Page 1

MO DE L

IS S UE E MD- P U 1642

9Z Z902 00 43

PKV101

INSTRUCTIONS FOR USE (USA only)

Page 2

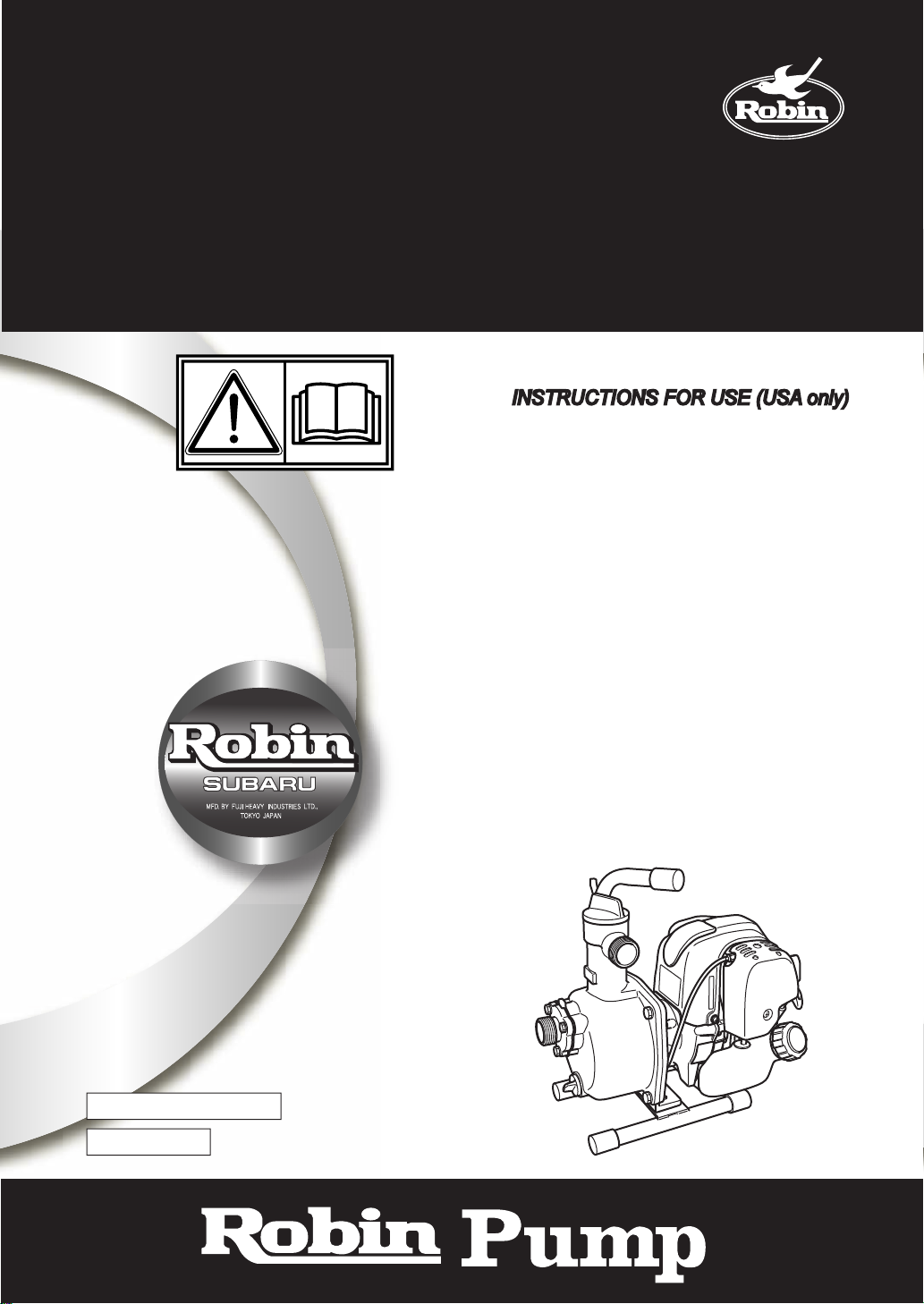

1 2

5

4

3

2

6

7

8

9

10

3

1

1

2

2

L

H

1

13

21

20

19

11

12

14

3

5W

10W

S ingle

gra de

Multi

gra de

Amb ient

15

tempe ratu re

20W

#20

#30

10W -30

10W -40

-20 -10 0 10 20 30

-4 1 4 32 50 68 86

#40

40 C

104 F

3

ON

OFF

4

18

4

17

16

22

23

2

3

5

1

1

5

6

24

6

25

26

7

Page 3

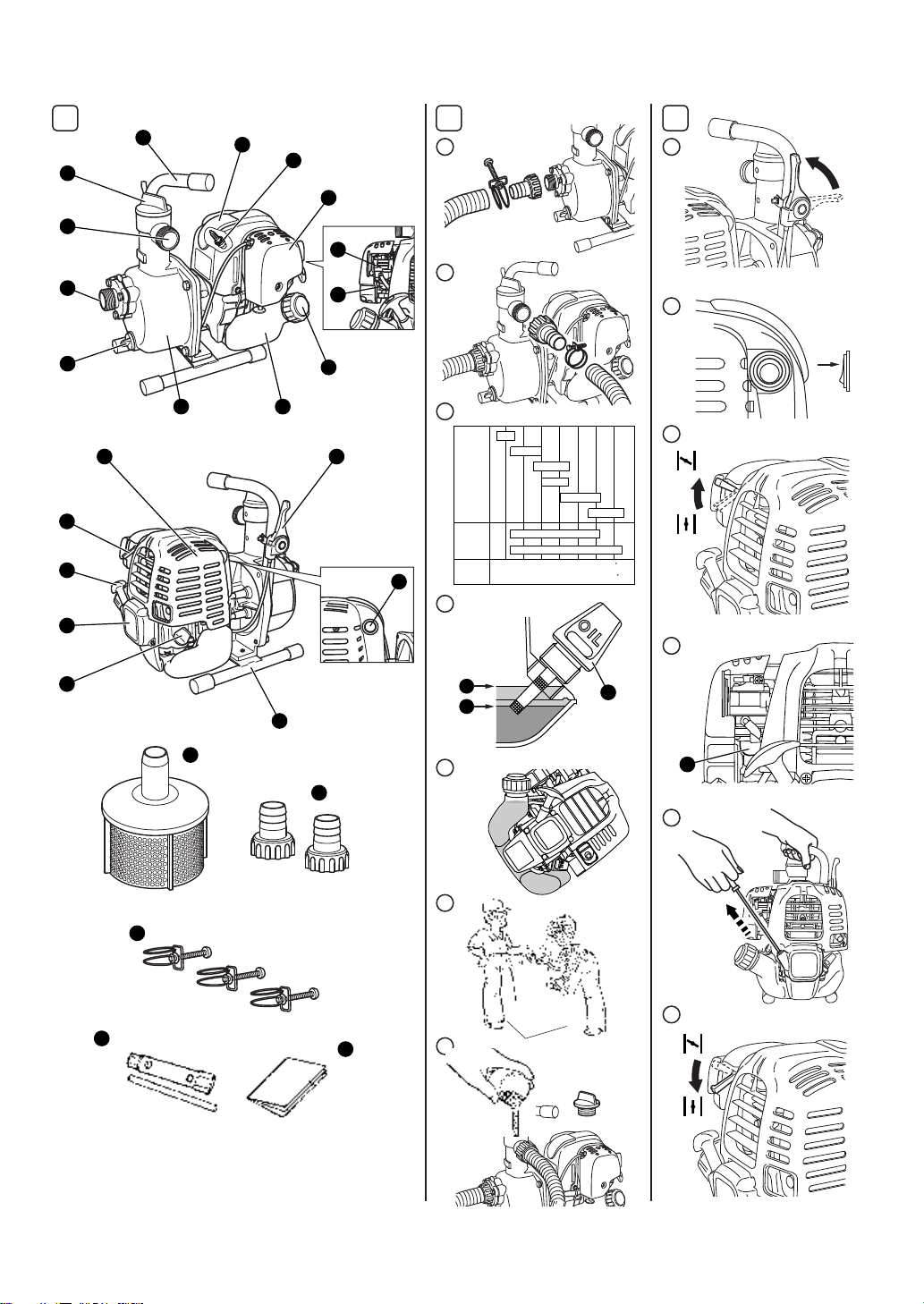

4

1

L

7

1

H

7

4

2

3

1

2

L

0. 7 ~ 0. 8 mm

H

2

5

1

L

1

8

9

2

2

5

6

4

1

3

H

2

4

ON

OFF

1

10

3

8

5

1

6

7

4

1

2

3

6

6

8

5

2

3

2

1

Page 4

WAR NIN G :

The engine exhaust from this product contains

chemica ls known to the S tate of C alifornia to

ca us e cancer, birth defects or other reproductive

harm.

NOT IC E

F E DE R AL E MIS S ION C OMP ON E NT DE F E C T W AR R ANT Y and C ALIF O R NIA

E MIS S ION C ON T R OL WAR R ANT Y are applicable to only thos e engines

complied with E P A (E nvironmental P rotection Agency) and CAR B (C a lifornia

Air R es ources B oa rd) emission regulations .

US

G B

G B

G B

G B

G B

G B

G B

G B

AIR INDE X

An Air Index Information ha ng tag was s upplied to this engine in a ccorda nce

with the emission regulations of the C alifornia Air R es ources B oard.

The bar graph on the ha ng tag shows the emission performance of this engine.

The bar graph ca n be us ed to compare the emis s ions performance with other

available engines . The lower the Air Index, the less pollution.

The following dura bility des cription is to provide you with information relating

to the emis s ion durability period of the engine.

Descriptive T erm Applica ble to E missions Dura bility P eriod

Moderate - 50 hours (engine from 0 to 65 cc)

Intermediate - 125 hours (engine from 0 to 65 cc)

E xtended - 300 hours (engine from 0 to 65 cc)

No tice : The Air Index Information ha ng tag must remain on the engine or on

the equipment until it is sold to the ultimate purcha s er. R emove the hang tag

before operating the engine.

G B

G B

G B

G B

G B

G B

G B

Page 5

F E DE R AL E MIS S IONS C OMPONE NT DE FE C T W A R R A NT Y

E MIS S ION S C OMP ONE NT DE FE C T WAR R A NT Y C OV E RAGE – This emiss ion warra nty is applica ble in all S tates , except the

state of California.

F uji He avy Industries Ltd. a nd R obin America Inc., Wood Da le Illinois , ( herein “R OB IN AME R IC A”) wa rrant(s) to the initial re tail purchas er a nd

