Page 1

Wine Storage Installation Guide

Page 2

WINE STORAGE

Contents

3 Wine Storage

4 Model 424G / 424FSG Site Preparation

7 Model 424G / 424FSG Installation

11 Model 427G / 427RG Site Preparation

14 Model 427G / 427RG Installation

18 Model WS-30 Site Preparation

25 Model WS-30 Installation

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

Page 3

WINE STORAGE

Product Information

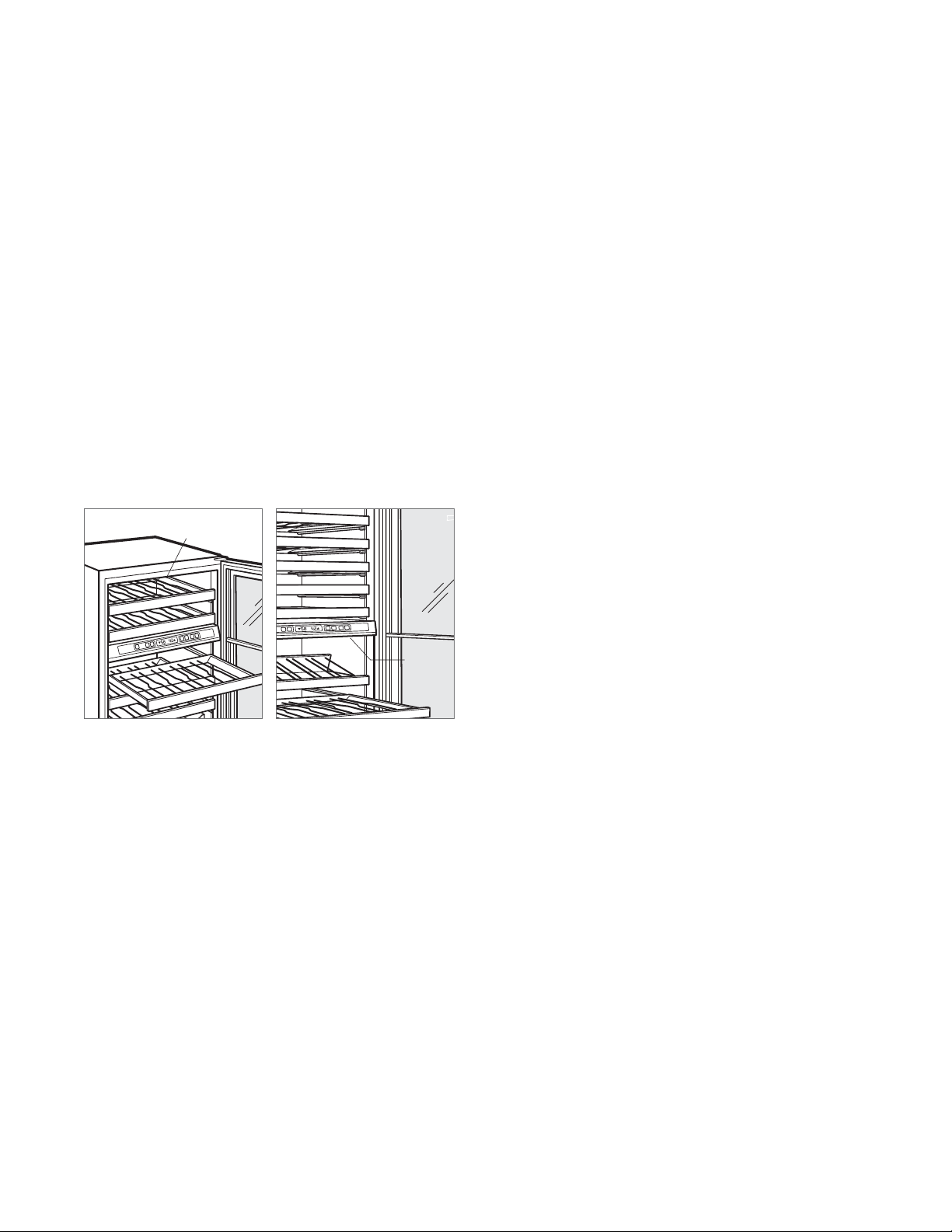

Important product information including the model and

serial number are listed on the product rating plate. For

undercounter models, the rating plate is located on the

underside of the top wall. For full-size models, it is attached

to the underside of the control panel. Refer to the illustrations below.

If service is necessary, contact Sub-Zero factory certied

service with the model and serial number. For the name

of the nearest Sub-Zero factory certied service or for

questions regarding the installation, visit the contact & support section of our website, subzero.com or call Sub-Zero

customer care at 800-222-7820.

RATING PLATE

Tools and Materials

t Screwdrivers—standard, Phillips and Torx.

t Power drill.

t Drill bits (masonry bits required for concrete installation).

t Standard socket and wrench set.

t 2' and 4' levels.

t Material to protect home, ooring and cabinetry during

installation.

Undercounter models.

RATING

PLATE

Full-size models.

subzero.com | 3

Page 4

MODEL 424G / 424FSG SITE PREPARATION

Opening Dimensions

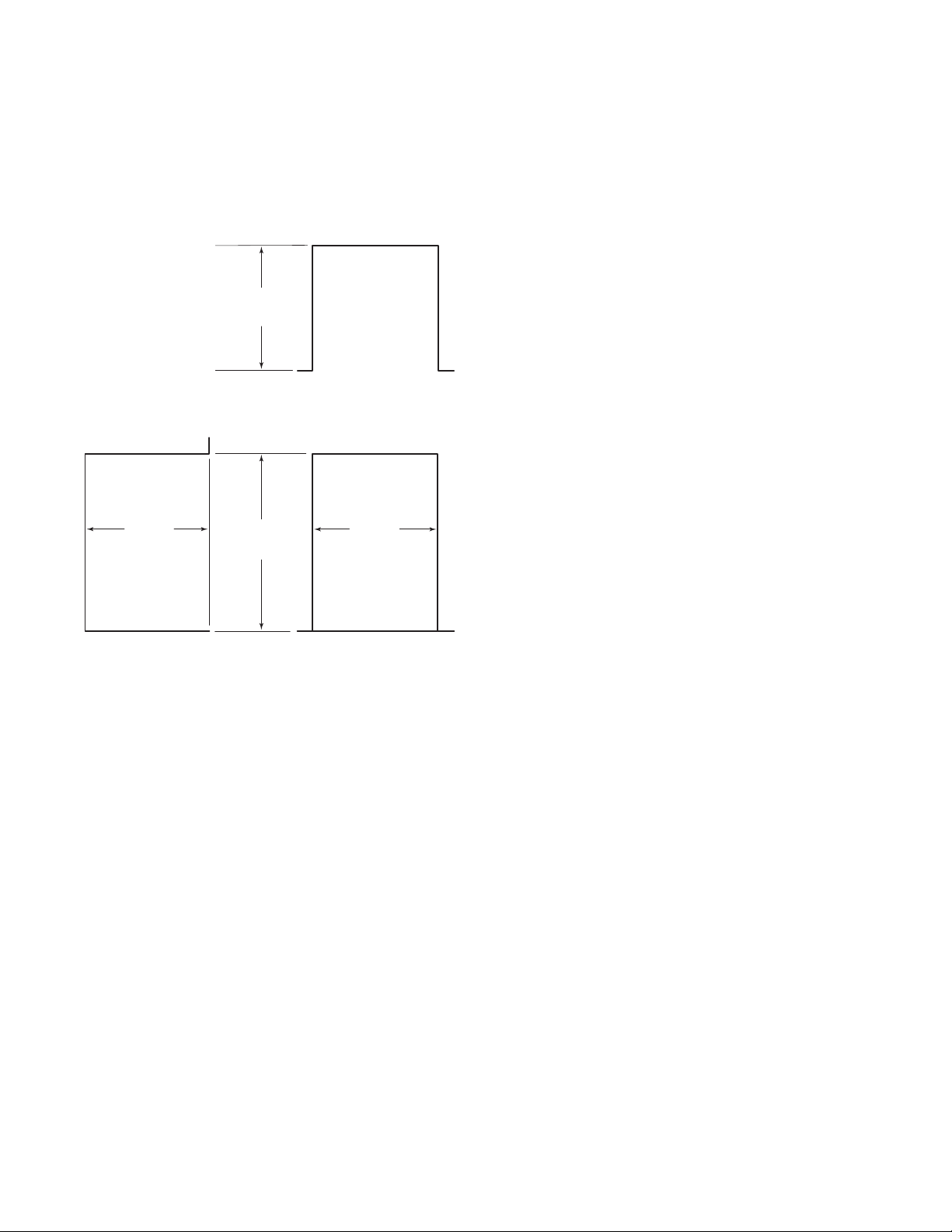

MODELS 424G AND 424FSG

24" (610)

OPENING

DEPTH

24" (610)

OPENING DEPTH

341/2" (876)

OPENING

HEIGHT

TOP VIEW

24" (610)

OPENING

FRONT VIEWSIDE VIEW

DUAL INSTALLATION

When installing two units side by side in a dual installation, the opening width is determined by adding the single

opening widths together. A dual installation kit is required,

but does not affect the opening width.

