemaker

Operation page 10) and dump the

unused ice out of the ice container.

Do not change the settings of your

controls.

VACANT HOMES

If for any reason this unit is put into

service on a temporary basis, and

later shut off, the doors should be

blocked open to allow fresh air to

circulate within the compartment.

Also, the circuit breaker to the

refrigerator or freezer should be

shut off (on Model 590, the master

power switch, see page 13).

CAUTION: The moisture

developed during even the

shortest amount of running

time could attack the metal.

16 Figure29

Page 17

iiiiiiii i i

Hill I IH I

FOOD STORAGE

SUGGESTIONS

i

H I

SUGGESTED

STORAGE*

New techniques are constantly

being developed. Consult the

College or County Extension

Service or your local Utility

Company for the latest

information on freezing and

storing foods.

*U.S. Department of

Agriculture

Fresh Food Storage

Shelf life of fresh foods may vary,

depending on the freshness at

time of purchase. To keep your

foods fresher longer, follow the

recommended storage

procedures.

Vegetables

Wash in cool water and drain.

Store in air-tight container or plastic

wrap. Most vegetables should be

stored in higher humidity.

Fruits

Wash and dry. Store in crisper

compartment. More aromatic fruits

should be stored in plastic bags.

Most fruits should be stored in

lower humidity.

Prepackaged Mea ts

Store in original packaging. After

opening rewrap tightly in plastic

wrap or aluminum foil.

Unfrozen Fish, Meats, and

Poultry

Remove store wrappings. Then

rewrap in plastic wrap, foil or

waxed paper, and refrigerate im-

mediately.

Eggs

Store unwashed in carton or port-

able egg tray. Use within 2 weeks.

Milk, Cream, Cottage Cheese

Keep carton closed. Store on re-

frigerator shelf and use within

5 days.

Cheese

Store in original packaging until

ready to use. After opening, re-

wrap tightly in plastic wrap or

aluminum foil.

Left Overs

Let cool and cover tightly with

plastic wrap or foil. Airtight plastic

containers work well to prevent

drying out and odor transfer.

Freezer Storage

Foods should be wrapped in mate-

rial designed for frozen food

storage. The wrap must be sealed

so as not to allow air or moisture

through the wrapping. DO NOT

refreeze thawed meats.

Ice Cream

The firmness of the ice cream will

depend on the cream content of

the ice cream. The higher quality

ice creams usually have a higher

cream content requiring colder

freezer temperatures to maintain

its firmness. Soft ice cream is not

always an indication of a tempera-

ture problem.

PRODUCT LOADING

SUGGESTIONS

Items that inhibit the proper

closing of your doors will affect

the temperatures and should

not extend beyond the front of

your shelves or beyond the

face of your door sheff

assemblies, DO NOT fill your

freezer with large quantities of

unfrozen foods expecting to

"fast freeze" these items. Space

out new unfrozen items to

allow for air circulation for best

freezing results.

17

Page 18

FOOD STORAGE

SUGGESTIONS

SERVICE

INFORMATION

IIIII

I IIIII II

Eating quafity drops after time shown in chart.

IN REFRIGERATOR

AT35 ° to 40 ° F

IN FREEZER

AT O° F

Fresh Meats

Roasts (Beef and Lamb) 3 to 5 days 6 to 12 months

Roasts (Pork and Veal) 3 to 5 days 4 to 8 months

Steaks (Beef) 3 to 5 days 6 to 12 months

Chops (Lamb) 3 to 5 days 6 to 9 months

Chops (Pork) 3 to 5 days 3 to 4 months

Ground and Stew Meats 1to 2 days 3 to 4 months

Variety Meats 1 to 2 days 3 to 4 months

Sausage (Pork) 1to 2 days 1 to 2 months

Processed Meats

Bacon 7 days 1 month

Frankfurters 7 days 1i2month

Ham (Whole) 7 days 1 to 2 months

Ham (Half) 3 to 5 days 1 to 2 months

Ham (Slices) 3 days 1 to 2months

Luncheon Meats 3 to 5 clays Freezing

Sausage (Smoked) 7 days not recom-

Sausage (Dry and Semi-Dry) 14 to 21 days mended

Cooked Meats

Cooked Meats and Meat

Dishes 3 to 4 days

Gravy and Meat Broth 1to 2 days

2 to 3 months

2 to 3 months

Before calling for service --

If you think your refrigerator or

freezer is not operating properly

check the following before calling

your Sub-Zero Factory Authorized

Service Agency or dealer. This

may save you time and the ex-

pense of a service call.

