Page 1

2002 LEGACY SERVICE MANUAL

NEW CAR INFORMATION SECTION

QUICK REFERENCE INDEX

Specifications SPC

FOREWORD

This manual has been prepared to provide information

for the construction, operation and other technical details of SUBARU vehicles.

Read this manual thoroughly and make the most of it

to give better service to your customers and improve

your knowledge of vehicle maintenance.

Fuel Injection (Fuel System) FU

Fuel Injection (Fuel System)

Emission Control

(Aux. Emission Control Devices)

Emission Control

(Aux. Emission Control Devices)EC (w/o OBD)

Intake (Induction) IN

Mechanical ME

Exhaust EX

Exhaust

Cooling CO

(w/o OBD)

(w/o OBD)

FU

EC

EX

All information, illustration and specifications contained in this manual are based on the latest product

information available at the time of publication approval.

FUJI HEAVY INDUSTRIES LTD.

Lubrication LU

Speed Control System SP

Ignition IG

Ignition

Starting/Charging SC

Fuel Injection (Fuel System)

Emission Control

(Aux. Emission Control Devices)

Intake (Induction)

(w/o OBD)

IG

FU

(H6)

EC

(H6)

IN

(H6)

W2290GE

Page 2

FOREWORD

QUICK REFERENCE INDEX

Mechanical

Exhaust

Cooling

Lubrication

Speed Control System

Ignition

Starting/Charging

Control System CS

Automatic Transmission AT

ME

(H6)

EX

(H6)

CO

(H6)

LU

(H6)

SP

(H6)

IG

(H6)

SC

(H6)

Manual Transmission and Differential MT

Clutch CL

Front Suspension FS

Rear Suspension RS

Differentials DI

Drive Shaft System DS

ABS ABS

VDC VDC

Brakes BR

Page 3

FOREWORD

Parking Brake PB

QUICK REFERENCE INDEX

Power Assisted System

(Power Steering)

HVAC System

(Heater, Ventilator and A/C)

Airbag System AB

Seat Belt System SB

Wiper and Washer Systems WW

Glass/Windows/Mirrors GW

Body Structure BS

Instrumentation/Driver Info IDI

Seats SE

PS

AC

Security and Locks SL

Sunroof/T-top/Convertible Top SR

Exterior Body Panels EB

Cruise Control System CC

Exterior/Interior Trim EI

Page 4

FOREWORD

All right reserved. This book may not be reproduced or

copied, in whole or in part, without the written permission of FUJI HEAVY INDUSTRIES LTD., TOKYO JAPA N

SUBARU, and are trademarks of FUJI

HEAVY INDUSTRIES LTD.

Copyright 2001 FUJI HEAVY INDUSTRIES LTD.

Page 5

SPECIFICATIONS

1. Legacy ............................................................................................................. 2

