Page 1

Page 2

3 Year Limited Engine Warranty

(Special Term for W elder Application)

(Effective with engines purchased from Robin America, Wood Dale, IL, after November 15,

1993)

Robin America, Inc., a division of Fuji Heavy Industries, Ltd. (herein “Robin”), warrants that

each new engine sold by it will be free, under normal use and service, from defects in material

and workmanship for a period listed below from the date of sale to the original retail purchaser.

Robin’s obligation under this Limited Warranty shall be limited to the repair and replacement,

at Robin’s option, of any part or parts which upon examination is/are found, in Robin’s

judgment, to have been defective in material or work manship. It shall be a condition of Robin’s

obligation under this Limited W arranty that Robin, directly or through one of its Distributors or

Service Centers authorized to service the particular engine involved, receive prompt notice of

any warranty claim and that the engine or the part or parts claimed to be defec tive be promptly

delivered, transportation prepaid, to such Distributor or Service Center for inspection and

repair. All repairs qualifying under this Limited Warranty must be performed by Robin or one

of its autho rized Distributors or Service Centers.

WARRANTY PERIODS:

Robin V-Twin, Welder Application Limited 3 years Warranty

(Applies to Original OEM installed engine)

The repair or replacement of any part or parts under this Limited Warranty shall not extend the

term of the engine warranty beyond the original term as set forth above.

LIMITATIONS AND EXCLUSIONS: This Limited Warranty shall not apply to:

1. Bent or broken crankshaft or resultant damage caused by vibration related to a

bent or broken crankshaft. Also, damage caused by loose engine mounting bolts or

improper or imbalanced accessories or blades mounted to the crankshaft.

2. Repairs required because of prolonged storage including damage caused by old or

contami nated fuel in the fuel tank, fuel lines or carburetor, sticky valves or corrosion

and rust of engine parts.

6. Engine tune-ups and normal maintenance service including, but not limited to, valve

adjust ment, normal replacement of service items, fuel and lubricating oil, etc.

7. Any engine which has been subject to negligence, misuse, accident, mis-

application or over-speeding.

8. Any engine that has been installed, repaired, or altered by anyone in a manner which

in Robin’s sole judgment adversely affects its performance or reliability.

9. Any engine which has been fi tted with or repaired with parts or components not

manufactured or approved by Robin which in Robin’s sole judgment adversely

affects its performance or reli ability.

10. Instances when normal use has exhausted the life of a component or an engine.

The customer is responsible for all transportation charges in connection with any warranty

work.

Robin reserves the right to modify, alter or improve any engines or parts without incurring any

oblig ation to modify or replace, any engine or parts previously sold without such modifi cation,

alternation or improvement.

No person is authorized to give any other warranty or to assume any additional obligation on

Robin’s behalf unless made in writing and signed by an offi cer of Robin.

THIS WARRANTY, AND ROBIN’S OBLIGATION HERE

UNDER, ARE IN LIEU OF ANY OTHER WARRANTIES

OR OBLIGATIONS OF ANY KIND, EXPRESSED

OR IMPLIED, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. THERE ARE NO WARRANTIES WHICH

EXTEND BEYOND THE DESCRIPTION ON THE

FACE HERE-OF. ROBIN SHALL IN NO EVENT BE

LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL

DAMAGES.

3. Repair required due to overheating. (Most often caused by overloaded or clogged or

damaged or missing fl ywheel, fan, inlet air passages, cooling fi ns or air shrouds.)

4. Dirt or grit related wear caused by improper air cleaner maintenance (most often

resulting in worn piston, piston rings, cylinders, valves, valve guides, carburetor or

other internal compo nents).

5. Broken or scored parts caused by low oil level, dirty or improper grade of oil.

3

4

Page 3

Safety Precautions

Before operating the engine, read this manual and become

familiar with it and the equipment. Safe and effi cient operation

can be achieved only if the equipment is properly operated and

maintained.

The following symbols, found throughout this manual, alert you to

potentially dangerous conditions to the operator, service personnel, or

the equipment.

This symbol warns of immediate hazards which will

! DANGER

result in severe personal injury or death.

This symbol refers to a hazard or unsafe practice

! WARNING

which can result in severe personal injury or death.

This symbol refers to a hazard or unsafe practice

! CAUTION

which can result in personal injury or product or property

damage.

Fuels, electrical equipment, batteries, exhaust gases and moving parts

present potential hazards that can result in severe personal injury.

Take care in following these recommended procedures. All local, state

and federal codes should be consulted and complied with.

This engine is not designed or intended for use in

! WARNING

any type of aircraft. Use of this engine in aircraft can result

in engine failure and cause severe personal injury or

death.

GENERAL

• Provide appropriate fi re extinguishers and install them in convenient

locations. Use an extinguisher rated ABC by NFPA.

• Make sure that all fasteners on the engine are secure and

accurately torqued. Keep guards in position over fans, driving belts,

etc.

• If it is necessary to make adjustments while the engine is

running, use extreme caution when close to hot exhausts,

5

6

Page 4

moving parts, etc.

• Used engine oils have been identifi ed by some state and

federal agencies as causing cancer or reproductive toxicity. When

checking or changing engine oil, take care not to ingest, breathe

the fumes, or contact used oil.

• Do not work on this equipment when mentally or physically

fatigued, or after consuming any alcohol or drug that makes

the operation of equipment unsafe.

BATTERIES

• Before starting work on the engine, disconnect batteries to prevent

inadvertent starting of the engine. Disconnect negative (-) cable fi rst.

• DO NOT SMOKE while servicing batteries. Lead acid batteries give

off a highly explosive hydrogen gas which can be ignited by fl ame,

electrical arcing or by smoking.

• Verify battery polarity before connecting battery cables. Connect

negative (-) cable last.

PROTECT AGAINST MOVING P ARTS

• Do not wear loose clothing in the vicinity of moving parts, such as

PTO shafts, fl ywheels, blowers, couplings, fans, belts, etc.

• Keep your hands away from moving parts

FUEL SYSTEMS

• DO NOT fi ll fuel tank while engine is running

• DO NOT smoke or use an open fl ame in the vicinity of the engine or

fuel tank. Internal combustion engine fuels are highly fl ammable.

• Fuel line must be made of steel tubing which adequately secured,

and free from leaks. Tubing which connects to the carburetor should

be factory approved fl exible line. Do not use copper tubing as the

fl exible lines as copper will harden and become brittle enough to

break.

• Be sure all fuel supplies have a positive shutoff valve.

• Benzene and lead, found in some gasoline, have been identifi ed by

some state and federal agencies as causing cancer or reproductive

toxicity. When checking, draining, or adding gasoline take care not

to ingest, breathe fumes, or contact the gasoline.

78

EXHAUST SYSTEM

• Exhaust products of any internal combustion engine are toxic and

can cause injury, or death it inhaled. When operating the engine in a

confi ned area, make sure the ventilation system is operating

properly.

• DO NOT use exhaust gases to heat a compartment.

• Make sure that your exhaust system is free of leaks. Make sure that

exhaust manifolds are secure and are not warped by bolts unevenly

torqued.

EXHAUST GAS IS DEADLY!

Exhaust gases contain carbon monoxide, a poisonous gas that can

cause unconsciousness and death. It is an odorless and colorless gas

formed during combustion of hydrocarbon fuels. Symptoms of carbon

monoxide poisoning are:

• Dizziness

• Vomiting

• Headache

• Muscular Twitching

• Throbbing in Temples

• Weakness and Sleepiness

If you experience any of these symptoms, get out into fresh air immediately, shut down the unit and do not use it until it has been inspected.

The best protection against carbon monoxide inhalation is proper

installation and regular, frequent inspections of the complete exhaust

system. If you notice a change in the sound or appearance of exhaust

system, shut the unit down immediately and have it inspected and

repaired at once by a competent mechanic.

KEEP THE UNIT AND SURROUNDING AREA CLEAN

• Make sure that oily rags are not left on or near the engine.

• Remove all unnecessary grease and oil from the unit. Accumulated

grease and oil can cause overheating and subsequent engine

damage and present a potential fi re hazard.