ea ch subs eque nt owner, that this Nonroad engine (herein “e ngine”) has be en des igned, built, a nd e quipped to c onform a t the time of initial

sale to a ll applica ble regulations of the U .S .

E nvironmental Protection Agency (E PA ), and that the e ngine is fre e of defects in materials and workmans hip which would c ause this e ngine to

fail to conform with E P A re gulations during its warranty pe riod.

F or the components lis ted unde r P A R T S COV E R ED , the s ervice dea ler a uthorized by R OBI N AME RI C A will, a t no c ost to you, make the

neces sary diagnosis , repair, or re plac ement neces sa ry to ensure that the engine complies with applica ble U .S . E P A re gulations.

E MIS S IS ON C OMP ONE NT DE FE C T WAR R A NT Y P E R IO D

The warranty period for this engine be gins on the date of sa le to the

initial purcha ser a nd c ontinues for a period of two y ears .

US

P AR T S C OV E R E D

G B

Lis ted below a re the parts c overe d by the E miss ion C ompone nts

Defect W arranty. S ome of the parts lis ted be low may re quire

G B

scheduled maintena nce a nd are warranted up to the firs t scheduled

replaceme nt point for that part.

G B

(1) F uel Metering S ys tem

G B

G B

G B

G B

G B

G B

G B

G B

G B

G B

G B

G B

(i) Ca rburetor and interna l parts

(ii) Fuel filter, if a pplica ble.

(iii) Throttle s topper, if a pplica ble.

(iv) C hoke S ystem, if applicable

(2) Air Induction S ys tem

(i) Air cleane r plate

(ii) Air cle aner cas e

(iii) Air cle aner eleme nt

(3) Ignition S ys tem

(i) Spark plug.

(ii) Flywheel Magneto

(iii) Ignition C oil

(4) Miscella neous Items Us ed in A bove S ys tems

(i) Fue l hos es , c lamps and s ealing ga ske ts

OB TA INING W AR R ANTY S E R VIC E

To obtain warra nty s ervice, take your e ngine to the neares t authorized

R obin A merica se rvice dea ler . B ring your sales receipts indicating

date of purchas e for this engine. The s ervice dea ler authorized by

R O B IN AME RIC A will perform the neces s ary repa irs or adjus tments

within a reasona ble amount of time a nd furnis h you with a copy of the

repa ir order. All pa rts and acc es s ories re placed unde r this warranty

become the property of R O BIN A ME RIC A.

WHA T IS N OT C OV ER E D

C onditions res ulting from tampering, misus e, improper adjustment

(unless they were ma de by the s ervice dealer a uthorized by

R O B IN AME RIC A during a warranty repair) , altera tion, a ccident,

failure to us e the re commended fuel and oil, or not performing

*

required maintena nce se rvices .

