Subaru PKX201 User Manual

SERVICE

MANUAL

Models

PTG109, PKV101, PKX201H,

PKX201, PKX301,

PKX201T, PKX301T,

PKX201ST, PKX301ST

Step by Step Procedure for Removal or

Repair of Pump Components on Subaru Robin

Pumps

(This Includes Mechanical Seal Replacement

and Proper Shimming)

PUB-PS001

Rev. 09/05

905 Telser Road • Lake Zurich, IL 60047 • Phone: 847-540-7300 • Fax: 847-438-5012

e-mail: sales@robinamerica.com • www.subarupower.com

© Copyright 2005 Robin America, Inc.

GROUP INDEX

Group Name ......................................................................................................................Page

PTG109 .....................................................................................................................................4

PKV101 ...................................................................................................................................16

PKX201, PKX301 - Centrifugal................................................................................................28

PKX201T, PKX301T - Trash ....................................................................................................42

PKX201ST, PKX301ST - Semi-Trash ......................................................................................60

PKX201H - High Pressure .......................................................................................................74

Service

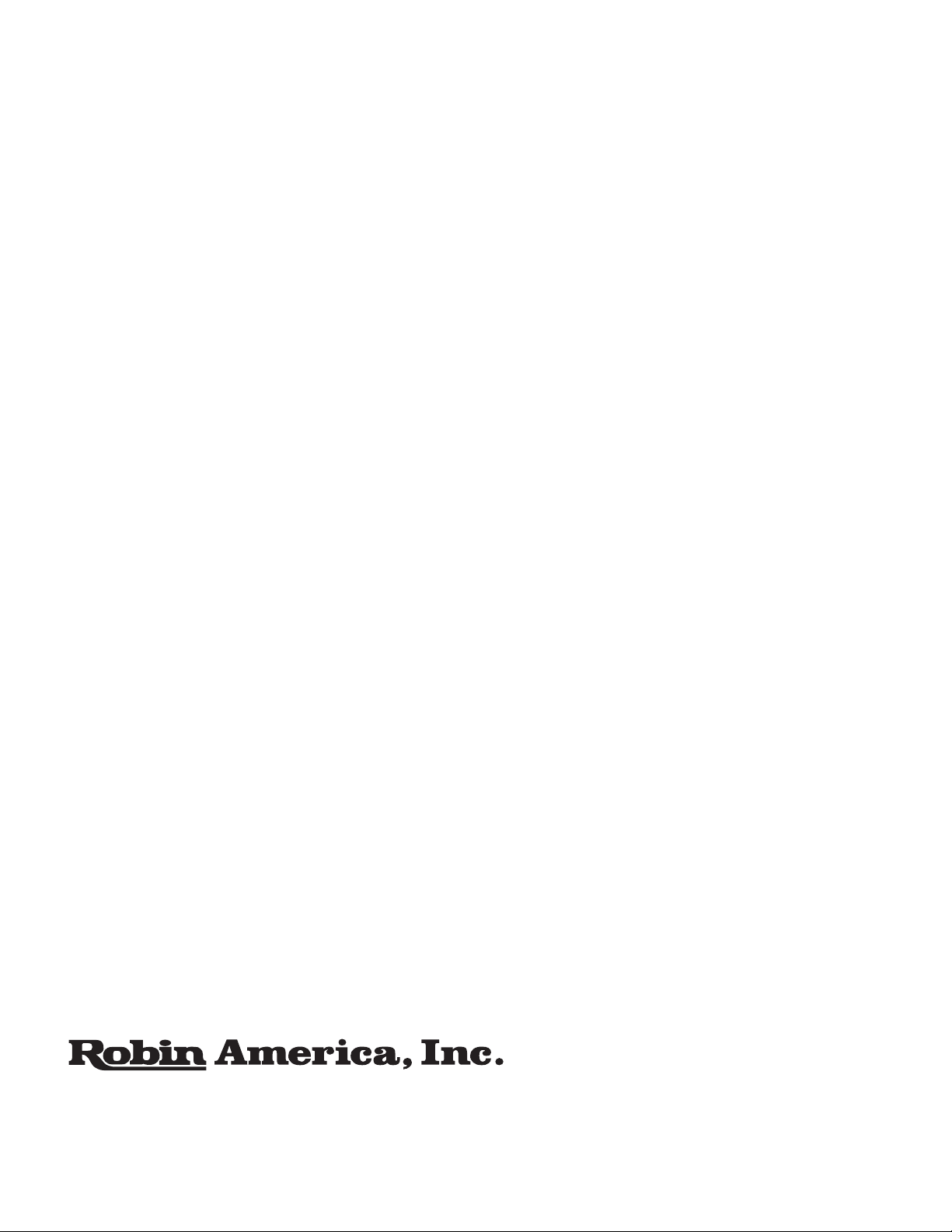

PTG109

PTG 109

Always refer to the pump ID tag when ordering parts for the

pump. The engine has a separate ID tag as well. Refer to

the engine tag when ordering engine parts.

