Specifications and Main Features

Engine: R 1200

Model: Forced air-cooled, 4-stroke, side valve gasoline engine

Displacement: 143 cc(8.73 cu.in)

Fuel tank capacity: 3.5 liters (0.93 U.S. gal)

Oil pan capacity: 600 cc (1.28 U.S. pints)

Ignition system: Solid state ignition system

Starting system: Recoil starter

Rated continuous operating hours: Approx.3.5 hours (at rated load of 50 Hz)

Generator type: 2 pole, revolving field type

Exciting system: Self exciting type

Voltage regulating system: AVR(Automatic Voltage Regulator)

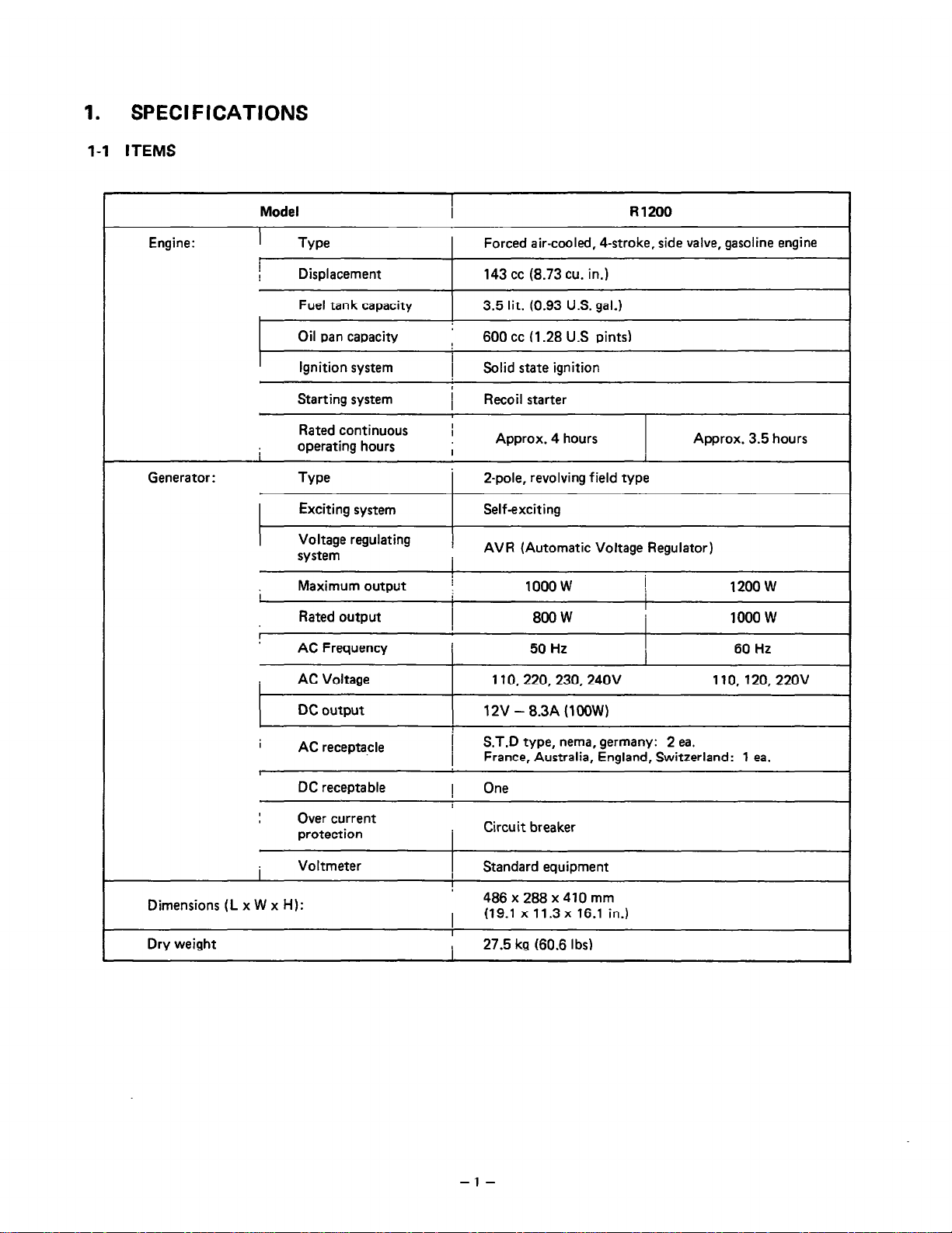

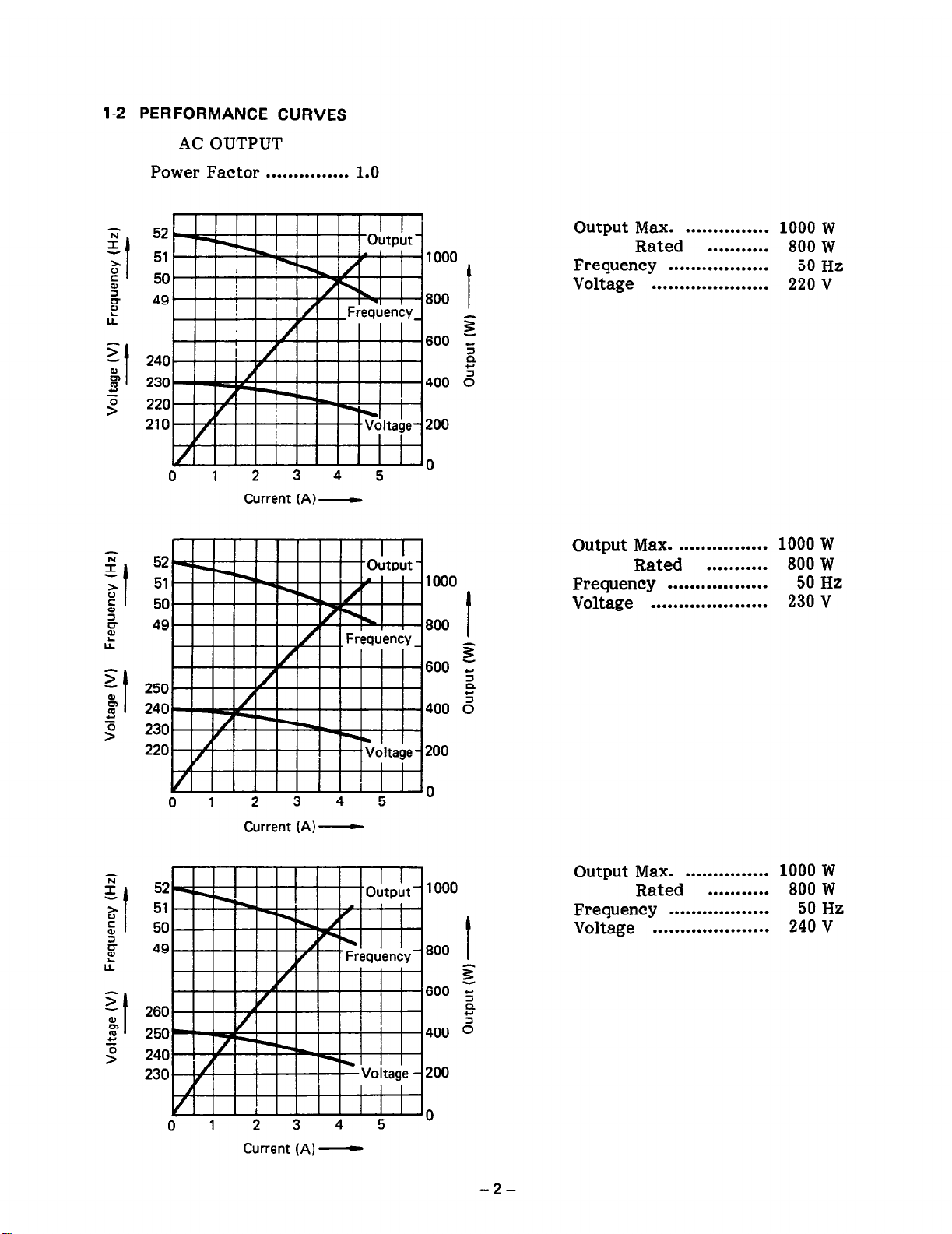

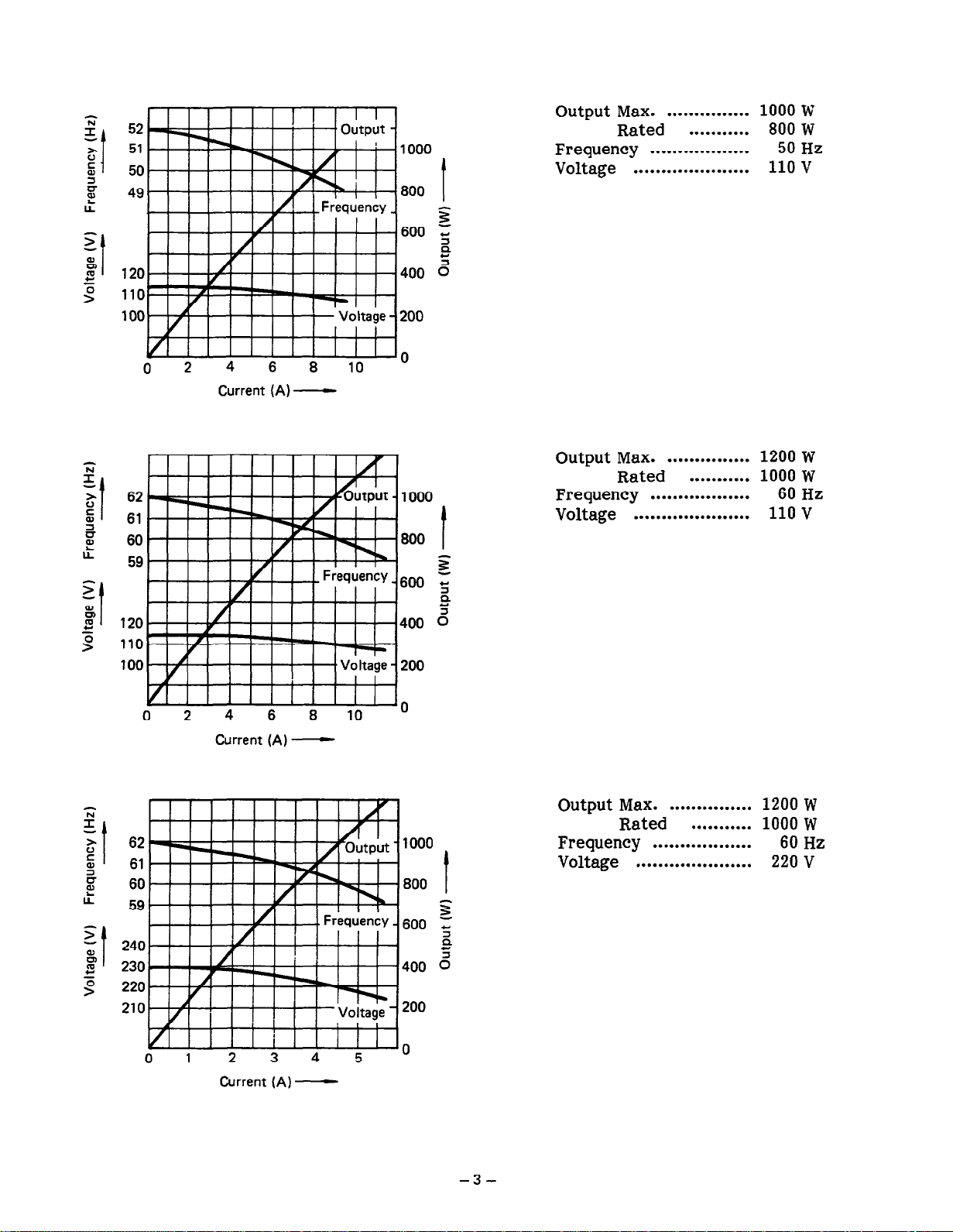

Maximum output: 1000 W

Rated output: 800 W (50Hz), 1000 W(60Hz)

Ac frequency: 50 Hz/60 Hz

Ac voltage rating: 110V, 220V, 230V, 240V (50Hz) / 110V, 120V, 220V (60Hz)

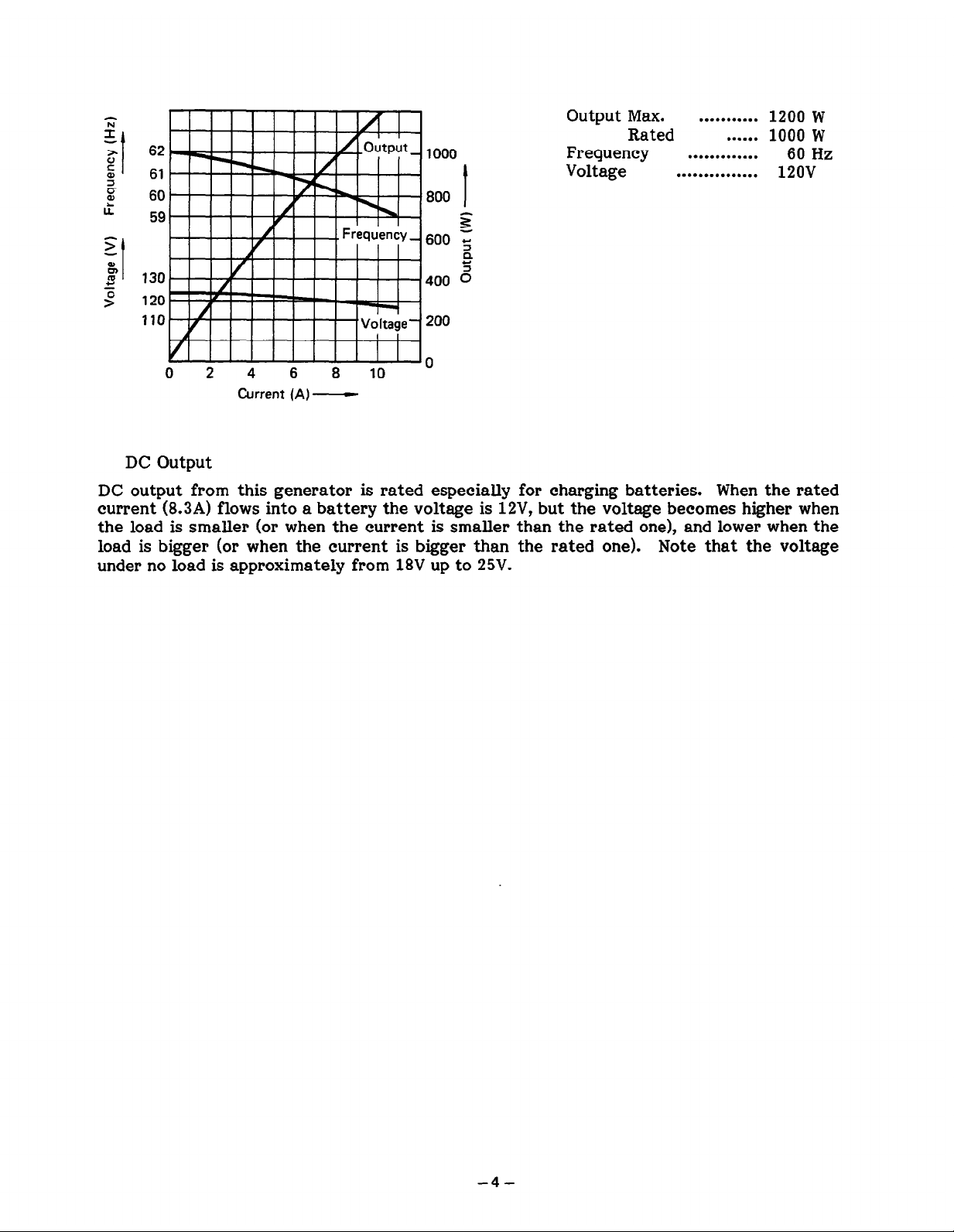

Dc output: 12V — 8.3A (100W)

