Page 1

SERVICE

MANUAL

Models

RGX2900

RGX3600

RGX4800

GENERATORS

PUB-GS2102

Rev. 05/06

Page 2

Page 3

CONTENTS

Section Title Page

1. SPECIFICATIONS

1-1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 PERFOMANCE CURVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. GENERAL DESCRIPTION

2-1 EXTERNAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-3 ALTERNATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2-4 LOCATION OF SERIAL NUMBER AND PRODUCTION NUMBER . . . . . . . . . . . .12

3. RANGE OF APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4. MEASURING AND CHECKING PROCEDURES

4-1 MEASURING INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4-2 AC OUTPUT MEASURING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4-3 DC OUTPUT MEASURING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4-4 MEASURING INSULATION RESISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4-5 CHECKING FUNCTIONAL MEMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5. DISASSEMBLY AND ASSEMBLY

5-1 PREPARATION AND PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5-2 DISASSEMBLY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5-3 REASSEMBLY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6. TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

7. WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

This manual covers only alternator and control unit portion of the generator.

As to the servicing information of engine portion, please refer to the “EX series” service manual.

The specifications and information included in this manual were in effect at the time of printing.

FUJI HEAVY INDUSTRIES LTD. reserve the right to change the specifications and to make modifications in the course of

technical progress, at anytime without notice.

No parts of this manual may be reproduced without written permission.

Page 4

– 1 –

1. SPECIFICATIONS

1-1 SPECIFICATIONS

MODEL

Type

Voltage regulating system

AC Output

Rated voltage-Frequency

VA (W)Rated output

Maximum output

Rated power factor

Safety device type

DC Output

Rated voltage

Rated current

Safety device type

Model

VA (W)

V-Hz

V

A

50Hz

60Hz

50Hz

60Hz

RGX2900

Brush-less, self-exciting, 2-poles, single phase

220-50, 240-50, 230-50, 120/240-60

2000

2400

2400

2900

Fuse-less circuit breaker

Fuse-less circuit breaker

EX17D

RGX3600 RGX4800

Condenser type

2400

2900

3000

3600

1.0

12

8.3

EX21D

3500

4100

4100

4800

EX27D

Type

Displacement

Fuel

Fuel tank capacity

Rated continuous operation

Engine Generator

Engine oil capacity

Spark plug

Starting system

Length

Width

Height

Dimension

Dry weight

Specifications are subject to change without notice.

mL

L

H

L

mm

mm

mm

kg

50Hz

60Hz

ROBIN, Air-cooled, 4-stroke, OHC

211

Automotive Unleaded Gasoline

16.6

12

0.6

BR-6HS (NGK) (Champion; RL86C)

9.5

8.4

Recoil starter

605

450

500

54

265169

7

610.5

1.0

650580

510420

540480

7048

Page 5

– 2 –

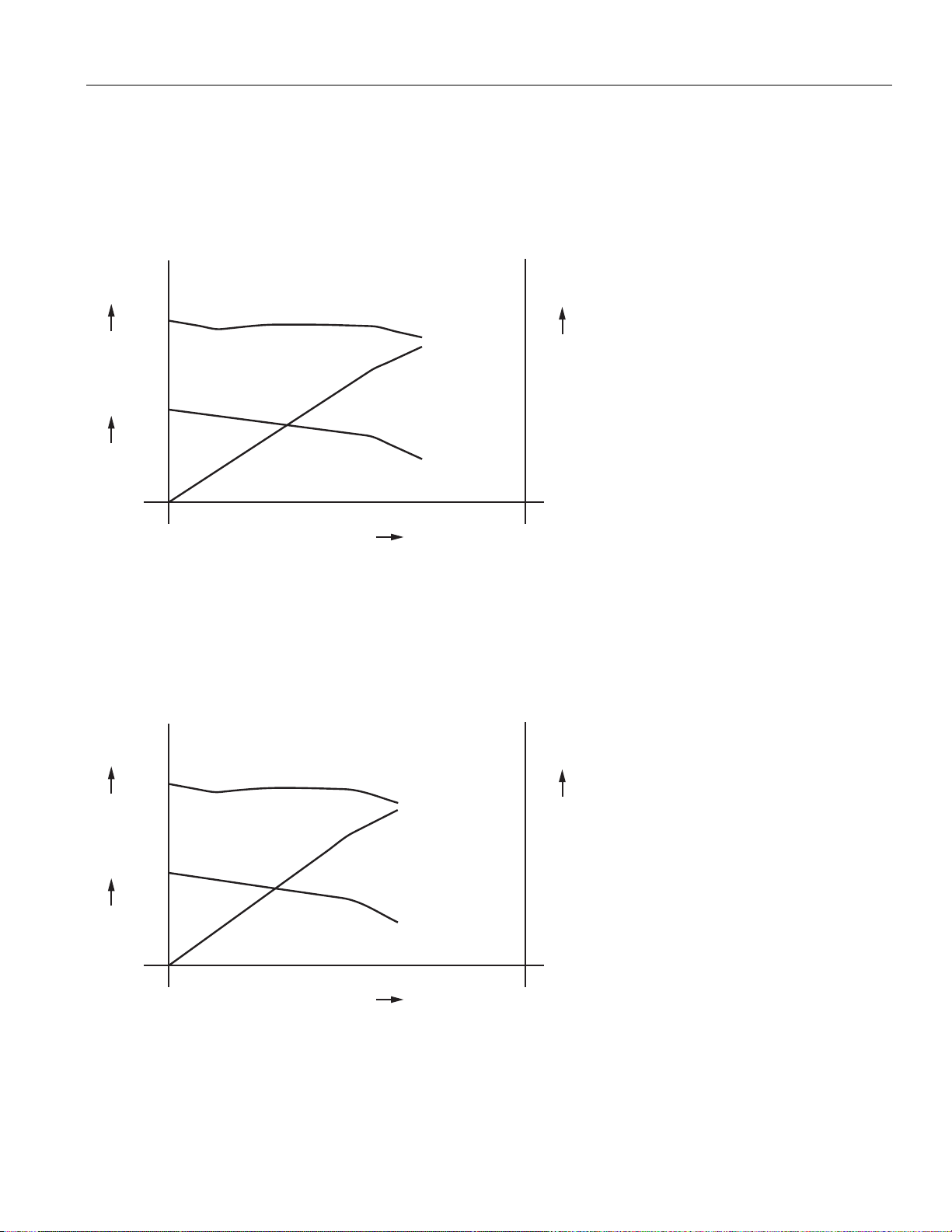

1-2 PERFOMANCE CURVES

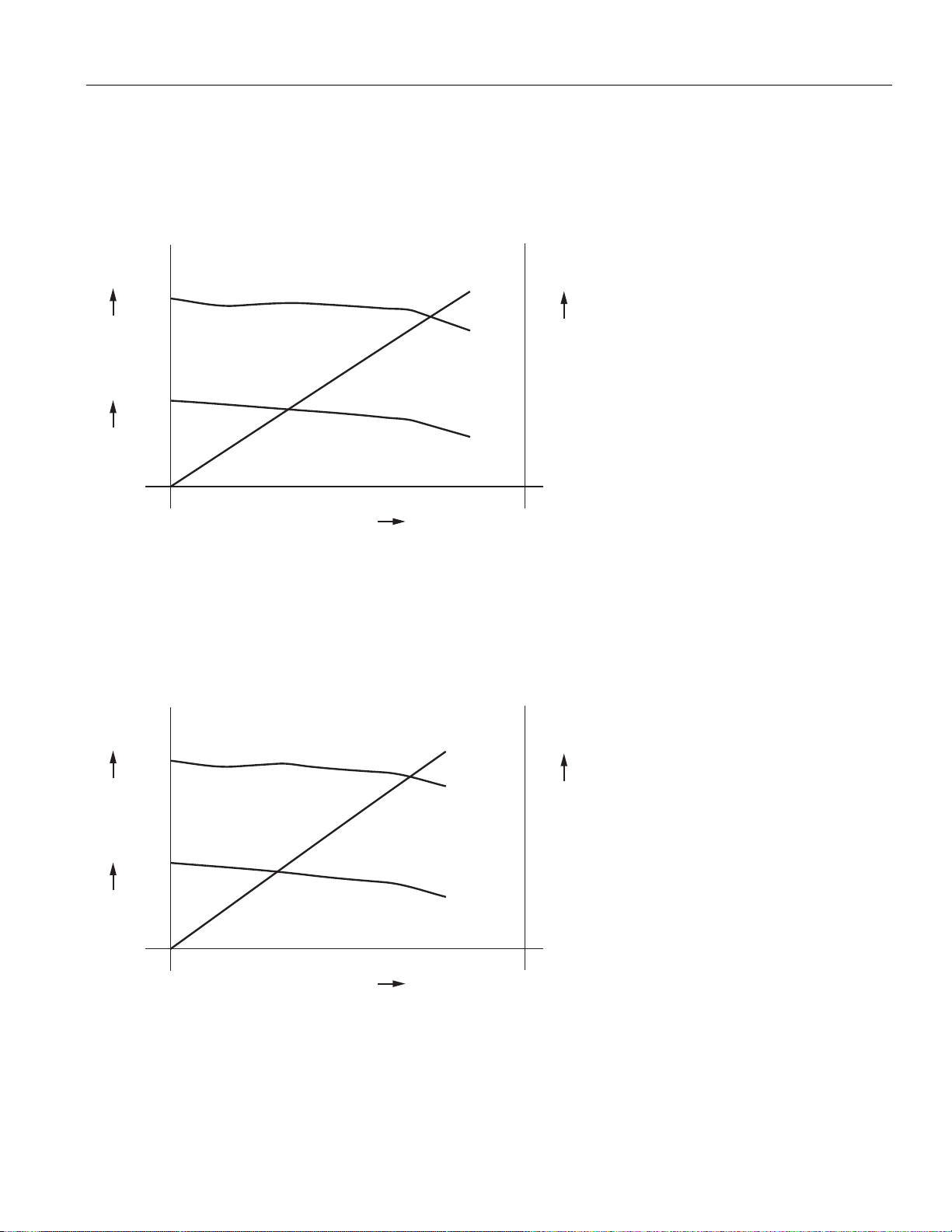

RGX2900

(50Hz-220, 230V)

230

220

210

52

50

48

FREQUENCY (Hz) VOLTAGE (V)

5010

CURRENT (A)