- 4 -

Service

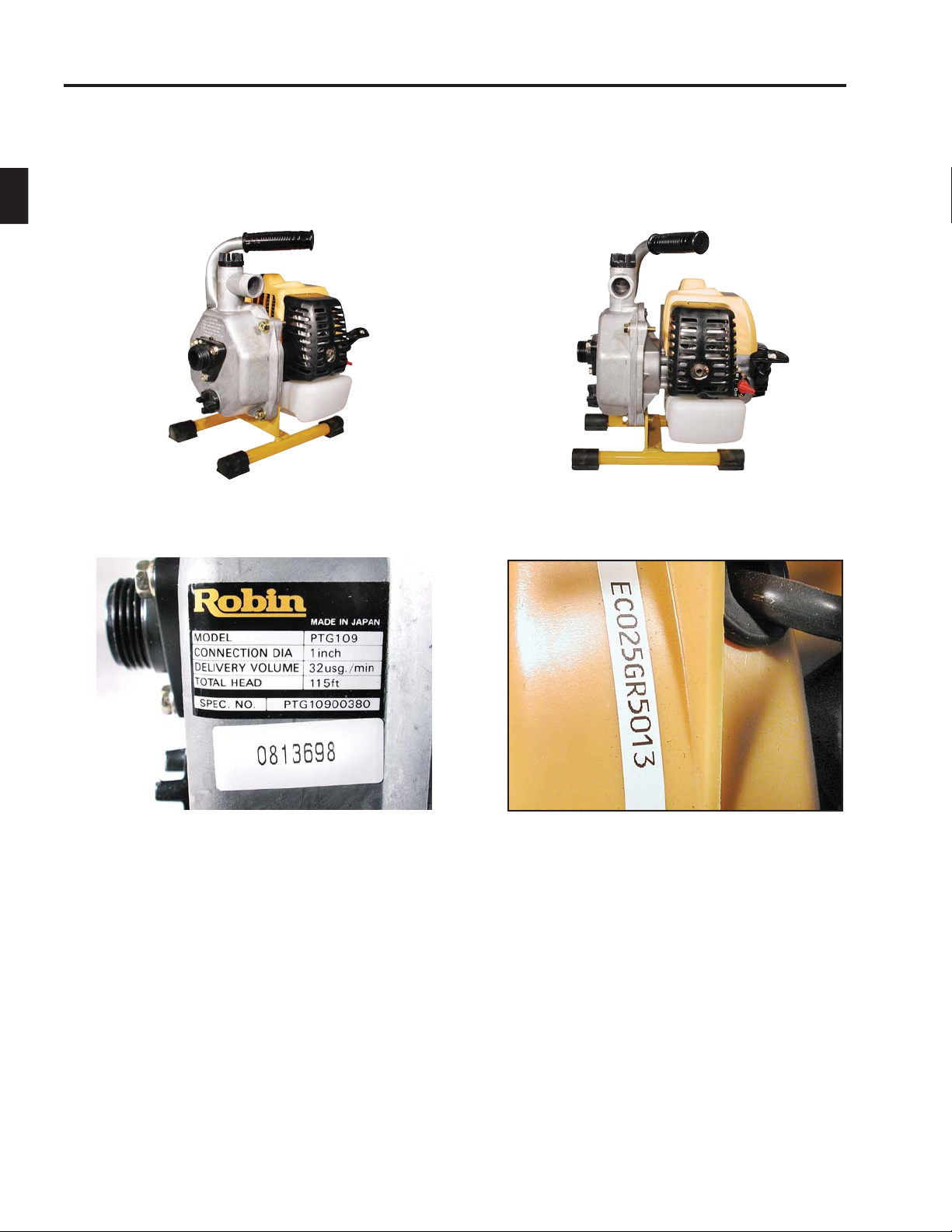

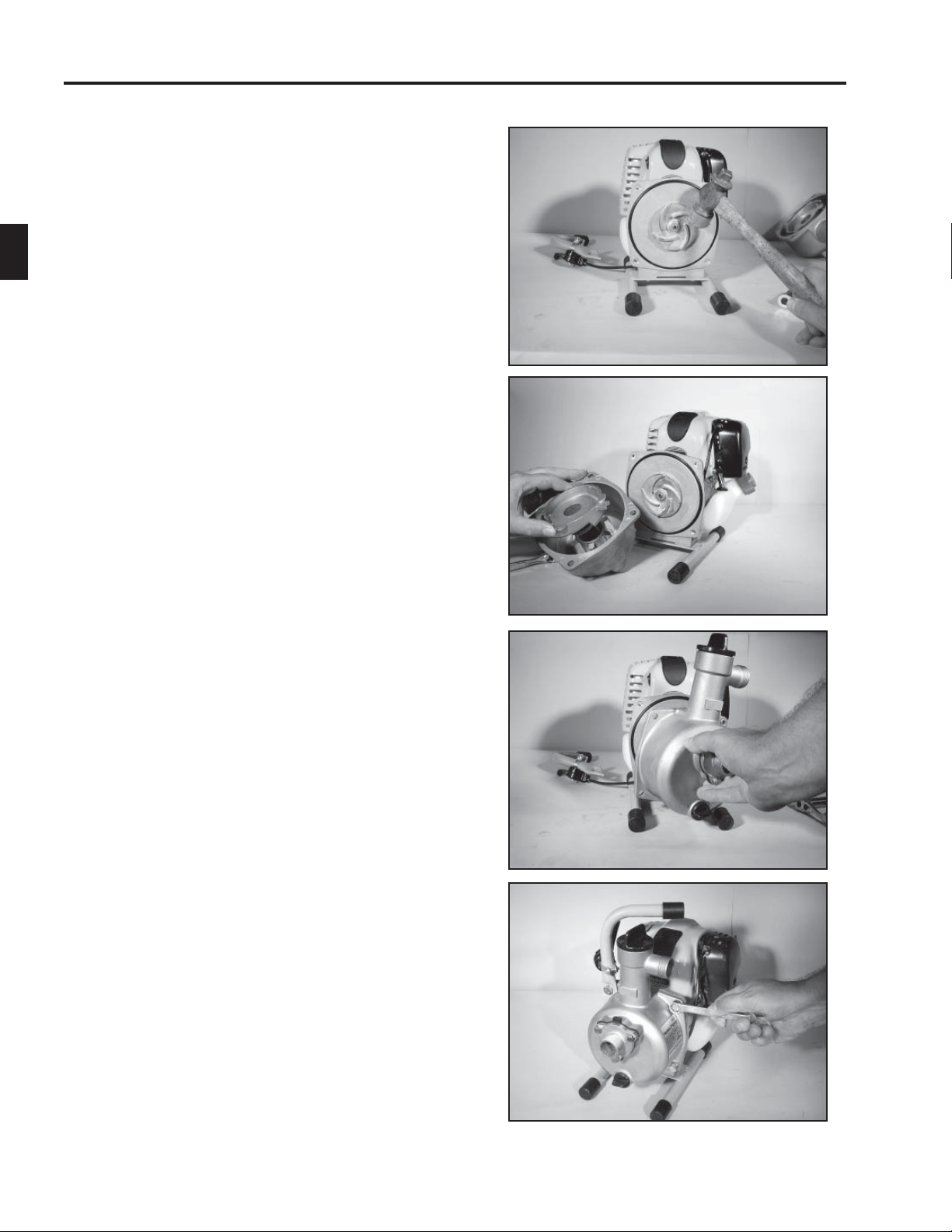

1. Remove the four outer pump housing bolts.

2. Remove the outer pump housing cover.

PTG109

3. Remove the volute from the pump back plate .

4. Remove the outer pump housing to pump back plate

gasket. This will be a good time to check the gasket for

cracks, tears, and overall condition. Replace if neces sary.

- 5 -

Service

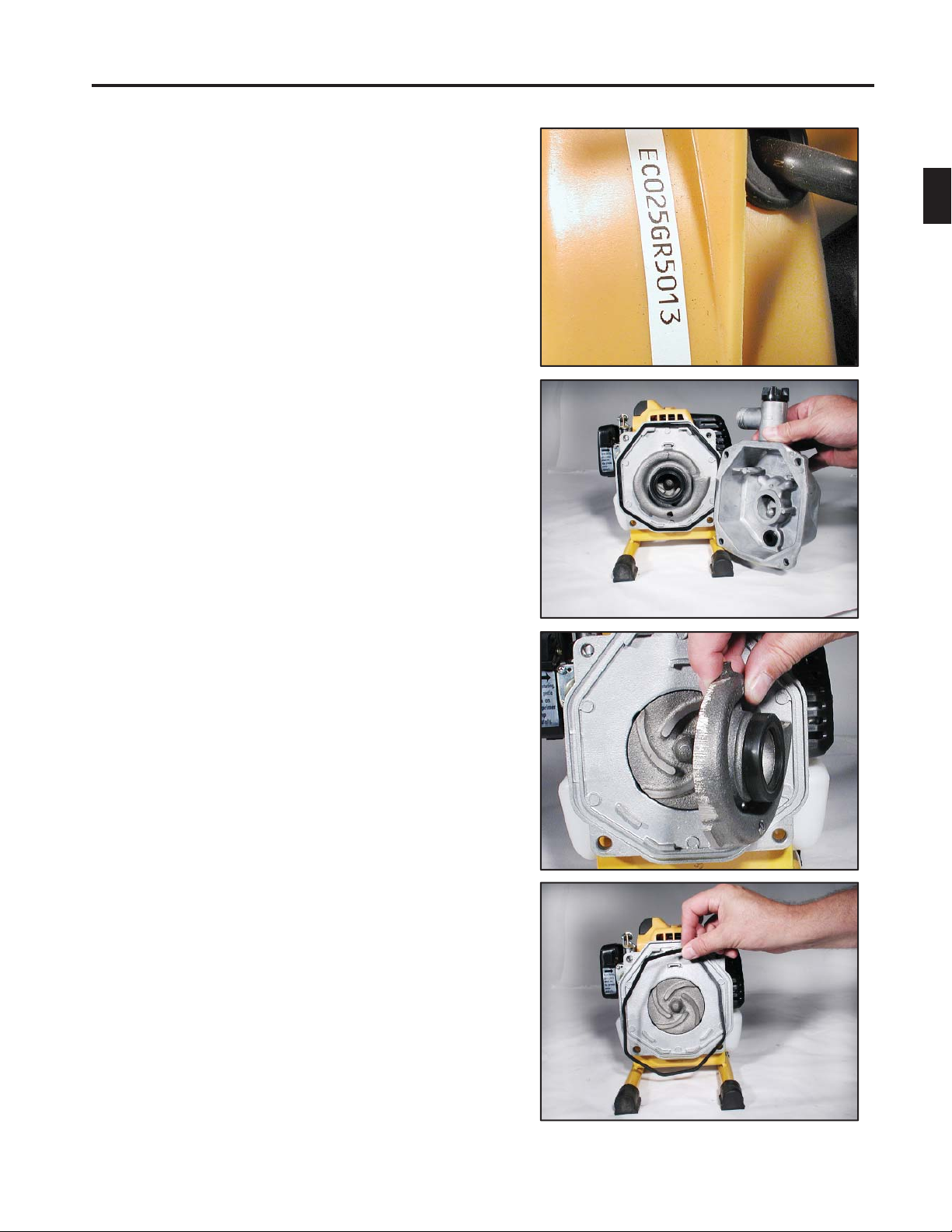

5. Loosen the impeller by hitting on one of the blades in a

counter clockwise position with a rubber mallet.