Page 5

Introduction

ABOUT THIS MANUAL

This manual covers the operation and maintenance of the horizontalshaft Robin Subaru EH65 engines for welder applications (OHV220

Performer Series). Each operator of the power equipment should study

this engine manual carefully and observe all of its instructions and

precautions. Proper use and periodic maintenance are responsibilities

of the operator(s) and are essential for top performance.

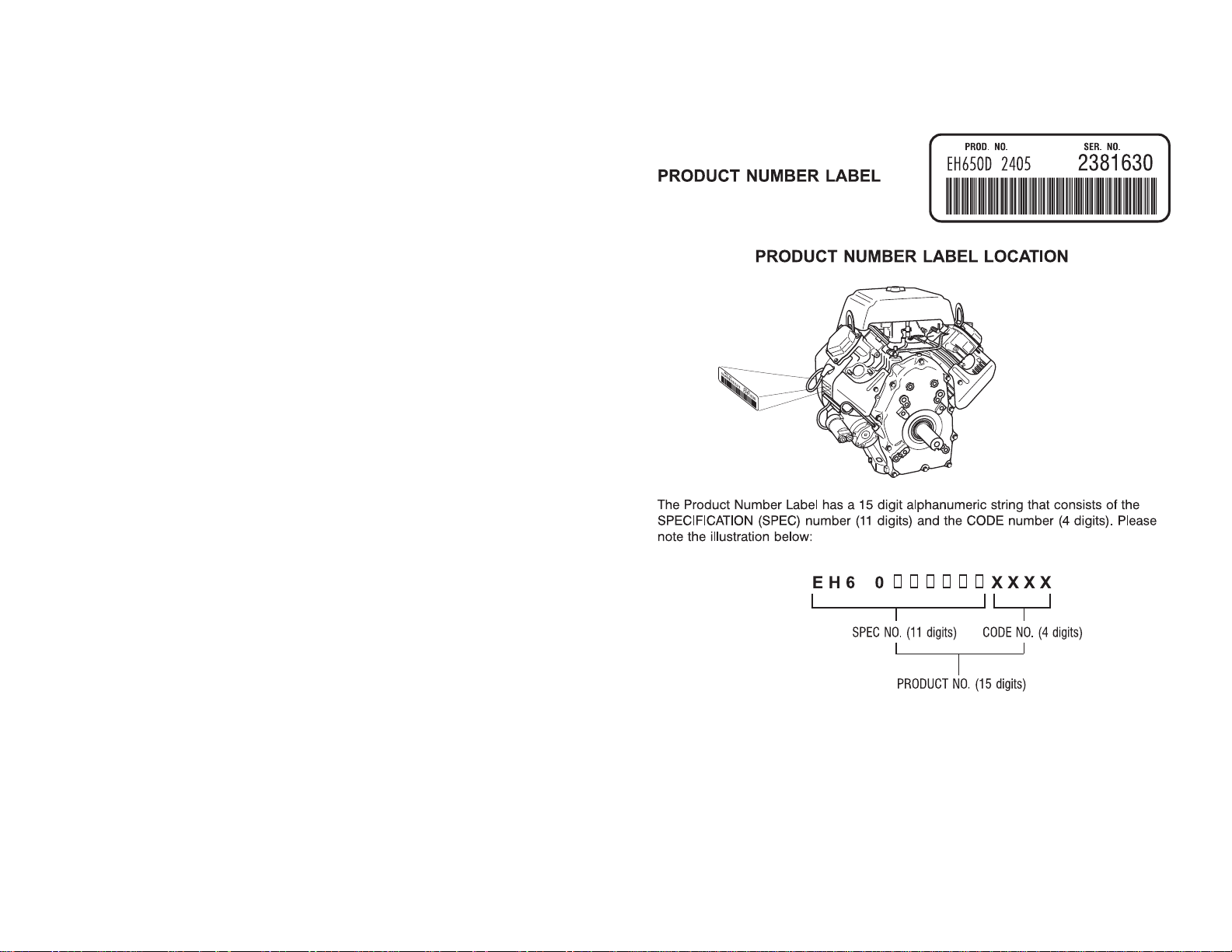

MODEL IDENTIFICATION

Whenever contacting a dealer or distributor for information, parts or

service, always provide the model number and the serial number

marked on the nameplate of the engine.

Robin engines are identifi ed by MODEL, SPECIFICATION, and CODE

NUMBER. For each model there may be many different versions

called specifi cations. Each specifi cation will be unique in some way.

The difference may only be the paint color or it may have a different

type of PTO or some other signifi cant difference.

In order to identify the correct service part number, it is important

to confi rm the specifi cation and code numbers for your engine. The

specifi cation and code number together are know as the PRODUCT

NUMBER.

All Robin 4 cycle engine have a Product Number label similar to the

label illustrated to the right.

C

5

9

10

Page 6

Description

FEATURES

• Overhead valve arrangement enables high power, and low fuel and

oil consumption

• V-Twin, four stroke design

• Air-cooled and gasoline fueled

• The light weight and compact design makes it easy to install and

utilize for many applications.

• A steel crankshaft and high-load bearing offer durability

• Pressure lubrication system and large capacity air cleaner enhance

reliability of the engine.

• The combustion chamber shape, along with a tuned exhaust valve

system, enhance the low exhaust emission and provides high

torque at low speed.

Standard features include a fuel cut-of valve, a 12V-15 amp alternator

and a pulse-type fuel pump.

The fl ywheel-type governor gear provides constant operation at the

selected speed against load variations.

The carburetor is a down draft, fl oat controlled fuel system with a fi xed

main jet. A fuel cut-off valve is provided to secure engine shut-down

when the switch is turned off. Carburetors are calibrated for sure

starting, good acceleration, low fuel consumption and adequate power

output.

A throttle solenoid (optional) automatically senses when the engine

needs to run at full power and when it requires idle speed. The solenoid operates using a 15 second delay before dropping to idle.

Specifi cations

Air-Cooled, 4-Stroke, V-Twin Cylinder, Horizontal Shaft,

Engine Type

Rated Output 22.0 HP/3600 rpm (16.4 kW/3600)

Continuous Output 17.0 HP/3600 rpm (12.7kW/3600)

Bore X Stroke 80 mm x 65 mm (3.15” x 2.56”)

Displacement 653cc (39.90 cu in)

Compression Ratio 8.3:1

Maximum Output 16.4 kW/22.0 HP / 3600 rpm

Maximum Torque 33.6 ft/lbs @ 2500 rpm

Starting System Electric Start

Carburetor Down draft, Float Type

Fuel Unleaded Gasoline using a Diaphragm Pulse Pump

Lubrication Full Pressure with full Flow Spin-On Filter

Oil Type Automobile Engine Oil; Class SJ or SL (see oil chart)

Oil Capacity 1550 cc (1.64qt)

Charging System 12 volt 15 amp

Dry Weight 44 kg (96.9 lbs)

Dimensions (L x W x H) 317mm x 477mm x 475mm (12.5” x 19.0” x 19.0”)

Direction of Rotation CCW as Viewed from the PTO shaft side

Cooling System Forced Air Cooling

OHV Gasoline Engine

11

Ignition System Flywheel Magneto (Solid State)

Spark Plug Type NGK-BP6ES or BRP6ES

Governor System Centrifugal Fly Weight

Air Cleaner Double Element Assembly

Valve Clearance

(Intake & Exhaust) 0.003-0.005 in (0.07-0.10mm)

Emission Durability Period

(California Only) 500 hours

Page 7

Installation

LOCATING

Locate the engine at least 1 meter (3.0 ft) away from buildings or other

structures. Provide proper exhaust routing. Refer to EXHAUST SYSTEM below. Do not use the engine near fl ammables or other hazard-

ous materials such as trash, rags, lubricants, or explosives.

When determining the mounting location, make sure of the following:

• Gas and oil can easily be checked and supplied

• Oil can be changed.

• The air cleaner can be serviced

• Spark plugs can be checked.

Carefully examine the engines position, the method of connecting it to

a machine, and the foundation and support structure.

Locate the engine in a safe area on a stable level surface free of small

rock, loose gravel, etc.

! CAUTION

Operating the engine on an incline may cause

seizure due to improper lubrication; even at

maximum oil level.

carburetor.

