Page 1

Use & Care Guide

Use & Care Guide

®

200

SERIES

SERIES

Page 2

®

200

SERIES

SERIES

Page 3

UB-ZERO

UB-ZERO 200 SERIES

S

Refrigeration

200 SERIES

Table of ContentsUndercounter

Thank you for purchasing your

new Sub-Zero 200 Series unit.

With Sub-Zero, you can rely on

a 50 year tradition of quality and

reliability. The 200 Series brings

together the latest and finest

features in undercounter

refrigeration.

Your Sub-Zero 200 Series unit is

protected by a warranty that is

one of the finest in the industry.

Take a moment to read the

warranty statement on page 14,

and refer to it should service

become necessary.

This Use and Care Guide will

answer most of your questions

about the features, operation and

maintenance of your 200 Series

unit. If you have questions that

are not addressed here, call

800-222-7820.

Features of the 200 Series

Models 245 and 249R . . . . 4

Models 249RP

and 249FF/FFI . . . . . . . . . 5

Using Your Sub-Zero

Temperature

Controls . . . . . . . . . . . . . . . 6

Door Closing . . . . . . . . . . . 7

Operations . . . . . . . . . . . . . 7

Sounds . . . . . . . . . . . . . . . . 7

Icemaker Operation . . . . . . 7

Caring For Your Sub-Zero

Ice Production . . . . . . . . . . 8

Maintenance and

Cleaning . . . . . . . . . . . . . . . 8

Cleaning the

Condenser . . . . . . . . . . . . . 8

Troubleshooting

Guide . . . . . . . . . . . . . . . 10-11

Keeping Food at its Best

Food Storage

Suggestions . . . . . . . . . . . 12

Service For Your Sub-Zero

If You Need Service . . . . 13

Sub-Zero Warranty . . . . . . 14

Light Bulb

Replacement . . . . . . . . . . . 9

Vacation Time . . . . . . . . . . 9

3

Page 4

2

00 Series Models

00 Series Models

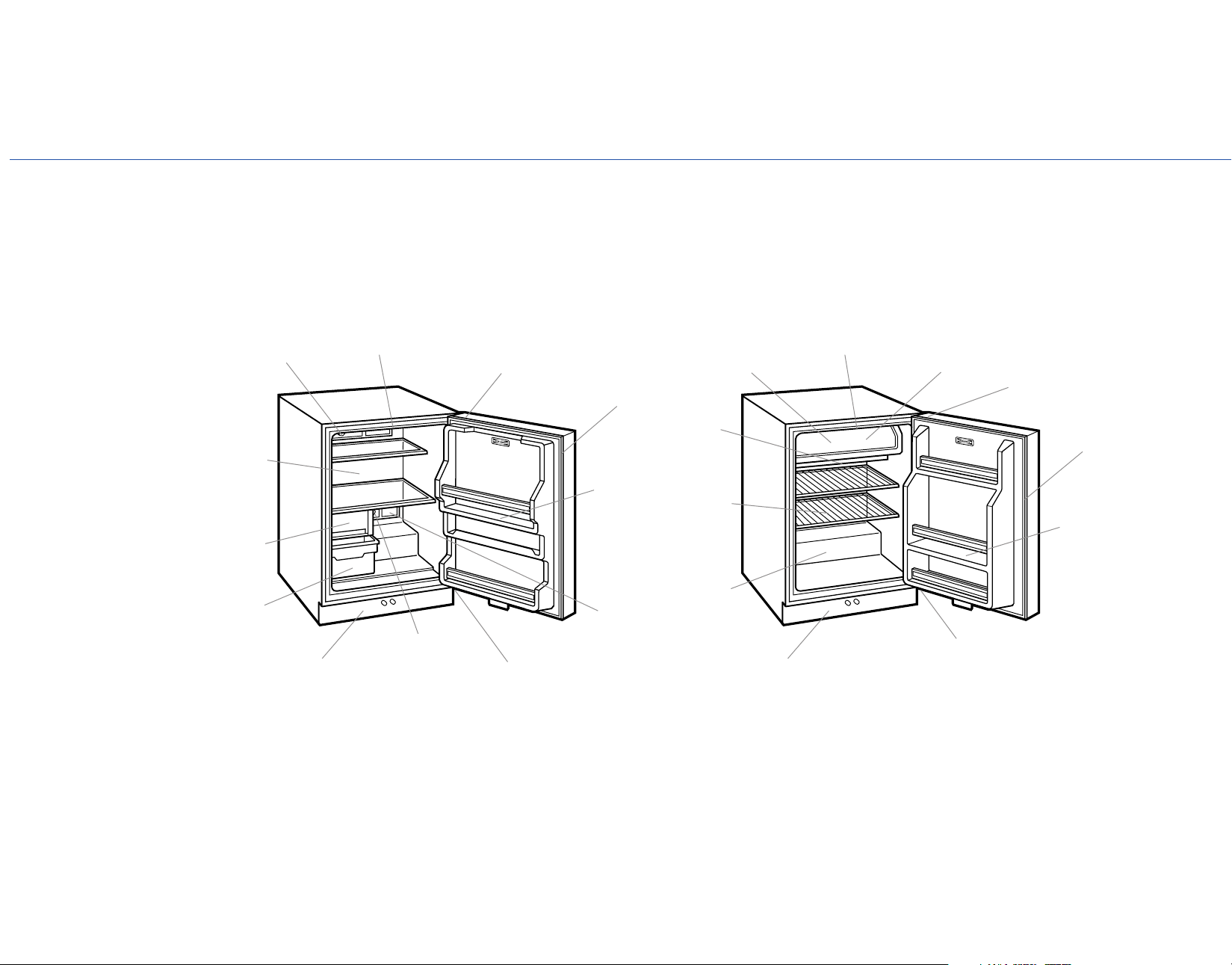

Model 245

Combination Unit

Adjustable

Refrigerator

Control

One-Piece

Interior

Stationary

Glass Shelves

Automatic

Ice Maker

Removable

Ice Bucket

Ventilated

Kickplate

Serial and Model

Number Plate

Adjustable

Freezer Control

Interchangeable

Door Hinge

Door Closer

Four Sided

Magnetic Gasket

Stationary

Door Shelves

Interior

Freezer Light

Model 249R

Combination Unit

Freezer Compartment

(with two cube trays)

