ROBIN

ENGINE

ROBIN

TO

MODEL

AMERICA,

WISCONSIN

CROSS

REFERENCE

INC.

ROBIN

LIST

ROBIN

EY08

EYl5

EY 15V

EY20

EY20V

EY23

EY28

EY35

EY40

EY45V

EY2 1

EY44

EY 1 8-3

EY25

EY27

WISCONSIN

ROBIN

S-

W 1-080

W1-145

W1-145V

Wl-185

WP-185V

Wl-230

W

1-280

W

1-340

Wl-390

W1-45OV

EY2 1

W

EY44W

EY 18-3W

EY25W

EY27W

EHl 1

EH12

EHl5

EH17

EH2 1

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY3O

DY3

5

DY4

1

v

TWO

DIESEL

CYCLE

WOl-115

wo1-120

WO1-150

WOI-I

wo1-210

WO1-250

WO1-300

WO1-3OOV

WO

WO 1 -340V

WO1-430V

WT1-125V

WRDI-230

WRD

WRDl-300

wRD1-350

WRD1-410

70

1-340

1 -270

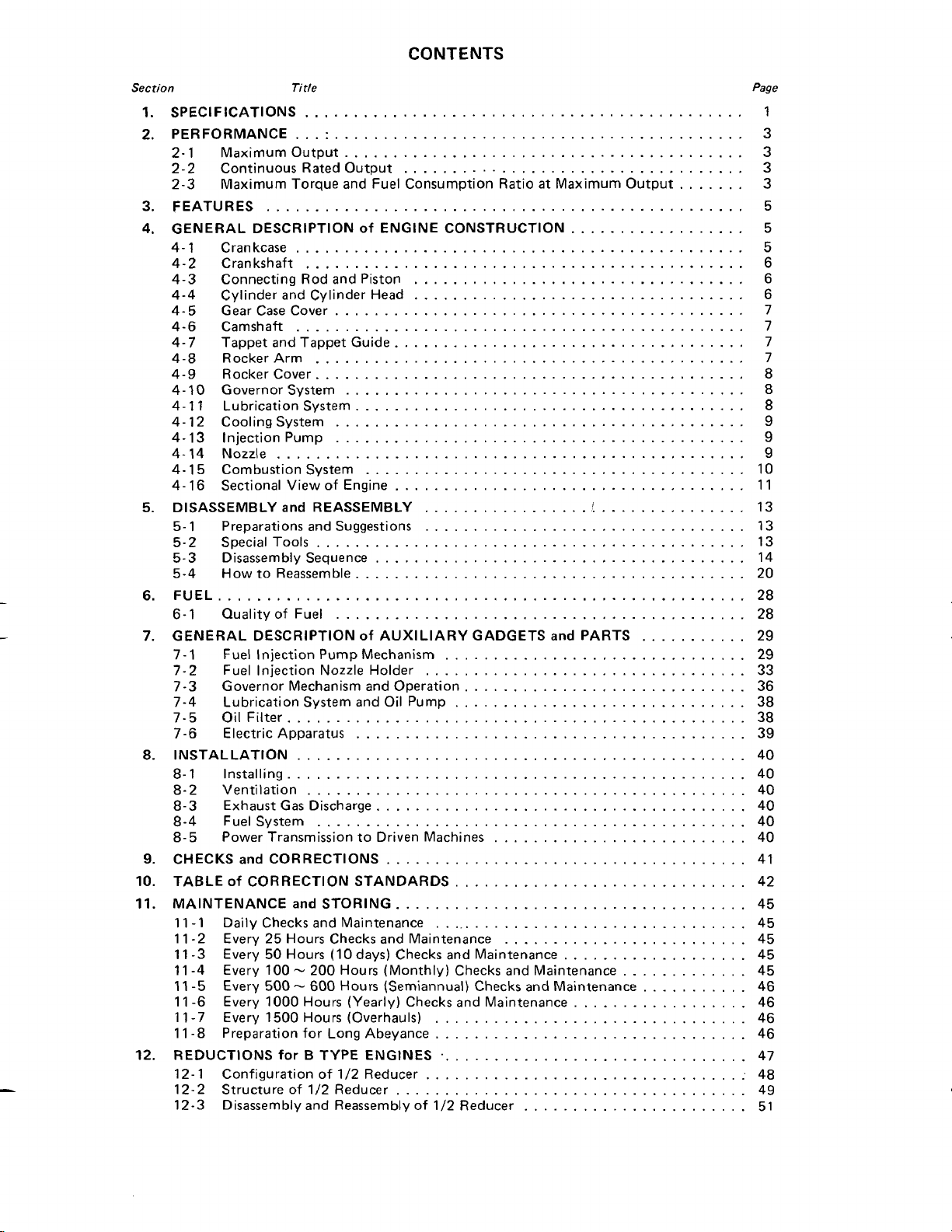

CONTENTS

See

ti0

n

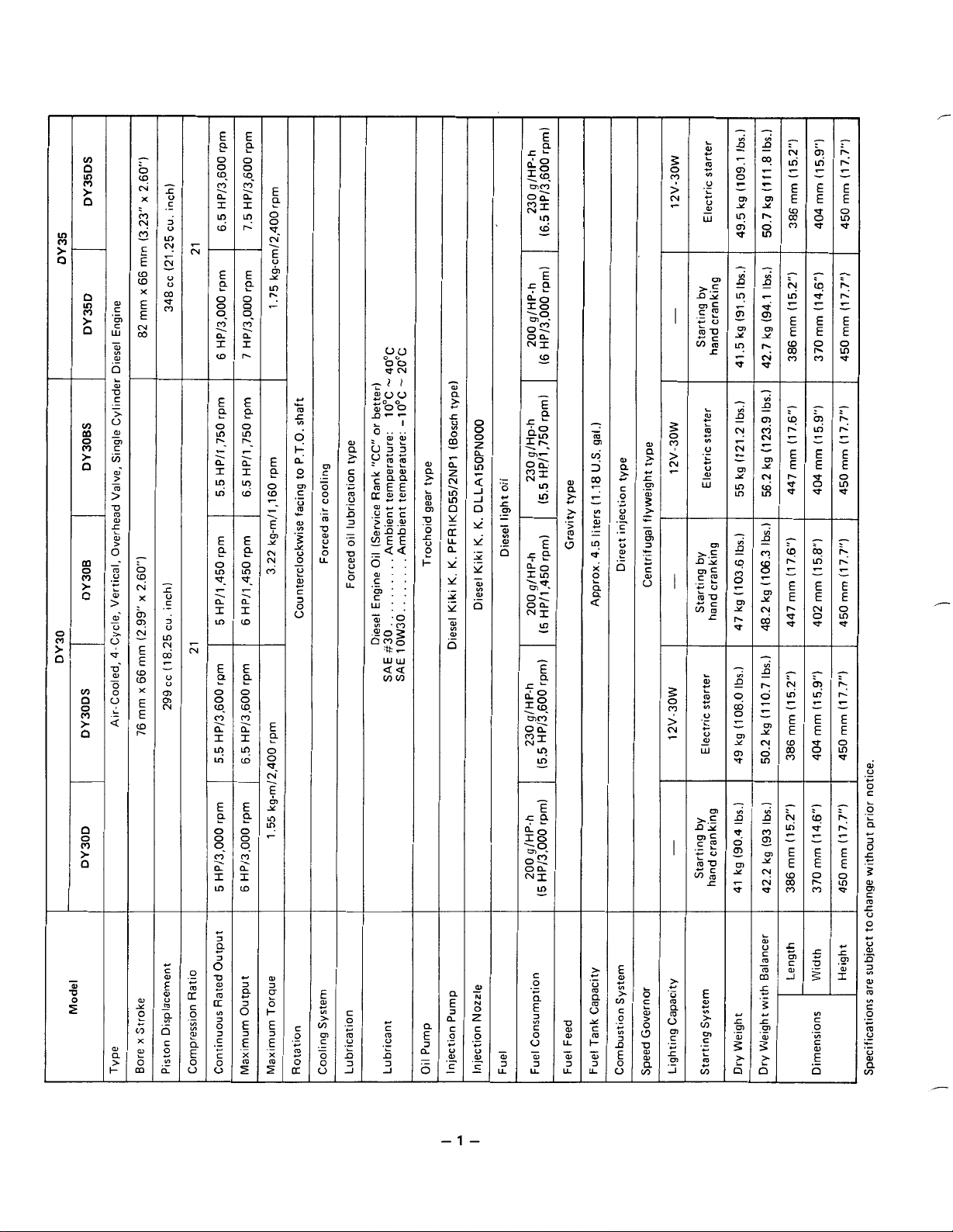

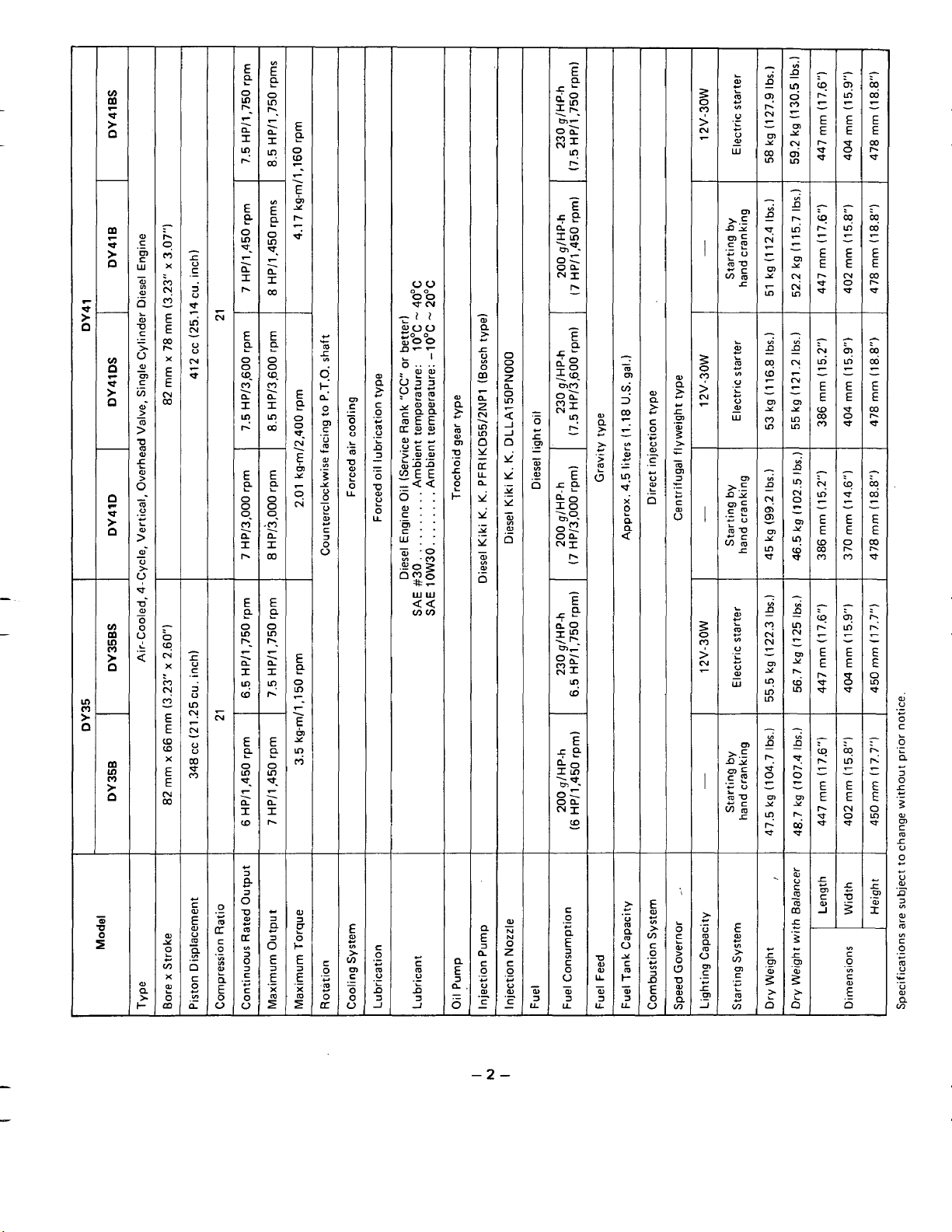

SPECIFICATIONS

1

.

PERFORMANCE

2

.

2-1 Maximum Output

2-2 Continuous Rated Output

2-3 Maximum Torque and Fuel Consumption Ratio

FEATURES

3

.

GENERAL DESCRIPTION

4

.

4- 1 Crankcase

4-2 Crankshaft

4-3 Connecting Rod and Piston

4-4 Cylinder and Cylinder Head

4-5 Gear Case Cover

4-6 Camshaft

4-7 Tappet and Tappet Guide

4-8 Rocker Arm

4-9 Rocker Cover

4-10 Governor System

4-1 1 Lubrication System

4- 12 Cooling System

4- 13 Injection Pump

4-14 Nozzle

4-

15 Combustion System

4- 16 Sectional View of Engine

DISASSEMBLY

5

.

5-

1

Preparations and Suggestions

5-2 Special

5-3 Disassembly Sequence

5-4 How to Reassemble

6

.

FUEL

.

.

7

8

9

10

11

12

.

.

.

.

.

.

......................................................

6-1

GENERAL DESCRIPTION

7

7-2

7-3 Governor Mechanism and Operation

7-4 Lubrication System and

7-5 Oil Filter

7-6 Electric Apparatus

INSTALLATION

8-1 Installing

8-2

8-3 Exhaust Gas Discharge

8-4

8-5

CHECKS

TABLE

MAINTENANCE

11

11

11

11 -4 Every

11

11

11

11

REDUCTIONS

12-1 Configuration

12-2 Structure

12-3 Disassembly and Reassembly

Qualityof Fuel

.

1 Fuel Injection

Fuel Injection Nozzle Holder

Ventilation

Fuel System

Power Transmission to Driven Machines

and

of

-1

Daily Checks and Maintenance

-2

Every

-3

Every

-5

Every

-6

Every

-7 Every

-8 Preparation for Long Abeyance

Ti

rle

.............................................

..............................................

.........................................

...................................

at

Maximum Output

.................................................

of

ENGINE CONSTRUCTION

..................

.............................................. 5

.............................................

..................................

..................................

..........................................

..............................................

....................................

............................................

............................................

.........................................

........................................

..........................................

..........................................

................................................

.......................................

....................................

and

REASSEMBLY

Tools

............................................

......................................

........................................

..........................................

of

Pump

Mechanism

...............................................

........................................

..............................................

...............................................

.............................................

......................................

............................................

CORRECTIONS

CORRECTION STANDARDS

and

STORING

25

Hours Checks and Maintenance

50

Hours

(10

days) Checks and Maintenance

100

-

200 Hours (Monthly) Checks and Maintenance

500

-

600 Hours (Semiannual) Checks

1000

Hours (Yearly) Checks and Maintenance

1500

Hours (Overhauls)

for

B TYPE ENGINES

of

1/2 Reducer

of

1/2 Reducer

.................

!

...............

.................................

AUXILIARY GADGETS

and

PARTS

...........

...............................

.................................

.............................

Oil

Pump

..............................

..........................

.....................................

..............................

....................................

.................................

.........................

...................

.............

and

Maintenance

...........

..................

................................

................................

................................

................................

....................................

of

1/2 Reducer

.......................

.......

:

Page

1

3

3

3

3

5

5

6

6

6

7

7

7

7

8

8

8

9

9

9

10

11

13

13

13

14

20

28

28

29

29

33

36

38

38

39

40

40

40

40

40

40

41

42

45

45

45

45

45

46

46

46

46

47

48

49

51

4

I

b

R

X

i?

p?

m

I

E

E

W

W

X

E

E

N

a3

-

-

0

R

X

6,

t?

N

E

E

W

[D

X

E

E

W

r.