If the tank is mounted above the carburetor, a fuel shut-off valve must

be connected between the fuel tank and the fuel pump.

Note: To prevent fuel from fl ooding the carburetor, the fuel valve

must be closed when the engine is not running.

Properly install fuel lines to the carburetor by completely inserting the

hose onto the fi tting and then secure it with a hose clamp.

Gaseous fuels are fl ammable and explosive and

! WARNING

can cause severe personal injury or death.

Do not smoke if you smell gas or are near fuel

tanks or fuel-buring equipment or are in an area

sharing ventilation with such equipment. Keep

fl ames, sparks, pilot lights, electrical switches,

arc-producing equipment and all other sources

of ignition well away. Keep a type ABC fi re

extinguisher handy.

EXHAUST SYSTEM

EXHAUST GAS IS DEADLY! Engine-powered equipment must never

be operated inside buildings or other enclosed spaces.

If a long exhaust pipe is used, the internal resistance results in loss

of engine power. The exhaust pipe ID must increase in proportion to

exhaust pipe length. For example, if the exhaust pipe is:

less than 3.0 m (9.8 ft.) long - pipe ID = 30mm (1-3/16in)

less than 5.0 m (16.4 ft)long - pipe ID = 33mm (1.3in)

It is the responsibility of the equipment operator(s) to check for

exhaust leaks on a daily basis and to have all leaks repaired before

continuing to operate the equipment.

FUEL

Fuel Tank

The fuel tank system must be provided by the OEM. A fuel

shut-off valve must connected between the fuel line and the fuel pump.

The fuel tank may be mounted up to 0.66 meters (2.0ft) below the

13 14

Do not refi ll the fuel tank while the engine is running. Do not overfi ll the

tank.

Wipe away any spilled fuel and wait until it has dried before starting

the engine.

Fuel recommendations

Use clean, fresh unleaded gasoline having a minimum octane rating (Anti-Knock Index) of 87. This engine is certifi ed to operate on

unleaded gasoline.

During some periods of the year only mandated “oxygenated” gasolines may be available. These are acceptable for use, but not preferable. Do not use gasoline or gasoline additives (de-icers) containing

methanol because methanol can be corrosive to fuel system compo-

nents.

! CAUTION

Do not use gasoline or gasoline additives

containing methanol because methanol can be

corrosive to fuel system components.

Page 8

Installation

ENGINE OIL

Recommendations

Use premium quality motor oil, Class SJ or SL. Look for the SAE

(Society of Automotive Engineers) or API viscosity grade. Referring to

the table below, choose the viscosity grade appropriate for the ambient

temperatures expected during the period of time until the next scheduled oil change.

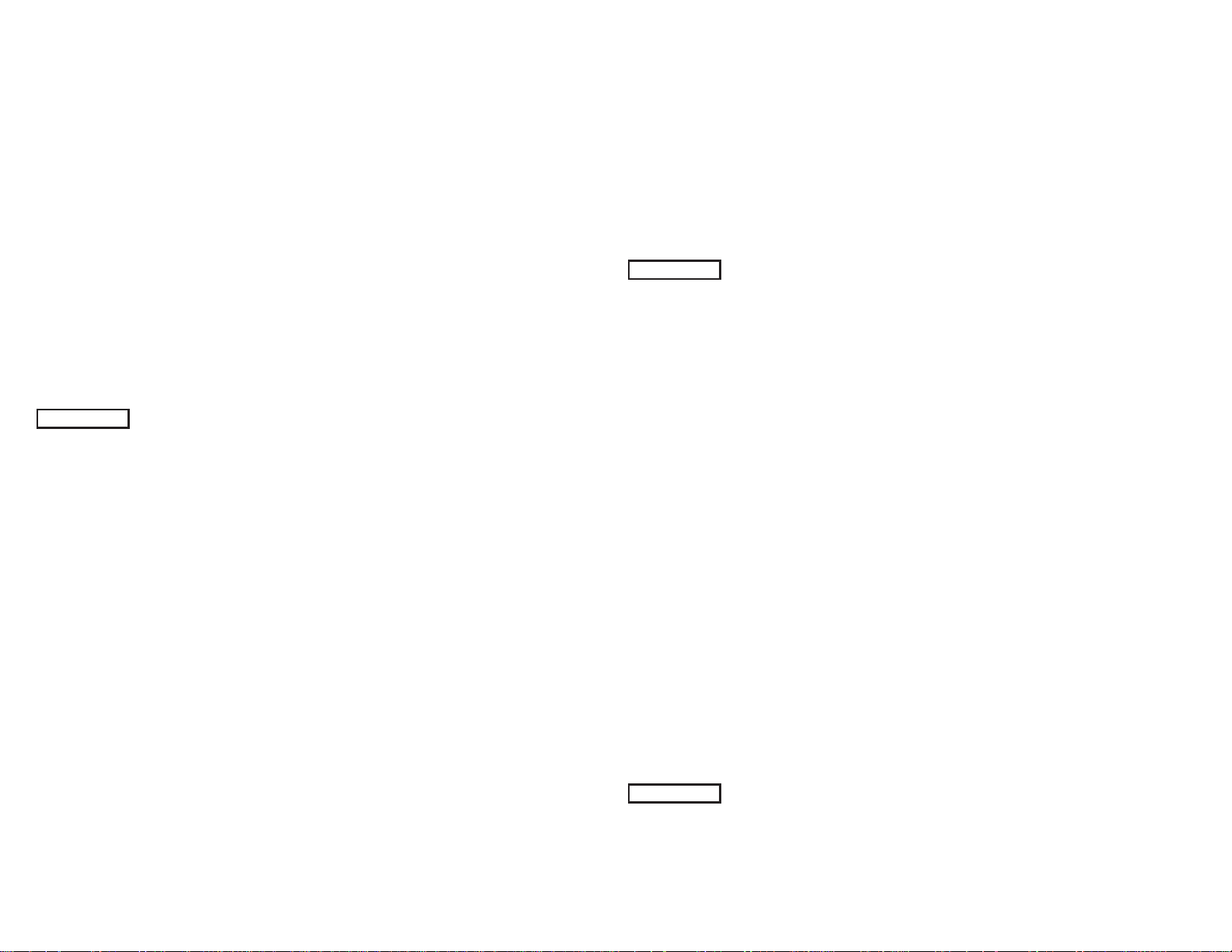

Check the oil level daily, before starting. Keep the oil level between the

upper and lower level on the gauge.

EXPECTED AMBIENT

TEMPERATURES

SAE VISCOSITY

GRADE

32°F (0° C) and higher 30

0°F to 80°F

(-18°C to 27°C)

Single-grade SAE 30 oil is preferable when temperatures are 50° and

90°F (10° - 32°C).

If multi-grade oil is used, oil consumption tends to increase if the ambient temperature is high.

Filling and Change Interval

After the fi rst 20 hours of operation the initial oil and oil fi lter should be

replaced.

Thereafter, change the oil every 100 hours of operation and change

the oil fi lter every 200 hours.

Apply a thin coat of oil to the oil fi lter gasket surface and install by

tightening the oil fi lter about 3/4 turn after the seal has reached the

crankcase surface.

The oil capacity of the crankcase is 1.55L (53 fl .oz.).

When fi lling the crankcase, keep the engine level and fi ll up to the up-

per mark of the oil gauge. Check the oil with the oil gauge pushed all

the way in its seat.

10W-30

10W-40

STARTING BATTERIES

An engine equipped with an electric starter requires a properly sized

battery along with appropriately sized interconnecting cables to insure

proper starting. Neither cranking performance or starter service life will

be satisfactory if an undersized battery is used.

Use a battery rated 12V-30 amp or larger.

The customer must supply battery cables. Use the table below to

select the proper cable for the positive side connection.

Connect a ground strap to the negative terminal. Use a fl at strap

25.0mm (0.25”) wide.

WIRE GAUGE

AWG (BS)

CABLE LENGTH CABLE DIA.

Less than 1.5m

(4.5ft)

1.5 - 2.5m

(4.5 - 7.6ft)

7.3mm

(5/16 in.) 1 6 AV15

8.5 mm

(3/8 in.) 0 4 AV20

BWG SAE JIS

Crankcase pressure can blow hot engine oil out

! WARNING

the fi ll tube causing severe burns. Always stop

the engine before removing the oil fi ll cap or the

oil gauge.