6. Turn the impeller by hand in a counter clockwise posi tion until free from the crankshaft of the engine.

PTG109

7. Pull the impeller away from the pump back plate and

make sure that any shim(s) that might be positioned

on the crankshaft or the impeller be saved and

counted.

8. Pull the engine away from the frame.

- 6 -

Service

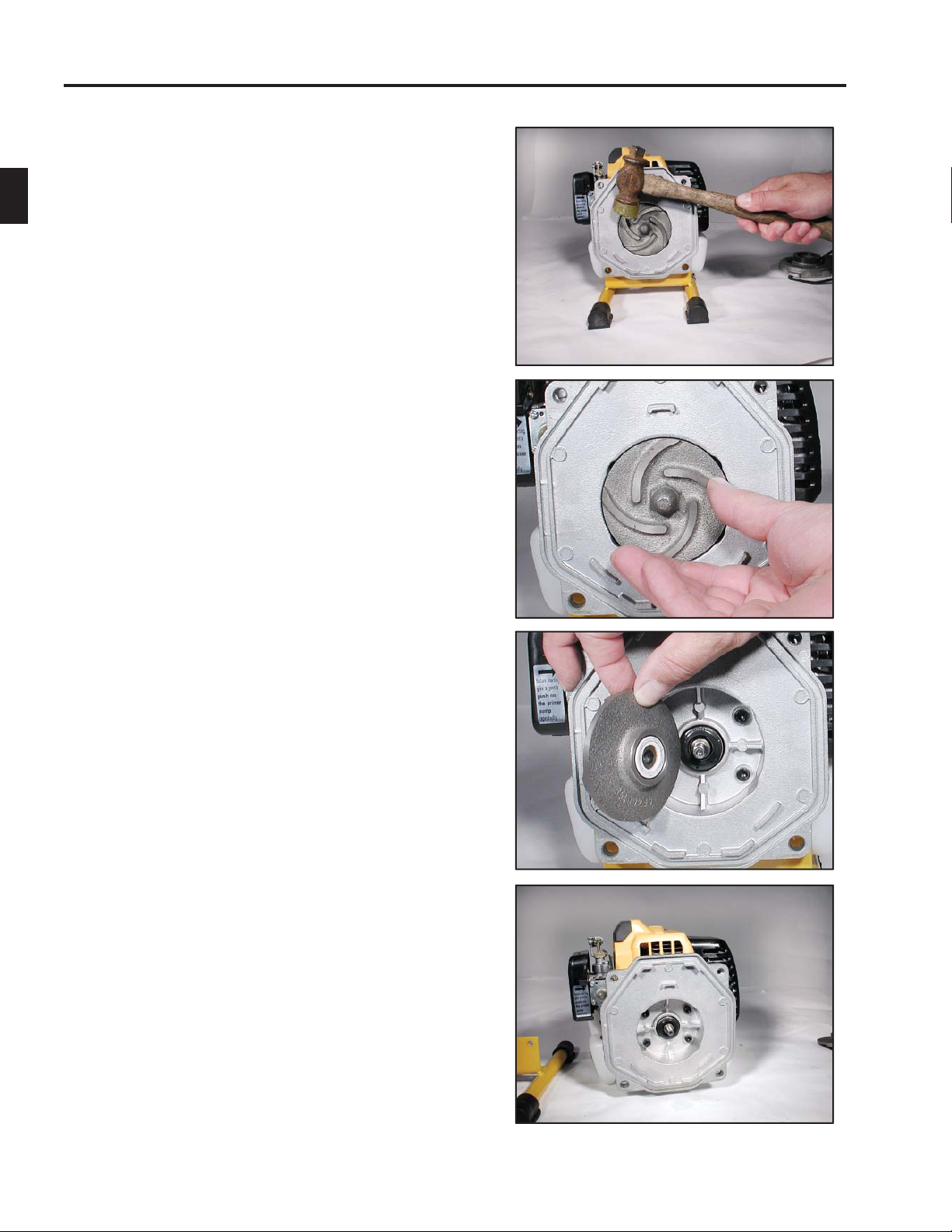

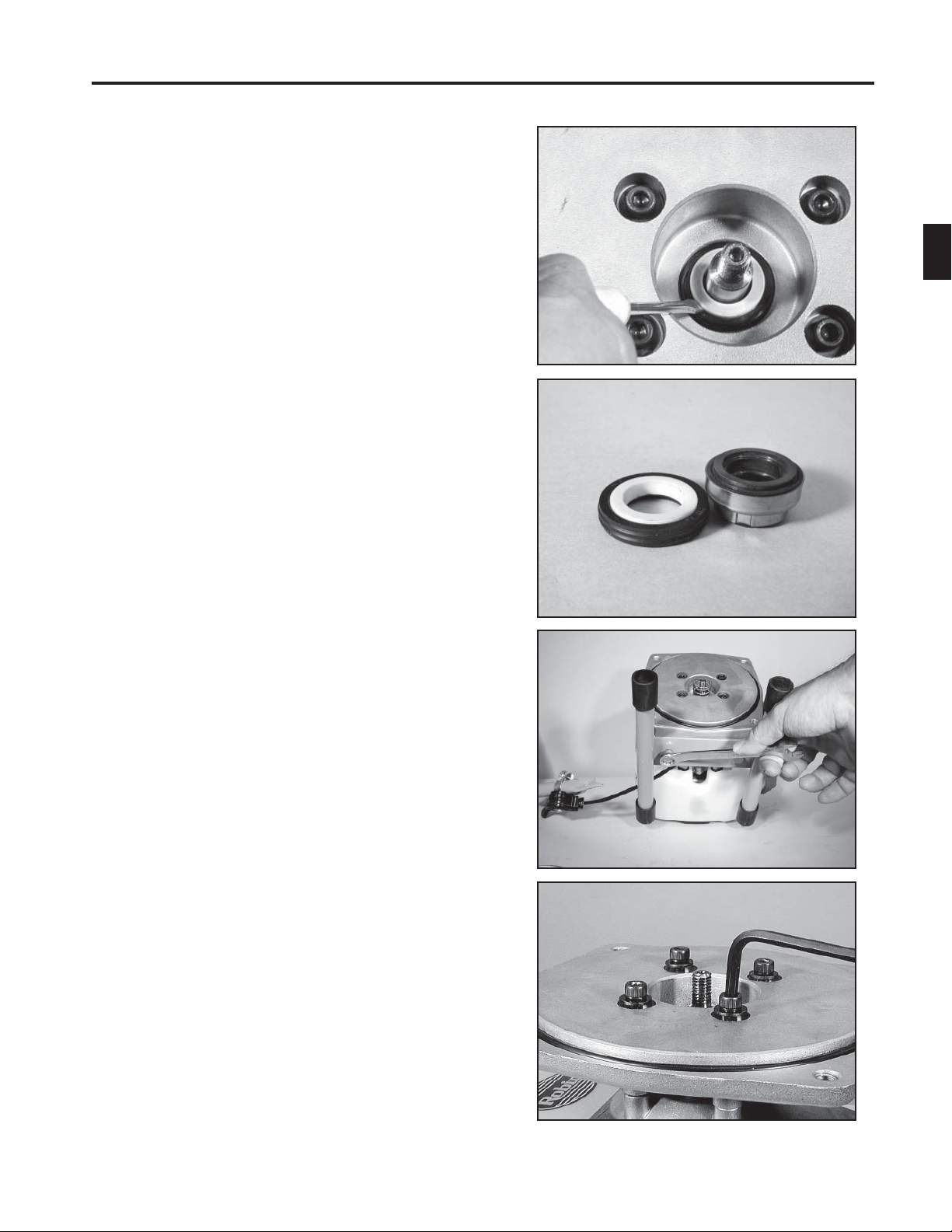

9. For engine service work, or seal replacement, the

pump back plate will need to be removed. Loosen and

remove the four bolts with a allen socket or wrench.

10. Pull the pump back plate away from the engine.

PTG109

11. The engine in now separated from the pump compo-

nents for service.