Ac receptacles: 2 ea. (S.T.D type, nema, germany)), 1 ea. (France Australia England Switzerland)

Dc receptacles: One

Over current protection: Circuit breaker

Voltmeter: Standard equipment items

Dimension (Length x Width x Height): 486 x 288 x 410 mm (19.1 x 11.3 x 16.1 in)

Dry weight: 27.5 kg (60.6lbs)

Frequently Asked Questions

Q: What is the fuel tank capacity of the R1200 generator?

A: The fuel tank capacity is 3.5 liters (0.93 U. S. gal).

Q: How long can the generator run on a full tank?

A: Provided the current load is close to that rated for a frequency of 50 Hz, then the generator may be able to last for four hours within a single full tank.

Q: What is the most output power capacity of R1200?

A: The stated limit for all R1200 generators is up to 1000 W.

Q: Can both AC and DC outputs be drawn at the same time?

A: Yes, the generator allows for both AC and DC outputs to be used simultaneously provided the combined output does not exceed the specified capacity.

Q: Which engine is fitted on R1200?

A: It features forced air-cooled 4 stroke gasoline side valve engine.

Q: Calculate the weight of the R1200 generator?

A: Weight without fuel or oil is calculated at 27.5 kg (60.6 lb ).

Q: What are the AC voltage ratings available with the generator?

A: Depending on the frequency, voltages of 110V, 220V, 230V and 240V can be chosen as AC voltage levels.

Q: Which type of ignition system is installed in R1200?

A: The generator has a modern ignition solid state system.

Q: By What means is the generator ignited?

A: The device uses a recoil starter.

Q: Do we need to service the generator?

A:In most cases the generator will not require much attention but it is wise to examine and service the device periodically.

