Page 1

INSTALLATION GUIDE

Wine Storage

Page 2

Wine Storage Installation Guide

Contents

Wine Storage Equipment . . . . . . . . . . . . . . . . . . . . . . . 3

Models 424 and 424FS Installation . . . . . . . . . . . . . . . 4

Models 427 and 427R Installation . . . . . . . . . . . . . . . 14

Model WS-30 Installation . . . . . . . . . . . . . . . . . . . . . . 26

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 50

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Features and specifications in this guide and on the website

are subject to change at any time without notice. Check our

website, subzero.com, for the most up-to-date specifications.

Important Note

o ensure the safe and efficient installation of Sub-Zero

T

equipment, please take note of the following types of

highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is

especially relevant to a problem-free installation.

CAUTION signals a situation where minor injury or

product damage may occur if instructions are not

followed.

WARNING states a hazard that may cause serious injury

or death if precautions are not followed.

Page 3

Wine Storage Equipment 3

subzero.com

Wine Storage Equipment

he importance of the installation of the Sub-Zero wine

T

storage unit cannot be overemphasized. Installation

should be done by a qualified installer.

Before you begin the installation process, it is recommended that you read this entire installation guide. There

are key details that you should take special care to

observe during the installation. By reading these instructions carefully, you will make the installation process

easier, problem-free and, most importantly, safe.

Any questions or problems regarding the installation

should be directed to your Sub-Zero dealer or Sub-Zero

customer service at 800-222-7820. You may also check

the contact & support sectionofour website, subzero.com.

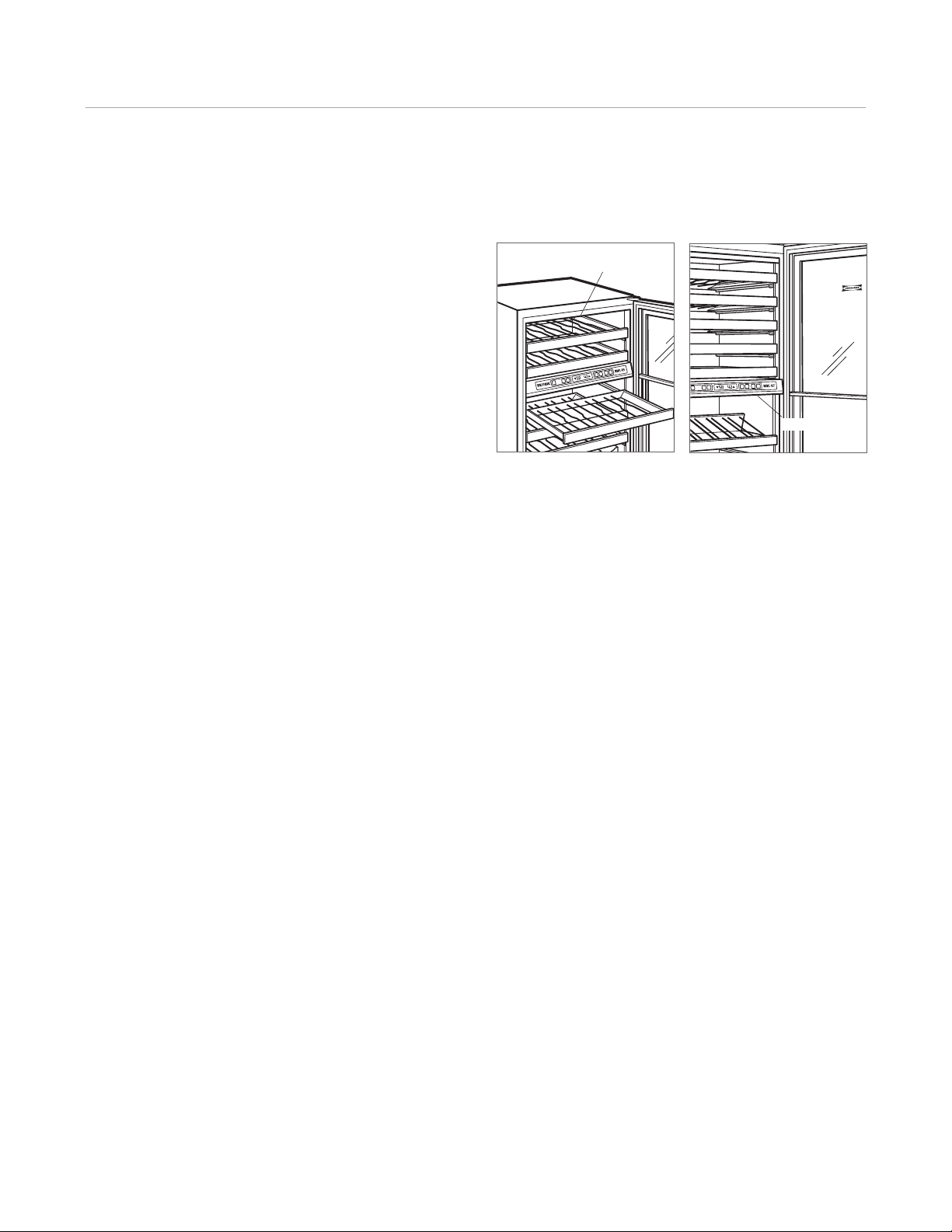

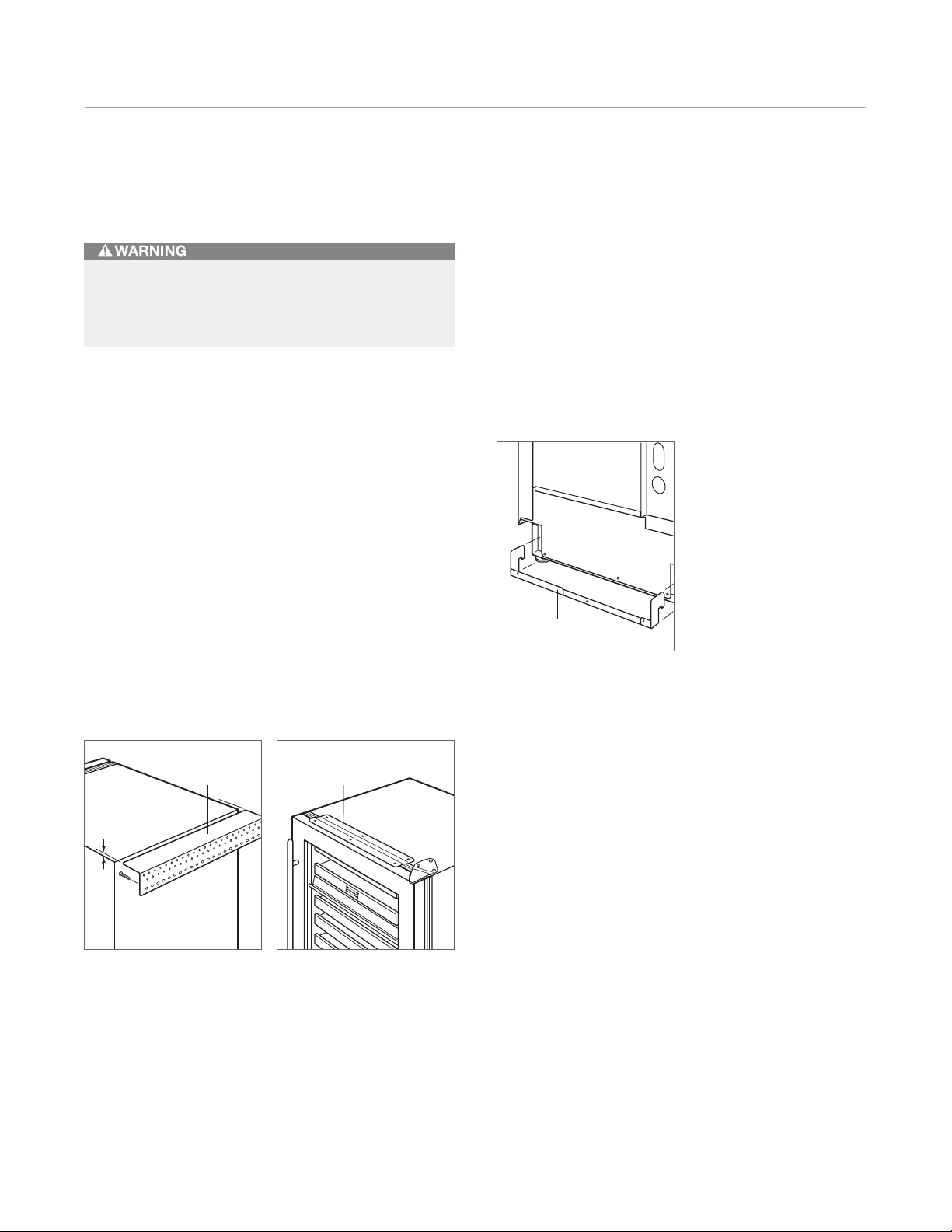

Important product information, including the model and

serial number of your unit are listed on the product rating

plate. For models 424 and 424FS, the rating plate is

located on the underside of the top wall. For models 427,

427R and WS-30, it is attached to the underside of the

control panel. Refer to the illustrations.

Models 424 and 424FS.

ATING PLATE

R

RATING PLATE

Models 427, 427R and WS-30.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specified.

Page 4

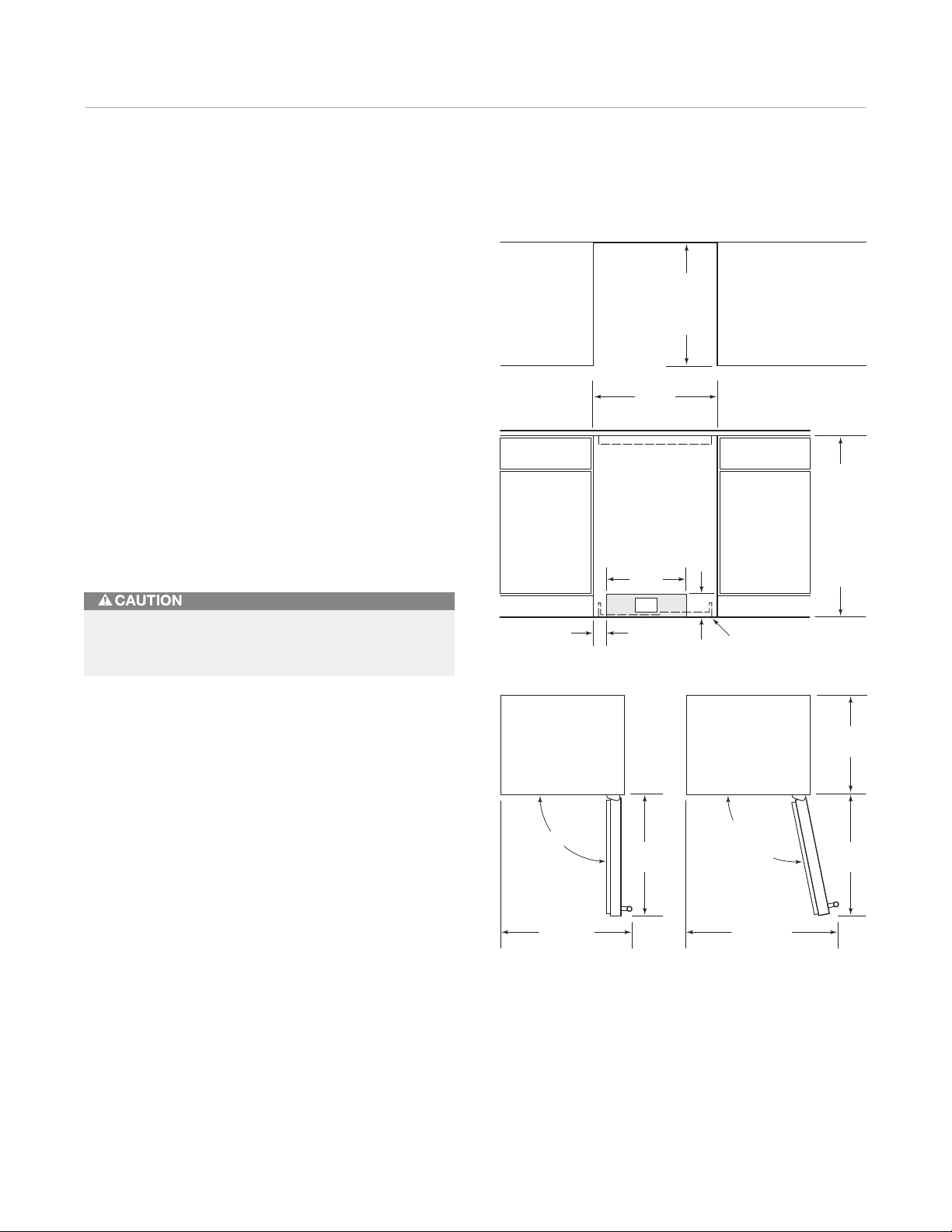

Models 424 and 424FS Installation 4

341/2"