12. To remove the stationary seal from the back plate it will

be necessary to turn the pump back plate face down

on the workbench. Take a 3/4 inch socket and position

it into the cavity behind the seal.

- 7 -

Service

13. Hit the backside of the socket until the seal drops to

the workbench below.

14. This is what the seal will look like when in new condi tion. The sealing face will not have gouges, cracks,

chips or burnt edges. Replace if any of the previous

conditions apply.

PTG109

15. To remove the rotating seal from the impeller it might

become necessary to apply some liquid soapy water

to loosen it from the impeller. After the soapy water

loosens the seal in the impeller, take a small screw

driver and pry gently upward making sure not to

gouge the surface.

16. The impeller must be inspected for no cracks, chips,

and blades that are missing or broken off. Replace

with new if these conditions apply.

- 8 -

Service

17. Check the condition of the volute seal for cracks, worn

spots, and overall condition. Replace with new if

necessary.

18. Check the condition of the volute. If cracked chipped or

bent, it must be replaced.

PTG109

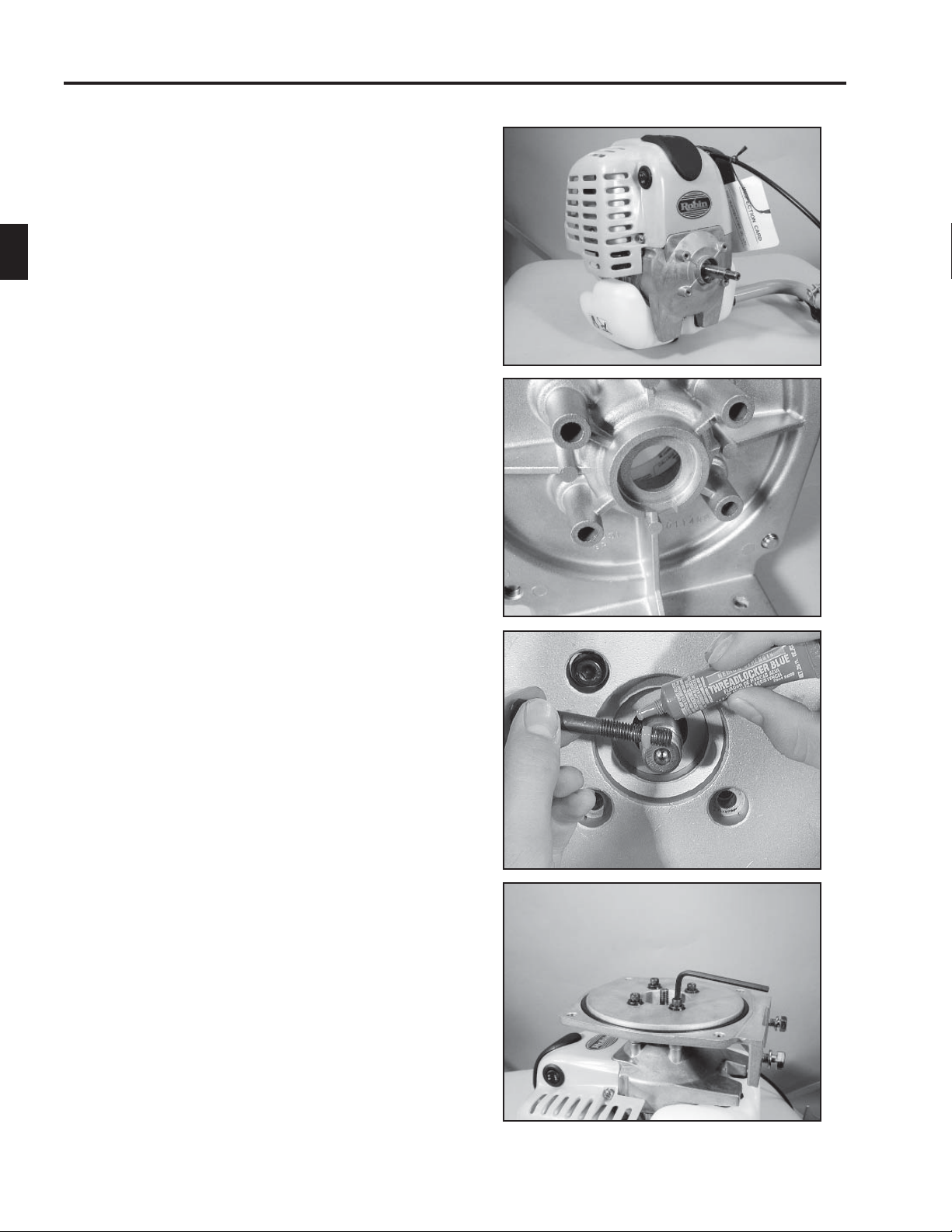

19. When reinstalling the back plate to the engine make

sure the weep hole faces downward. Weep hole must

be free from debris.

20. When replacing with a new seal, silicone compound

is not needed. However, if original seal is removed and

replaced back into pump back plate, then a small

amount of silicone sealant will help seal it. Place a thin

bead of sealant around the metal part of the seal.

- 9 -

Service

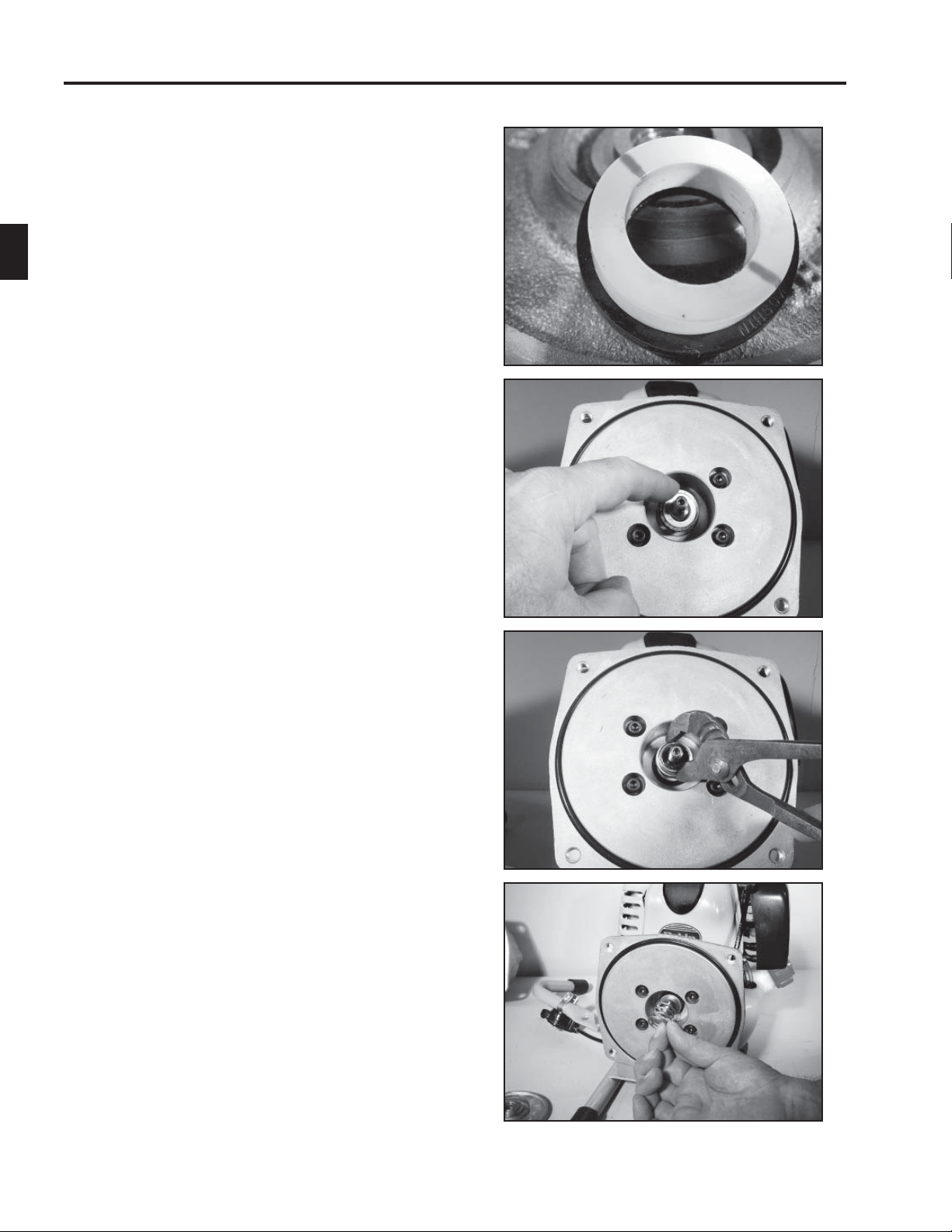

21. Place the seal over the pump back plate for alignment.

22. Using a 1" inch socket, place the socket over the seal

for installation.