3.0

2.0

1.0

0

Maximum output 2,400 VA

Rated output 2,000 VA

Frequency 50 Hz

Rated voltage 220V, 230 V

Rated amperage 9.1 A, 8.7 A

OUTPUT (kVA)

(50Hz-240V)

250

240

230

52

50

48

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

5010

0

CURRENT (A)

Maximum output 2,400 VA

Rated output 2,000 VA

Frequency 50 Hz

Rated voltage 240 V

Rated amperage 8.3 A

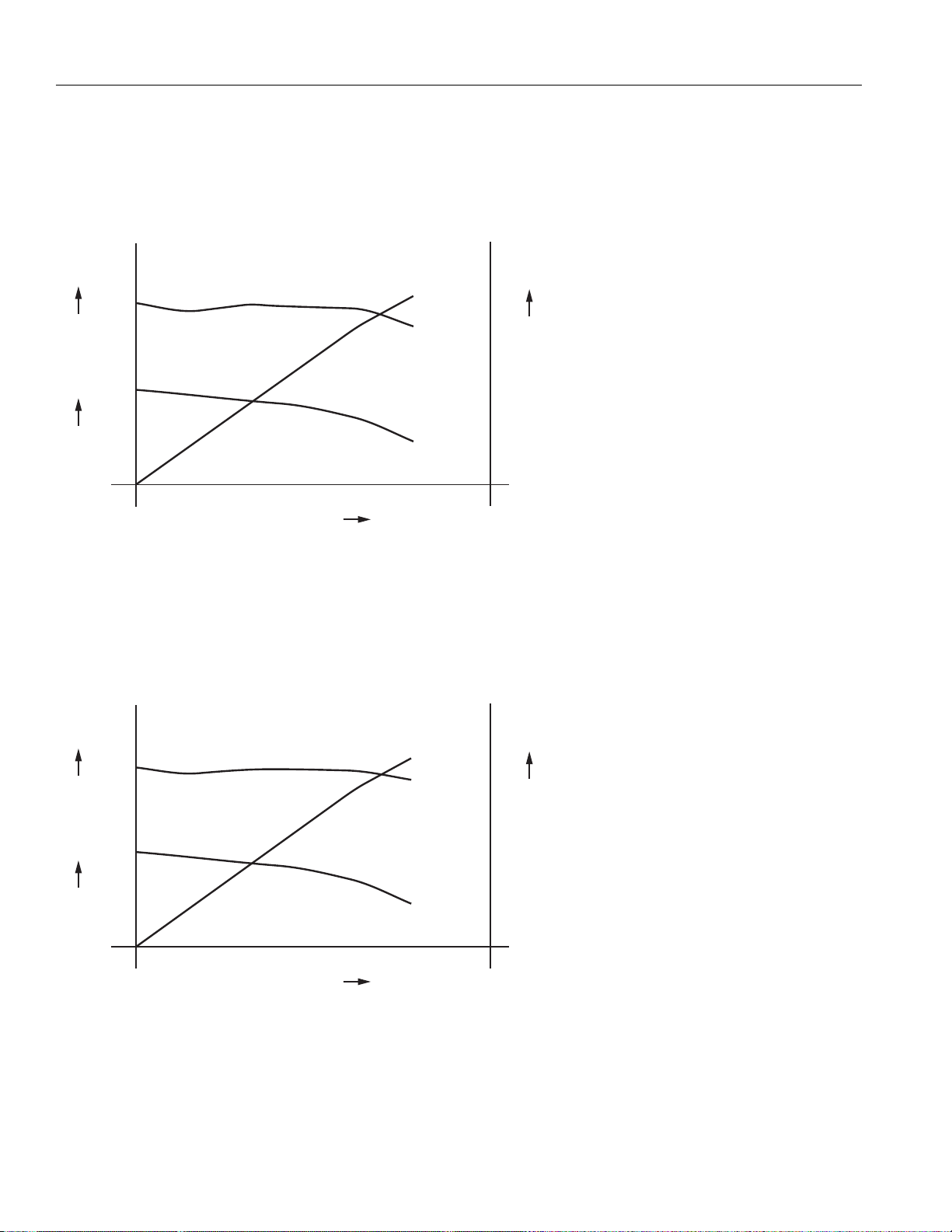

Page 6

– 3 –

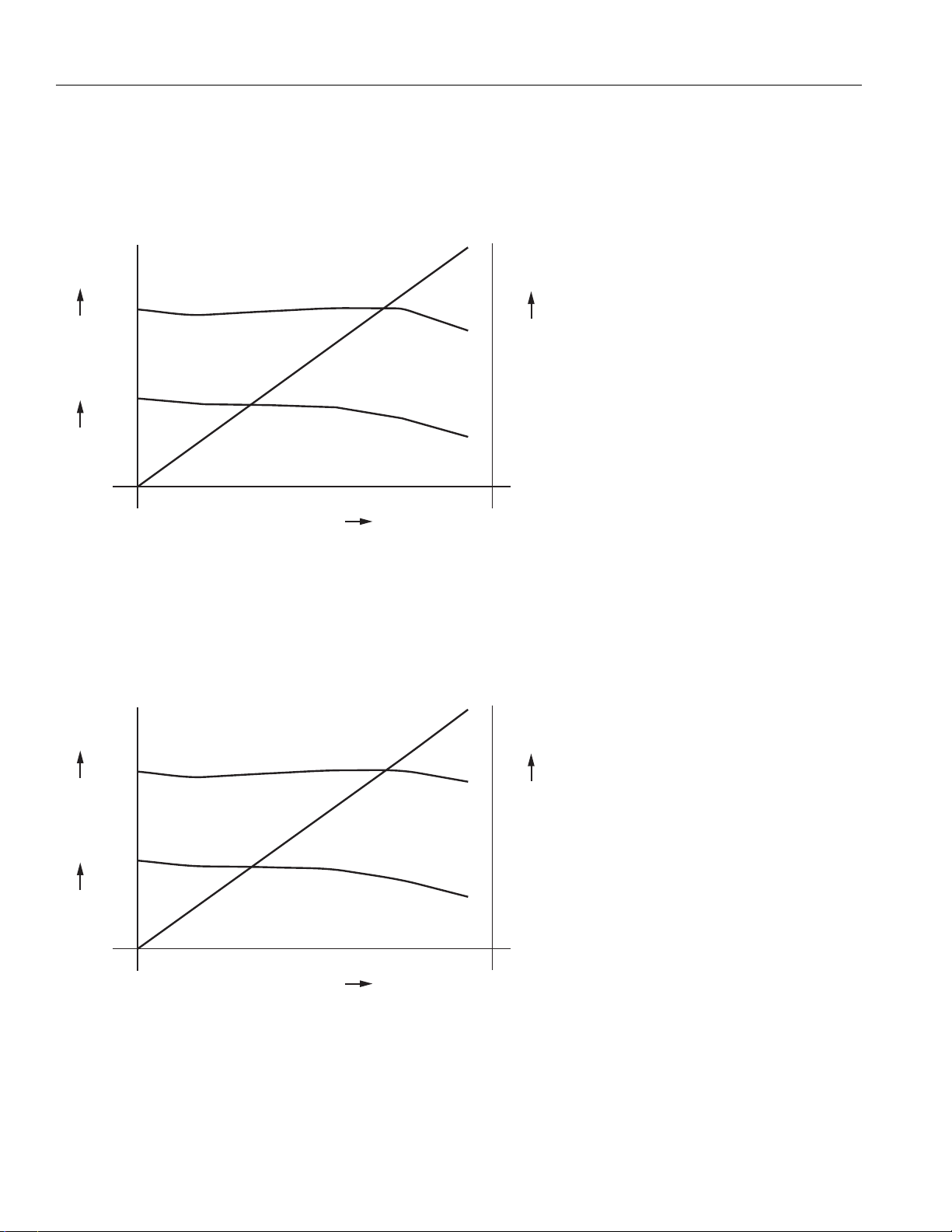

RGX2900

(60Hz-120/240V)

●

60Hz-240V output

250

240

230

62

60

58

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

515010

0

CURRENT (A)

Maximum output 2,900 VA

Rated output 2,400 VA

Frequency 60 Hz

Rated voltage 240 V

Rated amperage 10 A

●

60Hz-120V output

130

120

110

62

60

58

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

10020

0

CURRENT (A)