Dual installation kits are available through an authorized

Sub-Zero dealer. For local dealer information, visit the nd a

showroom section of our website, subzero.com. For questions regarding the installation, call Sub-Zero customer care

at 800-222-7820.

WIDTH

4 | Sub-Zero Customer Care 800.222.7820

Page 5

MODEL 424G / 424FSG SITE PREPARATION

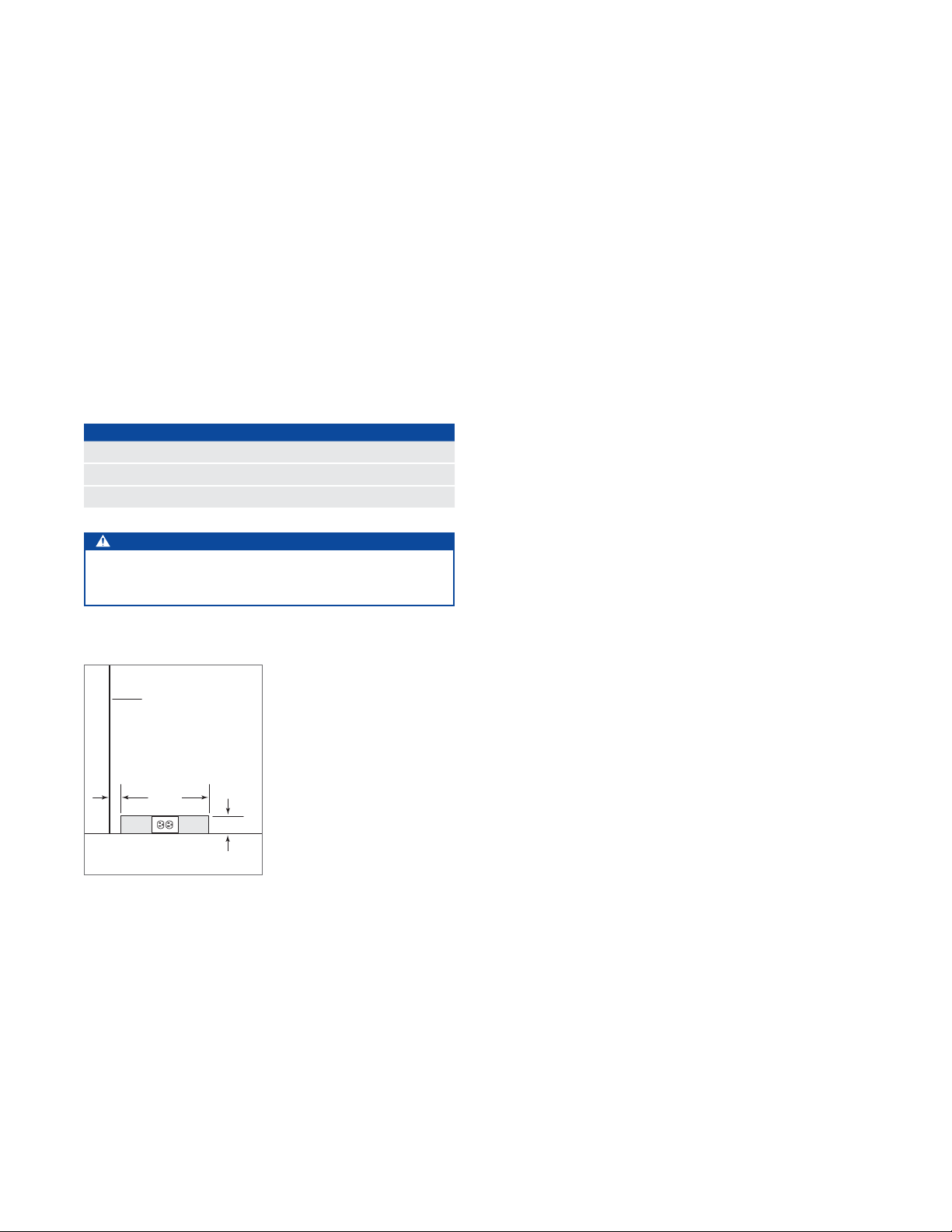

Electrical

Installation must comply with all applicable electrical codes.

The electrical supply should be located within the shaded

area shown in the illustration below. A separate circuit,

servicing only this appliance is required. A ground fault circuit interrupter (GFCI) is not recommended and may cause

interruption of operation.

IMPORTANT NOTE: The electrical outlet must be placed so

the grounding prong is to the right of the thinner blades.

The outlet must be ush with the back wall.

ELECTRICAL REQUIREMENTS

Power Supply 115 V AC, 60 Hz

Circuit Breaker 15 amp

Receptacle 3-prong grounding-type

WARNING

Do not use an extension cord, two-prong adapter or

remove the power cord ground prong.

Preparation

To operate properly, the door must open a minimum of 90°.

Use a minimum 3"

a 90° door opening.

Uncrate the unit and inspect for damage. Remove and

recycle packing materials. Do not discard the kickplate, antitip bracket, hardware and the leveling legs which hold the

wood base to the bottom of the unit.

(76) ller in corner installations to assure

LEFT SIDE

OF OPENING

2" (51)

151/2"

(394)

3" (76)

FRONT VIEW

Electrical supply location.