PTG109

23. After setting the seal in the pump back plate, set the

socket over the top.

24. Tap the seal into position, looking at the position of

the seal after each blow of the hammer to make sure it

is installing evenly.

- 10 -

Service

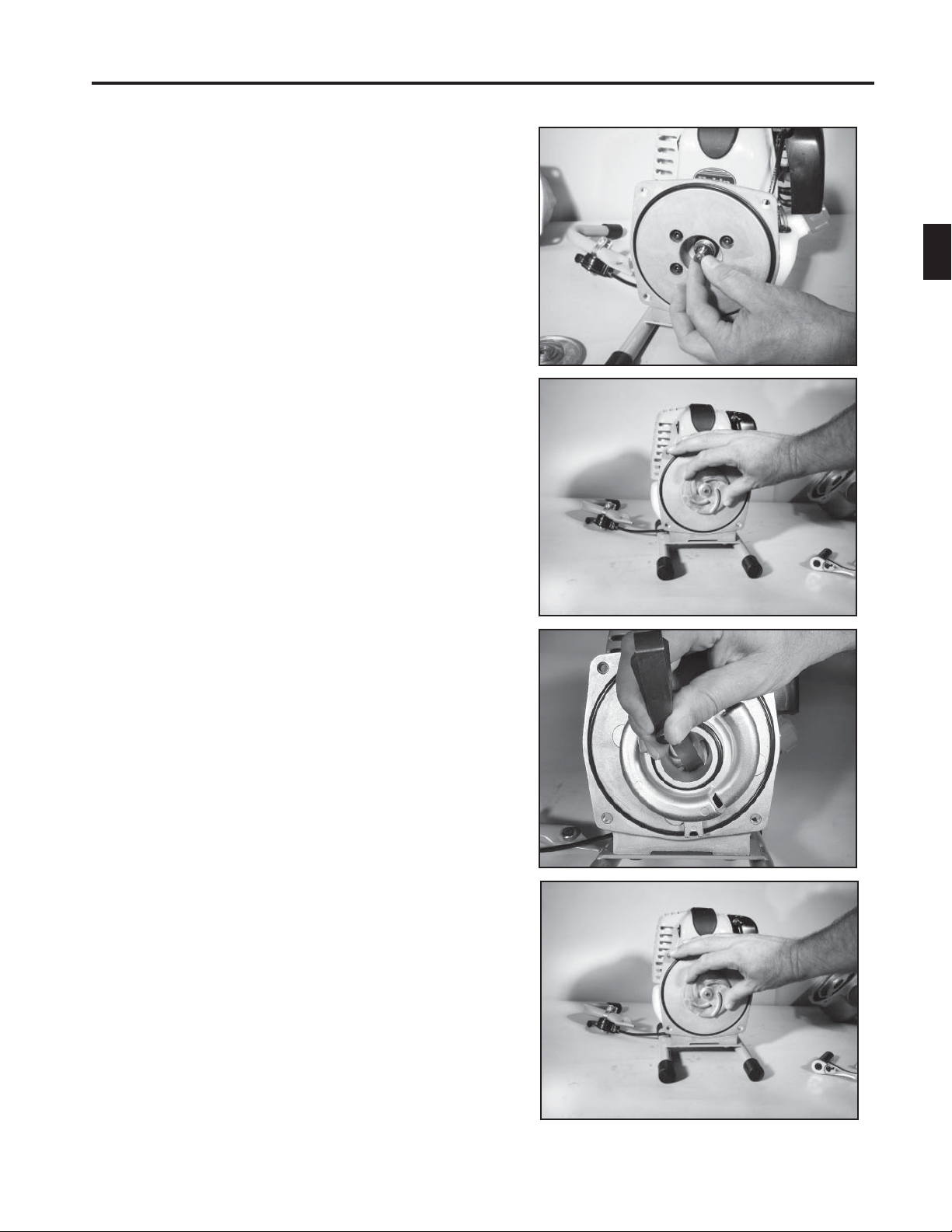

25. After the seal has been installed place the pump back

plate over the crankshaft and loosely install one of the

bolts to hold it in position.

26. A small amount of thread locker compound should be

used on the tip of the bolts. This thread locker should

be a service replaceable type such as Permatex® Blue

or Purple.

PTG109

27. After placing the bolts into the back plate, tighten the

bolts snugly.

Proper torque clearance should be 2.2 to 3.7 ft. lbs

28. If the pump came installed with shim(s) they must be

replaced with same number that came off. If none

were installed originally, then do no put a new shim on

unless gap between impeller and volute is wider than

the tolerance allows.

- 11 -

Service

29. The side of the rotating seal that has the colored

warning mark on it must be facing towards the impeller

and not facing towards the other seal face.

30. To help installation of the seal and rubber grommet

that holds it in the impeller, it might become necessary

to place a little liquid dish washing soap and water

around the seal to help slip it into the cavity of the

impeller.

PTG109

31. Using two thumbs, press the seal into the cavity

making sure that the rubber grommet does not bind.

The seal should be even and level.

32. Turn the impeller on the crankshaft in a clockwise

position until hand tight.

- 12 -

Service

33. Tighten the impeller with a rubber mallet by hitting on

one of blades in a clockwise position until tight.

34. The casting marks on the pump back plate indicate

where the volute must be placed. Make sure that the

volute is placed correctly inside these marks.

PTG109

35. After installing the rubber gasket on the face of the

volute, place the volute on the pump back plate. Tip

the unit back slightly to hold it in position.

36. Make sure there is enough clearance between the

volute and impeller, use a feeler gauge to check the

gap. While holding the volute tightly against the pump

back plate, insert different size feeler gauge blades

until the correct reading is obtained.

The recommended clearance is 0.024 to 0.039

thousands of an inch.

- 13 -

Service

37. Place the outer cover over the pump back plate. It

might make it easier if the pump is tipped back and the

volute is in position. Do not forget the outer pump

housing to back plate gasket.

38. Tighten the four bolts snugly.

The reccommended tightening torque is 9 to 11 ft.lbs.

PTG109

39. Should it become necessary to remove the intake

nozzle, remove the three bolts that hold it in position.

40. Watch the position of the gasket and nozzle when

removing from the pump housing. Also note the

correct position of the gasket tab which

should be facing upward.

- 14 -

Service

41. This picture shows the correct placement of the gasket

to the intake nozzle housing.

42. Tighten the three outer bolts, making sure not to over

tighten. The gasket will be distorted and squeezed

when overtightening these bolts.

The recommend tightenting torque is 3.3 to 4.8 ft. lbs.

PTG109

43. Pull the engine over by the start pull cord, making sure

nothing is binding in the pump.

44. After adding priming water and fuel, start the unit and

check with test vacuum plate to make sure there are

no vacuum leaks.

The recommended vacuum reading at sea level should

be 25 lbs of vacuum.

- 15 -

Service

PKV101

PKV101

Always refer to the ID tag when ordering parts for the

pump. The engine has a separate ID tag as well. Refer to

the engine tag when ordering engine parts.