Interior

Light

Removable

Wire Shelves

One-Piece

Interior

Ventilated

Kickplate

Serial and Model

Number Plate

Adjustable

Temperature

Control

Door Closer

Interchangeable

Door Hinge

Magnetic Gasket

Door Shelves

Four Sided

Stationary

4

Page 5

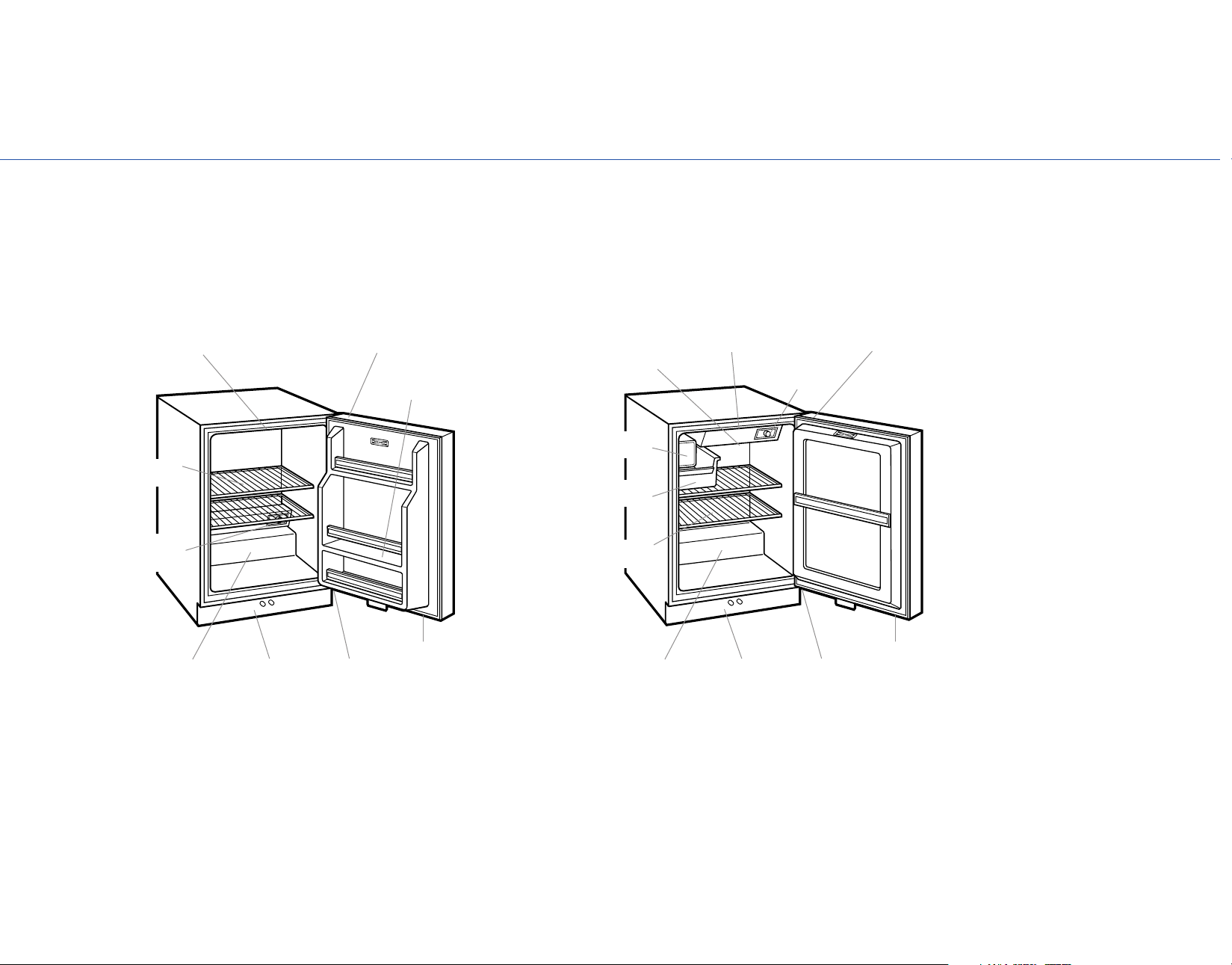

Model 249RP

All Refrigerator

Model 249FF/ FFI

All Freezer/

Freezer with Icemaker

Serial and Model

Removable

Wire Shelves

Adjustable

Temperature

Controls

One-Piece

Interior

Number Plate

Ventilated

Kickplate

Interchangeable

Door Hinge

Door Closer

Stationary

Door Shelves

Four Sided

Magnetic Gasket

Automatic Ice

Maker (249FFI)

Removable Ice

Bucket (249FFI)

Removable Wire

Shelves

One-Piece

Interior

Light

Interior

Serial and Model

Number Plate

Ventilated

Kickplate

Adjustable

Temperature

Controls

Door Closer

Interchangeable

Door Hinge

Four Sided

Magnetic Gasket

5

Page 6

U

sing your sub-Zero

sing your sub-Zero

Temperature

Controls

The importance of the

installation of your Sub-Zero

cannot be overemphasized. The

proper installation of your unit is

the responsibility of the selling

dealer or installer. Any questions

or problems pertaining to the

installation should be directed to

the selling dealer

Your new refrigerator and/or

freezer was thoroughly inspected

and tested before it was shipped

from the Sub-Zero factory.

During these procedures, the

temperatures were preset to

maintain approximately

38°F(3°C) in the refrigerator

section and approximately 0°F

(-18°C) in the freezer section