subzero.com | 5

Page 6

MODEL 424G / 424FSG SITE PREPARATION

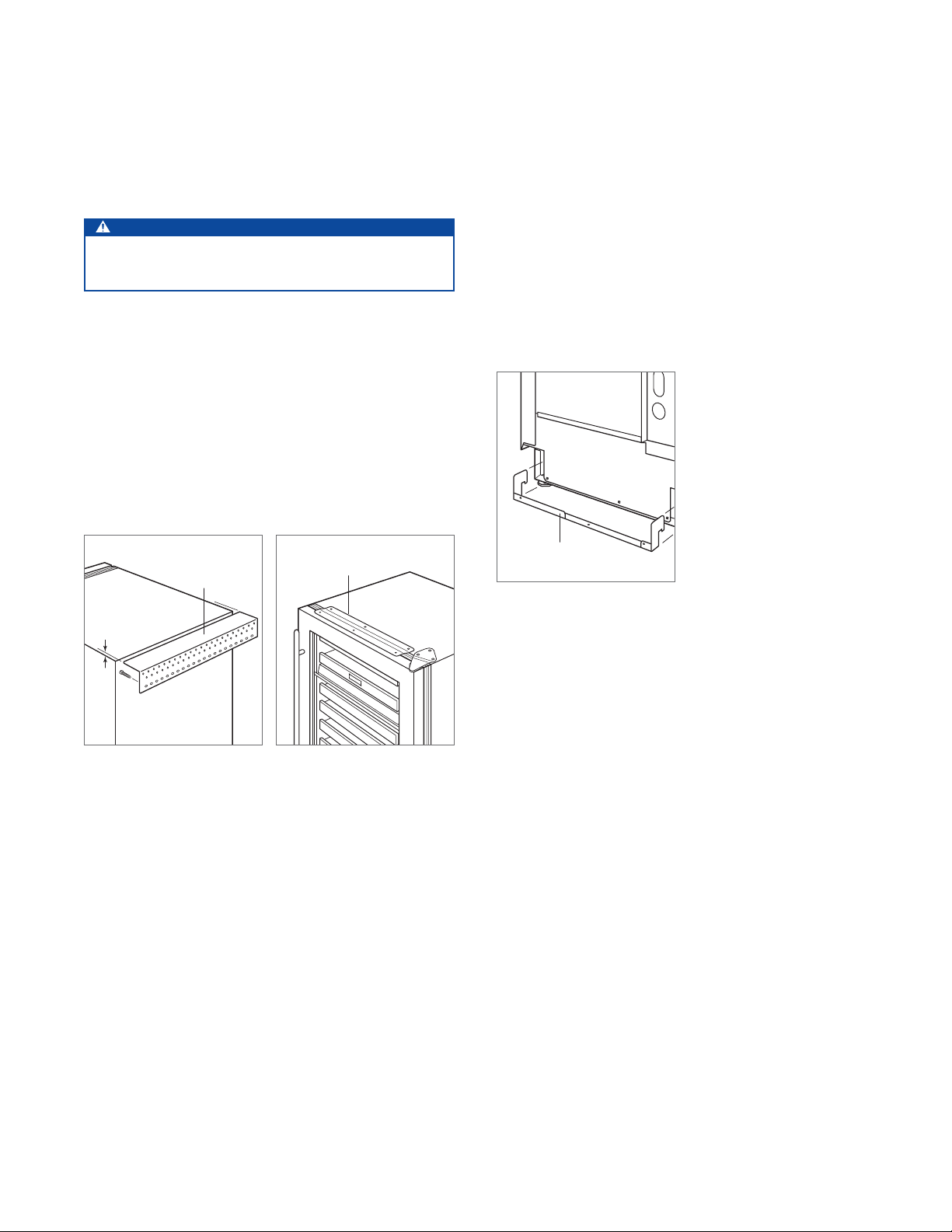

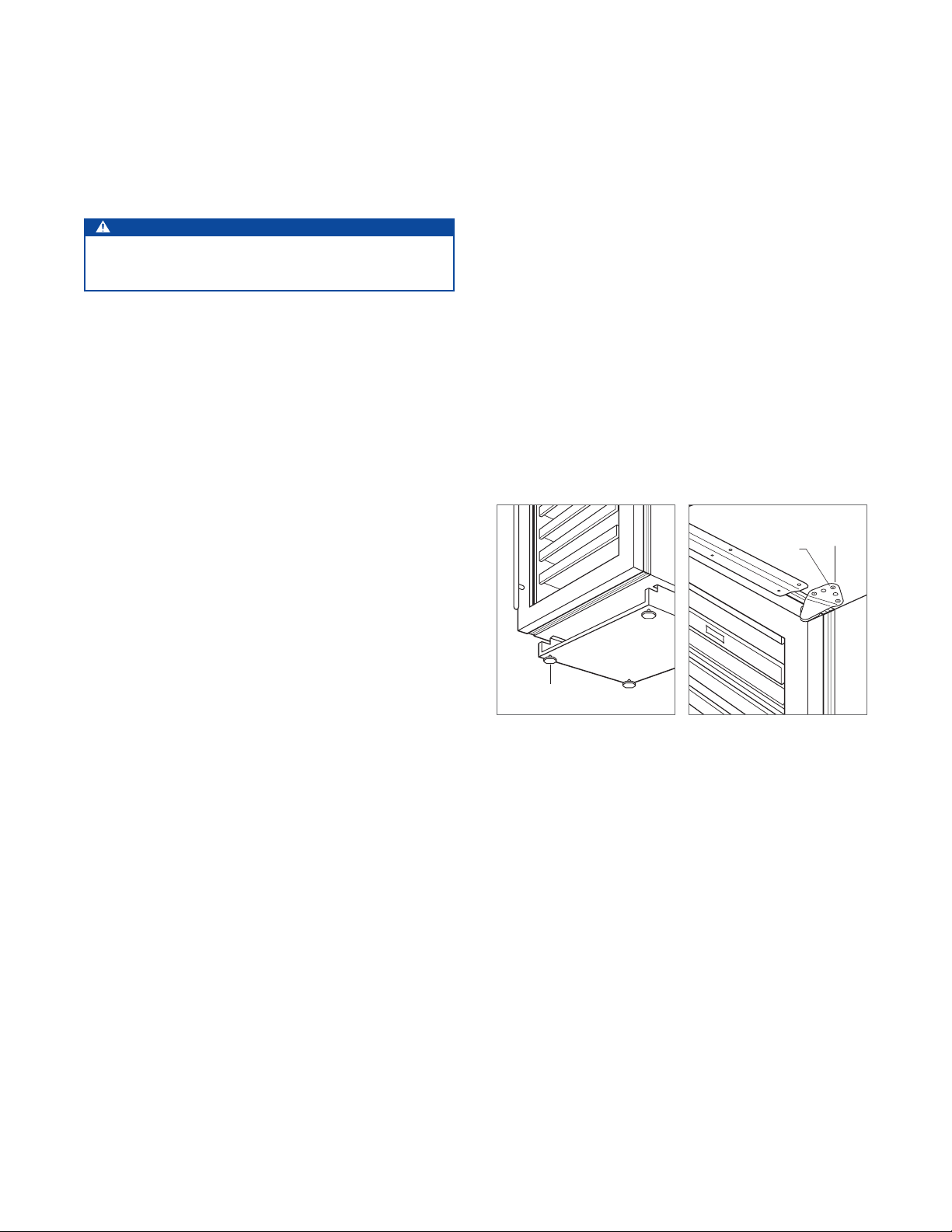

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

bracket must be installed.

MODEL 424G

The anti-tip bracket should be attached to the wall behind

1

the unit with the bracket ange located

/4" (6) above the top

of the unit. Refer to the illustration below. Failure to properly

position the anti-tip bracket will prevent proper engagement.

For installations that cannot accommodate the anti-tip

bracket, a countertop bracket is provided to secure the unit

to the countertop. Refer to the illustration below.

COUNTERTOP

BRACKET

1

/4" (6)

ANTI-TIP

BRACKET

MODEL 424FSG

The back of the anti-tip bracket must be installed 245/8"

(625)

from the front and centered behind the unit. Refer to

the illustration below. Refer to page 13 for wood and concrete oor applications.

ANTI-TIP BRACKET

Anti-tip bracket (424FSG).

Anti-tip bracket (424G).

6 | Sub-Zero Customer Care 800.222.7820

Countertop bracket.

Page 7

MODEL 424G / 424FSG INSTALLATION

Custom Panel

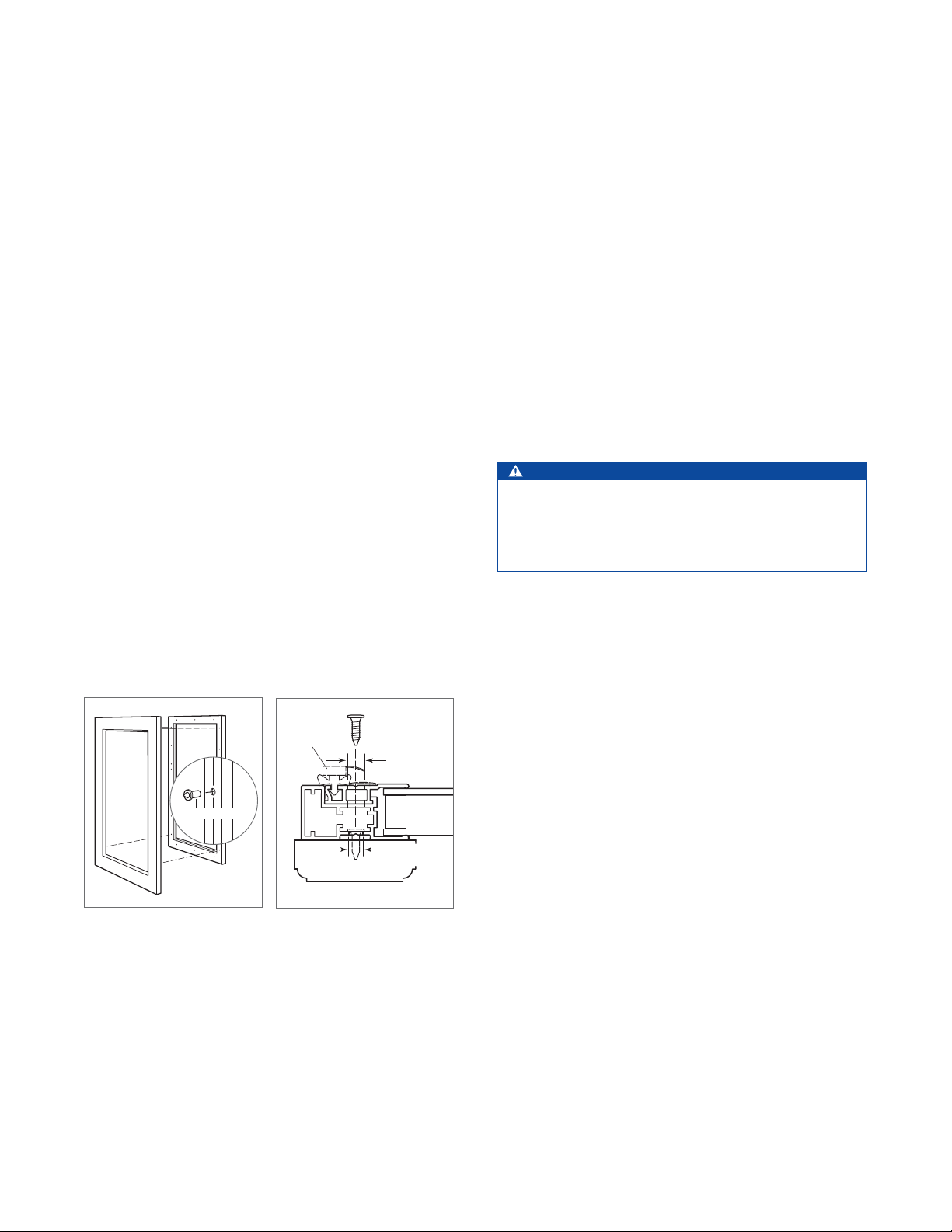

MODEL 424G

For overlay applications, a custom door panel must be

installed. Panel size is critical for a proper t. To verify panel

requirements and dimensions, refer to the Sub-Zero design

guide at subzero.com/specs.