- 16 -

Service

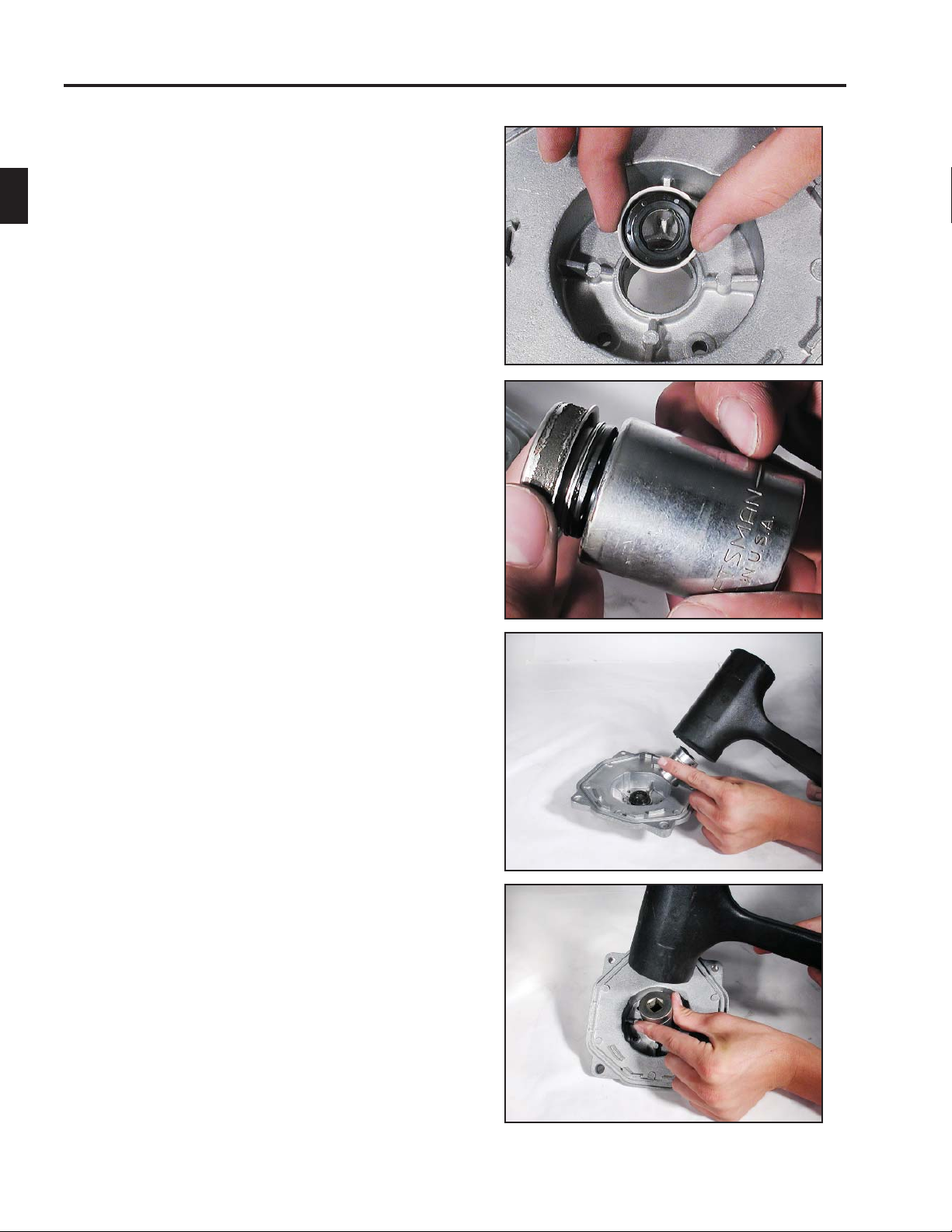

1. Drain any water from the reservoir and remove the 4

bolts that hold the outer casing to the pump back plate.

2. Pull the cover away from the back plate, keeping

tipped back.

PKV101

3. Note position of volute slot and outer case locating tab.

This tab and slot holds the volute in the correct posi-

tion. This must be positioned correctly during re-

assembly.

4. Remove volute from the outer pump housing, check-

ing for cracks or any other damage that may have oc curred.

- 17 -

Service

5. Turn the volute over and check the O-ring for nicks

or cracks. Damaged O-rings can cause loss

of pump prime as well as pumping performance.

6. Check O-ring on the back plate for nicks or cracking.

It should be soft and plyable. When reinstallling,

clean surfaces free from corrosion, and apply dish

washing soap for easier installation.

PKV101

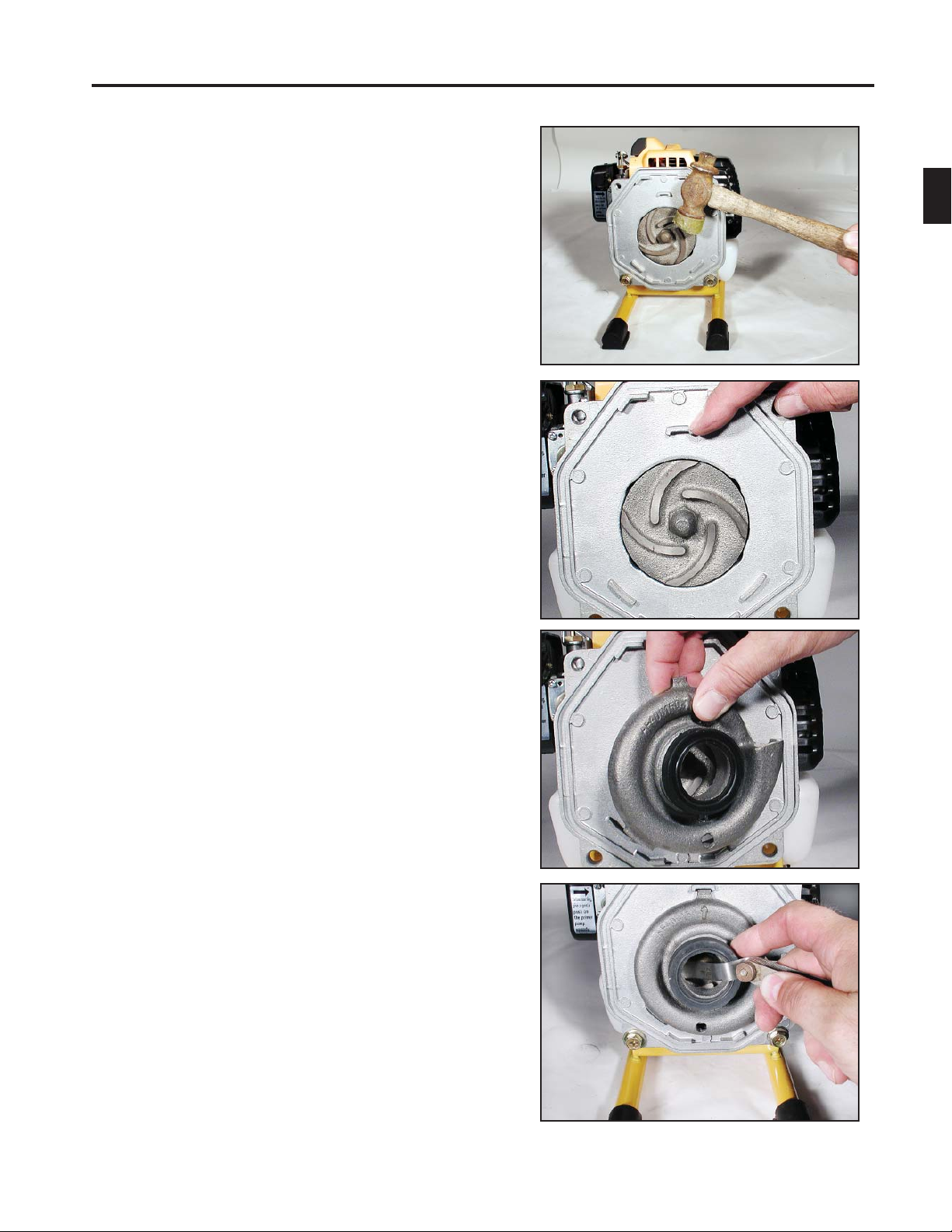

7. Remove impeller by hitting one of the blades counter-

clockwise with a soft mallet.

8. After the impeller is broken lose, slowly turn the impel ler couter-clockwise. Make sure any loose parts, such

as the spring and shims do not drop out when the im peller comes off the crankshaft.