15 16

2.5 - 4.0m

(7.6 - 12.2ft)

108 mm

(7/16in.) 3/0 2 AV30

Page 9

Installation

CABLE

LENGTH

Less than 1.5 m

(4.5ft)

1.5-3.0m

(4.5-9.8ft)

3.0-5.0m

(9.8-16.4ft)

BATTERY CABLES

CABLE DIA.

1.5mm

(1/16in)

1.9mm

(5/64in)

2.4mm

(1/10in)

WIRE GAUGE

AWG (BS)

BWG

14 16 AV1.25

12 14 AV2

10 13 AV3

SAE JIS

WIRING

The engine is equipped with a wiring harness that connects with the

accessory.

1. Connect the positive (+) battery cable between the starter solenoid

and the battery.

2. Connect the ground strap between the negative (-) battery terminal

and a clean, bare metal grounding location on the engine.

3. Connect wires from starter key switch to starter solenoid and

ground.

STARTER SWITCH

A customer supplied starter switch or key switch is recommended for the starter motor. See table below for switch cable

recommendations.

17 18

Page 10

Wiring Diagram

POWER TRANSMISSION

Belt Drive

If using a belt drive application, consider the following notes:

• V-belts are preferable to fl at belts

• The engine drive shaft must be parallel to the machine

drive shaft

• The engine drive pulley must be in line with the machine

drive pulley

• Install the engine pulley as close to the engine as

possible

• Span the drive belt horizontally, if possible.

ENGINE WIRING DIAGRAM (6 PIN)

Engine Specifi cation Numbers: EH650DC2405

EH650DC2415

• Disengage the load when starting the engine.

• Use a belt tension pulley if a clutch is not used.

Flex Coupling

When using a fl ex coupling, minimize run-out and misalignment be-

tween the drive shaft and the engine shaft. The run-out and misalignment tolerances are specifi ed by the coupling manufacturer.

19

20

Page 11

Operation

EXHAUST GAS IS DEADLY!

! WARNING

any indications of fuel leakage. Do not operate engine until

all leaks are repaired.

Exhaust gases contain carbon monoxide, an odorless and colorless gas. Carbon monoxide is poisonous and can cause unconsciousness and death. Symptoms of carbon monoxide poisoning

include:

• Dizziness • Throbbing in Temples

• Nausea • Muscular Twitching

• Headache • Vomiting

• Weakness and Sleepiness

• Inability to Think Coherently

IF YOU OR ANYONE ELSE EXPERIENCE ANY OF THESE SYMP-

TOMS, GET INTO THE FRESH AIR IMMEDIATELY. If symptoms

persist, seek medical attention. Shut down the engine and do not

operate it until it has been inspected and repaired.

Make certain the exhaust system is properly installed. Inspect

it every time the engine is started and after every eight hours of

continuous operation.

PRE-START CHECKS

Before the fi rst start of the day and after every eight hours of operation

perform the maintenance procedures in DAILY

(8 HOUR) MAINTENANCE in the Maintenance Section.

Keep a log of maintenance and the running hours. Perform any maintenance that may be due. If the equipment has been in storage, return

the engine to service as instructed under

RETURNING THE ENGINE TO SERVICE in this section.

1. Inspect exhaust system for loose joints, rusty, worn or damaged

areas. Do not operate engine until all leaks are repaired.

2. Check the fuel level and refi ll if necessary. Open the fuel shut-off

valve (if equipped).

4. Check and tighten any loose bolts or nuts.

5. Check the oil and refi ll, if necessary. Do not overfi ll.

Starting the engine without oil will cause severe

! CAUTION

engine damage.

Always keep the engine oil level between the

Full and Add marks on the dipstick.

6. Wear snug fi tting clothes when operating the engine. Loose

articles of clothing could get caught in the engine or drive train.

Moving parts can cause severe personal injury or

! WARNING

death. Hot exhaust parts can cause severe burns.

Stay clear of hot or moving parts. Make sure all

protective shields and guards are secure in place

before starting the equipment.

STARTING

1. Move the choke lever to the full-choke position. On equipment

with a solenoid operated choke, push the switch to its choke

position. In warm weather, however, or when the engine is warm,

try starting without the choke or in the half-way position.

2. Turn the ignition switch to START and hold it there until the engine

starts. Do not crank for more than 5 seconds at a time.

If the engine fails to start, set the switch to RUN and wait 10

seconds before the next attempt. See Troubleshooting if the

engine does not start after several tries. Never turn the switch to

START while the engine is running.

3. Make sure fuel hoses and connections are tight. Check for

21

22

Page 12

3. After the engine starts, slowly push the choke to the full-

open position. Pull it back, if necessary, to keep the engine

running smoothly until the engine is at operating temperature

In colder weather, the engine will take longer to begin

running smoothly with the choke open.

Do not operate the equipment until the choke is fully open.

OPERATING IN DUSTY CONDITIONS

1. Keep the engine cooling fi ns and fl ywheel air inlet screen clean.

2. Perform air cleaner maintenance more often than normal-as

required.

3. Change the engine oil and oil fi lter more often than normal.

STOPPING

To stop the engine turn the switch to the STOP position.

ENGINE BREAK-IN

For top engine performance, new or rebuilt engines require a breakin period to obtain the ideal fi tting of internal moving metal parts. To

break-in the engine:

1. Run the engine at 2500 rpm, without a load, for 10 minutes.

2. Run the engine at 3,000 rpm for 10 minutes.

3. Run the engine at 3,600 rpm for 10 minutes.

4. Run the engine with a load of 8HP at 3,600 rpm for 30 minutes.

5. Run the engine with a load of 16HP at 3,600 rpm for 30 minutes.

Frequently check for oil leaks during break-in.

After the fi rst 20 hours of normal operation, change the oil and oil fi lter.

Refer to

Maintenance for procedures.

HOT AND COLD WEATHER PRECAUTIONS

Hot Weather

Pay particular attention to the following items when operating the

engine in temperatures above 100°F (38°C):

1. Keep the fl ywheel air inlet screen and cylinder cooling fi ns clean.

Make sure that nothing obstructs air fl ow to and from the engine

2. Check the oil level more frequently.

3. Change the oil and oil fi lter more often than normal.

4. Make sure the engine oil viscosity is appropriate for the ambient

temperatures and change the oil if necessary.

Cold Weather

Pay particular attention to the following items when operating the

engine in temperatures blow freezing:

1. Make sure the engine oil viscosity is appropriate for the ambient

temperatures and change the oil if necessary. If the temperature

drops before you have the chance to change the oil, warn the

engine by moving the equipment into a heated space before

attempting to start the engine or change the oil.

23 24

Page 13

EXHAUST GAS IS DEADLY!

! WARNING

Never operate engine-powered equipment

indoors without a proper exhaust system, ample fresh

air ventilation and an operable carbon monoxide

detector.

2. Use fresh gasoline and fi ll the fuel tank after each day’s use to

reduce problems with moisture condensation if this is a gasoline

engine.

3. Keep the battery in a well-charged condition.

4. After each use push the equipment throttle knob or lever to the

middle of its speed range. Then, if ice forms on the linkage during

storage it will be easier to start the engine.

OUT-OF-SERVICE PROTECTION

6 Perform air cleaner maintenance as instructed in Periodic

Maintenance.

7 Plug the exhaust outlet to prevent moisture, dirt, bugs, ect. from

entering.

Battery gas is explosive. Wear safety glasses

! WARNING

and do not smoke while servicing batteries. Lead acid

batteries give off a highly explosive hydrogen gas

which can be ignited by fl ame, electrical arcing or

smoking.

8 Disconnect the battery (negative (-) cable fi rst) and follow the

battery or equipment manufacturer’s storage instructions.

9 Cover the engine with a plastic sheet or canvas and store in a dry

place.

RETURNING THE ENGINE TO SERVICE

Protect an engine that will be out of service for more than 30 days as

follows:

1 Run the engine until it reaches normal operating temperature then,

shut-off the fuel supply and let the engine run until it stops.