Maximum output 2,900 VA

Rated output 2,400 VA

Frequency 60 Hz

Rated voltage 120 V

Rated amperage 20 A

Page 7

– 4 –

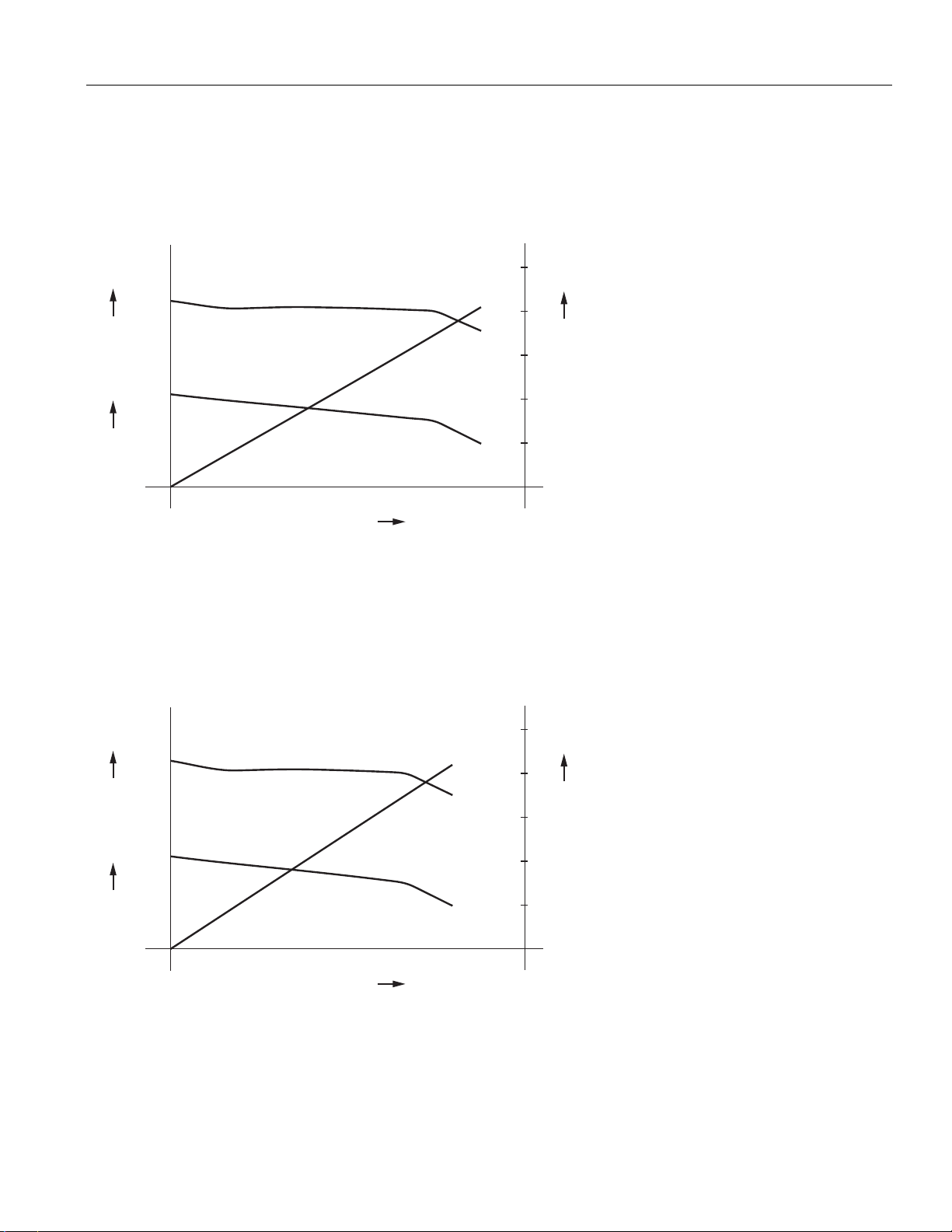

RGX3600

(50Hz-220, 230V)

230

220

210

52

50

48

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

515010

0

CURRENT (A)

Maximum output 3,000 VA

Rated output 2,400 VA

Frequency 50 Hz

Rated voltage 220V, 230 V

Rated amperage 10.9 A, 10.4 A

(50Hz-240V)

250

240

230

52

50

48

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

515010

0

CURRENT (A)

Maximum output 3,000 VA

Rated output 2,400 VA

Frequency 50 Hz

Rated voltage 240 V

Rated amperage 10 A

Page 8

– 5 –

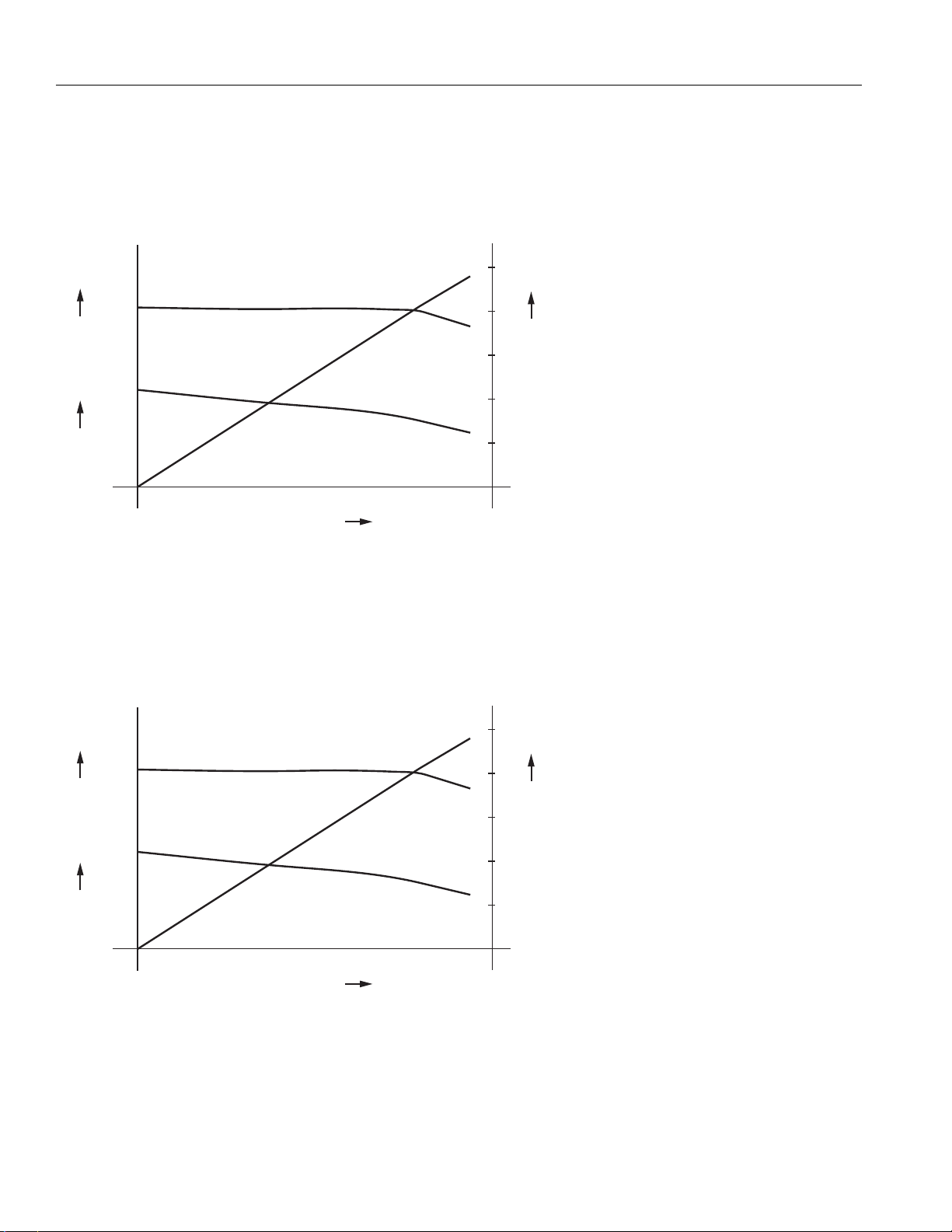

RGX3600

(60Hz-120/240V)

●

60Hz-240V output

250

240

230

62

60

58

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

515010

0

CURRENT (A)

Maximum output 3,600 VA

Rated output 2,900 VA

Frequency 60 Hz

Rated voltage 240 V

Rated amperage 12.1 A

●

60Hz-120V output

130

120

110

62

60

58

FREQUENCY (Hz) VOLTAGE (V)

3.0

2.0

OUTPUT (kVA)

1.0

10 30020

0

CURRENT (A)

Maximum output 3,600 VA

Rated output 2,900 VA

Frequency 60 Hz

Rated voltage 120 V

Rated amperage 24.2 A

Page 9

– 6 –

RGX4800

(50Hz-220V,230V)

230

220

210

52

50

48

FREQUENCY (Hz) VOLTAGE (V)

(50Hz-240V)

5.0

Maximum output 4,100 VA

Rated output 3,500 VA

4.0

Frequency 50 Hz

Rated voltage 220V, 230 V

3.0

2.0

1.0

0

481216 200

CURRENT (A)

Rated amperage 15.9 A, 15.2 A

OUTPUT (kVA)

250

240

230

52

50

48

FREQUENCY (Hz) VOLTAGE (V)

5.0

Maximum output 4,100 VA

Rated output 3,500 VA

4.0

Frequency 50 Hz

3.0

2.0

1.0

0

481216 200

CURRENT (A)

Rated voltage 240 V

Rated amperage 14.6 A

OUTPUT (kVA)

Page 10

– 7 –

RGX4800

(60Hz-120/240V)

●

60Hz-240V output

250

240

230

62

60

58

FREQUENCY (Hz) VOLTAGE (V)

●

60Hz-120V output

5.0

4.0

Maximum output 4,800 VA

Rated output 4,100 VA

Frequency 60 Hz

Rated voltage 240 V

3.0

2.0

1.0

0

481216 200

CURRENT (A)

Rated amperage 17.1 A

OUTPUT (kVA)

130

120

110

62

60

58

FREQUENCY (Hz) VOLTAGE (V)

5.0

Maximum output 4,800 VA

Rated output 4,100 VA

4.0

Frequency 60 Hz

Rated voltage 120 V

3.0

2.0

1.0

0

8162432 400

CURRENT (A)

Rated amperage 34.2 A

OUTPUT (kVA)