I

t

W

Y

P

.-

v)

X

m

-

-1

+

-

L

W

c

L

m

c

VI

V

.-

L

c

0

m

-

w

I

I

,

I

I

I

”

I

-2-

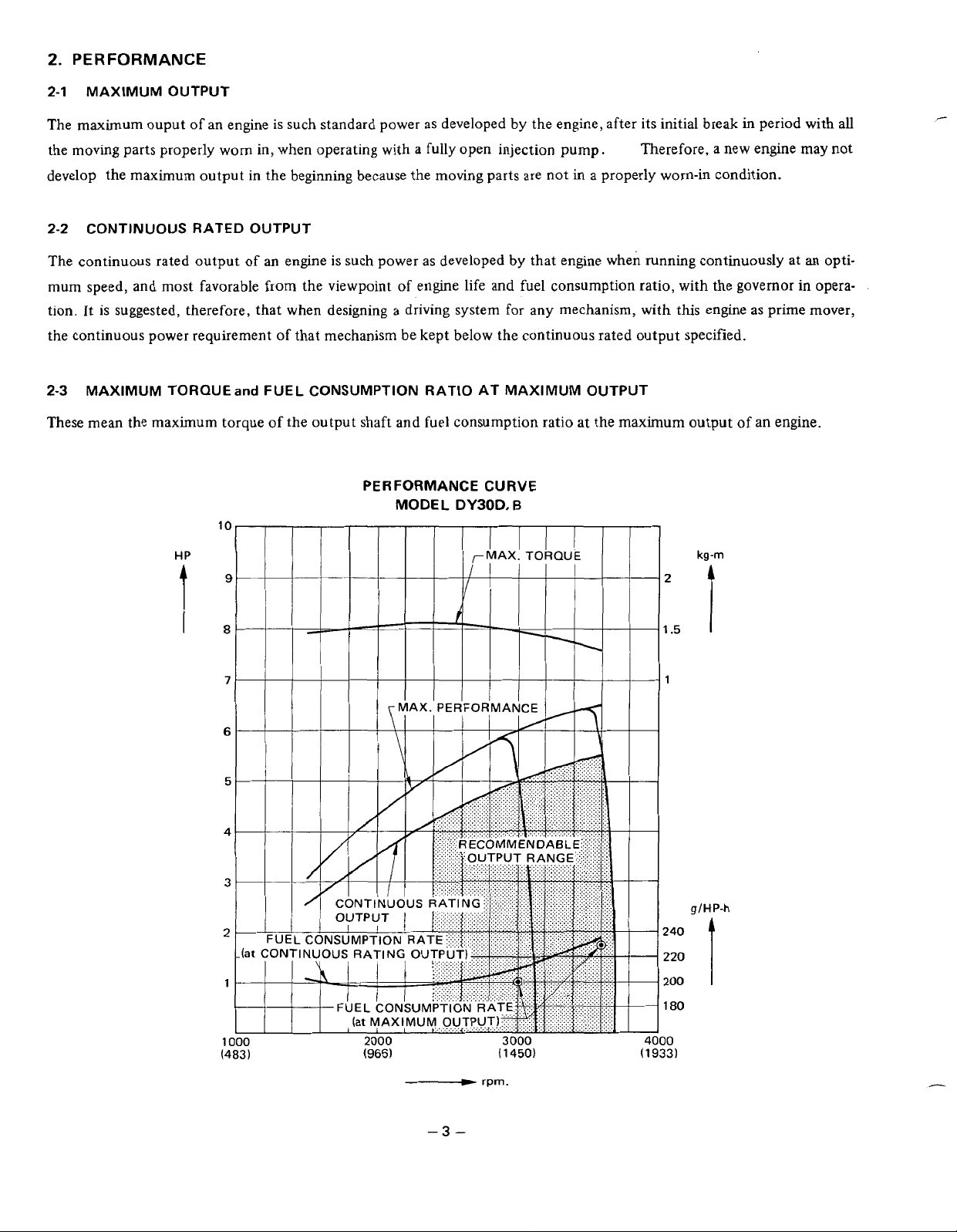

2.

PERFORMANCE

2-1 MAXIMUM OUTPUT

The maximum ouput of an engine is such standard power as developed by the engine, after its initial break in period with all

the moving parts properly worn in, when operating with a fully open injection pump. Therefore, a new engine may not

in

develop the maximum output in the beginning because the moving parts are not

2-2

CONTINUOUS

The continuous rated output

mum speed, and most favorable

is

tion. It

the continuous power requirement

2-3 MAXIMUM TORQUE

These mean the maximum torque

suggested, therefore, that when designing a driving system for any mechanism, with this engine as prime mover,

RATED

HP

OUTPUT

of

an engine

from

the viewpoint

of

that mechanism be kept below the continuous rated output specified.

and

FUEL CONSUMPTION

of

the output shaft and

10

9

is

such power as developed

of

engine life and fuel consumption ratio, with the governor in opera-

RATIO

fuel

consumption ratio at the maximum output of an engine,

PERFORMANCE CURVE

MODEL DYBOD,

by

that engine when running continuously at

AT MAXIMUM OUTPUT

B

a properly worn-in condition.

kg-m

2

an

opti-

-

t

I

8

7

6

5

4

3

2

1

1c

(1

450)

(1

1.5

1

t

JIHP-h

-

-3-

rpm.

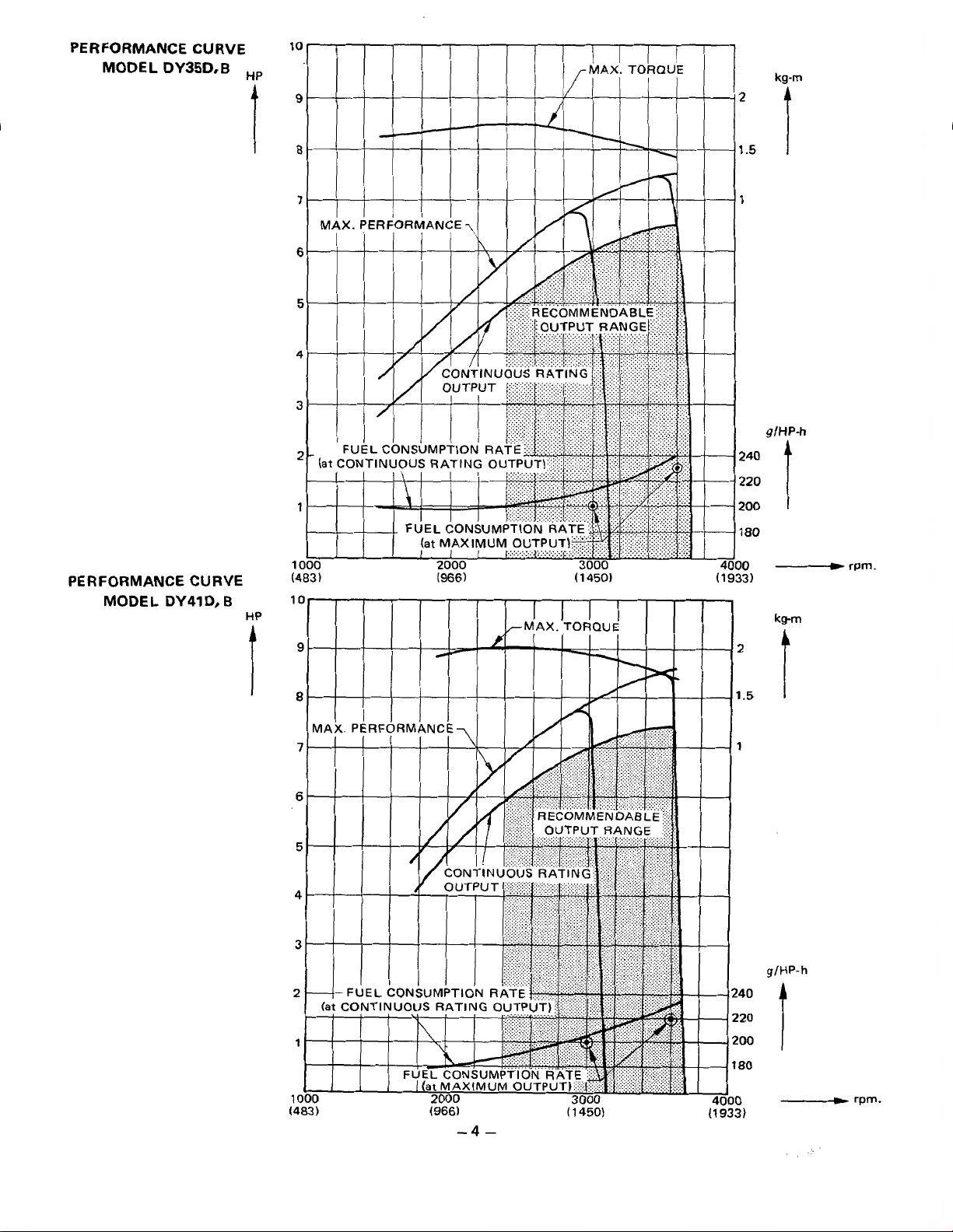

PERFORMANCE CURVE

MODEL

DY35DtB

10

-

MAX.

,,,,

9-

8-

7-

rv

6-

5-

4-

3-

TORQUE

I

PERFORMANCE

MODEL

DY41

CURVE

D,

B

HP

g/H

P-

h

LIGWWEIGWTand

1.

Lightweight because of aluminum alloy being used for various parts including the crankcase made of aluminum

2.

Compact in outside dimensions becausea) the camshaft

b)

the cooling fan and the flywheel are single piece die casting; and the cooling fan

may breathe in cooling air from the front, which means that the size of the fan casing becomes smaller and

of

the engine

FUEL

ECONOMY

Low

fuel consumption owing to improved fuel combustion system

tion owing to the highly effective muffler and air cleaner

As

an optional part a balancer is available for minimizing vibration.

EASY

to

TAKE-OUT POWER

A

faucet joint is set in the blower housing, which enables direct coupling with a machine.

flywheel and accordingly

(reverse side

to couple a machme

of

COMPACT

is

assembled inside of the gear case cover, and accordingly total width of the engine

is

set on the side of the case

is

also reduced.

and

NOISELESS TYPE ENGINE

having

adopted direct fuel injection; and noiseless

P.T.O.

this

engine

the machine coupled), it

to

the engine.

is

very easy to handle. Furthermore, as cooling air is taken into from the front

is

unnecessary

to

arrange air-intake

on

the

side

of

the machine. Therefore, it

is

shaft is connected

reduced,

total

die

so

casting

that it

length

opera-

to

the

of

case

is

easy

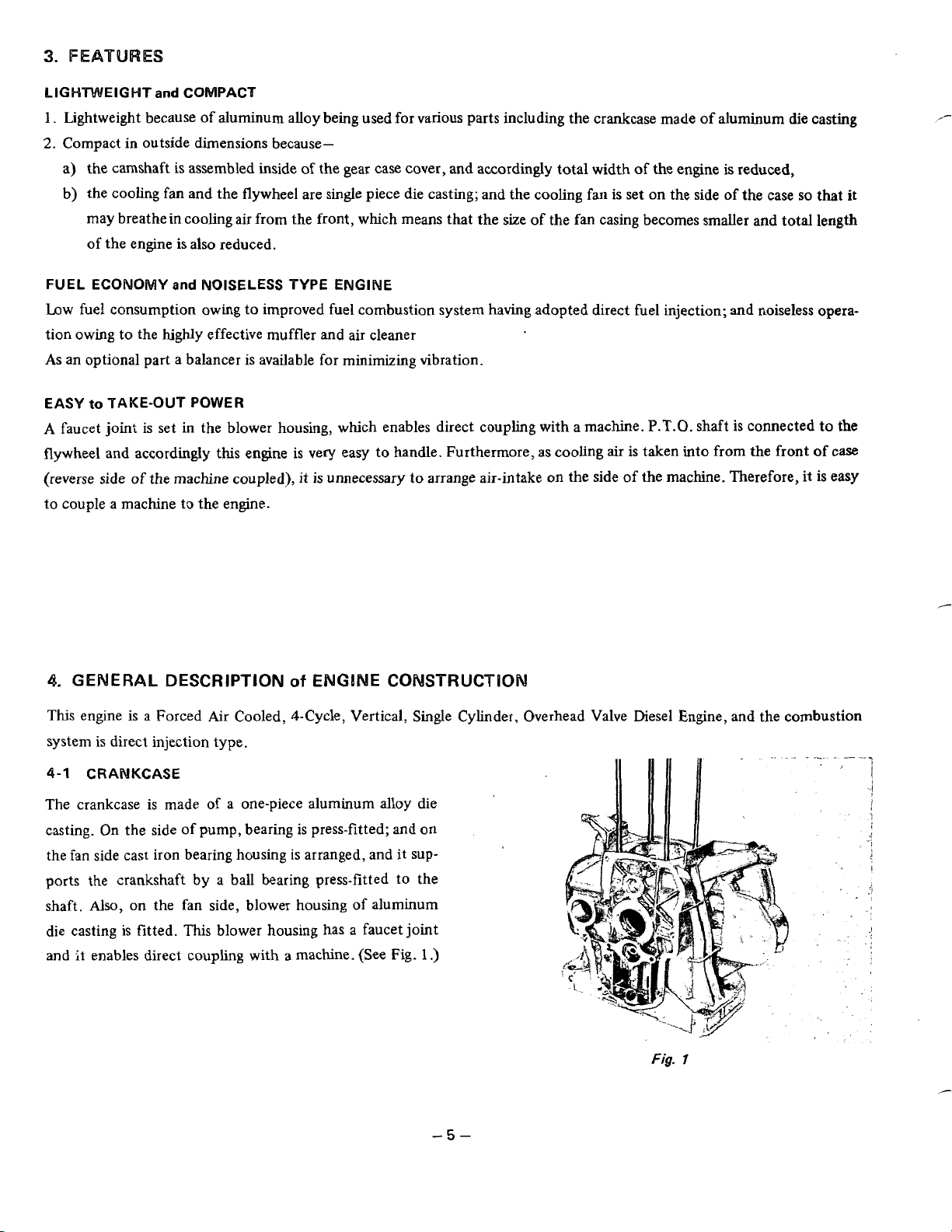

4.

GENERAL DESCRIPTION

This

engine is a Forced Air Cooled, 4-Cycle, Vertical, Single Cylinder, Overhead Valve Diesel Engine, and the combustion

system is direct injection type.

4-1

CRANKCASE

The crankcase is made of a one-piece aluminum alloy die

casting. On the side of pump, bearing is press-fitted; and on

the fan side cast iron bearing housing

ports the crankshaft by a ball bearing press-fitted to the

Also,

on

shaft.

die casting

and

it enables direct coupling with a machine. (See Fig.

the fan side, blower housing of aluminum

is

fitted.

This

blower housing has a faucet joint

of

ENGlME

is

arranged, and

CONSTRUCTION

it

sup-

1

.>

Fig.

1

1

I

I.

-

-5-

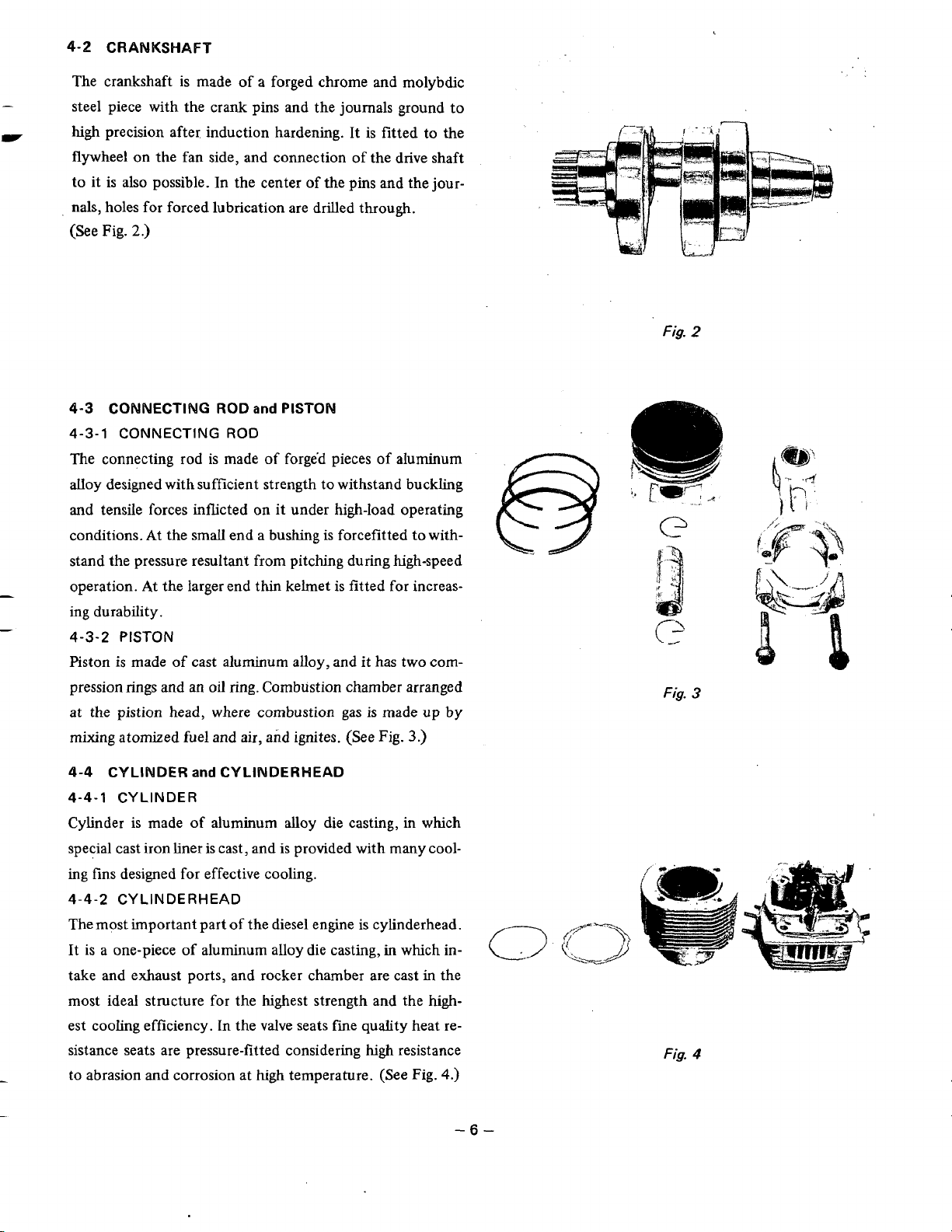

4-2

CRANKSHAFT

The crankshaft is made of a forged chrome and molybdic

steel piece with the crank pins and the journals ground to

high

precision after induction hardening. It is fitted

on

flywheel

to it is also possible.

the fan side, and connection of the drive shaft

In

the center of the pins and the jour-

to

the

nals, holes for forced lubrication are drilled through.