Finish all sides of the custom panel. They may be visible

when the door is open or through the glass door.

The custom overlay door panel is attached using screws

provided, through the door frame. Screw locations are

marked on the back of the custom panel using tenon centers inserted into holes of the door frame.

With the unit secured and door closed, hold the custom

panel in desired position on the door. Lightly tap the front

of the panel to locate mounting positions. Remove tenon

centers. Refer to the illustration below.

The door frame has mounting holes to accommodate

Sub-Zero accessory handles. If handle mounting holes are

not utilized, the handle should be attached to the custom

panel prior to mounting. Screw heads may need to be countersunk into the panel for proper alignment.

To mount the custom panel, open the door and use predrilled holes to position the panel. Drive screws into the

panel through black tape on the door frame. Screw holes

are hidden behind the door gasket. Use as many screws as

necessary to secure the custom panel. Refer to the illustration below.

Adjustments can be made to the custom panel with a few

mounting screws in place, but not fully tightened. Once the

proper position is achieved, install and secure all screws.

Cover holes on the inside of the door frame with the cover

patches or plugs provided.

CAUTION

A solid panel cannot be installed over the glass door. A

solid door is available through an authorized Sub-Zero

dealer. For local dealer information, visit the nd a

showroom section of our website, subzero.com.

Tenon center.

DOOR

FRAMEPANEL

TENON CENTER

GASKET

Door frame cross section.

13

/32" (11)

DIAMETER

GLASS

1

/4" (6)

DIAMETER

subzero.com | 7

Page 8

MODEL 424G / 424FSG INSTALLATION

Placement

CAUTION

Before moving the unit into position, secure the door

closed and protect any nished ooring.

Use an appliance dolly to move the unit near the opening.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

If the unit will be connected to a home security system,

run lead wires through the compressor compartment prior

to positioning the unit. Refer to page 9. Once the unit is in

position, wiring connection can be completed from the front.

Alignment

LEVELING

Level the unit before sliding it into position. Turn each of the

four leveling legs clockwise to raise the unit and counterclockwise to lower. Refer to the illustration below.

DOOR ADJUSTMENT

The top and bottom cabinet hinges are held in place with

three permanent adjustment screws. For adjustments,

loosen the screws, adjust the door and tighten screws.

Refer to the illustration below. For model 424FSG, only the

bottom door hinge can be adjusted.

SCREW

HINGEADJUSTMENT

LEVELING LEGS

Leveling.

Door adjustment.

8 | Sub-Zero Customer Care 800.222.7820

Page 9

MODEL 424G / 424FSG INSTALLATION

Completion

Plug the power cord into the grounded outlet, then slide

the unit into position. Verify the anti-tip bracket is properly

engaged.

1

It may be necessary to install the unit

/4" (6) beyond the

front surface of adjacent cabinetry, to prevent interference

when the door is opened to 145°. Refer to the full-scale

template on page 10.

HOME SECURITY CONNECTION

If the unit will be connected to a home security system,

make connections to the leads shown in the illustration

below. Refer to the following color codes:

t Normally open contacts—white with red stripe wire.

t Normally closed contacts—white with blue stripe wire.

t Common—gray with white stripe wire.

Use the spade terminals or wire nuts provided to make

proper wiring connections.

CAUTION

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be used

to switch line power. Any unused terminals should be

completely insulated and all wires should be secured

away from conductive or moving components.

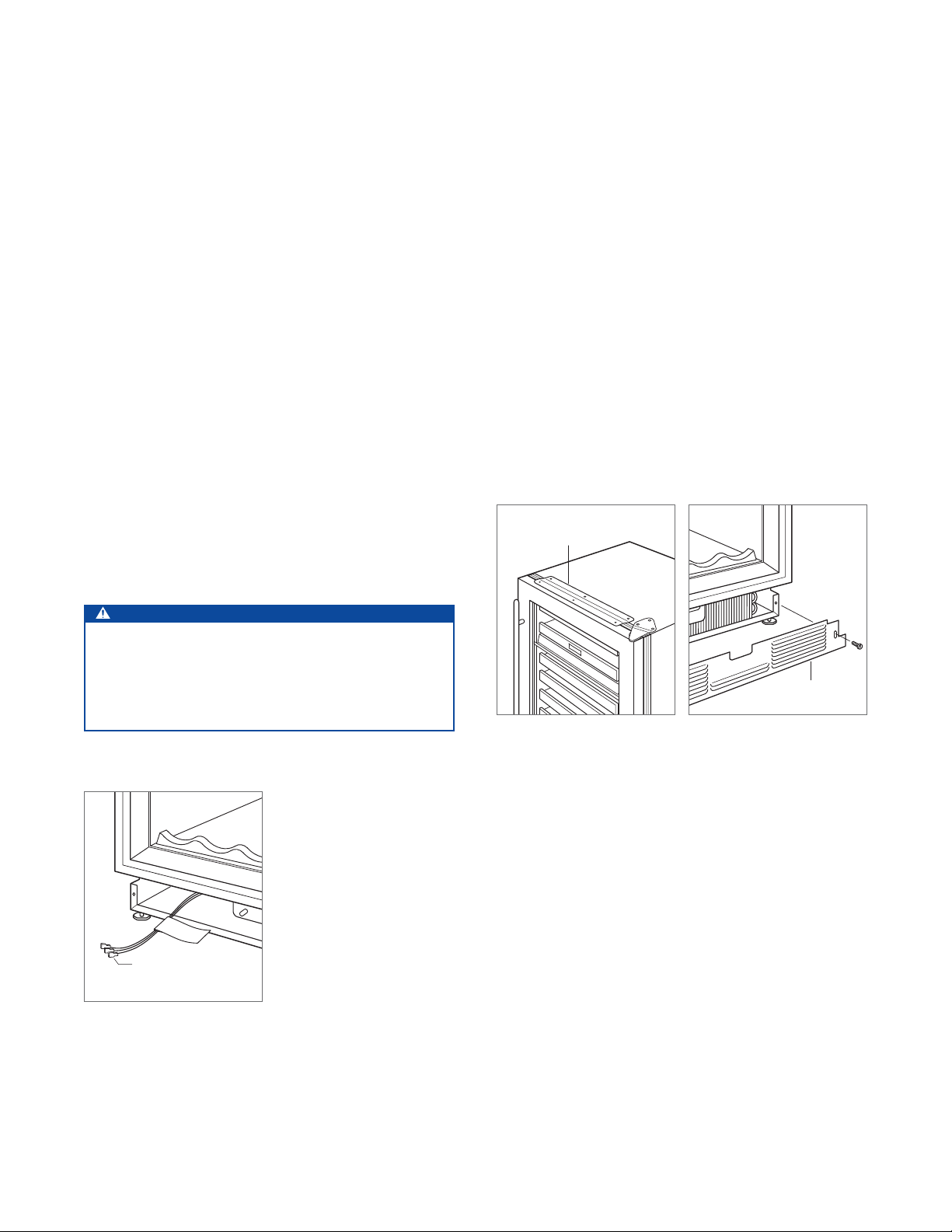

ANCHORING

To anchor, use the countertop bracket provided to secure

the unit to the underside of the countertop. Refer to the

illustration below. If the countertop bracket can not be

utilized, install shims along the top and sides of the unit.

KICKPLATE INSTALLATION

Install the kickplate using the two screws provided. Refer

to the illustration below. The kickplate must be removable

for service. The oor cannot interfere with removal. Do not

cover the louvered section of the kickplate.

COUNTERTOP

BRACKET

KICKPLATE

Anchoring.

Kickplate installation.

HOME SECURITY

LEADS

Home security connection.

subzero.com | 9

Page 10

MODEL 424G / 424FSG INSTALLATION

Door Clearance

FULL-SCALE TEMPLATE

To allow for a 145° door opening, the unit should extend

1

a minimum of

/4" (6) beyond the front surface of adjacent cabinetry. The unit can be installed ush, however,

there is potential for interference with the panel if the

door is opened past 90°.

UNDERCOUNTER

UNIT

DOOR CLOSED

1

/2"

(13)

ADJACENT

CABINETRY

3

/4" (19) DOOR PANEL

1" (25)0"

SCALE

145° door opening (top view).