Page 11

– 8 –

2. GENERAL DESCRIPTION

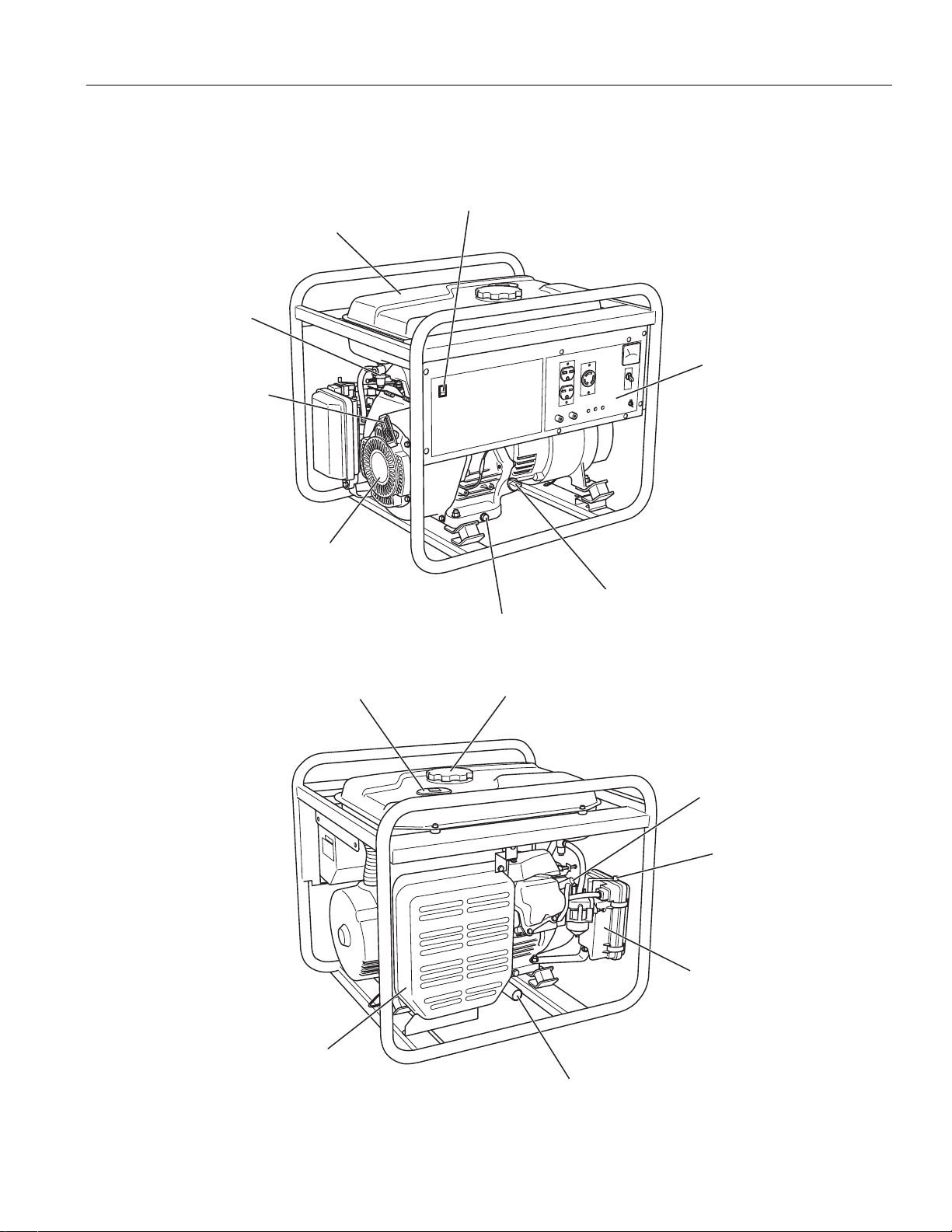

2-1 EXTERNAL VIEW

Fuel tank

Fuel strainer

(

Fuel cock

Recoil starter

handle

)

Engine switch

Control panel

Recoil starter

Fuel gauge

Oil gauge (oil filler)

Oil drain plug

Tank cap

Spark plug cap

Choke lever

Air cleaner

Muffler cover

Exhaust outlet

Page 12

– 9 –

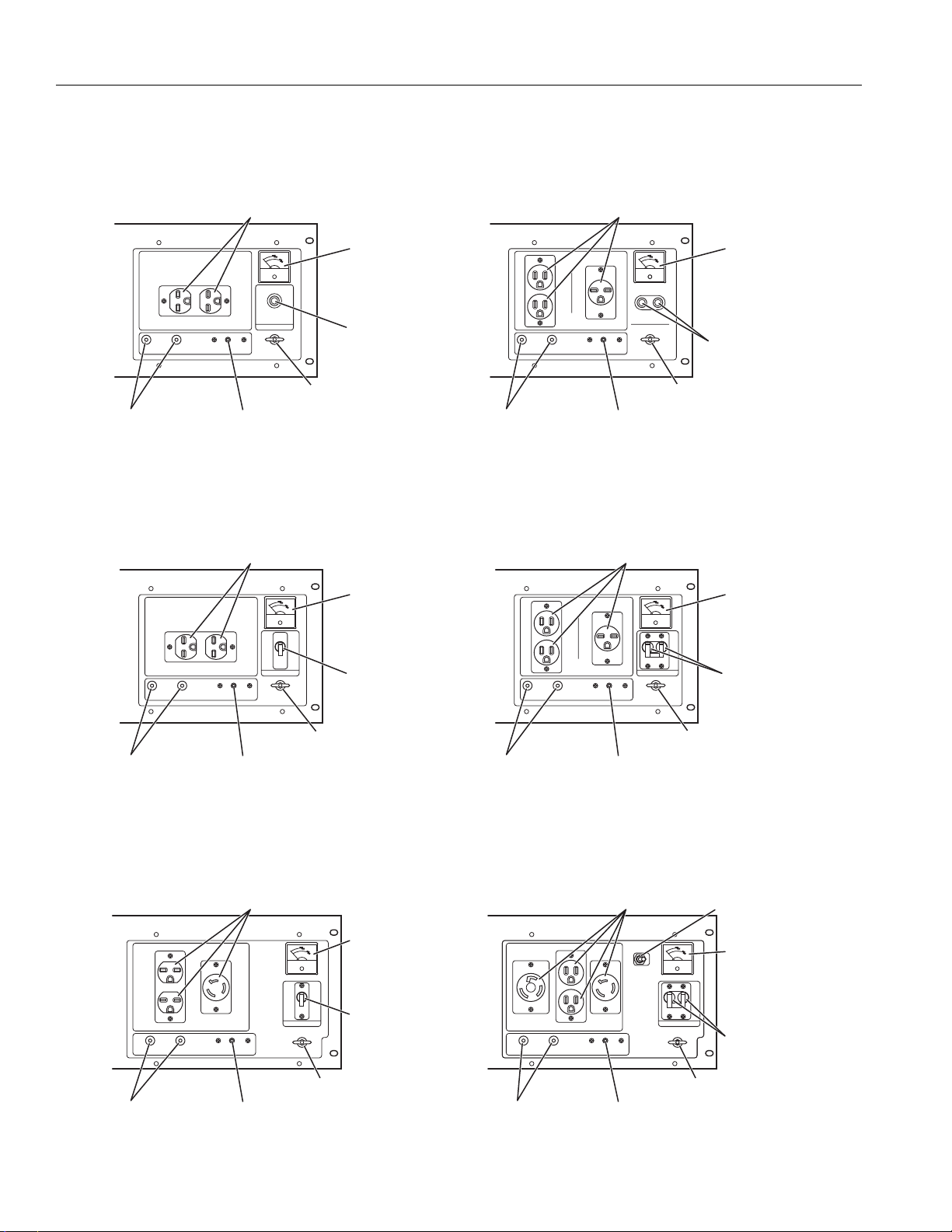

2-2 CONTROL PANEL

RGX2900

(50Hz-220V, 240V)

DC output

terminal

DC circuit

breaker

RGX3600

(50Hz-220V, 240V)

AC receptacle

Earth (ground

terminal

AC receptacle

Voltmeter

AC circuit

breaker

)

Voltmeter

RGX2900

(60Hz-120/240V)

DC output

terminal

DC circuit

breaker

RGX3600

(60Hz-120/240V)

AC receptacle

Earth (ground

terminal

AC receptacle

Voltmeter

AC circuit

breaker

)

Voltmeter

DC output

terminal

DC circuit

breaker

RGX4800

(50Hz-220V, 240V)

DC output

terminal

DC circuit

breaker

Earth (ground

terminal

AC receptacle

Earth (ground

terminal

AC circuit

breaker

Voltmeter

AC circuit

breaker

)

AC circuit

breaker

)

DC output

terminal

DC circuit

breaker

Earth (ground

terminal

)

RGX4800

(60Hz-120/240V)

Full power

switch

Voltmeter

AC circuit

breaker

Earth (ground

terminal

)

DC output

terminal

AC receptacle

DC circuit

breaker

Page 13

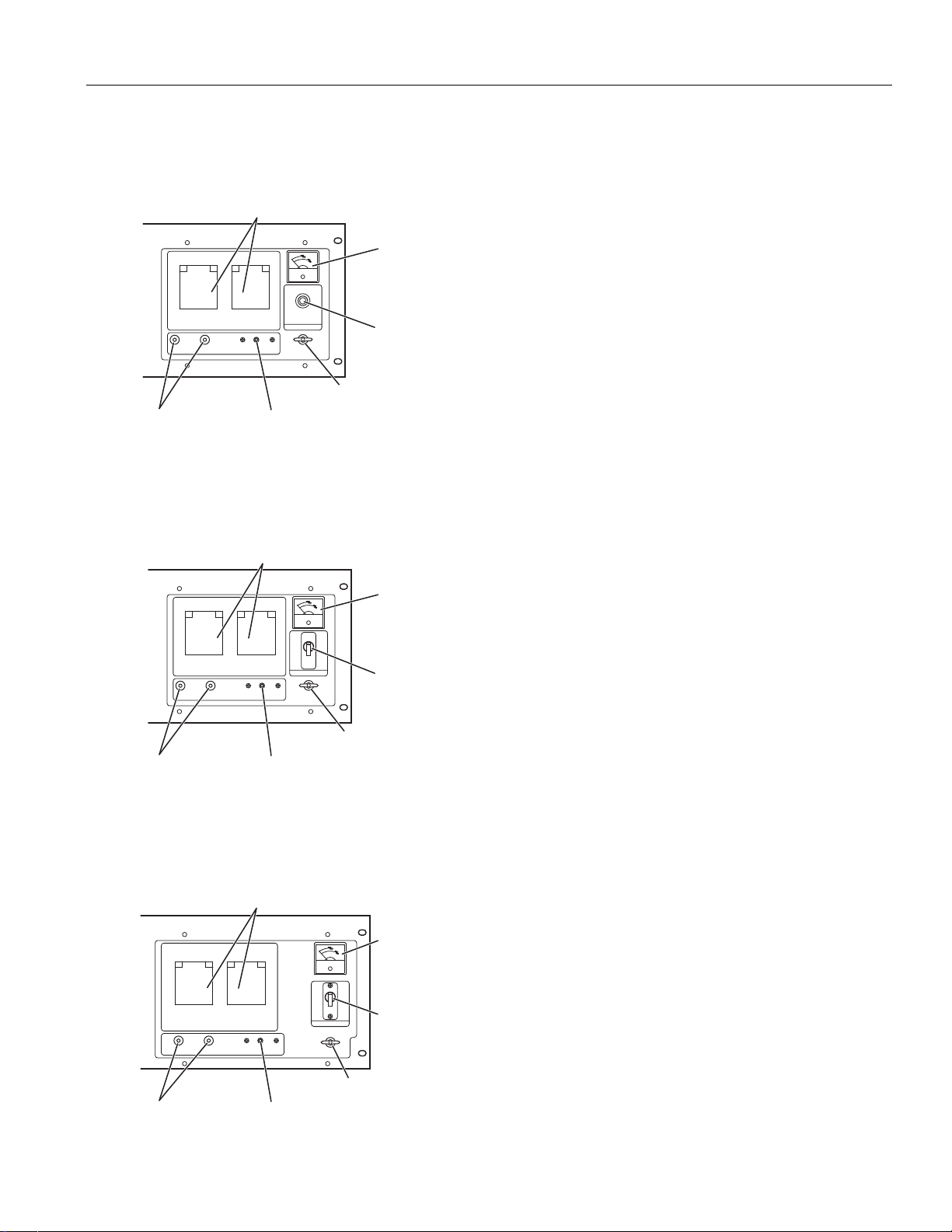

– 10 –

RGX2900

(50Hz-230V)