User Manual

SPECIFICATIONS

l-l ITEMS

1-2 PERFORMANCE CURVES

FEATURES

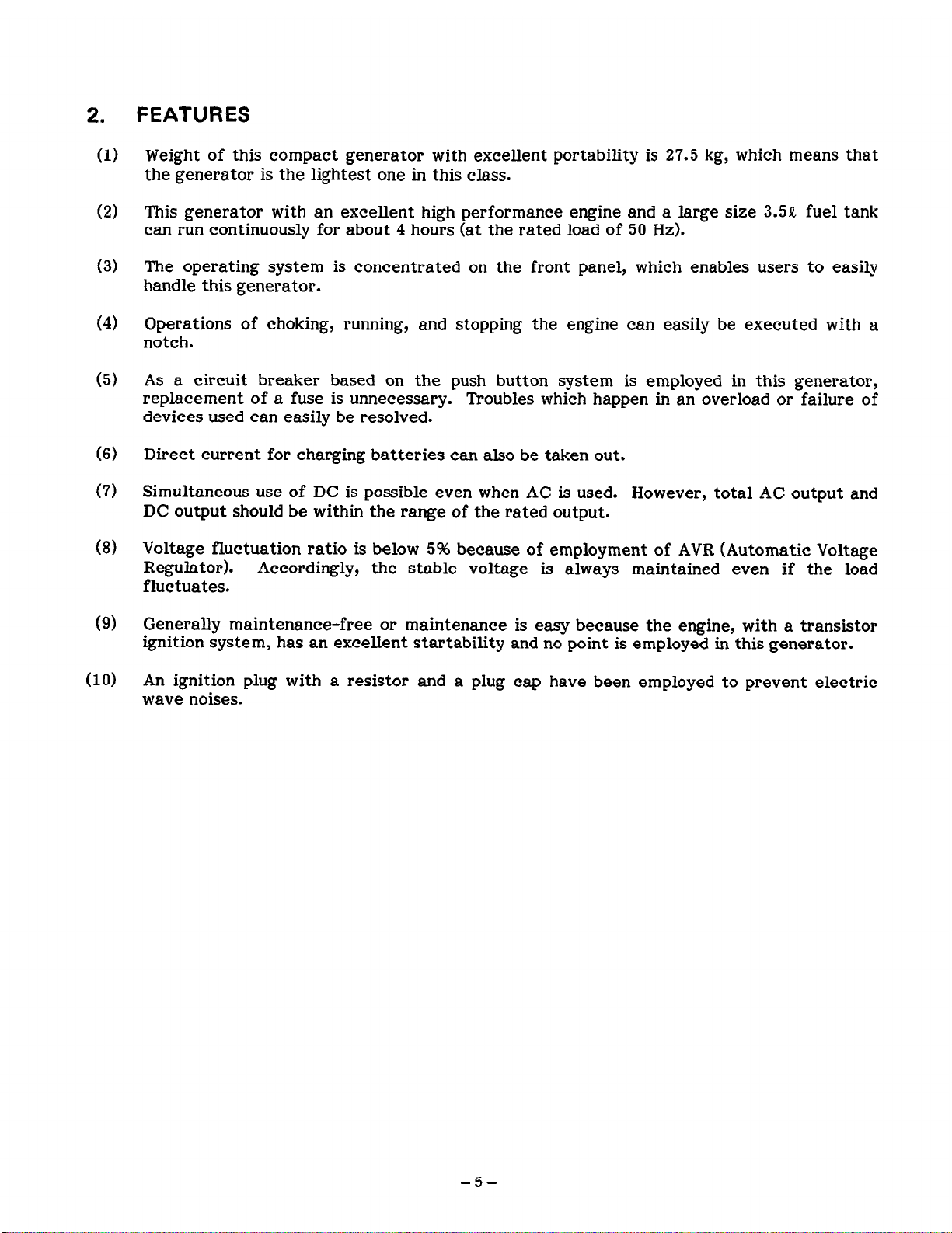

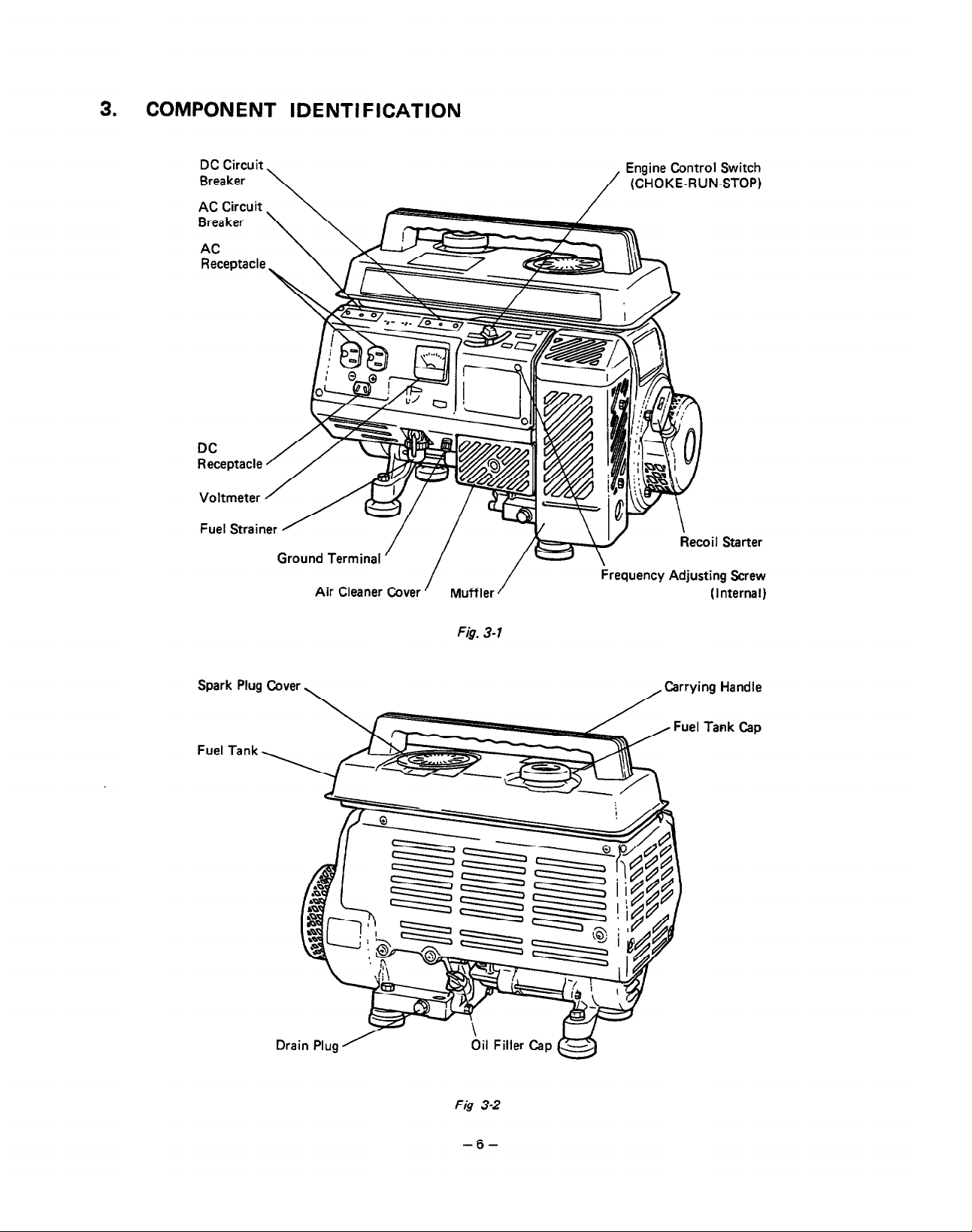

COMPONENT IDENTIFICATION

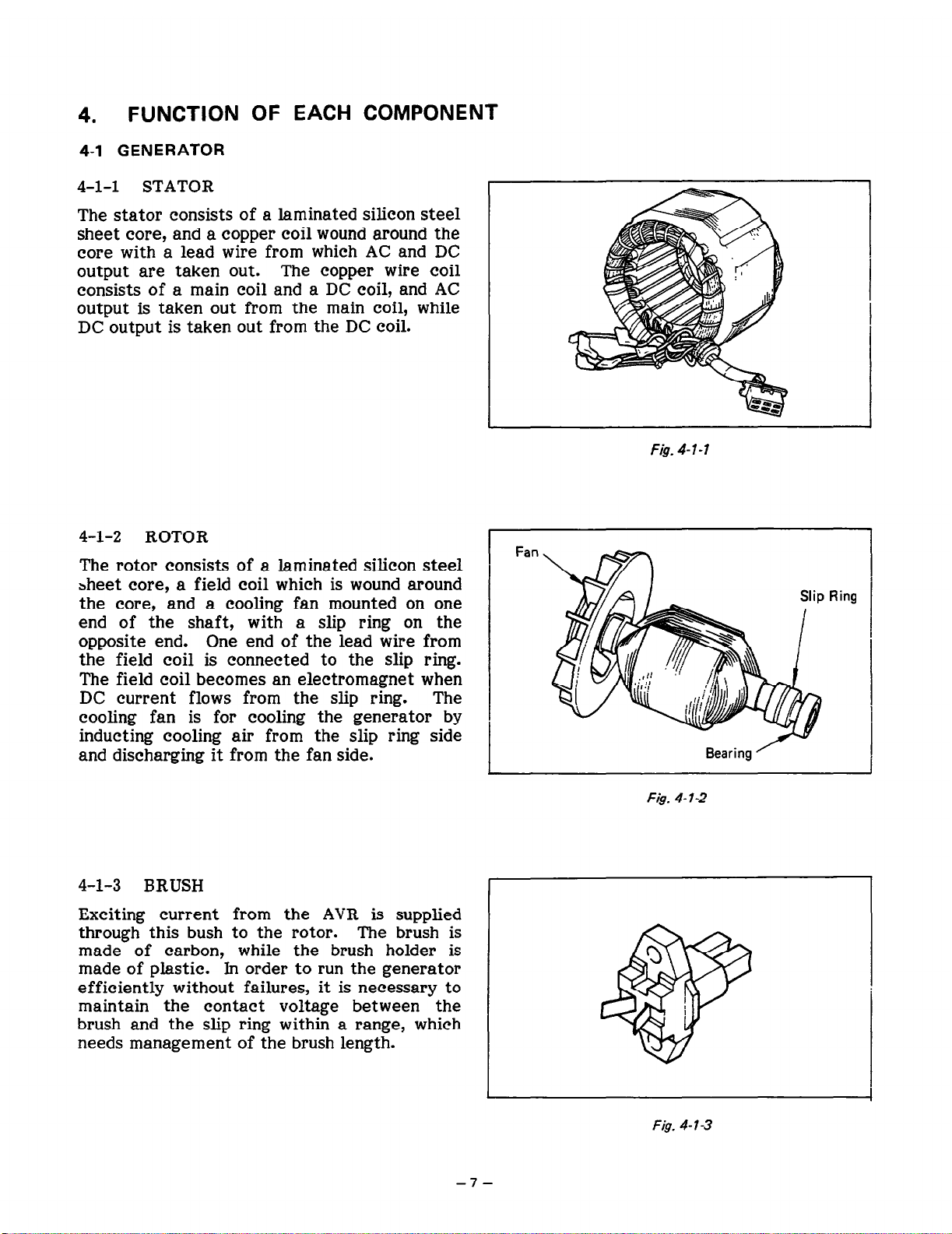

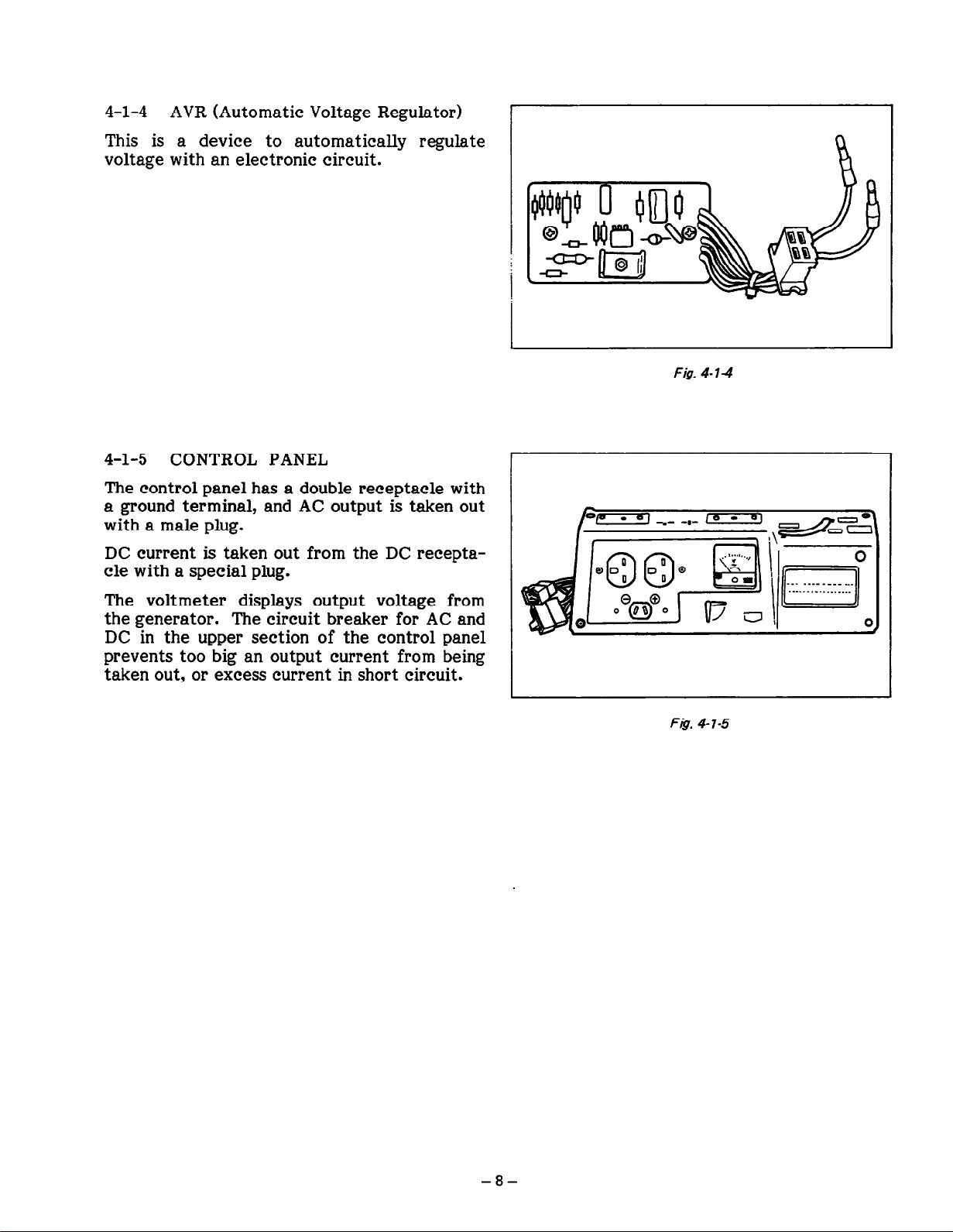

FUNCTION OF EACH COMPONENT

4-l GENERATOR

4-2 ENGINE