(876)

ROUGH

O

PENING

HEIGHT

341/4"

(870)

MINIMUM

HEIGHT

REQUIRED

ROUGH OPENING

WIDTH

24"(610) MODEL 424

243/8"(619) MODEL 424FS

151/2"

(394)

24"

(610)

ROUGH

OPENING

DEPTH

LOCATE ELECTRICAL

WITHIN SHADED AREA

E

4

1

/2"

(

114

)

21/2"

(64)

237/8"

(606)

MODEL 424

ANTI-TIP BRACKET

MODEL 424FS

ANTI-TIP BRACKET

90˚

145˚

MAXIMUM

DOOR SWING

44" (1118)

DOOR CLEARANCE

26" (660)

DOOR CLEARANCE

253/8"

(644)

253/8"

(645)

FRONT VIEW

T

OP VIEW

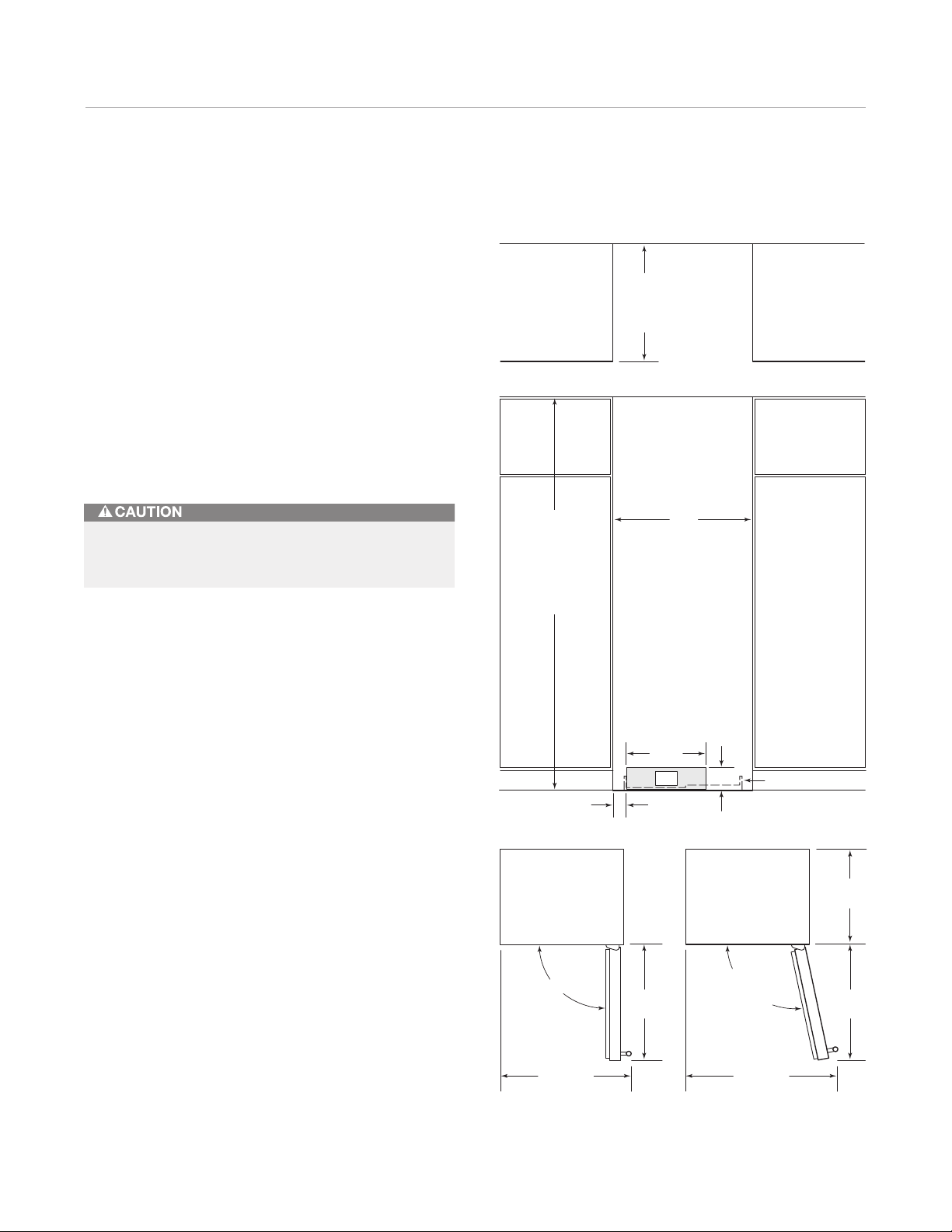

Models 424 and 424FS Installation

he Sub-Zero model 424FS wine storage unit is designed

T

to be attractive in a stand alone setting. It can also be slid

into surrounding cabinetry with clearance dimensions

slightly different than the standard built-in model 424.

Make sure that the finished rough opening where the wine

storage unit is to be installed is properly prepared. Refer

to the installation specifications illustration for rough

opening dimensions, door swing clearance and electrical

placement for models 424 and 424FS.

IMPORTANT NOTE: To operate properly, the door must

open a minimum of 90°. Use a minimum 3" (76) filler in

corner installations to assure a 90° door opening. Allow

enough clearance in front of the unit for full door swing.

IMPORTANT NOTE: Make sure the floor under the unit is

level with the surrounding finished floor.

Do not load wine into the wine storage unit until the

installation is complete.

Door swing clearances are based on stainless steel door and

handle dimensions.

Page 5

Models 424 and 424FS Installation 5

subzero.com

Electrical Requirements

115 V AC, 60 Hz, 15 amp circuit breaker and electrical

A

supply are required. A separate circuit, servicing only this

appliance, is required.

The power supply cord has a 3-prong grounding plug,

which must be plugged into a mating 3-prong groundingtype wall receptacle. Follow the National Electrical Code

and local codes and ordinances when installing the receptacle. For location of the electrical supply, refer to the

installation specifications illustration on the previous page.

IMPORTANT NOTE: For models 424 and 424FS, the elec-

trical outlet must be placed so the grounding prong is to

the right of the thinner blades. The outlet must be flush

with the back wall.

IMPORTANT NOTE: A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

HOME ALARM SYSTEM

If a home alarm system is to be used, refer to home alarm

connections on page 9. In addition to operating power, the

installer may also be required to supply a home automation system lead to the unit. This is for a low-voltage, lowcurrent signal similar to door and window sensor signals.

Common, normally open and normally closed contact

configurations are provided.

1

Three

/4" (6) female spade connectors are located in the

compressor compartment and are accessible behind the

kickplate on models 424 and 424FS. A minimum of 36"

(914) of lead wire should be provided for each contact,

exiting the back wall near the electrical outlet.

Unpacking and Moving

ncrate the unit, remove its wood base and discard the

U

shipping bolts that hold the wood base to the bottom of

the unit. Remove all packing materials and tape.

IMPORTANT NOTE: Do not discard the kickplate, anti-tip

bracket and hardware. These items will be needed for the

installation.

All roller-assembly wine shelves should be removed to

reduce weight and prevent them from rolling. To remove,

pull the shelf out to its full extension, gently and evenly lift

up on both sides of the front of the shelf and remove.

Reverse the procedure to reinstall the shelf.

Use an appliance dolly to move the wine storage unit.

Position the dolly at the back of the unit to prevent

damage to finished surfaces.

Before moving the wine storage unit in to position,

protect any finished flooring with appropriate materials and secure the door closed.

Do not use an extension cord or two-prong adapter.

Electrical ground is required on this appliance.

Page 6

Models 424 and 424FS Installation 6

1

/4" (6)