2. OUTBACK ....................................................................................................... 10

SPC

Page

Page 6

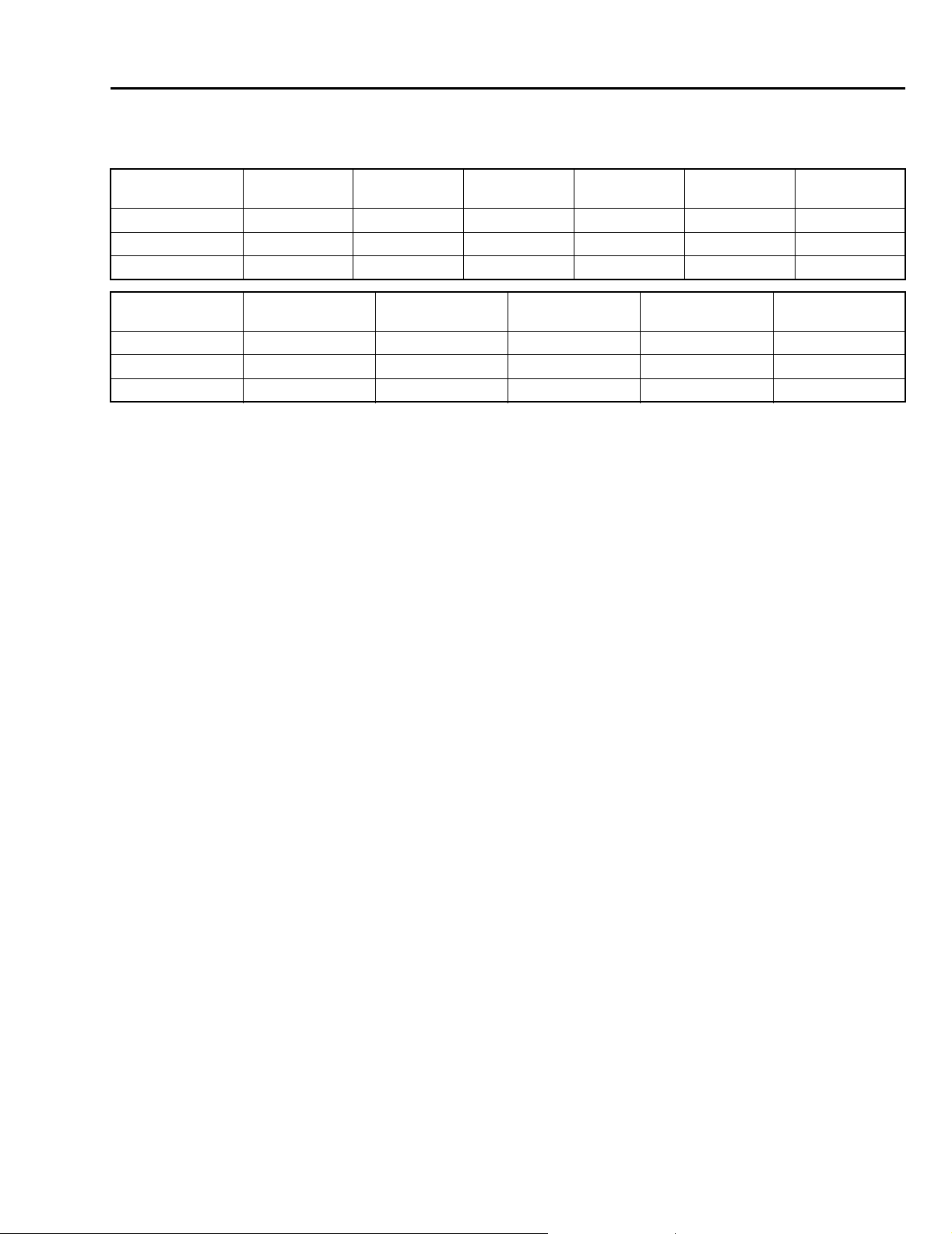

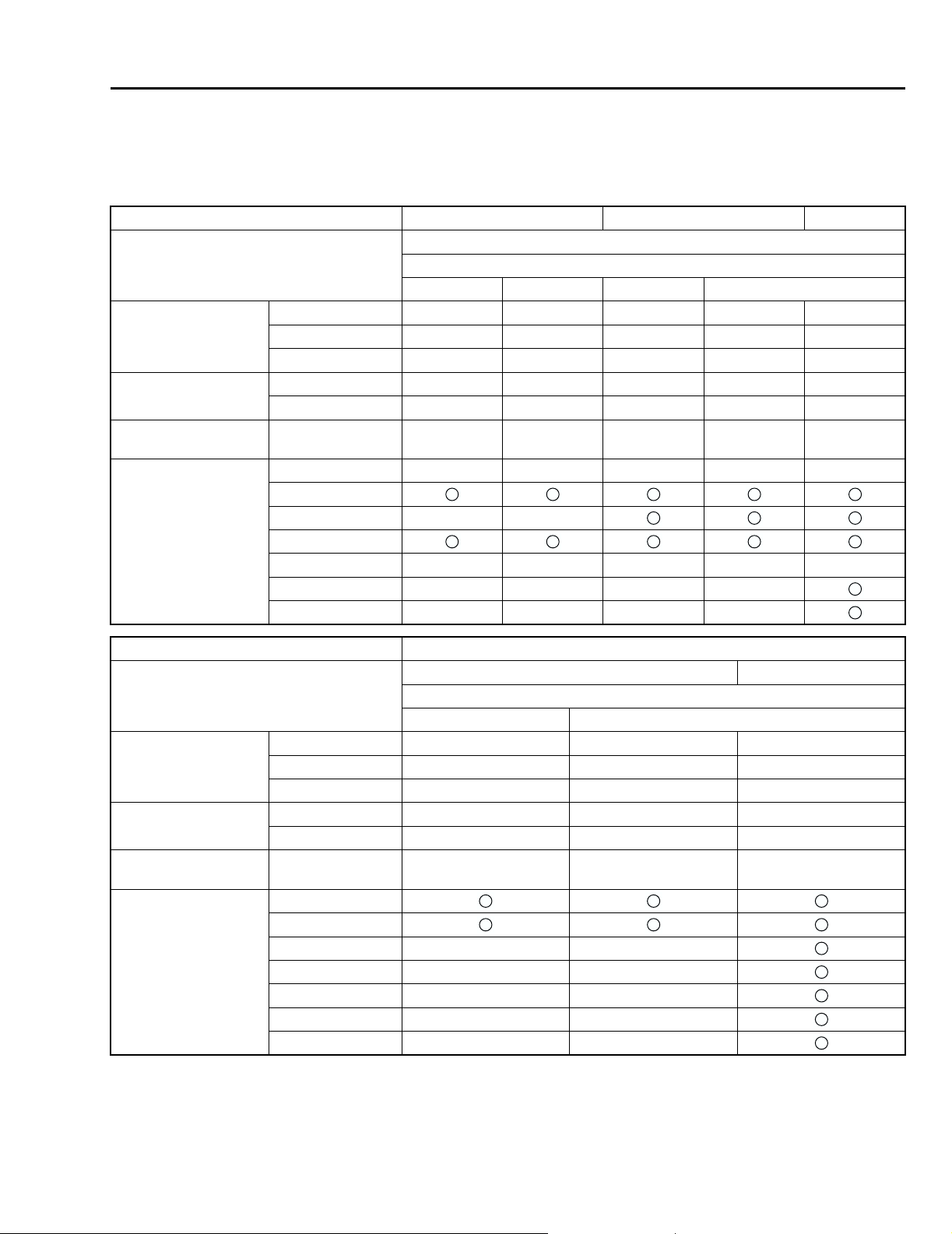

LEGACY

Specifications

1. Legacy

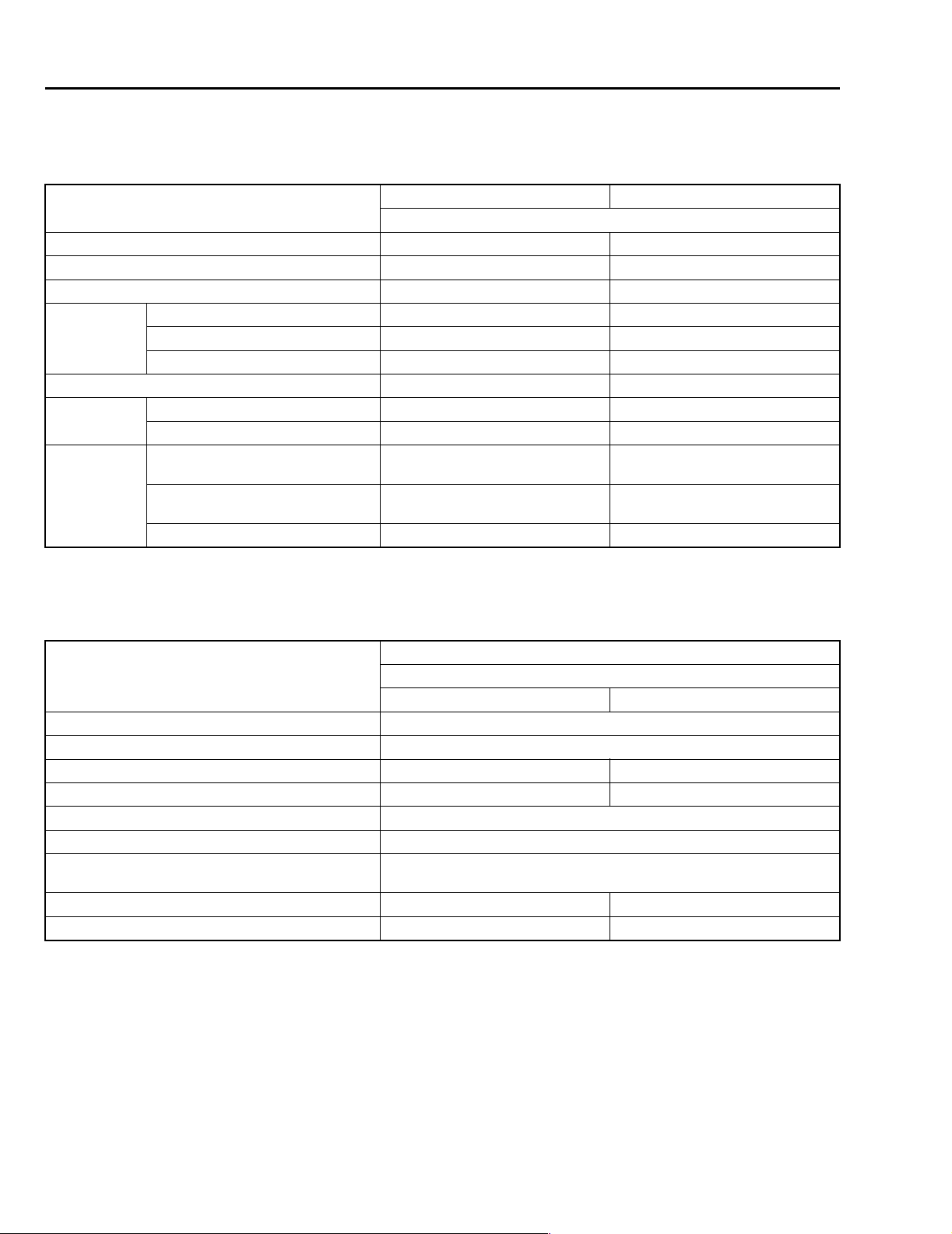

A: DIMENSIONS

Model Sedan Wagon

AWD

Overall length mm (in) 4,605 (181.3) 4,680 (184.3)

Overall width mm (in) 1,695 (66.7) 1,695 (66.7)

Overall height (at CW) mm (in) 1,415 (55.7) 1,515 (59.6)

Compartment Length mm (in) 1,965 (77.4) 1,925 (75.8)

Width mm (in) 1,440 (56.7), 1,420 (55.9)*1 1,440 (56.7), 1,420 (55.9)*1

Height mm (in) 1,155 (45.5) 1,190 (46.9), 1,175 (46.3)*2

Wheelbase mm (in) 2,650 (104.3) 2,650 (104.3)

Tread Front mm (in) 1,460 (57.5) 1,460 (57.5)

Rear mm (in) 1,460 (57.5) 1,455 (57.3)

Minimum road

clearance

Without catalytic

converter

With catalytic

converter

Australia mm (in) 155 (6.1) 155 (6.1)

mm (in) 160 (6.3) 165 (6.5)

mm (in) 155 (6.1) 155 (6.1)

*1: With leather seat

*2: With sunroof

B: ENGINE

Model Sedan/Wagon

AWD

2.0 L 2.5 L

Engine type Horizontally opposed, liquid cooled, 4-cylinder, 4-stroke gasoline engine

Valve arrangement Overhead camshaft type

Bore × Stroke mm (in) 92 × 75 (3.62 × 2.95) 99.5 × 79.0 (3.917 × 3.110)

Displacement cm

Compression ratio 10.0

Firing order 1 — 3 — 2 — 4

Idle speed at Park/Neutral

position

Maximum output kW (HP)/rpm 92 (123)/5,600 115 (154)/5,600

Maximum torque N·m (kgf-m, ft-lb)/rpm 184 (18.8, 136.0)/3,600 223 (22.7, 164.2)/3,600

3

(cu in) 1,994 (121.67) 2,457(149.9)

rpm 700±100

SPC-2

Page 7

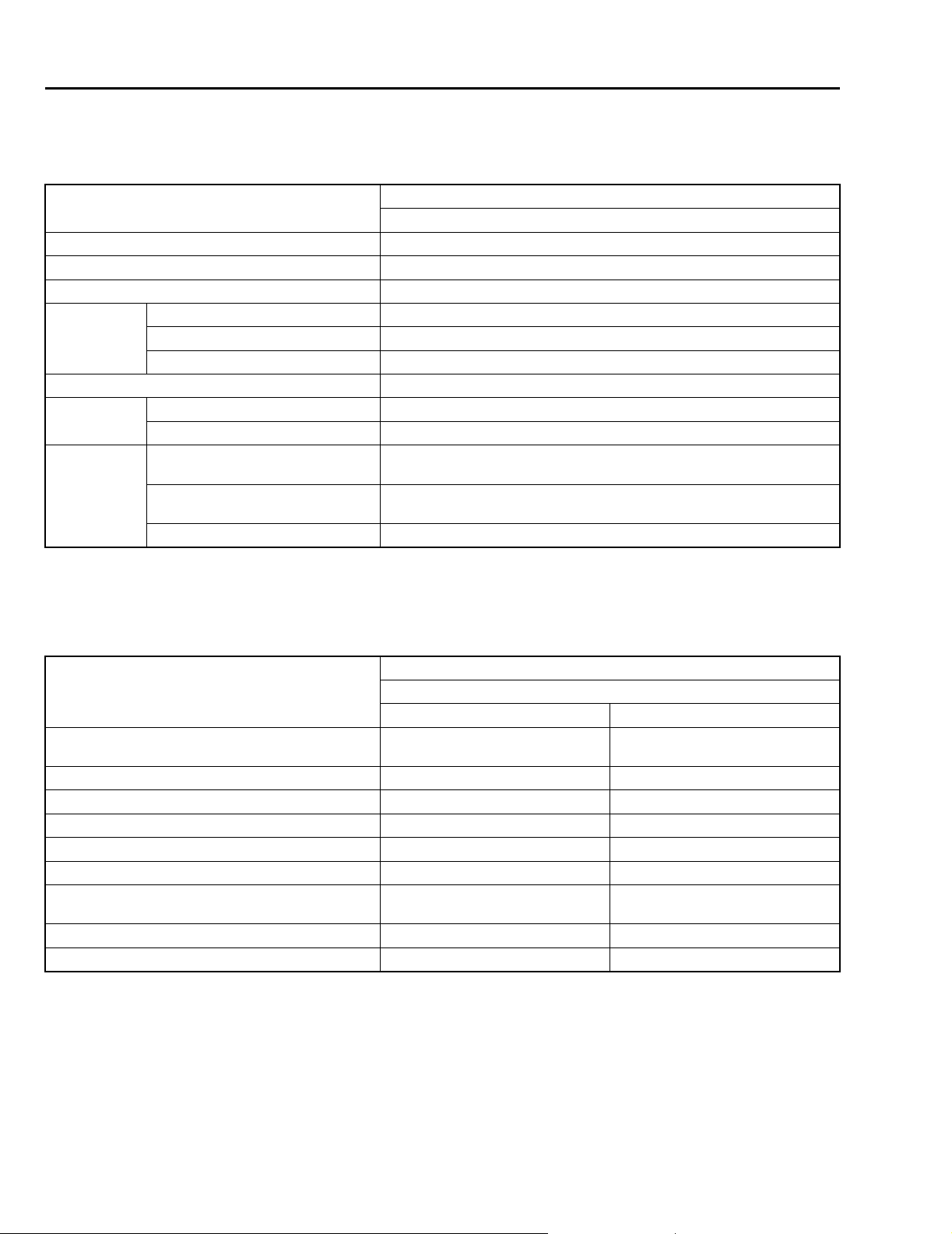

LEGACY

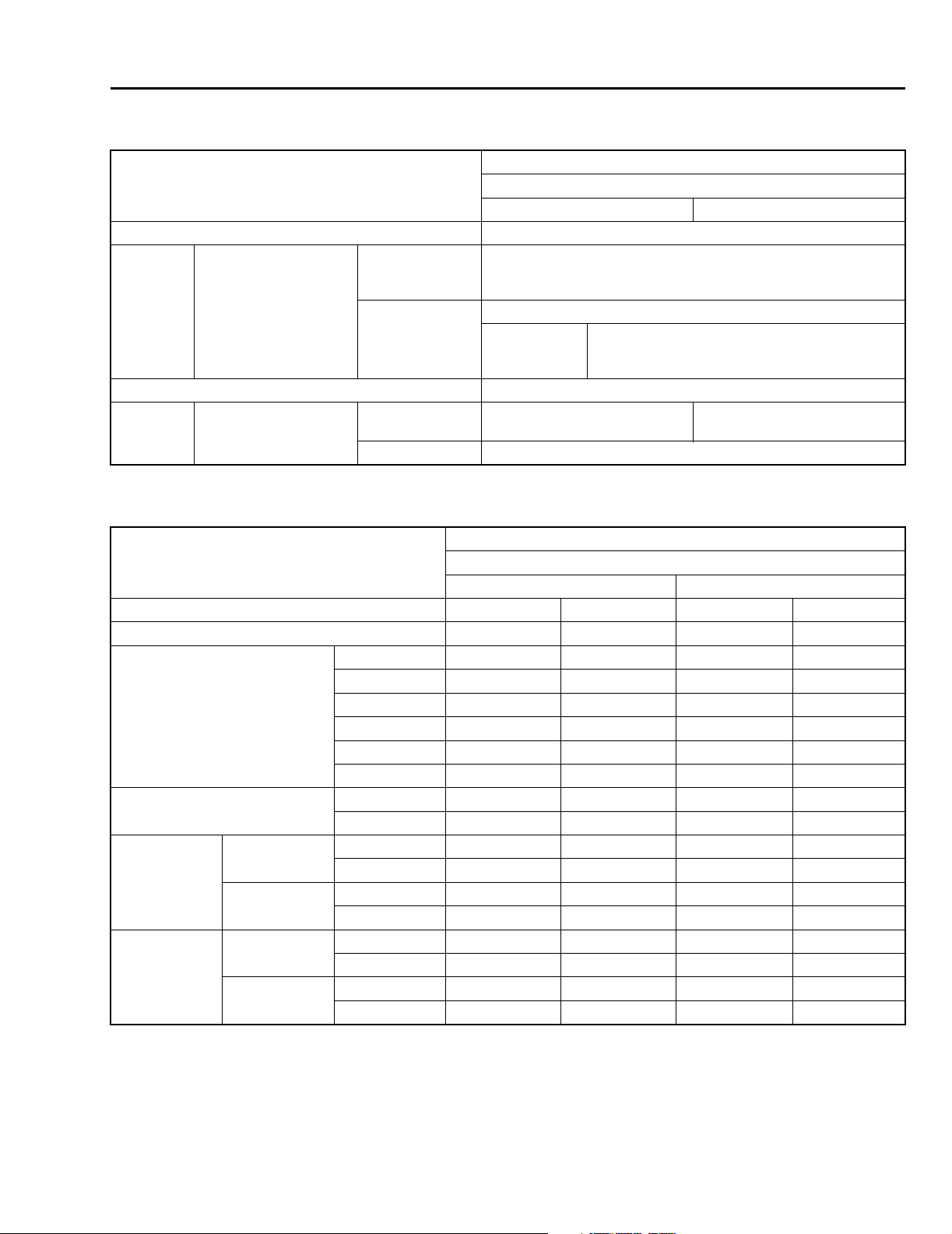

C: ELECTRICAL

Model Sedan/Wagon

AWD

2.0 L 2.5 L

Ignition timing at idling speed BTDC/rpm 10°±10°/700

Spark plug Type and manufacturer Without OBD NGK: BKR6E (without catalyst)

CHAMPION: RC10YC4 (with catalyst)

NGK: BKR5E-11 (with catalyst)

With OBD RC10YC4 .......... CHAMPION

Alternate RC8YC4 .......... CHAMPION

BKR6E-11 .......... NGK

K20PR-U11 .......... NIPPONDENSO

Generator 12V — 90A

Battery Type and capacity (5HR) For Europe and

South America

Others 12V — 27AH (34B19L)

MT: 12V — 48AH (55D23L)

AT: 12V — 52AH (65D23L)

MT: 12V — 48AH (55D23L)

AT: 12V — 52AH (75D23L)