(See Fig.

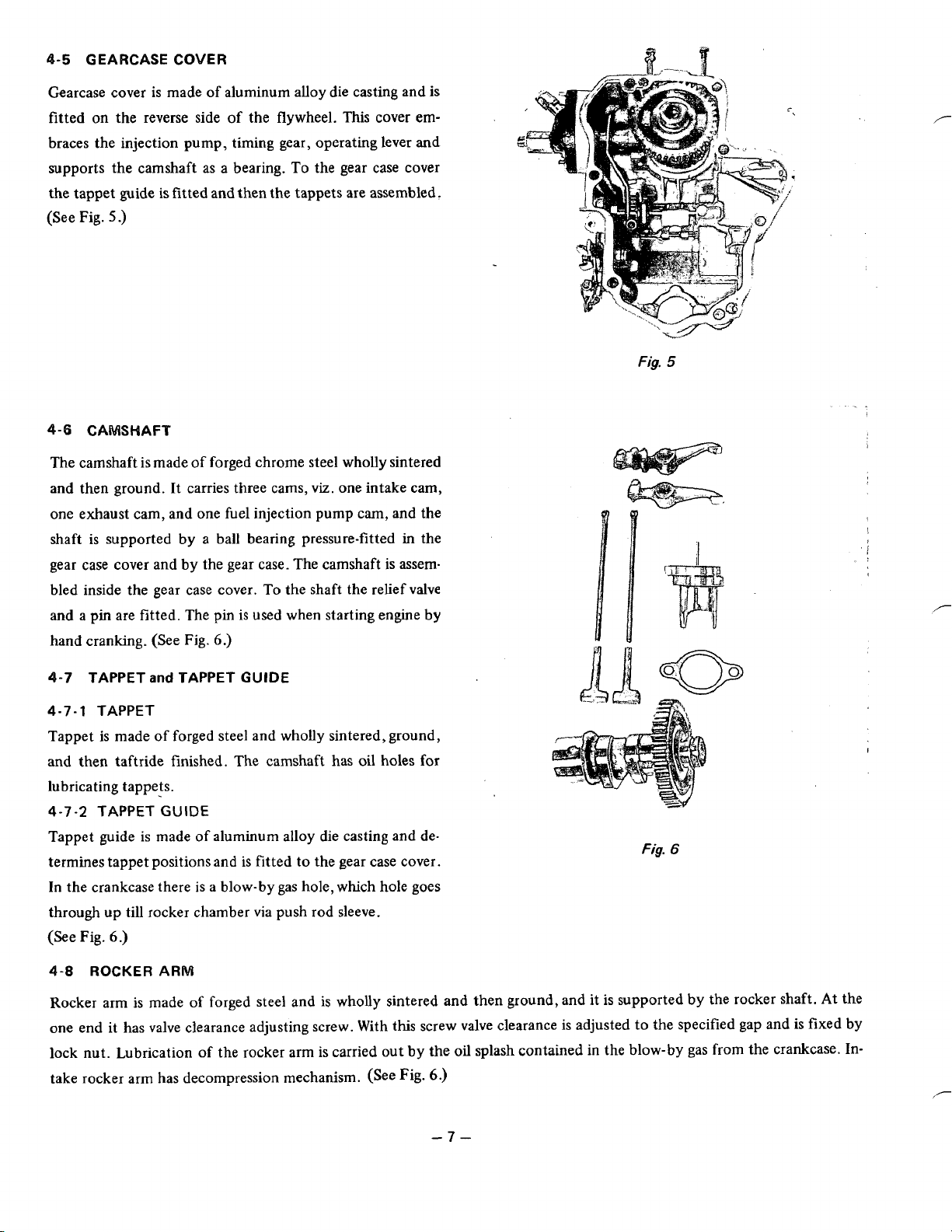

4-3

4-3-1

The connecting rod is made

2.)

CONNECTING ROD

CONNECTING

ROD

and

PISTON

of

forged pieces of aluminum

alloy designed with sufficient strength to withstand buckling

and tensile forces inflicted on it under high-load operating

conditions. At the small end a bushing is forcefitted to withstand the pressure resultant from pitching during high-speed

operation. At the larger end thin kelmet is fitted for increasing durability.

4-3-2

Piston

pression rings and an oil

at the pistion head, where combustion gas is made up

mixing atomized fuel and air, and ignites. (See Fig.

PISTON

is

made of cast aluminum alloy, and it has

ring.

Combustion chamber arranged

two

3.)

com-

by

Fig.

Fig.

2

3

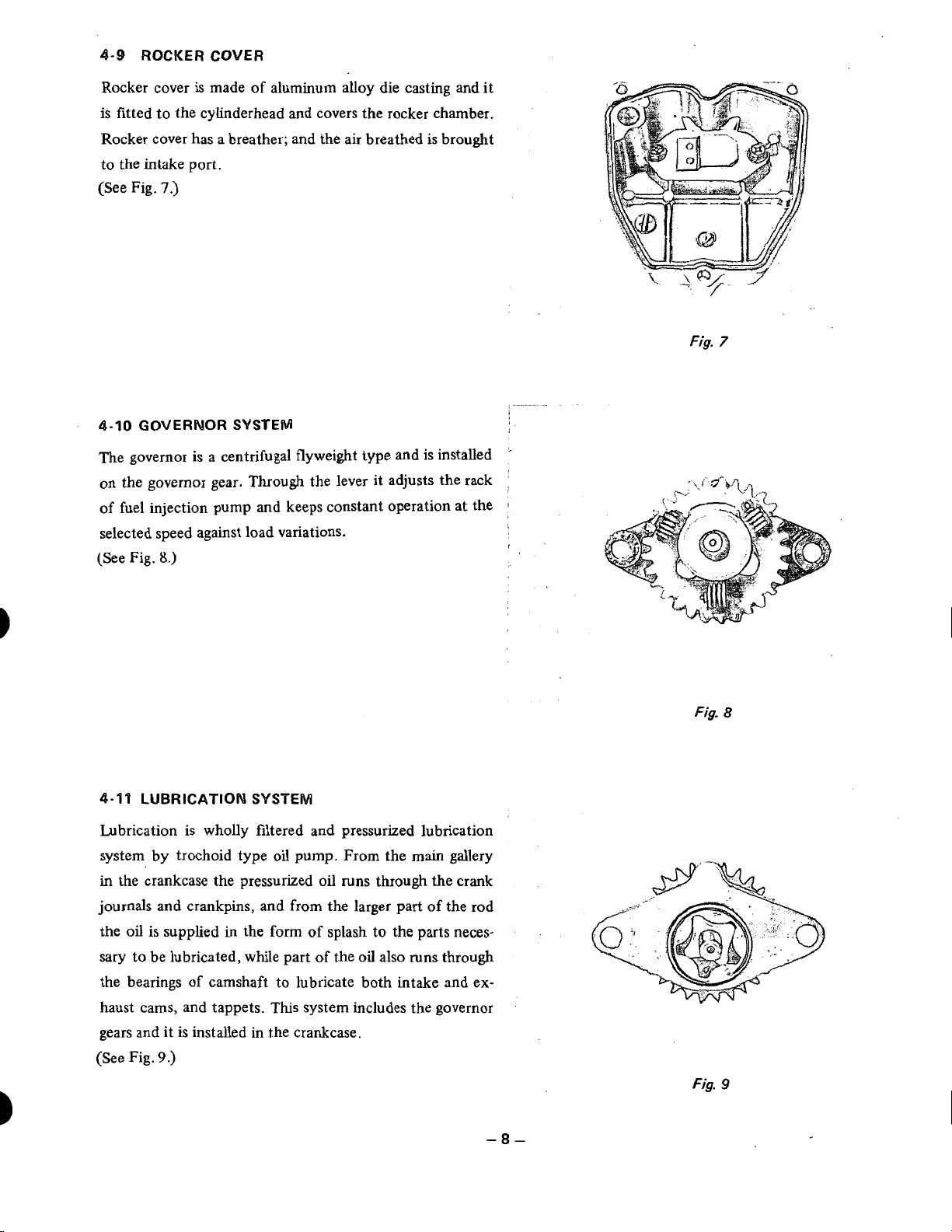

4-4

CYLINDER

4-4-1

CYLINDER

Cylinder is made

and

CYLiNDERHEAD

of

aluminum alloy die casting, in which

special cast iron liner is cast, and is provided with many cooling fins designed for effective cooling.

4-4-2

The most important part

It is a one-piece of aluminum alloy die casting,

take and exhaust ports, and rocker chamber are cast

CYLINDERHEAD

of

the diesel engine is cylinderhead.

in

which in-

in

the

most ideal structure for the highest strength and the highest cooling efficiency. In the valve seats fine quahty heat resistance seats are pressure-fitted considering

-

-

to

abrasion and corrosion at

high

temperature. (See Fig.

high

resistance

4.)

-6-

Fig.

4

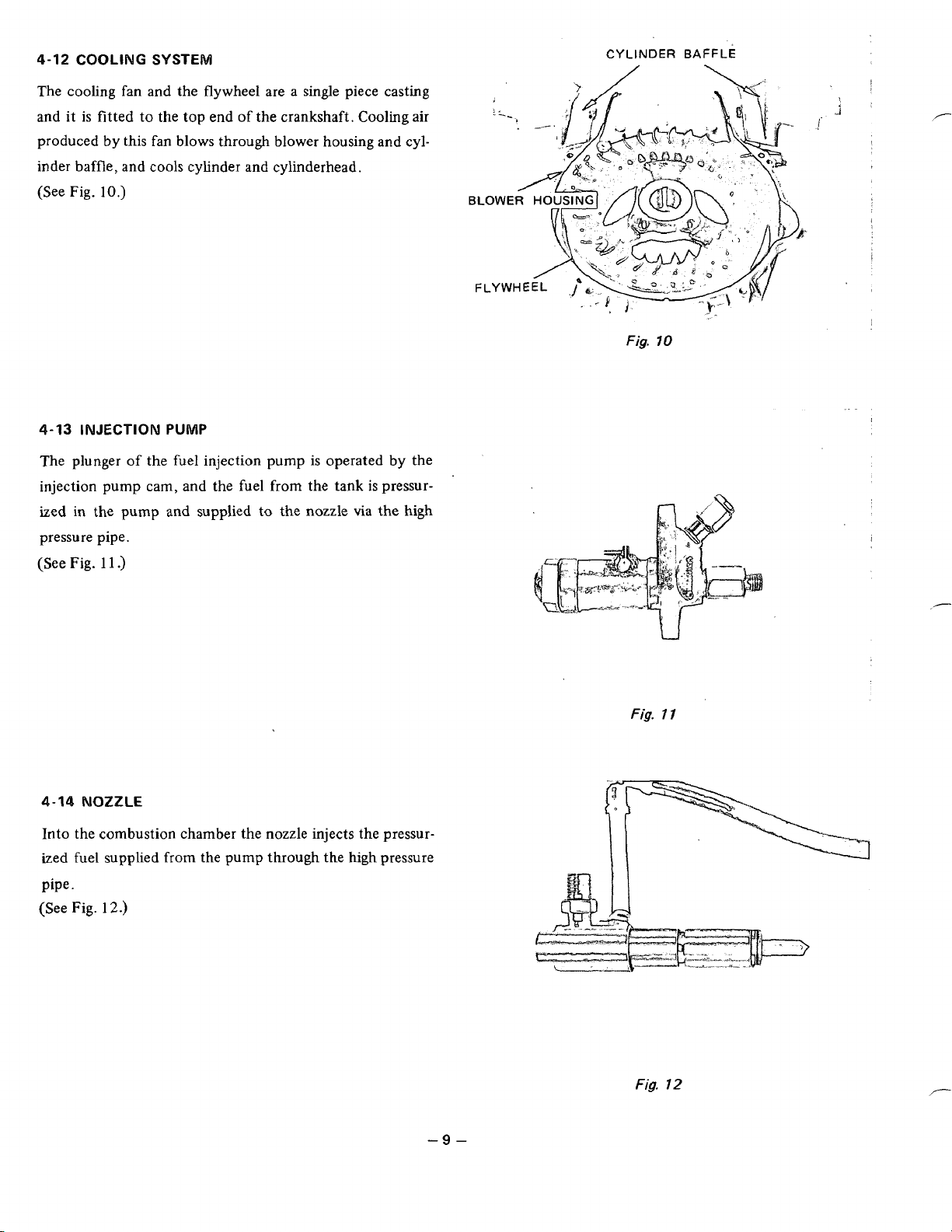

4-5

GEARCASE COVER

Gearcase cover is made of aluminum alloy die casting and

fitted on the reverse side of the flywheel.

This

cover em-

is

braces the injection pump, timing gear, operating lever and

supports the camshaft as a bearing. To the gear case cover

the tappet guide is fitted and then the tappets are assembled,

(See Fig.

4-6

5

.)

CAMSHAFT

The camshaft is made of forged chrome steel wholly sintered

viz.

and then ground. It carries three cams,

one intake cam,

one exhaust cam, and one fuel injection pump cam, and the

in

is

assem

the

shaft is supported by a ball bearing pressure-fitted

gear case cover and by the gear case. The camshaft

bled inside the gear case cover. To the shaft the relief valve

and a pin are fitted. The pin is used when starting engine by

Fig.

hand cranking. (See

6.)

Fig.

5

i

4-7

TAPPET

4

-7

-

1

TAPPET

Tappet is made

and then taftride finished. The camshaft has

and

TAPPET GUIDE

of

forged steel and wholly sintered, ground,

oil

holes for

lubricating tappets.

4-7-2

Tappet guide is made

termines tappet positionsand

In the crankcase there

through

(See Fig.

4-8

TAPPET GUIDE

up till rocker chamber via push rod sleeve.

6.)

ROCKER

Rocker arm

of

aluminum alloy die casting and de-

is

fitted

is

a blow-by gas hole, which hole goes

ARM

is

made of forged steel and

to

the gear case cover.

is

wholly sintered and then ground, and it

one end it has valve clearance adjusting screw. With this screw valve clearance

is

lock nut. Lubrication of the rocker arm

carried out by the

take rocker arm has decompression mechanism. (See Fig.

oil

splash contained in the blow-by

6.)

is

adjusted

Fig.

6

is

supported by the rocker shaft. At the

to

the specified gap and is fixed by

gas

from the crankcase. In-

-7-

4-9

ROCKER COWER

Rocker cover is made of aluminum ailoy die casting and it

is

fitted to the cylinderhead and covers the rocker chamber.

is

Rocker cover has a breather; and the air breathed

brought

to the intake port.

(See Fig.

4-10

7.)

GOVERNOR

SYSTEM

Fig.

7

.

.-

!

The governor is a centrifugal flyweight type

on

the governor gear. Through

the

lever it adjusts the rack

and

is installed

of fuel injection pump and keeps constant operation at the

selected speed against load variations.

(See Fig.

4-

8.)