AC receptacle

Voltmeter

AC circuit

breaker

DC output

terminal

RGX3600

(50Hz-230V)

DC output

terminal

DC circuit

breaker

AC receptacle

DC circuit

breaker

Earth (ground

terminal

Voltmeter

AC circuit

breaker

Earth (ground

terminal

)

)

RGX4800

(50Hz-230V)

DC output

terminal

AC receptacle

DC circuit

breaker

Voltmeter

AC circuit

breaker

Earth (ground

terminal

)

Page 14

– 11 –

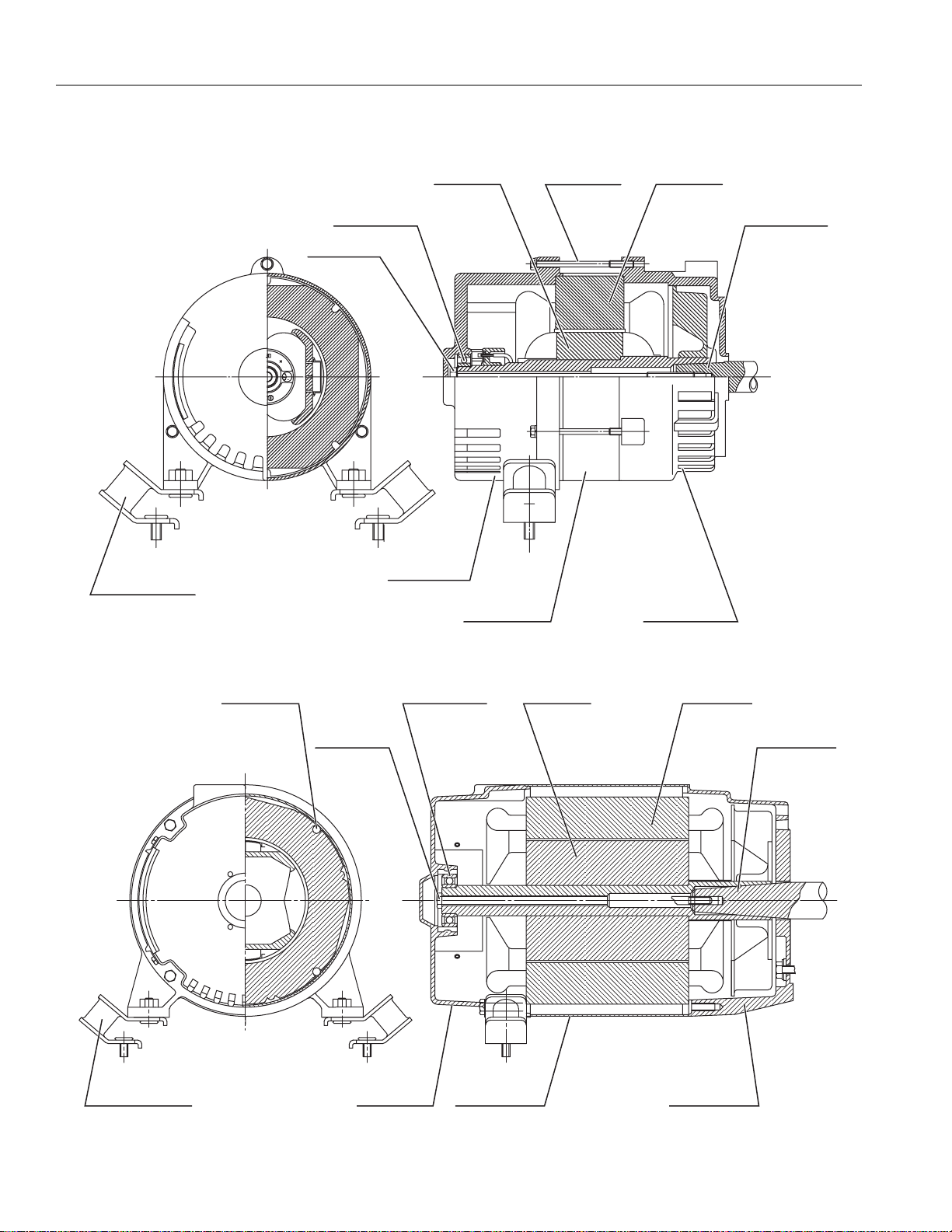

2-3 ALTERNATOR

RGX2900/3600

RGX4800

Mount rubber

Ball bearing

Rotor bolt

Rotor CP Cover bolt Stator CP

Rear cover

Stator cover

Crank shaft

Front cover

Ball bearing

Rear coverMount rubber

Stator cover

Rotor CPCover bolt Stator CP

Crank shaftRotor bolt

Front cover

Page 15

– 12 –

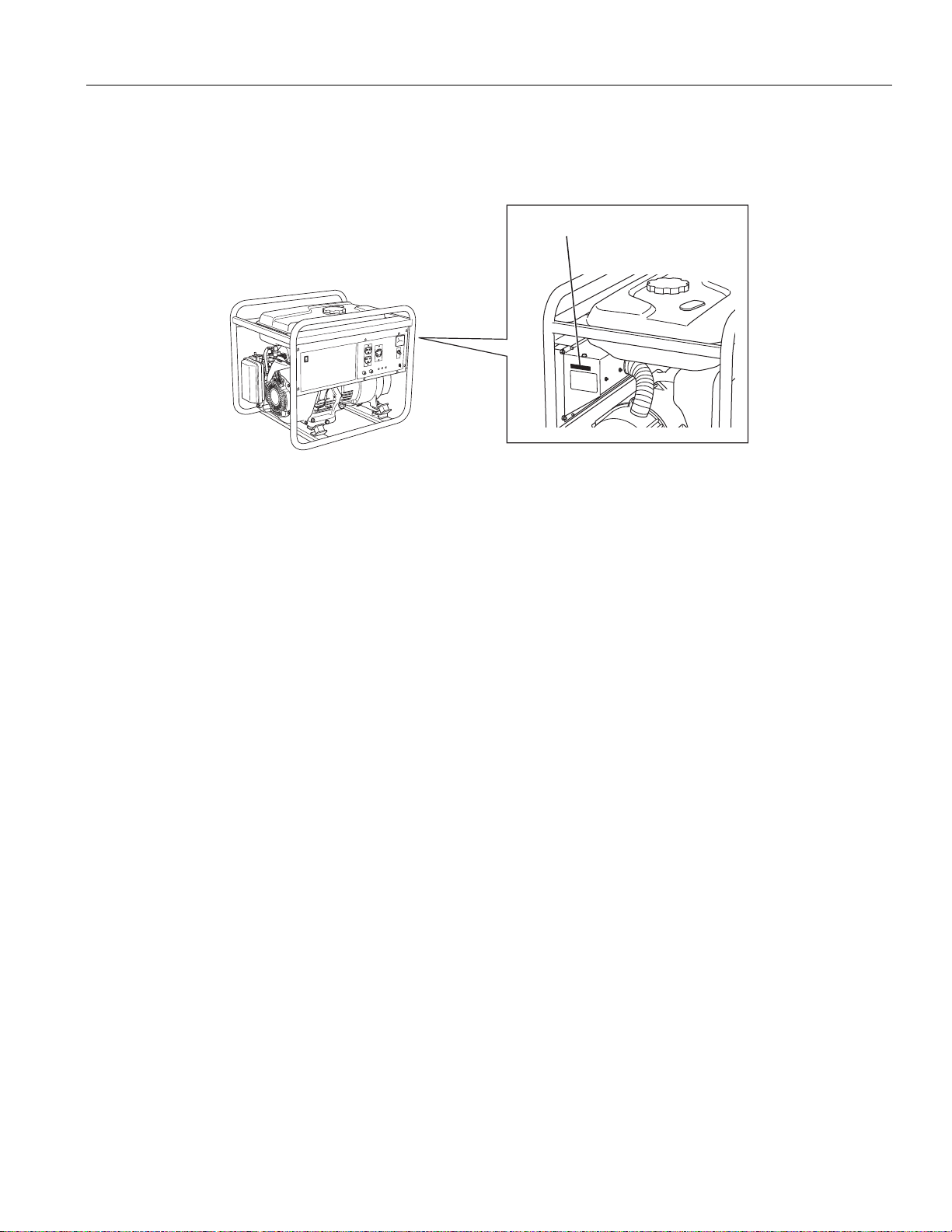

2-4 LOCATION OF SERIAL NUMBER AND PRODUCTION NUMBER

Generator serial number and production number are stamped on the label stuck on the side of fuel tank.

NOTE : When inquiring about your generator or ordering spare parts, always give us the Model, Serial

Number and Production Number.

PROD No. / SER No. (Label)

Page 16

– 13 –

3. RANGE OF APPLICATIONS

Generally, the power rating of an electrical appliance indicates the amount of work that can be done by it.

The electric power required for operating an electrical appliance is not always equal to the output wattage

of the appliance. The electrical appliances generally have a label showing their rated voltage, frequency,

and power consumption (input wattage). The power consumption of an electrical appliance is the power

necessary for using it. When using a generator for operating an electrical appliance, the power factor and

starting wattage must be taken into consideration.

In order to determine the right size generator, it is necessary to add the total wattage of all appliances to

be connected to the unit.

Refer to the followings to calculate the power consumption of each appliance or equipment by its type.

(1) Incandescent lamp, heater, etc. with a power factor of 1.0

Total power consumption must be equal to or less than the rated output of the generator.

Example : A rated 3000W generator can turn thirty 100W incandescent lamps on.

(2)

Fluorescent lamps, motor driven tools, light electrical appliances, etc. with a smaller power factor

Select a generator with a rated output equivalent to 1.2 to 2 times of the power consumption of the

load. Generally the starting wattage of motor driven tools and light electrical appliances are 1.2 to 3

times lager than their running wattage.

Example : A rated 250 W electric drill requires a 400 W generator to start it.

NOTE 1: If a power factor correction capacitor is not applied to the fluorescent lamp, the more power

shall be required to drive the lamps.