ANTI-TIP

BRACKET

COUNTERTOP

BRACKET

ANTI-TIP BRACKET

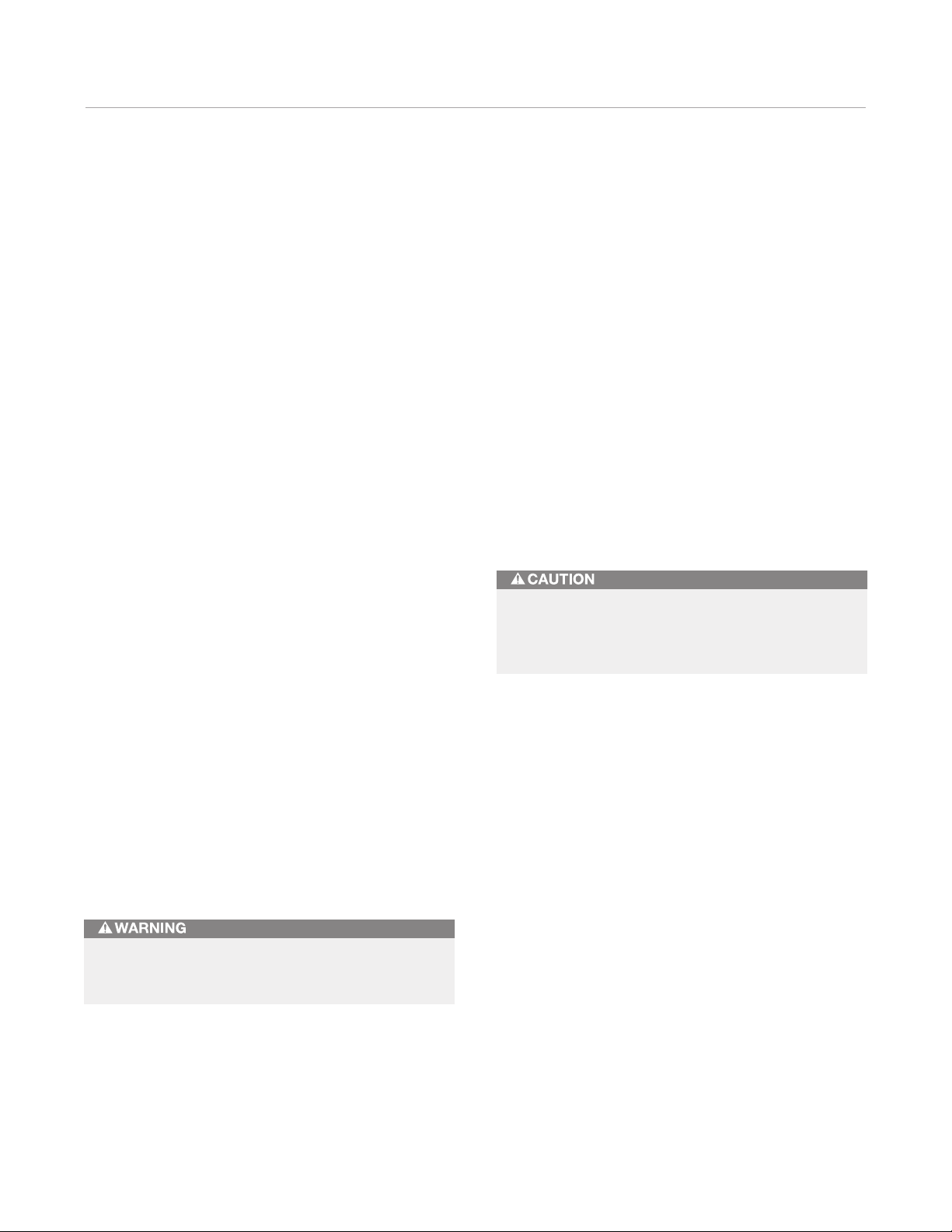

Anti-Tip Bracket Installation

MODEL 424FS

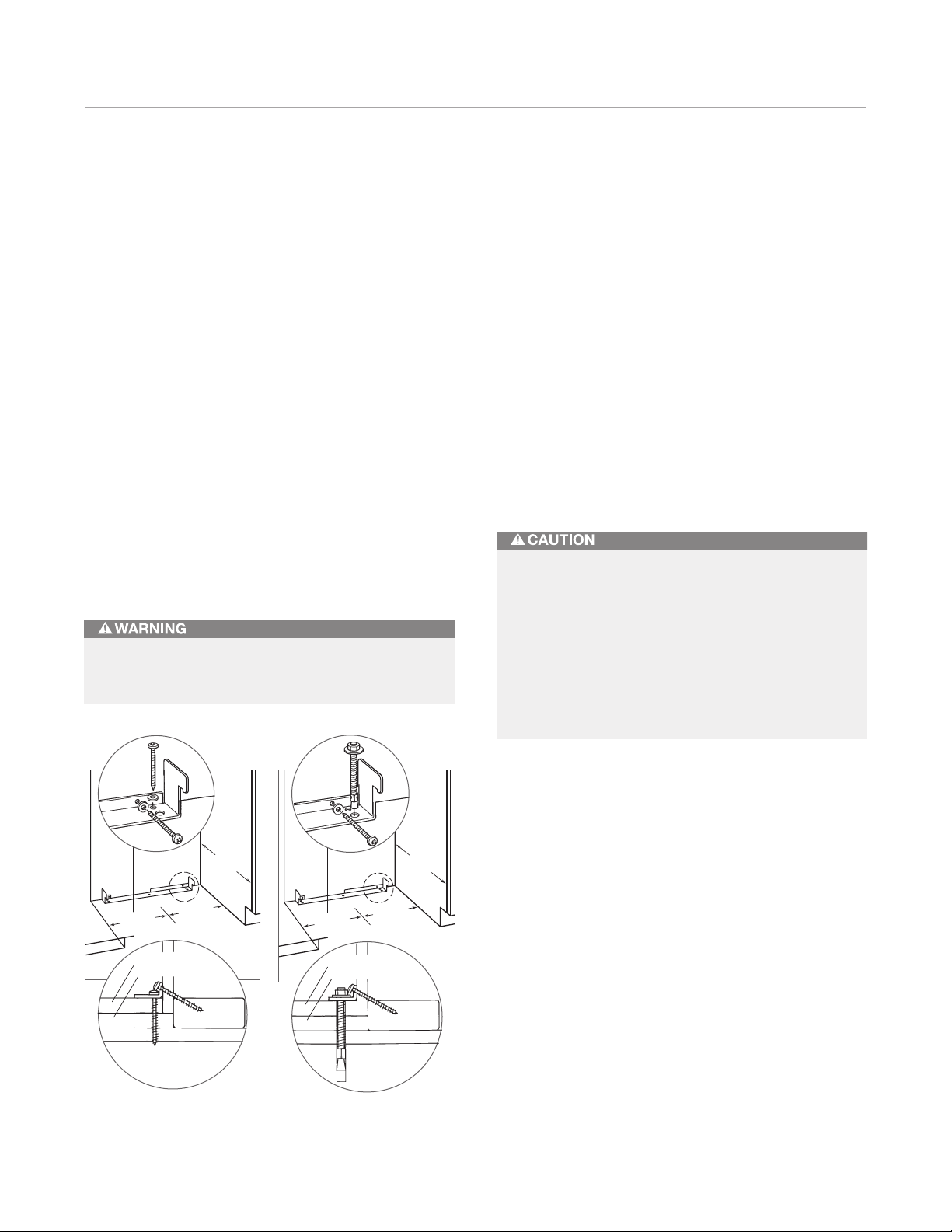

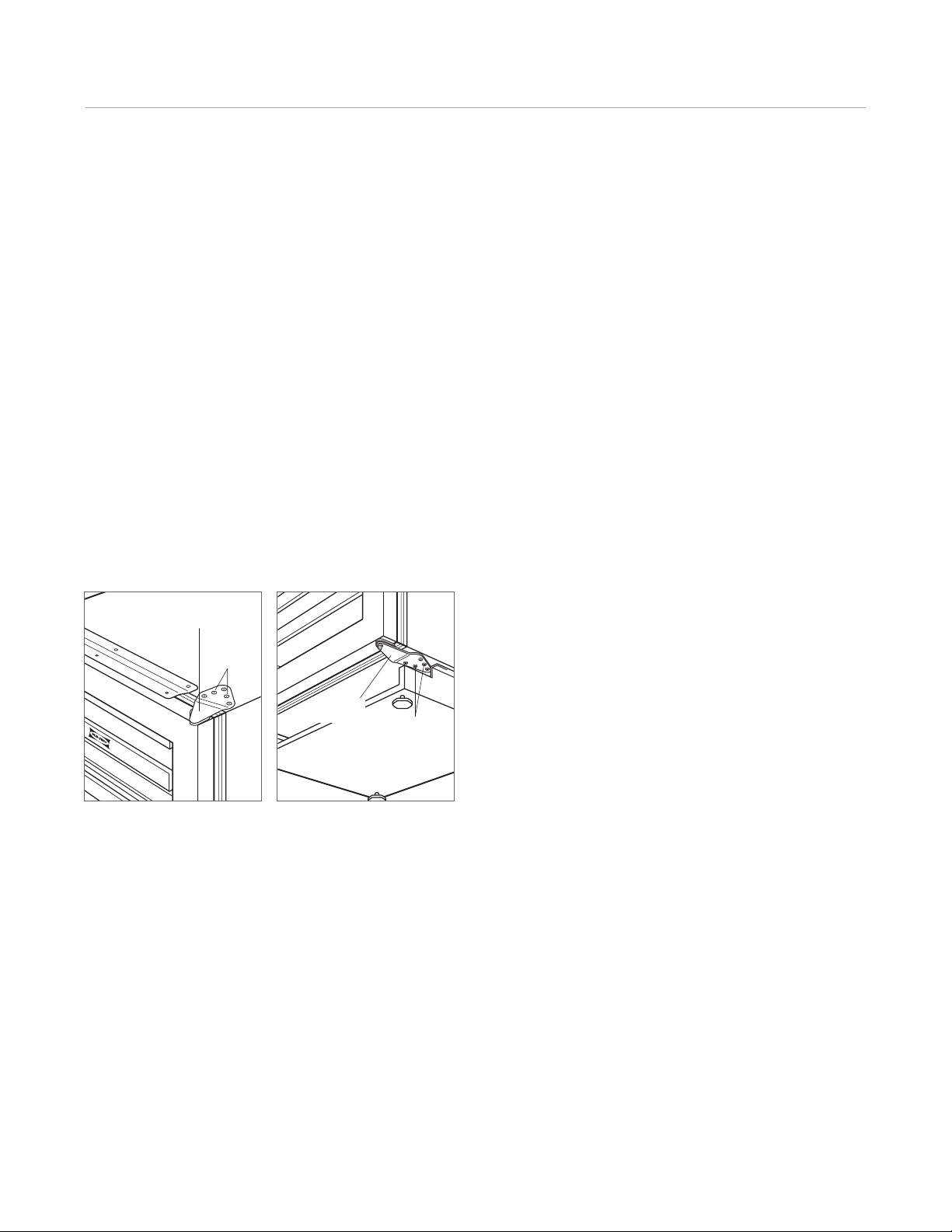

To prevent the unit from tipping forward and provide

a stable installation, the unit must be secured in

place with the anti-tip bracket.

An anti-tip bracket and hardware is provided with the wine

storage unit. The anti-tip bracket must be installed on a

solid base to prevent tipover in case several loaded wine

shelves are extended at the same time.

MODEL 424

The anti-tip bracket should be attached to the wall behind

the unit with the bracket flange located immediately above

the top of the unit. Refer to the illustration below.

A smaller metal ‘countertop’ bracket is also provided with

the model 424, for installations that need to be modified to

provide a secure surface for attaching the bracket. This

bracket will secure the front of the unit to the underside of

the countertop, above the unit. Refer to the illustration

below.

If you are installing the model 424FS in a space deeper

than 24

more than 24

5

/8" (625), the anti-tip bracket must be installed no

5

/8" (625) deep, so it engages the unit

properly. It is important that this measurement be made

from the front surface of the door, to the back of the antitip bracket. Refer to the illustration.

Anti-tip bracket—model 424FS.

Anti-tip bracket—model 424. Countertop bracket

Page 7

Models 424 and 424FS Installation 7

123/16"

(310)

123/16"

(310)

24"

(610)

C

L

FINISHED FLOORING

UNDERLAYMENT

WALL PLATE

SUBFLOORING

WOOD FLOOR

24"

(610)

C

L

11/2"

min

(38)

123/16"

(310)

123/16"

(310)

FINISHED FLOORING

UNDERLAYMENT

WALL PLATE

SUBFLOORING

CONCRETE

FLOOR

subzero.com

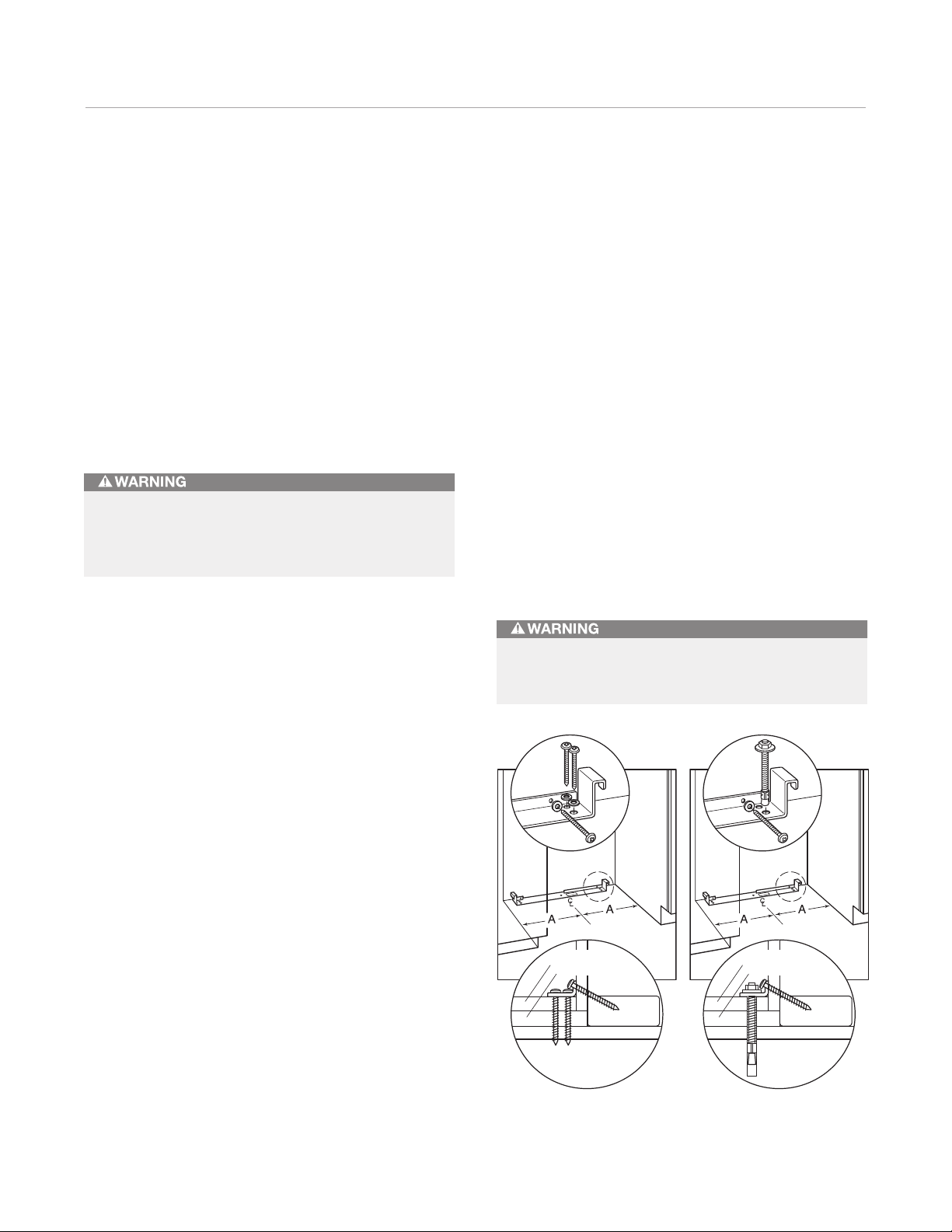

Anti-Tip Bracket Installation

WOOD FLOOR APPLICATIONS

Use the four #12 x 21/2" wood screws and the four1/4"

flat washers provided. Drill pilot holes

3

/16" (5) diameter

maximum, and be sure that the screws penetrate through

the flooring material and into the wall plate a minimum of

3

/4" (19). Be sure that the screws hold tight. Refer to the

illustration below.