I

f

LUBRICATION

SYSTEM

Lubrication is wholly filtered and pressurized lubrication

oil

system by trochoid type

pump. From the main gallery

in the crankcase the pressurized oil runs through the crank

of

journals and crankpins, and from the larger part

oil

is

the

supplied in the form

sary to be lubricated, while part

of

splash to the parts neces-

of

the

oil

also runs through

the rod

the bearings of camshaft to lubricate both intake and ex-

Ths

haust cams, and tappets.

system includes the governor

gears and it is installed in the crankcase.

Fig.

(See

9.)

’

:

1

Fig.

8

-8-

fig.

9

4-12

COOLING

SYSTEM

The cooling fan and the flywheel are a single piece casting

is

and it

fitted to the top end of the crankshaft.

produced by this fan blows

cools

inder baffle, and

(See Fig.

4-13

lo.)

INJECTION

cylinder and cylinderhead.

PUMP

through

blower housing and cyl-

Cooling

air

The plunger of the fuel injection pump is operated by the

injection pump cam, and the fuel

ized

in the pump and supplied to the nozzle

the tank

is

via

pressur-

the high

from

pressure pipe.

CYLINDER

Fig.

70

BAFFLE

11

(See Fig.

4-14

.)

NOZZLE

Into the combustion chamber the nozzle injects the pressur-

ized

fuel supplied from the pump through the high pressure

pipe.

(See Fig.

12.)

Fig.

U

11

-9-

Fig.

12

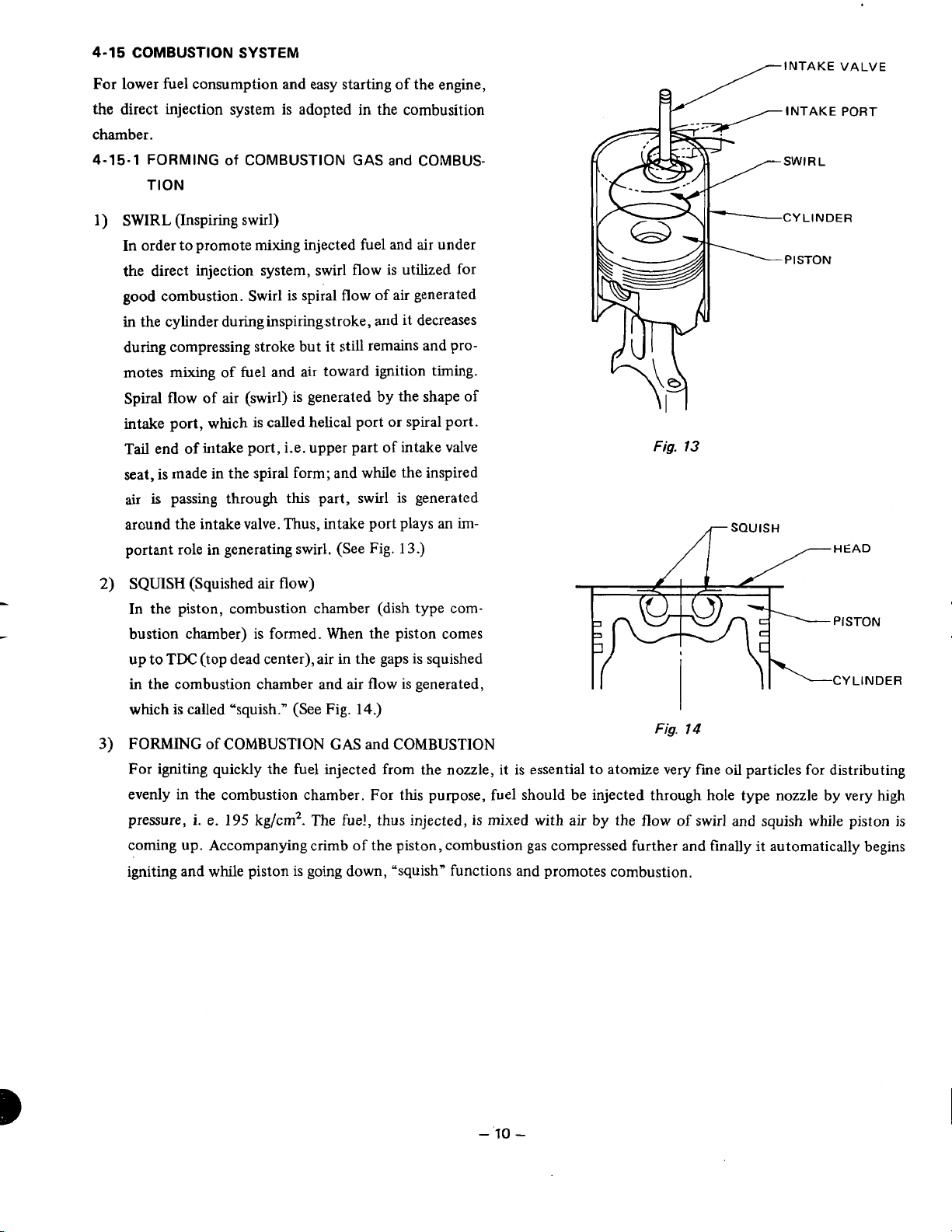

4-15

COMBUSTION

For

lower fuel consumption and easy starting of the engine,

SYSTEM

the direct injection system is adopted in the combusition

chamber.

4-15-1

FORMING

TION

of

COMBUSTION GAS

and

COMBUS-

/INTAKE

INTAKE

SWIRL

VALVE

PORT

SWIRL

(Inspiring swirl)

In order to promote mixing injected fuel and air under

the direct injection system, swirl flow is utilized for

good

Combustion. Swirl is spiral flow

in

the cylinder during inspiring stroke, and it decreases

of

air generated

during compressing stroke but it still remains and pro-

air

motes mixing of fuel and

of

air

Spiral flow

intake port, which

Tail

end of intake port, i.e. upper part of intake valve

(swirl)

is

called helical port

toward ignition timing.

is generated by the shape of

or

spiral port.

Fig.

13

seat, is made in the spiral form; and while the inspired

air

is

passing through this part, swirl

around the intake valve. Thus, intake port plays an

portant role in generating

SQUISH

(Squished air flow)

swirl.

(See Fig. 13.)

is

generated

im-

In the piston, combustion chamber (dish type com-

bustion chamber) is formed. When the piston comes

TDC

up to

in

the combustion chamber and air flow is generated,

which is called “squish.” (See Fig.

FORMING

(top dead center), air in the gaps is squished

14.)

of

COMBUSTION

GAS

and

COMBUSTION

Fig.

14

For igniting quickly the fuel injected from the nozzle, it is essential to atomize very fine

For

evenly in the combustion chamber.

pressure, i. e.

195

kg/cm2. The fue!, thus injected,

ths purpose, fuel should be injected through hole type nozzle by very

is

mixed with

air

by

the flow of swirl and squish while piston

oil

particles

CYLINDER

PISTON

for

distributing

high

is

Coming Up. Accompanying crimb

of

the piston, combustion gas compressed further and finally it automatically begins

igniting and while piston is going down, “squish” functions and promotes combustion.

-

10

-

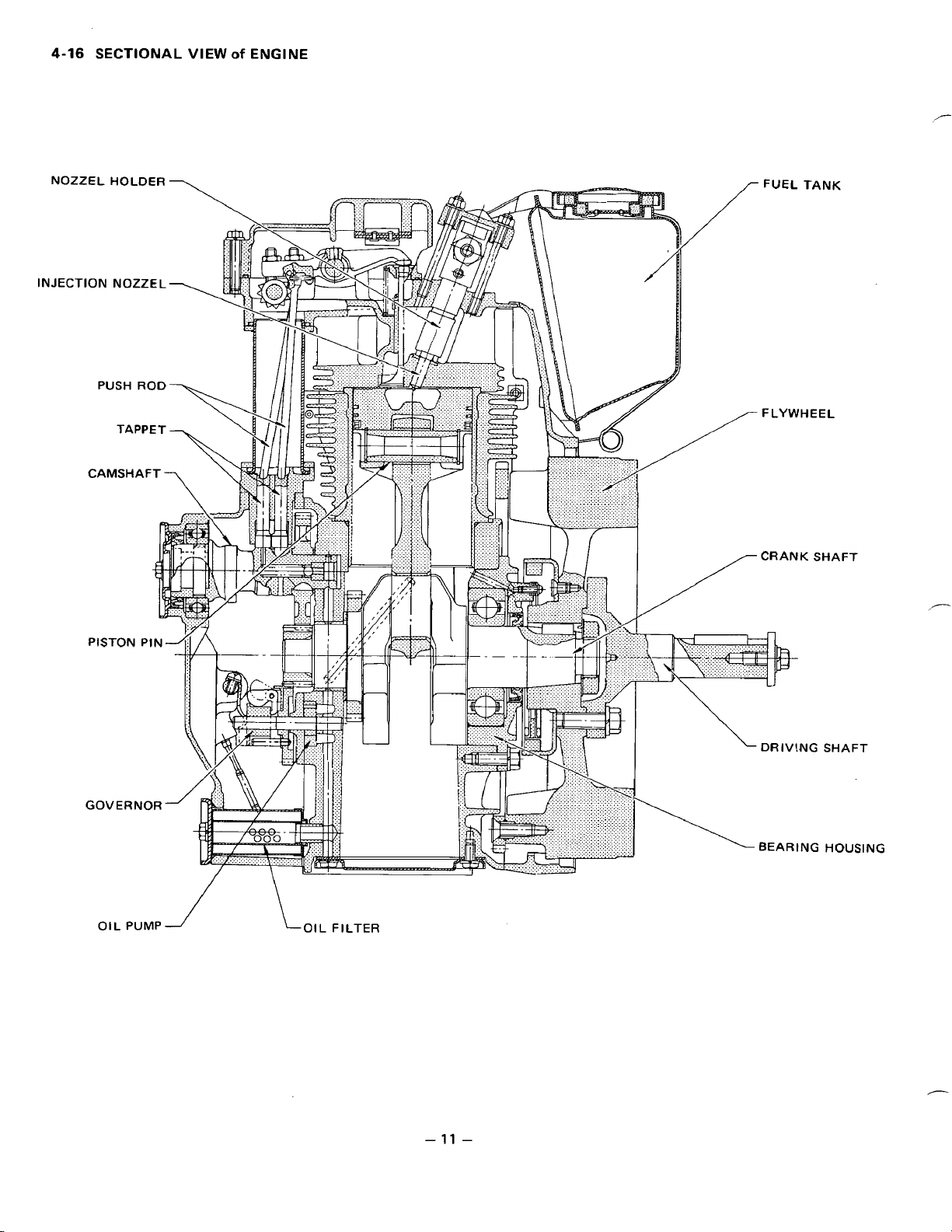

4-16

SECTIONAL

VIEW

of

ENGINE

-

11

-

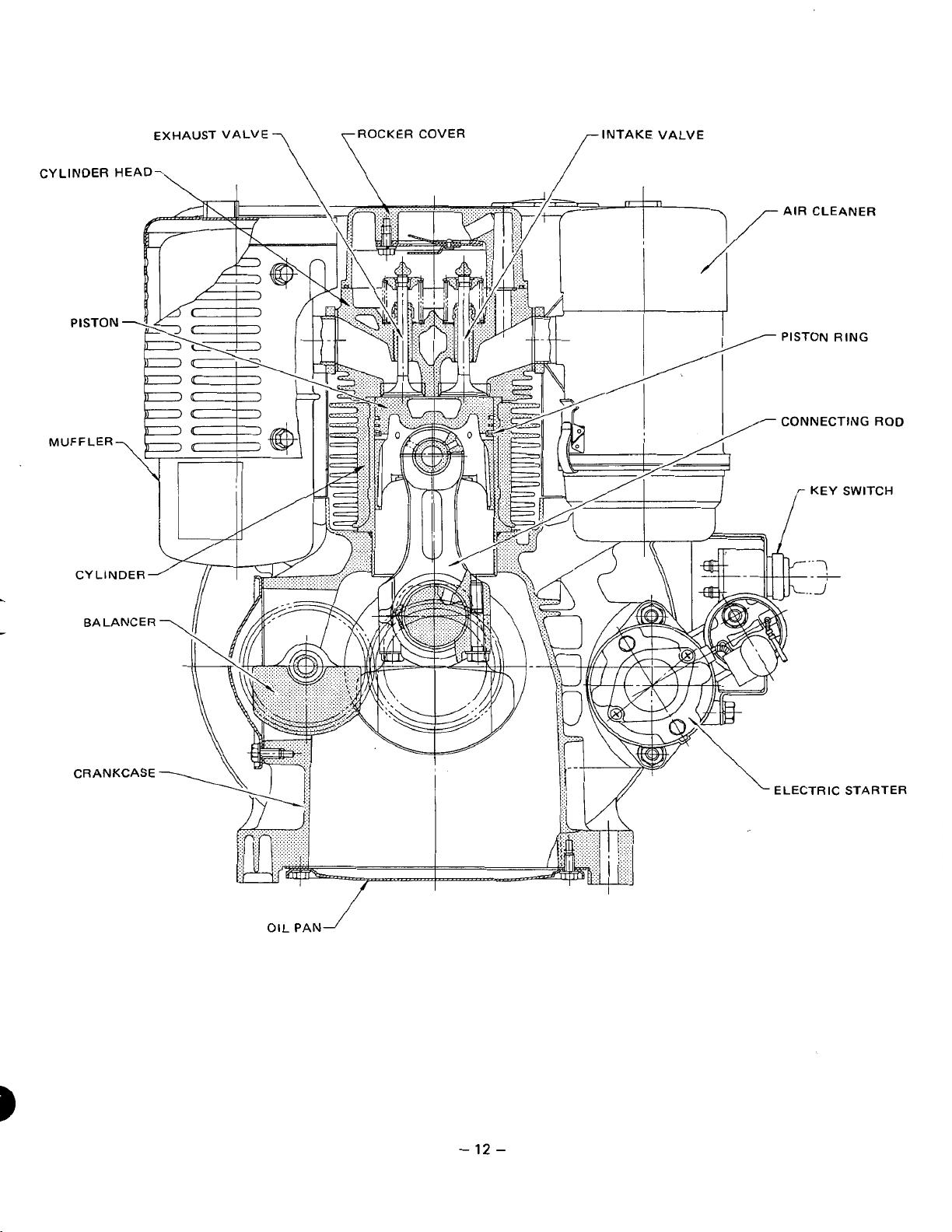

EXHAUST VALVE

ROCKER

COVER

INTAKE VALVE

CYLINDER HEAD-\

L

CY

BA

\\

AIR CLEANER

OIL

PAN-’

-

12

-

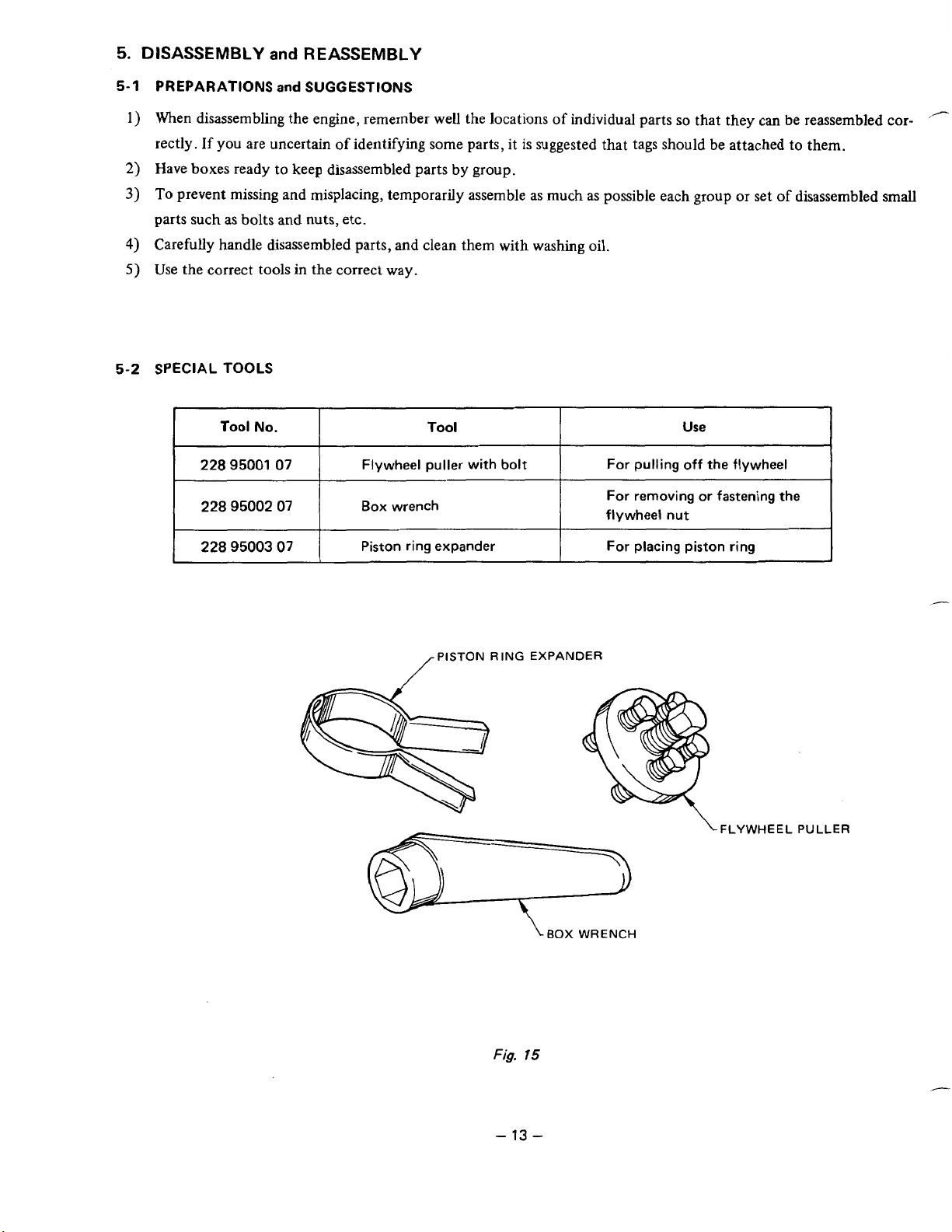

5.