10 | Sub-Zero Customer Care 800.222.7820

1

/4" (6)

1

/8" (3)

HINGE DETENT

AT 145° OPENING

(DOOR OPENS PAST 145°)

Page 11

MODEL 427G / 427RG SITE PREPARATION

Opening Dimensions

MODELS 427G AND 427RG

25" (635)

OPENING

25" (635)

OPENING DEPTH

80" (2032)

OPENING

HEIGHT

DEPTH

TOP VIEW

(686)

27"

OPENING WIDTH

DUAL INSTALLATION

When installing two units side by side in a dual installation, the opening width is determined by adding the single

opening widths together. A dual installation kit is required,

but does not affect the opening width.

Dual installation kits are available through an authorized

Sub-Zero dealer. For local dealer information, visit the nd a

showroom section of our website, subzero.com. For questions regarding the installation, call Sub-Zero customer care

at 800-222-7820.

FRONT VIEWSIDE VIEW

The depth of models 427G and 427RG is 24" (610). Allow for

panel thickness when planning the nished opening depth.

subzero.com | 11

Page 12

MODEL 427G / 427RG SITE PREPARATION

Electrical

Installation must comply with all applicable electrical codes.

The electrical supply must be located within the shaded

area shown in the illustration below. A separate circuit, servicing only this appliance is required. A ground fault circuit

interrupter (GFCI) is not recommended and may cause interruption of operation.

The electrical outlet must be positioned with the grounding

prong to the right of the thinner blades.

ELECTRICAL REQUIREMENTS

Power Supply 115 V AC, 60 Hz

Circuit Breaker 15 amp

Receptacle 3-prong grounding-type

CAUTION

The outlet must be checked by a qualied electrician to

be sure that it is wired with the correct polarity. Verify

that the outlet is properly grounded.

WARNING

Do not use an extension cord, two-prong adapter or

remove the power cord ground prong.

Preparation

Uncrate the unit and inspect for damage. Remove the wood

base and discard shipping bolts and brackets. Remove and

recycle packing materials. Do not discard the kickplate, antitip bracket and hardware.

IMPORTANT NOTE: For model 427RG, the upper drawer has

a control cable that must be disconnected before removing

the drawer. Refer to the illustration below.

Control cable (model 427RG).

LEFT SIDE

OF OPENING

21/2"

(64)

13" (330)

41/2"

(

)

114

1

/4"

(6)

Electrical supply location.

12 | Sub-Zero Customer Care 800.222.7820

FLOOR

FRONT VIEW

Page 13

MODEL 427G / 427RG SITE PREPARATION

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

bracket must be installed.

The back of the anti-tip bracket must be installed 24" (610)

from the front of the unit (without panels).

Use all anti-tip bracket hardware as instructed for wood or

concrete oors.

IMPORTANT NOTE: For wood or concrete oor applications,

if the #12 screws do not hit a wall stud or wall plate, use the

#8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subooring or

nished oor may necessitate angling the screws used to

fasten the anti-tip bracket to the back wall.

ANTI-TIP HARDWARE

1 Anti-tip bracket

12 #12 x 21/2" pan head screws

3

4

12 #12 at washers

4 #8–18 x 11/4" truss head screws

4 Nylon Zip-it® wall anchors

/8"–16 x 33/4" wedge anchors

WOOD FLOOR

After properly locating the anti-tip bracket in the opening,

3

drill pilot holes

/16" (5) diameter maximum in the wall studs

or wall plate. Use the #12 screws and washers to secure the

brackets. Verify the screws penetrate through the ooring

material and into wall studs or wall plate a minimum of

3

/4" (19). Refer to the illustration and chart below.

CONCRETE FLOOR

After properly locating the anti-tip bracket in the opening,

3

drill pilot holes

or wall plate. Drill

a minimum of 1

washers to secure the brackets to the wall, and use the

/16" (5) diameter maximum in the wall studs

3

/8" (10) diameter holes into the concrete

1

/2" (38) deep. Use the #12 screws and

3

/8"

wedge anchors to secure the brackets to the oor. Verify

the screws penetrate wall studs or wall plate a minimum of

3

/4" (19). Refer to the illustration and chart below.

ANTI-TIP BRACKET

MODEL A

427G and 427RG 131/2" (343)

WALL PLATE

SUBFLOORING

Wood oor.

A

FINISHED

FLOORING

WOOD FLOOR

A

A

WALL PLATE

SUBFLOORING

CONCRETE

FLOOR

A

FINISHED

FLOORING

11/2"(38)

min

Concrete oor.

subzero.com | 13

Page 14

MODEL 427G / 427RG INSTALLATION

Anti-Tip Bracket

CONCRETE WEDGE ANCHOR INSTALLATION

1 Drill a

2 Assemble the washer and nut ush with the end of

3 Expand the anchor by tightening the nut 3–5 turns past

Verify there are no electrical wires or plumbing in the

area which the screws could penetrate.

Always wear safety glasses and use other necessary

protective devices or apparel when installing or working

with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use in

new concrete which has not had sufcient time to cure.

The use of core drills is not recommended to drill holes

for the anchors.

3

/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or drill additional

depth to accommodate drill nes.

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is ush with the

surface material.

hand-tight position or to 25 ft-lb of torque.

WARNING

CAUTION

Custom Panels

For models 427G and 427RG, custom panels and handle

hardware must be installed. Stainless steel panels are

available through an authorized Sub-Zero dealer. For local

dealer information, visit the nd a showroom section of our

website, subzero.com.

PANEL REQUIREMENTS

PANEL WEIGHT MAX

Door 20 lbs (9 kg)

Drawer (427RG) 12 lbs (5 kg)

PANEL THICKNESS MIN

All Panels

Reveals between panels can vary, 1/8" (3) reveals are typical.

CAUTION

When using a panel thicker than 3/4" (19) with reveal less

1

than

/4" (6), panel may cause damage to the unit when

door is opened to 105°. Use the built-in 90° door stop.

CAUTION

As reveals between cabinetry and the unit decrease,

severe nger pinching can occur while door is closing.

Finish all sides of the custom panel. They may be visible

when the door is open or through the glass door.

5

/8" (16)

14 | Sub-Zero Customer Care 800.222.7820

D-style handles are recommended. Stainless steel tubular

and pro handles are avail able through an authorized

Sub-Zero dealer. For local dealer information, visit the nd

a showroom section of our website, subzero.com. The door

handle must be located near the edge of the panel opposite

the hinge and should be centered top to bottom.

CAUTION

A solid panel cannot be installed over the glass door. A

solid door is available through an authorized Sub-Zero

dealer. For local dealer information, visit the nd a

showroom section of our website, subzero.com.

Page 15

MODEL 427G / 427RG INSTALLATION

Panel Installation

The custom overlay door panel is attached using screws

provided through the door frame. Screw locations are

marked on the back of the custom panel using tenon centers inserted into holes of the door frame.

With the unit secured and door closed, hold the custom

panel in desired position on the door. Lightly tap the front

of the panel to locate mounting positions. Remove tenon

centers. Refer to the illustration below.

The door frame has mounting holes to accommodate

Sub-Zero accessory handles. If handle mounting holes are

not utilized, the handle should be attached to the custom

panel prior to mounting. Screw heads may need to be countersunk into the panel for proper alignment.

To mount the custom panel, open the door and use predrilled holes to position the panel. Drive screws into the

panel through black tape on the door frame. Screw holes

are hidden behind the door gasket. Use as many screws as

necessary to secure the custom panel. Refer to the illustration below.

Adjustments can be made to the custom panel with a few

mounting screws in place, but not fully tightened. Once the

proper position is achieved, install and secure all screws.

Cover holes on the inside of the door frame with the cover

patches or plugs provided.

DRAWER PANELS (MODEL 427RG)

Remove the mounting hardware attached to the front of the

unit and set aside. Place the panel face down on a protected work surface.

Position the top edge of the template ush with the top

edge of the panel. Depending on the height and thickness of

the lower drawer panel, the bracket may need to be inverted

for proper placement. Mark and drill pilot holes, then secure

1

brackets to panel using the #8 x

/2" screws provided. Refer

to the illustration below.

To help with placement of drawer panels, examine the lower

L-bracket and panel to determine the slotted holes on the

bracket that will be used. Then position screws into the

lower portion of the drawer that correspond with these slots.

Leave the screws out slightly so the slotted holes will slide

under the heads.

Install the panel by engaging the tabbed bracket to the top

of the drawer, then rotate the panel until the lower bracket

is properly positioned below the drawer. The panel can be

1

adjusted

/4" (6) up and down and side to side.

Once the panel is properly aligned, attach the remaining

1

/2" screws to the mounting bracket.