- 18 -

Service

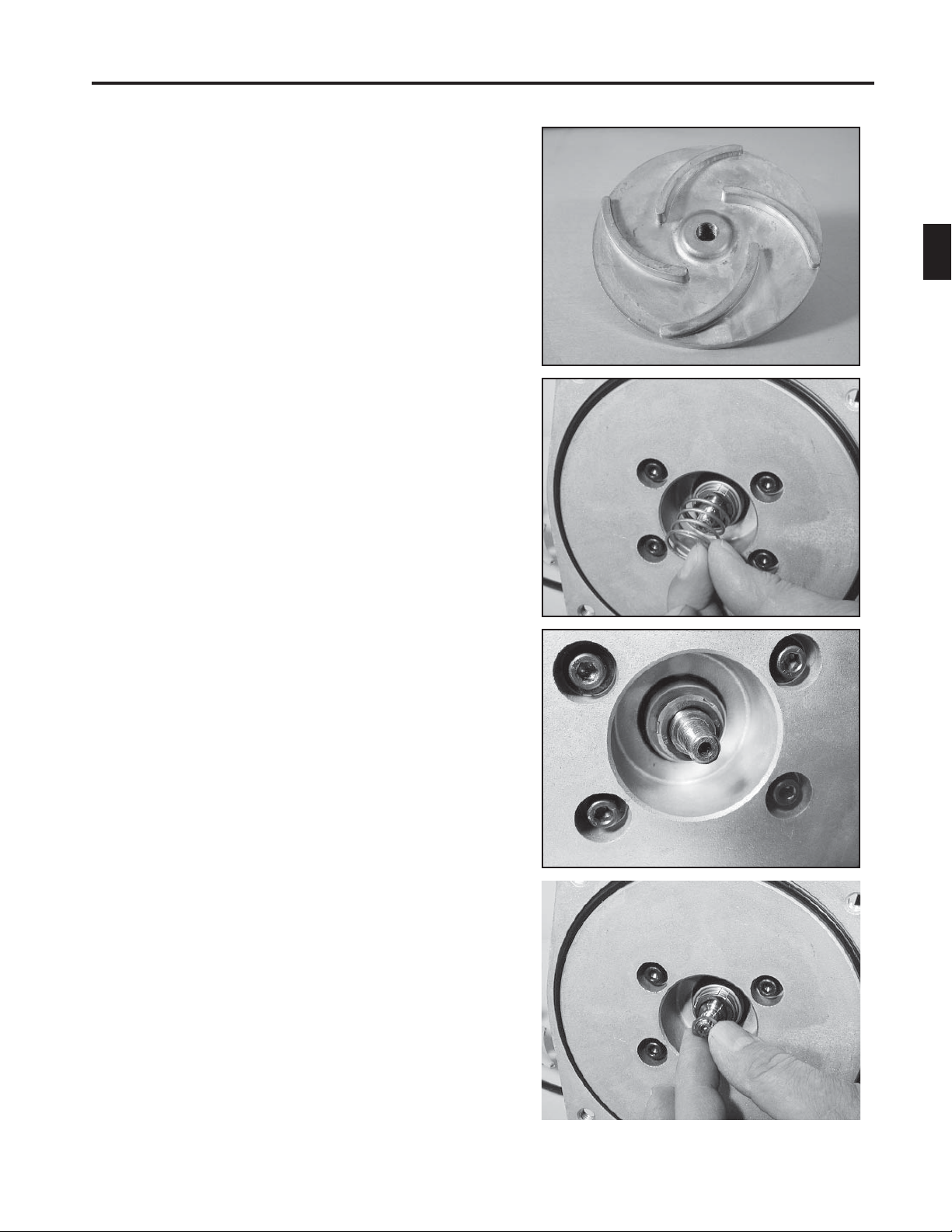

9. Inspect the impeller for cracks in the casting or chips in

the blades.

10. Remove the spring and set aside.

PKV101

11. The shim(s) should be located over the crankshaft in

this position.

12. Remove the shim(s). Count the number taken off and

make sure to replace the same amount when reinstall ing.

- 19 -

Service

13. It is possible that the shim(s) will get stuck to the in-

side of the impeller housing. Take a small screwdriver

and slowly remove, trying not to bend or distort. Re

place with new shim(s) if necessary.

14. Squirt some liquid detergent or soapy water on the

shaft and seals. This lubrication will keep the

seals from tearing when removing.

PKV101

15. Remove the outer seal very carefully with a pliers.

Note: Do not squeeze the seal. Place a small amount of

dish washing soap or light oil on the crankshaft to

keep the sealing lip from tearing.

16. Inspect the outer rotating seal surface for cracks, nicks

or burn marks.

- 20 -

Service

17. Carefully pry the stationary seal outward, using two

screwdrivers if necessary. Note: if the seal is stuck in

casing it may become necessary to squirt a small

amount of liquid soap and water on sealing surface to

loosen seal . It also may become necessary to re-

move the back plate to push the seal out when

prying from the front does not work.

18. Inspect both halfs of the seals for imperfections and

replace as necessary.

PKV101

19. If it becomes necessary to remove the frame and back

plate from the engine for engine service remove the

two bolts that hold the frame to the bottom of

back plate.

20. Remove the four bolts that hold the back plate to the

engine.

- 21 -

Service

21. The engine is now free from the pump components for

easier servicing if necessary.

22. When reinstalling the back plate, make sure that the

weep hole points downward.

PKV101

23. Place a small amount of thread lock sealer on the tip

of the bolts before reinstallation. Note: Thread locker

Blue or Purple from Permatex© is recommended. It is

a light or medium strength, and service removable.

24. Reinstall and hand tighten the bolts that hold the back

plate to the engine. Inspect the sealilng washers that

are attached to the bolts. Replace as necessary if

cracked or worn.

- 22 -

Service

25. Torque the 4 bolts to the specifi ed value.

The recommended torque is 7-9 ft. lbs.

26. Position the frame under the back plate for reinstalla tion

PKV101

27. Install and tighten the two bolts that hold the frame to

the back plate.

28. Squirt a small amount of liquid detergent on the seal

and crankshaft before trying to reinstall. The detergent

acts as a libricant for the rubber seal.

- 23 -

Service

29. The seal will have some colored marks indicating that

this is the back side. Do not install towards the rotating

seal. The marks should face the engine.

30. Push the mechanical seal into the cavity making sure it

is seated properly and even. Using your two thumbs

works great. If the backplate was removed, then in-

stall the seal into the backplate before putting on

crankshaft.

Note: Lubricating with a small amount of soap detergent

and water will ease installation signifi cantly.

PKV101

31. Re-install the other half of the seal. by pushing tight

against the other half.

Note: Lubricating with a small amount of soap detergent

and water will ease installation.

32. Re-install the spring. It can be installed in either direc tion.

- 24 -

Service

33. Re-install the shim(s) making sure you replaced the

same number that came installed with the pump. If a

new component such as a impeller or volute was

installed, refer to the section on proper shimming.

34. Screw and snug the impeller hand tight on the crank

shaft, making sure it is fl ush with the back plate.

Note: If shims are not properly installed onto crankshaft,

the impeller will not fi t fl ush to backing plate. If this

condition occures, remove impeller and push the

shims onto crankshaft further, making sure the

sims are not bent out of shape.

PKV101

35. To inure the impeller is installed correctly, place the vo-

lute against the back plate. While holding the volute

tight against the back plate with one hand, check

the clearance between the volute and impeller with a

feeler gauge. If the clearance is larger than 0.040

thousands of an inch, then another shim must be

added.

The recommended clearance is 0.020 to 0.040 thou

sands of an inch.

36. If shims need to be added or subtracted then re

move the volute and impeller, taking note of how many

shims were added or subtracted. Re-install impeller

and check again. After proper clearance is

obtained install impeller once again.

- 25 -

Service

37. Tighten impeller with rubber mallet by hitting on one of

vanes until snug.

38. Install the volute into the outer pump housing making

sure to put the volute slot into the tab that is em

bossed in the outer cover. Check the outer o-ring

condition as noted earlier.

PKV101

39. Re-install the cover and volute onto the back plate with

the four bolts.

40. Tighten all bolts and fi ll with prime water. The proper

torque value for these bolts is 9 to 11 ft. lbs.