(except 249R). If you wish to

make temperature adjustments,

simply turn the control knob so

the indicator lines up with the

desired number.

The higher the number the

colder the temperature (#1 is the

warmest and #7 is the coldest

setting).

For the location of the control,

refer to the model of your Sub-

Zero on pages 4 and 5.

You should be aware it is normal

for these temperatures to

fluctuate slightly, depending on

external influence such as: open

door for extended periods, the

degree of humidity present and

room temperature.

Model 245

The freezer control is located on

the back wall above and right of

the icemaker assembly. The

refrigerator control is situated

left of center at the top of the

refrigerator compartment (see

Model 245 on page 4).

Model 249R

(Manual Defrost)

The control is situated on the

right hand side of the back wall

in the upper freezer com-

partment (see Model 249R on

page 4).

Model 249RP

The control is located on the

right side of the back wall just

below the lower shelf assembly

(see Model 249RP on page 5).

Model 249FF

The control is found at the top of

the freezer on the right side of

the defrost blower assembly (see

Model 249FF on page 5).

6

Page 7

Door Closing Operations Sounds Icemaker

Operation

Model 245

The door on the Model 245 is

equipped with a door closing

cam system to assist in the

closing of the door. As you close

the door, the cam will take over

at approximately the 15 degree

position to assist in the closing

of the door.