*The replaceme nt parts use d for required maintenance services .

onsequential dama ges s uch as loss of time, inconvenienc e, los s

of us e of the engine or equipment, etc.

Dia gnosis and inspection cha rges that do not re sult in warra ntyeligible se rvice being performed.

*C

Any non-authorize d replac ement part, or malfunction of authorized

parts due to use of non-authorized pa rts.

*

*

OWN ER ’ S WAR R ANTY R E S PO NS IB IL ITIE S

As the e ngine owner, you a re re sponsible for the pe rformance of the

required maintena nce lis ted in your owne r’s manual. R O B IN

AME RI C A recommends that you retain all rec eipts cove ring

maintena nce on your e ngine, but R O B IN AME R I C A cannot deny

warra nty s olely for the lack of receipts or for your fa ilure to ens ure

the performance of all s cheduled maintenanc e.

As the engine owner, y ou s hould howe ver be aware that R O BIN

AME R IC A ma y deny warranty cove rage if your engine or a pa rt ha s

failed due to abus e, ne glect, improper maintena nce or unapprove d

modifications .

Y ou are respons ible for presenting your engine to the nea rest se rvice

dea ler authorized by R OB IN AME R IC A when a problem exists .

If y ou ha ve any ques tions rega rding your warranty rights a nd

res pons ibilities , you should contac t the R obin A merica cus tomer

service department at 1-630 -350-8200 for the information.

THING S Y OU S HOUL D K NOW A BOU T THE E MIS S IO N

C ONT R OL S Y STE M W AR R ANT Y MAINTE NANC E A ND

R E PA IR S

Y ou are res ponsible for the proper ma intenance of the engine.

Y ou s hould keep all rece ipts and ma intenanc e records cove ring the

performa nce of re gular maintena nce in the eve nt ques tions aris e.

Thes e rece ipts and ma intenanc e records should be trans ferred to

ea ch subs eque nt owner of the engine. R OB IN AME R ICA res erves

the right to de ny warra nty coverage if the engine has not been properly

maintaine d. Wa rranty claims will not be denied, howe ver, s olely

beca us e of the lack of required maintena nce or failure to keep

maintena nce records .

MAI NT E N ANCE , R E P L AC E ME NT OR R E P AIR OF E MIS SI ON

C ON T R O L DE V ICE S AND S YS TE MS MAY B E P E R FO R ME D B Y

AN Y R EPAIR E ST AB LIS H MENT OR INDIVI DUAL;

HO WE VE R , W AR R ANTY R E PA IR S MUS T BE P ER FO R ME D B Y A

S E RVI CE D EALE R AU TH OR IZE D B Y ROB IN AME R IC A. TH E US E

OF P AR TS THAT AR E NOT E QU IVALE NT IN P E R FOR MANC E AND

DU R AB ILITY TO AUTH OR IZE D P AR T S MAY IMP A IR T HE

E FF E CT IVE NE SS O F TH E E MIS S ION C ON TR OL S YS T E M AN D MA Y

HA VE A B E AR ING ON TH E O UTCOME OF A W AR R ANT Y CL AIM.

If other than the parts authorized by R OBI N AME R IC A a re used for

maintena nce replacements or for the repair of c omponents affecting

emis sion control, you should ass ure yours elf that s uch parts are

warra nted by their ma nufac turer to be equivalent to the pa rts

authorized by R OB IN A ME RIC A in their performa nce and durability.

HO W TO MA K E A C LAIM

All repair qualifying under this limited wa rranty must be performed by a

service dealer authorized by R O B IN AME R IC A. In the e vent that any

emis sion-related part is found to be defe ctive during the warranty period,

you sha ll notify R obin Ame rica customer service de partment a t 1-6 30350 -8200 and you will be a dvised of the a ppropriate warranty s ervice

d

ea ler or se rvice providers where the warranty re pair can be pe rformed.

Page 6

C A LIF OR NIA E MIS S ION C ONT R O LWAR R ANT Y S TAT E ME NT

Y O UR WAR R ANT Y R IG HT S A N D OB LIG ATIO NS

The California Air R es ources B oard a nd Fuji He avy Industries Ltd. ( herein “F UJ I”) a re pleas ed to explain the emiss ion control s ystem warranty

on your 20 04 and later S mall Off-R oad engine (he rein "engine"). In C alifornia, new e ngine must be designed, built a nd e quipped to me et the

S tate's s tringent anti-s mog s tanda rds . FUJ I mus t warrant the emiss ion control s ystem on your engine for the periods of time described below,

provided there has been no a bus e, neglect or improper maintena nce of your engine. Your emis sion control sys tem may include pa rts suc h a s

the c arburetor or fue l-injection s ys tem, and the ignition s ys tem. Als o included may be hose s, belts, connectors a nd other emis sion-related

as se mblies . W here a wa rrantable condition e xists, FU JI will repair your engine at no cost to you including diagnos is, parts and labor.

MA NUF AC T UR E R'S WAR R A NTY CO VE R AGE :

The 2004 and later engines are warra nted for two (2 ) years . I f a ny emiss ion rela ted pa rt on your engine is defective, the part will be repaired

or re placed by FUJ I.

OW NE R 'S WAR R A NTY R E S PO NS IB IL ITI ES :

-As the engine owner, you a re res pons ible for the performance of the re quired maintenance listed in your Owner's Ma nual. F U J I

recommends that y ou re tain a ll receipts cove ring ma intenanc e on your engine, but FUJ I cannot deny warra nty s olely for the lac k of

receipts or for your failure to ens ure the performance of all sche duled maintenance.

-As the engine owner, you should , however, be aware that FUJ I ma y deny you warranty c overage if your engine or a pa rt ha s fa iled due

to abus e, negle ct, improper maintenanc e or unapproved modifications.

-Y ou are res ponsible for pre senting your engine to a s ervic e deale r or warra nty s tation a uthorized by R OB IN AME R ICA I nc. 94 0 Lively

B lvd., W ood D ale , IL 60191 (he rein R OBI N AME R IC A) a s s oon a s a problem exis ts. T he warranty repairs should be completed in a

rea sonable a mount of time, not to e xceed 30 days.

If y ou ha ve any ques tions rega rding your warranty rights a nd respons ibilities, you s hould contact the R obin A merica Inc. C us tomer S ervic e

Department a t 1- 630-350-8 200

US

G B

G B

G B

G B

L IMITE D W A R R ANT Y

on E mis sion C ontro l S ys tems

-

C a lifornia Only

F UJ I wa rrants to the owner of the 20 04 and later engine that the e ngine 1)has bee n des igned, built and equipped s o a s to c onform a t the time

of ma nufacture with the applica ble re gulations of the C alifornia A ir R es ources B oard, a nd (2) is free from defects in materia ls and workmans hip

that could ca use it to fa il to conform with thos e regulations as may be applicablein the terms and c onditions stated below.