CONCRETE FLOOR APPLICATIONS

Use the two3/8" x 33/4" concrete wedge anchors, two

1

#12 x 2

/2" wood screws and two1/4" flat washers

provided. Be sure that the anchors and screws hold tight.

Refer to the illustration below.

IMPORTANT NOTE: In some installations the subflooring

or finished floor may require angling the wood screws

used to fasten the anti-tip bracket to the back wall.

Make sure that there are no electrical wires in the

area which the screws could penetrate.

INSTALLATION FOR CONCRETE WEDGE ANCHORS

1) Drill a3/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or continue

drilling additional depth to accommodate drill fines.

Use a carbide drill bit manufactured within ANSI

B94.12-77.

2) Assemble the washer and nut flush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is flush with

the surface material.

3) Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 25 foot-pounds of torque.

Always wear safety glasses and use other necessary

protective devices or apparel when installing or

working with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use

in new concrete which has not had sufficient time to

cure. The use of core drills is not recommended to

drill holes for the anchors.

Wood floors. Concrete floors.

Page 8

Models 424 and 424FS Installation 8

Lock Installation

f a home alarm system is to be used with the wine

IMPORTANT NOTE: I

f you are adding an accessory lock kit

to your wine storage unit, it should be installed before you

position the unit. Installation instructions are included with

the lock kit.

For model 424, the lock is attached to the bottom of the

metal door frame. The decorative door panel is not

involved in the installation or operation of the lock. The

catch portion of the lock is attached to the bottom of the

appliance cabinet in pre-punched holes. When installing

the lock kit, it may be helpful to tip the unit on its back for

easier access.

POSITION THE UNIT

I

storage unit, the lead wires should be threaded into the

compressor compartment before you position the unit.

Refer to home alarm connections on page 9, for the

location of these lead wires. After the unit is in position,

the alarm wiring can be completed from the front.

Pre-level the wine storage unit before sliding it into

position. Leveling cannot be completed with the unit

pushed back in the installation opening.

For model 424FS, adust the leveling legs so the top of the

unit is no more than 34

5

/8" (879) above the floor. This is to

allow the unit to engage the anti-tip bracket properly.

Center the model 424FS in front of the anti-tip bracket.

IMPORTANT NOTE:

If for any reason the wine storage unit

has been laid on its back or side, you must allow the unit

to stand upright for a minimum of 24 hours before connecting power.

Plug the power supply cord into the 15 amp grounded

electrical outlet. With power applied to the appliance,

check for lighting and cooling before going any further.

Once you are satisfied that the unit is operating properly,

shut off power to the electrical outlet at the circuit breaker

and proceed.

Shut off the power to the electrical outlet.

Slide the unit into position, making sure the anti-tip

bracket is engaged properly.

IMPORTANT NOTE: When the wine storage unit is

installed, the anti-tip bracket will be positioned just below

the engaging bracket on the unit. It is not necessary to

raise the unit up so that it locks into the anti-tip bracket,

but the unit must be in alignment with the anti-tip bracket.

The wine storage unit provides the best access to its

contents when the front surface of the door panel extends

out from surrounding cabinets approximately

1

/4" (6). For

model 424FS, if there are no surrounding cabinet surfaces

to gauge depth, slide the unit back until it engages the

anti-tip bracket.

IMPORTANT NOTE: The floor under the wine storage unit

must be at the same level as the surrounding finished floor

to allow for removal of the unit for servicing.

Page 9

Models 424 and 424FS Installation 9

LEVELING LEGS

HOME ALARM

CONNECTIONS

subzero.com

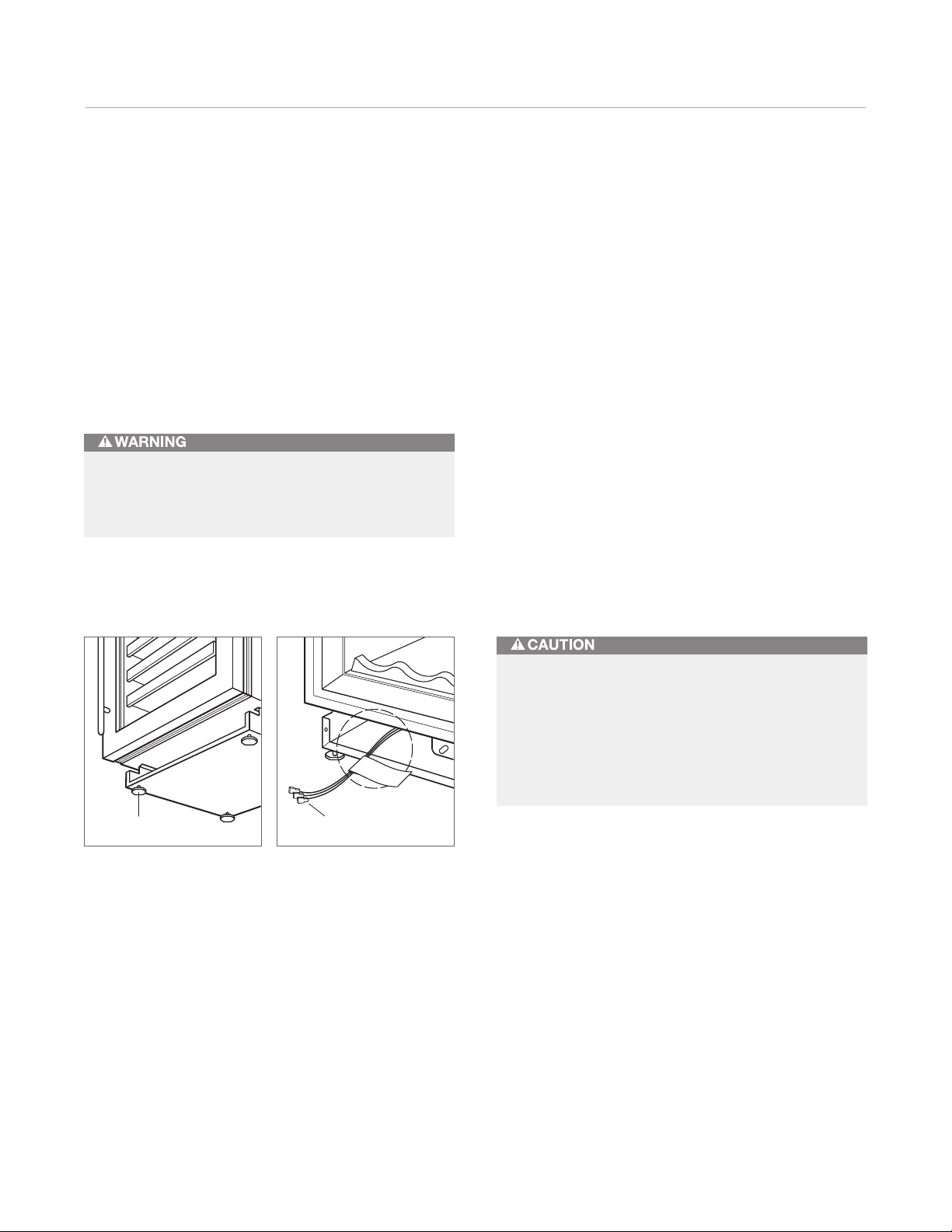

Level the Unit

sing an adjustable wrench or pliers, turn each of the four

U

leveling legs clockwise to raise the unit and counterclockwise to lower the unit. Refer to the illustration below for

location of the leveling legs.

For model 424, the countertop bracket should be used

to make a solid installation. Refer to the illustration on

page 6. If this is not possible, wedge shims along the

sides and top.

To reduce the possibility of the unit tipping forward,

the front leveling legs must be in contact with the

floor.

Home Alarm Connections

efore the kickplate is installed, all necessary wiring

B

connections in the compressor compartment should be

completed.

If a home alarm system is to be installed on the wine

storage unit, the connections should be made using the

logic supplied with the alarm specifications. Refer to the

illustration for the appliance lead locations, and refer to

the following for color codes:

• Normally open contacts – white with red stripe wire

• Normally closed contacts – white with blue stripe wire

• Common – gray with white stripe wire

Use the

make the proper wiring connections.

IMPORTANT NOTE: If you are not responsible for alarm

system connection, this information should be supplied to

the home security system contractor.

1

/4" (6) spade terminals or wire nuts provided to

Leveling legs. Home alarm connections.

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be

used to switch line power.

Any unused terminals should be completely insulated and all wires should be secured away from

conductive or moving components.

Page 10

Models 424 and 424FS Installation 10

KICKPLATE

Kickplate Installation

nce the unit is leveled and wiring connections made, the

O

kickplate can be installed. Use the two #10 x 1/2" stainless steel screws that are provided with the kickplate.

Refer to the illustration below.

IMPORTANT NOTE: The kickplate must be removed for

servicing. The floor cannot interfere with removal. The

louvered section of the kickplate must not be covered so

as to prevent air circulation.

Turn power back on to the electrical outlet.

Door Panel—Model 424

odel 424 is offered in two design applications; stainless

M

steel (/S) and overlay (/O). Each of these designs are available as a glass door (G) model.

The stainless steel model 424/S is available as a glass

door (G) model only, with the classic finish and is shipped

from the factory with the decorative stainless steel door

panel and matching handle in place.

The overlay model 424/O is available as a glass door (G)

or solid door (S) model and is designed to accept a

decorative door panel to match surrounding cabinetry.

The door panel and the handle will be provided by the

customer.

Before beginning installation, check for the correct components for the fit and finish desired. All overlay doors

require a decorative panel 23

a minimum

IMPORTANT NOTE: For installations at or above 5,000'

5

/8" (16) thick.

(1524 m) in altitude, a special high altitude glass door unit

(HA) must be ordered.

3

/4" (603) by 301/16" (764) and

Kickplate installation.

If you have questions, contact your Sub-Zero dealer or

cabinet supplier. Additional panel information can be

found in the Sub-Zero design guide.

A solid panel must not be installed on a glass door

unit, as this may cause moisture to form behind the

panel.