2 If the equipment will not be operated for more than 30days, add a

fuel preservative (ie. Sta-Bil) to the equipment fuel tank. Follow the

instructions on the container label. Unless a preservative is added,

gasoline will deteriorate causing fuel system corrosion, gum

formation and varnish-like deposits which can lead to hard starting

and rough operation.

3 Drain oil from the engine while it is still warm. Refi ll with fresh oil

and attach a tag stating the viscosity of the oil used.

4 To prevent rust in the cylinder bore, remove the spark plug and pour

30mL (2 tbsp. or 1oz.) of SAE 30 oil in the opening. Turn the

crankshaft several times by hand and reinstall the spark plug.

5 Clean the outside of the engine with an oiled cloth.

25 26

1 Remove the cover and all protective wrapping and the plug from the

exhaust outlet.

2 Check the tag on the oil base. Change the oil if the viscosity is not

appropriate for the expected ambient temperatures.

3 Check the fuel fi lter and fuel lines to make sure they are secure and

have no cracks.

4 Check that the choke, throttle and governor linkages move freely.

5 If so equipped, clean and check the battery according to the battery

or equipment manufacturer’s instructions and connect the battery

cables (positive (+) cable fi rst).

6 Start the engine. The initial startup may be slow and there may be

smoke and rough operation for a few minutes until the oil in

the cylinder burns off. If the engine does not start, clean or replace

the spark plug as it may have been fouled by the oil added to the

cylinder when the equipment was stored.

Page 14

Periodic Maintenance

MAINTENANCE, REPLACEMENT, OR REPAIR OF THE EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY

NON-ROAD ENGINE REPAIR ESTABLISHMENTS OR

INDIVIDUALS.

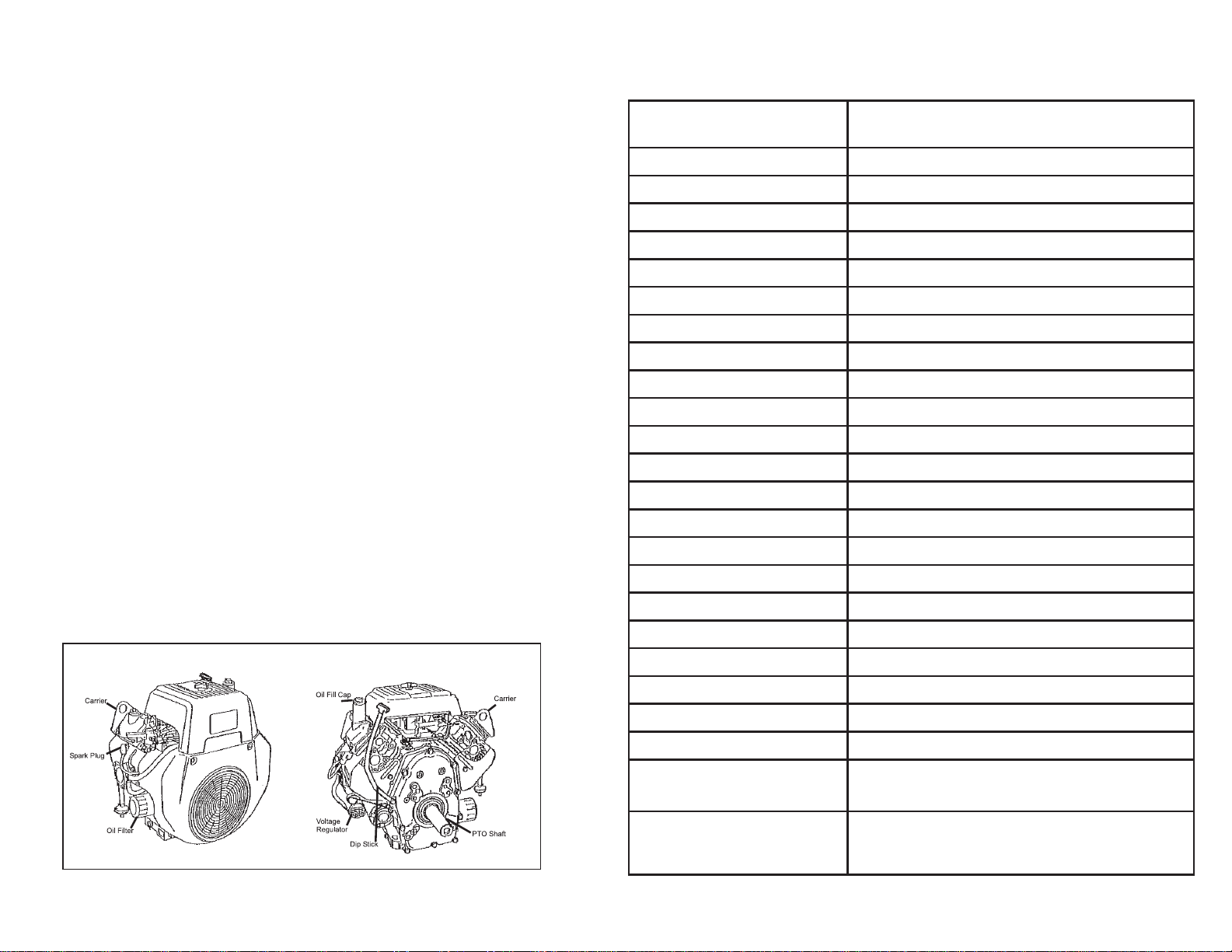

Periodic maintenance is essential for top engine performance. See the

Table below as a guide for normal periodic maintenance. Under hot or

dusty operating conditions some maintenance operations should be

performed more frequently, as indicated by footnotes in the table.