DESCRIPTION OF MAIN OPERATIONS

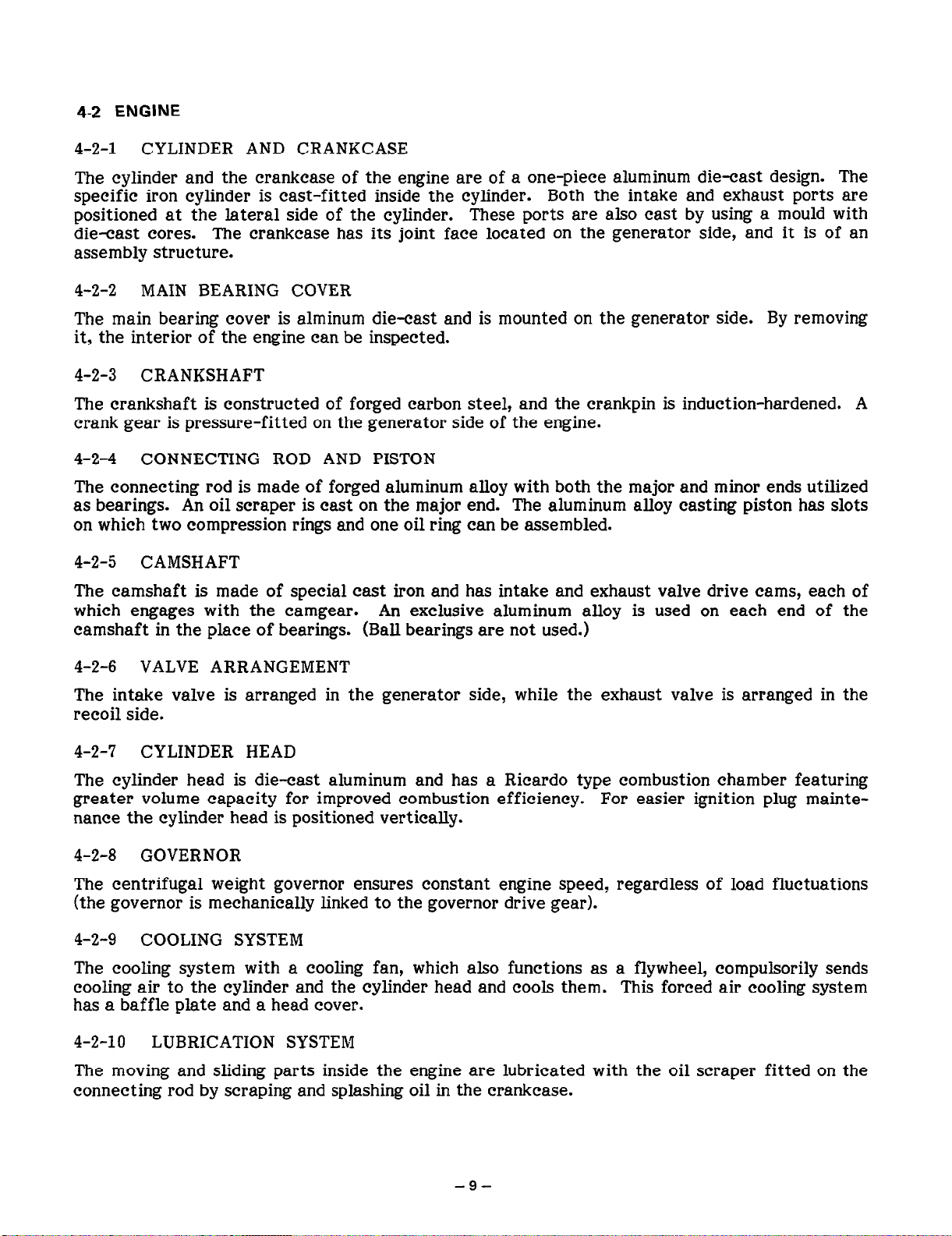

5-l ELECTRONIC IGNITION MECHANISM

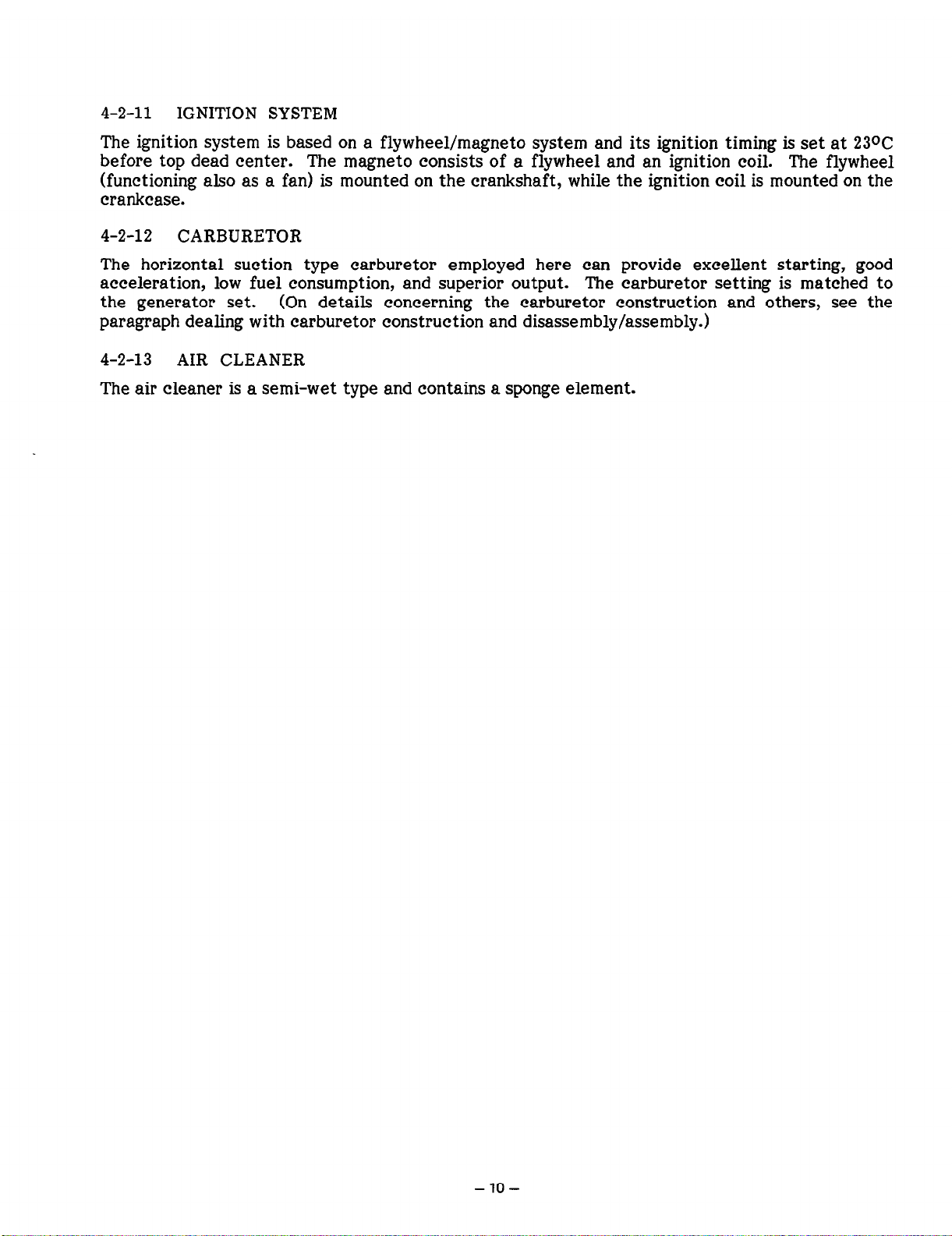

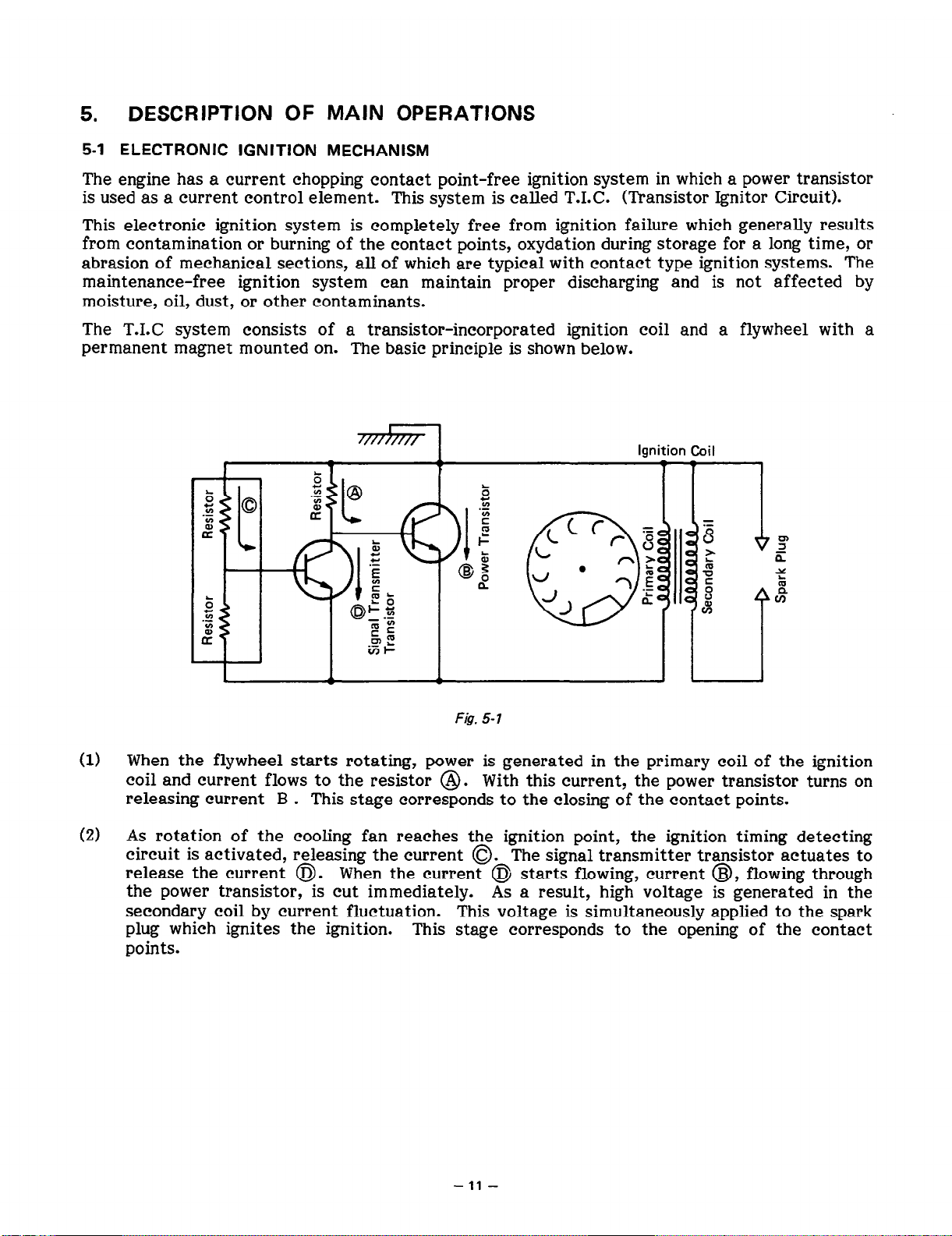

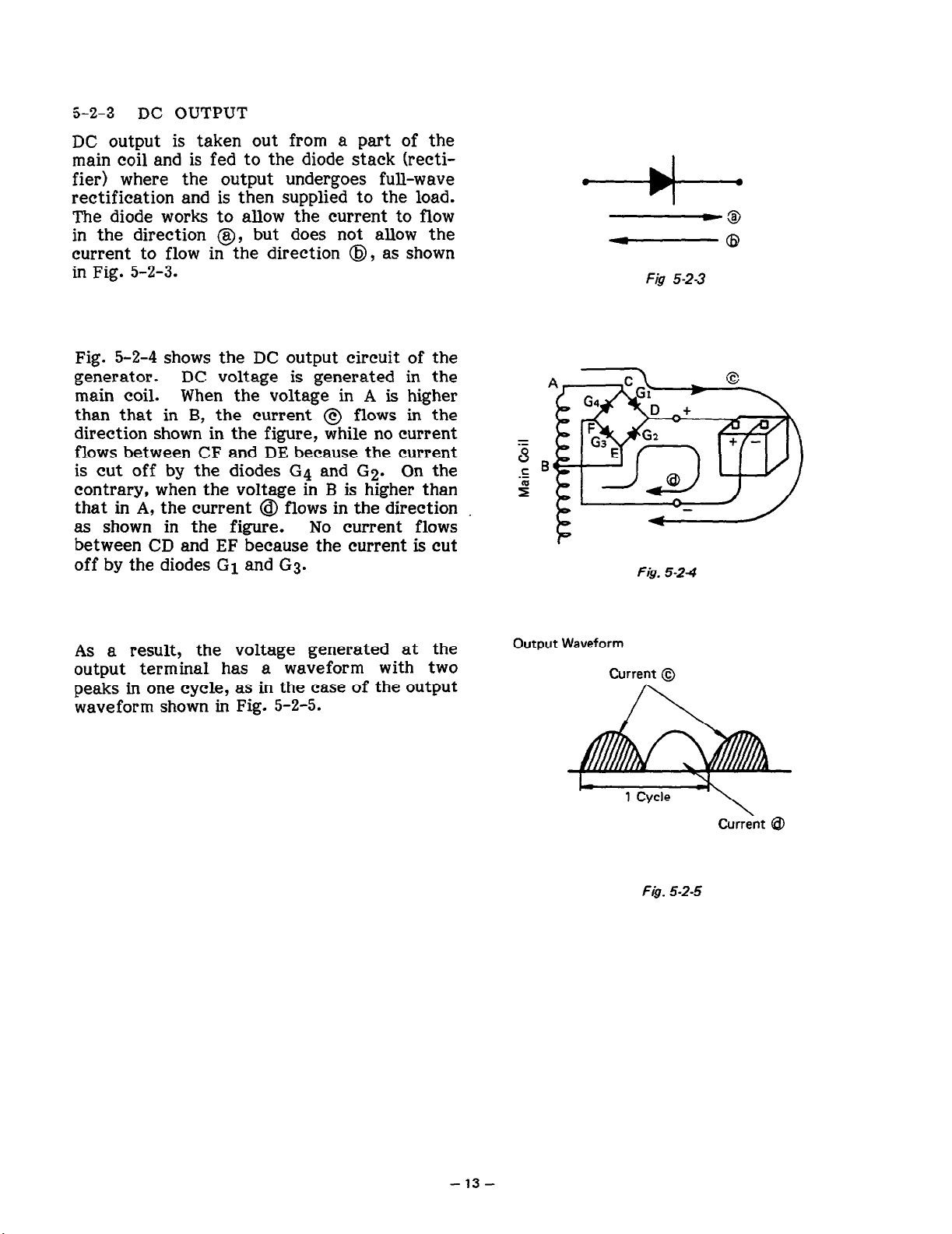

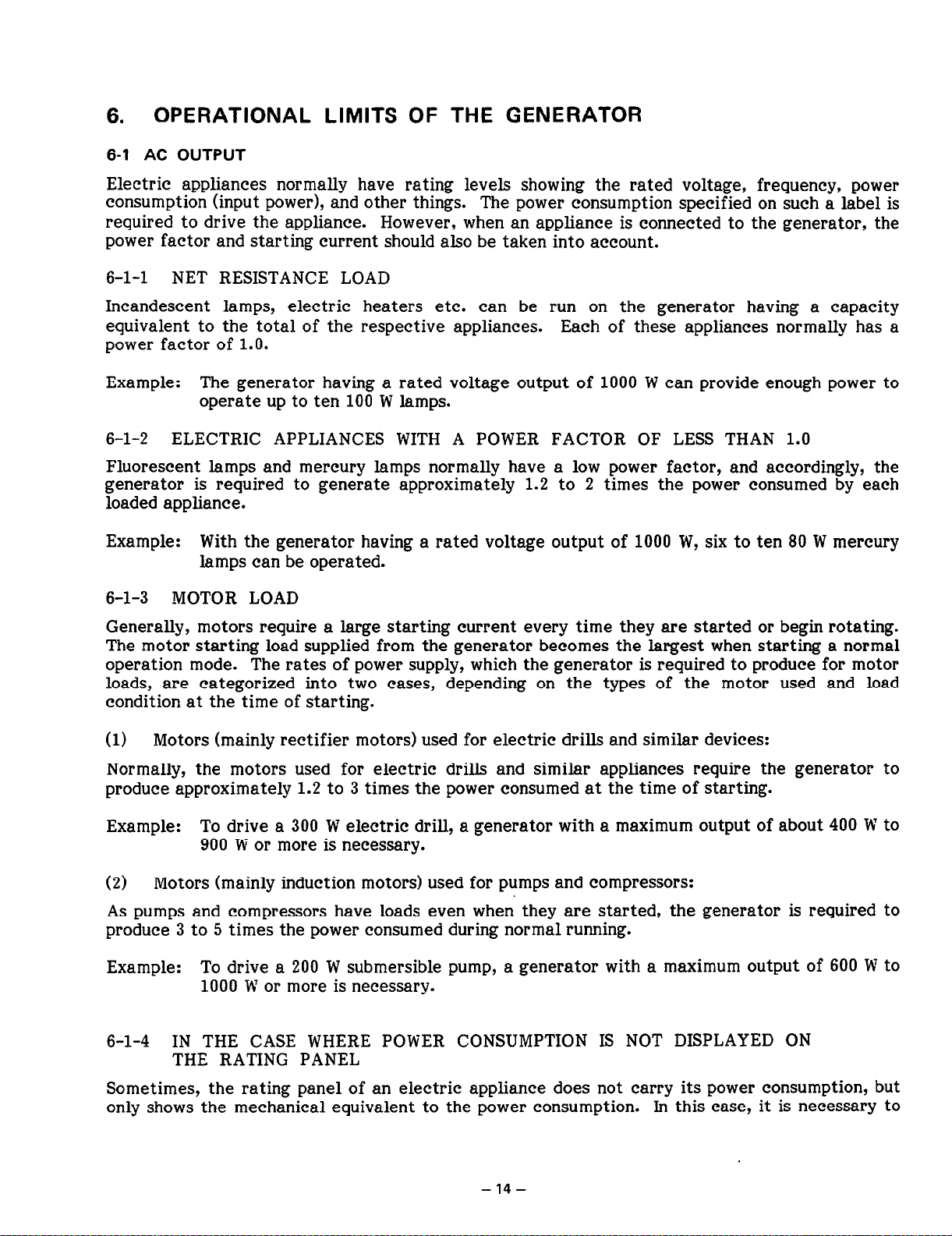

5-2 DESCRIPTION OF GENERATING OPERATION