Page 11

Models 424 and 424FS Installation 11

GASKET

GLASS

13

/32" (11)

DIAMETER

1

/4" (6)

DIAMETER

OVERLAY

PANEL

DOOR

FRAME

TENON CENTER

subzero.com

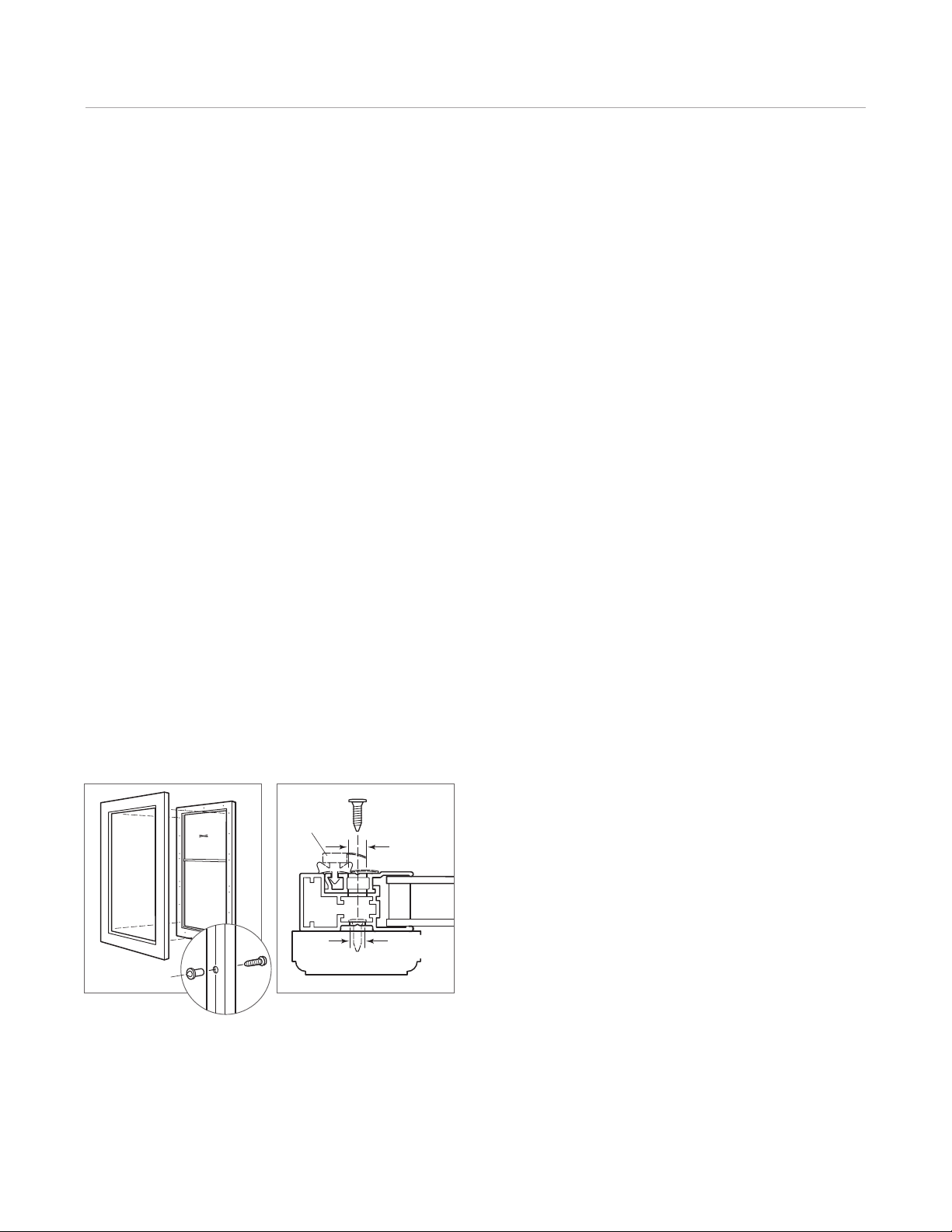

Overlay Door Panel—Model 424

nspect the door panel for the minimum

I

5

(16) thickness,

/8"

the finished inside edge. The glass door has a 10 lbs (5 kg)

weight limit and the solid door has a 20 lb (9 kg) weight

limit. Refer to the wine storage section of the Sub-Zero

design guide for additional panel information.

Decide if the handle will be attached through the glass

door frame or just through the decorative door panel. If it

is just through the door panel, the handle must be

attached first.

Decorative panels are attached to the model 424 door

using #8 x

5

/8" square drive screws passing through the

door frame from the rear, behind the gasket into the panel.

The door panel is marked for screw locations by the use of

‘tenon centers’, which are temporarily inserted into the

1

/4" (6) diameter holes in the front of the glass door frame.

Refer to the illustration below.

With the wine storage unit secured in position and the

door closed, the panel is held in the desired position on

the door and rapped by hand from the front, putting center

marks on the rear surface of the panel. If the door panel is

made of such a material that pre-drilling is needed, all of

the mounting holes should be marked. If not, only enough

holes to hold the panel in place temporarily, are necessary.

he door panel is then lowered from the door frame, tenon

T

centers removed, the door opened and the screws driven

into the panel through the black tape on the door frame,

using the center marks to locate the screws.

The screw holes inside the door are hidden under a cover

flap on the door gasket. It is necessary to lift the flap to

insert the screws. Use as many screws as necessary to

hold the door panel in place properly.

IMPORTANT NOTE: After the first three or four mounting

screws are in place, but not completely tightened, close

the door and check your panel fit. This is the time to make

small adjustments. Once you are satisfied with the appearance, open the door and apply the remainder of the

screws. Check all screws for tightness.

The metal frame on the glass door has numerous

mounting holes on each side of the door. This is to accommodate the Sub-Zero accessory handles and provide for

easy attachment of the handle through the door frame.

If you choose not to use the pre-drilled handle mounting

holes, it will be necessary to fasten the handle from the

rear of the door panel only, or drill one or more additional

holes through the metal frame of the glass door.

The cross section illustration shows how this hole passes

through the door frame. The hole center is on the small

locator groove in the front of the frame. A

hole is made in the front wall of the extrusion and a

1

/4" (6) diameter

13

/32"

(11) diameter hole through the rest of the frame.

Overlay panel. Door frame cross section.

Page 12

Models 424 and 424FS Installation 12

Overlay Door Panel—Model 424

IMPORTANT NOTE: I

in the door frame. The nature of the door panel with a

narrow outer rim and no connecting center member

requires the support provided by the glass door.

After the door panel installation is complete, apply the

cover patches or plugs provided over the holes on the

inside surface of the door.

The cover patches or plugs are part of the insulation

system on the door of the wine storage unit. Be sure

to cover all the holes in the door that were used.

nstall screws in all the mounting holes

The wine storage unit door is made with a sealed

double wall tempered glass core. The drill must not

contact this core when drilling. Be sure the hole is

centered on the small groove in the front of the door

frame and the drill passes squarely through the

frame. If you are inexperienced with drilling, fasten

the handle from the rear of the door panel only.

Page 13

Models 424 and 424FS Installation 13

TOP DOOR HINGE

SHIPPING

SCREWS

BOTTOM

DOOR HINGE

SHIPPING

SCREWS

subzero.com

Hinge Adjustment

IMPORTANT NOTE: T

installed and leveled before door hinge adjustments can

be made.

The top and bottom cabinet hinges on models 424 and

424FS are held in place with three permanent adjustment

screws and two shipping screws. Refer to the illustrations

below. The shipping screws must be removed and discarded to adjust the door alignment and fit. If no adjustments are necessary, it is recommended that all five

screws remain in place.

On the model 424FS, only the bottom door hinge can be

adjusted. Remove and discard the two shipping screws

and loosen the three hinge screws to adjust the door.

Refer to illustration 12.

he wine storage unit must be

Completing the Installation

IMPORTANT NOTE: W

lation of the model 424 or 424FS wine storage unit, refer

to page 50 for an installation checklist and page 51 for

service information.

hen you have completed the instal-

Top hinge. Bottom hinge.

Page 14

Models 427 and 427R Installation 14

27"

(686)

ROUGH OPENING WIDTH

25"

(635)

ROUGH

OPENING

D

EPTH

237/8"

(606)

90˚

105˚

MAXIMUM

DOOR SWING

35" (889)

DOOR CLEARANCE

28" (711)

DOOR CLEARANCE

251/2"

(648)

251/2"

(648)

151/2"

(394)

LOCATE ELECTRICAL

WITHIN SHADED AREA

E

4

1

/2"

(

114

)

21/2"

(64)

ANTI-TIP BRACKET

FRONT VIEW

TOP VIEW

80" (

2032)

R

OUGH OPENING

HEIGHT

T

O FINISHED

FLOORING

791/2" (2019)

MIN HEIGHT

R

EQUIRED

Models 427 and 427R Installation

ake sure that the finished rough opening where the wine

M

storage unit is to be installed is properly prepared. Refer

to the installation specifications illustration for rough

opening dimensions, door swing clearance and electrical

placement for models 427 and 427R.

IMPORTANT NOTE: To operate properly, the door must

open a minimum of 90°. Use a minimum 2" (51) filler in

corner installations to assure a 90° door opening. Allow

enough clearance in front of the unit for full door swing.

IMPORTANT NOTE: Make sure the floor under the unit is

level with the surrounding finished floor.

Do not load wine into the wine storage unit until the

installation is complete.

Door swing clearances are based on stainless steel door and

handle dimensions.

Page 15

Models 427 and 427R Installation 15

subzero.com

Electrical Requirements

115 V AC, 60 Hz, 15 amp circuit breaker and electrical

A

supply are required. A separate circuit, servicing only this

appliance, is required.

The power supply cord has a 3-prong grounding plug,

which must be plugged into a mating 3-prong groundingtype wall receptacle. Follow the National Electrical Code

and local codes and ordinances when installing the receptacle. For location of the electrical supply, refer to the

installation specifications illustration on the previous page.

IMPORTANT NOTE: For models 427 and 427R, the elec-

trical outlet must be placed so the grounding prong is to

the right of the thinner blades. The outlet must be flush

with the back wall.

IMPORTANT NOTE: A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

Do not use an extension cord or two-prong adapter.

Electrical ground is required on this appliance.

Unpacking and Moving

ncrate the unit, remove its wood base and discard the

U

shipping bolts that hold the wood base to the bottom of

the unit. Remove all packing materials and tape.

IMPORTANT NOTE: Do not discard the kickplate/ grille,

anti-tip bracket and hardware. These items will be needed

for the installation.

All roller-assembly wine shelves should be removed to

reduce weight and prevent them from rolling. To remove,

pull the shelf out to its full extension, gently and evenly lift

up on both sides of the front of the shelf and remove.

Reverse the procedure to reinstall the shelf.

Retract the front leveling legs to allow you to move the

unit more easily during installation. You will extend the

leveling legs when the unit is in its final position to reduce

the possibility of the unit tipping forward.

Use an appliance dolly to move the wine storage unit.

Position the dolly at the side of the unit to prevent damage

to finished surfaces.

HOME ALARM SYSTEM

If a home alarm system is to be used, refer to wiring

connections on page 20. In addition to operating power,

the installer may also be required to supply a home

automation system lead to the unit. This is for a lowvoltage, low-current signal similar to door and window

sensor signals. Common, normally open and normally

closed contact configurations are provided.

1

Three

/4" (6) female spade connectors are located in the

compressor compartment and are accessible behind the

kickplate/grille on models 427 and 427R. A minimum of

36" (914) of lead wire should be provided for each contact,

exiting the back wall near the electrical outlet.

Before moving the wine storage unit into position,

protect any finished flooring with appropriate

materials.

Page 16

Models 427 and 427R Installation 16

WOOD FLOOR

Finished Flooring

Underlayment

Subflooring

Wall Plate

Finished Flooring

Underlayment

Subflooring

Wall Plate

CONCRETE

FLOOR

1

1

/2"

min

(38)

Anti-Tip Bracket Installation

n anti-tip bracket and hardware is provided with the wine

A

storage unit. The anti-tip bracket must be installed on a

solid base to prevent tipover in case several loaded wine

shelves are extended at the same time.

If you are installing the model 427 or 427R in a space

deeper than 24" (610), the anti-tip bracket must be

installed no more than 24" (610) deep, so it engages the

unit properly. It is important that this measurement be

made from the front of the unit without panels, to the back

of the anti-tip bracket.

To prevent the unit from tipping forward and provide a

stable installation, install the anti-tip bracket and

extend the front leveling legs to the floor.

WOOD FLOOR APPLICATIONS

Use the six #12 x 21/2" wood screws and the six1/4" flat

washers provided. Drill pilot holes

3

/16" (5) diameter

maximum, and be sure that the screws penetrate through

the flooring material and into the wall plate a minimum of

3

/4" (19). Be sure that the screws hold tight. Refer to the

illustration below.

CONCRETE FLOOR APPLICATIONS

Use the two3/8" x 33/4" concrete wedge anchors, two

#12 x 2

1

/2" wood screws and two1/4" flat washers

provided. Be sure that the anchors and screws hold tight.

Refer to the illustration below.

IMPORTANT NOTE: In some installations the subflooring

or finished floor may require angling the wood screws

used to fasten the anti-tip bracket to the back wall.

Make sure that there are no electrical wires in the

area which the screws could penetrate.

Wood floors—

dimension A is 13

1

/2" (343).

Concrete floors—

dimension A is 131/2" (343).

Page 17

Models 427 and 427R Installation 17

subzero.com

Anti-Tip Bracket Installation

CONCRETE WEDGE ANCHOR INSTALLATION

1) Drill a3/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or continue

drilling additional depth to accommodate drill fines.

Use a carbide drill bit manufactured within ANSI

B94.12-77.

2) Assemble the washer and nut flush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is flush with

the surface material.

3) Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 25 foot-pounds of torque.

Always wear safety glasses and use other necessary

protective devices or apparel when installing or

working with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use

in new concrete which has not had sufficient time to

cure. The use of core drills is not recommended to

drill holes for the anchors.