A. WA R R ANTY C OMME NC E ME NT DATE

The warranty period begins on the date the engine is delivere d to a

first retail purc haser.

B . LE NG TH O F C OVE R AG E

F UJI wa rrants to a first re tail purchas er and eac h subsequent purcha ser

that the engine is free from defects in materia ls and workmanship that

ca use the failure of a warranted emis s ion-rela ted pa rt for a period of

two (2) years after the date of de livery to the firs t re tail purchas er.

C . W HA T IS C OV E RE D:

1. R E PAIR OR R E P LAC E ME NT P AR TS

R epairs a nd re place ment of any warranted pa rt will be performe d

at no charge to you by an authorize d s ervice dealer or a warranty

station. Y ou may c ontact the Robin Ame rica Inc . C ustomer S ervice

Department a t 1-630-3 50-8200 to obtain the na me of the nea res t

appropriate loca tion whe re your warranty repairs are performed.

2. WA RR ANT Y PE R IO D

This warra nty continues for a period of two ( 2) yea rs a nd a pplies

only to the repair, repla ceme nt or adjustment of the component

parts that a re not s cheduled for replac ement as required

maintena nce. Further, component parts which are s cheduled only

for re gular inspe ction to the effec t of "re pair or re place a s

neces sa ry" are wa rranted for the warra nty period. A ny wa rranted

part which is s cheduled for replace ment a s require d ma intenance

is warra nted for the pe riod of time up to the first sc heduled

replaceme nt point for that part.

3. DIA GN OS IS

Y ou will not be c harged for diagnos tic labor that leads to the

determination that a warra nted pa rt is defective, if the diagnos tic

work is performed at an authorized s ervice dealer or warra nty s tation.

4. DAM AGE S

If a wa rranted part failed causing dama ge to other engine

components, consult an warranty s tation.

D. W HA T IS NOT C OV E RE D

1. T his limited warranty does not c over any part which ma lfunctions,

2. Add-on or modified parts

3. E xpens es incurred by proces sing warranty c laims

E . HOW T O FI L E A C LAIM

All repairs qualifying under this Limited W arra nty mus t be pe rformed

by a de aler who sold you the engine or warra nty s tation authorized

by R OB IN A ME RIC A. In the event that any emis sion-rela ted pa rt is

found to be defe ctive during the warranty period, you mus t notify the

R obin A merica Inc. C ustomer S ervic e Depa rtment at 1-63 0-350-8200

and you will be a dvis ed of the a ppropriate warra nty s ervice fac ilities

where the warranty repa ir is to be performe d.

F . WHE R E T O O B TA IN WA R RANT Y S E RVIC E

It is recommended that wa rranty s ervice be pe rformed by the

authorized de aler who s old you the engine, although warra nty

service will be performe d by a ny authorized s ervice de alers or

warra nty stations anywhe re in the United States.

-

fails or is dama ged due to failure to follow the maintena nce and

opera ting instructions s et forth in the 2004 a nd later O wner's

Manual including:

(1) improper maintenance of any warranted parts

(2) improper installation, adjus tment or re pair of the engine or of

any warranted part unles s pe rformed by a n a uthorized se rvice

dea ler

(3) failure to follow re commendations on fue l us e containe d in the

200 4 and later Owner's Ma nual

(4) repairs performed outside of the authorize d warranty s ervice

dea lers

(5) use of parts which are not authorize d by F UJ I.

This warranty doe s not cover any pa rt that ma lfunctions, fails or is

dama ged due to alterations by cha nging, adding to or re moving

parts from the engine.

F UJ I, any a uthorize d s ervice dealer a nd warra nty s tation s hall not

be liable for any los s of us e of the e ngine, for any a lternative usa ge,

for a ny dama ge to goods, loss of time or inconve nienc e.

G B

G B

G B

G B

G B

G B

G B

G B

G B

G B

G B

Page 7

When wa rranty repair is needed, the engine mus t be brought to an

authorized s ervice dealer or warranty station’s plac e of bus iness during

normal business hours . In a ll cas es , a reas onable time, not to e xce ed

30 days , must be a llowed for the warra nty repa ir to be completed after

the e ngine is re ceived by the authorized se rvice deale r or wa rranty s tation.

G . MA INT E NA NC E , R EPL AC EME NT A ND

R E PA IR O F E MIS S ION -R E LATE D P AR TS

Only warranted engine replaceme nt parts approved by F UJ I s hould

be use d in the performa nce of any warra nty ma intenance or repa irs

on e mis sion-related parts. If other than authorized parts a re us ed for

maintena nce, replac ement or repair of compone nts affecting emis sion

control, you s hould a ss ure y ourself that suc h parts a re wa rranted by

their ma nufacturer to be equivalent to authorize d parts in performa nce

and durability. F UJ I , however, as sumes no lia bility under this wa rranty

with res pect to parts other than a uthorized parts . The us e of nonauthorized re placement pa rts does not invalidate the wa rranty on

other c omponents unles s the non-a uthorized parts caus e dama ge to

warra nted parts.

H. P AR T S C OV E R E D U NDE R T HE C AL IFO R NIA E MIS S IONS

WAR R ANT Y

(1) F uel Metering S ys tem

(i) Ca rburetor and interna l parts

(ii) Air cle aner plate (including c hoke s ystem)

(iii) Air cle aner cover

(iv) Air cleaner e lement

(v) Fuel F ilter

(2) Ignition S ys tem

(i) Spark plug

(ii) Flywheel ma gneto

(iii) Ignition c oil

(3) Miscella neous Items Us ed in A bove S ys tems

(i) Hos es and s ealing gas kets, bolts, conne ctors, and as semblies.

US

I. MA INT ENA NC E STA TE ME NTS

It is your res ponsibility to ha ve a ll s cheduled inspection a nd maintenance services performed at the times re commende d in the 2 000 and later

Owne r's Ma nual and to retain proof that inspec tion and maintena nce s ervic es a re performed at the times when rec ommended. F UJ I will not

deny a warranty claim solely becaus e y ou ha ve no record of ma intena nce; howeve r, FUJ I ma y de ny a warranty c laim if your failure to perform

required maintena nce res ulted in the failure of warra nted pa rt. The proof which y ou maintain should be given to each s ubse quent owner of the

engine. Y ou are re sponsible for pe rforming the sc heduled maintena nce des cribed below bas ed on the procedures s pec ified in the 2004 and

later Owner's Ma nual. The sche duled maintena nce below is bas ed on a norma l engine opera ting s chedule.