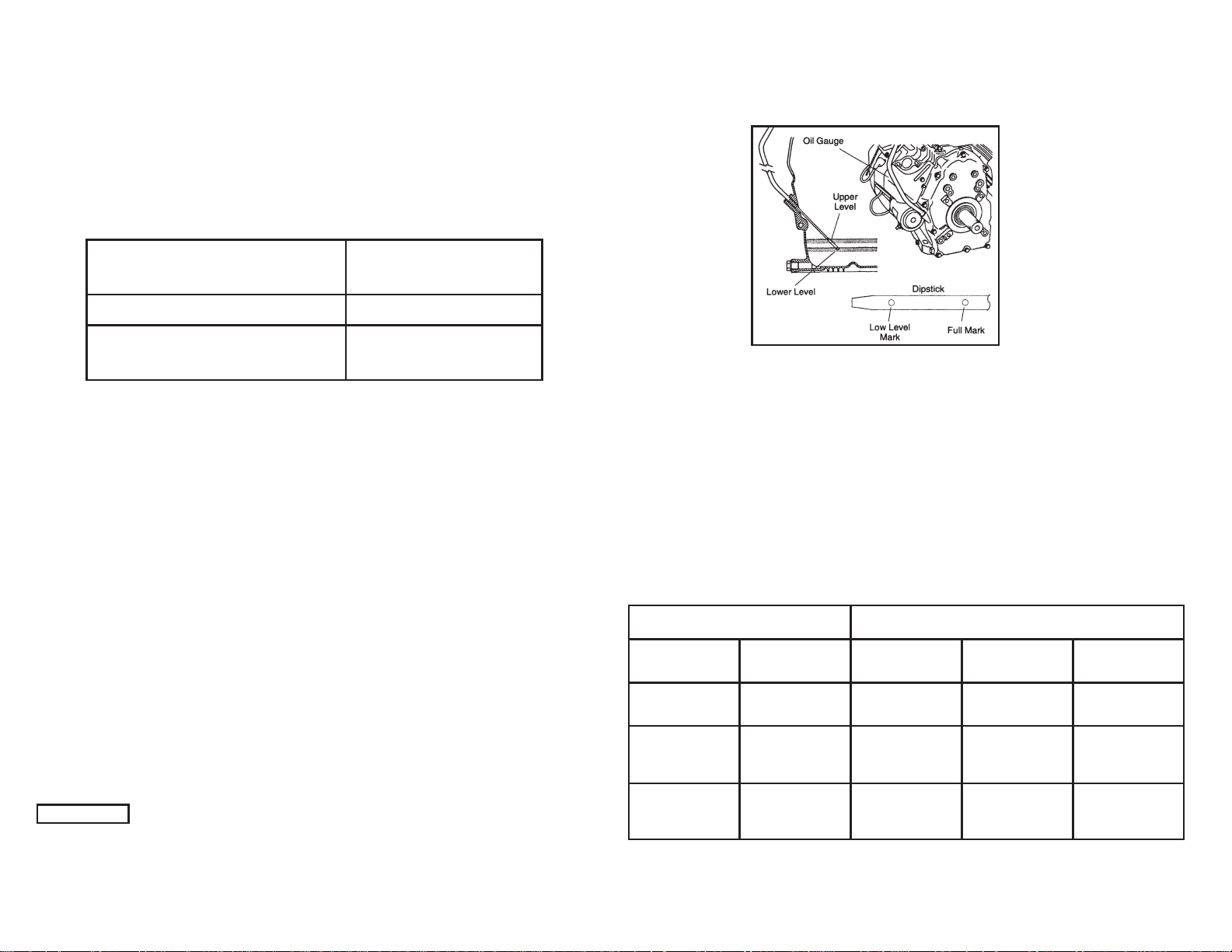

FREQUENCY

Daily or

MAINTENANCE OPERATION

Clean Dust and Debris

from Engine X

Check fuel leakage from

fuel system. Retighten

fasteners or replace parts

if needed. X

Inspect for Loose Hardware

and Retighten X

Check Oil Level and Add to

Full Level X

Change Engine Oil X

Check Battery Fluid Level X

Clean Spark Plugs X

Clean Outer Element of

Air Cleaner X

Clean Fuel Strainer X

Replace Air Cleaner Assembly X

Inspect, Clean and Re-Gap

Spark Plugs X

Change Engine Oil Filter X

Clean Carburetor X

Clean Cylinder Head X

Adjust Engine Valve Clearance X

Replace Spark Plugs X

Replace Fuel Lines and Filter X

1. Check for oil, fuel and exhaust leaks, loose parts and unusual noises and vibrations.

2. Change oil and fi lter after the fi rst 20 hours of operation as a part of engine break-in.

3. Perform more often when operating in dusty conditions.

4. Perform more often when operating in hot conditions.

5. See instructions for battery care provided by the equipment or battery manufacturer.

6. Must be performed by a qualifi ed mechanic (equipment or Robin dealer).

Every 8

Hours

Every

Hours

1

50

Every

100

Hours

5

Every

Hours

2,4

200

3,4

Every

500

Hours

6

Every

1,000

Hours

Periodic Maintenance

Keep a log of maintenance performed and the run time hours. Keeping

a record of procedures will help you keep scheduled maintenance and

provide a basis for supporting warranty claims

Maintenance, replacement or repair of emission control devices and

systems may be performed by any engine repair establishment or

individual. However, warranty work must be done completed by an

authorized Robin Subaru dealer or distributor.

DAILY (8 HOUR) MAINTENANCE

The operator should check the following before the fi rst start of the day

and after every eight hours of operation:

1 Inspect fuel lines and fi ttings for leaks. Repair leaks immediately.

2 Look and listen for exhaust system leaks while the engine is

running. Look for cracks and severe rusting in the muffl er and

tailpipe. Have all leaks repaired before continuing to operate the

equipment.

! WARNING

Hot exhaust parts can cause severe burns.

Allow the engine time to cool before servicing

the exhaust system.

3 Check the engine for dirt and debris and clean the fl ywheel air inlet

screen and cylinder cooling fi ns as necessary.

! CAUTION

A clogged fl ywheel air inlet screen or dirty cooling

fi ns can cause overheating and engine damage. Keep

the cooling fi ns and air inlet screen clean.

4 Check the engine oil level The equipment must be parked on a level

surface ad the engine stopped. To get an accurate reading, wait a

minute or so to allow the oil to settle in the crankcase if the engine

has been running.

27 28

Page 15

! WARNING

Crankcase pressure can blow hot engine oil out

the fi ll tube causing severe burns. Always stop

the engine before removing the oil fi ll cap.

If the engine is equipped with the long oil fi ll tube, turn the oil fi ll cap

counterclockwise and lift it up. Wipe the dip stick clean, push it back

into the oil fi ll tube until the cap seats. Withdraw it again to check the

oil level.

CHANGING OIL AND FILTER

Change the oil and fi lter after the fi rst 20 hours of operation. Thereaf-

ter, change oil every 50 hours and the fi lter every 200 hours.

! WARNING

State and federal agencies have determined that

contact with used engine oil can cause cancer or

reproductive toxicity. Take care to limit skin contact

and breathing of vapors as much as possible. Use

rubber gloves and wash exposed skin.

1 Run the engine until it is warm. Stop the engine and disconnect the

spark plug wires and the battery (negative (-) cable).

! WARNING

Accidental starting of the engine can result in severe

personal injury or death. Always disconnect the spark

plug wires and the battery (negative (-) cable) before

changing oil.

2 Remove the oil fi ll cap.

4 Place a pan under the oil drain opening and open the oil drain plug.

Close the plug securely after the oil has drained completely.

5 Spin off the oil fi lter, drain the oil and discard the fi lter according to

local regulations.

6 Thoroughly wipe off the fi lter mounting surface.

7 Make sure the gasket is in place on the fi lter canister and apply a

thin fi lm of oil to the gasket.

8 Spin the new fi lter on by hand until the gasket just touches the

mounting surface, then turn it an additional 1/2 to 3/4 turn. Do not

overtighten.

Crankcase pressure can blow hot engine oil out the

! WARNING

fi ll opening causing severe burns. Always stop the

engine before removing the oil fi ll cap.

3 To drain oil from crankcase, loosen the drain valve then twist the

outer casing to unlock. The valve is fi tted with an adapter for a drain

tube if desired.

29

9 Refi ll with class SE (API) of higher having a viscosity grade

appropriate for the expected ambient temperature.

30

Page 16

10 DO NOT FILL TO A LEVEL ABOVE THE FULL MARK ON THE

DIPSTICK. Drain the excess oil if too much has been added.

! CAUTION

Too much oil can cause high oil consumption, high

operating temperatures and oil foaming. Too little oil

can cause severe engine damage. Keep the oil level

between the Full and Add marks on the dipstick.

Foam Filter

Remove and wash the urethane foam in water and detergent.

Squeeze the foam wrapper dry like a sponge. Rinse with clean water

and allow it to dry. Coat the wrapper evenly with 14 mL (one tbsp.) of

SAE 30 engine oil. Knead the oil into the wrapper and squeeze out the

excess oil.

Note: Failure to adequately wring out excess oil from the wrapper

may cause a drop in engine power due to restriction of inlet air.

Install the foam wrapper over the paper air cleaner element by stretching it over the inner cover. Completely cover all exposed paper pleats.

Replace the air cleaner assembly when it becomes torn or stretched.

Air Cleaner Element Replacement

To keep anything from entering the carburetor and engine while the

air cleaner element is off, pull the choke knob to the full-choke position to close the choke plate in the carburetor. Remove the outer cover

and wipe away loose dust and debris from the air cleaner assembly.

Remove the air cleaner assembly. Wipe off dust and debris from the air

cleaner base. Use forced air to blow off dust and debris from the paper

element.

11 Reconnect the spark plug wires and battery.

12 Start the engine and run it for a short time while checking for oil

leaks around the drain plug and oil fi lter. Do not overtighten: tighten

only as necessary to eliminate leaks.

Used oil is harmful to the environment. Pour the used oil into a sealed

container and deliver it to the nearest recycling center.

AIR CLEANER MAINTENANCE

Refer to the Maintenance Table for the air cleaner assembly.

Outer Cover

To remove the air cleaner cover, rotate the wing nut counterclockwise

and remove.

31

Reinstall the paper element on the engine. Replace the foam wrapper

and outer cover. Secure with the wing nut.

Element Set

P/N 263-32610-A1

32

Page 17

SPARK PLUG MAINTENANCE AND REPLACEMENT

To adjust the speed control solenoid:

Refer to the Specifi cations for spark plug type and gap specifi cations.

Check and clean spark plugs every 200 hours. Replace plugs every

500 hours.