OPERATIONAL LIMITS OF THE GENERATOR

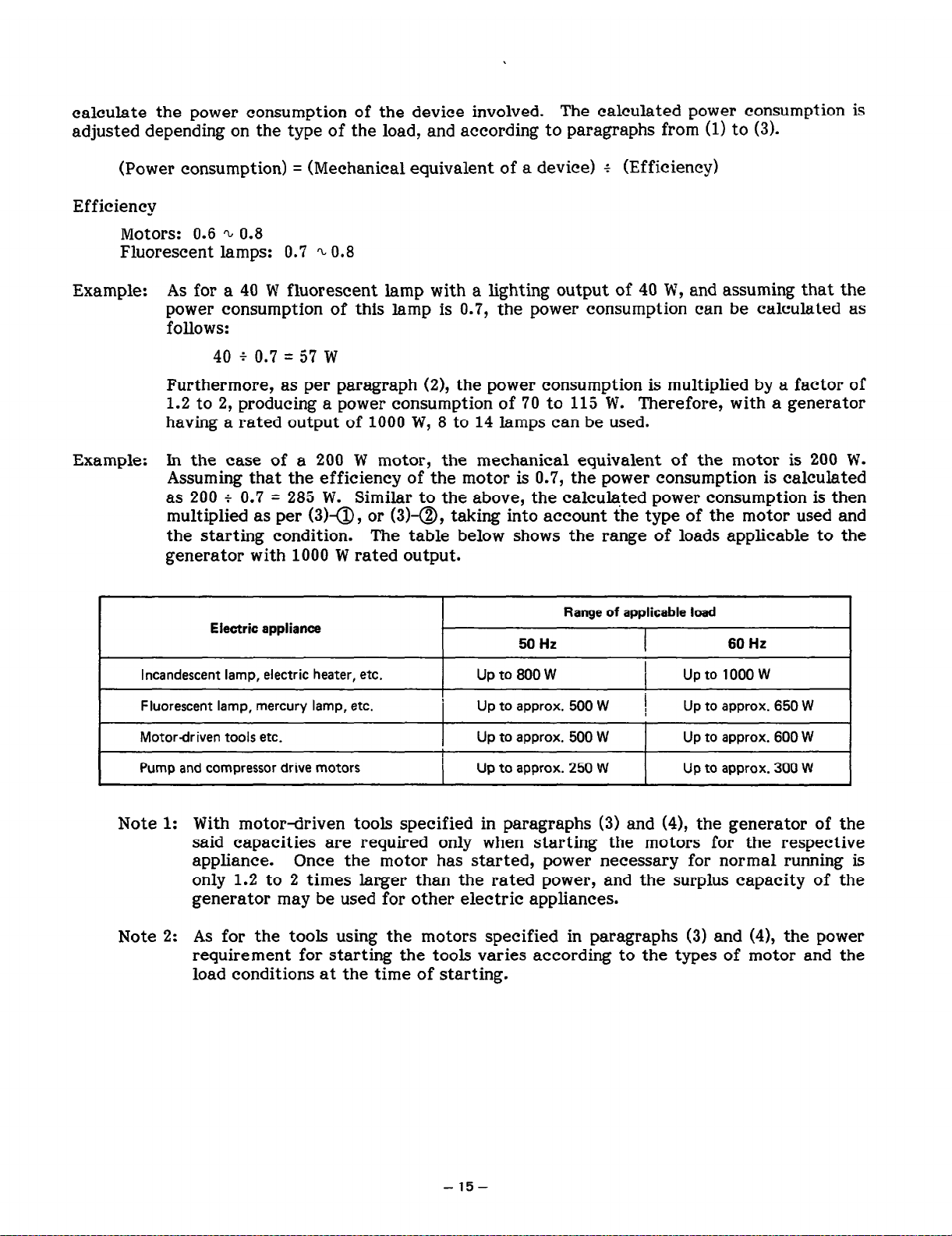

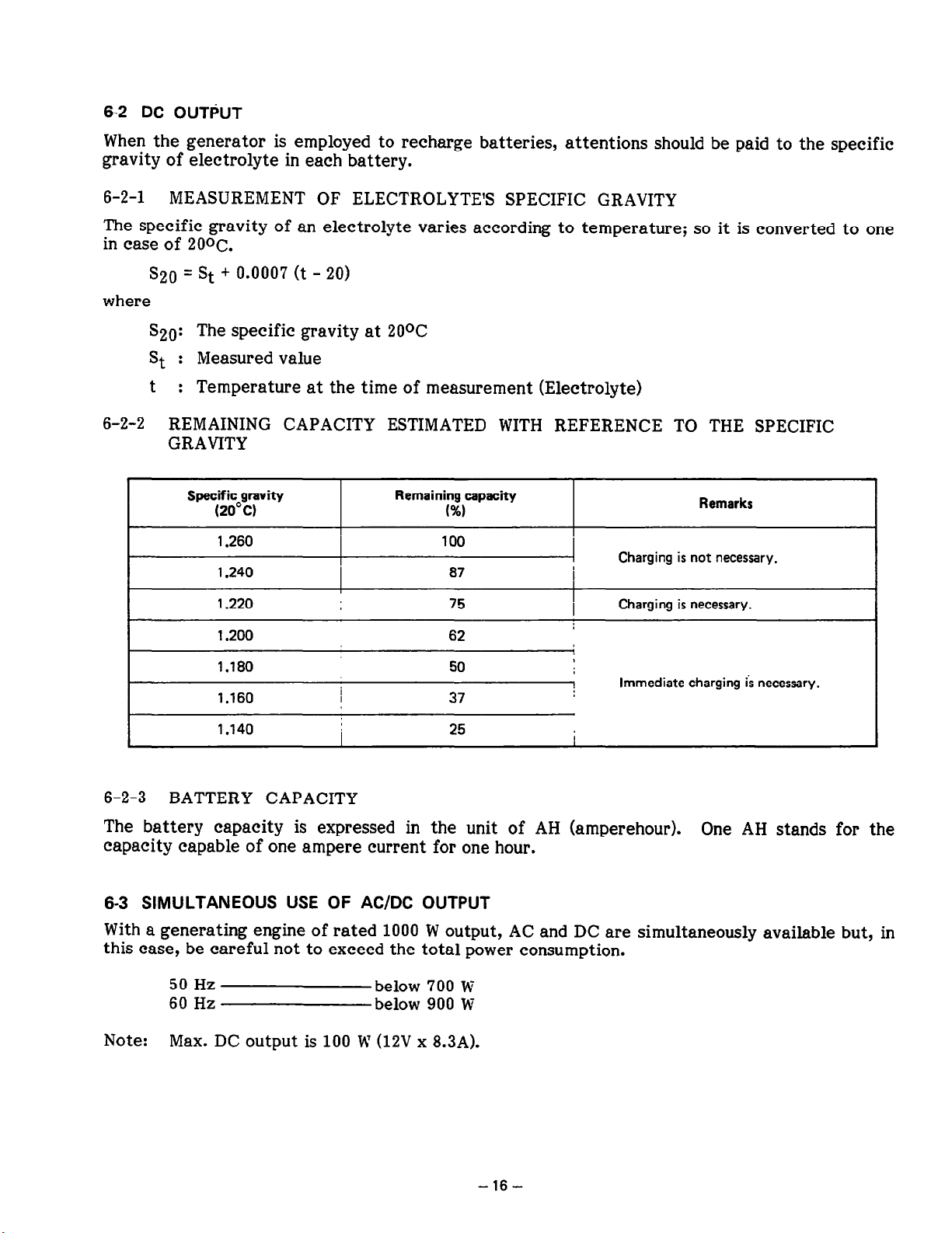

6-1 AC OUTPUT

6-3 SIMULTANEOUS USE OF AC/DC OUTPUT

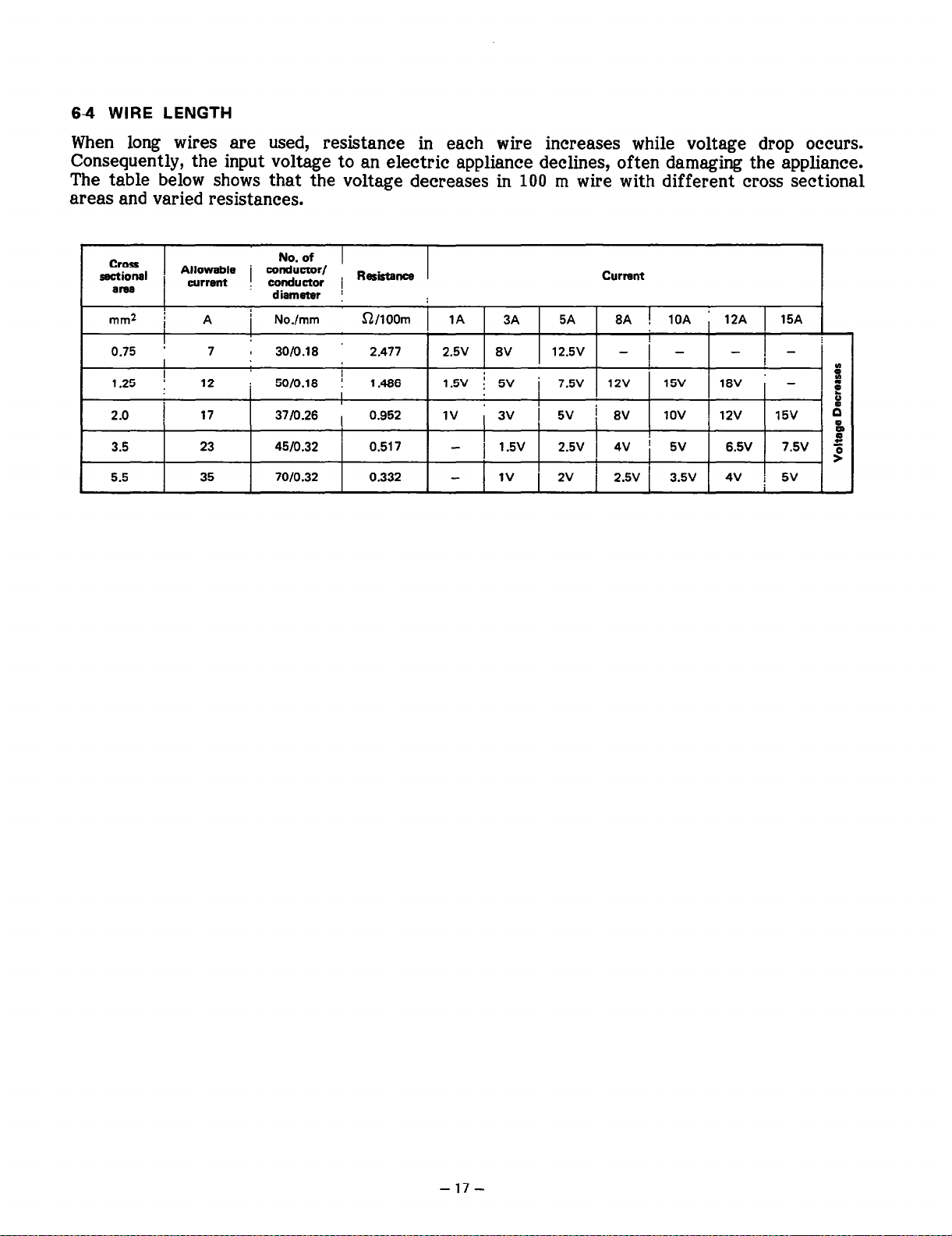

64 WIRE LENGTH

MEASURING PROCEDURES

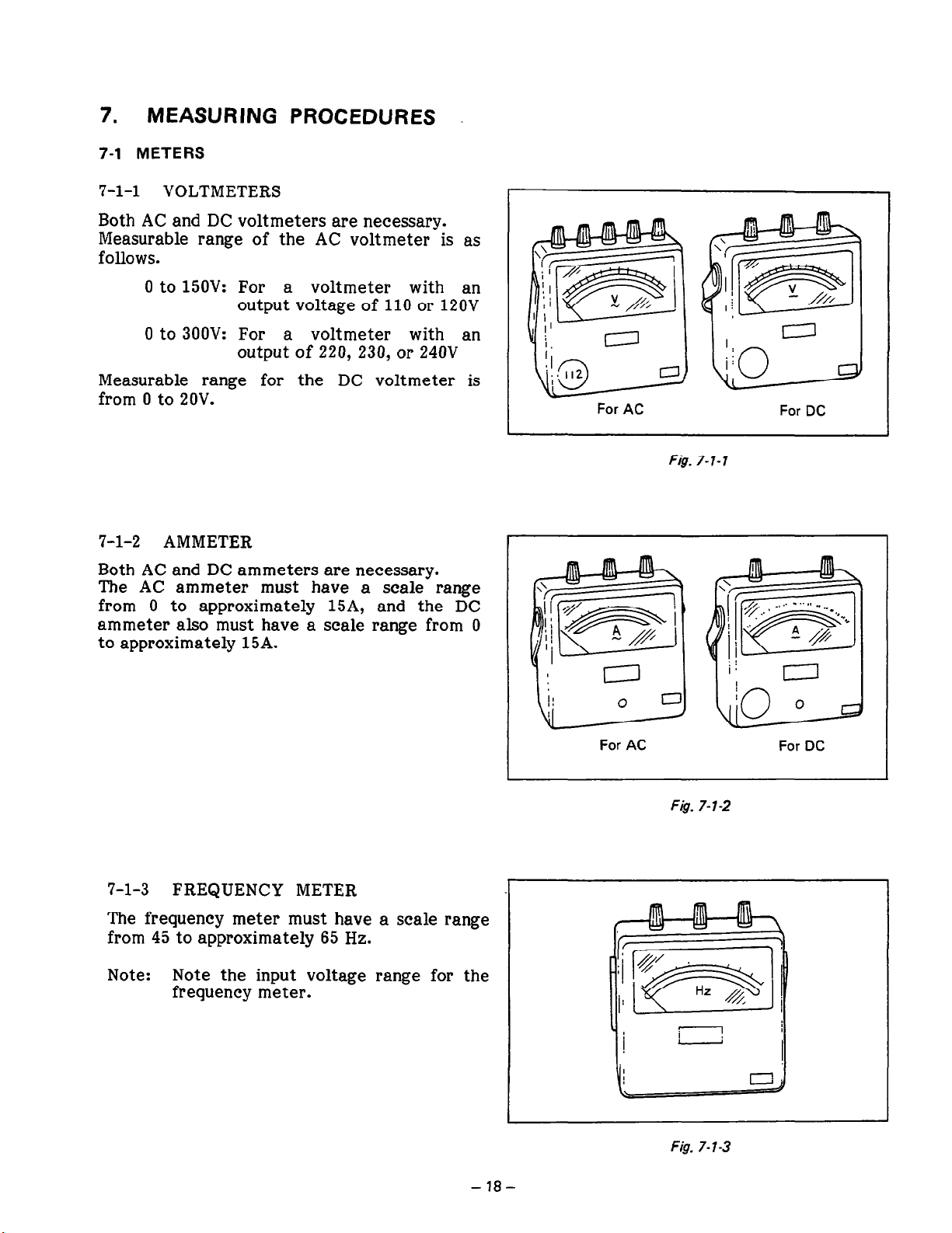

7-1 METERS