P ROC E DUR E INTE R V AL

1) Cle an engine a nd check bolts and nuts. R etighten if ne ces sary. : Every 8 hours (da ily)

2) Che ck a nd refill e ngine oil (4 stroke) : Every 8 hours (re fill daily up to upper limit)

3) Cha nge engine oil (4 s troke) : Initial 20 hours a nd every 100 hours afterward

4) Che ck c logging of cooling air passa ge a nd cylinder fins. : Every 8 hours (da ily)

R emove and clean if nece ss ary.

5) Cle an a ir c leaner

6) Che ck s park plug. Cle an a nd a djust if ne ces sary.

G B

7) Che ck muffler exhaust outlet ( or port). Clean if nec ess ary.

8) Che ck fuel filter. If clogged, replac e with new one.

G B

9) Adjust valve cle arance, if a pplica ble (4 s troke)

10) R epla ce fule lines.

G B

11) O verhaul engine.

12) R epla ce pa ckings and gaskets with new ones.

G B

: Every 8 hours (da ily)

: Every 8 hours (da ily)

: Every 50 hours (monthly)

: Every 50 hours (monthly)

: Every 200 hours

: Every 200 hours

: Every 200 hours

: Every reas sembling

Note: More frequent ma intenance may be ne ces sary under dus ty, dirty or s evere conditions.

G B

Page 8

FOREWORD

SER No.

Thank you very much for purchasing a ROBIN PUMP.

This manual covers operation and maintenance of ROBIN PUMP.

All information in this publication is based on the latest product information available at the

time of approval for printing. Please read this manual carefully before operating.

Please take a moment to familiarize yourself with the proper operation and maintenance

procedures in order to maximize the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at any time.

Due to constant efforts to improve our products, certain procedures and specifications are

subjected to change without notice.

When ordering spare parts, always give us the MODEL, PRODUCTION NUMBER and SERIAL

NUMBER of your pump.

Please fill in the following blanks after checking the production number on your pump.

(Location of label is different depending on the pump specification.)

PROD No.

GB

PROD No. / SER No.

(

)

Label

CONTENTS

SER No.

(

)

Label

Page

1. SAFETY PRECAUTIONS................................................................................... 2

2. COMPONENTS.................................................................................................. 4

3. PRE-OPERATION FOR STARTING .................................................................. 5

4. OPERATING YOUR PUMP................................................................................ 5

5. MAINTENANCE ................................................................................................. 6

6. PREPARATIONS FOR STORAGE..................................................................... 8

7. EASY TROUBLESHOOTING............................................................................. 9

8. SPECIFICATIONS.............................................................................................. 10

NOTE Please refer to the illustrations on the back page of the front

cover or back cover for Fig.

1 1

1 to

1 1

88

8 indicated in the sentence.

88

1

Page 9

1. SAFETY PRECAUTIONS

Please make sure you review each precaution carefully.

Pay special attention to statement preceded by the following words.

GB

WARNING

“WARNING” indicates a strong possibility of severe personal injury or loss of life if

instructions are not followed.

CAUTION

“CAUTION” indicates a possibility of personal injury or equipment damage if instructions

are not followed.

WARNING

■

Never inhale exhaust gasses.

They contain carbon monoxide, a colorless, odorless and extremely dangerous gas

which can cause unconsciousness or death.

■

Never operate the pump indoors or in a poorly ventilated area, such as tunnel, cave,

etc.

■

Exercise extreme care when operating the pump near people or animals.

■

Keep the exhaust pipe free of foreign objects.

WARNING

■

Gasoline is extremely flammable and its vapors can explode if ignited.

■

Do not refuel indoors or in a poorly ventilated area.

■

Be sure to stop the pump prior to refueling.

■

Do not remove fuel tank cap nor fill fuel tank while engine is hot or running.

Allow engine to cool at least 2 minutes before refueling.

■

Do not overfill the fuel tank.

■

If fuel is spilt, wipe it away carefully and wait until the fuel has dried before starting the

engine.

■

After refueling, make sure that the fuel cap is secured to prevent spillage.

: EXHAUST PRECAUTIONS

: REFUELING PRECAUTIONS

WARNING

■

Do not operate the pump while smoking or near an open flame.

■

Do not use around dry brush, twigs, cloth rags, or other flammable materials.

■

Keep cooling air intake (recoil starter area) and muffler side of the engine at least

: FIRE PREVENTION

1 meter (3 feet) away from buildings, obstructions and other burnable objects.

■

Keep the pump away from flammables and other hazardous materials (trash, rags,

lubricants, explosives).

WARNING

■

Be careful of hot parts.

: OTHER SAFETY PRECAUTIONS

The muffler and other engine parts become very hot while the pump is running or just

after it has stopped. Operate the pump in a safe area and keep children away from

the running pump.

■

Do not use diaphram pump for the mixture of water and oil.

2

1m

1m

Page 10

■

Do not touch the spark plug and ignition cable when starting and operating the engine.

■

Operate the pump on a stable, level surface.

If the engine is tilted, fuel spillage may result.

NOTE

Operating the pump at a steep incline may cause seizure due to improper lubrication

even with a maximum oil level.

■

Drain the fuel when transporting the pump.

■

Keep the unit dry (do not operate it in rainy conditions).

GB

CAUTION

■

Carefully check fuel hoses and joints for looseness and fuel leakage. Leaked fuel

: PRE-OPERATION CHECKS

creates a potentially dangerous situation.

■

Check bolts and nuts for looseness. A loose bolt or nut may cause serious engine

trouble.

■

Check the engine oil and refill if necessary.

■

Check the fuel level and refill if necessary. Take care not to overfill the tank.

■

Keep cylinder fins and recoil starter free of dirt, grass and other debris.

■

Wear snug fitting working clothes when operating the engine.

Loose aprons, towels, belt, etc., may be caught in the engine or drive train, causing a

dangerous situation.

3

Page 11

SYMBOLS

GB

.launams'renwoehtdaeR

.ecafrustohehtforaelcyatS

.suonosiopsisagtsuahxE

.aeradetalitnevnunanietarepotonoD

.gnileufererofebenigneehtpotS

.detibihorpgnikomsdnaemalfnepo,eriF

)nuR(nOytiralopevitisoP;sulP

)potS(ffOyrettaB

lioenignE)tratscirtcelE(tratsenignE

lioddA

2. COMPONENTS

(See Fig.

NOTE Please refer to the illustrations on the back page of the front

q Plug (drain)

w Suction

e Delivery

r Plug (priming)

t Handle

y Spark plug cover

11

1)

11

cover or back cover for Fig.

!0 Primer button

!1 Tank cap

!2 Fuel tank

!3 Casing cover

!4 Speed control lever

!5 Stop Switch

1 1

1 to

1 1

88

8 indicated in the sentence.