D: TRANSMISSION

Specifications

Model Sedan/Wagon

AWD

2.0 L 2.5 L

Transmission type 5MT 4AT 5MT 4AT

Clutch type DSPD TCC DSPD TCC

Gear ratio 1st 3.454 2.785 3.454 2.785

2nd 2.062 1.545 2.062 1.545

3rd 1.448 1.000 1.448 1.000

4th 1.088 0.694 1.088 0.694

5th 0.825 — 0.825*1, 0.780*2 —

Reverse 3.333 2.272 3.333 2.272

Auxiliary transmission gear ratio High 1.000 — 1.000 —

Low 1.447 — 1.196 —

Reduction gear

(Front drive)

Reduction gear

(Rear drive)

1st reduction Type of gear — Helical — Helical

Gear ratio — 1.000 — 1.000

Final reduction Type of gear Hypoid Hypoid Hypoid Hypoid

Gear ratio 3.900 4.111 3.700*1, 4.111*2 4.111

Tr a n sf e r

reduction

Final reduction Type of gear Hypoid Hypoid Hypoid Hypoid

Type of gear Helical — Helical —

Gear ratio 1.000 — 1.000 —

Gear ratio 3.900 4.111 3.700*1, 4.111*2 4.111

5MT: 5-forward speeds with synchromesh and 1-reverse

4AT: Electronically controlled fully-automatic, 4-forward speeds and 1-reverse

DSPD: Dry Single Plate Diaphragm

TCC: Torque Converter Clutch

*1: Except Australia spec. vehicles

*2: Australia spec. vehicles

SPC-3

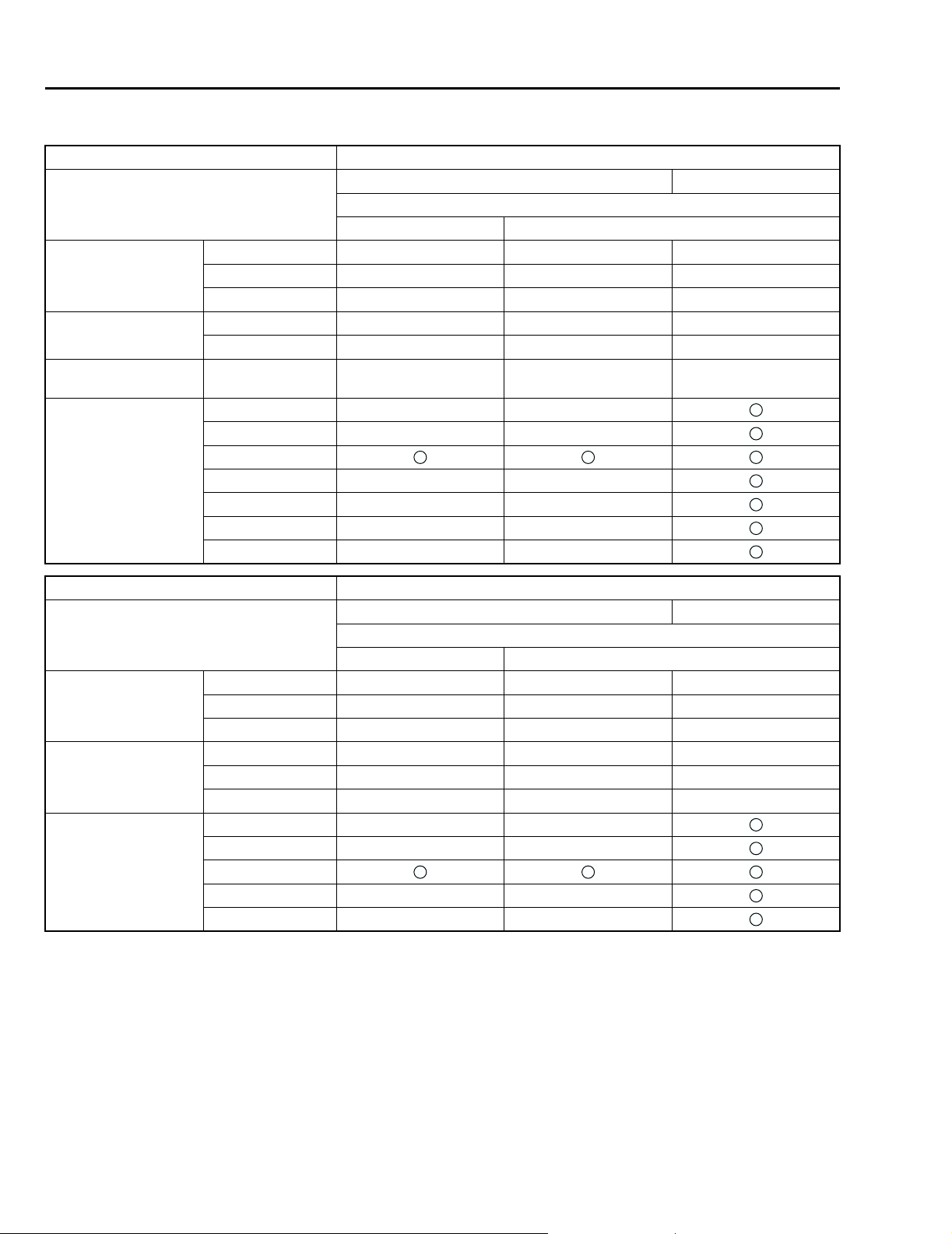

Page 8

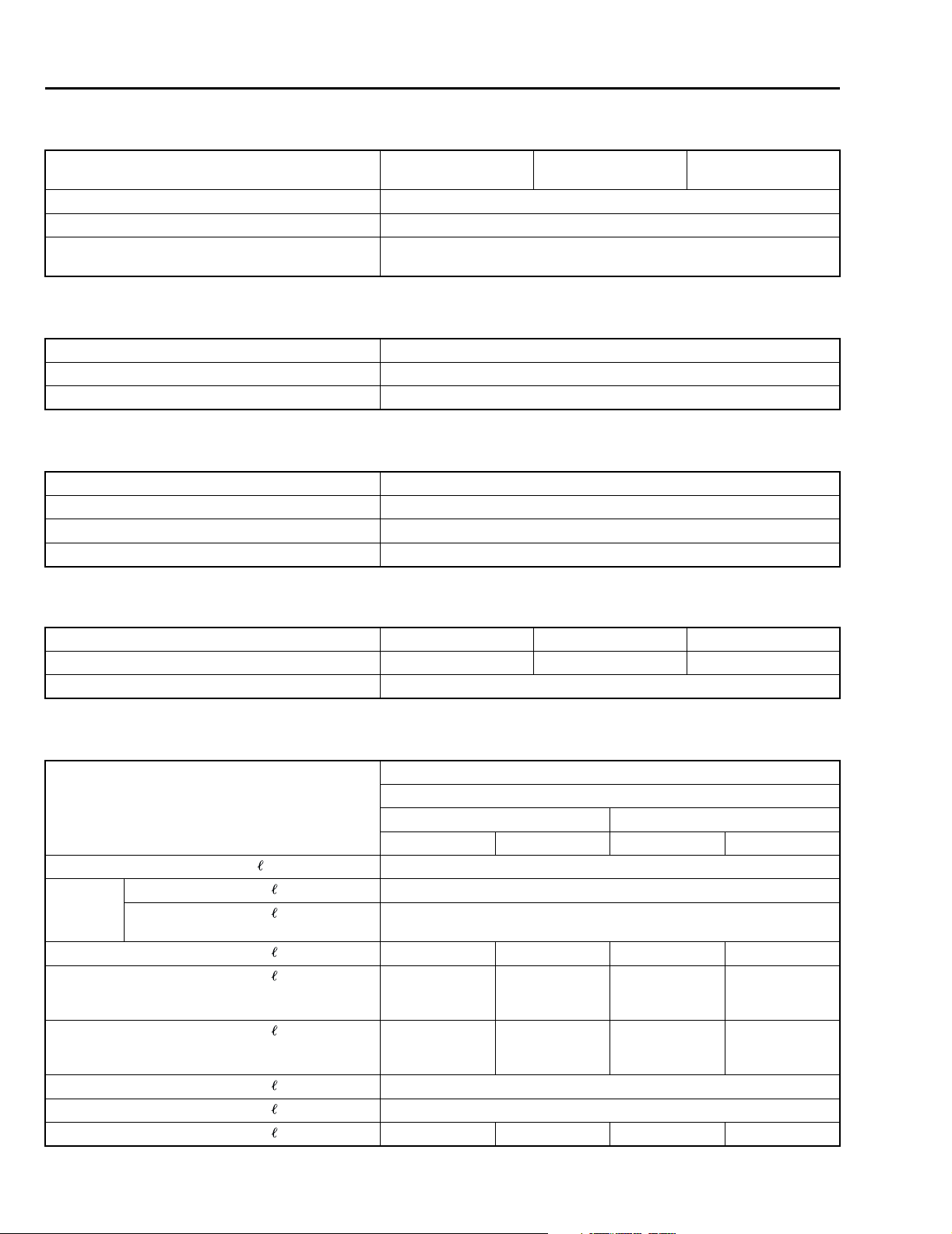

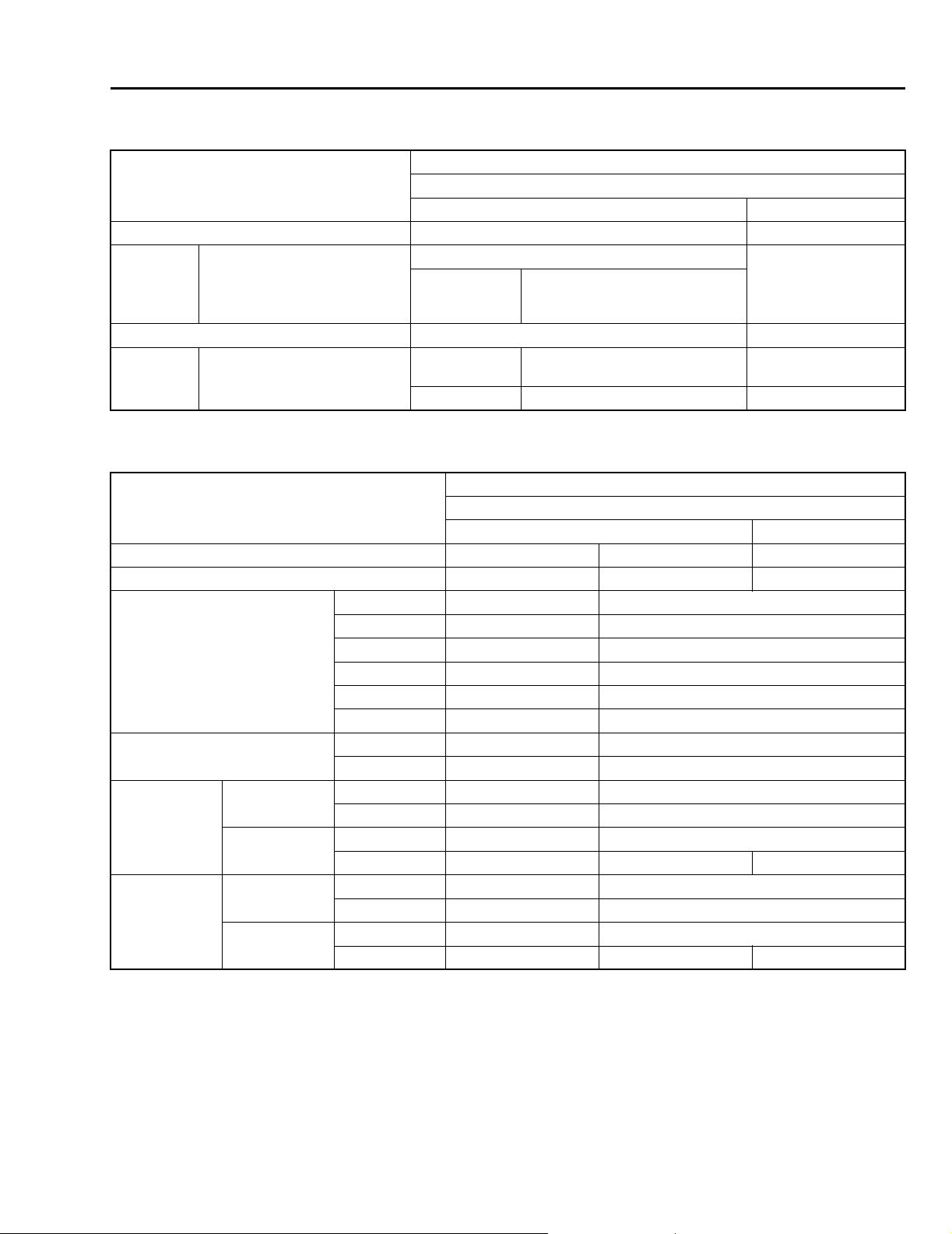

Specifications

E: STEERING

LEGACY

Model Models with

185/70R14 tires

Ty pe Rack and Pinion

Turns, lock to lock 3.1

Minimum turning circle m (ft) Curb to curb: 10.8±1.0 (35.4±3.3)