DISASSEMBLY

5-1

PREPARATIONS

1)

When disassembling the engine, remember well the locations

rectly. If you are uncertain

2)

Have boxes ready to keep disassembled parts

3)

To

prevent missing and misplacing, temporarily assemble as much as possible each

parts such

4)

Carefully handle disassembled parts, and clean them with washing oil.

5)

Use the correct tools in the correct way.

5-2

SPECIAL

as

TOOLS

and

REASSEMBLY

and

SUGGESTIONS

of

identifying some parts, it

bolts and nuts, etc.

by

is

group.

of

individual parts

suggested that tags should be attached to them.

so

that they can be reassembled cor-

group

or set

of

disassembled

,-

small

I

228

I

22895002

I

228

Tool

95001

95003

No.

07

07

07

I

Flywheel puller with bolt

1

Box wrench

I

Piston ring expander

Tool

/

I

I

PISTON RING EXPANDER

Use

For pulling off the flywheel

For removing or fastening the

flywheel nut

For placing piston ring

I

I

Fig.

-

13

\BOX

15

-

WRENCH

5-3

DISASSEMBLING

SEQUENCE

Se-

quence

1

2

I

3

4

*Length

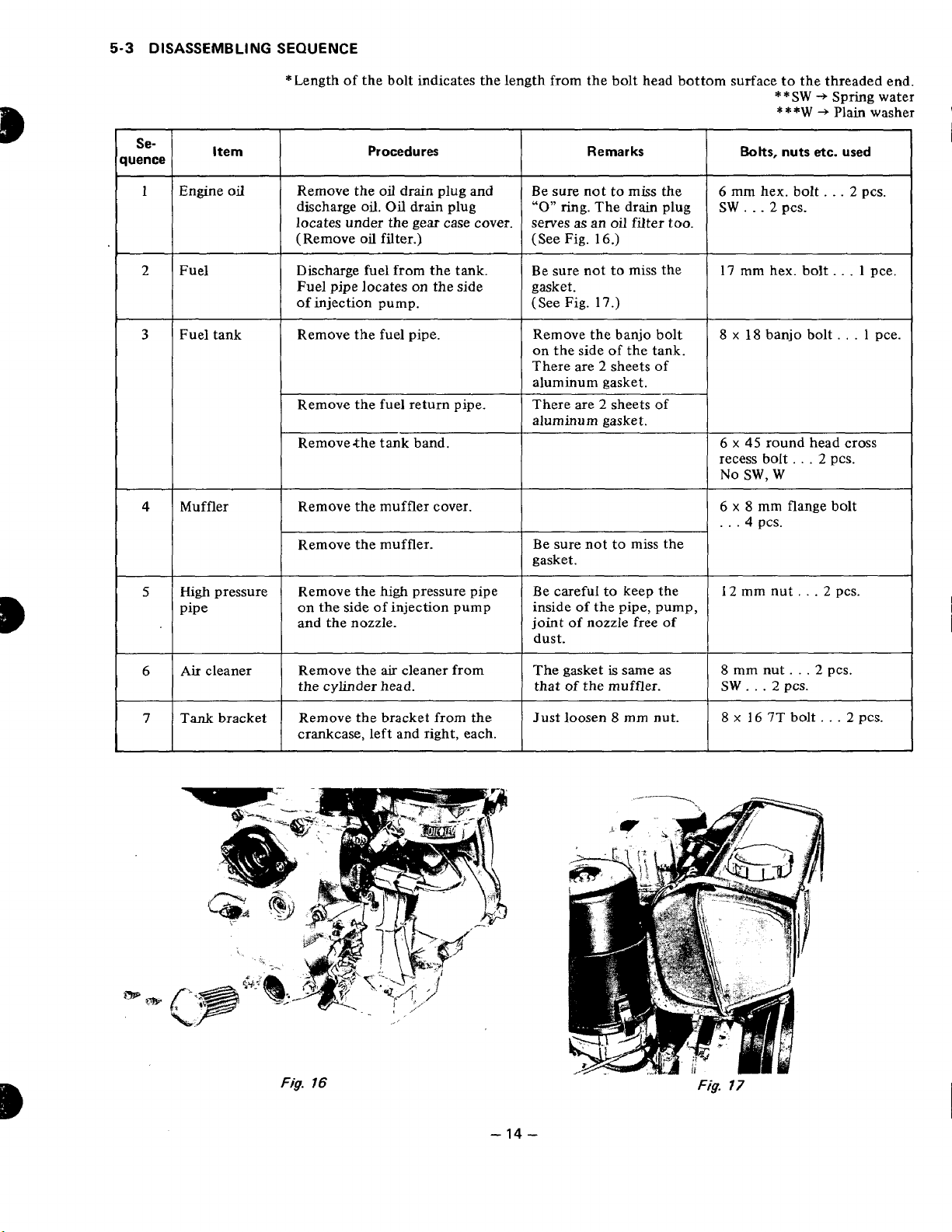

Item Procedures Remarks

~~~~~~~

Engine

oil

Fuel

Fuel tank

of

the bolt indicates the length from the bolt head bottom surface

~ ~~~ ~ ~ ~~~ ~

Remove the

discharge

oil

drain plug and

oil.

Oil

drain plug

locates under the gear case cover.

(Remove

oil

filter.)

Discharge fuel from the tank.

Fuel pipe locates

of

injection pump.

on

the side

Remove the fuel pipe.

-

~~~ ~ ~~

Be sure not

“0”

ring. The drain plug

serves as an

(See Fig.

Be sure not

gasket.

(See Fig.

Remove the banjo bolt

on the side

There are

aluminum gasket.

Remove the fuel return pipe.

There are

aluminum gasket.

Remove the tank band.

Muffler

Remove the muffler cover.

Remove the muffler.

Be sure not

gasket.

to

oil

16.)

to

17.)

of

2

sheets

2

sheets

to

miss

the

fiIter too.

miss the

the tank.

of

of

miss the

to

*

*

*

**W

Bolts,

nuts etc. used

6

mrn

hex. bolt

SW

.

. . 2

pcs.

17

mm hex. bolt.

8

x

18 banjo bolt

6

x

45

round head cross

recess bolt

No

SW,

W

6

x

X

mm flange bolt

. . .

4

pcs.

the threaded end.

SW

+

Spring

water

Plain washer

2

pcs.

.

.

1 pce.

.

.

.

1

pce.

. . .

+

. . .

~

2

pcs.

b

5

6

7

High

Pipe

Air

Tank

pressure

cleaner

bracket

high

Remove the

pressure pipe

on the side of injection pump

and the nozzle.

Be careful

inside

of

joint

of

nozzle free

the pipe, pump,

dust.

Remove the

the

cylinder head.

air

cleaner from

The gasket

that of the muffler.

Remove the bracket from the Just loosen

crankcase, left and right, each.

to

keep the

is

same as

8

mm nut.

of

12

mm nut.

8

mm nut.

sw

.

. .

8 x 16

2

7T

. .

.

.

pcs.

bolt..

2

2

pcs.

pcs.

.

2

pcs.

Fig.

16

-14-

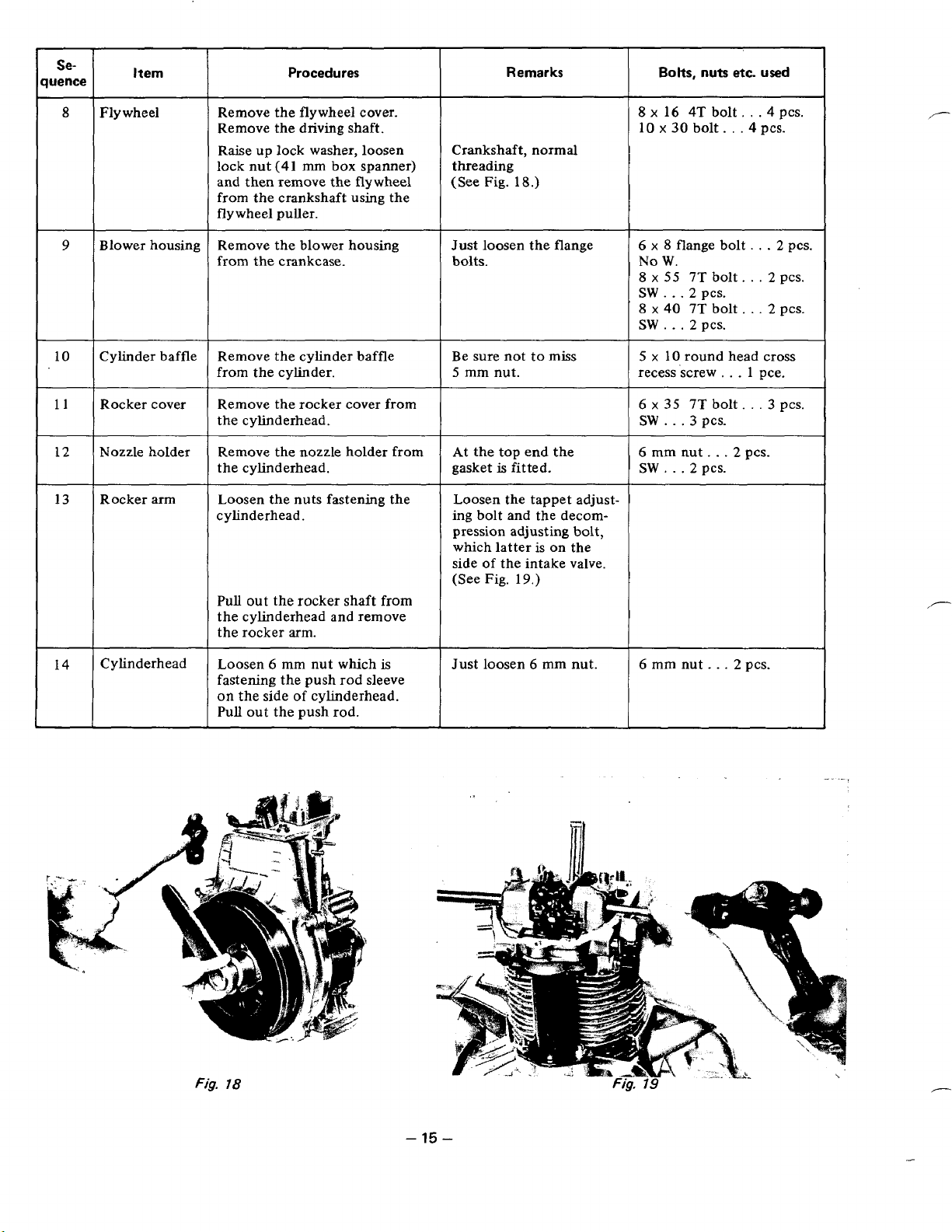

Fig.

17

-

Se-

quence

8

Fly

Item

wheel

Procedures

Remove the flywheel cover.

Remove the driving shaft.

Raise up lock washer, loosen

lock nut

and then remove the flywheel

from the crankshaft using the

flywheel puller.

(41

mm box spanner)

Crankshaft, normal

threading

(See Fig. 18.)

Bolts,

nuts etc. used Remarks

Blower housing

9

Cylinder baffle Remove the cylinder baffle

10

Rocker cover

Nozzle holder

l3

I

14

Rocker

Cylinderhead

arm

Remove the blower housing

from the crankcase.

from the cylinder.

Remove the rocker cover from

the cylinderhead.

the cylinderhead.

Loosen the nuts fastening the Loosen the tappet adjust-

cylinderhead. ing bolt and

I

Pull

out

the rocker shaft from

the cylinderhead and remove

the rocker

Loosen

fastening

on

the side

Pull

arm.

6

mm

the

out the push rod.

nut

which

push rod sleeve

of

cylinderhead.

Just loosen the flange

bolts.

~~ ~~

Be sure not to miss

5 mm nut.

At the top end the Remove the nozzle holder from

gasket

is

fitted.

the

decompression adjusting bolt,

which latter

side

of

(See Fig.

is

Just loosen

is

on the

the intake valve.

19.)

6

mm nut.

6

x

8

flange bolt

No

W.

8

x

55

7T bolt..

sw

.

..

2

pcs.

8

x

40

7T bolt.

sw .

.

.

2

pcs.

~ ~~ ~~ ~~

5

x

10

round head cross

recess screw

6

x

35 7T bolt.

sw

. . . 3

6

mm nut.

sw

. . .

6

mm nut.

2

. .

pcs.

.

pcs.

. . 2

.

2

.

pcs.

pcs.

.

.

.

.

2

.

.

2

1 pce.

.

.

3 pcs.

2

pcs.

pcs.

pcs.

Fig.

78

-

15

-

l"2L

quence

I

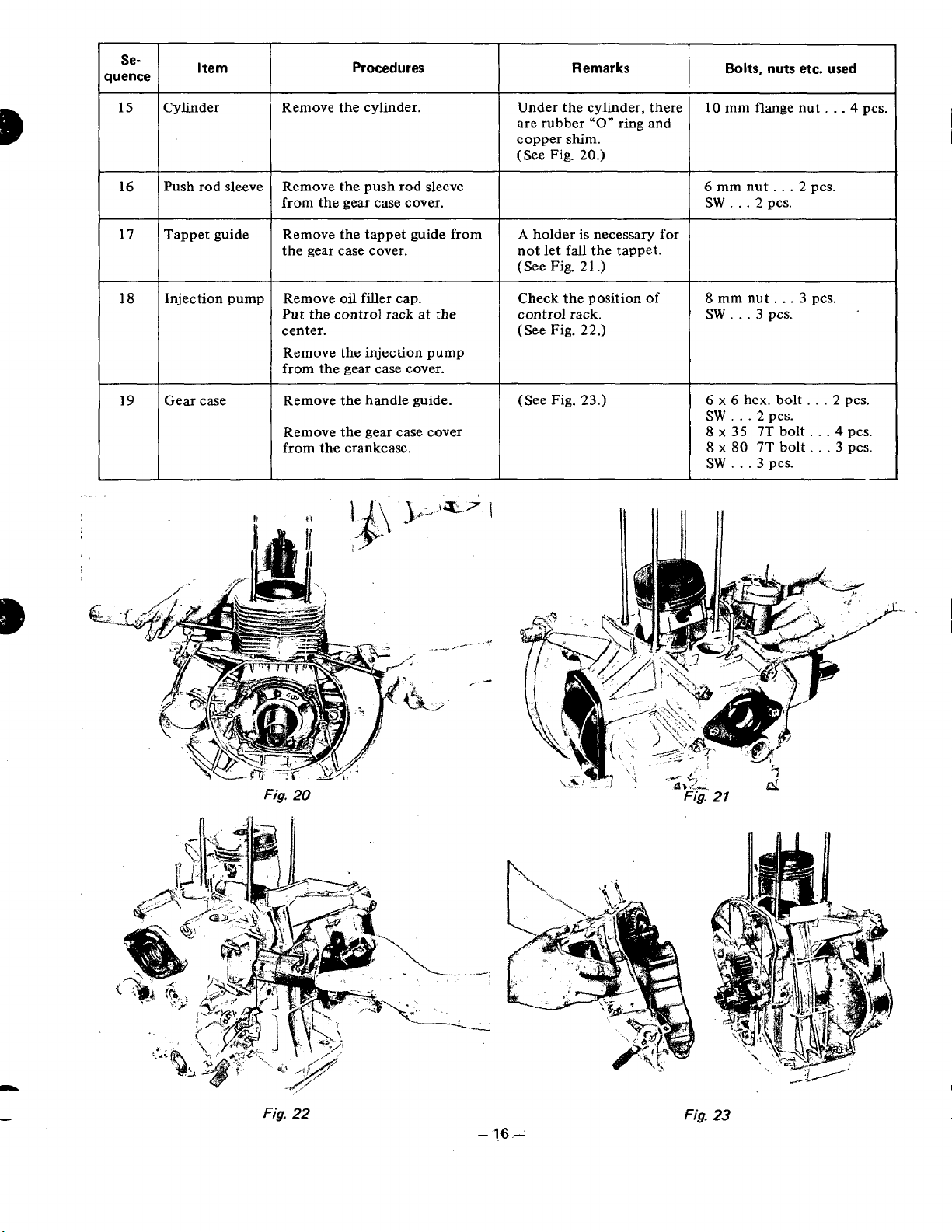

l5

ICylrnder

Procedures

Remove the cylinder.