To prevent cross threading the spark plug, always thread it in by hand

until it seats. If the spark plug is being reused, turn it with a wrench

and additional 1/4 turn. If the spark plug is new, turn it an additional 3/8

to 1/2 turn. If you have a torque wrench, tighten a new spark plug to

11.8-14.7 N-m (120-150 Kg/cm) (8.7-10.9 ft/lb).

CHECKING BATTERIES

Every 50 hours or once a month check the fl uid level of the battery.

Refi ll with distilled water if levels are low.

Battery gas is explosive. Wear safety glasses and do

! WARNING

not smoke while servicing batteries. Lead acid

batteries give off a highly explosive hydrogen gas

which can be ignited by fl ame, electrical arcing or

smoking.

! WARNING

If the battery is to be replaced, disconnect the

negative cable fi rst, and reconnect it last.

1 Run the engine with no load until the engine control times out

(about 15 seconds) and energizes the solenoid.

2 Adjust engine to 2200 RPM by loosening the two slotted screws

retaining the solenoid.

3 Slide solenoid forward to increase the speed, or backwards to

decrease the speed.

4 Retighten the two screws.

Following reassembly of either the carburetor or intake manifold, re-

align the governor arm on the governor shaft BEFORE making speed

adjustments to compensate for the slightly different alignment of parts.

Governor and Speed Control Assembly

1

2

3

4

6

Adjustments

CARBURETOR ADJUSTMENTS

These engines have precision-manufactured carburetors which are not

adjustable.

Engine Speed Solenoid (Optional)

Normally, the engine speed does not require any adjustment. These

instructions are for the equipment manufacturer in setting up and

adjusting the equipment.

The speed control solenoid monitors the rate of the load and automatically adjusts the engine to the appropriate idle speed.

33

5

7

1 Speed Control Solenoid Adjust Screw (2) (Optional)

2 Governor Adjust Screws

3 Governor Lever

4 Speed Control High Stop Adjust Screw

5 Manual Throttle Control Link

6 Low Idle Adjust Screw

7 Choke Control Linkage

34

Page 18

Speed Control Adjustments

Engine speed adjustment must be attempted only by a qualifi ed me-

chanic and the adjustments must be made using an accurate tachometer. It is recommended that low-idle speed be adjusted between 2150

to 2250 RPM and high idle speed 3700 to 3800 RPM. Check in your

welder manufacture’s manual for exact speed settings.

Troubleshooting

The table below provides basic troubleshooting guidance. If you fail

to resolve the problem after taking the corrective actions suggested,

contact the equipment manufacturer or a Robin Subaru dealer.

Engine Starting

Engine cranks but

fails to start

Damaged spark plug(s). Check the spark plug gap. Check for

a bad insulator on plug and replace if damaged. Clean carbon

deposit from electrode. Id wet, dry electrode.

Fuel Supply. Check fuel supply and shut-off valve. Check fuel fi lter

and clean if dirty. Check fuel fi lter: clean or replace if dirty. Check

fuel line connections into carburetor for air leaks.

Fuel. Gasoline may have water mixed in or the gasoline grade is

not correct.

Carburetor problems. Flooding carburetor, the fl oat may be bad

or stuck. Varnish build up deposits in the carburetor, the carburetor

will have to be disassembled.

Many troubleshooting procedures present hazards

! WARNING

that can result in severe personal injury. Only

qualifi ed service personnel with knowledge of fuels,

electricity, and machinery hazards should perform

service procedures.

Review the safety precautions on the inside cover

page.

Hot engine parts can cause severe burns. Always

! WARNING

allow the engine time to cool before performing any

maintenance or service.

Problem Probable Cause and Remedy

Engine Starting

Engine cranks

slowly or not at all

Poor battery connections: Clean and tighten the positive (+) and

negative (-) connections at battery and engine.

Battery is not fully charged: Recharge the battery.

Electric starter is faulty: Check starter brushes and bearings.

Improper engine oil: Change oil having the proper viscosity for

the ambient temperature.

There is a load on the engine: Remove load and retry.

Back pressure: There is excessive back pressure due to a

plugged or bent exhaust pipe.

Engine Starting

Electric starter

does not operate

Engine Starting

Electric starter

operates but

engine does not

start

Governor and throttle linkage. Check linkage connections. Check

tension in springs. Check governor, throttle and speed adjustments

.

The fuel cut-off solenoid is faulty. Check for lose or damaged

wires and connectors. Check voltage levels at the connector to the

solenoid. Replace harness or solenoid.

Check air cleaner and service if dirty.

Key or start switch. Check wiring connections and switch.

No continuity between the key switch and the starter. Replace

wires.

No continuity between the battery and starter. Replace cable.

Low battery. Change or recharge battery.

Starter solenoid is bad. Check voltages, clean repair, or replace.

Starter motor is bad. Check brushes and wiring, repair or replace.

Engine seizure. The crankshaft has seized or the piston and cylin-

der have seized. Check crankshaft bearings and bearing surface. 1

Low fuel.

Poor wiring connection or no continuity of ignition system.

Check wiring connections and ignition coils for a short.

Electric starter is bad. Slow cranking RPM is caused by low volt-

age at starter or worn brushes or bearings. Repair or replace.

Page 19

Engine Overheats Air fl ow is obstructed at inlet or cylinder baffl e. Clean out

debris in baffl e.

Improper engine oil. Replace oil.

Lean air/fuel mixture. Check for plugged passages in carburetor.

Excessive back pressure on exhaust. Check muffl er and spark

arrester.

Engine is overloaded. Change to rated load.

Engine Idles

Rough

Low idle speed. Adjust idle on carburetor.

Air is mixing at air intake connection. Check, tighten or replace

gasket.1

There is blow-by on the head gasket. Replace the gasket. 1

Improper valve clearance. Adjust clearance. 1

Excessive clearance between valve stem and guide. Replace

valve stem and guides.1

IMPORTANT INFORMATION FOR CALIFORNIA ENGINE USERS

These engines meet the requirements of California’s Exhaust Emissions Standards for 1995 and later for Utility and Lawn and Garden

Equipment Engines.

As a California user of these engines, please be aware that unauthorized modifi cations or replacement of fuel, exhaust, air intake, or speed

control system components that affect engine emissions are prohibited. Unauthorized modifi cations, removal or replacement of the engine

label is prohibited.

You should carefully review Operator (Owner), Installation and other

manuals and information you receive with your engine or equipment.

If you are unsure that the installation, use, maintenance or service of

your engine or equipment is authorized, you should seek assistance

from an approved Robin Subaru engine dealer or an approved dealer

for your equipment.

California engine users may use Table 1-1 as an aid in locating information related to the California Air Resources Board requirements for

emissions control.

TABLE 1-1 EMISSION CONTROL INFORMATION

Engine Support Material

Robin America has established the Robin Subaru Fulfi llment Center to take and

ship orders to anyone wanting Robin Subaru reference material. This allows

for the prompt fulfi llment of Robin Subaru part and service manuals, counter

catalogs, price books and other support material to dealers and end users at

the lowest possible price.

Robin Fulfi llment Center

PO Box 6978 • Rockford, IL 61125-1978 USA

Phone: 888-576-2465 • Fax: 630-563-0403

website: www.robinsubaru.com • email: info@robinamerica.com

37 38

Engine Warranty

Information

Engine Valve Lash See Specifi cations

Engine Ignition Timing See Specifi cations

Engine Fuel Requirements

Engine Lubricating Oil

Requirements

Engine Fuel Mixture

Settings

Engine Adjustments See Adjustments

Engine Emission Control

System

The California emissions control warranty statement is located the back

of this manual

This engine is certifi ed to operate on unleaded gasoline. See Fuel

Recommendations in Introduction.

See Engine Oil Recommendations in Introduction.

These engine have precision-manufactured carburetors which are not

adjustable

The engine emission control system consists of internal engine

modifi cations.

Page 20

39

40

Page 21

Emissions Control System Warranty Statement

CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Fuji Heavy Industries Ltd. (herein “FUJI”)

are pleased to explain the emissions control system warranty on your small off-road

engine (SORE). InCalifornia, new SOREs must be designed, built and equipped to

meet the State’s stringent anti-smog standards. FUJI must warrant the emissions

control system on your SOREs for the periods of time listed below provided there

has been no abuse, neglect or improper maintenance of your SOREs.