Wall to wall: 11.5±1.0 (37.7±3.3)

Models with

195/60R15 tires

Models with

205/50R16 tires

F: SUSPENSION

Model Conventional suspension

Front Macpherson strut type, Independent, Coil spring

Rear Multi-link type, Independent, Coil spring

G: BRAKE

Service brake system Dual circuit hydraulic with vacuum suspended power unit

Front Ventilated disc brake

Rear Disc brake

Parking brake Mechanical on rear brakes

H: TIRE

Rim size 14 × 5½JJ 15 × 6JJ 16 × 6½JJ

Tire size 185/70R14 195/60R15 205/50R16

Type Steel belted radial, Tubeless

I: CAPACITY

Model Sedan/Wagon

AWD

2.0 L 2.5 L

5MT4AT5MT4AT

Fuel tank (US gal, Imp gal) 64 (16.9, 14.1)

Engine oil Total capacity (US qt, Imp qt) 4.0 (4.2, 3.5)

Engine oil

amount for refill

Transmission gear oil (US qt, Imp qt) 3.5 (3.7, 3.1) — 3.5 (3.7, 3.1) —

Automatic transmission fluid (US qt, Imp qt) — 8.4 – 8.7

AT differential gear oil (US qt, Imp qt) — 1.1 – 1.3

AWD rear differential gear oil (US qt, Imp qt) 0.8 (0.8, 0.6)

Power steering fluid (US qt, Imp qt) 0.7 (0.7, 0.6)

Engine coolant (US qt, Imp qt) 7.0 (7.4, 6.2) 6.9 (7.3, 6.1) 6.8 (7.2, 6.0) 6.7 (7.1, 5.9)

(US qt, Imp qt) Approx. 4.0 (4.2, 3.5)

— 9.3 – 9.6

(8.9 – 9.2,

7.4 – 7.7)

— 1.1 – 1.3

(1.2 – 1.4,

1.0 – 1.1)

(9.8 – 10.1,

8.2 – 8.4)

(1.2 – 1.4,

1.0 – 1.1)

SPC-4

Page 9

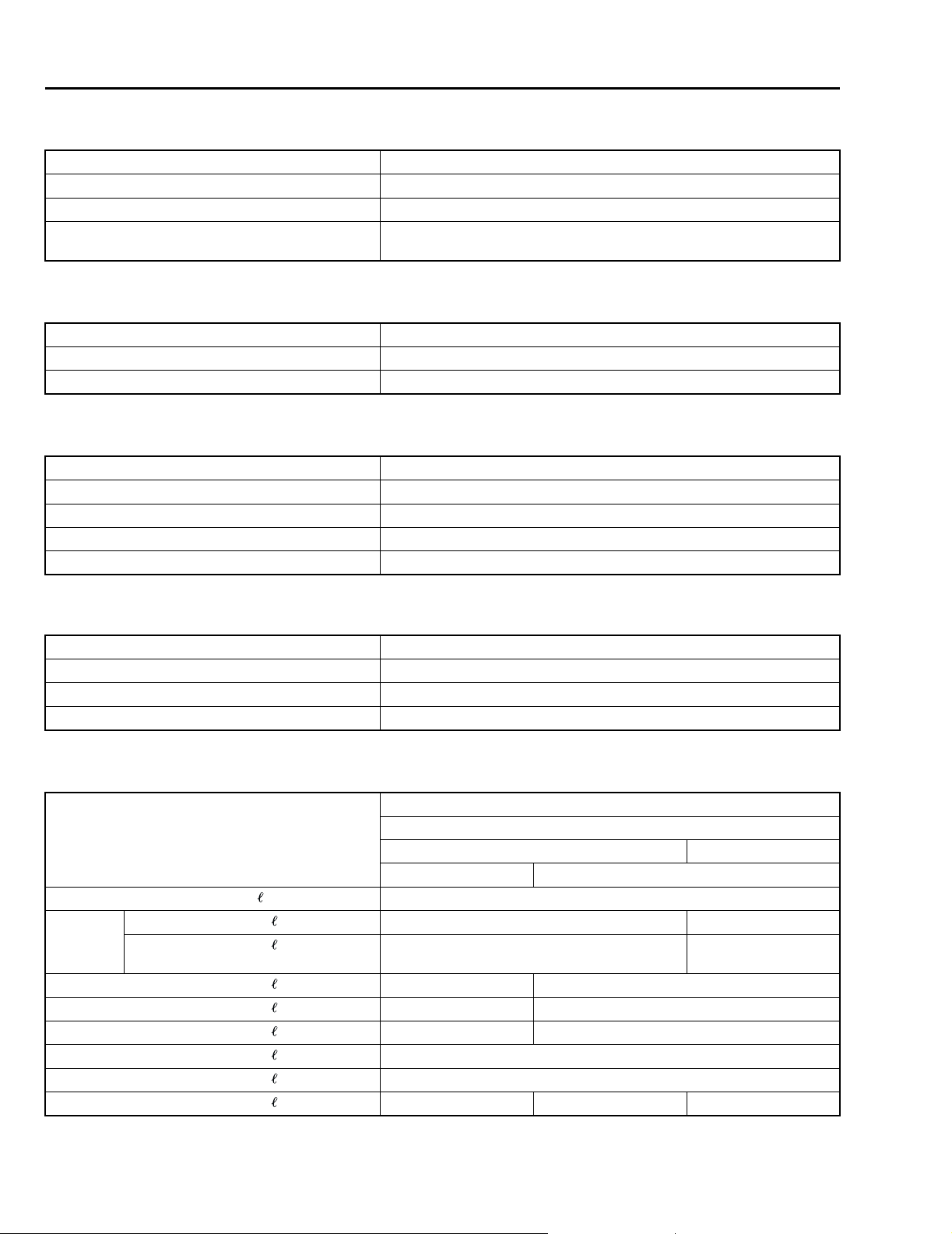

LEGACY

Specifications

J: WEIGHT

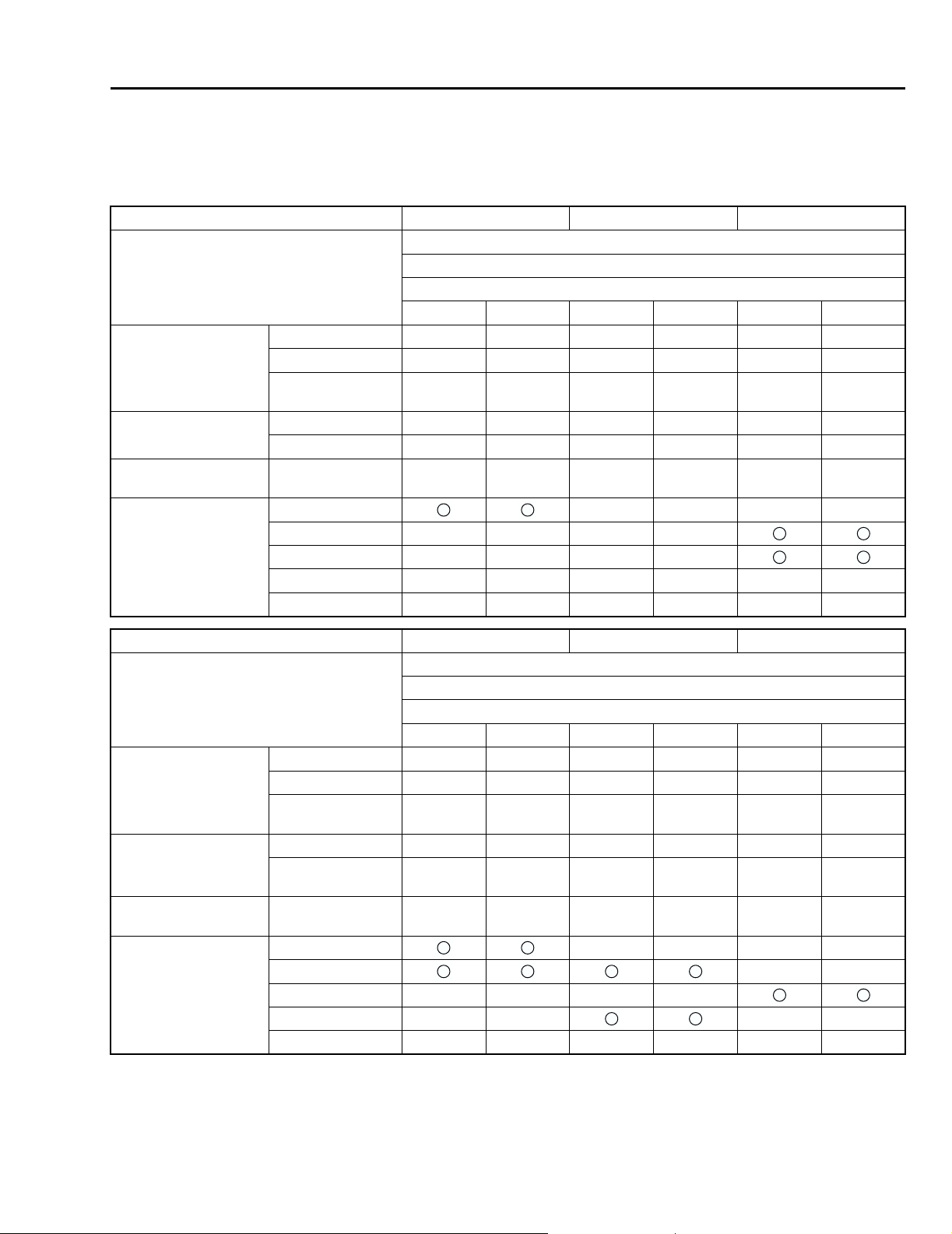

1. SEDAN

! LHD Vehicle

Option code *1 EC K4 KO, KS

Model 2.0 L

4WD

GL

5MT 4AT 5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 785 (1,730) 810 (1,785) 775 (1,710) 800 (1,765) 790 (1,740) 815 (1,795)

Rear kg (lb) 605 (1,335) 605 (1,335) 610 (1,345) 610 (1,345) 610 (1,345) 610 (1,345)

Total kg (lb) 1,390

(3,065)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag ————

Front kg (lb) 970 (2,140) 970 (2,140) 970 (2,140) 970 (2,140) 970 (2,140) 970 (2,140)

Rear kg (lb) 975 (2,150) 975 (2,150) 975 (2,150) 975 (2,150) 975 (2,150) 975 (2,150)

Total kg (lb) 1,870

(4,125)

Air conditioner ————

Audio ————

Cruise control ——————

Cold weather pack ——————

1,415

(3,120)

1,870

(4,125)

1,385

(3,055)

1,870

(4,125)

1,410

(3,110)

1,870

(4,125)

1,400

(3,085)

1,870

(4,125)

1,425

(3,140)

1,870

(4,125)

Option code *1 EC K4 KO, KS

Model 2.5 L

4WD

GX

5MT 4AT 5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 805 (1,775) 830 (1,830) 795 (1,755) 820 (1,810) 785 (1,730) 810 (1,785)

Rear kg (lb) 605 (1,335) 610 (1,345) 610 (1,345) 615 (1,355) 610 (1,345) 615 (1,355)

Total kg (lb) 1,410

(3,110)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag ————

*1: For option code, refer to ID section. <Ref. to ID-5, MODEL NUMBER PLATE, IDENTIFICATION, Identification.>

Front kg (lb) 985 (2,170) 985 (2,170) 985 (2,170) 985 (2,170) 985 (2,170) 985 (2,170)

Rear kg (lb) 1,000

(2,205)

Total kg (lb) 1,910

(4,210)

Air conditioner ——

Audio ————

Cruise control —— ——

Cold weather pack ——————

1,440

(3,175)

1,000

(2,205)

1,910

(4,210)

1,405

(3,110)

1,000

(2,205)

1,910

(4,210)

1,435

(3,165)

1,000

(2,205)

1,910

(4,210)

1,395

(3,075)

1,000

(2,205)

1,910

(4,210)

1,425

(3,140)

1,000

(2,205)