#10 x

Reconnect the control cable before reinstalling the top

drawer. Refer to page 12.

Tenon center.

DOOR

FRAMEPANEL

TENON CENTER

GASKET

Door frame cross section.

13

/32" (11)

DIAMETER

GLASS

1

/4" (6)

DIAMETER

TEMPLATE FLUSH WITH

TOP OF PANEL

SIDE

EDGE GAP

WILL VARY

BACK OF PANEL

Template position.

TABBED BRACKET

L BRACKET

Drawer panel installation.

subzero.com | 15

Page 16

MODEL 427G / 427RG INSTALLATION

Placement

CAUTION

Before moving the unit into position, secure the door/

drawers closed and protect any nished ooring.

Use an appliance dolly to move the unit near the opening.

Front and rear leveling legs can be adjusted from the front

once the unit is positioned.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

If the unit will be connected to a home security system, run

lead wires through the compressor compartment prior to

positioning the unit. Refer to page 17. Once the unit is in

position, wiring connection can be completed from the front.

Plug the power cord into the grounded outlet, then slide

the unit into position. Verify the anti-tip bracket is properly

engaged.

Alignment

LEVELING

Once the unit is in position, height adjustment can be made

from the front. Using a standard screwdriver, turn front

leveling legs clockwise to raise the unit or counterclockwise

to lower. Using a Phillips drive, turn rear adjustment screws

clockwise to raise the unit or counterclockwise to lower. Use

the lowest torque setting when using a power drill (18 revolutions equals

rear leveling legs by hand. Refer to the illustrations below.

Level the unit to the oor, not surrounding cabinetry. This

could affect the operation of the unit, such as door closing.

When the unit is properly leveled, door/drawer adjustments

are less likely to be necessary.

Secure the unit in place using the side mounting clips and

1

/2" screws provided.

#8 x

WARNING

To reduce the possibility of the unit tipping forward,

the front leveling legs must be in contact with the oor.

1

/16" of height adjustment). Do not turn the

16 | Sub-Zero Customer Care 800.222.7820

Front adjustment.

Rear adjustment.

Page 17

MODEL 427G / 427RG INSTALLATION

Completion

TRIM INSTALLATION

Install decorative trim strips to the top and sides of the unit.

Attach the top trim using the double-sided velcro, then snap

side trim over brackets on the sides of the unit. Refer to the

illustration below.

HOME SECURITY CONNECTION

If the unit will be connected to a home security system,

make connections to the leads shown in the illustration

below. Refer to the following color codes:

t Normally open contacts—white with red stripe wire.

t Normally closed contacts—white with blue stripe wire.

t Common—gray with white stripe wire.

Use the spade terminals or wire nuts provided to make

proper wiring connections.

CAUTION

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be used

to switch line power. Any unused terminals should be

completely insulated and all wires should be secured

away from conductive or moving components.

KICKPLATE INSTALLATION

Install the kickplate using the screws provided. The

mounting bracket may be adjusted slightly for a ush t. The

kickplate must be removable for service. The oor cannot

interfere with removal. Refer to the illustration below.

A decorative kickplate can be added to the factory-installed

kickplate but cannot block the kickplate louvers.

Turn power on by touching POWER on the control panel.

90° DOOR STOP

The door opens to 105°. A 90° door stop is built into the

hinge system for installations where the door opening must

be limited.

To engage the door stop, use a standard screwdriver and

rotate the center cam of the hinge. The adjustment must be

made to both upper and lower hinges. Refer to the illustration below.

HOME SECURITY

LEADS

Home security connection.

SIDE TRIM

Trim installation.

TOP TRIM

Kickplate installation.

MOUNTING

BRACKET

90° door stop.

subzero.com | 17

Page 18

MODEL WS-30 SITE PREPARATION

Opening Dimensions

STANDARD INSTALLATION

24" (610)

OPENING

DEPTH

TOP VIEW

24" (610)

OPENING DEPTH

833/4"

(2127)

OPENING

HEIGHT

291/2" (746)

OPENING WIDTH

FRONT VIEWSIDE VIEW

If two units are installed side by side, refer to page 20.

18 | Sub-Zero Customer Care 800.222.7820

Page 19

MODEL WS-30 SITE PREPARATION

11/4"

(32)

24" (610)

OPENING

DEPTH

TO CLEAT

CLEAT

TOP VIEW

263/16"

(665)

FLUSH

INSET

DEPTH

23/16" (56)

3" (76)

typical

24" (610)

OPENING

DEPTH TO

CLEAT

11/4"

(32)

23/16" (56)

CLEAT

SHADED

AREA

MUST BE

FINISHED

3" typical

(76)

4" (102)

Opening Dimensions

FLUSH INSET INSTALLATION

24" (610)

263/16"

DEPTH

(665)

TO CLEAT

FLUSH

INSET

DEPTH

CLEAT

24" (610)

DEPTH TO CLEAT

263/16" (665)

FLUSH INSET DEPTH

23/16"

(56)

1

/4"

(6)

23/16"

(56)

11/4"

(32)

TOP VIEW

OUTLINE OF

UNIT WITH

3

/4" (19)

PANEL

CLEAT

DETAIL A

Detail A

833/4"

(2127)

SIDE VIEW

HEIGHT

TO CLEAT

83" min

(2108)

84"

(2134)

FLUSH

INSET

HEIGHT

11/4"

(32)

291/2" (746)

WIDTH TO CLEAT

32" (813)

FLUSH INSET WIDTH

DETAIL B

FRONT VIEW

Dimensions assume a 3/4" (19) panel thickness. If two units

are installed side by side, refer to page 21.

11/4"

(32)

Detail B

subzero.com | 19

Page 20

MODEL WS-30 SITE PREPARATION

Opening Dimensions

DUAL STANDARD INSTALLATION

(610)

24"

OPENING

DEPTH

TOP VIEW

24" (610)

OPENING DEPTH

833/4"

(2127)

OPENING

HEIGHT

OPENING WIDTH

FRONT VIEWSIDE VIEW

OPENING WIDTH A

WS-30 and 30" Built-In Model 593/4" (1518)

WS-30 and 36" Built-In Model 653/4" (1670)

A

A dual installation kit will be required for this installation.

20 | Sub-Zero Customer Care 800.222.7820

Page 21

11/4"

(32)

24" (610)

OPENING

DEPTH

TO CLEAT

CLEAT

TOP VIEW

263/16"

(665)

FLUSH

INSET

DEPTH

23/16" (56)

3" (76)

typical

24" (610)

OPENING

DEPTH TO

CLEAT

11/4"

(32)

23/16" (56)

CLEAT

SHADED

AREA

MUST BE

FINISHED

3" typical

(76)

4" (102)

MODEL WS-30 SITE PREPARATION

Opening Dimensions

DUAL FLUSH INSET INSTALLATION

24" (610)

263/16"

DEPTH

(665)

TO CLEAT

FLUSH

INSET

DEPTH

CLEAT

1

/4"

(6)

23/16"

(56)

11/4"

(32)

TOP VIEW

TWO UNITS WITH

3

/4"

(19)

PANEL

CLEAT

DETAIL A

24" (610)

DEPTH TO CLEAT

263/16" (665)

FLUSH INSET DEPTH

SIDE VIEW

23/16"

(56)

833/4"

(2127)

HEIGHT

TO CLEAT

84"

(2134)

FLUSH

INSET

HEIGHT

11/4"

(32)

A

WIDTH TO CLEAT

B

FLUSH INSET WIDTH

FRONT VIEW

DETAIL B

11/4"

(32)

Detail A

Detail B

OPENING WIDTH A B

WS-30 and 30" Built-In Model 593/4" (1518) 621/4" (1581)

WS-30 and 36" Built-In Model 653/4" (1670) 681/4" (1734)

Dimensions assume a 3/4" (19) panel thickness. A dual installation kit will be required for this installation.

subzero.com | 21

Page 22

MODEL WS-30 SITE PREPARATION

Dual Installation

If two units are installed side by side, a dual installation kit

may be required. Installations without a custom ller strip

require a dual installation kit. If a dual installation kit is not

specied, a 2"

Dual installations without a ller strip can only be accomplished using two units with opposite hinges. Refer to the

illustrations below.

Dual installation kits are available through an authorized

Sub-Zero dealer. For local dealer information, visit the nd a

showroom section of our website, subzero.com. For questions regarding the installation, call Sub-Zero customer care

at 800-222-7820.

(51) ller strip is recommended between units.

Electrical

Installation must comply with all applicable electrical codes.

The electrical supply should be located within the shaded

area shown in the illustration below. A separate circuit, servicing only this appliance is required. A ground fault circuit

interrupter (GFCI) is not recommended and may cause interruption of operation.