NOTE 2: Nominal wattage of the fluorscent lamp generally indicates the output wattage of the lamp.

Therefore, if the fluorescent lamp has no special indication as to the power consumption,

efficiency should be taken into account as explained in ltem (5) on the following page.

(3) Mercury lamps with a smaller power factor

Loads for mercury lamps require 2 to 3 times the indicated wattage during start-up.

Example : A 400 W mercury lamp requires 800 W to 1200 W power source to be turned on. A rated

3000 W generator can power two or three 400 W mercury lamps.

(4) Initially loaded motor driven appliances such as water pumps, compressors, etc.

These appliances require large starting wattage which is 3 to 5 times of running wattage.

Example : A rated 900 W compressor requires a 4500 W generator to drive it.

NOTE 1: Motor-driven appliances require the aforementioned generator output only at the starting.

Once their motors are started, the appliances consume about 1.2 to 2 times their rated power

consumption so that the excess power generated by the generator can be used for other

electrical appliances.

NOTE 2: Motor-driven appliances mentioned in items (3) and (4) vary in their required motor starting

power depending on the kind of motor and start-up load. If it is difficult to determine the

optimum generator capacity, select a generator with a larger capacity.

Page 17

– 14 –

(5) Appliances without any indication as to power consumption

Some appliances have no indication as to power consumption; but instead the work load (output) is

indicated. In such a case, power consumption is to be worked out according to the numerical formula

mentioned below.

Efficiencies of some electrical appliances are as follows :

Single-phase motor . . . . . .0.6 to 0.75 (The smaller the motor, the lower the efficiency)

Fluorescent lamp . . . . . . . .0.7 to 0.8

Example 1: A 40W fluorescent lamp means that its luminous output is 40W. Its efficiency is 0.7 and

accordingly, power consumption will be 40÷0.7= 57W. As explained in Item (2), multiply this

power consumption value of 57W by 1.2 to 2 and you will get the figure of the necessary

capacity of a generator. In other words, a generator with a rated output of 1000W capacity

can light nine to fourteen 40W fluorescent lamps.

Example 2: Generally speaking, a 400W motor means that its work load is 400W. Efficiency of this motor

is 0.7 and power consumption will be 400÷0.7= 570W. When this motor is used for a

motor-driven tool, the capacity of the generator should be multipled by 1.2 to 3 and 570W as

explained in the ltem (3). 570 (W) x 1.2 to 3 = 684 (W) to 1710 (W)

(Output of electrical appliance)

(Efficiency)

= (Power consumption)

Applicable Wattage (approx. W)

Applications

RGX2900

RGX3600 RGX4800

Incandescent lamp, Heater, etc

Fluorescent lamp, Electric tool, etc

Mercury lamp, etc

Pump, Compressor, etc

2000

1100 1200

800 900

500 550

2400

2400 2900

1200 1500

900 1100

550 650

50Hz 60Hz50Hz 60Hz50Hz 60Hz

3500 4100

1800 2100

1300 1500

800 950

Page 18

– 15 –

NOTES : Wiring between generator and electrical appliances

1. Allowable current of cable

Use a cable with an allowable current that is higher than the rated input current of the load (electrical

appliance). If the input current is higher than the allowable current of the cable used, the cable will

become excessively heated and deteriorate the insulation, possibly burning it out. The table below

shows cables and their allowable currents for your reference.

2. Cable length

If a long cable is used, a voltage drop occurs due to the increased resistance in the conductors

decreasing the input voltage to the load (electrical product). As a result, the load can be damaged.

The table below shows voltage drops per 30 meters of cable.

2

Allowable

Current

Cable

Resistance

Ω/100m

1.486

0.952

0.517

0.332

1

100

Voltage drops per 30 meters of cable

R : Resistance (Ω/100m)

Cross

sectional

Voltage drop indicates as V= x R x I x L

I : Electric current (A)

L : Length (m)

The length of wire (L) indicates round length, which is the length from the generator

to the electrical tools and back.

2

<Example>

R : Resistance 1.25mm

= 1.48 Ω/100m

I : Electric current 10A

L : Length 30m

The voltage drop of the case described above is

30A25A20A15A10A5AAmm

****8.9V4.5V121.25

***8.6V5.7V2.8V172.0

**6.2V4.7V3.1V1.6V233.5

6.0V5.0V4.0V3.0V2.0V1.0V355.5

1.48Ωx 10A x (30m x 2)

V =

100

≒ 8.9 (V)

Page 19

– 16 –

4. MEASURING AND CHECKING PROCEDURES

4-1 MEASURING INSTRUMENTS

(1) VOLTMETER

AC voltmeter is necessary.

The approximate AC voltage ranges of the

voltmeters to be used for various types of

generators are as follows :

0 to 150 V : Type with an output voltage of 110 or

120 V

0 to 300 V : Type with an output voltage of 220,

230 or 240 V

0 to 150 V, 0 to 330 V : Dual voltage type

(2) AMMETER

AC ammeter is necessary.

An AC ammeter with a range that can be changed

according to the current rating of a given generator

is most desirable. (About 10 A, 20 A, 100 A)

(3) FREQUENCY METER

Frequency range : To cover 45 to 65Hz

NOTE : Be careful of the frequency meter's input voltage

range.

For AC For DC

For AC For DC

Page 20

– 17 –

(5) MEAGER TESTER

Used for measuring generator insulation resistance.

Select the one with testing voltage range of 500V.

(4) CIRCUIT TESTER

For measuring resistance, etc.

NOTE : The ordinary circuit tester may cause erroneous

readings due to their measuring method.

Use a high-grade, precise circuit tester to check

the generator components.

(6) TACHOMETER

Use the contactless type tacho meter for checking

engine speed.

Page 21

– 18 –

(7) "Dr.Robin" GENERATOR TESTER

The "Dr.Robin" generator tester is exclusively

designed for fast, easy diagnosis and repair of

Robin generators.

The "Dr.Robin" has the following features :

1) Functions of voltmeter, frequency meter, megger

tester, capacitance meter and circuit tester are

combined in one unit.

2) Fast and easy readout by digital indicator.

3) Built-in automatic battery checker indicates the

time to change batteries.

4) Tester and accessories are installed in a handy,

sturdy case for easy carrying.

The "Dr.Robin" generator tester can be ordered from Robin generator distributors by the following part number.

Dr.Robin_Part_Number_:_388-47565-08

If you do not have a "Dr.Robin" generator tester, use the instruments described in the following section for

checking generator parts.

●

SPECIFICATIONS

MODEL Dr.Robin

Part Number

Voltage

Frequency

Measuring

Range

Resistance

Condenser Capacity

Insulation Resistance

Circuit Protector

Power Source

Accessories

Dimensions (L x W x H)

2 x 6F44P (006P) Dry Cell Battery

Te st leads with needle probes ... 1 set

Te st leads with jack plugs ... 1 set

285 mm x 200 mm x 110 mm

Weight

388-47565-08

0 to 500 V AC

25 to 70 Hz

0.1 to 1,999 Ω

10 to 100μF

3MΩ

Fuse

1.6 kg

Page 22

– 19 –

4-2 AC OUTPUT MEASURING

Use a circuit above for measuring AC output. A hot plate or lamp with a power factor of 1.0 may be used as a

load. Adjust the load and rpm, and check that the voltage range is as specified in the following table at the

rated amperage and rated rpm.

4-3 DC OUTPUT MEASURING

Measurement of DC output is executed with the switch turned ON while the current is regulated at 8.3A by

adjusting the load to the generator. If the voltage is within the range from 6V to 14V, the voltage output is

normal.

NOTE : If a battery is connected as a load to the generator, the DC output voltage will increase by

approximately 1 to 2 V.

Therefore, carefully observe the electrolyte level and do not overcharge the battery.

SWITCH

A

~

TO AC RECEPTACLE

Model

50Hz-220V,230V 60Hz-120/240V

F

Specification

50Hz-240V

RGX2900

RGX3600

207-238

226-259

V

~

226-259

113-130

LOAD

RGX4800

Voltage range

SW

To DC Terminal

Load

Page 23

– 20 –

4-4 MEASURING INSULATION RESISTANCE

Use a “Dr. Robin” generator tester in megger tester

mode or use a megger tester to check the insulation

resistance. Connect a megger tester to one of

receptacle output terminals and the ground terminal,

then measure the insulation resistance. An insulation

resistance of 1 megohm or more is normal. (The original

insulation resistance at the time of shipment from the

factory is 10 megohm or more.) If it is less than 1

megohm, disassemble the generator and measure the

insulation resistance of the stator, rotor and control

panel individually.

●

STATOR

Measure insulation resistance between each terminal

from the stator and the stator core.

Measured insulation resistance of 1M ohm or

more is normal.

If it is less than 1M ohm, leakage current and

electric shock might occur due to faulty insulation.

Replace with new one.

●

CONTROL PANEL

With AC circuit breaker turned on, measure insulation

resistance between each portion of electrical parts

and earth (grounding) terminal or control panel itself.

Measured insulation resistance of 1M ohm or

more is normal.

If it is less than 1M ohm, leakage current and electric

shock might occur due to faulty insulation.

Replace with new one.

Any part where the insulation resistance is less than 1M

Ω has faulty insulation, and may cause electric leakage

and electric shock.

Replace the faulty part.

Page 24

– 21 –

4-5 CHECKING FUNCTIONAL MEMBERS

(1) STATOR

Disengage connectors on the wires from stator and

check the resistance between the wires using a circuit

tester referring to the table below.

NOTE :

If the circuit tester is not sufficiently accurate, it may not show the values given and may give erroneous readings.

Erroneous readings will also occur when there is a wide variation of resistance among coil windings or

when measurement is performed at ambient temperature different from 20°C (68°F).

(2) ROTOR

Measure resistance between the field coil.

NOTE1 :

When measuring the field coil resistance, be sure

to disconnect the soldering connection and take

out diode rectifier and surge absorber.

NOTE2 :

When measuring, tolerance should be considered

because of the tester inaccuracy, winding number

variation, ambient temperature etc.