Models 249R, 249RP

and 249FF

The refrigerator and freezer

doors are both equipped with a

spring-loaded door closure

mechanism. As the doors are

closed, the door closure engages

at approximately the 15 degree

position to assist the door in

closing and sealing.

Condenser Fan

All undercounter units have one

fan located behind the kickplate

at the base of the unit. On all

undercounter models the fan

operates only only when the

compressor is running.

Evaporator Fan

Models 245 and 249FF

A fan motor is located in the

freezer section on th models

listed above. These fans operate

only when the compressor is

running.

Automatic Defrost

For your convenience, Sub-Zero

has equipped the following

models with an automatic

defrost system: 245, 249RP and

249FF.

NOTE: Model 249R is not

equipped with automatic defrost.

To manually defrost, turn the a

control knob to the off position.

Certain noises may be evident

with normal operation of the unit.

Surrounding acoustics like walls,

floors and cabinets may affect the

sound level of your unit.

A gurgling sound or running

water sound may be evident as

the refrigerant circulates through

the tubing.

During the icemaker cycle, you

may hear the sound of ice

dropping into the bucket or the

solenoid valve while refilling the

icemaker with water.

During the freezer defrost, you

may hear crackling and/or

sizzling as the heat from the

defrost element clears the frost

from the freezer coil and water

runs into the defrost water pan.

While the compressor is in

operation, a slight hum might be

evident. During the startup and

shutdown of the compressor,

some vibration may occur lasting

only a few seconds.

Models 245 and 249FFI

The icemaker in Models 245 and

249FFI is fully automatic and

has been factory pretested. To

put into operation, it requires

only a connection to the house

water supply.

7

Page 8

C

CAUTION

aring for your sub-Zero

aring for your sub-Zero

Ice Production

Models 245 and 249FFI

The level of ice in the ice

container is controlled by an ice

level arm. When the containers

are filled with ice, the ice level

arm senses the level and shuts

down the icemaker. As ice is

used, the level drops and the

level arm signals the icemaker to

restore ice production.

The icemaker is designed to

produce a more than adequate

supply of ice for normal family

consumption. the length of time

between ice harvest cycles will

vary depending on load

conditions, door openings and

ambient room temperatures. On

the average, you can expect a

harvest of ice every two hours.

If ice is not used regularly, it

will tend to fuse together. To

avoid this, empty the ice

container periodically.

NOTE: To shut off icemaker, lift

icemaker stop arm to the up or

off position. See illustration.

Automatic Icemaker

Maintenance

and Cleaning

For maintenance and

cleaning, the circuit

breaker to the refrigerator

should be shut off and

protective gloves worn.

For general cleaning of the

refrigerator and freezer interior

surfaces and removable parts,

wash with a mild solution of

soap and water to which a small

amount of baking soda has been

added. Rinse and dry

thoroughly. Avoid getting water

on lights and/or control dial.

To insure proper performance,

the cleaning of your unit’s

condenser is required.

Cleaning the

Condenser

To expose the condenser,

remove the kickplate at the base

of the unit. To do this, remove

the screws located at each corner

of the kickplate.

Use a "soft" bristle brush and

vacuum hose to remove the

accumulation of dust and lint

particles on the condenser.

IMPORTANT NOTE: Failure

to properly clean this area could

result in temperature lost and/or

possible mechanical failure of

the refrigerator and/or freezer.

IMPORTANT NOTE: This

should be performed every 3 to 6

months under normal use and

living conditions.

8

Cleaning the Condenser

Page 9

CAUTION

Light Bulb

CAUTION

Replacement

Vacation Time

Always shut off the circuit

breaker to the unit and

wear protective gloves

when replacing light bulbs.

Model 245

To replace the refrigerator light

bulb (25 watt), remove upper

shelf and pull control knob off.

Grip refrigerator control diffuser

firmly on top and bottom and

snap out of position. The light

bulb is now accessible.

To replace the freezer light bulb

(25 watt), pull control knob off.

Grip freezer control diffuser

firmly on top and bottom and

snap out of position. The bulb is

now accessible.

To reinstall, reverse procedure.

Model 249R

The light bulb (25 watt) is

located beneath the freezer

evaporator and is accessed by

reaching up underneath behind

the right hand side of the freezer

section. Unscrew and replace.

Model 249RP

The light bulb (25 watt) is

accessible by removing three

screws which anchor the light

bracket. Remove bracket and

reach behind the light diffuser

and unscrew bulb.

To reinstall, reverse procedure.