Check engine oil and test for proper vacuum with

vac uum plate tester. The vacuum guage should read

25 lbs of pressure.

Note: See test procedures under separate heading.

- 26 -

Service

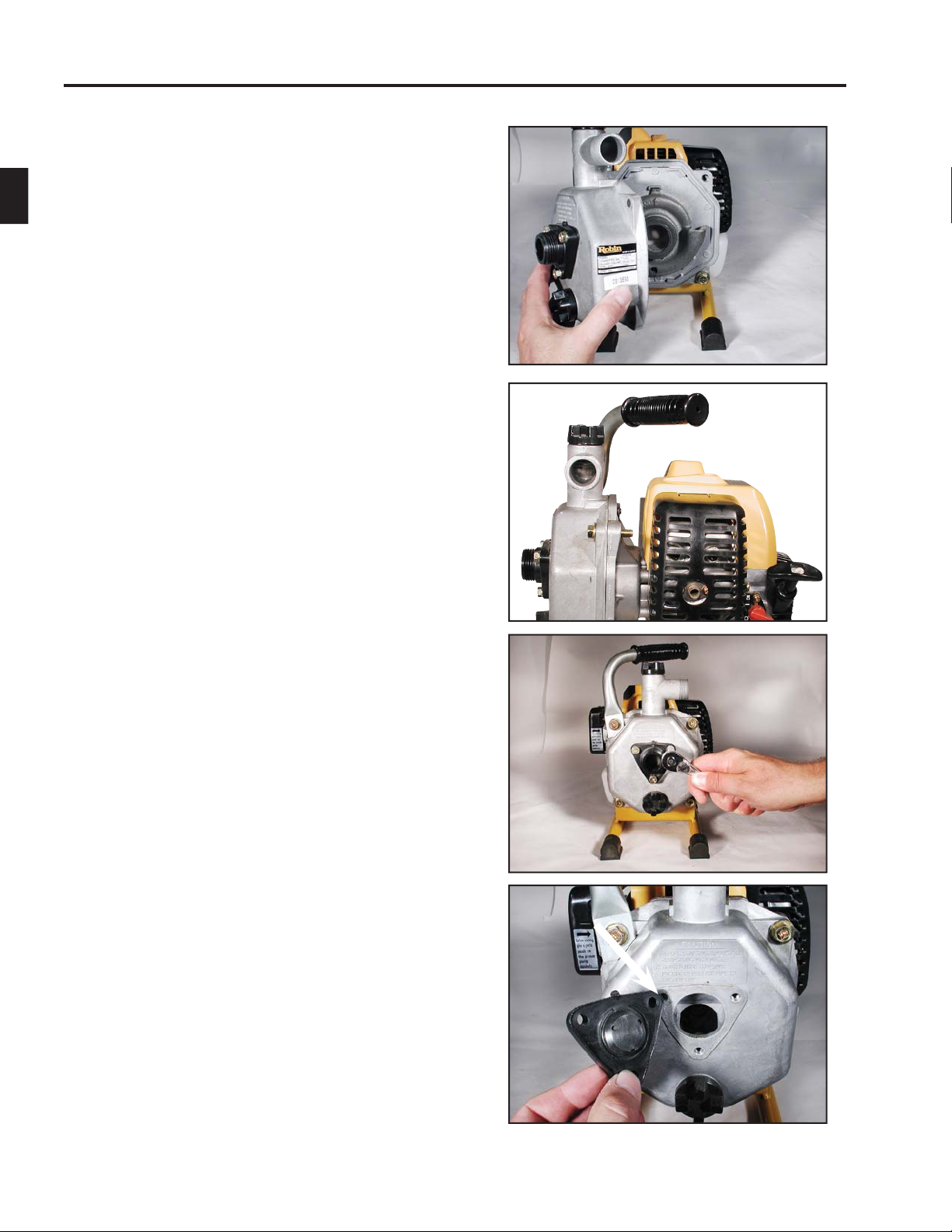

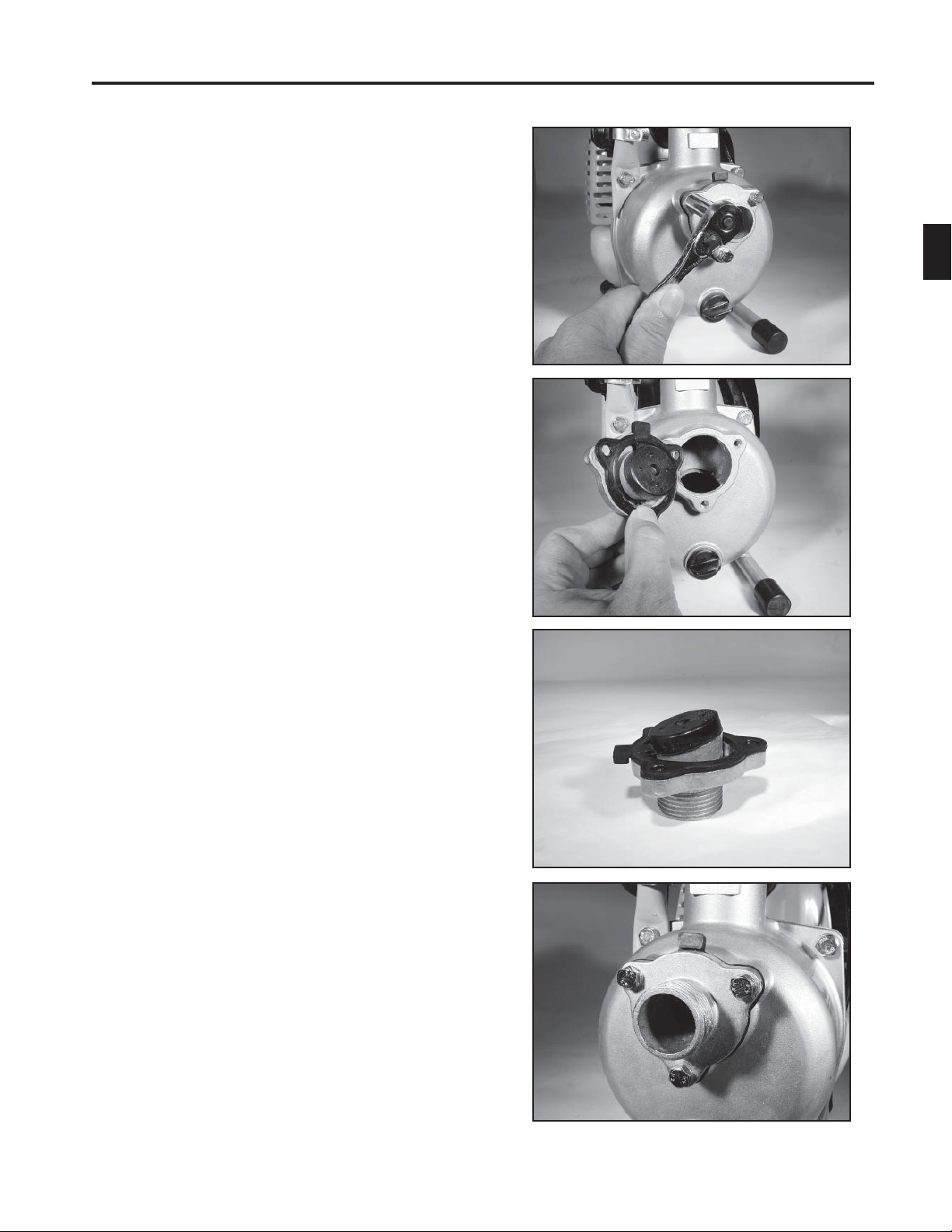

41. Should it become necessary to remove the inlet nozzle

and gasket, follow these steps. Remove the three bolts

that hold the inlet nozzle to the outer pump case.

42. Inspect the check valve gasket, noting that there is a

correct way to install it.

PKV101

43. Picture show the correct installation of the check valve

gasket on the inlet nozzle.

When reinstalling inlet nozzle it is important not to over

tighten.

The correct torque value is 2 to 3 ft lbs.

44. The picture shows the correct position of the gasket

tab facing upwards.

- 27 -

Loading...

Loading...