Coils

(Wire color)

AC coil 1

(Black - Blue)

AC coil 2

(Red - White)

Condenser coil

(Yellow - Yellow)

DC coil

(Brown - Brown)

50Hz-220V

50Hz-230V

0.8 0.6 0.4

0.8 0.6 0.4

2.2 1.3 0.9

0.3 0.2 0.2

RGX2900 RGX4800RGX3600

50Hz-240V

0.9

0.9

2.2

0.3

60Hz-120/240V

0.6

0.6

1.7

0.2

Coil resistance (Ω)

50Hz-220V

50Hz-230V

50Hz-240V

0.7

0.7

1.3

0.2

60Hz-120/240V

0.4

0.4

1.0

0.2

50Hz-220V

50Hz-230V

50Hz-240V

0.4

0.4

0.9

0.2

60Hz-120/240V

0.3

0.3

0.6

0.1

Coil resistance (Ω)

RGX2900 RGX4800RGX3600

Field coil

1.8 1.61.6

Page 25

– 22 –

The diode rectifier and surge absorber are located as

shown in the following illustrations.

SURGE ABSORBER

DIODE

RECTIFIER

RGX4800

RGX2900/3600

(3) SURGE ABSORBER

Measure the surge absorber resistance.

Resistance (Ω)

∞Ω

SURGE ABSORBER

DIODE RECTIFIER

Page 26

– 23 –

(4)AC CIRCUIT BREAKER

Check continuity between each of two terminals at the

rear of the AC circuit breaker while it is mounted on

the control panel.

(5) DC CIRCUIT BREAKER

Make sure that there is continuity between the two

terminals of DC circuit breaker when its push button

is pressed.

AC circuit breaker

OFF

:No continuity

ON :Continuity

RGX2900 RGX3600/4800

A

A

B

B

Page 27

– 24 –

(9) FLOAT TYPE OIL SENSOR

Check the oil sensor when it is installed on the engine.

Check that sufficient engine oil is filled in the crankcase.

Check that there is continuity between the lead wire of

oil sensor and the ground (engine crankcase) when the

oil level is above the minimum level mark of oil gauge.

Check that there is no continuity as above when the oil

level is below the minimum level mark of oil gauge.

(8) AC RECEPTACLES

Make sure that no live part wire or plastic part is burnt out.

(6) CONDENSER

Use "Dr. ROBIN" in capacitance mode to check the

capacity of condenser.

NOTE: Be sure to discharge by shorting condenser leads

each other before checking the capacitance, or the

accurate reading cannot be obtained.

If such instrument is unavailable, the condenser can be

checked by replacing with new one.

If the generator performs good with new condenser, the

cause of trouble is defect in original condenser.

MODEL RGX290024RGX360037RGX4800

CAPACITY(μF)

20 and 30

Oil sensor

Page 28

– 25 –

5. DISASSEMBLY AND ASSEMBLY

5-1 PREPARATION AND PRECAUTIONS

(1) Be sure to memorize the location of individual parts when disassembling the generator so that the generator

can be reassembled correctly. Tag the disassembled part with the necessary information to facilitate easier and

smoother reassembly.

(2) For more convenience, divide the parts into several groups and store them in boxes.

(3) To prevent bolts and nuts from being misplaced or installed incorrectly, replace them temporarily to their

original position.

(4) Handle disassembled parts with care; clean them before reassembly using a neutral cleaning fluid.

(5) Remove the battery before disassembling the generator. (Electric start models)

(6) Use all disassembly/assembly tools properly, and use the proper tool for each specific job.

(7) Be sure to attach the foam rubber linings inside the covers on their original position when reassembling the

generator. When deformation or damage or falling-off of foam rubber lining is found, replace it with new part.

Failure to do so will result in poor performance and durability of the generator.

(8) Bind the wires and fuel pipes using wire bands as they have been done in original configuration.

NOTE : As to detailed information for servicing procedures on engine portion, please refer to Robin engine service

manual for "EX series".

NOTE : Illustrations adopted for the following procedures are ones for RGX4800 model.

Also illustrations for RGX2900/3600 are adopted as necessary.

Page 29

– 26 –

5-2 DISASSEMBLY PROCEDURES

5-2-1 Fuel Draining

(1) Make sure fuel strainer cock is closed.

Disconnect fuel pipe from carburetor.

Turn fuel cock lever to the OPEN position, and the drain

fuel from fuel tank.

Tool : Pliers

(2) Remove drain screw from carburetor, and drain fuel

from carburetor.

After draining, install drain screw in position.

Tool : Socket wrench (8 mm)

(3) Remove strainer and drain fuel from strainer cap.

After draining, install strainer in position.

Drain screw

Page 30

– 27 –

5-2-2 Fuel Tank

Remove bolts and take out fuek tank.

Fastener : M6 -12 mm Flange reamer bolts (2 pcs)

Tool : Box wrench (10 mm)

CAUTION :

Before removing fuel tank, make sure to drain

fuel from fuel tank and pipings.

NOTE : Don't forget to keep rubbers (2 pcs) commonly

fixed with bolts.

Fuel tank

Cussion rubber

Control panel

side

Frange reamer bolt

Cussion rubber

Rubber

Page 31

– 28 –

5-2-3 Electric Connectors

Remove bushing from control panel on back side, pull out

wiring harness connectors, and then disconnect electric

wirings.

Disconnect electric wirings from engine switch terminals.

5-2-4 Control Panel

Remove screws and take out control panel from frame.

Fastener : M6 - 12 mm Screws (4 pcs)

Tool : Box wrench (10 mm)

5-2-5 Muffler

(1) Remove screws and take out cover from engine.

Fastener : M6 - 12 mm Flange bolts (3 pcs)

Tool : Box wrench (10 mm)

Page 32

– 29 –

(3) Remove muffler and cover.

Fastener : M8 - 10 mm Flange bolts (6 pcs)

Tool : Box wrench (12 mm)

(4) Remove muffler bracket commonly fixed with alternator.

Fastener :

M8 - 20 mm Bolt & washers (2 pcs-RGX 4800)

M8 Flange nuts (2 pcs)

M8 - 20 mm Bolt & washers (4 pcs-RGX 2900/3600)

Tool : Socket wrench (12 mm)

(2) Remove nuts and take out exhaust pipe.

Fastener : M8 Flange nuts (2 pcs)

Tool : Box wrench (12 mm)

RGX2900/3600

Frange nut Bolt and washer AY

Muffler bracket B

Bolt and washer AY

Muffler bracket A

Page 33

– 30 –

5-2-8 Bushing

Take out bushing from rear cover, pinching with hand.

5-2-6 Rear Cover Arms and Grounding Terminal

Remove nuts fixing rear cover onto mounting rubbers.

Fastener : M8 Flange nuts (2 pcs)

Tool : Box wrench (12 mm)

5-2-7 Stator Cover

Take out stator cover with crows (2 pcs) raised up by using

screw driver.

Tool : Screwdriver

Grounding

Terminal

Page 34

– 31 –

5-2-9 Rear Cover

(1) Remove stator bolts (RGX4800) or cover bolts

(RGX2900/3600).

Fastener : M6 - 150 mm Stator bolts (4 pcs - RGX4800)

M6 -130 mm Cover bolts (3 pcs - RGX3600)

M6 -110 mm Cover bolts (3 pcs - RGX2900)

Tool : Box wrench (12 mm)

NOTE: For easy operation, set wooden pieces under the

alternator.

5-2-10 Wire CP

Remove screw and disconnect wire CP from inside rear

cover.

Fastener : M4 -6 mm Screw

Tool : Philips (cross-head) screwdriver

(2) Take off rear cover from stator, by lightly hitting at boss

portions with plastic hammer.

Tool : Plastic hammer

Wire CP

Screw

Page 35

– 32 –

5-2-12 Through Bolts

Remove through bolt, by tapping the wrench with plastic

hammer.

Fastener : M10x1.5 - 240 mm Through bolt (RGX4800)

M8x1.25 - 260 mm Through bolt (RGX3600)

M8x1.25 - 240 mm Through bolt (RGX2900)

Tool : Box-end wrench (14 mm) and Plastic hammer

5-2-13 Rotor

(1) Set the engine in the condition of recoil starter side

downward.

5-2-11 Stator

Take out stator, holding with hands.

Page 36

– 33 –

5-2-14 Front Cover

Remove bolts and washers and take out front cover.

Fastener : M8 - 20 mm Bolt & washers (4 pcs)

Tool : Box-end wrench (12 mm)

c. Apply a few turns of seal tape around the tip of the bolt.

d. Screw the bolt into the thread of the rotor shaft.

e. Torque up the bolt by using socket wrench until rotor

comes off loose.

NOTE: The hydraulic pressure inside the rotor shaft takes

apart the rotor from the engine PTO shaft.

f. Wipe off engine oil thoroughly from rotor, rotor shaft,

engine PTO shaft and front cover.

(2) Use engine oil and the bolt with seal tape as a tool for

pulling out rotor as follows;

a. Pour engine oil into the center (through bolt) hole of rotor

shaft.

b. prepare a bolt with the following thread size;

Model

RGX4800

RGX2900

RGX3600

Bolt

M12×1.5

M10×1.5

Seal tape

Page 37

– 34 –

5-3-1 Front Cover

Install front cover onto main bearing cover of the engine in

position.

Fastener :

M8 - 20 mm (4 pcs) Bolt with spring washer & washer

5-3-2 Rotor

Install rotor onto crankshaft.

Fastener :

M8x1.25 - 240 mm Through bolt with washer (RGX2900)

M8x1.25 - 260 mm Through bolt with washer (RGX3600)

M10x1.5 - 240 mm Through bolt with washer (RGX4800)

RGX2900/3600

NOTE: Before installing, clean and wipe off oil and foreign

materials from taper portion of crankshaft.

RGX4800

5-3 REASSEMBLY PROCEDURES

Tightening torque : 11.3

-

13.2 N・m

(115

-

135 kgf・cm)

(8.3-9.7 ft・lbs)

Tightening torque : 22.5-24.5 N・m

(230-250 kgf・cm)

(16.6

-

18.1ft・lbs)

Tightening torque : 11.8

-

13.7 N・m

(120-140 kgf・cm)

(8.7-10.1 ft・lbs)

Page 38

– 35 –

5-3-3 Stator

Install stator into front cover.

Adjust the stator grove position (4 places) so that stator bolt

can be tightened later. (RGX4800)

5-3-4 Wire CP

Fix wire CP at inside of rear cover in position.

Fastener : M4 -6 mm Screw

Tool : Philips (cross-head) screwdriver

(Stator bolt)

Stator bolt

fixed hole(4 places)

Grove

(4 places)

Roter

Stator

Front cover

Wire CP

Screw

Page 39

– 36 –

5-3-5 Rear Cover

(1) Install rear cover over stator, lightly hitting at the center

portion of rear cover with plastic hammer.