ELECTRICAL REQUIREMENTS

Power Supply 115 V AC, 60 Hz

Circuit Breaker 15 amp

Receptacle 3-prong grounding-type

CAUTION

The outlet must be checked by a qualied electrician to

be sure that it is wired with the correct polarity. Verify

that the outlet is properly grounded.

WARNING

Do not use an extension cord, two-prong adapter or

remove the power cord ground prong.

WITHOUT FILLER STRIP

Opposite hinges.

FILLER STRIP

Same side hinges.

FRONT VIEW

7"

E

(178)

6"

(152)

751/2"

(1918)

FROM

FLOOR

Electrical supply location.

22 | Sub-Zero Customer Care 800.222.7820

Page 23

MODEL WS-30 SITE PREPARATION

Preparation

Uncrate the unit and inspect for damage. Remove the wood

base and discard shipping bolts and brackets. Remove and

recycle packing materials. Do not discard the kickplate, antitip brackets and hardware.

Completely retract the front leveling legs to allow the unit to

be moved into position. The front and rear leveling legs can

be adjusted from the front once the unit is in position.

Remove the drain pan to avoid damage, and allow for

proper appliance dolly placement.

The grille assembly should be removed prior to moving the

unit. To remove, pull out on the bottom edge of the grille and

rotate upward. Loosen the two back grille mounting screws

and remove the two front grille mounting screws. With the

grille held rmly, pull forward to remove. Refer to the illustrations below.

Grille removal.

FRONT

ADJUSTMENT

SCREWS

BACK GRILLE

SCREW

GRILLE SCREW

Grille mounting screws.

GRILLE

subzero.com | 23

Page 24

MODEL WS-30 SITE PREPARATION

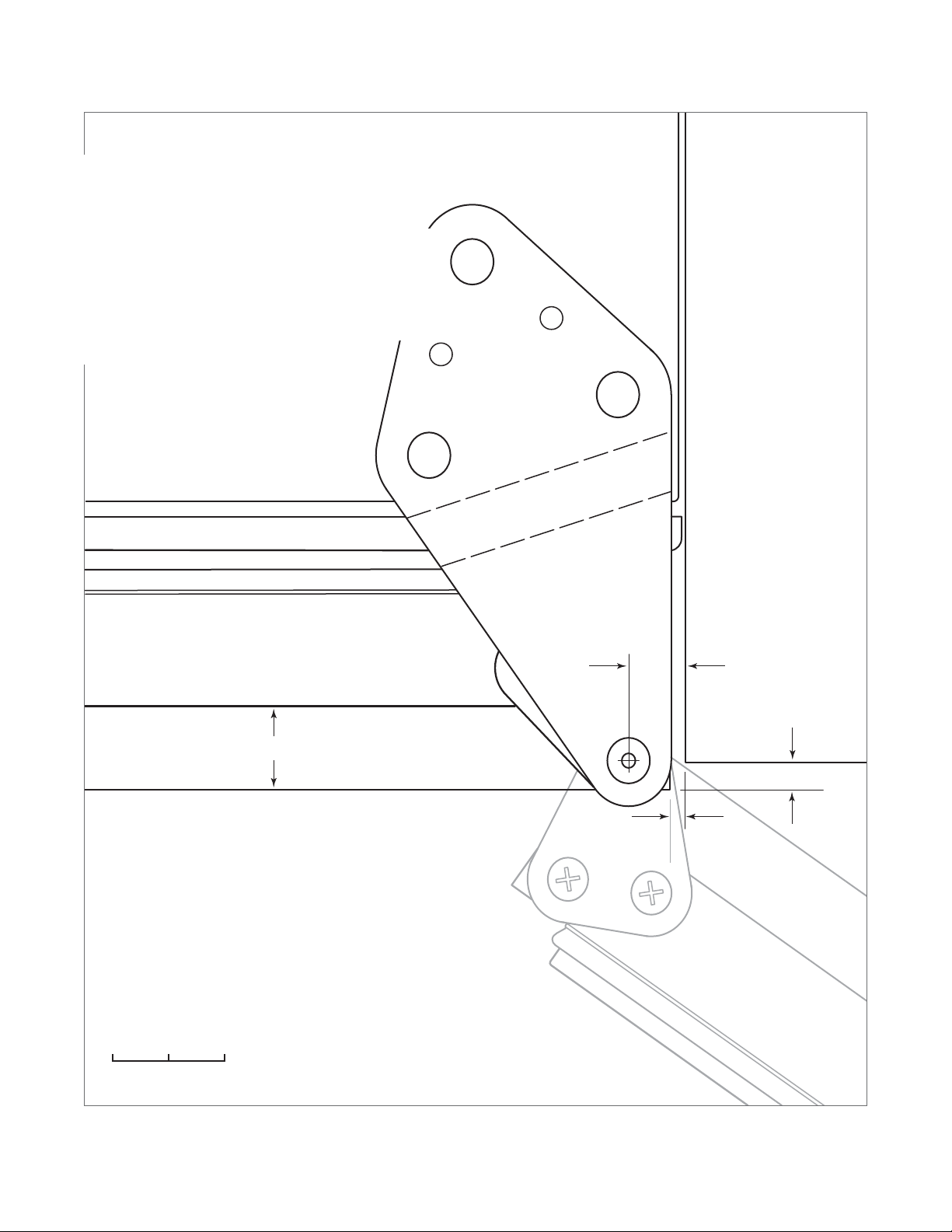

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

brackets must be installed.

The two anti-tip brackets must be installed exactly 24"

(610)

from the front of the opening to the back of the

brackets and a minimum of 4"

opening. This depth will increase to 26

inset installation, based on

(102) from the sides of the

3

3

/4" (19) thick panels. Failure to

/16" (665) for a ush

properly position the anti-tip brackets will prevent proper

engagement.

Use all anti-tip bracket hardware as instructed for wood or

concrete oors.

IMPORTANT NOTE: For wood or concrete oor applications,

if the #12 screws do not hit a wall stud or wall plate, use the

#8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subooring or

nished oor may necessitate angling the screws used to

fasten the anti-tip brackets to the back wall.

ANTI-TIP HARDWARE

2 Anti-tip brackets

12 #12 x 21/2" pan head screws

3

4

12 #12 at washers

4 #8–18 x 11/4" truss head screws

4 Nylon Zip-it® wall anchors

/8"–16 x 33/4" wedge anchors

WOOD FLOOR

After properly locating the anti-tip brackets in the opening,

3

drill pilot holes

/16" (5) diameter maximum in the wall studs

or wall plate. Use the #12 screws and washers to secure the

brackets. Verify the screws penetrate through the ooring

3

material and into wall studs or wall plate a minimum of

(19)

. Refer to the illustration below.

/4"

CONCRETE FLOOR

After properly locating the anti-tip brackets in the opening,

3

drill pilot holes

or wall plate. Drill

a minimum of 1

washers to secure the brackets to the wall, and use the

/16" (5) diameter maximum in the wall studs

3

/8" (10) diameter holes into the concrete

1

/2" (38) deep. Use the #12 screws and

3

/8"

wedge anchors to secure the brackets to the oor. Verify the

3

24"

(610)

4" (102)

MIN

/4"

screws penetrate wall studs or wall plate a minimum of

(19)

. Refer to the illustration below.

24"

(610)

4" (102)

MIN

24 | Sub-Zero Customer Care 800.222.7820

WALL PLATE

SUBFLOORING

Wood oor.

FINISHED

FLOORING

WOOD FLOOR

WALL PLATE

WALL PLATE

SUBFLOORING

SUBFLOORING

CONCRETE

CONCRETE

FLOOR

FLOOR

Concrete oor.

FINISHED

FINISHED

FLOORING

FLOORING

11/2"(38)

11/2"(38)

min

MIN

Page 25

MODEL WS-30 INSTALLATION

Anti-Tip Bracket

CONCRETE WEDGE ANCHOR INSTALLATION

1 Drill a

2 Assemble the washer and nut ush with the end of

3 Expand the anchor by tightening the nut 3–5 turns past

Verify there are no electrical wires or plumbing in the

area which the screws could penetrate.

Always wear safety glasses and use other necessary

protective devices or apparel when installing or working

with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use in

new concrete which has not had sufcient time to cure.

The use of core drills is not recommended to drill holes

for the anchors.

3

/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or drill additional

depth to accommodate drill nes.

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is ush with the

surface material.

hand-tight position or to 25 ft-lb of torque.

WARNING

CAUTION

Custom Panels

For overlay and ush inset applications, custom door and

grille panels must be installed. Panel size is critical for a

proper t. To verify panel requirements and dimensions,

refer to the Sub-Zero design guide at subzero.com/specs.

IMPORTANT NOTE: Flush inset applications require a

minimum

Finish all sides of the custom panel. They may be visible

when the door is open or through the glass door.