Position Unit

IMPORTANT NOTE: F

control cable that needs to be disconnected before

removing this drawer. Refer to illustration 3 below for

placement and how to disconnect this fitting.

For model 427R, the drawers should be placed aside until

you are ready for installation of the door and drawer

panels.

IMPORTANT NOTE: When two models 427, 427R or

integrated units are installed closer than 2" (51) to one

another, it is necessary to use the Sub-Zero dual installation heater kit. The heater from this kit must be attached

to the left side exterior of the right-hand unit before the

unit is slid into position. The dual installation heater kit and

additional instructions is available through your Sub-Zero

dealer, or call Sub-Zero at 800-222-7820. You can also

visit our website at subzero.com.

or model 427R, the top drawer has a

Control cable.

Page 18

Models 427 and 427R Installation 18

Lock Installation

or models 427 and 427R, the optional lock is attached

F

to the decorative door panel through a field-drilled hole in

the panel. The catch should be installed on the top of

appliance cabinet before the unit is moved into position.

The accessory lock kit and additional instructions are

available through your Sub-Zero dealer, or call Sub-Zero

at 800-222-7820. You can also visit our website at

subzero.com.

IMPORTANT NOTE: For accessory stainless steel panels

requiring a lock, panels must be ordered with the lock

mounting hole pre-drilled.

Position the Unit

Remove the decorative top and side moldings and the

kickplate/grille of the wine storage unit.

IMPORTANT NOTE: If for any reason the wine storage unit

has been laid on its back or side, you must allow the unit

to stand upright for a minimum of 24 hours before connecting power.

Plug the power supply cord into the 15 amp grounded

electrical outlet. With power applied to the appliance,

check for lighting and cooling before going any further.

Once you are satisfied that the unit is operating properly,

shut off power to the electrical outlet at the circuit breaker

and proceed.

f a home alarm system is to be used with the wine

I

storage unit, the lead wires should be threaded into the

compressor compartment before you position the unit.

Refer to wiring connections on page 20 for the location of

these lead wires. After the unit is in position, the alarm

wiring can be completed from the front.

Pre-level the wine storage unit before rolling into position.

This is to allow the unit to engage the anti-tip bracket

properly.

Roll the unit into position, making sure the anti-tip bracket

is engaged properly. Screw the front leveling legs out

approximately

easier.

IMPORTANT NOTE: When the wine storage unit is

installed, the anti-tip bracket will be positioned just below

the engaging bracket on the unit. It is not necessary to

raise the unit up so that it locks into the anti-tip bracket,

but the unit must be in alignment with the anti-tip bracket.

IMPORTANT NOTE: The floor under the wine storage unit

must be at the same level as the surrounding finished floor

to allow for removal of the unit for servicing.

3

/16" (5) to make any future adjustments

Shut off the power to the electrical outlet.

Page 19

Models 427 and 427R Installation 19

TOP MOLDING

subzero.com

Leveling

evel the unit by turning the front leveling legs clockwise

L

to raise the unit, or counterclockwise to lower it. To assist

you in adjusting the front leveling legs up or down, use a

standard screwdriver blade and place it in the front

leveling leg as shown in the illustration below.

The rear leveling legs are adjusted from the front of the

base by turning the Phillips head screw. Refer to the illustration below.

IMPORTANT NOTE: The rear leveling legs will only move

1

/16" (2) for every 18 revolutions on the Phillips head screw.

Do not over torque. Use the lowest torque setting on any

power screwdriver. Do not turn the rear leveling legs by

hand. Damage will occur if you turn these legs.

To reduce the possibility of the unit tipping forward,

the front leveling legs must be in contact with the

floor.

Install Molding

he decorative white molding strips for the top and sides

T

of models 427 and 427R can be snapped into place as

shown in the illustrations below. The top molding piece

must be installed before the side molding can be

attached. For installations where units are positioned side

by side, refer to side panels on page 25.

Top molding installation.

Front leveling leg adjustment. Rear leveling leg adjustment.

Side molding installation.

Page 20

Models 427 and 427R Installation 20

HOME ALARM

CONNECTIONS

Wiring Connections

efore the kickplate/grille is installed, all necessary wiring

B

connections in the compressor compartment should be

completed.

If the dual installation heater kit (7007529) is used with

model 427 or 427R, the power supply leads should be

connected according to instructions included with the kit.

If a home alarm system is to be installed on the wine

storage unit, the connections should be made using the

logic supplied with the alarm specifications. Refer to the

illustration below for the appliance lead locations, and

refer to the following for color codes:

• Normally open contacts: white with red stripe wire.

• Normally closed contacts: white with blue stripe wire.

• Common: gray with white stripe wire.

Use the

1

/4" (6) spade terminals or wire nuts provided to

make the proper wiring connections.

IMPORTANT NOTE: I

f you are not responsible for alarm

system connection, this information should be supplied to

the home security system contractor.

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be

used to switch line power.

Any unused terminals should be completely insulated and all wires should be secured away from

conductive or moving components.

Home alarm connections.

Page 21

Models 427 and 427R Installation 21

subzero.com

Kickplate /Grille

nce the unit is leveled and wiring connections made, the

O

kickplate/grille can be installed.

IMPORTANT NOTE: The kickplate/grille must be removed

for servicing. The floor cannot interfere with removal. The

louvered section of the kickplate/ grille must not be

covered so as to prevent air circulation.

For models 427 and 427R, there is some adjustment to the

mounting assembly so that the kickplate/grille can fit flush

with the surrounding area. Refer to the illustration below.

IMPORTANT NOTE: The unit must be allowed to have ven-

tilation through the fins of the kickplate/grille. You may

cover the solid area, but do not block the fins. For model

427R, the lower drawer panel may hang in front of the fins,

but your baseboard molding must not cover them.

Turn power back on to the electrical outlet.

Door Panels

odels 427 and 427R are available as a glass door (G) or

M

solid door (S) model. Each of these wine storage units are

set up at the job site as either the stainless steel or integrated design.

Stainless steel panels in three finishes in most cases;

classic (/S), platinum (/P) and carbon (/B)—available as

sales accessories—may be configured several ways and

are shipped separately. Stainless steel panels are shipped

with matching handles in place.

The integrated design uses custom wood or other decorative panels and handles provided by the customer.

Model 427R requires solid panels on the drawers that may

match the door panel, or be complementary. The model

427R stainless steel drawer panel set and stainless steel

door panel are ordered and shipped as two items.

The solid door model 427/S or 427R/S—with no glass

window—requires a different door panel than the glass

door design.

Before beginning installation, check for the correct components for the fit and finish desired. The door and

drawers (model 427R) require a decorative panel that is a

minimum

5

/8" (16) thick.

Kickplate /grille installation.

IMPORTANT NOTE: For installations at or above 5,000'

(1524 m) in altitude, a special high altitude glass door unit

(HA) must be ordered.

If you have questions, contact your Sub-Zero dealer or

cabinet supplier. Additional panel information can be

found in the Sub-Zero design guide, or visit our website at

subzero.com.

A solid panel must not be installed on a glass door

unit, as this may cause moisture to form behind the

panel.

Page 22

Models 427 and 427R Installation 22

DOOR

FRAME

BACK OF

PANEL

STAINLESS

STEEL

PANEL

OVERLAY

PANEL

DOOR

FRAME

TENON

CENTER

Stainless Steel Door Panel

efore installing the stainless steel door panel, check the

B

panel carefully. Options are available for kickplate/grille

height, overall height, door swing and door lock.

The stainless steel panel is mounted to the door by

passing the #8–32 x

the door frame from the rear, and into the threaded holes

in the door panel. Refer to the illustration below. The

screw holes inside the door are hidden under a cover flap

on the door gasket. It is necessary to lift the flap to insert

the screws.

After the door panel installation is complete, apply the

cover patches or plugs provided over the holes on the

inside surface of the door.

For installation of stainless steel panels on model 427R

drawers, refer to model 427R drawer panels on page 24.

The cover patches or plugs are part of the insulation

system on the door of the wine storage unit. Be sure

to cover all the holes in the door that were used.

5

/8" screws provided, through holes in

Overlay Door Panel

nspect the door panel for the minimum

I

the greater width requirements for the stiles (to cover the

door hinges), and the finished inside edge. The glass door

panel has a weight limit of 20 lbs (9 kg) and the solid door

panel has a weight limit of 40 lbs (18 kg). Refer to the wine

storage section of the Sub-Zero design guide for additional panel information.

Decide if the handle will be attached through the glass

door frame or just through the decorative door panel. If it

is just through the door panel, the handle must be

attached first.

If a lock is to be used, the body of the lock should be

installed on the door panel after the panel is mounted.

Decorative panels are attached to the model 427 and

427R door using #8 x

5

/8" square drive screws passing

through the door frame from the rear, behind the gasket

into the panel. The door panel is marked for screw locations by the use of ‘tenon centers’, which are temporarily

inserted into the

1

/4" (6) diameter holes in the front of the

glass door frame. Refer to the illustration.

With the wine storage unit secured in position and the

door closed, the panel is held in the desired position on

the door and rapped by hand from the front, putting center

marks on the rear surface of the panel. If the door panel is

made of such a material that pre-drilling is needed, all of

the mounting holes should be marked. If not, only enough

holes to hold the panel in place temporarily, are necessary.

5

(16) thickness,

/8"

Stainless steel panel. Overlay panel.

The door panel is then lowered from the door frame, tenon

centers removed, the door opened and the screws driven

into the panel through the black tape on the door frame,

using the center marks to locate the screws.

Page 23

Models 427 and 427R Installation 23

GASKET

GLASS

13

/32" (11)

DIAMETER

1

/4" (6)

DIAMETER

subzero.com

Overlay Door Panel

he screw holes inside the door are hidden under a cover

T

flap on the door gasket. It is necessary to lift the flap to

insert the screws. Use as many screws as necessary to

hold the door panel in place properly.

IMPORTANT NOTE: After the first three or four mounting

screws are in place, but not completely tightened, close

the door and check your panel fit. This is the time to make

small adjustments. Once you are satisfied with the appearance, open the door and apply the remainder of the

screws. Check all screws for tightness.

The metal frame on the glass door has numerous

mounting holes on each side of the door. This is to accommodate the Sub-Zero accessory handles and provide for

easy attachment of the handle through the door frame.

If you choose not to use the pre-drilled handle mounting

holes, it will be necessary to fasten the handle from the

rear of the door panel only, or drill one or more additional

holes through the metal frame of the glass door.

The cross section illustration below shows how this hole

passes through the door frame. The hole center is on the

small locator groove in the front of the frame. A

1

/4" (6)

diameter hole is made in the front wall of the extrusion and

13

a

/32" (11) diameter hole through the rest of the frame.

IMPORTANT NOTE: I

nstall screws in all the mounting holes

in the door frame. The nature of the door panel with a

narrow outer rim and no connecting center member

requires the support provided by the glass door.

After the door panel installation is complete, apply the

cover patches or plugs provided over the holes on the

inside surface of the door.

The wine storage unit door is made with a sealed

double wall tempered glass core. The drill must not

contact this core when drilling. Be sure the hole is

centered on the small groove in the front of the door

frame and the drill passes squarely through the

frame. If you are inexperienced with drilling, fasten

the handle from the rear of the door panel only.

The cover patches or plugs are part of the insulation

system on the door of the wine storage unit. Be sure

to cover all the holes in the door that were used.

Door frame cross section.

Page 24

Models 427 and 427R Installation 24

BACK OF

DRAWER PANEL

T

OP OF TEMPLATE

FLUSH WITH TOP OF

DRAWER PANEL

GAP ON SIDE

EDGES WILL

V

ARY WITH

D

ESIGN

Model 427R Drawer Panels

IMPORTANT NOTE: D

be a minimum of

rawer panels for model 427R must

5

/8" (16) thick and cannot exceed 12 lbs

(5 kg) for each panel.

Remove the mounting hardware provided and set aside.

You should work on the back side of each drawer panel

and you should protect the fronts of these panels.

Position the top edge of the drawer template flush with the

top edge of each drawer. For the top drawer, there is only

one place for the lower mounting bracket to be placed.

However, depending on the depth of the lower drawer

panel, you have two options for placement of the bracket.