88

!9 Starter handle

@0 Choke lever

@1 Muffler

@2 Strainer

@3 Hose coupling

@4 Hose band

u Spark plug

i Air cleaner

o Carburetor

4

!6 Set base

!7 Oil filler (with oil gauge)

!8 Recoil starter

@5 Tools

@6 Instruction for use

(This publication)

Page 12

3. PRE-OPERA TION FOR ST ARTING

(See Fig.

22

2

22

)

1. CONNECT SUCTION HOSE

22

(See Fig.

Use a reinforced-wall or wire braided hose to prevent suction

collapse.

Since the pump self-priming time is directly proportional to

hose length, a short hose is recommended.

2

22

-

qq

q)

qq

CAUTION

Always use a strainer with the suction hose. Gravel

or debris sucked into the pump will cause serious

damage to the impeller and the pump casting.

2. CONNECT DELIVERY HOSE

22

(See Fig.

When using a fabric hose, always use a hose band to prevent

the hose from disconnecting under high pressure.

3. CHECK ENGINE OIL (See Fig.

Before checking or refilling engine oil, be sure the engine is

located on stable, level surface and stopped.

■

Do not screw the oil gauge into the oil filler neck to check

oil level. If the oil level is low, refill to the upper level with

the following recommended oil.

■

Use 4-stroke automotive detergent oil of API service

class SF or higher grade.

■

Select the viscosity based on the air temperature at the

time of operation as shown in the table. (See Fig.2

OIL CAPACITY : 0.8 liter

Explanation of Fig.

q Oil Gauge

w Upper Level (0.8 liter)

e Lower Level

4. CHECK FUEL (See Fig.

2

22

-

ww

w)

ww

22

2

22

rr

22

-

r)

2

rr

22

-

e)

rr

r

-

rr

22

tt

2

-

t)

22

tt

WARNING

Do not refuel while smoking, near an open flame

or other such potential fire hazards. Otherwise

fire accident may occur.

■

Stop the engine and open the cap.

■

Incline the engine as fuel inlet upward, then refill fuel to

the upper level. Do not fill fuel too much.

■

Use unleaded automotive gasoline only.

Fuel Tank Capacity (This engine is 4-stroke gasoline

engine). Refer to “8. SPECIFICATIONS” Page 10 for fuel

tank capacity

■

When filling the fuel tank, always use the fuel filter.

■

Wipe off any spilled fuel before starting the engine.

-

(See Fig.2

y)

5. CHECK PRIMING WATER

uu

22

-

(See Fig.

It is recommended that the water chamber of pump casing

should be primed with full of water before operating.

2

22

u)

uu

WARNING

Never attempt to operate the pump without priming

water or the pump will overheat. Extended dry

operation will destroy the mechanical seal.

If the unit has been operated dry , stop the engine

immediately and allow the pump to cool before

adding priming water.

4. OPERATING YOUR PUMP

-

-r-

44

4)

44

q)

33

3)

33

-

w)

-

e)

q)

-

y)

1. STARTING (See Fig.

(1) Set the throttle lever to the idling position (L). (See Fig.3-q)

(2) Set the stop switch to the position “ON”. (See Fig.3

(3) Close the choke lever. (See Fig.3

■

If the engine is cold or the ambient temperature is low,

close the choke lever fully.

■

If the engine is warm or the ambient temperature is high,

open the choke lever half-way, or keep it fully open.

(4) Push the primer pump 7 to 10 times to feed the fuel to

the carburetor. (See Fig.3

(5) Pull the starter handle slowly until resistance is felt. This

is the “compression” point. Return the handle to its

original position and pull swiftly.

Do not pull out the rope all the way.

After starting the engine, allow the starter handle to return

to its original position while still holding the handle.

(See Fig.3

(6) After starting the engine, gradually open choke by turning

the choke lever and finally keep it fully opened. Do not

fully open the choke lever immediately when the engine

is cold or the ambient temperature is low, because the

engine may stop. (See Fig.3

-

t)

2. RUNNING (See Fig.

(1) After the engine starts, set the speed control lever at the

low speed position (L) and warm it up without load for a

few minutes. (See Fig.4

(2) Gradually move the speed control lever toward the high

speed position (H) and set it at the required engine speed.

(See Fig.4

■

Whenever high speed operation is not required, slow the

engine down (idle) by moving the speed control lever to

save fuel and extend engine life.

NOTE

If the engine is operated at upside down, white smoke may

be exhausted from the muffler.

-

w)

GB

5

Page 13

3. STOPPING (See Fig.

(1) Set the speed control lever at the low speed position and

allow the engine to run at low speed for 2 or 3 minutes

before stopping. (See Fig.5

(2) Set the stop switch to the position “OFF”. (See Fig.5

■Do not stop the engine suddenly when it is running at

high speed.

(3) Pull the starter handle slowly and return the handle to its

original position when resistance is felt. This operation is

necessary to prevent outside moist air from intruding

into the combustion chamber. (See Fig.5

GB

5. MAINTENANCE

(See Fig.

66

6

66

)

55

5)

55

-

q)

1. DAILY INSPECTION

Before running the engine, check the following service items.

q Loose or broken bolts and nuts

w Clean air cleaner element

e Enough clean engine oil

r Leakage of gasoline and engine oil

t Enough gasoline

y Safe surroundings

u Check the priming water

i Excessive vibration, noise

2. PERIODIC INSPECTION

Periodic maintenance is vital to the safe and efficient operation

of your pump.

Check the table below for periodic maintenance intervals. The

below chart is based on the normal pump operation schedule.

-

w)

CAUTION

Replace rubber pipes for fuel passage every two

years. If fuel leakage is found, replace the pipe

immediately.

-

e)