Model 249FF

The light bulb (25 watt) is

mounted behind the left side of

the blower fan assembly at the

top of the back wall of the

freezer. Unscrew and replace.

For short vacations: Remove all

perishable items. Shut off the

icemaker. See Icemaker

Operation on page 7. Do not

change the settings of your

controls.

For extended vacations: The

control(s) to your refrigerator or

freezer should be shut off.

Empty all contents in the

refrigerator/freezer and wash,

rinse and dry interior of unit.

Vacant homes: If for any reason

this unit is put into service on a

temporary basis and later shut

off, the control(s) to the

refrigerator or freezer should be

shut off.

For extended vacations or vacant

homes, you should block door(s)

open slightly. About one inch, so

fresh air can circulate and keep

interior dry. You should also

turn off power to the unit or

loosen light bulb(s).

The moisture developed

during even the shortest

amount of running time

could attack the metal parts

if the doors are left closed

after shutting down. Be

sure the doors are blocked

open after any operation.

9

Page 10

T

roubleshooting Guide

roubleshooting Guide

If you think that your

refrigerator is not operating

properly, check the following

before calling your Sub-Zero

Factory Authorized Service

Center or dealer. This guide may

save you time and the expense of

a service call.

If refrigerator/ freezer is

not operating:

• Is there electrical power to

equipment?

• Is home fuse blown or circuit

breaker off?

• Is refrigerator/freezer control

on?

• Is condenser clean?

• Has door been left open? Be

sure no foods are obstructing

proper door closing.

• If still not running, unit may

be in defrost; wait 30 minutes

to see if unit will restart.

If refrigerator/ freezer is

warmer than usual:

• Check control for proper

setting.

• Has door been left open too

long?

• Have you recently added a

large quantity of food?

• Is condenser behind grille

clean?

If refrigerator/ freezer

runs too much:

• Is condenser behind grille

clean?

• On hot days and warm room

ambients, the motor runs

longer.

• Have doors been open for

extended times or large

amounts of food added?

If refrigerator/ freezer is

frosted up:

• Have the doors been left open?

• Are doors closing and sealing

properly?

If you hear unusual

noises:

• These may be normal

operating sounds (see page 7).

If condensation forms

inside the unit:

• This is normal during high

humidity and frequent door

openings.

• Are doors closing and sealing

properly?

10

Page 11

If condensation forms on

the outside:

• It is possible during periods of

high humidity that some

condensation could appear.

This condition will subside

when humidity levels drop. If

condensation is excessive,

contact your Sub-Zero Factory

Authorized Service Center.

• Be sure doors are closed and

gaskets are sealing.

If it is too hot around

freezer compartment:

• Clean condenser.

If there is odor in the unit

and ice:

• Completely clean the unit.

• Cover foods tightly.

If light bulb needs

replacing:

• Turn off circuit breaker to

unit, wear gloves to protect

against glass (see page 9).

If you hear occasional

buzzing:

• Is water supply connected to

icemaker and turned on?

If you need service:

• Please have model and serial

number available.

• Call your nearest Sub-Zero

Authorized Service Center. For

the name of a local

Sub-Zero Authorized Service

Center, contact your dealer

or Sub-Zero Freezer Company

at 800-222-7820, write P.O.

Box 44130, Madison, WI

53744, or e-mail us at

customerservice@subzero.com.

11

Page 12

K

Food Storage

Suggestions

eeping food at its best

eeping food at its best

Shelf life of fresh foods varies

depending on how fresh it is

when you buy it. To keep your

food fresher longer, follow the

recommended storage tips.

• Vegetables: Wash vegetables

in cool water and drain. Store

in air-tight containers or

plastic wrap. Vegetables do

well in high-humidity storage.

• Fruits: Wash and dry fresh

fruits. Store more aromatic

fruits in plastic bags. Fruits do

well stored in low humidity.

• Prepackaged Meats: Store in

original packaging. After

opening, rewrap tightly in

plastic wrap or aluminum foil.

• Fresh Meats, Fish and

Poultry: Remove store

wrappings, then rewrap in

plastic wrap, foil or waxed

paper and refrigerate

immediately.

• Eggs: Store eggs unwashed in

their carton or a portable egg

tray. Use within 2 weeks.

• Milk, Cream, Cottage Cheese:

Keep carton closed. Store on

refrigerator shelf and use

within 5 days.

• Cheese: Store in original

packaging until ready to use.

After opening, rewrap tightly

in plastic wrap or aluminum

foil.