Fresh Poultry

Chicken and Turkey (Whole) 1to 2 days 12 months

Chicken (Pieces) 1 to 2 days 9 months

Turkey (Pieces) 1 to 2 days 6 months

Duck and Goose (Whole) 1to 2 clays 6 months

Giblets 1 to 2 clays 3 months

Cooked Poultry

Pieces (Covered with Broth) 1

Pieces (Not Covered) 3

Cooked Poultry Dishes 3

Fried Chicken 3

(Other than for meats and poultry)

Most fruits and vegetables

Lean fish

Fatty fish, rolls and breads, soups, stew,

casseroles

Cakes, pies, sandwiches, leftovers (cooked),

ice cream (original carton)

to 2 days

to 4 days

to 4 days

to 4 days

6 months

1 month

4 to 6 months

4 months

FREEZER

8-12 months

6-8 months

2-3 months

1 month max.

18

Page 19

i iiii illllll i,ill i _lll_llllUL_J_m

I I I I' I'1 IIII IIIII I .................._' ""_

'f Refrigerator/Freezer is not

_perating --

, Is there electrical power to

equipment?

, Is home fuse blown or circuit

breaker off?.

0Is refrigerator/freezer control on?

, Is your condenser clean?

, Has either door been left open?

Be sure no foods are obstructing

proper door closing.

, If still not running, unit may be in

defrost; wait 30 minutes to see if

unit will restart.

'f Refrigerator/Freezer is

Narmer than usual --

, Is control set properly?

Has door been open too long?

• Have you recentlyadded a large

quantity offood?

f Refrigerator/Freezer runs too

nuch --

, Is condenser behind grille

clean? See pages 13 and 14.

, On hot days and warm room

ambients the motor runs longer.

, Have doors been open for

extended times or large amounts

of food added?

_fRefrigerator/Freezer is

_rosted up --

• Have doors been left open?

• Are doors closingand sealing

properly? Contact your dealer if

door not adjusted properly.

, When opening the freezer

drawer you may notice side to

side motion in the drawer. This

motion is normal withthe

tolerance built-in to the drawer

slides.When the drawer is

closed itwill automatically adjust

and close with the proper

alignment.

If you hear unusual noises --

• These may be normal operating

sounds (see page 13,

"Sounds").

ff condensation forms inside

the unit --

* This is normal during high

hLimidity and frequent door

openings.

• Are doors closing and sealing

properly?

If condensation forms on the

outside --

• It is possible during periods of

high humidity some

condensation could appear. This

condition will subside when

hum!dity levels drop. If

condensation is excessive

contact your Sub-Zero Factory

Authorized Service Agency.

• Be sure doors are closed and

gaskets are sealing.

If it is too hot around freezer

compartment --

• Clean condenser (see pages 13

and 14).

If no ice --

• Models 511,550 and 501 F,is ice

container in position (see page

10)?

• Models 532, 542 and 561, is

icemaker switch turned on

(see pag_ 10)?

• Model 590, is icemaker switch

turned on (see page 12)?

If there is odor in the unit -

• Completely clean product

(see pages 13 and 14).

• Cover allfood tightly.

If light bulb needs replacing --

• Turn offcircuit breaker to

refrigerator, wear gloves to

protect against broken glass

(see pages 15 and 16).

If you hear occasional

buzzing --

• Iswater supply connected to

icemaker and turned on?

If you need product

information --

• Please call 1-800-222-7820 for

information on planning,

installation or product knowledge.

If you need product service --

• Please have model and serial

number available (for model

and serial numbers refer to

plate located on top frame of

unit insidedoor.)

• Call your nearest Sub-Zero

Factory Authorized Service

Center. For the location of a

Sub-Zero Factory Authorized

Service Center in your area,

contact your dealer or: Sub-

Zero Freezer Co., Inc., Service

Department, P.O.Box 44130,

Madison, W153744-4130,

Telephone 1-800-222-7820.

3UE TO OUR CONTINUOUS IMPROVEMENT PROGRAM, MODELS AND SPECIRCA TIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

19

Page 20

SUB-ZERO FREEZER CO., INC.

FORMNO. 3-75-217-14

P.O. BOX 44130, MADISON, Wl

PRINTED IN U.S.A.

53744-4130

(608) 271-2233

9/96

Loading...

Loading...