Remarks

are rubber

copper shim.

(See

Fig.

"0"

20.)

ring and

I

Bolts,

nuts

etc.

used

b

17

18

19

Tappet guide

Injection pump

Gear case

Remove the push rod sleeve

from the gear case cover.

Remove the tappet guide from

the gear case cover.

Remove

Put

center.

Remove the injection pump

from the gear case cover.

Remove the handle guide.

Remove the gear case cover

from the crankcase.

It

oil

filler cap.

the control

rack

at the

.

r-

.c.

.P

A

holder

not let

(See Fig.

Check the

control rack.

(See

(See Fig.

fall

Fig.

is

necessary for

the tappet.

2

1

.)

position

22.)

23.)

6

mm

nut

. . .

2

pcs.

sw

. . .

2

pcs.

of

8

mm

sw

6 x 6

sw

8

x

8

x

sw

nut

. . .

3

pcs.

hex. bolt

. .

.

2

35

7T

80

7T

.

.

.

3

.

.

.

pcs.

bolt..

bolt.

pcs.

3

pcs.

.

.

.

.4

. .

2

3

pcs.

pcs.

pcs.

/."-

Fig.

Fig.

20

22

/"

\-

Fig.

23

Procedures Remarks

20

Camshaft Pull out the camshaft. Between camshaft and

gear case there

(See Fig.

24.)

is

a shim.

Bolts,

nuts etc. used

Piston Remove the piston from the

21

connecting rod. (Remove the

clip and pull out the piston.)

22

23

Governor

oil

Oil

and

pump

pan Remove the

From the crankcase remove

the governor and

the

form

of

one

oil

crankcase.

oil

pump

in

piece.

pan from the

Watch the direction of

the clip, also pay attention to the direction of

the piston.

(

"f

mark indicates "to-

ward the fan side.")

(See Fig.

Be careful

25.)

of

the pack-

ings.

6

x

20

sw

.

6 x 12

sw

. . .

.

7T

.

2

bolt

8

bolt

pcs.

.

pcs.

. .

.

8

.

.

pcs.

2

pcs.

/"-

Fig.

24

Fig.

25

-

17

-

Se-

tuence

I_

24

Item

Connecting

rod

Procedures

Remove the connecting rod

from the crankshaft.

Remarks

No

lock washer.

Be careful of the direction of rod. (Fan mark

is on the side of the

flywheel.)

Be careful

mark

(See Fig.

of

of

the

26.)

cap.

the setting

Bolts,

nuts etc.

used

25

Bearing housing and crankshaft

From the crankshaft remove

the key on the side

of

fan.

Remove the bolt fastening the

bearing housing.

Pull

the crankshaft together

with the bearing housing.

(Gently tap the side of crank

gear with plastic hammer.)

Be careful of the copper

shim

and

“0”

ring

between the bearing housing and the case.

Also

be careful

hole for

oil.

of

the

After pulling out the

crankshaft from the

case, remove housing.

The bearing remains on

the crankshaft.

(See Figs.

27,

28

and

29.)

8

x

SW

22

. .

7T

.6

bolt.

pcs.

.

.

6

pcs.

Fig.

Fig.

26

28

-18-

Fig.

27

1

quence

T

Item

Procedures

1

I

Remarks

1

I

Bolts,

nuts

~Pc.

used

Intake and

exhaust valve

Fj

Remove the intake and exhaust

valves

from

the cylinderhead.

Fig.

of

is

30.)

intake

a stem

On the side

valve, there

seal. Be sure not to miss

retainer lock.

(See Fig.

30

J

Se-

2

3

I

tem

Snap ring

Balancer shaft

Balancer

Procedures

Remove the

Remove the balancer shaft.

Remove the balancer from

the case.

snap

ring.

Remarks

Be sure not

snap

(See Fig.

Gently tap with plastic

hammer.

Be careful not

the

thrust

side of the pump.

The gear and the needle

bearing are

(See

ring.

Fig.

to

3

1

.)

metal

in

32.)

miss the

to

damage

on

the

one piece.

Bolts,

nuts etc.

used

Fig.

31

-19-

Fig.

/“-

32

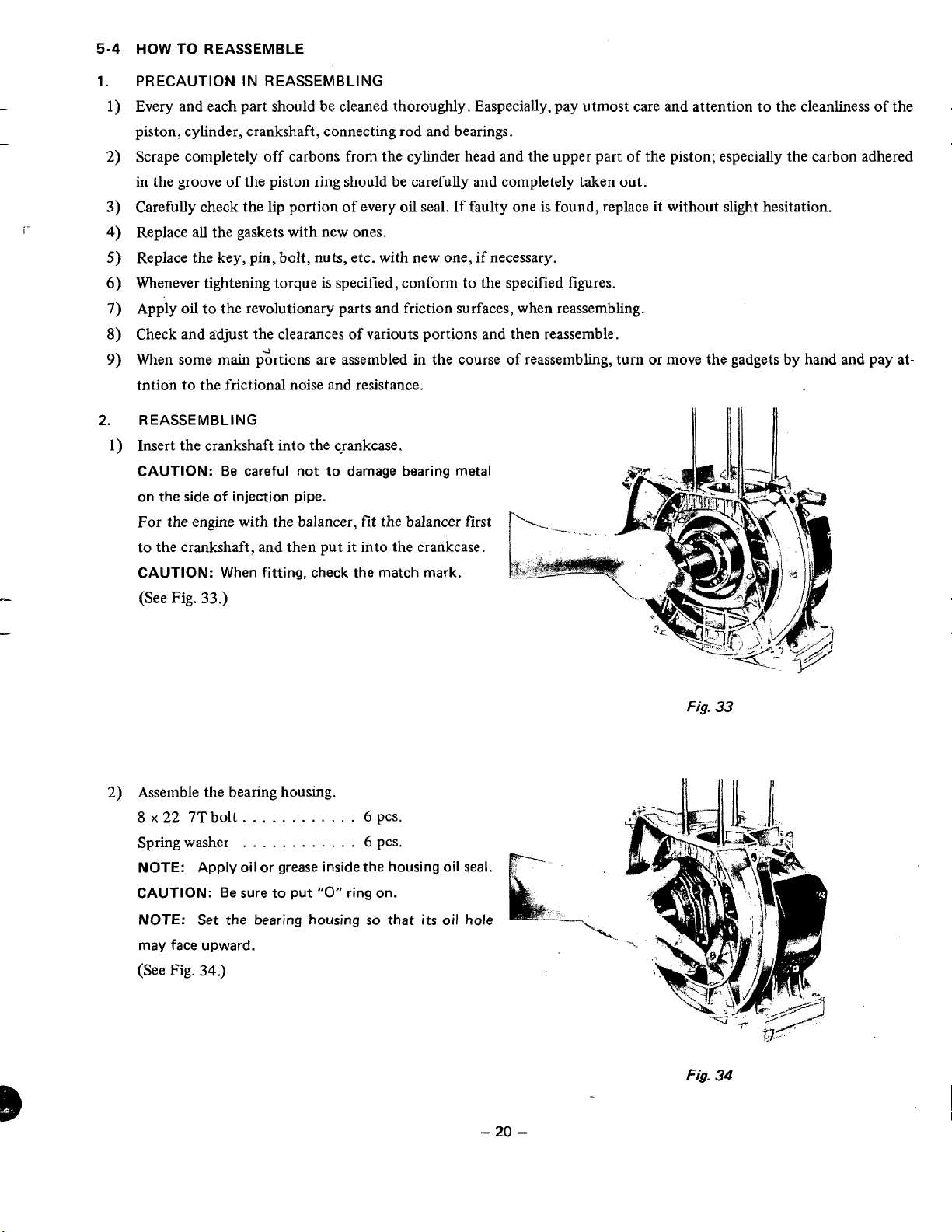

5-4

HOW

TO REASSEMBLE

1.

PRECAUTION IN REASSEMBLING

1)

Every and each part should be cleaned thoroughly. Easpecially, pay utmost care and attention to the cleanliness of the

piston, cylinder, crankshaft, connecting rod and bearings.

2)

Scrape completely off carbons from the cylinder head and the upper part of the piston; especially the carbon adhered

in

the groove of the piston ring should be carefully and completely taken out.

3)

Carefully check the lip portion of every

4)

Replace all the gaskets with new ones.

5)

Replace the key, pin, bolt, nuts, etc. with new one, if necessary.

6)

Whenever tightening torque is specified, conform

7)

Apply

oil

to the revolutionary parts and friction surfaces, when reassembling.

8)

Check and cidjust the clearances of variouts portions and then reassemble.

9)

When

some

main Grtions are assembled in the course of reassembling, turn or move the gadgets by hand and pay at-

oil

seal.

If

faulty one is found, replace it without slight hesitation.

to

the specified figures.

tntion to the frictional noise and resistance.

2.

REASSEMBLING

1)

Insert the crankshaft into the crankcase.

CAUTION:

on the side

Be careful not to damage bearing metal

of

injection pipe.

For the engine with the balancer, fit the balancer first

it

to the crankshaft, and then put

CAUTION:

(See Fig.

33.)

When

fitting,

check the match mark.

into the crankcase.

2)

Assemble the bearing housing.

8

x

22

7T

bolt

............

Spring washer

NOTE:

CAUTION:

NOTE:

............

Apply

oil

Be sure

Set

the

or

bearing housing

may face upward.

(See Fig.

34.)

6

pcs.

6

pcs.

grease inside the housing oil seal.

to

put

"0"

ring

on.

so

that

its

oil

hole

Fig.

33

-q

3

Fig.

34

-

20

-

NOTE: With the copper shim adjust the side clear-

of

ance

Three kinds

and

[Tightening toruque:

the crankshaft be

of

shim

0.3

mm

thick.

0.1

-

are available,

200

-

230

0.2

mm.

viz.

kg-cm]

0.1

mm,

0.2

mm,

:-

(See Fig.

Assemble the connecting

3)

CAUTION: Pay attention to the direction

(FAN

NOTE: Check the match mark

NOTE: The lock washer

the bolt. [Tightening torque: 250

(See Fig.

35.)

mark

36.)

is

to be

rod.

set

on the side

is

not used when fastening

of

the flywheel.)

on

the cap.

-

270

of

the

kg-cml

rod.

Fig.

35

u

4)

Assemble the

6 x 12

Spring washer

NOTE:

(See Fig.

oil

pan.

bolt

..............

............

Pay

attention to the packings.

37.)

8

8

pcs.

pcs.

Fig.

36

Fig.

37

-

21

-

Assemble the

MOTE:

be faced to the fan side.

MOTE:

MOTE:

(See

Fig.

piston.

+

mark in the upper part

Piston rings are not assembled.

Shape of the piston pin.is

38

.)

Assemble the cylinder

NOTE:

ring

the head

NOTE:

Insert the piston into the cylinder (piston

is

not inserted.), and measure the dimensions of

of

piston and upper surface of the cylinder.

The concave dimensions of the pistion

of

the piston

(D

.

is

is

to

-0.6

-

Fig. 38

-0.7

mm from the upper Surface of the Piston.

MOTE:

ness

MOTE:

Punched mark

to be

NOTE:

Be sure to

Notched portion

Adjustment

of

the shim are

Fit the piston rings on

set

to the different three directions.

Set

the cylinder.

fit

rubber

TOP

RING

SECOND

OIL

RING

of

the concavedimensions

0.1

mm and

"N"

are to be faced up. Open end

"0"

ring and

of

the cylinder skirt must

0.2

the

mm.

piston.

shim.

D

RING

I

23

is

to be made by the shim underneath the cylinder, and available thick-

of

each ring must avoid the direction toward the thrust side and

be

set

on the side

of

the gear case cover.

(See

Figs.

39-1

and

39-2.)

it

is

1

7)

'

Install

the

41

(Use

NOTE:

bend the tabs securely.

[Tightening

(See

mm

When putting lock washers on, be sure to

Fig.

40.)

flywheel.

box

wrench.)

torque:

Fig. 39-

7

2,000 - 2,200

kg-cml

Fig. 39-2

fig.

40

-

22

-

8)

Install the camshaft.

NOTE:

NOTE:

0.1

Apply

Set the match mark

-

0.3

oil

mm.

Three kinds

or

grease

to

the inside

of

the camshaft

of

shim are available, viz.

of

oit

seal

so

for

the gear case cover.

as

to

fit

to

that

0.8

mm,

1

of

the crank gear. Side clearance

.O

mm

and

1.2

mm.

is

to

be adjusted

to

r

9)

Assemble the

6

x20

Spring

NOTE:

downward.

NOTE:

Outer surface

side. (See

[Tightening torque:

10)

Assemble the gear case cover.

8

x

5

7T

Spring washer

NOTE:

top

of

the camshaft.

8 x 65

Spring

NOTE:

[Tightening torque:

oil

7Tbolt.

washer

The hole

Check

of

Fig.

bolt,

When

7T

bolt.

washer

Check

pump

...........

............

if

the governor sleeve moves

the

43.)

...

............

the pin

...........

............

if

Fig.

41

and the governor.

2

pcs.

2

pcs.

in

the

oil

pump

cover is

trochoid

80 - 100

,

........

the governor link operates.

200

pump

must face the case

kg-crn]

4

pcs.

4

pcs.

is

replaced, apply "Three Bond" at the

3

pcs.

3

pcs.

-

230

kg-cm]

to

smoothly.

face

both

ends

of

the

pin

Fig.

42

Fig.

43

for

cranking. This

\

pin

locates at the

-

23

-

Assemble the injection pump.

8

mm

nut

...............

Spring washer

NOTE:

fitted. And adjust

0.3

mm.

CAUTION:

(See Figs.

............

Measure the distance between the face

it

may become

Remove the

44

and

45

oil

filler cap and check

.)

-

.

.-

l._l

3

pcs.

3

pcs.

76 k 0.05

___

of

the cam base and the surface to which the injection pump

mm, using the shims. Two kinds of

if

the control rack comes off from the governor lever.

"I

~

."

,

,-

the

shim are available,

viz.

0.1

is

to be

mm, and

Assembe the tappet guide.

CAUTION:

case.

NOTE:

at

the right side

(See

Fig.

13)

Temporarily assemble the push rod sleeve.

6

mm

Spring washer

NOTE:

Be careful not

The roll pin of the tappet guide

as

viewed from the gear case side.

let

46.)

nut

...............

............

2

pcs.

of the plate (push rod

the tappet

2

pcs.

2

pcs.

sleeve)

fall

in

the

is

to

be

set

are to be assembled temporarily.

Fig.

Fig.

45

46

-

24

-

Assemble

10

Washer

NOTE: Install the intake and exhaust

intake side there

NOTE: Insert the push rod. (Exhaust

of

the

ward or downward, and direction

haust.

NOTE: Install the rocker arm

It

is

ing the head.

(See

NOTE: Clamp the head to the cylinder.

Apply "Three Bond

bolt (on the side of the rocker

reverse

nuts.

[Tightening torque:

.

Tightening of the nuts

I.

e.:

1

st

2nd round

3rd round

NOTE: Fasten tightly the plate (push rod sleeve).

6

mm

(See

the

cylinderhead.

mrn

flange

nut

..........

.................

is

a

stem

seal.

gear case.) Pay attention to the

advisable to insert the rocker shaft before clamp-

Fig.

47

.)

#I

21

5"

surfaces

round

of

the

washer, and then tighten

350

kg-cm]

is

to be done in three rounds,

...............

...............

...............

nut

...............

Fig.

48.)

4

pcs.