A solid panel cannot be installed over the glass door.

1

/2" (13) reveal on all sides.

CAUTION

subzero.com | 25

Page 26

MODEL WS-30 INSTALLATION

Panel Installation

DOOR PANEL

To install the custom door panel, remove the handle side

trim molding. Insert a screwdriver tip into the top corner slot

on the handle side and pop out the trim. Remove the screws

and frame. Refer to the illustration below.

1

The door has a

into. If the panel is thicker than a

around the panel or mount the panel on a sheet of

/4" (6) frame for the custom panel to slide

1

/4" (6), rout an edge

1

/4" (6)

thick material, then insert into the frame.

Door side trim.

(3) space is required between the backer panel and

A .10"

the custom panel to allow the panel to slide into the door

frame. Refer to the illustrations below for critical dimensions.

Install handle hardware before inserting the panel. Large

D-style handles are recommend rather than knobs. Screw

heads must be countersunk into the panel.

Slide the panel into the frame.

To reinstall the door trim molding, insert the top of the trim

into grooves at the top of the door and work downward,

snapping the trim into clips on the door frame.

SPACER PANEL

CUSTOM PANEL

BACKER PANEL

TRIM

5

/16" (8) min

1

/8" (3) (OVERLAY)

Panel assembly cross section

(overlay).

CUSTOM

PANEL

3

/4"

(19)

.10" (3)

typical

Panel assembly rear view.

1

/4" (6)

SPACER

PANEL

BACKER

PANEL

26 | Sub-Zero Customer Care 800.222.7820

Page 27

MODEL WS-30 INSTALLATION

Panel Installation

GRILLE PANEL

Remove the bottom grille frame by extracting the lower

two corner screws from each side of the grille assembly.

Refer to the illustration below.

With the bottom section removed, slide the custom grille

1

panel into the frame. If the panel is thinner than

/4" (6), a

ller material will need to be installed to achieve a proper

t. Once the panel is installed, reattach the bottom grille

frame by sliding the corner brackets back into position, then

reinstall the four corner screws.

BOTTOM

GRILLE

FRAME

Grille frame assembly.

SIDE PANEL

When installing a custom side panel, an accessory kit is

required and is available through an authorized Sub-Zero

dealer. For local dealer information, visit the nd a showroom section of our website, subzero.com. Stainless steel

and white enamel side panels are also available from an

authorized Sub-Zero dealer.

IMPORTANT NOTE: The use of side panels may change the

width of the opening.

A custom side panel must be a minimum of 24"

1

/2" (13) thick. Routing will be necessary for the side

and

(610) deep

panel to t ush against the side of the unit. Refer to the

illustrations below.

IMPORTANT NOTE: The height of the side panel will vary

with the height of the grille. Verify the nished height before

modifying panels.

24" (610)

FRONT

OF SIDE

PANEL

1" (25)

17/8" (48)

1

ROUT TO

/8" (3)

17/8"(48)

1" (25)

4" (102)

OPTIONAL

TOE KICK

CUT-OUT

Side panel dimensions.

(2134)

25/8"

(67)

84"

1

/8" (3)

1

/2" (13)

MAIN

FRAME

Routing detail.

subzero.com | 27

SIDE PANEL

ROUTING

Page 28

MODEL WS-30 INSTALLATION

Placement

CAUTION

Before moving the unit into position, secure the door

closed and protect any nished ooring.

Use an appliance dolly to move the unit near the opening.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

If the unit will be connected to a home security system, run

lead wires through the compressor compartment prior to

positioning the unit. Refer to page 30. Once the unit is in

position, wiring connection can be completed from the front.

Plug the power cord into the grounded outlet, then roll the

unit into position. Verify the anti-tip brackets are properly

engaged.

IMPORTANT NOTE: If used, side panels will need to be

installed before the unit is placed in its nal position. Refer

to page 27.

Alignment

LEVELING

Once the unit is in position, turn the front leveling legs

clockwise to adjust the height. The rear height adjustment

can be made from the front of the roller base. Using a

3

socket, turn the

/8" hex bolt clockwise to raise the unit or

counterclockwise to lower. Use the lowest torque setting

when using a power drill. Do not turn the rear leveling legs

by hand. Refer to the illustration below.

When the unit is properly leveled, door adjustments are less

likely to be necessary.

IMPORTANT NOTE: Level the unit to the oor, not sur-

rounding cabinetry. This could affect the operation of the

unit, such as door closing.

WARNING

To reduce the possibility of the unit tipping forward, the

front leveling legs must be in contact with the oor.

3

/8"

28 | Sub-Zero Customer Care 800.222.7820

Leveling.

FRONT

LEVELING LEG

REAR

ADJUSTMENT

Page 29

MODEL WS-30 INSTALLATION

Alignment

DOOR ADJUSTMENT

The door can be adjusted in and out, side to side tilt and up

and down.

To make adjustments, slightly loosening the two upper hinge

bolts on the upper hinge plate using a

the illustration below.

In and out adjustment | For a left-hinge door, using a

5

/32" allen wrench, turn the adjustment bolt clockwise to

bring the handle side of the door inward, and counterclockwise to move the handle side outward. Reverse directions

for a right-hinge door.

Side to side tilt adjustment | For a left-hinge door, using a

3

/8" wrench, turn the adjustment bolt clockwise to raise the

handle side of the door, and counterclockwise to lower the

handle side. Reverse directions for a right-hinge door.

Up and down adjustment | For a left-hinge door, using a

1

/4" allen wrench, turn the adjustment bolt clockwise to raise

the door and counterclockwise to lower. Refer to the illustration below. Reverse directions for a right-hinge door.

1

/2" wrench. Refer to

Completion

GRILLE INSTALLATION

Install the grille assembly and check for proper t. The grille

is designed to rest on the upper door hinge to minimize the

reveal between the top of the door and bottom of the grille.

To eliminate interference, the grille height can be adjusted.

Loosen the four grille adjustment screws (two on each side)

and adjust the grille height as needed. Refer to the illustration below.

GRILLE

FRONT

ADJUSTMENT

SCREWS

BACK GRILLE

SCREW

GRILLE SCREW

UPPER

HINGE BOLTS

IN AND OUT

SIDE TO SIDE

TILT ADJUSTMENT

ADJUSTMENT

Door adjustment bolts.

Up and down door adjustment.

Grille height adjustment.

subzero.com | 29

Page 30

MODEL WS-30 INSTALLATION

Completion

HOME SECURITY CONNECTION

If the unit will be connected to a home security system,

make connections to the leads shown in the illustration

below. Refer to the following color codes:

t Normally open contacts—white with red stripe wire.

t Normally closed contacts—white with blue stripe wire.

t Common—gray with white stripe wire.

Use the spade terminals or wire nuts provided to make

proper wiring connections.

CAUTION

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be used

to switch line power. Any unused terminals should be

completely insulated and all wires should be secured

away from conductive or moving components.

ANCHORING

After the unit has been leveled and door adjustment completed, anchor the unit to the opening to ensure a proper t

and secure installation.

To anchor the top of the unit, open the grille and install the

screws provided, through the grille frame into cabinetry.

There are several hole locations. Refer to the illustration

below. Check for proper door clearance by opening the

door.

To anchor the bottom of the unit, drive a screw through the

side hole inside each roller base assembly. The screw will

need to go in at an angle to attach properly. Refer to the

illustration below. Additional material may be needed behind

the cleat to ensure sufcient anchoring.

CAUTION

If the screws provided are not suitable for the installation, use adequate screws.

HOME SECURITY

LEADS

Home security connection.

ANCHORING

SCREWS

Top anchoring.

Bottom anchoring.

ANCHORING

SCREW

30 | Sub-Zero Customer Care 800.222.7820

Page 31

MODEL WS-30 INSTALLATION

Completion

KICKPLATE INSTALLATION

Reinstall the drain pan and verify it is in the proper position.

Install the kickplate using screws to attach it to brackets on

the inside of each roller base. Refer to the illustration below.

The kickplate must be removable for service. The oor

cannot interfere with removal. Refer to the label mounted on

the kickplate support for height clearance.

Turn power on by touching POWER on the control panel.

Kickplate installation.

90° DOOR STOP

The door opens to 110°. A 90° door stop is provided with

the unit (located behind the grille). Additional 90° door stop

kits are available through an authorized Sub-Zero dealer.

WARNING

Follow all city and state laws when storing, recycling or

discarding unused refrigerators and freezers.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, and Ingredients are registered trademarks and service marks of Sub-Zero, Inc. Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf

Appliance, Inc. (collectively, the “Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

subzero.com | 31

Page 32

SUB-ZERO, INC. P.O. BOX 44848 MADISON, WI 53744 SUBZERO.COM 800.222.7820

12/2012

Loading...

Loading...