Tool : Plastic hammer

(2) Tighten stator bolts (RGX4800) or cover bolts

(RGX2900/3600).

Fastener : M6 - 150 mm Stator bolts (4 pcs - RGX4800)

M6 - 130 mm Cover bolts (3 pcs - RGX3600)

M6 - 110 mm Cover bolts (3 pcs - RGX2900)

Tool : Box wrench (12 mm)

RGX2900/3600

5-3-6 Bushing

Insert wirings into bushing, and push bush (big grove side)

into rear cover hole.

Tightening torque : 4.5

-

5.9 N・m

(50

-

60 kgf・cm)

(3.6-4.3 ft・lbs)

RGX4800

Tightening torque : 11.8-13.7 N・m

(120-140 kgf・cm)

(8.7-10.1 ft・lbs)

Page 40

– 37 –

5-3-8 Rear Cover Arm and Grounding Terminal

Fix rear cover arms with mount rubbers, along with

grounding terminal.

Fastener : M8 Flange nuts (2 pcs)

Tool : Box wrench (12 mm)

5-3-7 Stator Cover

Set stator cover with the crow inserted into slit and bent

(2 pcs).

Tool : Screwdriver

Tightening torque : 11.8-13.7 N・m

(120

-

140 kgf・cm)

(8.7

-

10.1 ft・lbs)

Grounding

Terminal

Page 41

– 38 –

(2) Install muffler and cover.

Fastener : M8 - 10 mm Flange bolts (6 pcs)

Tool : Box wrench (12 mm)

(3) Install exhaust pipe.

Fastener : M8 Flange nuts (2 pcs)

Tool : Box wrench (12 mm)

5-3-9 Muffler

(1) Install muffler bracket.

Fastener

: M8 - 20 mm Bolt & washers (2 pcs - RGX4800)

M8 Flange nuts (2 pcs)

M8 - 20 mm Bolt & washers (4 pcs - RGX2900/3600)

Tool : Socket wrench (12 mm)

Tightening torque : 11.8-13.7 N・m

(120-140 kgf・cm)

(8.7-10.1 ft・lbs)

Tightening torque : 11.8

-

13.7 N・m

(120

-

140 kgf・cm)

(8.7-10.1 ft・lbs)

Tightening torque : 11.8-13.7 N・m

(120-140 kgf・cm)

(8.7

-

10.1 ft・lbs)

Page 42

– 39 –

(4) Attach exhaust pipe cover.

Fastener : M6 - 12 mm Flange bolts (3 pcs)

Tool : Box wrench (10 mm)

5-3-11 Electric Connectors

(1) Connect all wirings of the same appearance each other

between control panel and alternator.

5-3-10 Control Panel

Fix control panel into frame.

Fastener : M6 - 12 mm Screws (4 pcs)

Tool : Box wrench (10 mm)

Tightening torque : 4.5

-

5.9 N・m

(50

-

60 kgf・cm)

(3.6-4.3 ft・lbs)

Tightening torque : 4.5-5.9 N・m

(50

-

60 kgf・cm)

(3.6

-

4.3 ft・lbs)

Page 43

– 40 –

5-3-12 Fuel Tank

(1) Set fuel tank with cushion rubber sliding into stay

(2 places).

(2) Fix with bolts.

Fastener : M6 -12 mm Flange reamer bolts (2 pcs)

Tool : Box wrench (10 mm)

(2) Push into bushing into the hole on the back side of

control panel.

Also connect electric wirings with engine switch

terminals. Either wiring can be connected with terminal.

Tightening torque : 4.5-5.9 N・m

(50

-

60 kgf・cm)

(3.6-4.3 ft・lbs)

Cussion rubber

Stay

Control panel

side

Page 44

– 41 –

5-3-13 Fuel piping

Connect fuel pipe to carburetor with clam.

Tool : Pliers

Fuel pipe

Clamp

Carburetor

Page 45

– 42 –

6. TROUBLE SHOOTING

Check if engine speed is normal.

50Hz : 3,000rpm

60Hz : 3,600rpm

OK

Check if stator coil is normal.

Main coil

OK

Check if rotor coil is normal.

NG

NG

NG

Refer to

"Engine dose not start (Start failure )"

Replace

Replace

OK

Check if condenser coil is normal.

OK

Check if wiring is break or

improper connection.

NG

NG

Replace

Replace when wiring is break or damage.

Connect properly.

Page 46

– 43 –

No DC current

Check if DC coil of stator is normal.

OK

Check if diode rectifier is normal.

OK

Check if DC circuit breaker is normal.

OK

NG

NG

NG

Replace

Replace

Replace

Check if wiring is break or

improper connection.

NG

Replace when wiring is break or damage.

Connect properly.

Page 47

– 44 –

Engine does not start (Start failure)

Check the gasoline

in the tank

Yes

Check the oil volume

Yes

Confirm of the oil SW

E/g

GND

Fuel cock is in

the ON position

Gasoline leaks when the

carburetor drain is loosened

Tester

Yes

Yes

None

None

Resistance

value≒0 Ω

NO

NO

Open

the cock

Clean,

change

the filter

Add gasoline

Add oil (up to the

rated volume)

Change the Oil sensor unit

Check for

gasoline corrosion

OK

Remove the spark plug

and check the electrode

Wet

Attach the plug to the plug

cap, and check for sparks

by grounding the electrode

Sparks

Check the valve clearance

of the compressed pressure

(compression)

Corrosion

Dry

No spark

NG

Change

gasoline

Blockage of the fuel tube

carburetor, such as noise, etc.

・Check for dirty plugs, or gap

・Check the connection

(coupler, high tension cord)

Adjustment

Page 48

7. WIRING DIAGRAM

(60Hz-120V) RGX2900 [U.S.A. model]

ENGINE

Oil sensor

Ignition coil

Spark plug

GENERATOR

Rotor

Condenser

Winding

Field

Winding

AC

Winding 1

Winding 2

AC

DC

Winding

Blk

Blu

R

W

Brn

Brn

Y

Y

CONTROL BOX

Blk

Grn

Hour

meter

AC circuit

breaker

Hr

Diode stack

Assy

Pilot

lamp

Org

Brn/W

Condenser

PL

Engine switch

R

Rec

Circuit breaker

Grn

Wiring color code

Blk : Black

Blk/W : Black/White

Blu : Blue

LBlu : Light blue

Brn : Brown

Brn/W : Brown/White

Grn : Green

Grn/W : Green/White

Org : Orange

Gry : Gray

R : Red

W : White

Y : Yellow

W/Blk : White/Black

Grn/Y : Green/Yellow

Pur : Purple

Grn

Gry

WH

DC output

terminal

Earth

(Ground)

terminal

(60Hz-120/240V) RGX3600 [U.S.A. model]

ENGINE

Oil sensor

Blk

Blu

R

W

Brn

Brn

Y

Y

Blk

LBlu

W

W

Hour

meter

Hr

Ignition coil

Spark plug

Solenoid

GENERATOR

Rotor

Condenser

Winding

Field

Winding

AC

Winding 1

AC

Winding 2

DC

Winding

Charge coil

CONTROL BOX

Grn

Blu

Idle control switch

AC circuit

breaker

Pilot

PL

lamp

Engine switch

Full power

switch

1

2

3

4

5

6

7

8

9

Diode stack

Assy

Condenser

3

2

1

5

Org

Brn/W

control

Idle

unit

Rec1

Circuit breaker

Rec2

Grn

G

X

W

G

Y

X

W

Rec3

DC output

terminal

G

WH

Gry

Earth

(Ground)

terminal

– 45 –

Page 49

(60Hz-120/240V) RGX4800 [U.S.A. model]

ENGINE

Oil sensor

Ignition coil

Spark plug

Solenoid

GENERATOR

Rotor

Condenser

Winding

Field

Winding

AC

Winding 1

AC

Winding 2

DC

Winding

Charge coil

Blk

Blu

R

W

Brn

Brn

Y

Y

Blk

Blu

LBlu

W

W

Hour

meter

CONTROL BOX

Grn

Idle control switch

AC circuit

breaker

Pilot

lamp

Hr

PL

Engine switch

Full power

switch

2

5

8

Diode stack

Assy

1

3

4

6

7

9

3

2

1

5

Org

Brn/W

control

CondenserCondenser

Idle

unit

Rec1

Circuit breaker

Wiring color code

Blk : Black

Blk/W : Black/White

Blu : Blue

LBlu : Light blue

Brn : Brown

Brn/W : Brown/White

Grn : Green

Grn/W : Green/White

Org : Orange

Gry : Gray

R : Red

W : White

Y : Yellow

W/Blk : White/Black

Grn/Y : Green/Yellow

y

Gr

Earth

(Ground)

terminal

Grn

Circuit

breaker

X

Y

W

Rec2

G

Rec3

G

W

X

DC output

terminal

G

WH

Pur : Purple

(60Hz-120/240V) RGX4800 w / Starter motor [U.S.A. model]

ENGINE

-

+

Battery

Oil sensor

Ignition coil

Spark plug

Solenoid

GENERATOR

Rotor

Condenser

Winding

Field

Winding

Electric

starter

Magnetiec switch

Charge coil

Blk

AC

Winding 1

Blu

R

AC

Winding 2

W

Brn

DC

Winding

Brn

Y

Y

Hour

meter

Blu

LBlu

W

W

CONTROL BOX

Idle control switch

AC circuit

breaker

Pilot

lamp

Hr

Fuse

Org

Blk

Diode stack

Assy

3

Idle

2

control

1

unit

5

Full power

switch

1

2

PL

3

4

5

6

7

8

9

Diode stack

Assy

Org

Brn/W

CondenserCondenser

Key switch

B

ST

+M

R

Grn

Rec1

G

WH

Circuit breaker

IG

-M

X

Circuit

breaker

Grn

Rec2

G

Y

W

Rec3

DC output

terminal

Grn

Gry

G

W

X

Earth

(Ground)

terminal

– 46 –

Page 50

940 Lively Blvd. • Wood Dale, IL 60191 • Phone: 630-350-8200 • Fax: 630-350-8212

e-mail: sales@robinamerica.com • www.robinamerica.com

© Copyright 2006 Robin America, Inc.

PRINTED IN THE USA

Loading...

Loading...