4

pcs.

valves.

is

valve

of

intake and ex-

to

the cylinder.

to two pieces

shaft)

and upper and

100

kg-cm

200

kg-crn

330

-

4

pcs.

on the side

of

350

On the

facing,

the stud

kgcm

UP-

the

a

Fig.

47

I

15)

Adjust

the

valve

clearance.

NOTE: Turn the flywheel by hand

sion

at

TDC (top dead center). At TDC

cranking pin stands vertically.

NOTE: Adjust the

tween

when the engine

(See

0.07

Fig.

-

49.)

valve

0.10

mm (both intake and exhaust),

is

cold.

to

the compres-

the

camshaft

clearance to anywhere be-

-

25

DECOMPRESSiON

ADJUSTING

Fig.

49

\,

SCREW

-

INTAKE, EXHAUST VALVE TIMING

TDC

(TOP

INTAKE VALV

DEAD CENTER)

When valve clearance

heated,

intake valve opens at

intake valve closes

exhaust valve

exhuast valve closes at

(See

Fig.

opens

50.)

at

at

is

16O

54'

54'

14"

at

0.4

mm

before TDC,

after BDC,

before BDC, and

after TDC.

Adjust the decompression clearance.

NOTE:

NOTE:

NOTE:

another half

Turn

The

decompression device locates

Set

the

decompression lever at

Clearance

turn.

the flywheel

is

about

0.5

mm.

Threading

by

of

this

hand and check a contact between the valve and the

Assemble the rocker cover.

6

x35

7Tbolt.

Spring washer

NOTE:

NOTE:

Check

Check

...........

............

if

there

is

an

"0"

if

the gasket

for

3pcs.

3

ring

the

and the engine

in

the rocker arm

the

position

Turn

the adjust screw

screw

is

1

.O

mm.

pcs.

for

breather hole

rocker cover

is

is

INTAKE VALV AUST

BDC

(BOTTOM

on

the intake valve side.

of

decompression. (Push the lever

until

it

touches the decompression shaft, and then make

piston.

on

put

correctly

the surface

of

the head (intake breather's side).

in

the groove.

DEAD CENTER)

Fig.

50

to

the

VALVE

horizontal position.)

Install the nozzle holder.

6

mm

nut

...............

Spring washer

NOTE:

[Tightening torque:

............

Pay attention

90

to

the gasket at the top.

-

100

Install the blower housing.

8

x

55

7T

7T

shaft.

bolt

....

bolt

....

Upper part:

Lower part:

Install the

10

x

30

bolt

Spring washer

8

x

40

Spring washer

driving

.............

Assemble the flywheel cover.

8

x

16 bolt

..............

Assemble the cylinder baffle.

6 x 8

flange bolt

5

x

75

round head cross recess

bolt and nut

(See

Fig. 5 1

...........

5

mm

.........

.)

2

2

kg-cml

...

2

2

...

2

2

4

4

2

pcs.

pcs.

pcs.

pcs.

pcs.

pcs.

pcs.

pcs.

pcs.

1

pce. each

It

is

advisable

to

utilize the driver foreasy installation.

Fig.

51

26

-

Install the tank brackets, left

8

x

16

7T

bolt

............

Spring washer

8

mm nut bolt

............

............

and

right.

2 PCS.

2 pcs.

2

pcs. each

Connect the fuel pipe and fuel return pipe securely.

8

x

18 banjo

Aluminum packing

NOTE:

bolt

..........

.........

Connect the pipe to the nozzle first, and then connect the fuel pipe to

2

pcs.

2 pcs.

Install the air cleaner.

8

mm

nut

Spring washer

NOTE:

Pay attention to the gasket.

...............

............

2

2

pcs.

pcs.

Install the muffler and the muffler cover.

8

Muffler:

mm brass nut

Spring washer

Muffler cover:

NOTE:

Pay attention

Connect the

It

is

advisable

then connect.

6

x

8

high

pressure pipe. (See Fig.

to

remove the cap of the

.....

.......

flang bolt.

to

the

gasket.

2

2 pcs.

.

4

pcs.

pcs.

52.)

air

cleaner and

Mount the fuel tank.

x

45

round head cross recess

6

..................

screw

When installing

tank, fasten the filter by hand and then make

with

a

spanner.

Install the

6

x

12 bolt

Spring washer

The

oil

filter serves

Be sure to install

the

fuel filter once removed from the

oil

filter

..............

............

as

the oil drain plug too.

"0"

ring.

2

2

2

pcs.

pcs.

pcs.

1/4

turn

Install the handle guide.

6

x

12

bolt

Spring washer

..............

............

2

pcs.

2 pcs.

Supply engine oil.

Upper level

Lower level

Also

pour oil into the

..............

..............

Supply diesel light

Fuel tank capacity

air

cleaner, watching oil

oil.

.........

1

.O

0.6

4.5

R

max.

II

min.

R

level.

the

tank.

Fig.

I.-

52

-

27

-

6.

0-1

FUEL

QUALITY

Of

FUEL

Because

pump, nozzle, and

HIGH

of

the

high

NOZZLE

PRESSURE PIPE

speed diesel engine, be sure to use the good quality diesel light

piston

develop troubles. (See

Fig.

53.)

FUEL RETURN PIPE

i

f

T

"

\

/

f

UEL

TANK

/

\

oil.

If

improper fuel

is

used, the injection

AIR RELEASE

FUEL

FILTER

PIPE

FUEL INJECTION PUMP

TANK FILTER PIPE PUMP PRESSURE

t

FUEL RETURN

PIPE

Fig.

53

FUEL PIPE

PIPE

-

28

-

7.

GENERAL DESCRIPTION

7-1

FUEL

INJECTION

It

is

not too much to say that the fuel injection pump is the heart of the diesel engine, and it must be precise enough to sat-

PUMP

of

AUXILIARY

MECHANISM

GADGETS

and

PARTS

isfy the following functions.

Function

Injecting fuel, starting with

high

pressure and ending with low pressure.

Injecting the predetermined amount of fuel accurately at each stroke.

Injecting fuel at specified time within a specified time interval.

Quantity being injected is closely vaned by the governor to suit to varying load.

This

engine has no automatic advancing device, but in starting (max. delivery), the injection timeing

Theory

The

plunger of the injection pump

this up

of

the

injection pump mechanism

and down motion in a stroke, suction and forced supply of fuel are conducted. (See Fig.

is

pushed up by the cam of the camshaft, and it is pushed down

54.)

is

to be delayed.

by

the plunger spring. By

Suction of fuel

Through the filter in the fuel tank, fuel

supplied and is

in

full around the intake port of the plunger barrel. When

is

the top of the cam lobe passed the tappet and cam function ended, plunger spring pushes down the plunger.

is

When the plunger is pushed down passing the fuel intake, fuel

of

arrival

the plunger at the bottom of its stroke.

This

is on the stage of "suction."

sucked into the barrel, and suction is continued until

Forced supply of fuel.

The camshaft rotates and pushes up the plunger. Forced supply of the fuel is started only when the upper part

plunger closed the fuel intake in the course of being pushed up by the cam rotation. The fuel in the barrel is pressur-

(100

ized by a,very strong force

the damping valve, and then it injects the fuel into combustion chamber.

kg/cm2 and up), and as a result, the force of the fuel pushes up the delivery valve and

This

is on the stage of "pressurized supply."

of

the

VERTICAL

INTAKE

(EXHAUST PORT)

HOLE

PORT

DAMPING VALVE

DELIVERY VALVE

PLUNGER BARREL

PLUNGER

LEAD

Fig.

-

29

EFFECTIVE STROKE

54

-

3.

Variation in quantity

The quantity

of

fuel injected vanes according to the condition

loaded or unloaded operation. (See Figs.

The plunger lead is engraved

of

the upper part

Rotation

rotates,

of

which

the plunger and the suction port

the plunger

is connected to the plunger

of

fuel

to

be injected

of

the engine, i. e. high speed or low speed operation and

55

and

56.)

on

the surface of plunger in

is

is

made by the control rack. When this control rack

by

means of the control sleeve. In other words, the plunger turns as much amount

an

inclined curve. By rotating the plunger, the distance between

varied. (Variation in effective stroke)

is

shifted to left and/or right, the geared pinion

as the rack rotates. Accordingly, the effective stroke varies coincident with the position where the rack is set.

1)

Relation between the plunger and the barrel

EFFECTIVE STROKE

PLUNGER BARREL

INTAKEEXHAUST

2)

Relation between the plunger and the rack

PORT

INJECTION INJECTION INJECTION INJECTION

STARTS. ENDS. STARTS. ENDS.

MAX.

DELIVERY

Fig.

55

HALF DELIVERY

NO DELIVERY

MAX.

DELIVERY

CONTROL SLEEVE

HALF

Fig.

-

DELIVERY

56

30

-

NO DELIVERY

4.

Injection timing and effective starting

When the plunger closes suction port of the barrel, forced

is

delivery of fuel starts. But fuel

2le.at ence because of contraction of,fuel,'etc.

Injection timing of this engine is fixed constant

TDC)

irrespective of engine rpm. On the other hand, in start-

a

proper delay from the timing for

ing,

not injected from the noz-

.

(23O

before

high

speed running

INSTALLED ONLY

TO

DY30

and increased fuel injection is indispensable for effective

starting.

this purpose a notch is

made

at the plunger

Fig.

57

For

head, whch reserves to delay the injection timing by nearly

8"

to facilitate starting. (See Fig.

5.

Function

of

the delivery valve

By the plunger stroke, fuel pressure is raised. And when it becomes higher than the pressure remained in the

pipe, the delivery valve spring is pushed down and the valve opens.

57.)

As

the result, the fuel

in

the

high

high

pressure pipe is delivered

forcibly.When the plunger lead meets suction port of the plunger barrel, deliveryof fuel ends, and the delivery valve

spring

by the

tension of the valve. At this time, delivery valve prevents reverse

around the upper part of the plunger sucks back the fuel

high

pressure in the

pressure pipe. The nozzle jets the fuel clearly off and prevents after dripping. (See Fig.

in

the equal amount of the stroke [A] and decreases remaining

flow

of the fuel.

Also

suction back motion

58.)

pressure

is

closed

!I!

6.

Function

The damping valve is assembled in the end

pump and it reaches the

at the seat. The

fuel to the chamber

ly, descending velocity of the delivery valve

of

the damping valve

seat

small

orifice

in

the delivery valve holder. Accordhg-

before arrival of delivery valve

in

the valve

/

DELIVERY VALVE SPRING

DELIVERY VALVE

of

injection

is

the passage

is

decreased,

Fig.

of

which prevents the negative pressure being produced suddenly.

engine noise is decreased. (See Fig.

As

a result, proper injection is conducted and the

59.)

58

DAMPING VALVE

DEL,VERY

VALVE

ION BACK

Fig.

59

STROKE

-

31

-

0

FUEL

INJECTION PUMP

DAMPING VALVE DAMPING VALVE

SPRING

DELIVERY VALVE

PUMP

HOUSING

-

STOP

AIR RELEASE BOLT HOLDER

CONTROL RACK PLUNGER ASSEMBLY

CONTROL SLEEVE

SPRING

SEAT

Fig.

DELIVERY VALVE

DELIVERY VALVE

PLUNGER SPRING

PIN

60

0

SPECIFICATIONS

of

FUEL INJECTION PUMP

Model

Maker

Plunger diameter

Lead

Plunger spring arbitrary

valve

Delivery

Delivery valve spring constant

Pump rack friction load

opening pressure

for

THIS

DIESEL ENGINE

-32

-

PFRIKD55/2NP1

Diesel Kiki

5.5 mm

Right twist lead

2.46 kg/cm

27.5 kg/cm2

0.51

0.062 kg

K.K.

kg/mm

16 mm Rack stroke

7-2

FUEL

1.

Specifications

INJECTION

~ ~~

Part

Name

Part No.

NOZZLE

HOLDER

I

NOZZLE

105

11840

HOLDER

00

I

(0.22

195

kg/cm2

13.2

C

4 No.

mm)

kg/cm2

-

a

fog

for combustion. There are

Identification

of

nozzle

mark

hole

(Diameter)

Valve opening pressure

Spring constant

2.

Features

Both the injection nozzle and the injection pump are very important parts for producing fuel

two types of injection nozzle, one is hole type and the other is pintle type. The injection nozzle for DY30 and DY35 Diesel

engine

developed as a result

of

joint research and development project by Diesel Kiki,

K. K.

and our company, and it is

is

direct combustion system, having the special hole type nozzle.

For producing better combustion gas, it utilizes

up

to

195

pressure is raised

3.

Structure

Ths consists

of

of

the

the nozzle holder and nozzle. The nozzle

kg/cm2.

ignition

nozzle holder

swirl

and

squish

flows

and for producing the most proper fuel fog, injection

IDENTIFICATION

\

MARK

FUEL

/

INLET

holder fixes the nozzle to the cytinderhead and at the same

of

time it plays the role

valve opening pressure

fuel passage

of

nozzle is adjustable. However, the

nozzle for DY30 and DY35 engines includes spacer

to

the nozzle. (The

in

it and

TlNG WASHER

it is unadjustable.)

The nozzle consists

of

the nozzle body and needle valve;

NOZZLE SPRING

and when the pressure reaches the limit to open the valve,

nozzle

unadjustable.)

for

this diesel engine includes spacer

in

it and it is

Fig.

61

NOZZLE

BODY

/-

4.

Function

of

nozzle

Through the injection pump, fuel is delivered forcibly into

up

the nozzle body and it raise

the needle valve and is at-

omized in the combustion chamber through the holes of

of

the nozzle body. In case

of

the opening

the holes does not alter. (See

the hole type nozzle, the size of

Fig.

62.)

-

33

-

VALVE

CLOSED

Fig.

VALVE OPENED

62

5.

Fuel

passage

1

From the plunger pump fuel is sent through the highpressure pipe

to the fuel passage

2.

Then, at the nozzle body

3,

2

1

it is pressurized up till 195 kg/cm2 and it lifts up the needle

4

for

0.18

valve

chamber via the jet hole

An

excess fuel which lubricated the inside of the nozzle and

nozzle holder returns to the fuel tank via the needle valve

nozzle spring

(See Fig.

6.

63

Inspection and maintenance

Fuel spraying condition

function, insufficient output, increase

main courses of the nozzle trouble. Therefore, exert good care for managment

mm, and is sprayed into the combustion

5.

6

+

overflow pipe

7

+

fuel tank,

.)

of

the nozzle and the state of pressure at starting injection are quite influential to the engine mal-

of

noise and exhaust smoke. Use

+

3

4

Fig.

of

improper fuel and contaminated fuel is one of the

of

fuel.

As

the nozzle is one of the very pre-

cisely processed parts, utmost care and attention must be paid when inspecting and checking.

1)

Inspection

in

After cleaning nozzle holder outside, inspect

the be-

low sequence.

a) Visual inspection

*Whether or not injection hole is damaged, or clog-

ged with carbon.

*Whether or not injection hole is clogged with dust

and carbon.

b)

Inspection by nozzle tester

Fig.

*Fit the nozzle holder to the nozzle tester.

CAUTION: When removing the nozzle from

engine or fitting

the nozzle free of dust.

it

to the tester, be sure

*Move the lever of the nozzle up and down for

3

times and suck the air inside the hozzle.

CAUTION: Never bring your face near the pressurized

hands from the fog.

fog

from the

nozzle.

Also

keep away your

to

the

keep

2

-

*Gently push down the lever of the nozzle tester

and read the pressure gauge just before the fuel

being injected. If the figure coincides with the standard value, the nozzle is in a good condition,

*Push

further and check whether or not the fuel fog

NOZZLE

is injected straight.

CAUTION: Good injection

Just

after

injection, check "after dripping."

is

straight forward.

Fig.