Refer to the illustration.

Secure the template in place with tape or small clamps

and mark positions for your pilot holes. Remove template.

Drill pilot holes and place the hardware in the proper place

(dog-ear bracket on top) and fasten securely with the

1

#8 x

/2" screws provided. Refer to the illustration.

To help with proper placement of drawer panels, examine

the lower panel mounting bracket and determine which

slotted holes to use. Position screws into the lower portion

of the drawer that correspond with these slotted holes.

Leave these screws out a small distance so they can help

when you mount the drawer panels to the drawer.

Template position. Hardware

placement.

With the two brackets in place on the drawer panel,

engage the top dog-ear bracket first and then the lower

bracket onto the protruding screws. You will have a 1/4"

(6) adjustment up and down and side to side in each

drawer panel. Fasten all screws to the lower bracket to

secure the drawer panel.

IMPORTANT NOTE: Once drawer panels have been

adjusted for proper spacing, be sure to reconnect the

control cable on the upper drawer after you have installed

the drawer. Refer to the illustration on page 17.

Page 25

Models 427 and 427R Installation 25

subzero.com

Side Panels

ide panels for models 427 and 427R are not attached to

S

the unit. You must securely fasten the panels to adjacent

cabinets and floor.

Panels should be fastened to the floor and walls using ‘L’

brackets (hardware not provided). To help you move the

unit into place, rout out an area in the floor so the ‘L’

bracket will sit flush with the floor level.

Anchoring

Brackets and screws are provided for mounting the unit to

adjoining cabinets and side panels. Each unit has four

side-mounting clips on each side.

IMPORTANT NOTE: For installations where you are not

attaching to a side wall, or you are installing two model

427, 427R or integrated units together, you must remove

the side-mounting clips before moving the unit into

position. After removing the clips, replace the screws into

the appliance.

A dual installation heater kit (7007529) is necessary for

anchoring two model 427, 427R or integrated units

together. The kit is available through your Sub-Zero dealer,

or call Sub-Zero at 800-222-7820. You can also visit our

website at subzero.com.

90° door stop.

Completing the Installation

IMPORTANT NOTE: When you have completed the instal-

lation of the model 427 or 427R wine storage unit, refer to

page 50 for an installation checklist and page 51 for

service information.

90° Door Stop

Models 427 and 427R have a 90° door stop built into the

hinge system. Use the blade edge of a standard screwdriver and rotate the brass cam in the center portion of

the hinge until you reach the stop. You must make this

adjustment to both the bottom and top hinge. Refer to the

illustration.

Page 26

Model WS-30 Installation 26

30"

(762)

84"

(

2134)

24"

(610)

237/8"

(606)

BEHIND

FRAME

23/8"

(60)

311/4"*

(794)

17"

(432)

*Add 1/2" (13) for flush inset application.

Model WS-30 Installation

ake sure that the actual equipment that was shipped to

M

you matches the design you are expecting to install.

Before you begin the installation process, check the exact

model number you need against the model number on the

shipping carton. If the unit you receive does not match

your requirements, contact your Sub-Zero dealer.

The model WS-30 wine storage unit offers the following

design alternatives—framed, overlay, flush inset and stainless steel models. The overlay model has two design

applications—overlay and flush inset.

Each of these design options has specific installation

requirements, which means it is vital that the unit match

your planning and space needs. Refer to the overall

dimensions illustration for model WS-30 shown in the

stainless steel design. Dimensions will be the same for all

design applications.

The door of the model WS-30 opens to a maximum of

110°. A 90° door stop is shipped with the unit. The handle

depth reflects a tubular, curved or pro handle. For additional information, refer to the full-scale templates in the

Sub-Zero design guide.

Page 27

Model WS-30 Installation 27

subzero.com

Site Preparation

ake sure that the finished rough opening where the wine

M

storage unit is being installed is properly prepared. Refer

to installation specifications on the following pages. These

specifications are identical for the framed, overlay and

stainless steel applications. Installation specifications are

different for the flush inset application, whether you are

using custom panels or Sub-Zero accessory flush inset

panels.

If you are installing two models WS-30, or a model WS-30

and a built-in unit side by side in the framed, overlay, flush

inset or stainless steel application, a filler strip is recommended. Add the filler strip width to the finished rough

opening dimension. For installation of two units side by

side without a filler strip, a dual installation kit will be

necessary.

IMPORTANT NOTE: To operate properly, the door must

open a minimum of 90°. Use a minimum 3" (76) filler in

corner installations to assure a 90° door opening. Allow

enough clearance in front of the unit for full door swing.

IMPORTANT NOTE: Make sure the floor under the unit is

level with the surrounding finished floor.

TOOLS AND MATERIALS REQUIRED:

• Phillips screwdriver set

• Slotted screwdriver set

• Torx drive screwdriver set

1

• 4' (1.2 m) of

/4" copper tubing and saddle valve for the

water line (4200880)—do not use self-piercing valves

• Copper tubing cutter

• Level—2' (.6 m) and 4' (1.2 m) recommended

• Appliance dolly able to support 700 lbs (317 kg) and

adequate manpower to handle the weight of the unit

• Various sized pliers

• Wrench set

• Allen wrench set

3

•

/8" hex bolt nut driver

• Crescent wrenches

• Cordless drill and assorted drill bits

• Masonite, plywood,

1

/8" pressed fiberboard, cardboard

or other suitable material to protect finished flooring

• Appropriate materials to cover and protect the home

and its furnishings during installation

Page 28

Model WS-30 Installation 28

24" (610)

OPENING

DEPTH

FRONT VIEWSIDE VIEW

T

OP VIEW

291/2" (746)

OPENING WIDTH

24" (610)

O

PENING DEPTH

833/4"

(2127)

OPENING

HEIGHT

83" min

(2108)

OUTLINE

OF UNIT WITH

3

/4" (

19)

PANEL

Standard Installation Opening Dimensions

Framed, Overlay and Classic Stainless Steel Models

IMPORTANT NOTE: If two units are installed side by side,

refer to page 30 for dual standard installations.

Classic stainless steel models are ready to install out of the

box.

Page 29

Model WS-30 Installation 29

OUTLINE OF

UNIT WITH

3

/4" (

19)

PANEL

DETAIL A

DETAIL B

FRONT VIEW

291/2" (746)

WIDTH TO CLEAT

32" (813)

FLUSH INSET WIDTH

11/4"

(32)

11/4"

(32)

SIDE VIEW

84"

(2134)

FLUSH

INSET

HEIGHT

1

/4"

(6)

24" (610)

DEPTH TO CLEAT

263/16" (665)

FLUSH INSET DEPTH

23/16"

(56)

833/4"

(2127)

HEIGHT

TO CLEAT

83" min

(2108)

24" (610)

DEPTH

TO CLEAT

263/16"

(665)

FLUSH

INSET

DEPTH

TOP VIEW

23/16"

(56)

11/4"

(

32)

CLEAT

CLEAT

11/4"

(32)

24" (610)

O

PENING

DEPTH

T

O CLEAT

CLEAT

TOP VIEW

263/16"

(

665)

FLUSH

I

NSET

DEPTH

23/16" (

56)

3" (76)

typical

24" (610)

OPENING

DEPTH TO

CLEAT

11/4"

(32)

23/16"(56)

CLEAT

SHADED

AREA

M

UST BE

F

INISHED

3" typical

(76)

4" (102)

3

subzero.com

Flush Inset Installation Opening Dimensions

Detail A

IMPORTANT NOTE: Dimensions assume a3/4" (19) panel

thickness.

IMPORTANT NOTE: If two units are installed side by side,

refer to page 31 for dual flush inset installations.

Detail B

Page 30

Model WS-30 Installation 30

24" (

610)

OPENING

DEPTH

FRONT VIEWSIDE VIEW

TOP VIEW

833/4"

(

2127)

OPENING

HEIGHT

83" min

(2108)

A

OPENING WIDTH

2

4"

(610)

OPENING DEPTH

OUTLINE

O

F TWO UNITS WITH

3

/4" (19) PANEL

Dual Standard Installation Opening Dimensions

Framed, Overlay and Classic Stainless Steel Models

Opening Widths A

Two 30" (762) Models 593/4" (1518)

Model WS-30 and a 36" (914) Model 653/4" (1670)

IMPORTANT NOTE: A dual installation kit will be required for

this installation.

Classic stainless steel models are ready to install out of the

box.

Page 31

Model WS-30 Installation 31

24" (610)

DEPTH

T

O CLEAT

263/16"

(665)

FLUSH

I

NSET

DEPTH

FRONT VIEW

TOP VIEW

23/16"

(56)

A

WIDTH TO CLEAT

B

FLUSH INSET WIDTH

11/4"

(32)

11/4"

(32)

SIDE VIEW

84"

(2134)

FLUSH

INSET

HEIGHT

1

/4"

(

6)

24" (610)

D

EPTH TO CLEAT

263/16" (

665)

FLUSH INSET DEPTH

23/16"

(56)

833/4"

(

2127)

HEIGHT

TO CLEAT

83" m

in

(2108)

C

LEAT

OUTLINE OF

T

WO UNITS WITH

3

/4" (19) PANEL

DETAIL A

DETAIL B

11/4"

(32)

CLEAT

11/4"

(32)

24" (610)

O

PENING

DEPTH

T

O CLEAT

CLEAT

TOP VIEW

263/16"

(

665)

FLUSH

I

NSET

DEPTH

23/16" (

56)

3" (76)

typical

24" (610)

OPENING

DEPTH TO

CLEAT

11/4"

(32)

23/16"(56)

CLEAT

SHADED

AREA

M

UST BE

F

INISHED

3" typical

(76)

4" (102)

3

subzero.com

Dual Flush Inset Installation Opening Dimensions

Detail A

Opening Widths AB

Two 30" (762) Models 593/4" (1518) 621/4" (1581)

Model WS-30 and a 36" (914) Model 653/4" (1670) 681/2" (1740)

Detail B

IMPORTANT NOTE: Dimensions assume a3/4" (19) panel

thickness. A dual installation kit will be required for this installation.

Page 32

Model WS-30 Installation 32

751/2"

(1918)

7"

(178)

6

"

(

152)

E

FRONT VIEW

Electrical Requirements

or model WS-30, the electrical supply should be located

F

within the shaded area shown in the illustration. Follow the

National Electrical Code and local codes and ordinances

when installing the receptacle. A separate circuit, servicing

only this appliance is required.

IMPORTANT NOTE: A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

The outlet must be checked by a qualified electrician

to be sure that it is wired with the correct polarity.

Verify that the outlet provides 115 V AC and is

properly grounded.

Do not use an extension cord or two-prong adapter.

Electrical ground is required on this appliance. Do

not remove the power supply cord ground prong.

Location of electrical supply.

Electrical Requirements

Power Supply 115 V AC, 60 Hz

Circuit Breaker 15 amp

Receptacle 3-prong grounding-type

Page 33

Model WS-30 Installation 33

FRONT

GRILLE SCREW

BACK GRILLE

SCREW

LOCATION

OF GRILLE

ADJUSTMENT

SCREWS

subzero.com

Unpack the Unit

ncrate the unit and inspect for any damages. Remove

U

the wood base and discard the shipping bolts and

brackets that hold the wood base to the bottom of the

unit. Remove and discard all packing materials.

IMPORTANT NOTE: Do not discard the kickplate, anti-tip

brackets and hardware. These items will be needed for

installation.

Retract the front leveling legs all the way up to allow the

unit to be moved into position more easily. You will extend

the leveling legs when the unit is in its final position to

reduce the possibility of the unit tipping forward.

IMPORTANT NOTE: The rear levelers must be in their

lowest position in order to push the unit back into the

rough opening. Therefore, leveling cannot be completed

until the unit is in position.

Remove the drain pan from the base of the unit to avoid

damage to the drain pan, and allow for proper placement

of the appliance dolly.

Be sure to secure the door closed before moving the

unit.

Grille Removal

n order to prevent damage to the grille and to access the

I

power cord, the top grille assembly should be removed

prior to moving the unit.

To remove the grille assembly, pull out on the bottom edge

of the grille and tilt upward. Loosen the back two grille

mounting screws and remove the front two grille mounting

screws. Refer to the illustrations below. With the grille held

firmly, pull forward to remove.