1,910

(4,210)

SPC-5

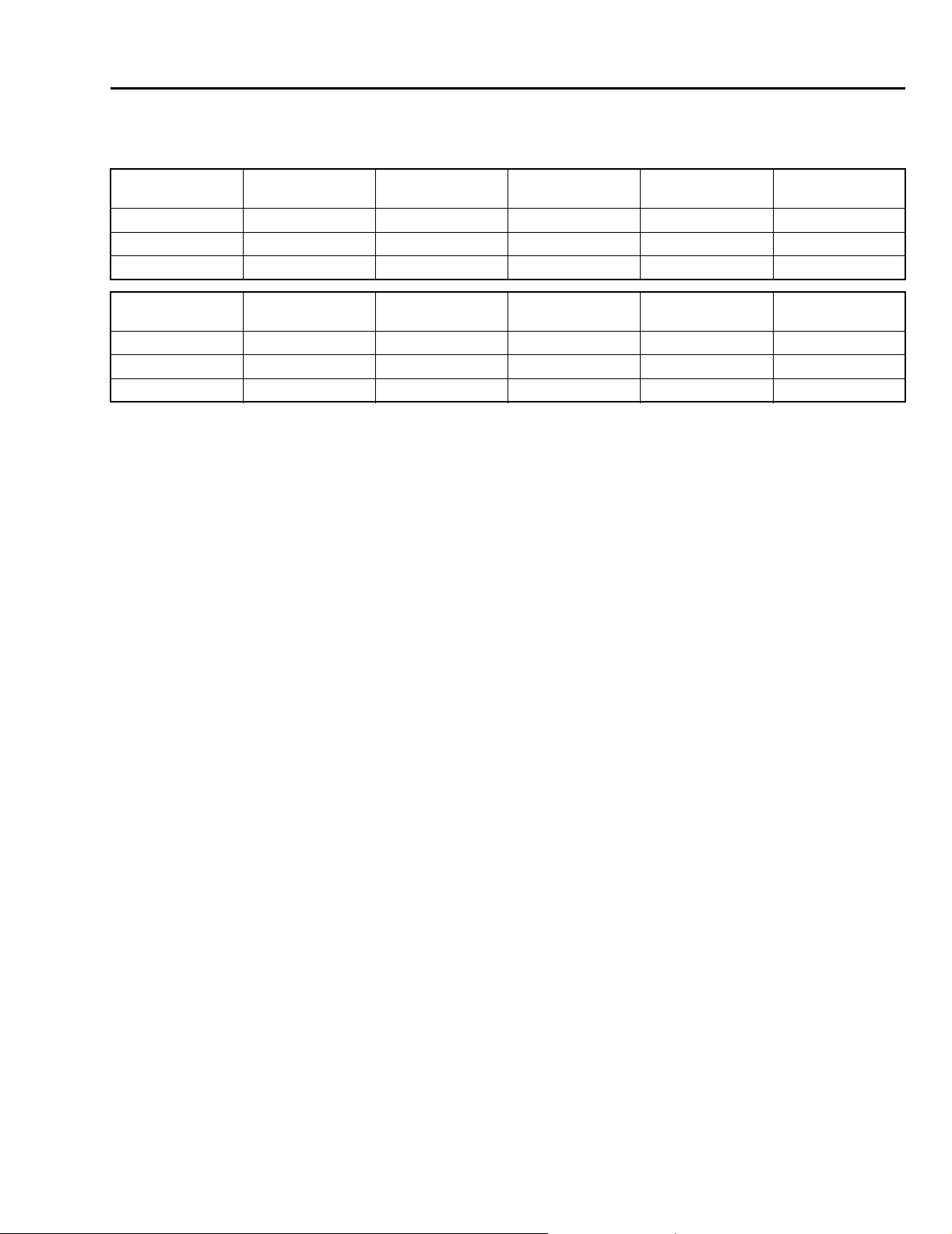

Page 10

LEGACY

Specifications

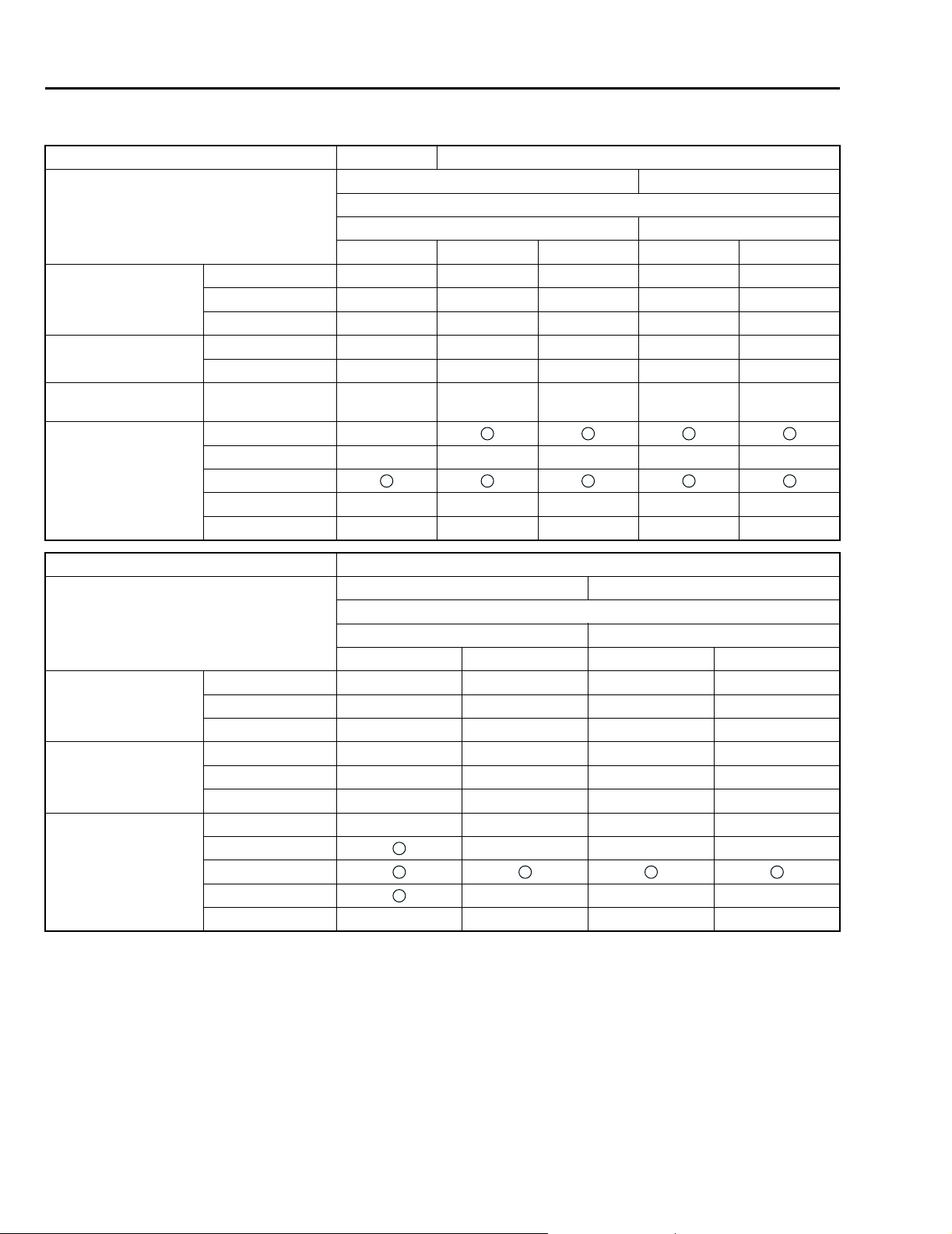

! RHD Vehicle

Option code *1 K1 EK

Model 2.0 L 2.5 L

4WD

GL GX

4AT 5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 800 (1,765) 785 (1,730) 810 (1,785) 795 (1,755) 820 (1,810)

Rear kg (lb) 605 (1,335) 605 (1,335) 605 (1,335) 605 (1,335) 610 (1,345)

Total kg (lb) 1,405 (3,100) 1,390 (3,065) 1,415 (3,120) 1,400 (3,085) 1,430 (3,155)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag —

Front kg (lb) 970 (2,140) 970 (2,140) 970 (2,140) 985 (2,170) 985 (2,170)

Rear kg (lb) 975 (2,150) 975 (2,150) 975 (2,150) 1,000 (2,205) 1,000 (2,205)

Total kg (lb) 1,870 (4,125) 1,870 (4,125) 1,870 (4,125) 1,910 (4,210) 1,910 (4,210)

Air conditioner —————

Audio

Cruise control —————

Cold weather pack —————

Option code *1 KA

Model 2.0 L 2.5 L

4WD

GL (GX) GX (RX)

5MT4AT5MT4AT

Unladen mass (U.M.) Front kg (lb) 780 (1,720) 775 (1,710) 775 (1,710) 785 (1,730)

Rear kg (lb) 585 (1,290) 585 (1,290) 595 (1,310) 595 (1,310)

Total kg (lb) 1,365 (3,010) 1,360 (3,000) 1,370 (3,020) 1,380 (3,045)

Gross vehicle mass

(G.V.M.)

Option Side airbag ————

*1: For option code, refer to ID section. <Ref. to ID-5, MODEL NUMBER PLATE, IDENTIFICATION, Identification.>

Front kg (lb) 930 (2,050) 930 (2,050) 940 (2,075) 940 (2,075)

Rear kg (lb) 970 (2,140) 970 (2,140) 980 (2,160) 980 (2,160)

Total kg (lb) 1,900 (4,190) 1,900 (4,190) 1,920 (4,235) 1,920 (4,235)

Air conditioner ———

Audio

Cruise control ———

Cold weather pack ————

SPC-6

Page 11

LEGACY

Specifications

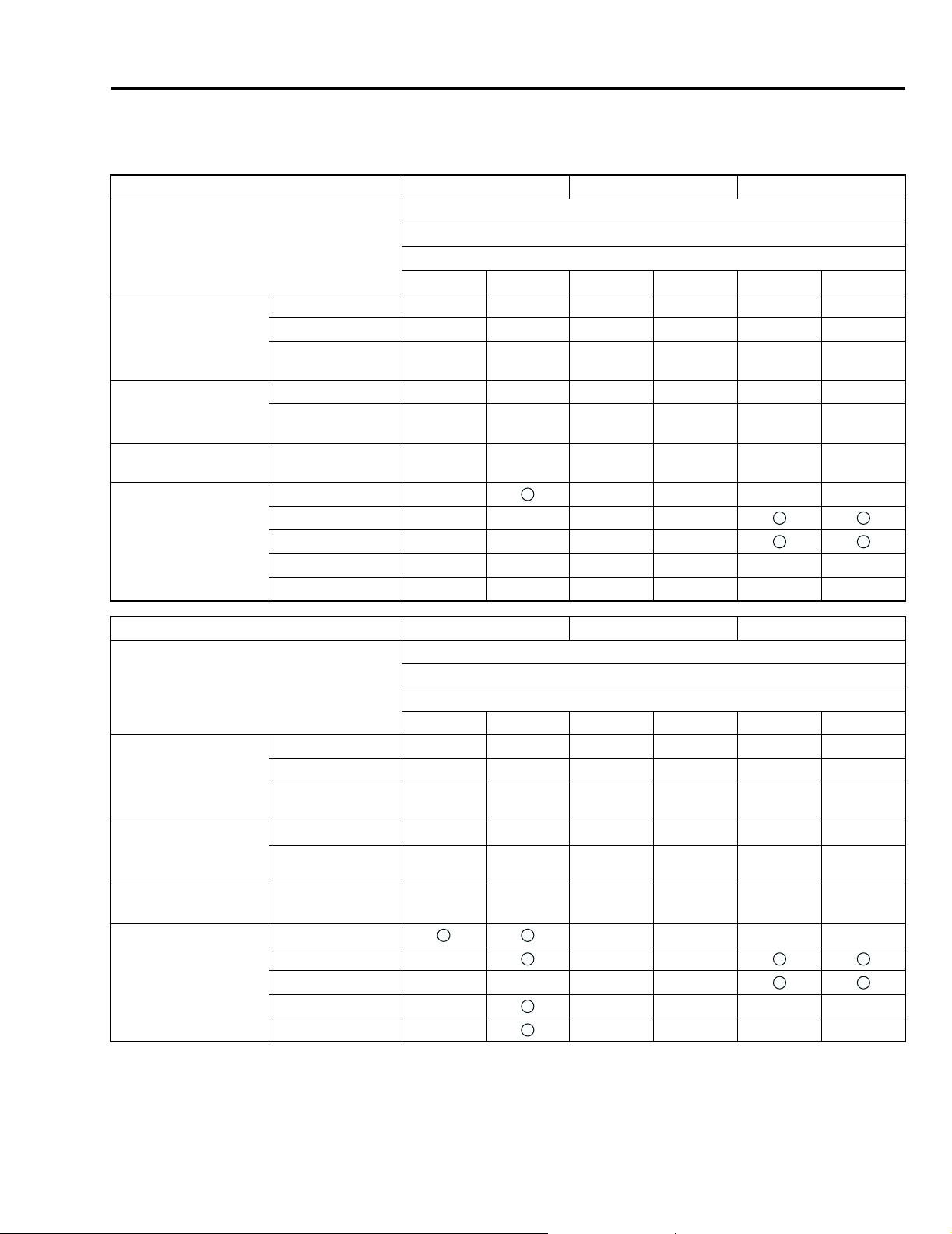

2. WAGON

! LHD Vehicle

Option code *1 EC K4 KO, KS

Model 2.0 L

4WD

GL

5MT 4AT 5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 780 (1,720) 800 (1,765) 775 (1,710) 790 (1,740) 790 (1,740) 805 (1,775)