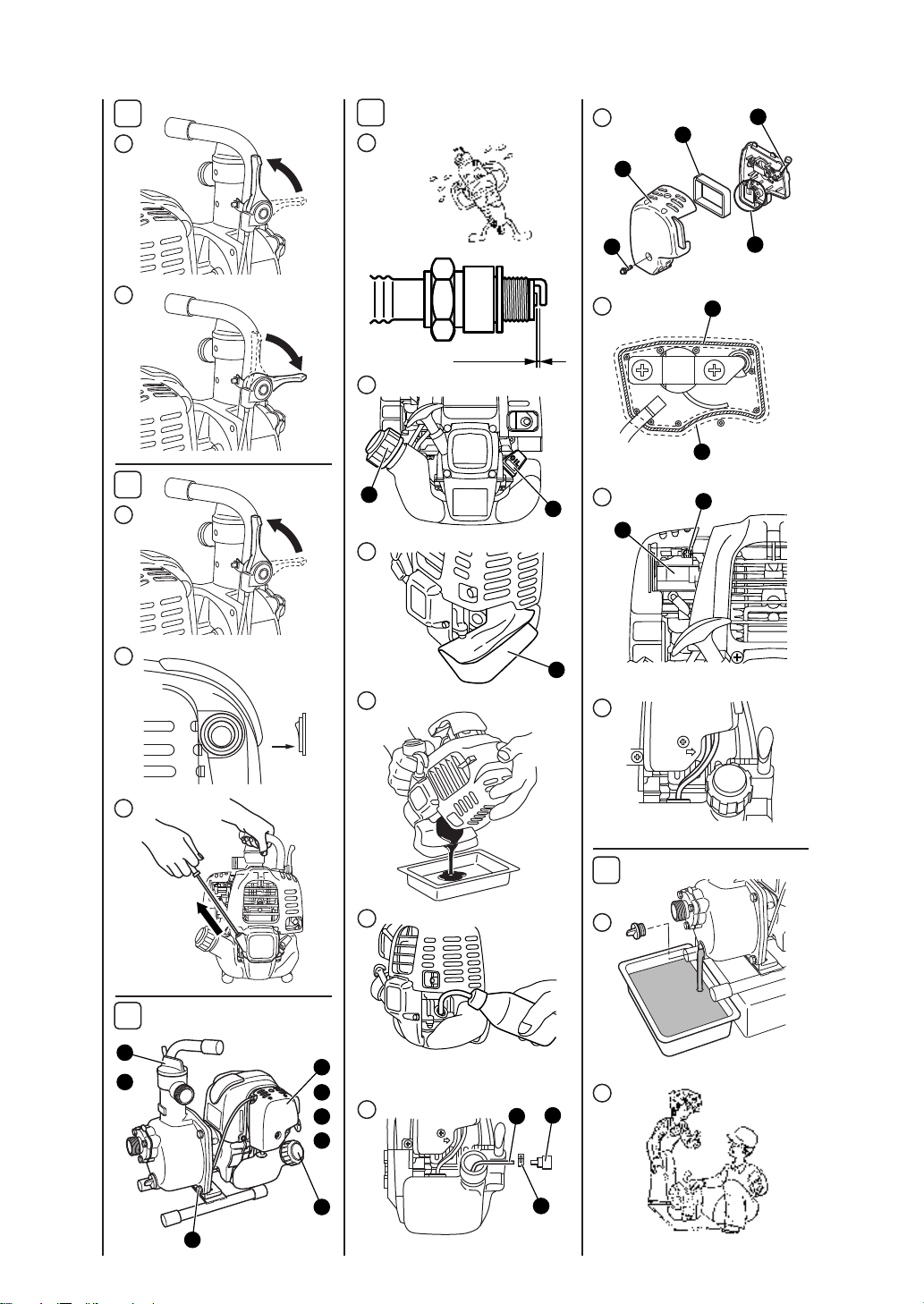

3. INSPECTING THE SPARK PLUG

qq

77

-

(See Fig.

(1) Clean off carbon deposits on the spark plug electrode

using a plug cleaner or wire brush.

(2) Check electrode gap. The gap should be 0.7 mm to 0.8

mm (0.03 inch.). Adjust the gap, if necessary, by carefully

bending the side electrode.

Recommended Spark Plug : NGK CMR6A

7

77

q)

qq

Periodic Maintenance Schedule table

smetiecnanetniaM

STUNDNASTLOBKCEHCDNATESPMUPNAELC

LIOENIGNELLIFERDNAKCEHC

RENAELCRIANAELC

LIOENIGNEEGNAHC )sruoh02laitnI(

GULPKRAPSNAELC

RETLIFLEUFNAELC

NAELCDNAGNISACPMUPEHTEVOMER

KRAPSTSUJDADNANAELC

SEDORTCELEDNAGULP

KCEHCECNARAELCEVLAVTSUJDADNA)1etoN*(

ROTERUBRACTSUJDADNANAELC

SEVLAVKCEHC

*Note: 1. As to the procedures for these items, please refer to the SERVICE MANUAL or consult your nearest Robin

service dealer.

NOTE

Replace rubber hoses for passage every one year. If and when fuel leakage is found, replace hose at once.

YREVILEDDNANOITCUSKCEHC

)1etoN*(YRASSECENFIENIGNELUAHREVO

● )yliaD(

●

sruoh8yrevE

)yliaD(

(Refill daily up to upper level.)

●

sruoh05yrevE

)ylkeeW(

●

●

●

)ylhtnoM(

●

●

●

●

●

●

sruoh002yrevE

6

Page 14

77

ww

4.

ENGINE OIL CHANGE (See Fig.

7-

77

w

ww

〜

tt

t

tt

Initial oil cha n ge : After 20 hours of operati on

Thereafter : Every 50 hours of operation

(1) When changing oil, stop the engine and loosen the drain

plug. Drain the used oil while the engine is warm. Warm

oil drains quickly and completely.

CAUTION

To prevent injury, pay attention to the hot oil.

Make sure the fuel cap is tightly secured to avoid

spillage.

5. CLEANING FUEL FILTER

)

(See Fig.

77

7

77

-

yy

y)

yy

WARNING Flame Prohibited

Remove the hose clamp and pull out the fuel filter from fuel

pipe. Wash the fuel filter with kerosene. After washing,

reassemble it. If the fuel filter is heavy dirty, replace it with

new one.

Explanation of Fig.

q Fuel filter

w Fuel pipe

e Hose clamp

yy

77

y

-

7

yy

77

GB

(2) Re-install the drain plug before refilling oil.

OIL CAPACITY : 0.8 liter

(3) Refer to page 5 for the recommended oil.

■

Always use the best grade and clean oil. Contaminated

oil, poor quality oil and shortage of oil cause damage to

engine or shorten the engine life.

(4) Remove the oil gauge. Be cautious to place the oil gauge

in a place where it will not gather dirt, dust or other foreign

matter. (See Fig.7

(5) Place a cloth or paper towel to the area around the oil

filler hole. (See Fig.7

(6) Remove the oil gauge, then tilt the engine and drain the

oil into a pan or other receptacle. (See Fig.7

(7) Put the engine on a level surface, then fill with the oil up to

the point of overflowing the filler neck. Pour the oil in from

a squeeze bottle or other appropriate. (See Fig.7

(8) After filling the engine with oil, reinsert the oil gauge.

Ensure that the oil gauge is tight, as if it loosens later oil

will leak out. (See Fig.7

-

w)

-

e, q)

-

t)

-

r)

-

r)

6. CLEANING AIR CLEANER

WARNING Flame Prohibited

A dirty air cleaner element will cause starting difficulty, power

loss, engine malfunctions, and shorten engine life extremely.

Always keep the air cleaner element clean.

■

Remove the fixing bolt of air cleaner cover.