To reinstall the grille, insert the grille into position and be

sure that the grille catch tabs are engaged. Reinstall the

front two grille screws, then retighten the back two grille

screws. Check for proper fit.

GRILLE HEIGHT ADJUSTMENT

The grille was designed to rest on the upper door hinge

in an attempt to minimize the reveal between the top of

the door and bottom of the grille. To eliminate potential

interference of the grille and hinge, the grille height can be

adjusted. Loosen the four grille adjustment screws (two on

each side) and adjust the grille height as needed. For

screw location, refer to the illustration below.

Grille removal. Grille mounting and adjust-

ment screws.

Page 34

Model WS-30 Installation 34

Anti-Tip Bracket Installation

To prevent the unit from tipping forward and provide

a stable installation, the unit must be secured in place

with the anti-tip brackets shipped with the unit.

IMPORTANT NOTE: Placement of the anti-tip brackets is

critical to a stable installation. Failure to properly position

the anti-tip brackets will prevent them from engaging the

unit.

IMPORTANT NOTE: The two anti-tip brackets must be

installed exactly 24" (610) from the front of the rough

opening to the back of the brackets and a minimum of 4"

(102) from the sides of the rough opening. This depth will

increase to 26

3

on

/4" (19) deep decorative panels. Proper placement will

3

/16" (665) for a flush inset installation based

ensure that the anti-tip brackets engage the anti-tip bar at

the back of the unit.

Anti-Tip Hardware Included

2 Anti-tip brackets

12 #12 x 21/2" PH pan HD zinc screws

43/8"–16 x 33/4" wedge anchors

12 #12 flat washers

4 #8–18 x 11/4" PH truss HD screws

4 Nylon zip-it wall anchors

IMPORTANT NOTE: F

applications, if the #12 x 2

or either wood or concrete floor

1

/2" screws do not hit a wall

stud or the wall plate in any of the back holes of the

brackets, use the provided #8–18 x 1

1

/4" PH truss HD

screws and #12 flat washers with the nylon zip-it wall

anchors.

IMPORTANT NOTE: In some installations the subflooring

or finished floor may necessitate angling the screws used

to fasten the anti-tip brackets to the back wall.

WOOD FLOOR APPLICATIONS

After properly locating the anti-tip brackets in the rough

opening, drill pilot holes

wall studs and/or wall plate. Use the #12 x 2

3

/16" (5) diameter maximum in the

1

/2" PH pan

HD zinc screws and #12 flat washers to secure the

brackets in place. Be sure that the screws penetrate

through the flooring material and into wall studs or wall

plate a minimum of

3

/4" (19). Refer to the illustration on the

following page.

Page 35

Model WS-30 Installation 35

4" MIN

(

102

)

24"

(

610

)

SUBFLOORING

WOOD FLOOR

WALL

PLATE

FINISHED

FLOORING

UNDERLAYMENT

4" MIN

(

102

)

24"

(

610

)

SUBFLOORING

CONCRETE

WALL

PLATE

FINISHED

FLOORING

UNDERLAYMENT

1

/2" MIN

(13)

subzero.com

Anti-Tip Bracket Installation

CONCRETE FLOOR APPLICATIONS

After properly locating the anti-tip brackets in the rough

opening, drill pilot holes

wall studs and/or wall plate. Then drill

holes into the concrete a minimum of

the #12 x 2

1

/2" PH pan HD zinc screws and #12 flat

3

/16" (5) diameter maximum in the

3

/8" (10) diameter

1

/2" (13) deep. Use

washers to secure the brackets to the wall and use the

3

/8"–16 x 33/4" wedge anchors to secure the brackets to

the floor. Be sure that the screws penetrate the wall studs

or wall plate a minimum of

3

/4" (19). Refer to the illustration

below.

Make sure there are no electrical wires or plumbing

in the area which the screws could penetrate.

INSTALL CONCRETE WEDGE ANCHORS:

1) Drill a3/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or continue

drilling additional depth to accommodate drill fines.

Use a carbide drill bit manufactured within ANSI

B94.12-77.

2) Assemble the washer and nut flush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is flush with

the surface material.

3) Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 25 foot-pounds of torque.

Always wear safety glasses and use other necessary

protective devices or apparel when installing or

working with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use

in new concrete which has not had sufficient time to

cure. The use of core drills is not recommended to

drill holes for the anchors.

Wood floors. Concrete floors.

Page 36

Model WS-30 Installation 36

FRONT

LEVELING LEG

REAR

ADJUSTMENT

Position the Unit

se an appliance dolly to move the unit near the rough

U

opening. Model WS-30 is equipped with rollers, so it can

be moved into position more easily.

Shut off power to the electrical outlet. Plug the power

supply cord into the 15 amp grounded outlet and roll the

unit into position. Be sure that the anti-tip brackets are

properly engaged.

IMPORTANT NOTE: If possible, keep the door closed until

the unit is properly anchored.

IMPORTANT NOTE: If for any reason the unit has been laid

on its back or side, you must allow the unit to stand

upright for a minimum of 24 hours before connecting

power.

Protect any finished flooring before moving the unit

into place

Level the Unit

nce the unit is in position, extend the front leveling legs

O

down by turning the legs clockwise to adjust the height.

The rear height adjustment can be made from the front of

the base. Use a

3

the

/8" hex bolt clockwise to raise the unit or counterclockwise to lower it. Refer to the illustration below for

location of the rear roller base adjustment.

IMPORTANT NOTE: Be sure to reference leveling of the

unit to the floor and not to surrounding cabinetry. This

could affect the operation of the unit, such as door

closing.

3

/8" socket to adjust the rear rollers. Turn

To reduce the possibility of the unit tipping forward,

the front leveling legs must be in contact with the

floor once the unit is in position.

Rear roller base adjustment.

Page 37

Model WS-30 Installation 37

UPPER

HINGE BOLTS

SIDE TO SIDE

TILT ADJUSTMENT

IN AND OUT

ADJUSTMENT

subzero.com

Door Adjustment

he door of the model WS-30 can be adjusted in three

T

ways: In and out, side to side tilt, and up and down.

Regardless of the adjustment being made, start by slightly

loosening the two upper hinge bolts on the upper hinge

plate using a

IN AND OUT ADJUSTMENT

Refer to the illustration for location of the bolt for in and

out door adjustment. To adjust a left-hinge door; using a

5

/32" allen wrench, turn the bolt clockwise to bring the

handle side of the door inward, and counterclockwise to

move the handle side of the door outward. Reverse the

directions for a right-hinge door.

1

/2" wrench. Refer to the illustration below.

Door height adjustment.

SIDE TO SIDE TILT ADJUSTMENT

Refer to the illustration for location of the bolt for side to

side tilt door adjustment. To adjust a left-hinge door; using

3

a

/8" wrench, turn the bolt clockwise to raise the handle

side of the door up and counterclockwise to tilt the handle

side of the door down. Reverse the directions for a righthinge door.

Upper hinge bolts. Door adjustment bolts.

DOOR HEIGHT ADJUSTMENT

To adjust a left-hinge door; using a1/4" allen wrench, turn

the bolt clockwise to raise the door and counterclockwise

to lower the door. Refer to the illustration above. Reverse

the directions for a right-hinge door.

Page 38

Model WS-30 Installation 38

ANCHORING

SCREWS

ANCHORING

SCREW

HOME ALARM

CONNECTIONS

Anchoring

fter door and side panels have been installed, the unit

A

has been leveled and door adjustment completed, anchor

the wine storage unit to the opening. This will assure a

proper fit and a secure installation.

IMPORTANT NOTE: Be sure to level and square the unit

before anchoring it.

To anchor the unit to cabinetry, open the grille, and install

the screws provided through the grille frame into the cabinetry. There are several hole locations provided. Check for

proper door clearance by fully opening the door. Refer to

the illustration below.

Next, drill a screw through the side hole inside the roller

base assembly. There is one on each side. The screw will

need to go in at an angle in order to attach properly.

In a flush inset application, additional material may be

needed behind the cleat to ensure sufficient anchoring.

If the screws provided are not suitable for your

application, you must provide adequate screws.

Home Alarm Connections

f a home alarm system is to be installed on the wine

I

storage unit, the connections should be made using the

logic supplied with the alarm specifications. Refer to the

illustration for the appliance lead locations, and refer to

the following for color codes:

• Normally open contacts – white with red stripe wire

• Normally closed contacts – white with blue stripe wire

• Common – gray with white stripe wire

Use the

make the proper wiring connections.

IMPORTANT NOTE: If you are not responsible for alarm

system connection, this information should be supplied to

the home security system contractor.

1

/4" (6) spade terminals or wire nuts provided to

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be

used to switch line power.

Any unused terminals should be completely insulated and all wires should be secured away from

conductive or moving components.

Top anchoring. Bottom anchoring.

Home alarm connections.

Page 39

Model WS-30 Installation 39

subzero.com

Complete the Installation – Model WS-30/S

or framed, overlay and flush inset applications, refer to

F

the following pages for front and side panel information.

Before installing the kickplate, be sure to reinstall the drain

pan. Once the drain pan is in place, screw the kickplate

the to brackets attached to the inside surface of each

roller base. Reinstall the grille following the instructions on

page 33. Turn power back on to the electrical outlet.

90° Door Stop

The door of the model WS-30 opens to 110°. A 90° door

stop ships with the unit and is located behind the flip-up

grille. Additional 90° door stop kits (7005865) are available

through your Sub-Zero dealer. To obtain local dealer

information, visit the showroom locator section of our

website, subzero.com.

The 90° door stop will be installed in the top hinge of the

door. To install, open the door to approximately 90°. At the

top of the door, insert the door stop down between the

door hinge and the door closer arm. Insert the screw

through the door stop and into the door as shown in the

illustration below.

Panel Installation

efore you install the front panel, refer to panel specifica-

B

tions for framed, overlay or flush inset applications and be

sure you are working with the panel design called for in

your installation. If your customer has chosen the stainless

steel design, the unit has been shipped complete with a

finished stainless steel look. It will not be necessary to

install a front panel or handle hardware. In your final

preparation for stainless steel units, use a stainless steel

cleaner to remove any marks. Abrasive cleaners should

not be used, as they may scratch the surface.

If your customer has ordered either a framed or overlay

model, you will be installing a front panel to give the unit

the custom Sub-Zero look.

IMPORTANT NOTE: For overlay models, there are two

design applications—overlay and flush inset. Be sure to

use the correct panel size for your application.

90° door stop.

Page 40

Model WS-30 Installation 40

1

/4" (6)

PANEL

TRIM

REVEAL

1

/4" (6) min

T

DOOR

MAIN FRAME

TRIM

REVEAL

1

/4" (6) min

ROUT TO

1

/4" (6)

MAIN FRAME

Framed Panel

f your customer has chosen a framed design application,

I

make sure that the panel you are about to install matches

dimensions listed in the framed panel specifications on the

following page. Additional panel design information can be

found in the Sub-Zero design guide and on our website,

subzero.com.

If the thickness of the custom panel is less than a

1

/4" (6),

back it up with a sheet of shim material to build the total

thickness to a

1

/4" (6). If the panel is thicker than a1/4" (6),

rout an edge around the panel to achieve a proper fit.

Refer to the illustrations.

IMPORTANT NOTE: The weight of the framed panel must

not exceed 75 lbs (34 kg).

IMPORTANT NOTE: For model WS-30, routing, recessing

or optional extended handles may be required on raised

panels for finger clearance under the handle.

FRAMED PANEL INSTALLATION

To install the framed panel, the door handle must be

removed. To install framed panels, first remove the door

trim molding. Insert a screwdriver tip into the top corner

slot on the handle side and pop out the trim molding.

Refer to the illustration below.

With a Phillips screwdriver, remove the handle. Slide the

panel into the frame on the door. With the panel in

position, replace the handle. Be sure the panel is inserted

completely into the channel for proper fit and alignment.

To reinstall the trim molding, insert the top of the trim

molding into the grooves at the top of the door and work

downward, snapping the trim molding into the clips on the

handle.

Panels1/4" (6) thick or less. Panels thicker than1/4" (6).

Door trim.

Page 41

Model WS-30 Installation 41

W

H

AA

A

A

subzero.com

Framed Panel

RAISED PANEL

With some door panel designs, you may have to rout,

recess or use optional extended handles to allow for finger