Rear kg (lb) 650 (1,435) 650 (1,435) 655 (1,445) 655 (1,445) 655 (1,445) 655 (1,445)

Total kg (lb) 1,430

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag —————

Front kg (lb) 960 (2,115) 960 (2,115) 960 (2,115) 960 (2,115) 960 (2,115) 960 (2,115)

Rear kg (lb) 1,030

Total kg (lb) 1,920

Air conditioner ————

Audio ————

Cruise control ——————

Cold weather pack ——————

(3,155)

(2,270)

(4,235)

1,450

(3,195)

1,030

(2,270)

1,920

(4,235)

1,430

(3,155)

1,030

(2,270)

1,920

(4,235)

1,445

(3,185)

1,030

(2,270)

1,920

(4,235)

1,445

(3,185)

1,030

(2,270)

1,920

(4,235)

1,460

(3,220)

1,030

(2,270)

1,920

(4,235)

Option code *1 EC K4 KO, KS

Model 2.5 L

4WD

GX

5MT 4AT 5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 790 (1,740) 820 (1,810) 775 (1,710) 790 (1,740) 790 (1,740) 805 (1,775)

Rear kg (lb) 655 (1,445) 655 (1,445) 655 (1,445) 655 (1,445) 655 (1,445) 655 (1,445)

Total kg (lb) 1,445

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag ————

*1: For option code, refer to ID section. <Ref. to ID-5, MODEL NUMBER PLATE, IDENTIFICATION, Identification.>

Front kg (lb) 995 (2,195) 995 (2,195) 960 (2,115) 960 (2,115) 960 (2,115) 960 (2,115)

Rear kg (lb) 1,050

Total kg (lb) 1,980

Air conditioner ———

Audio ————

Cruise control —————

Cold weather pack —————

(3,185)

(2,315)

(4,365)

1,475

(3,250)

1,050

(2,315)

1,980

(4,365)

1,430

(3,155)

1,030

(2,270)

1,920

(4,235)

1,445

(3,185)

1,030

(2,270)

1,920

(4,235)

1,445

(3,185)

1,030

(2,270)

1,920

(4,235)

1,460

(3,220)

1,030

(2,270)

1,920

(4,235)

SPC-7

Page 12

LEGACY

Specifications

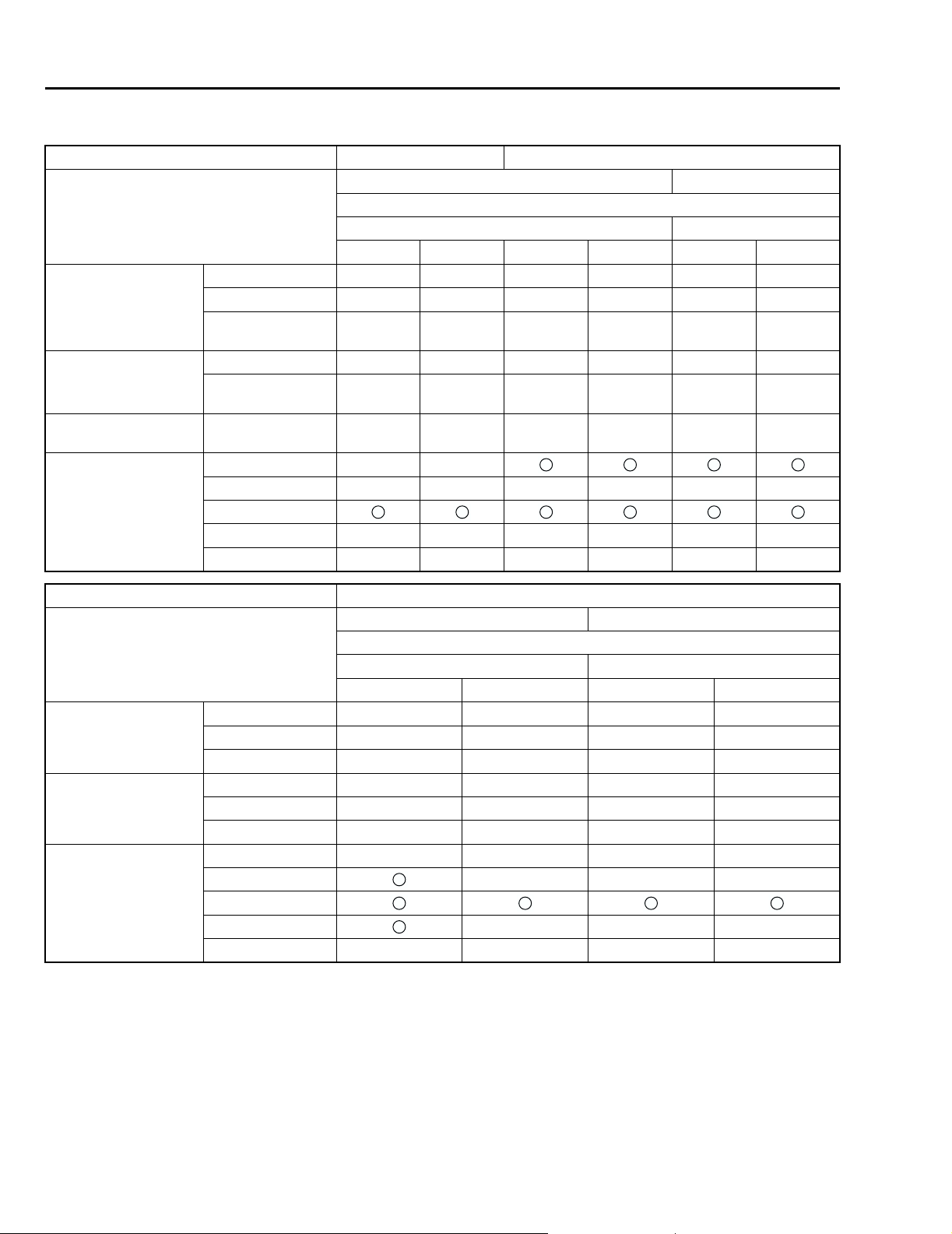

! RHD Vehicle

Option code *1 K1 EK

Model 2.0 L 2.5 L

4WD

GL GX

5MT 4AT 5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 775 (1,710) 790 (1,740) 785 (1,731) 800 (1,765) 790 (1,740) 805 (1,775)

Rear kg (lb) 655 (1,445) 655 (1,445) 650 (1,435) 650 (1,435) 655 (1,445) 655 (1,445)

Total kg (lb) 1,430

(3,155)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag ——

Front kg (lb) 960 (2,115) 960 (2,115) 960 (2,115) 960 (2,115) 995 (2,195) 995 (2,195)

Rear kg (lb) 1,030

(2,270)

Total kg (lb) 1,920

(4,235)

Air conditioner ——————

Audio

Cruise control ——————

Cold weather pack ——————

1,445

(3,185)

1,030

(2,270)

1,920

(4,235)

1,435

(3,165)

1,030

(2,270)

1,920

(4,235)

1,450

(3,195)

1,030

(2,270)

1,920

(4,235)

1,445

(3,185)

1,050

(2,315)

1,980

(4,365)

1,460

(3,220)

1,050

(2,315)

1,980

(4,365)

Option code *1 KA

Model 2.0 L 2.5 L

4WD

GL (GX) GX (RX)

5MT4AT5MT4AT

Unladen mass (U.M.) Front kg (lb) 775 (1,710) 775 (1,710) 765 (1,685) 780 (1,720)

Rear kg (lb) 635 (1,400) 635 (1,400) 645 (1,420) 645 (1,420)

Total kg (lb) 1,410 (3,110) 1,410 (3,110) 1,410 (3,110) 1,425 (3,140)

Gross vehicle mass

(G.V.M.)

Option Side airbag ————

*1: For option code, refer to ID section. <Ref. to ID-5, MODEL NUMBER PLATE, IDENTIFICATION, Identification.>

Front kg (lb) 930 (2,050) 930 (2,050) 950 (2,095) 950 (2,095)

Rear kg (lb) 1,010 (2,225) 1,010 (2,225) 1,040 (2,295) 1,040 (2,295)

Total kg (lb) 1,940 (4,280) 1,940 (4,280) 1,990 (4,390) 1,990 (4,390)

Air conditioner ———

Audio

Cruise control ———

Cold weather pack ————

SPC-8

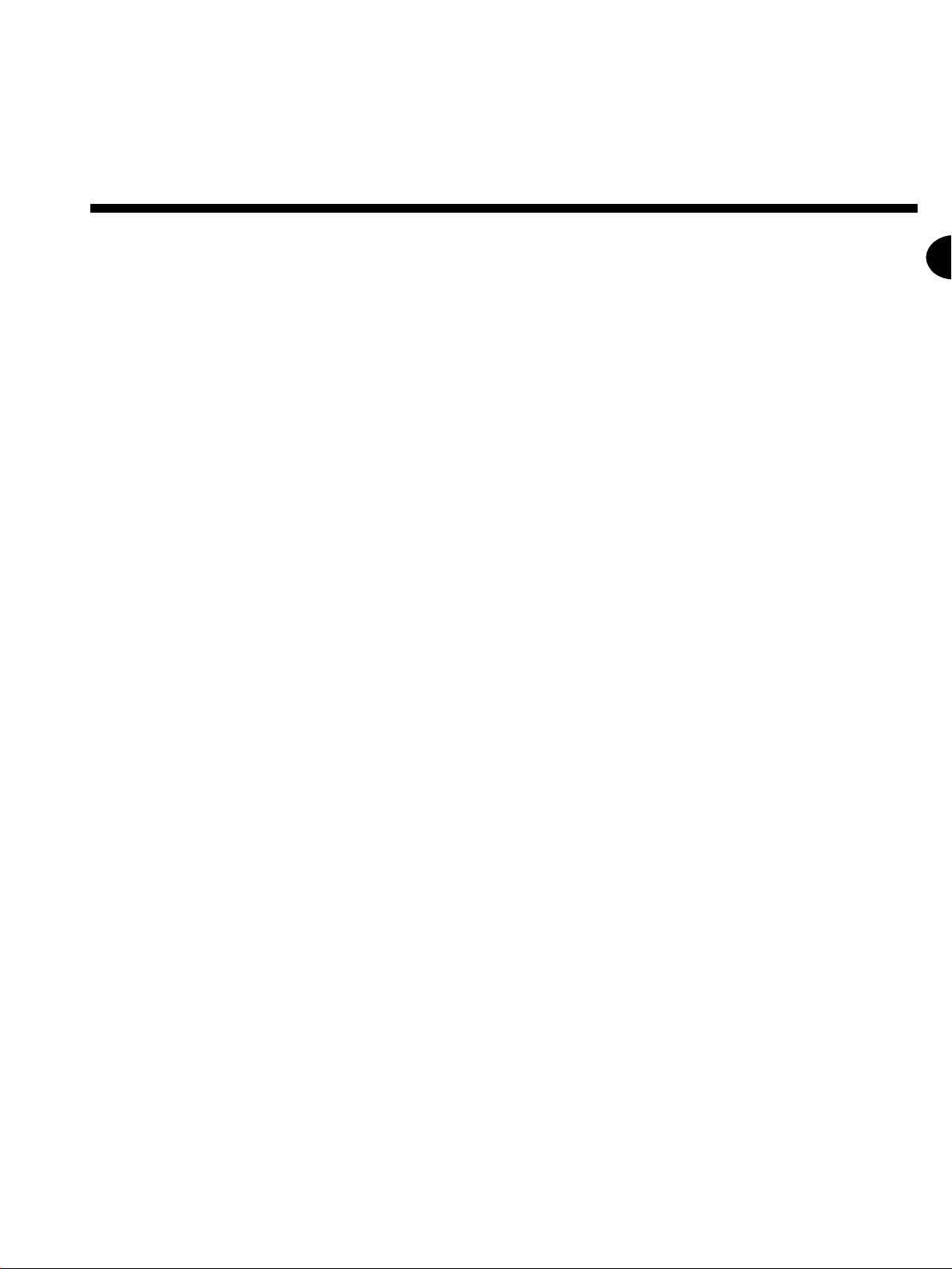

Page 13

LEGACY

Specifications

NOTE:

When any of the following optional parts are installed, add the weight to the curb weight.