7

6

5

63

64

65

-

34

-

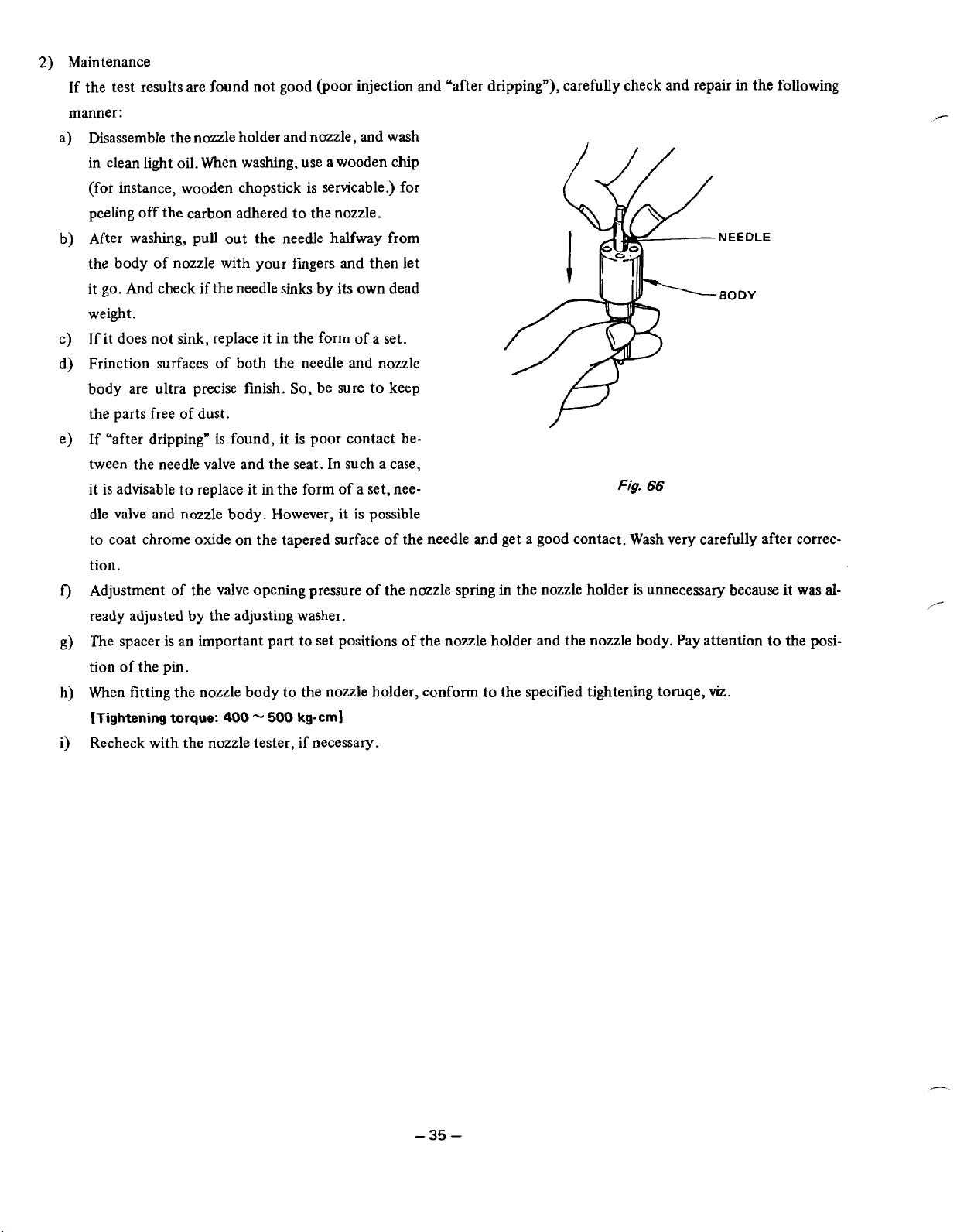

2)

Maintenance

If the test results are found not good (poor injection and "after dripping"), carefully check and repair

manner:

a) Disassemble the nozzle holder and nozzle, and wash

oil.

in clean light

(for instance, wooden chopstick is servicable.) for

peeling off the carbon adhered to the nozzle.

b) After washing, pull out the needle halfway from

the body of nozzle with your fingers and then let

go.

And check

it

weight.

c) If it does not sink, replace

d) Frinction surfaces of both the needle and nozzle

body are ultra precise finish.

the parts free

e) If "after dripping" is found, it is poor contact be-

tween the needle valve and the seat. In such a case,

is

advisable to replace it in the form of a set, nee-

it

dle valve and nozzle body. However,

to coat chrome oxide on the tapered surface of the needle and get a good contact. Wash very carefully after correc-

tion.

f)

Adjustment of the valve opening pressure of the nozzle spring in the nozzle holder

ready adjusted

g)

The spacer is an important part to set positions of the nozzle holder and the nozzle body. Pay attention to the posi-

tion of the pin.

h) When fitting the nozzle body to the nozzle holder, conform to the specified tightening toruqe,

[Tightening torque:

i)

Recheck with the nozzle tester, if necessary.

When washng, use a wooden chip

if

the needle sinks by its own dead

it

in the form of a set.

So,

be sure to keep

of

dust.

it

is possible

by

the adjusting washer.

400

-

500

kg-cml

Fig.

66

is

unnecessary because

in

NEEDLE

BODY

viz.

the

following

it

was

al-

-35

-

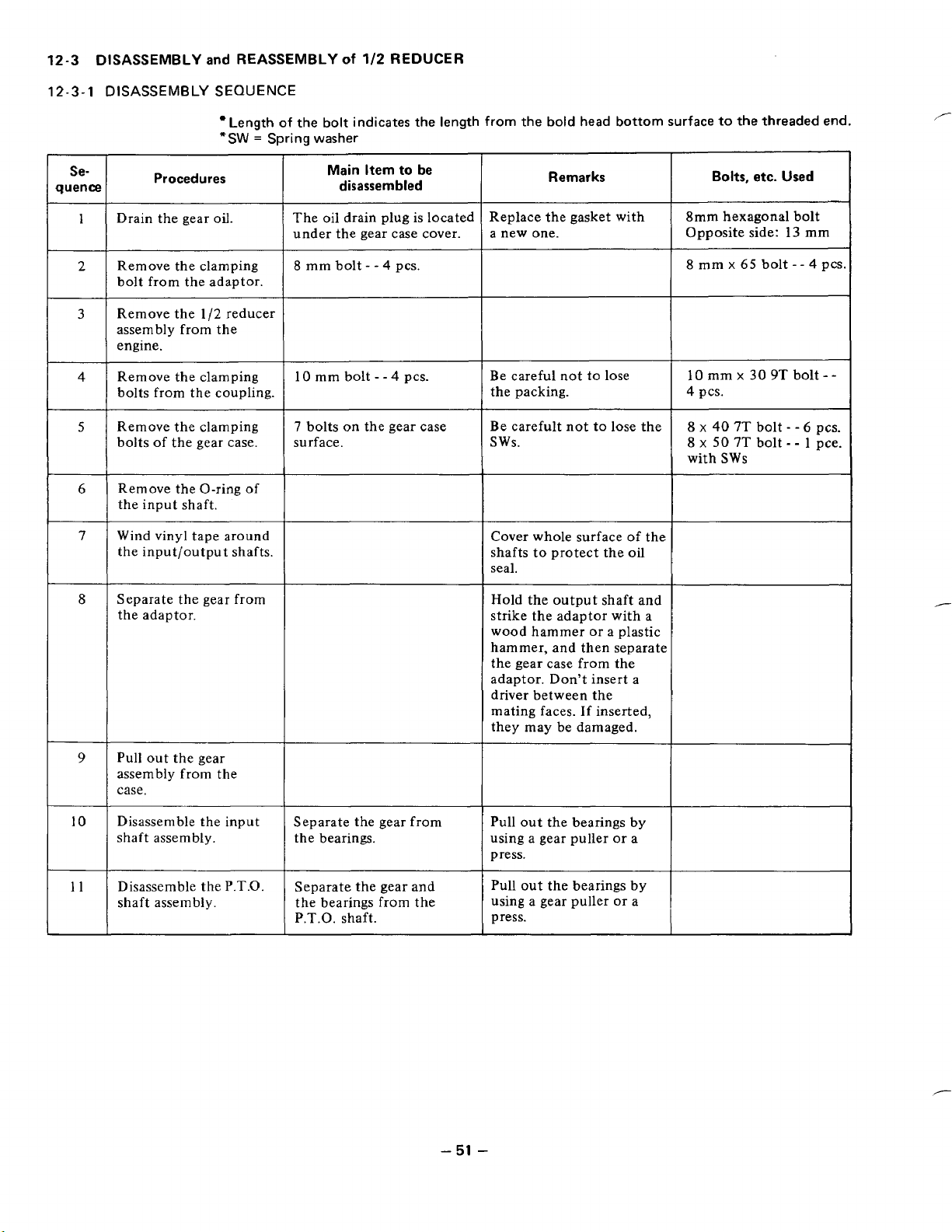

7-3

GOVERNOR MECHANISM

1.

Mechanism

The governor

sembled

is

centrifugal flyweight type, which means a flyweight is fitted to the governor

so

that it may slide toward the direction

governor sleeve gets

This

pump operate.

mechanism enables to maintain constant operation irrespective

and

OPERATION

gear.

The governor sleeve is as-

of

the axis

in

touch with the governor yoke, and through the governor lever it makes the control rack

FUEL INCREASE

of

the pump shaft, and it

FUELDECREASE

is

in

contact with the flyweight. The

of

load variation.

7

INJECTION PUMP

of

injection

GOVERNOR

FUNCTION

FUNCTION

GOVERNOR

at

STARTING

at

OPERATING

YOKE

OBLONG HOLE

GOVERNOR

GOVERNOR SPRING

LEVER

SPEED CONTROL LEVER

=I>

1

CONTROL LINK

LOW

HIGH SPEED

SPEED

GOVERNOR

START

SPRl

SHAFT

NG

-

36

-

Fig.

67

2.

Operation

1)

Starting

When the speed control lever is set on the side of high speed, the governor spring is pulled via the control

1

governor levers

and 2 are pulled by the tension

toward “fuel increase.” The governor lever

of

the governor spring. The control rack

1

has an oblong hole, and the governor lever 2 moves to the extent of this

of

injection pump is pushed

oblong hole by means of the start spring tension. The control rack of injection pump is pushed toward the maximum

of

of ”fuel increase.” This movement within the extent

oblong hole is called “revolution playing angle,” for which we

will explain later.

2)

After starting and during operation

When engine starts up, centrifugal force acts on the flyweight and it pushes the governor sleeve. The governor yoke,

governor shaft, and governor lever

pushes the control rack of the injection pump toward “fuel decrease.’’ The governor lever again moves

of the oblong hole. Thereafter, the governor lever

the specified revolution. Suppose that a load

2

are assembled in one piece, and accordingly the motion of the governor sleeve

to

1

and the governor lever 2 move simultaneously

is

put suddenly on, the fuel supply is as it

is

at that instance, accordingly

and

are balanced at

the fuel supply is insufficient against the load. As a resut, engine revolution decreases, which means that the centrifugal

force on the flyweight decreases. Then the governor lever

governor spring. The control rack of injection pump

3)

Stopping

2

moves to the position where it balances the tension

is

pushed toward “fuel increase” and engine revolution revives.

The governor plays a role exactly reverse to that of starting. When the speed control lever is set at the position

“Stop,” it pushes the control rack

of

injection pump toward

“No

Injection” and the engine stops.

link.

The

the extent

of

the

of

,“-

3.

“Revolution Playing Angle”

This mechanism is to supply more fuel than the maximum supply for normal high speed operation. This mechanism is developed for the purpose of improving starting ability.

1.

Required amount of fuel supply is set by the governor lever

2

governor lever

control rack

is fitted.

of

the injection pump is pushed to “Maximum supply.” The angle the governor lever 2 moves within the extent

of oblong hole is called ‘Revolution Playing Angle

At the time

of

starting, the governor does not function as yet and the governor lever 2 functions.However, during operation,

As

the start spring

is

pulling the governor lever

.”

the governor functions and accordingly the governor lever

1

hole. The governor levers

and 2 incroporate each other and pushes the control rack

The governor lever 1 has an oblong hole, to which pins of the

2,

it moves toward the arrow mark

2

moves toward the arrow mark B within the extent of oblong

of

the injection pump.

A.

Then the

-

37

-

7-4

LUBRICATION SYSTEM

and

OIL

PUMP

Lubrication

assembled in one piece, which

Revolution of the crankshaft is reduced by the reduction gear

lubricated to the crank journal. That

splashed to the piston, small end of the connecting,rod, cylinder, etc. Also from the main gallery oil

the cam shaft bearing and is sent to cam lobe

relief valve is assembled, and it adjusts the

splash of

Furthermore, blow-by gas containing oil

LUBRICATION CHART

is

forced lubrication

oil

pushed up by blow-by gas, which lubricates rocker arm, etc.

and

wholly fdtered system by trochoid type oil pump. The oil pump, and the governor are

is

fitted to the crankcase.

oil

will

further be supplied to the crankpin, large end of the connecting rod, and then

of

oil

pressure at 3 kg/cm2. Lubrication

will

pass through the breather, intake port and the cylinder, where

(1 : 1.4)

intake and exhaust valves and lubricate the tappets.

of the pump; and from the

in

the rocker chamber is conducted by the

r

BREATHER

I

main

I

1-1

*

gallery oil

is

forcibly supplied to

In

r

INTAK: PORT1

is

forcibly

the camshaft

it

is finally burnt.

I

t

COMBUSTION

oil

I

7-5.

OIL

Oil

filter

element

t

I

OIL FILTER

FILTER

is

made of double sheets of wire netting, and it

is

made

of

wire, it can be washed and used for many times.

1

$=I”!

PISTON, BEARING

CYLINDER

SMALL END

Fig.

68

is

less flow resistance type, and

k’

is

called full-flow type. As the

-

38

-

7-6

ELECTRIC APPARATUS (Electric Starter)

1.

Wiring diagram

KEY SWITCH

GENERATOR

ELECTRIC STARTE

1)

Circulation

When starting by the electric starter, (Key is at the position

(+)

-+

BAT

of

Battery

Charging, operating (Key is

Generator

2.

Lead wire

for

electric starter

"f

Rectifier

key + ST

at

the position

+

IC

of

key + Starter + Battery

of

operation.)

of

key

+.

BAT

of

key

of

+.

start.)

Battery

(-)

(+)

12V35AH

(earth)

When mounting the engine, location of the battery may comes into question, but set the lead wire following method:

3.

Earth band

BATTERY

StDE

TERMINAL ELECTRIC STARTER

JIS

Plain woven

Approx.

BA-508

lead

wire

I"

25

sectional

area

20

mm2

and

up.

L

Fasten tightly

crankcase

4,

Other remarks

1)

All

Meantime, insert the connectors each other up till the

2)

The wire

the

3)

Select the wire

4)

When the key switch is set apart from the engine body, select the wire

length

m

1.5

to

of

the engine.

the place made

of

metal and not paint coated. The place must be electrically conducted completely to the

lead wires are classified by coloring,

from

(+)

terminal

(-)

terminal must be connected to the earth

from

of

the wire between the key switch and the magnetic switch

I

Length

or shorter

Description

of

the battery must be connected to

the below Table

AV15

so

when connecting, select and connect by color.

roots.

of

the engme body.

A,

based

on

the required length

Outside dia.

7.3

mm

(+)

1.5

terminal

of

on

the side

Length.

m

or

shorter

JIS

of

the wire.

from

below Table B, based on the required

of

SIDE

BA-508

TERMINAL

the electric starter, and the wire from

engine.

Description

1

-25

Outside dia.

1.5

mm AV

I-

2.5

m

m

-

-

2.5

3

m

m

AV30

Table A Table

8.5

mm AV20 1.5

10.8 mm

-39

'i.5m-31-17

3m "5m

-

AV2

B

1.9

1.4

mm

mm AV3

,"-

8.

INSTALLATION

Engine life, ease of maintenance and inspection, frequency of checks and repairs, and operating cost all depend on the way

in

which the engine is installed. Carefully observe the following instructions for installing the engine.

8-1

INSTALLING

When mounting the engine, carefully examine its position, the method of connecting it to a load (machine), the foundation,

and the method of supporting the engine.

8-2

VENTILATION

Fresh air is necessary for cooling the engine and burning the fuel.

In cases where the engine is operated under a hood

oil

lock,

ble to operate the engine properly. It is necessary, therefore, to provide a duct or baffle to guide cooling air to the engine to

prevent recirculation of the hot air used

Take steps as necessary to keep the engine room temperature below

8-3

deterioration, increased

EXHAUST GAS DISCHARGE

oil

consumption,

for

engine cooling, and temperature rise of the load (machine).

or

in a small room, temperature rise in the engine room can cause vapor

loss

of power, piston seizure, shorter engine life, etc., making it impossi-

60°C

even in the hottest period of the year.

Exhaust

pipe is used in such a case, the internal resistance increases causing loss of engine power. Thus pipe inside diameter must in

crease in proportion to exhaust pipe length.

8-4

If the fuel tank is removed from the engine when mounting the engine with a machine, set the fuel tank

above the fuel injection pump. If the tank is set too low, the fuel

When piping be careful of heat conduction, pipe size, bends, and leaks from the joints and make the fuel pipe as short as

possible

8-5

1.