Your emissions control system may include parts such as the carburetor, fuel-injection system, the ignition system, catalytic converter, fuel tanks, fuel lines, fuel caps,

valves, canisters, fi lters, vapor hoses, clamps, connectors, and other associated

emission-related components.

(herein ROBIN AMERICA) as soon as the problem exists. The warranty repairs should

be completed in a reasonable amount of time, not to exceed 30 days.

If you have a question regarding your warranty coverage, you should contact the

Robin America Inc. Customer Service Department at 1-630-350-8200.

GENERAL EMISSIONS WARRANTY COVERAGE

- California Only -

FUJI warrants to the ultimate purchaser and each subsequent purchaser that the

SORE (1) has been designed, built and equipped so as to conform with all applicable

regulations; and (2) is free from defects in materials and workmanship that cause the

failure of a warranted part to conform with those regulations as may be applicable to

the terms and conditions stated below.

Where a warrantable condition exist, FUJI will repair your small off-road engine at

no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emissions-related

part on your engine is defective, the part will be repaired or replaced by FUJI.

OWNER’S WARRANTY RESPONSIBILITIES:

-As the SORE owner, you are responsible for performance of the required maintenance listed in your owner’s manual. FUJI recommends that you retain all receipts

covering maintenance on your SORE , but FUJI cannot deny warranty solely for the

lack of receipts.

-As the SORE owner, you should however be aware that FUJI may deny you

warranty coverage if your SORE or a part has failed due to abuse, neglect, or

improper maintenance or unapproved modifi cations.

-You are responsible for presenting your SORE to distribution center or service

center authorized by ROBIN AMERICA Inc. 940 Lively Blvd., Wood Dale, IL 60191

(a) The warranty period begins on the date the engine is delivered to an ultimate

purchaser or fi rst placed into service. The warranty period is two years.

(b) Subject to certain conditions and exclusions as stated below, the warranty on

emissions related parts is as follows:

(1)Any warranted part that is not scheduled for replacement as required maintenance

in your owner’s manual is warranted for the warranty period stated above. If the part

fails during the period of warranty coverage, the part will be repaired or replaced by

FUJI according to subsection (4) below. Any such part repaired or replaced under

warranty will be warranted

for the remainder of the period.

(2) Any warranted part that is scheduled only for regular inspection in your owner’s

manual is warranted for the warranty period stated above. Any such part repaired or

replaced under warranty will be warranted for the remaining warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance

in your owner’s manual is warranted for the period of time before the fi rst scheduled

replacement date for that part. If the part fails before the fi rst scheduled replacement,

41

42

Page 22

the part will be repaired or replaced by FUJI according to subsection (4) below. Any

such part repaired or replaced under warranty will be warranted for the remainder of

the period prior to the fi rst scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions herein

must be performed at a warranty station at no charge to the owner.

(5) Notwithstanding the provisions herein, warranty services or repair will be provided

at all of our distribution centers that are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that leads to the determination

that a warranted part is in fact defective, provided that such diagnostic work is

performed at a warranty station.

(7) FUJI is liable for damages to other engine components proximately caused by a

failure under warranty of any warranted part.

(8) Throughout the engine warranty period stated above, FUJI will maintain a supply of

warranted parts suffi cient to meet the expected demand for such parts.

or replacement of the part. That notwithstanding, any adjustment of a component that

has a factory installed, and properly operating, adjustment limiting device is till eligible

for warranty coverage. The following emissions warranty parts list are covered.

EXHAUST EMISSIONS

(1) Fuel Metering System

(A) Carburetor and internal parts.

(2) Air Induction System

(A) Air fi lter.

(3) Ignition System

(A) Spark plugs.

(B) Magneto or electronic ignition system.

NOTE: This list based upon the items found in Title 13 Section 2405(d) for exhaust

emissions.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to the owner. Such use will not

reduce the warranty obligations of FUJI.

(10) Add-on or modifi ed parts that are not exempted by the Air Resources Board may

not be used. The use of any non-exempted add-on or modifi ed parts by the ultimate

purchaser will be grounds for disallowing a warranty claims. FUJI will not be liable to

warrant failures of warranted parts caused by the use of a non-exempted add-on or

modifi ed part.

(c) WARRANTED PARTS:

The repair or replacement of any warranted part otherwise eligible for warranty

coverage may be excluded from such warranty coverage if FUJI demonstrates that

the engine has been abused, neglected, or improperly maintained, and that such

abuse , neglect ,or improper maintenance was the direct cause of the need for repair

43 44

Page 23

High Altitude Engine Operation

How to remove the spark arrestor

• Please have an authorized Robin America service dealer modify

this engine if it is to be run continuously above 5,000 feet (1,500

meters). Failure to do so, may result in poor engine performance,

spark plug fouling, hard starting, and increased emissions.

• Carburetor modifi cation by an authorized Robin America service

dealer will improve performance and allow that this engine meets

EPA (Environmental Protection Agency) and California ARB (Air

Resources Board) emission standards throughout its useful life.

• An engine converted for high altitudes can not be run at 5,000 feet

or lower. In doing so, the engine will overheat and cause serious

engine damage. Please have an authorized Robin America service

dealer restore high altitude modifi ed engines to the original factory

specifi cation before operating below 5,000 feet.

Spark Arrestor (Optional)

In a dry or wooded area, it is recommendable to use the engine with a

spark arrestor. Some areas require the use of a spark arrestor. Please

check your local laws and regulations before operating your engine.

The spark arrestor must be cleaned regularly to keep it functioning as

designed.

1. Remove the fl ange bolts from the muffl er cover and remove the

muffl er cover.

2. Remove the special screw from the spark arrestor and remove the

spark arrestor from the muffl er.

Clean the spark arrestor screen

Use a brush to remove carbon deposits from the spark arrestor

screen. Be careful to avoid damaging the screen.

The spark arrestor must be free of breaks and holes. Replace the

spark arrestor if it is damaged.

Install the spark arrestor, and muffl er protector in the reverse order of

disassembly.

Spark Arrestor Screen

A clogged spark arrestor:

• Prevents the fl ow of exhaust gas

• Reduces engine output

• Increases fuel consumption

• Makes starting diffi cult

If the engine has been running, the muffl er and the spark arrestor will

be very hot. Allow the muffl er to cool before cleaning the spark arres-

tor.

45 46

Page 24

How to Select a Robin Service Dealer

Robin Distribution Method

Robin engines and equipment are distributed in North America through

a network of independent wholesale distributors. Each authorized

Robin wholesale distributor is

responsible for stocking Robin

products and service parts at

each of their distribution warehouses. These distributors

supply a network of Robin

service dealers with parts,

engines, and/or equipment

within the distributors assigned marketing area.

The Robin service dealers are established by the Robin wholesale

distributor to provide sales and service support throughout the marketing area. Because of the wide variety of Robin engine models and

applications, many of the service dealers will specialize in selling and

servicing specifi c types of products.

Service dealers may specialize in the following areas:

• Lawn & Garden Power Equipment

• Small Construction Equipment

• Portable Generators and Welders

• Specifi c Brand of Equipment Powered by Robin Engines

Finding the Robin Service Dealer to Meet Your Needs

Since the Robin wholesale distributors establish and supply the Robin

service dealers, please contact the Robin wholesale distributor to

select the best service dealer for your needs. When contacting the

Robin wholesale distributor, explain the type of Robin product you are

interested in purchasing or having serviced and where you are located.

The Robin wholesale distributor will direct you to the most suitable

Robin service dealers in your area.

There are over 4000 registered Robin service dealers in North America, so there should be one near you. Contact Robin America with any

questions at 1-800-277-6246.

940 Lively Blvd.

Wood Dale, IL 60191 U.S.A.

Phone: 630-350-8200

Fax: 630-350-8212

Website: http://www.robinsubaru.com

INDUSTRIAL PRODUCTS DIVISION

4-410 Asahi, Kitamoto-shi

Saitama, 364-8511, Japan

Phone +81(48) 593-7798

Fax +81(48) 593-7946

Web site

http://www.fhi.co.jp/robin//

47

48

Loading...

Loading...