Weight of

optional parts

Front kg (lb) 6.5 (14.33) 2.1 (4.6) 13.9 (30.6) 10.9 (24.0) 1.8 (4.0) 2.9 (6.4)

Rear kg (lb) 0.1 (0.22) 0.3 (0.7) –0.1 (–0.2) 16.4 (36.2) 3.1 (6.8) 3.0 (6.6)

Total kg (lb) 6.6 (14.55) 2.4 (5.3) 13.8 (30.4) 27.3 (60.2) 4.9 (10.8) 5.9 (13.0)

Weight of

optional parts

Front kg (lb) 0.2 (0.44) 1.8 (4.0) –0.7 (–1.54) –1.4 (–3.09) 0.2 (0.4)

Rear kg (lb) 0.2 (0.44) 0.7 (1.5) 3.2 (7.06) –3.8 (–8.38) 4.2 (9.3)

Total kg (lb) 0.4 (0.88) 2.5 (5.5) 2.5 (5.51) –5.2 (–11.47) 4.4 (9.7)

VDC Cruise control Air conditioner Sunroof Leather interior SRS Airbag

(Side)

Cold weather pack Audio Rear spoiler Sports package Self-leveling

rear suspension

SPC-9

Page 14

OUTBACK

Specifications

2. OUTBACK

A: DIMENSIONS

Model OUTBACK

AWD

Overall length mm (in) 4,720 (185.8)

Overall width mm (in) 1,745 (68.7)

Overall height (at CW) mm (in) 1,580 (62.2), 1,590 (62.6)*3

Compartment Length mm (in) 1,925 (75.8)

Width mm (in) 1,440 (56.7), 1,420 (55.9)*1

Height mm (in) 1,190 (46.9), 1,175 (46.3)*2

Wheelbase mm (in) 2,650 (104.3)

Tread Front mm (in) 1,470 (57.9)

Rear mm (in) 1,460 (57.5)*3, 1,465 (57.7)

Minimum road

clearance

Without catalytic

converter

With catalytic

converter

Australia mm (in) 200 (7.9)

mm (in) 195 (7.7)

mm (in) 190 (7.5)

*1: With leather seat

*2: With sunroof

*3: Australia spec. vehicles

B: ENGINE

Model OUTBACK

AWD

2.5 L 3.0 L

Engine type Horizontally opposed, liquid cooled,

4-cylinder, 4-stroke gasoline engine

Valve arrangement Overhead camshaft type Double overhead camshaft type

Bore × Stroke mm (in) 99.5 × 79.0 (3.917 × 3.110) 89.2 × 80.0 (3.512 × 3.150)

Displacement cm

Compression ratio 10.0 10.7

Firing order 1 — 3 — 2 — 41 — 6 — 3 — 2 — 5 — 4

Idle speed at Park/Neutral

position

Maximum output kW (HP)/rpm 115 (154)/5,600 154 (206)/6,000

Maximum torque N·m (kgf-m, ft-lb)/rpm 223 (22.7, 164.2)/3,600 282 (28.8, 208)/4,400

3

(cu in) 2,457 (149.9) 3,000 (183.06)

rpm 700±100 600±100

Horizontally opposed, liquid cooled,

6-cylinder, 4-stroke gasoline engine

SPC-10

Page 15

OUTBACK

Specifications

C: ELECTRICAL

Model OUTBACK

AWD

2.5 L 3.0 L

Ignition timing at idling speed BTDC/rpm 10°±10°/700 10°±8°/600

Spark plug Type and manufacturer RC10YC4 ....... CHAMPION PLFR6A ....... NGK

Alternate RC8YC4 ....... CHAMPION

Generator 12V — 90A 12V — 100A

Battery Type and capacity (5HR) For Europe and

South America

Others 12V — 27AH (34B19L) 12V — 48H (55D23L)

BKR6E-11 ....... NGK

K20PR-U11 ....... NIPPONDENSO

MT: 12V — 48AH (55D23L)

AT: 1 2V — 52AH (75D23L)

12V — 52AH (75D23L)

D: TRANSMISSION

Model OUTBACK

AWD

2.5 L 3.0 L

Transmission type 5MT 4AT 4AT

Clutch type DSPD TCC TCC

Gear ratio 1st 3.454 2.785

2nd 2.062 1.545

3rd 1.448 1.000

4th 1.088 0.694

5th 0.825 —

Reverse 3.333 2.272

Auxiliary transmission gear ratio High 1.000 —

Low 1.196 —

Reduction gear

(Front drive)

Reduction gear

(Rear drive)

1st reduction Type of gear — Helical

Gear ratio — 1.000

Final reduction Type of gear Hypoid Hypoid

Gear ratio 3.900*1, 4.111*2 4.444 4.111

Tr a n sf e r

reduction

Final reduction Type of gear Hypoid Hypoid

Type of gear Helical —

Gear ratio 1.000 —

Gear ratio 3.900*1, 4.111*2 4.444 4.111

5MT: 5 × 2 forward speeds with synchromesh and 1-reverse

4AT: Electronically controlled fully-automatic, 4-forward speeds and 1-reverse

DSPD: Dry Single Plate Diaphragm

TCC: Torque Converter Clutch

*1: Except Australia spec. vehicles

*2: Australia spec. vehicles

SPC-11

Page 16

OUTBACK

Specifications

E: STEERING

Model OUTBACK

Ty pe Rack and Pinion

Turns, lock to lock 3.0

Minimum turning circle m (ft) Curb to curb: 11.2±1.0 (36.7±3.3)

Wall to wall: 12.0±1.0 (39.4±3.3)

F: SUSPENSION

Model OUTBACK

Front Macpherson strut type, Independent, Coil spring

Rear Multi-link type, Independent, Coil spring

G: BRAKE

Model OUTBACK

Service brake system Dual circuit hydraulic with vacuum suspended power unit

Front Ventilated disc brake

Rear Disc brake

Parking brake Mechanical on rear brakes

H: TIRE

Model OUTBACK

Rim size 16 × 6½JJ

Tire size 215/60R16

Type Steel belted radial, Tubeless

I: CAPACITY

Model OUTBACK

AWD

2.5 L 3.0 L

5MT 4AT

Fuel tank (US gal, Imp gal) 64 (16.9, 14.1)

Engine oil Total capacity (US qt, Imp qt) 4.0 (4.2, 3.5) 6.8 (7.2, 6.0)

Engine oil

amount for refill

Transmission gear oil (US qt, Imp qt) 4.0 (4.2, 3.5) —

Automatic transmission fluid (US qt, Imp qt) — 9.3 – 9.6 (9.8 – 10.1, 8.2 – 8.4)

AT differential gear oil (US qt, Imp qt) — 1.1 – 1.3 (1.2 – 1.4, 1.0 – 1.1)

AWD rear differential gear oil (US qt, Imp qt) 0.8 (0.8, 0.7)

Power steering fluid (US qt, Imp qt) 0.7 (0.7, 0.6)

Engine coolant (US qt, Imp qt) 6.8 (7.2, 6.0) 6.7 (7.1, 5.9) 7.7 (8.1, 6.8)

(US qt, Imp qt) Approx. 4.0 (4.2, 3.5) Approx. 5.8 (6.1, 5.1)

SPC-12

Page 17

OUTBACK

Specifications

J: WEIGHT

1. OUTBACK

! LHD Vehicle

Option code *1 K4 KS KO

Model 2.5 L

4WD

5MT 4AT 5MT 4AT

Curb weight (C.W.) Front kg (lb) 810 (1,785) 825 (1,820) 815 (1,795) 830 (1,830) 785 (1,730)

Rear kg (lb) 670 (1,475) 670 (1,475) 670 (1,475) 670 (1,475) 650 (1,435)

Total kg (lb) 1,480 (3,265) 1,495 (3,295) 1,485 (3,275) 1,500 (3,310) 1,435 (3,165)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag —————

Front kg (lb) 995 (2,195) 995 (2,195) 995 (2,195) 995 (2,195) 960 (2,115)

Rear kg (lb) 1,050 (2,315) 1,050 (2,315) 1,050 (2,315) 1,050 (2,315) 1,030 (2,270)

Total kg (lb) 2,000 (4,410) 2,000 (4,410) 2,000 (4,410) 2,000 (4,410) 1,920 (4,235)

Air conditioner

Audio ——

Cruise control

Cold weather pack —————

Leather interior ————

Sunroof ————

Option code *1 EC

Model 2.5 L 3.0 L

4WD

5MT 4AT

Curb weight (C.W.) Front kg (lb) 815 (1,795) 830 (1,830) 915 (2,020)

Rear kg (lb) 675 (1,490) 675 (1,490) 695 (1,530)

Total kg (lb) 1,490 (3,285) 1,505 (3,320) 1,610 (3,550)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag

*1: For option code, refer to ID section. <Ref. to ID-5, MODEL NUMBER PLATE, IDENTIFICATION, Identification.>

Front kg (lb) 1,010 (2,225) 1,010 (2,225) 1,040 (2,295)

Rear kg (lb) 1,060 (2,335) 1,060 (2,335) 1,060 (2,335)

Total kg (lb) 2,015 (4,445) 2,015 (4,445) 2,085 (4,595)

Air conditioner

Audio ——

Cruise control ——

Cold weather pack ——

Leather interior ——

Sunroof ——

SPC-13

Page 18

OUTBACK

Specifications

! RHD Vehicle

Option code *1 EK

Model 2.5 L 3.0 L

4WD

5MT 4AT

Curb weight (C.W.) Front kg (lb) 800 (1,765) 815 (1,795) 915 (2,020)

Rear kg (lb) 670 (1,475) 670 (1,475) 695 (1,530)

Total kg (lb) 1,470 (3,240) 1,485 (3,275) 1,610 (3,550)

Maximum permissible

axle weight (M.P.A.W.)

Maximum permissible

weight (M.P.W.)

Option Side airbag ——

Front kg (lb) 1,010 (2,225) 1,010 (2,225) 1,040 (2,295)

Rear kg (lb) 1,060 (2,335) 1,060 (2,335) 1,060 (2,335)

Total kg (lb) 2,015 (4,445) 2,015 (4,445) 2,085 (4,595)

Air conditioner ——

Audio

Cruise control ——

Cold weather pack ——

Leather interior ——

Sunroof ——

Option code *1 KA

Model 2.5 L 3.0 L

4WD

5MT 4AT

Unladen mass (U.M.) Front kg (lb) 790 (1,740) 800 (1,765) 900 (1,985)

Rear kg (lb) 650 (1,435) 650 (1,435) 690 (1,520)

Total kg (lb) 1,440 (3,175) 1,410 (3,110) 1,590 (3,505)

Gross vehicle mass

(G.V.M.)

Option Side airbag ——

*1: For option code, refer to ID section. <Ref. to ID-5, MODEL NUMBER PLATE, IDENTIFICATION, Identification.>

Front kg (lb) 970 (2,140) 970 (2,140) 1,035 (2,280)

Rear kg (lb) 1,050 (2,315) 1,050 (2,315) 1,050 (2,315)

Total kg (lb) 2,020 (4,455) 2,020 (4,455) 2,085 (4,595)

Air conditioner ——

Audio

Cruise control ——

Cold weather pack ——

SPC-14

Page 19

OUTBACK

Specifications

NOTE:

When any of the following optional parts are installed, add the weight to the curb weight.