• Freezer Storage: Wrap foods

in material designed for frozen

food storage. The wrap must

seal out air and moisture. Do

not refreeze thawed meats.

• Ice Cream: The firmness of

the ice cream will depend on

its cream content. Higher

quality ice creams usually

have a higher cream content

requiring colder freezer

temperatures to maintain their

firmness. Soft ice cream is not

always an indication of a

temperature problem.

Make sure your refrigerator and

freezer doors close freely and

completely. Overloading will

affect temperatures inside the

unit. Do not fill your freezer

with large quantities of unfrozen

foods expecting them to "fast

freeze". Give the freezer ample

time to circulate cold air around

unfrozen items before adding

additional items.

12

• Leftovers: Let cool and cover

tightly with plastic wrap or

foil. Airtight plastic containers

work well to prevent drying

out and odor transfer.

Page 13

S

If You Need

Service …

ervice for Your Sub-zero

ervice for Your Sub-zero

This Use and Care Guide

gives you the tools necessary to

preserve food at optimum

quality in your Sub-Zero unit.

Keep doors closed as much as

possible whenever the unit is

operating.

If you think that your refriger-

ator is not operating properly,

refer to the Troubleshooting

Guide on pages 10-11 before

calling for service.

If you do need service, have the

model and serial number when

you call.

On undercounter models 245,

249R, 249RP and 249FF, the

serial number is found on the

inside cabinet liner at the top;

open the door to read.

Call your nearest Sub-Zero

Factory Authorized Service

Center, your dealer or Sub-Zero

Freezer Company at 800-222-

7820, write P.O. Box 44130,

Madison, WI 53744, or e-mail

customerservice@subzero.com.

13

Page 14

Sub-Zero Freezer Company Products

Limited Warranty

RESIDENTIAL USE ONLY

Full 5 Year Sealed System Warranty and Limited 6th Through 12th Year Warranty

on the Sealed System and Full 2 Year Warranty on Total Product

Full Five Year Sealed System Warranty

For five years from the date of original installation, your Sub-Zero warranty covers all parts and labor to repair or replace any

components that prove to be defective in materials or workmanship in the sealed system. The sealed system consists of the

compressor, condenser, evaporator, drier and all connecting tubing.

Full Two Year Warranty*

For two years from the date of original installation, your Sub-Zero warranty covers all parts and labor to repair or replace any

part of the product which proves to be defective in materials or workmanship.

Limited 6th Through 12th Year Warranty

From the 6th through the 12th year from the date of original installation, your Sub-Zero warranty covers all parts that prove to

be defective in materials or workmanship in the sealed system (parts only). The sealed system consists of the compressor,

condenser, evaporator, drier and all connecting tubing.

Terms Applicable To Each Warranty

All service provided by Sub-Zero under the above warranty must be performed by Sub-Zero factory authorized service

centers, unless otherwise specified by Sub-Zero. Service will be provided in the home during the normal business hours. This

warranty applies only to products installed for normal residential use. Details regarding a non-residential warranty are available

upon request.

The warranty applies only to products installed in any one of the fifty states of the United States, the District of Columbia or

the ten provinces of Canada. This warranty does not cover any parts or labor to correct any defect caused by negligence,

accident or improper use, maintenance, installation, service or repair, including but not limited to improper removal and

reinstallation (whether in the unit or at a remote location) of the condensing unit.

The remedies described above for each warranty are the only ones which Sub-Zero will provide, either under these

warranties or under any warranty arising by operation of law. Sub-Zero will not be responsible for any consequential or

incidental damages arising from the breach of these warranties or any other warranties, whether express, implied or

statutory.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other legal rights which

vary from state to state.

To receive parts and/or service and the name of the Sub-Zero factory authorized service centers nearest you,

contact your Sub-Zero dealer, distributor or Sub-Zero Freezer Company, Customer Service Department,

P.O. Box 44130, Madison, Wisconsin, 53744-4130, call (800) 222-7820 or e-mail us at customerservice@subzero.com.

* Stainless Steel (Classic, Platinum & Carbon) doors, panels and product frames are covered by a limited 60 day parts

and labor warranty for cosmetic defects.

14

Page 15

®

Page 16

®

Sub-Zero Freezer Company, Inc. 4717 Hammersley Road Madison, Wisconsin 53711 (800) 222-7820 or (608) 271-2233

200 UCG 3758377 1/04

Loading...

Loading...