-u-

(See Fig.7

■

Pull out the lower edge of the cover to remove the air

cleaner cover. (See Fig.7

■

Place the choke lever to the fully closed position, taking

care to ensure that dust and dirt are not allowed to enter

the carburetor.

■

Remove the element, then clean it with a solution of warm

water and a mild detergent, thoroughly drying it afterward.

Install it in alignment with the lines as shown in illustration.

■

Wipe off any oil adhering to the area around the air

cleaner cover and breather with a cloth.

■

After cleaning, reassemble the cleaner cover (insert the

tab at the top first, then insert the bottom tab) and tighten

the fixing bolt.

q)

-u-

w)

7

Page 15

7. ADJUSTING CARBURETOR

oo

77

-

(See Fig.

Adjusting idling rpm.

When adjust screw is turned right, engine rpm increases, and

when it is turned left, rpm decreases. (Refer to illustration.)

Normal idling rpm 3000± 100rpm

NOTE

The carburetor greatly affects the performance of the

engine.

Since it has been adjusted carefully at our factory

GB

before shipment, avoid adjusting unless absolutely

necessary. If adjustments are needed, contact your

nearest dealer.

7

77

o)

oo

6. PREP ARATIONS FOR ST ORAGE

88

1. WATER (See Fig.

Drain all water from the drain plug.

When retightening drain plug, be sure to clean

the drain plug and the thread of casing. Otherwise,

the thread may be damaged.

2. DISCONNECT THE DELIVERY HOSE

Tilt the pump and drain all water from delivery hole. Severe

damage to pump may result if water freezes in the pumping

chamber.

3. DISCHARGE FUEL

qq

8

-

q)

88

qq

CAUTION

8. FUEL HOSE REPLACEMENT

77

(See Fig.

7

77

-

!0!0

!0)

!0!0

WARNING

Take extreme caution when replacing fuel hose ;

gasoline is extremely flammable.

Replace the fuel hose every 2 years. If fuel leaks from fuel

hose, replace the fuel hose immediately.

9. CHECKING BOLTS, NUTS AND SCREWS

■ Retighten loose bolts and nuts.

■ Check for fuel and oil leaks.

■ Replace damaged parts with new ones.

WARNING Flame Prohibited

In case the engine is not going to be used for more than 1

month, discharge fuel thoroughly from fuel tank and carburetor

in order to prevent from hard starting and/or poor engine

operation due to deteriorated fuel when you use the engine

next time.

■

Pour out the fuel in the tank from its filler neck.

■

Push the primer pump of the carburetor until the fuel in

it is thoroughly discharged.

88

4. ENGINE OIL (See Fig.

■

Change the engine oil with fresh oil.

■

Remove the spark plug, pour about 5 cc of engine oil

into the cylinder, slowly pull the starter handle of the

recoil starter 2 or 3 times, and reinstall the spark plug.

8

88

-

ww

w)

ww

5. CLEAN AND STORE

■

Slowly pull the recoil starter handle until resistance is

felt and leave it in that position.

■

Clean the pump thoroughly with an oiled cloth, put the

cover on, and store the pump indoors in a well ventilated,

low humidity area.

8

Page 16

7. EASY TROUBLESHOOTING

1. PUMP DOES NOT RUN .

■ Engine dose not start.

(See 7.-4 “4. WHEN ENGINE DOES NOT START”)

■ Sticking of impeller

(Disassemble and clean.)

2. PUMPING VOLUME IS SMALL.

■ Sucking air at suction side.

(Check piping at suction side.)

■ Drop off engine output

(Consult your nearest dealer.)

■ Breakage of mechanical seal.

(Consult your nearest dealer.)

■ High suction lift (Lower.)

■ Suction hose is too long or thin.

(Use a thick hose in minimum length.)

■ Leak of water from water passage.

(Stop leaking.)

■ Clogging of foreign substance in impeller.

(Disassemble and clean.)

■ Wear of impeller.

■ Strainer is clogged. (Clean.)

■ Engine speed is too low.

(Consult your nearest dealer.)

4. WHEN ENGINE DOES NOT START :

Perform the following checks before you take the pump to

your Robin dealer. If you still have trouble after completing

the checks, take the pump to your nearest Robin dealer.

WARNING

Before testing, carefully wipe off spilled fuel.

Put the plug as far away from the spark plug hole

as possible.

Ground the side of the electrode to any engine

ground.

(1) Is the engine switch set OK?

ww

33

-

(See Fig.

(2) Is there a strong spark across the electrode ?

■ Remove the spark plug and connect it to the plug cap.

Pull the starter handle while grounding spark plug against

engine body.

■Try with a new spark plug if the spark is weak or there is

no spark.

■ The ignition system is faulty if there is no spark with a

new spark plug.

3

33

w)

ww

GB

3. PUMP DOES NOT SELFPRIME.

■ Suction of air at suction side.

(Check piping at suction side.)

■ Insufficient priming water inside pump casing

(Prime fully.)

■ Imperfect tightening of drain plug.

(Tighten the plugs completely.)

■ Engine speed is too low.

(Consult your nearest dealer.)

■ Sucking air from mechanical seal.

(Consult your nearest dealer.)

(3) Is there enough compression?

■ Pull the starter handle slowly and check if resistance is

felt.

■If little force is required to pull the starter handle, check if

the spark plug is tightened firmly.

■If the spark plug is loose, tighten it.

(4) Is the spark plug wet with fuel?

■ Choke (close choke lever) and pull the starter handle five

or six times. Remove the plug and check if its electrode is

wet. If the electrode is wet, fuel is well supplied to your

engine.

■ When the electrode is dry, check where the fuel stops.

(Check the fuel intake of the carburetor and fuel filter

intake.)

■ In case the engine does not start with well supplied fuel,

try using fresh fuel.

9

Page 17

8. SPECIFICATIONS

epyT pmuplagufirtneC,gnimirp-fleS

daeHlatoTm53

PUMP

ledoM520HE

epyT enigneenilosaGVHO,ekorts-4,delooc-riAniboR

GB

leuF enilosagdedaelnuevitomotuA

ENGINE

thgieWteNgk3.5

LEDOM101VKP

sretemaiDyrevileDxnoitcS).ni1x1(mm4.52x4.52

emuloVyrevileDmumixaMnim/L011

daeHnoitcuSm8

aireteMlaeSelxA

)laeSlacinahceM(

yticapaCknaTleuFL5.0

metsySgnitratSretratSlioceR

)HxWxL(snoisnemiD mm913x312x333

seirosseccAdradnatS

nobrac-cimareC

).cp1(reniartS,)tes1(tiklootenignE

).scp3(dnabesoH,).scp2(gnilpuocesoH

10

Page 18

PRINTED IN JAPAN

January 2004 CE

80

Loading...

Loading...