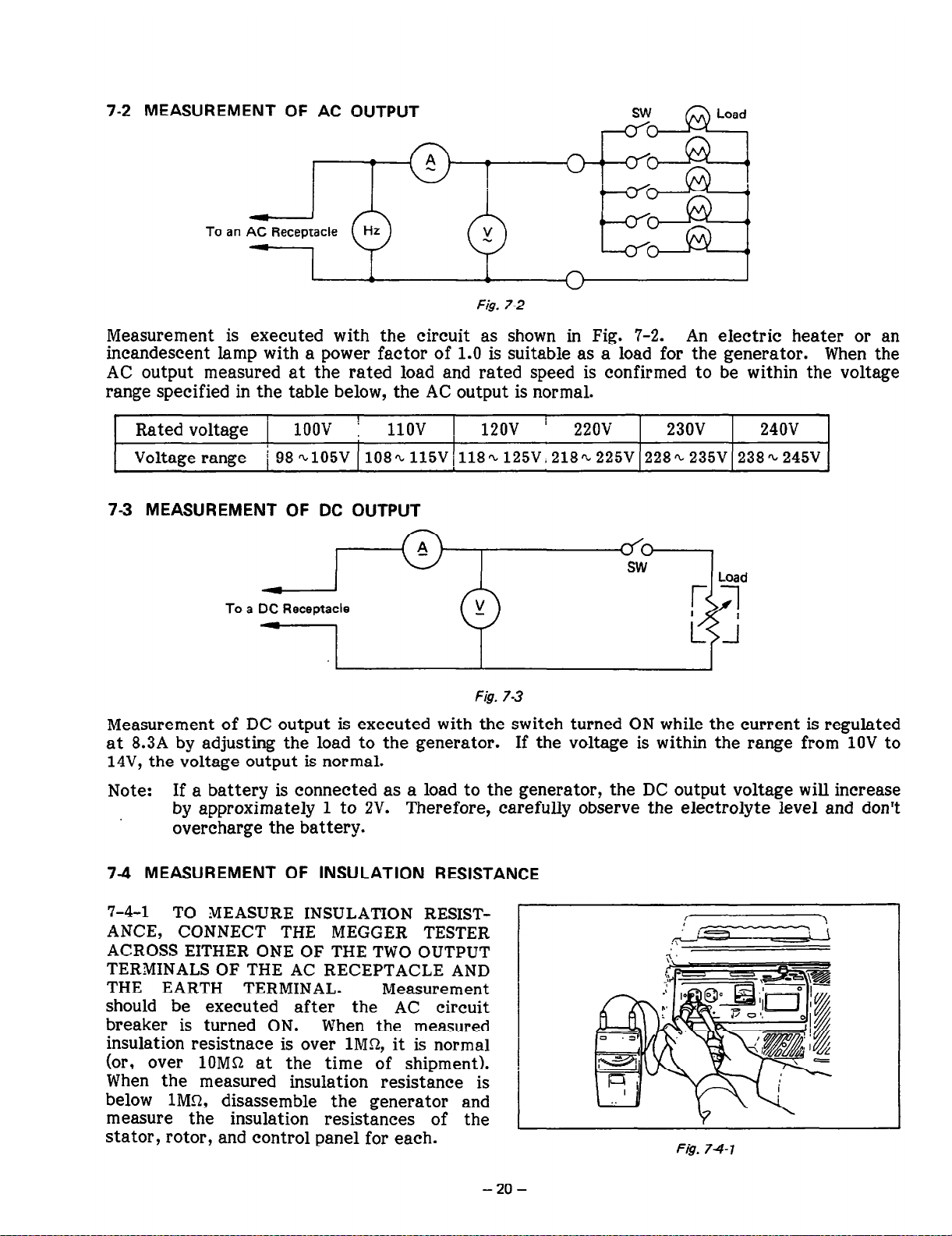

73 MEASUREMENT OF DC OUTPUT

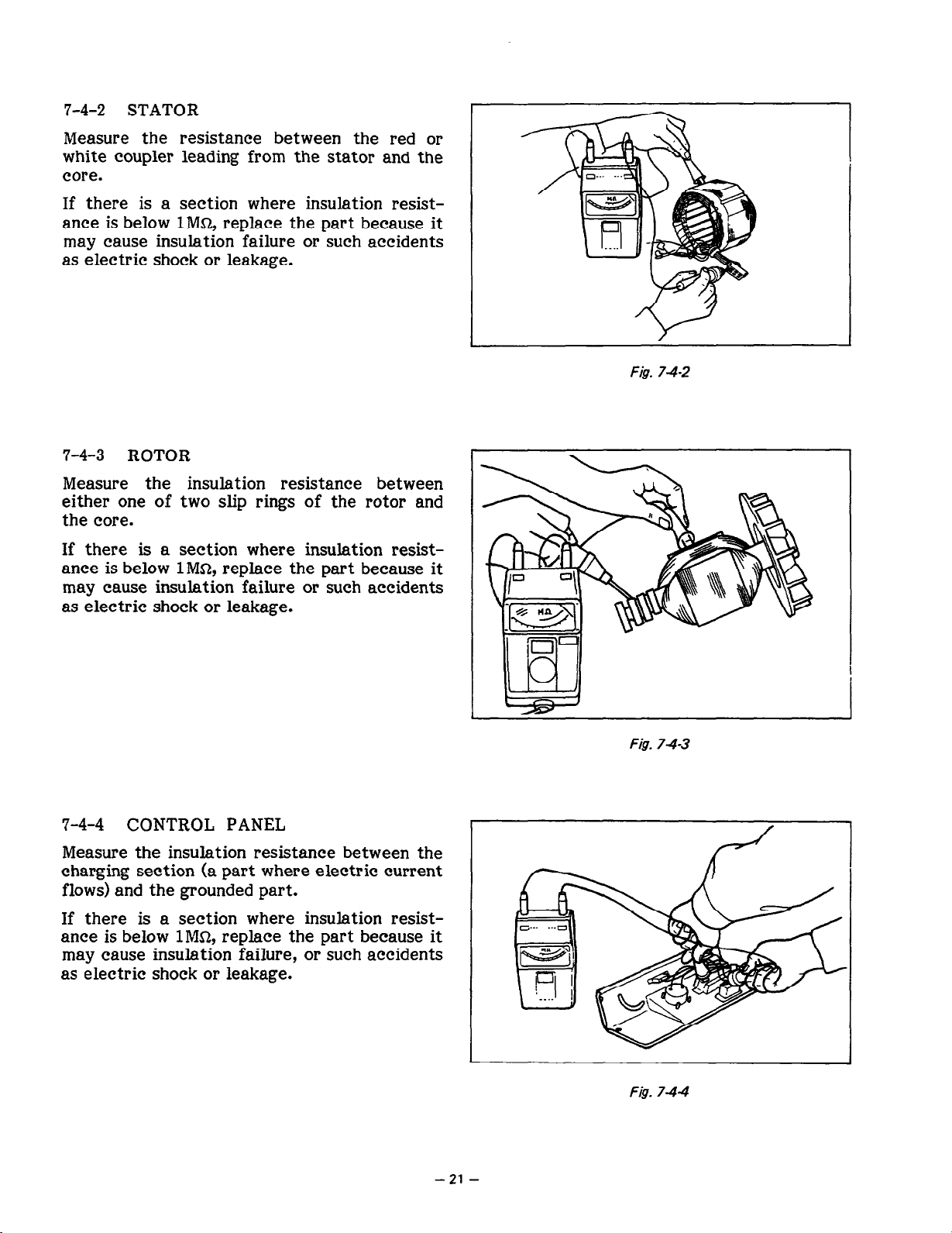

7-4 MEASUREMENT OF INSULATION RESISTANCE

FUNCTIONAL CHECK OF EACH COMPONENT

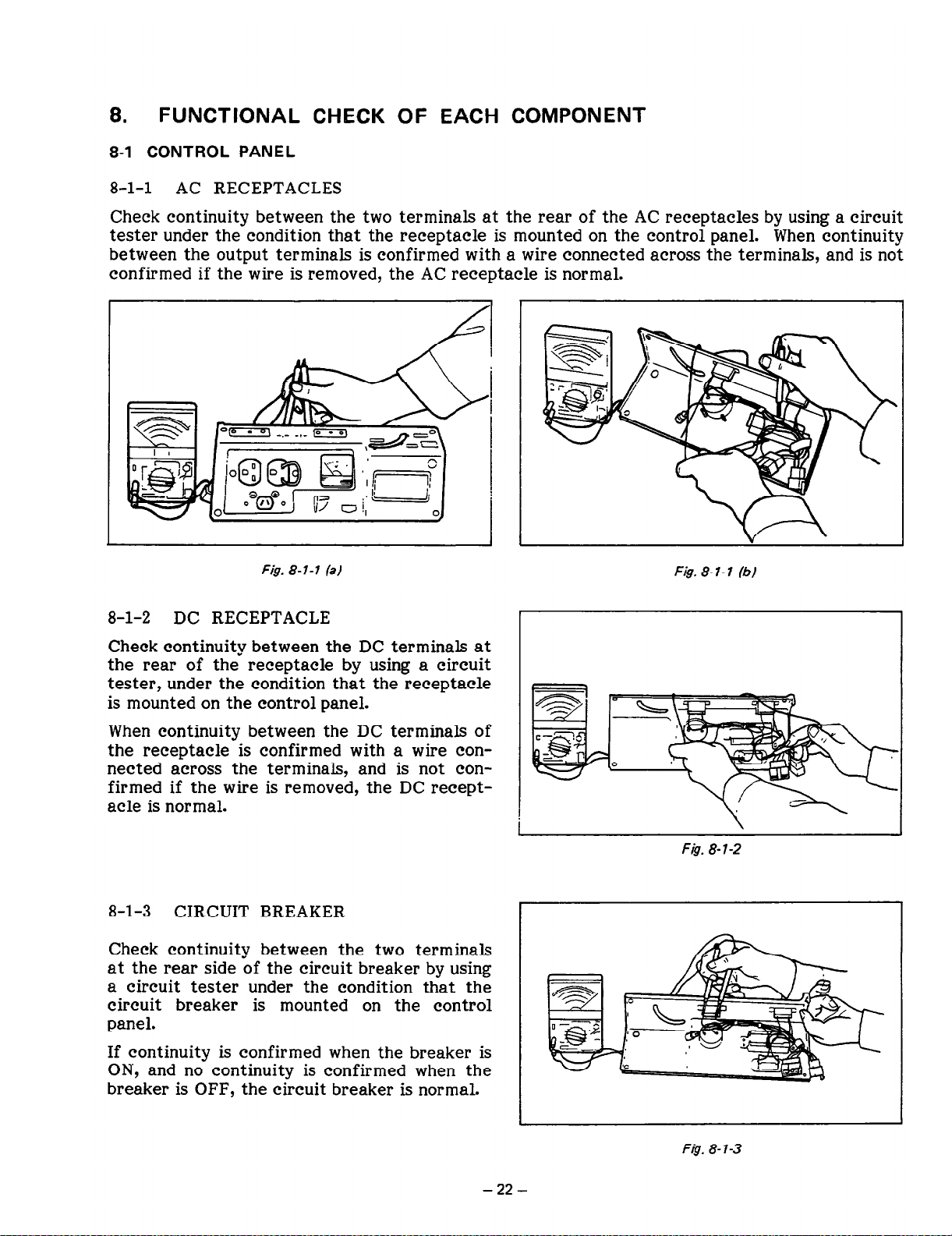

8-1 CONTROL PANEL

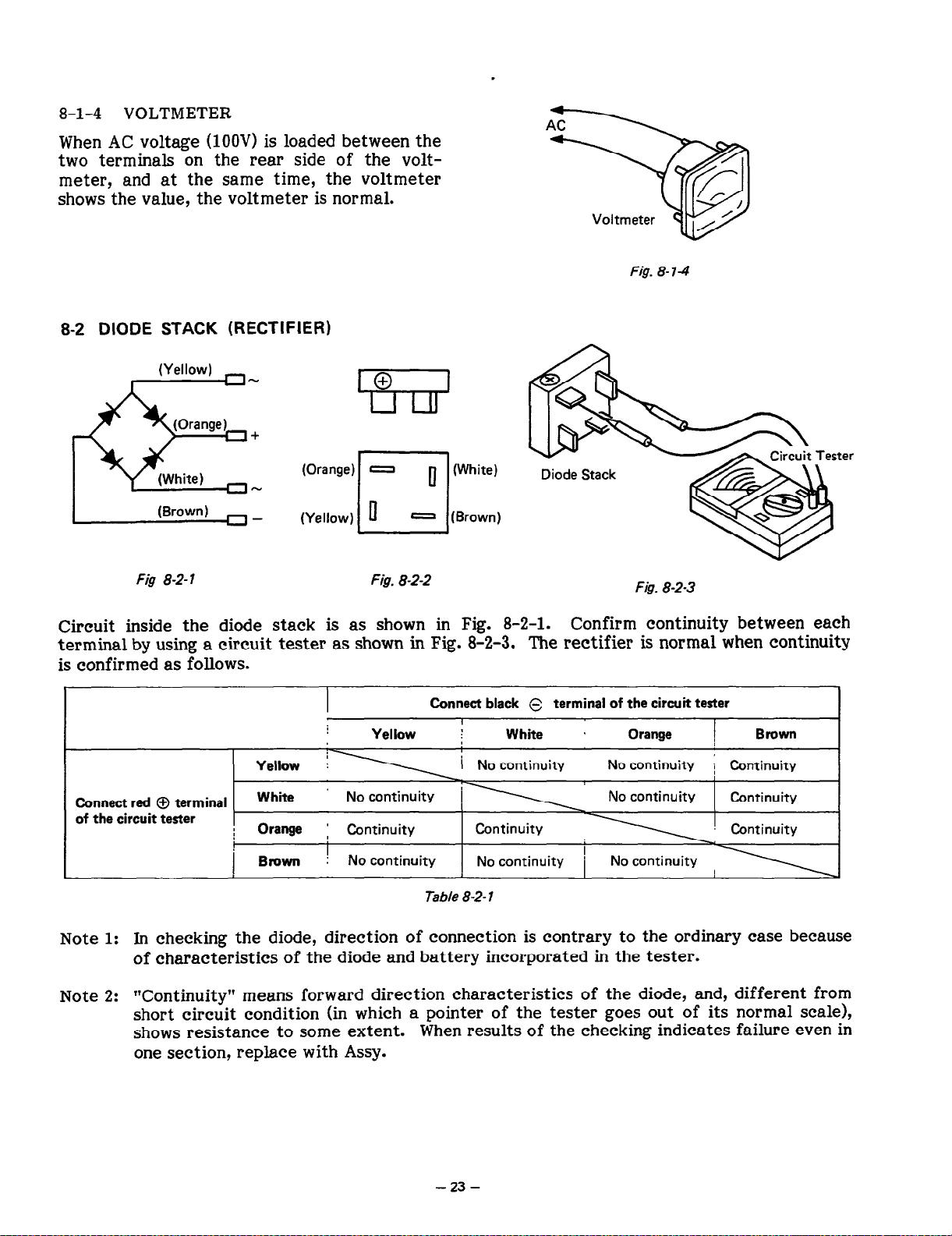

8-2 DIODE STACK (RECTIFIER)

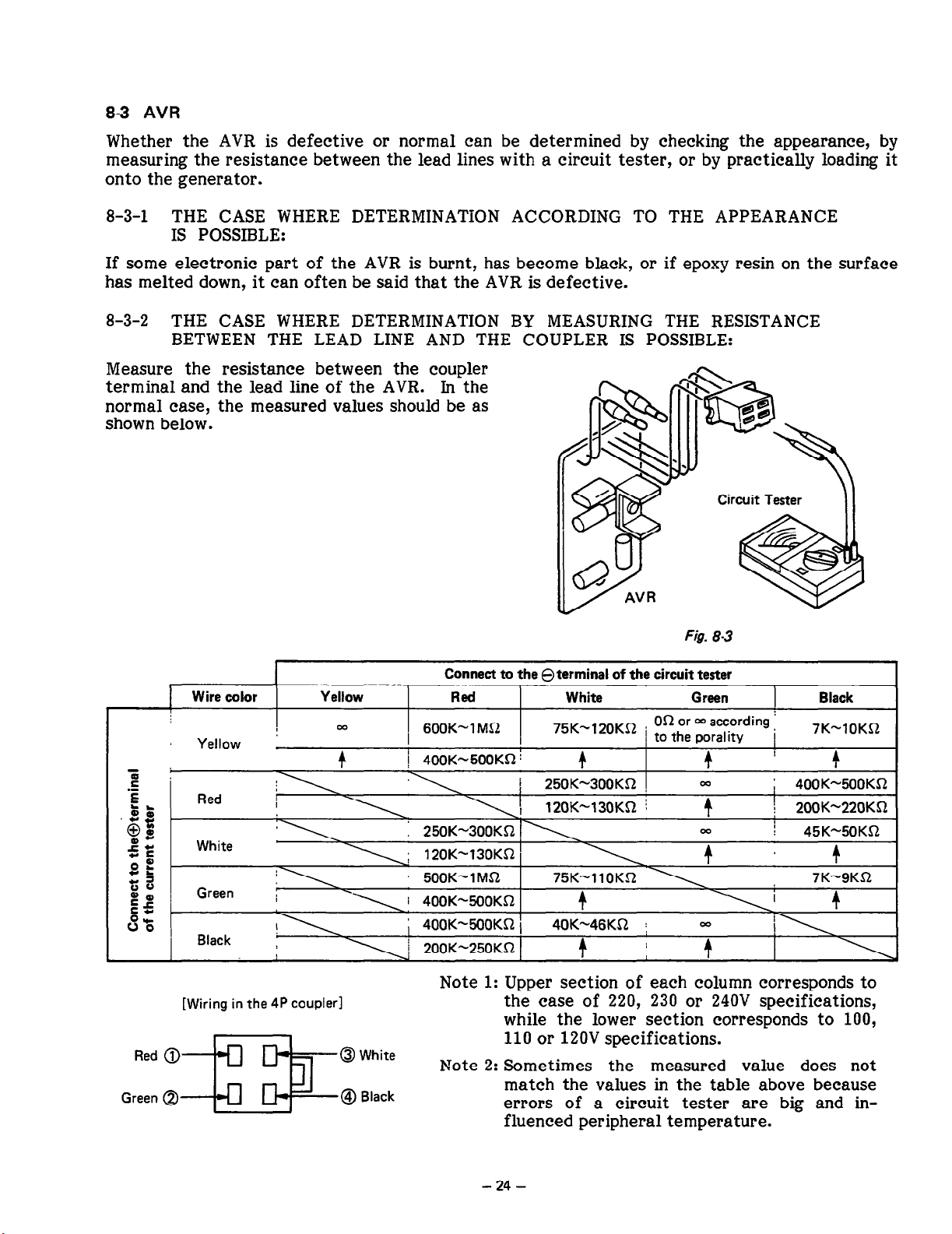

83 AVR

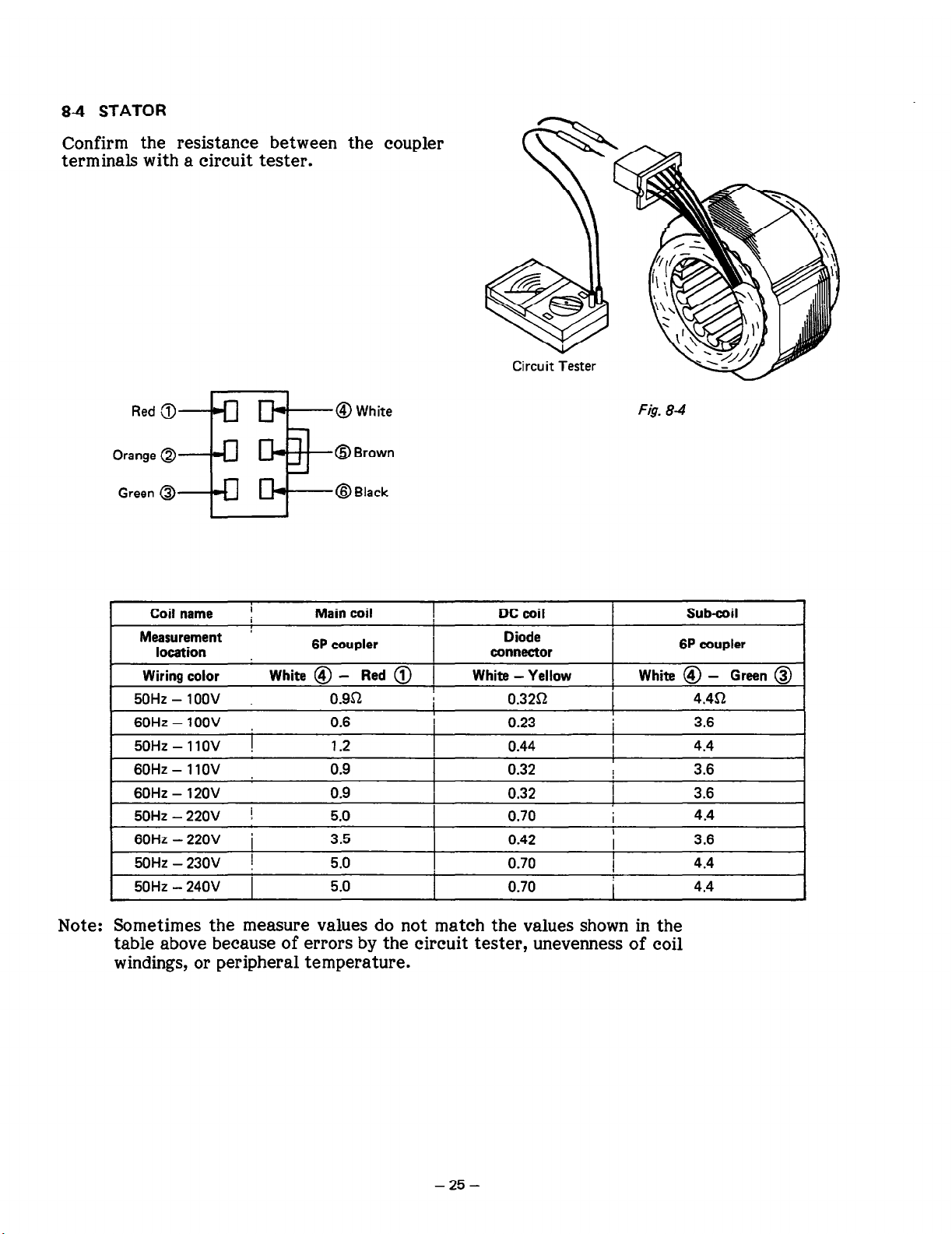

84 STATOR

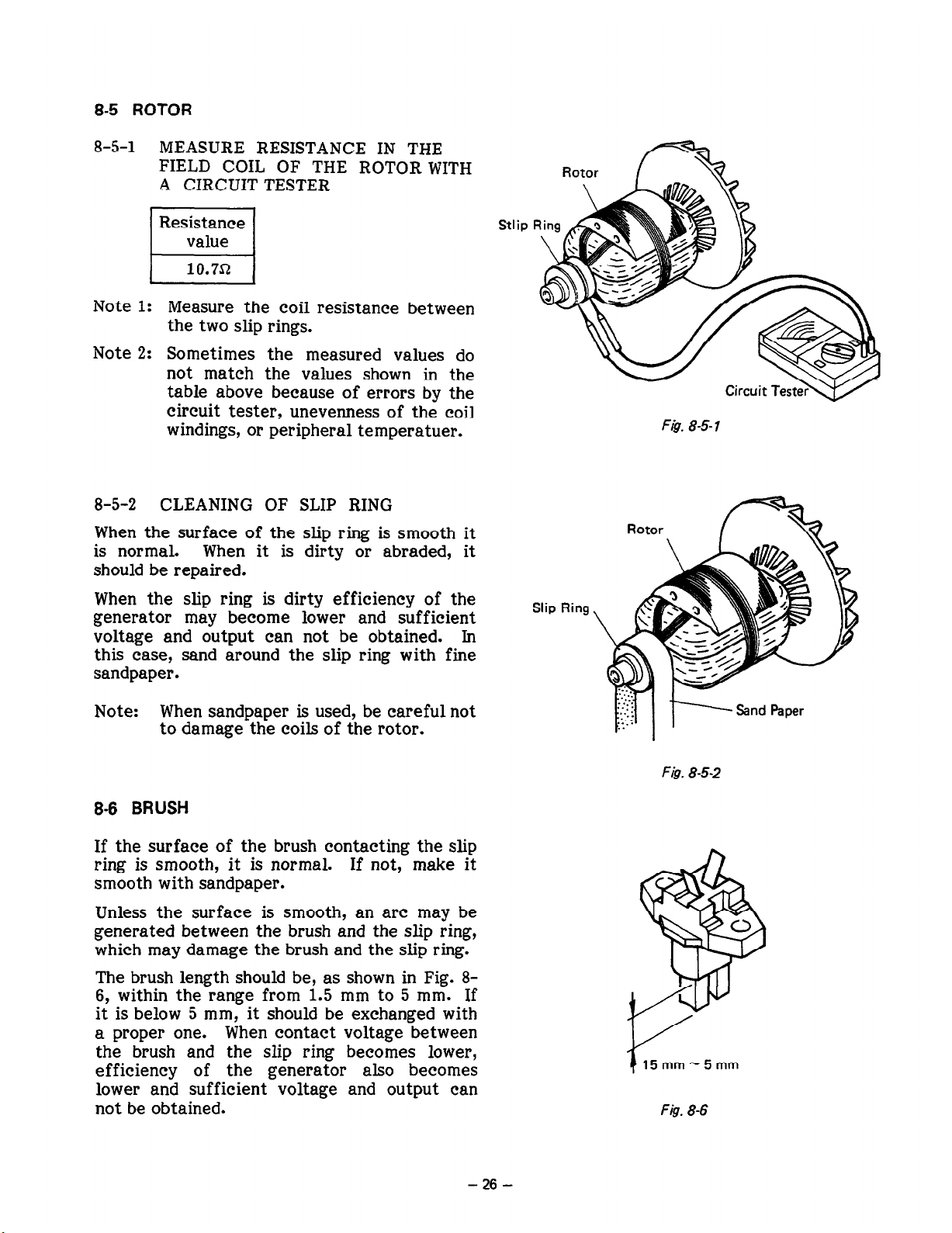

8-5 ROTOR

8-6 BRUSH

8-7 IGNITION COIL

8-8 EXCITING COIL

DISASSEMBLY AND ASSEMBLY

9-2 SPECIAL TOOLS FOR DISASSEMBLY/ASSEMBLY

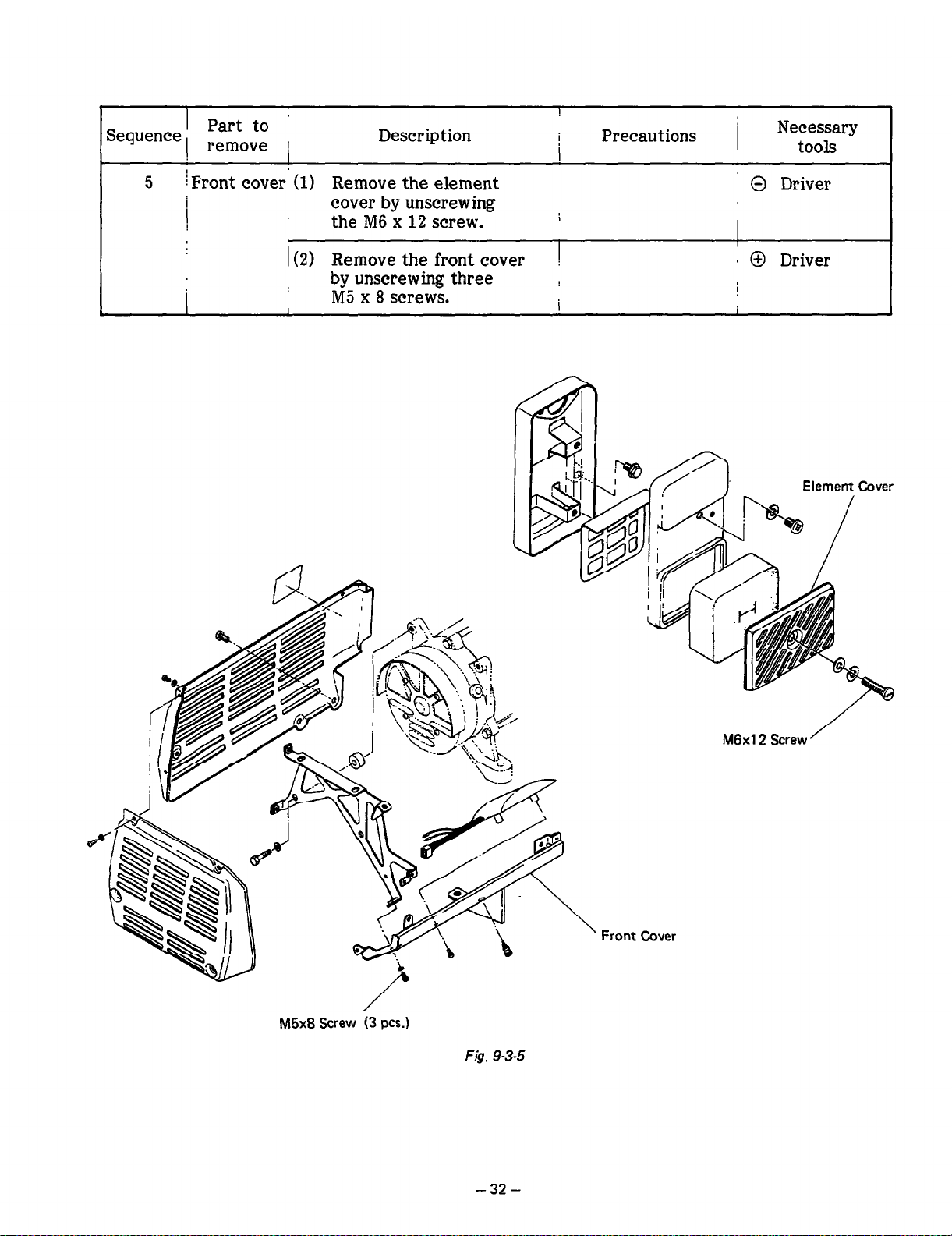

9-3 DISASSEMBLY SEQUENCE

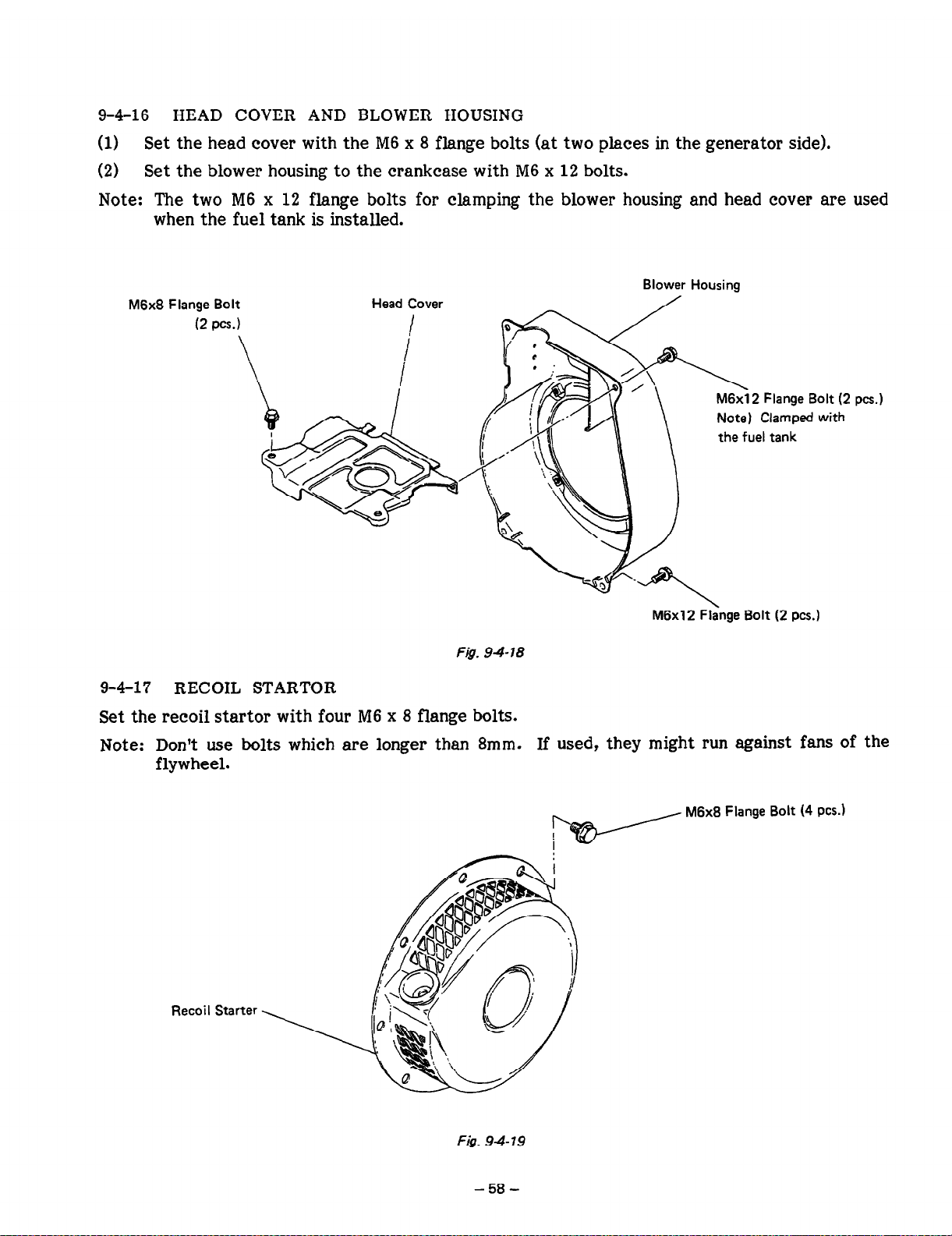

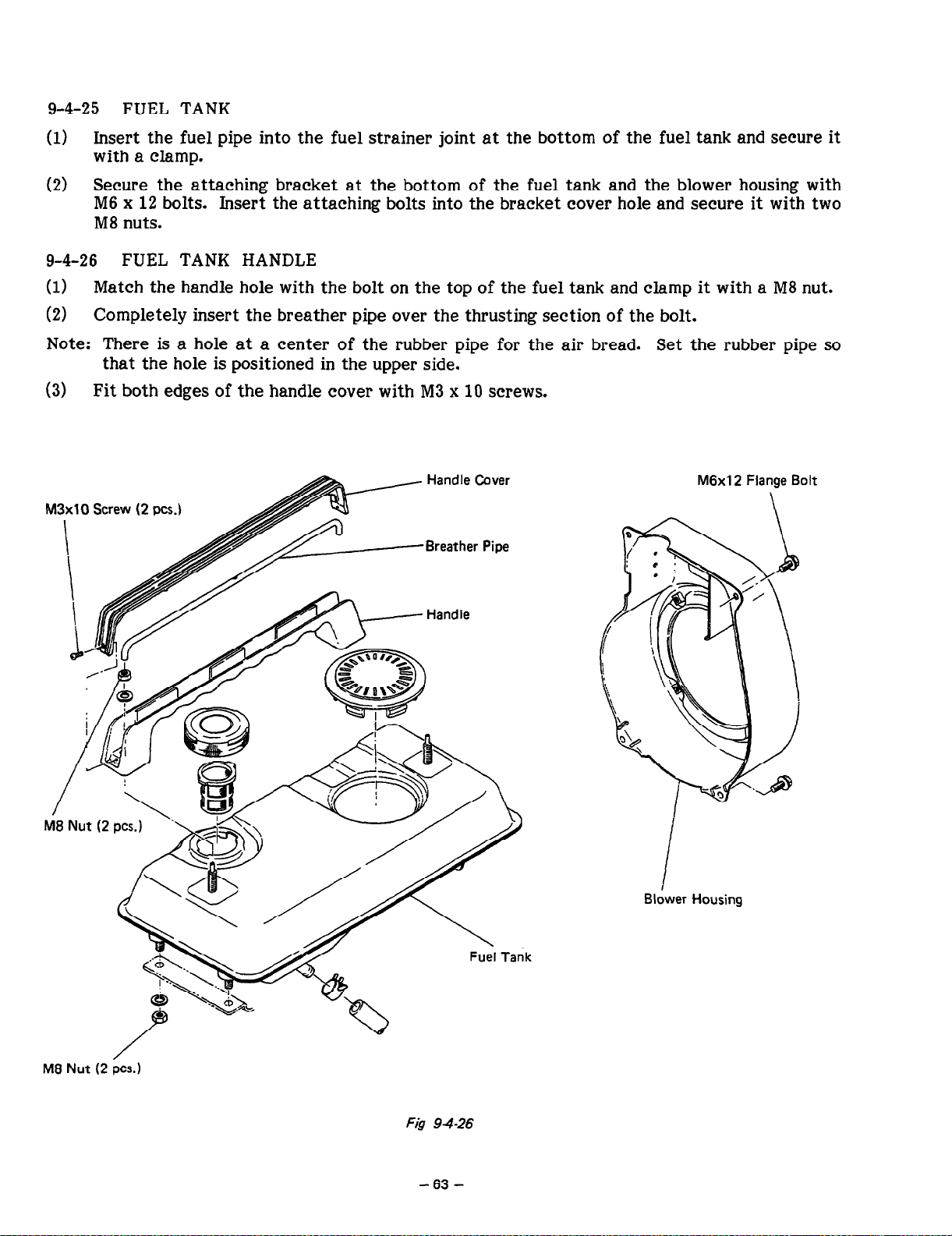

9-4 ASSEMBLY PROCEDURE

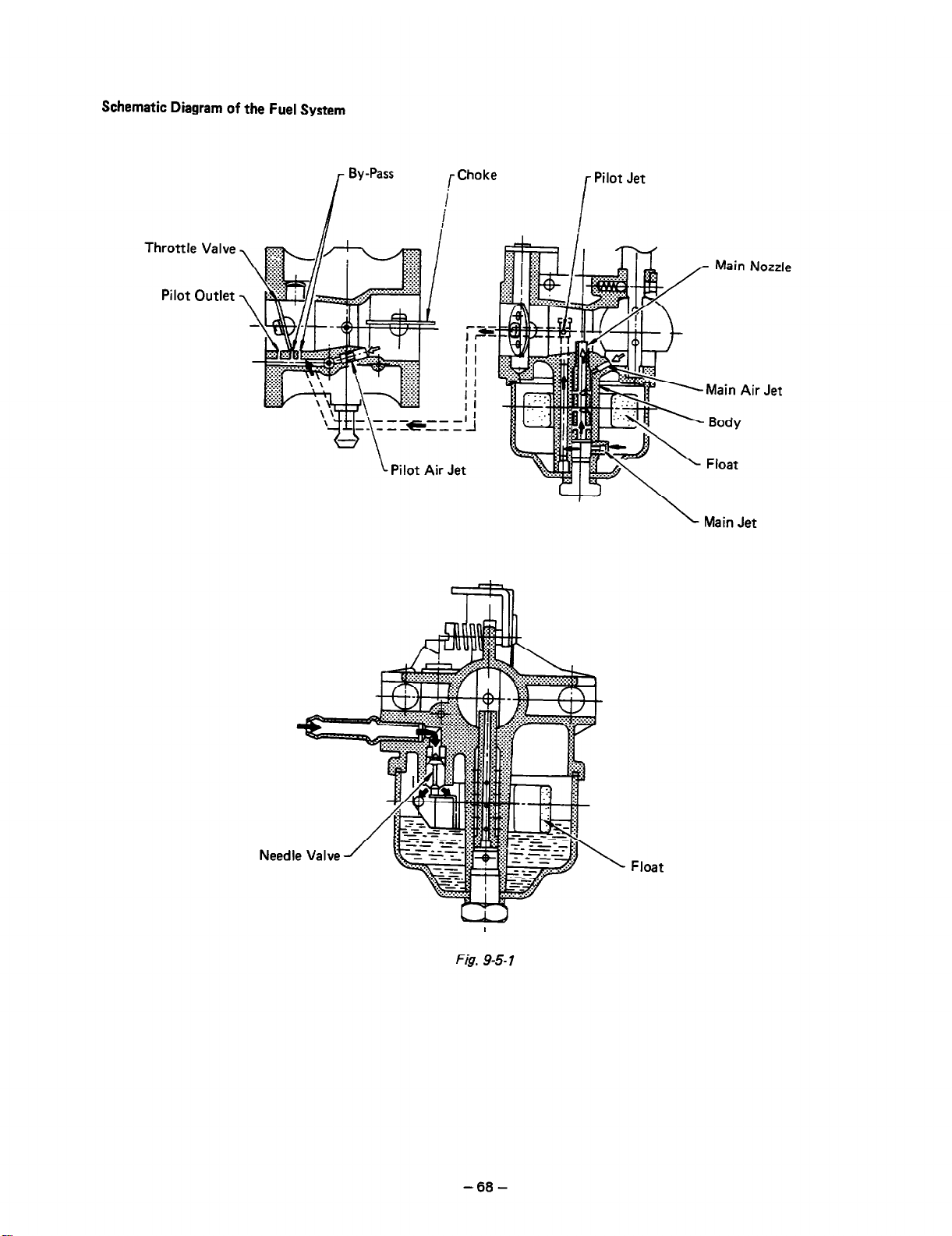

9-5 CARBURETOR

SAFETY PRECAUTIONS

10-l FIRE PREVENTION

10-2 PRECAUTIONS FOR EXHAUST GASES

103 OTHER PRECAUTIONS

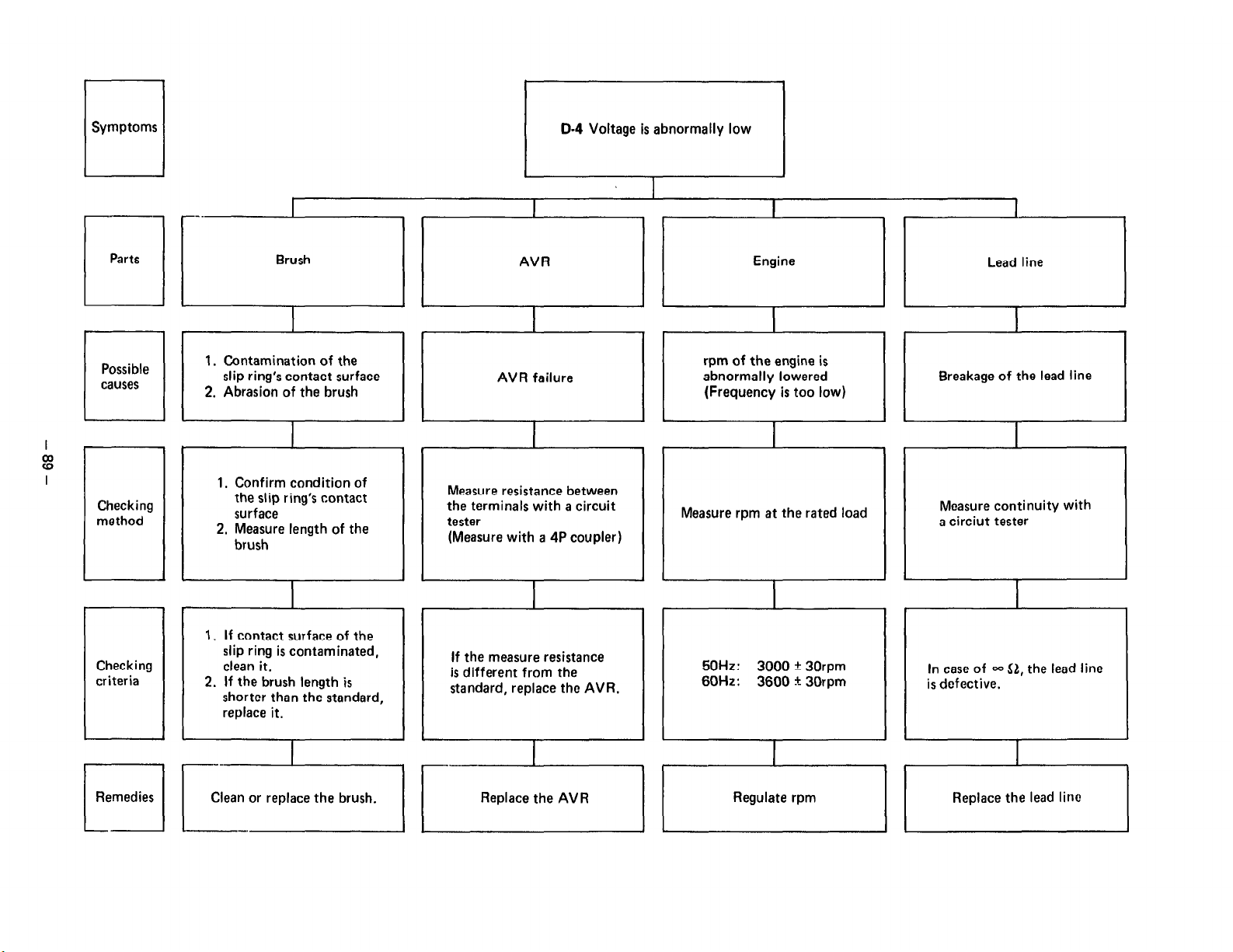

TROUBLESHOOTING

CRITERIA TABLE FOR ADJUSTMENT

WIRING DIAGRAM

MAINTENANCE

14-1 DAILY CHECKS AND MAINTENANCE (EVERY 8 HOURS)

14-2 CHECKS AND MAINTENANCE FOR EVERY 20 HOURS

14-3 CHECKS AND MAINTENANCE FOR EVERY 50 HOURS (EVERY 10 DAYS)

144 CHECKS AND MAINTENANCE FOR EVERY 200 HOURS (EVERY MONTH)

14-5 CHECKS AND MAINTENANCE FOR EVERY 500 HOURS (SEMI-ANNUALLY)

14-5 CHECKS AND MAINTENANCE FOR EVERY 1000 HOURS (ANNUALLY)

Loading...

Loading...