Weight of

optional parts

Front kg (lb) 2.1 (4.6) 0.2 (0.4) 13.9 (30.6) 10.9 (24.0) 1.8 (4.0)

Rear kg (lb) 0.3 (0.7) 4.2 (9.3) –0.1 (–0.2) 16.4 (36.2) 3.1 (6.8)

Total kg (lb) 2.4 (5.3) 4.4 (9.7) 13.8 (30.4) 27.3 (60.2) 4.9 (10.8)

Weight of

optional parts

Front kg (lb) 2.9 (6.4) 0.2 (0.44) 1.8 (4.0) –0.7 (–1.54) –1.4 (–3.09)

Rear kg (lb) 3.0 (6.6) 0.2 (0.44) 0.7 (1.5) 3.2 (7.06) –3.8 (–8.38)

Total kg (lb) 5.9 (13.0) 0.4 (0.88) 2.5 (5.5) 2.5 (5.51) –5.2 (–11.47)

Cruise control Self

levelizer

SRS Airbag (Side) Cold weather pack Audio Rear spoiler Sports package

Air conditioner Sunroof Leather interior

SPC-15

Page 20

Specifications

MEMO

OUTBACK

SPC-16

Page 21

FUEL INJECTION (FUEL SYSTEM) FU

Page

1. General ............................................................................................................ 2

2. Air Line ............................................................................................................ 3

3. Fuel Line .......................................................................................................... 8

4. Sensors and Switches .....................................................................................19

5. Control System ................................................................................................ 30

6. On-board Diagnosis System ...........................................................................38

Page 22

GENERAL

Fuel Injection (Fuel System)

1. General

! The Multipoint Fuel Injection (MFI) system supplies optimum air-fuel mixture under every engine

operating condition through the use of the latest electronic control technology.

This system pressurizes the fuel to a constant pressure and injects it into each intake air port in

the cylinder head. The injection quantity of fuel is controlled by an intermittent injection system

where an electro-magnetic injection valve or injector opens for a short period that is precisely controlled depending on the quantity of air appropriate for each condition of operation. In actual control, an optimum fuel injection quantity is achieved by varying the duration of an electric pulse

applied to the injector. This way of control enables simple, yet highly precise metering of the fuel.

! The engine control module (ECM) that controls the fuel injection system corrects the fuel injec-

tion amount depending on the vehicle speed, throttle opening, coolant temperature and other vehicle-operation-related information. The ECM receives the information in the form of electric

signals from the corresponding sensors and switches.

The MFI system also has the following features:

! Reduced exhaust emissions

! Reduced fuel consumption

! Increased engine output

! Quick response to accelerator and brake pedal operation

! Superior startability and warm-up performance in cold weather due to corrective controls made

according to coolant and intake air temperatures

FU-2

Page 23

AIR LINE

Fuel Injection (Fuel System)

2. Air Line

A: GENERAL

The air filtered by the air cleaner enters the throttle body where it is regulated in the volume by the

throttle valve and then enters the intake manifold. It is then distributed to each cylinder where the

air is mixed with fuel injected by the injector. During idling operation, air flows into the cylinder

through the idle air control solenoid valve, bypassing the throttle valve. This enables controlling the

engine idling speed properly.

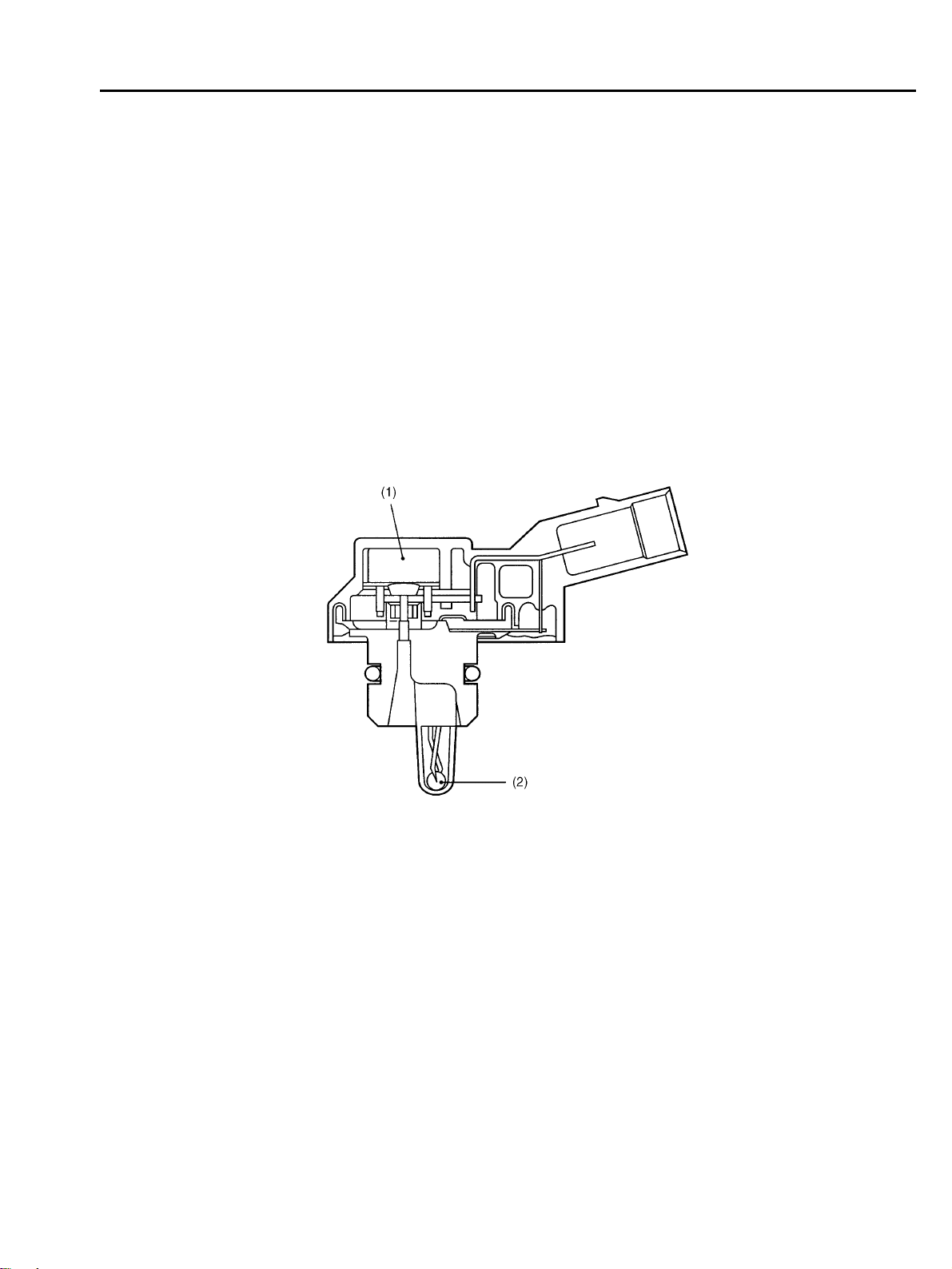

B: INTAKE MANIFOLD PRESSURE AND AIR TEMPERATURE SENSORS

The intake manifold pressure sensor and the intake air temperature sensor are integrated into a

single unit. The unit is mounted on the intake manifold and measures the absolute air pressure in

the intake manifold as well as the temperature of the intake air.

The measured pressure and temperature are converted into electrical signals and sent to the

ECM. The ECM uses these signals to control injection and ignition timing as well as the fuel injection amount.

(1) Pressure sensor

(2) Intake air temperature sensor

H2H2825B

FU-3

Page 24

AIR LINE

Fuel Injection (Fuel System)

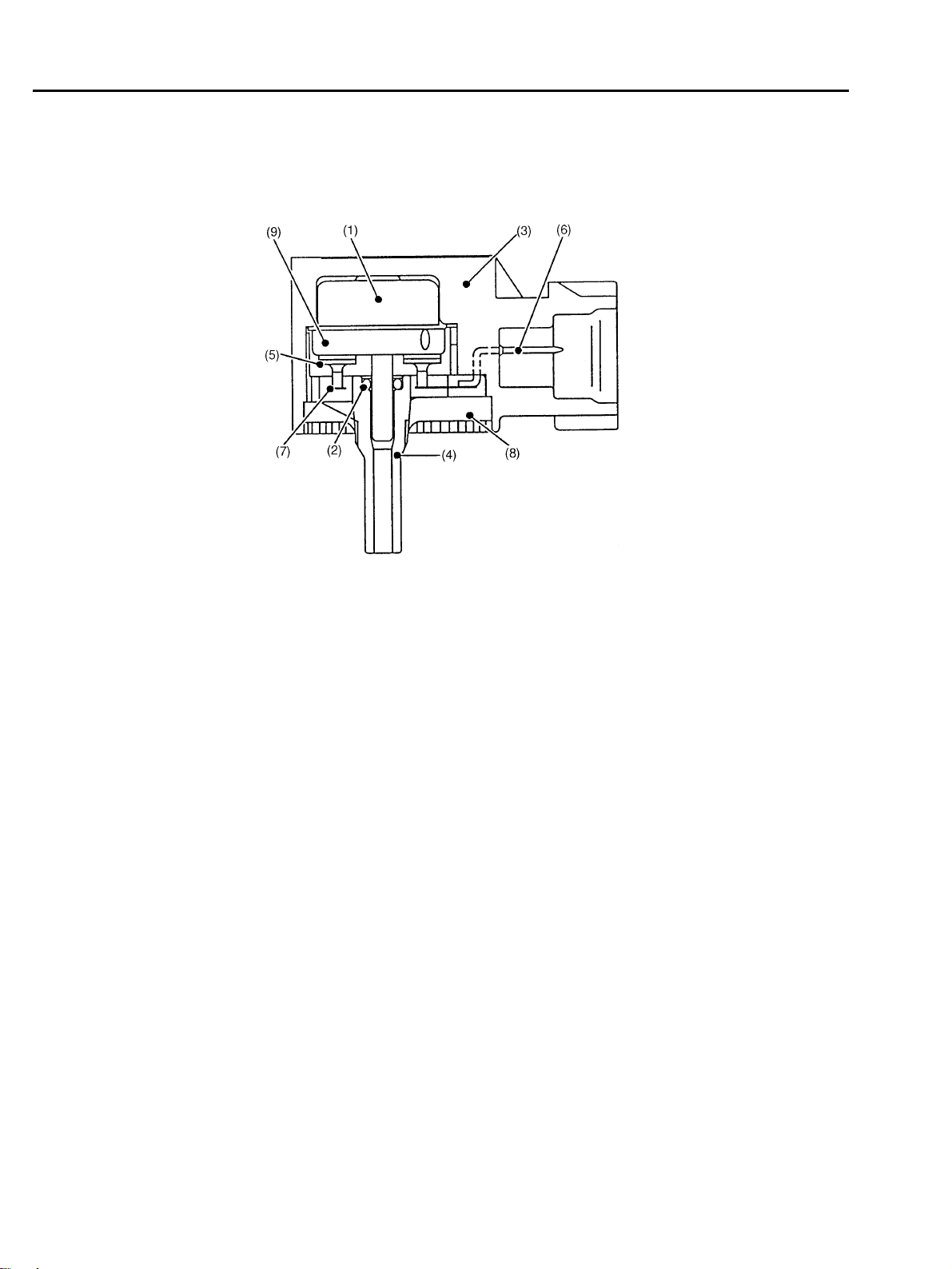

C: ATMOSPHERIC PRESSURE SENSOR

The atmospheric pressure sensor converts pressure values into electric signals, and sends the

signals to the ECM.

H2H1869B

(1) Sensor unit (6) Terminal

(2) O-ring (7) Inner lead

(3) Case (8) Resin

(4) Pipe (9) Metal lid

(5) Through capacity

D: THROTTLE BODY

In response to operation of the accelerator pedal, the throttle valve in the throttle body opens/closes to regulate the volume of the air drawn into the combustion chamber.

During idling, the throttle valve is almost fully closed and the volume of air passing through the

throttle body is less than that passing through the idle air control solenoid valve.

More than half of the air necessary for idling is supplied to the intake manifold via the idle air control solenoid valve which controls properly the engine idling speed, so the idling speed needs not

be adjusted.

FU-4

Page 25

AIR LINE

Fuel Injection (Fuel System)

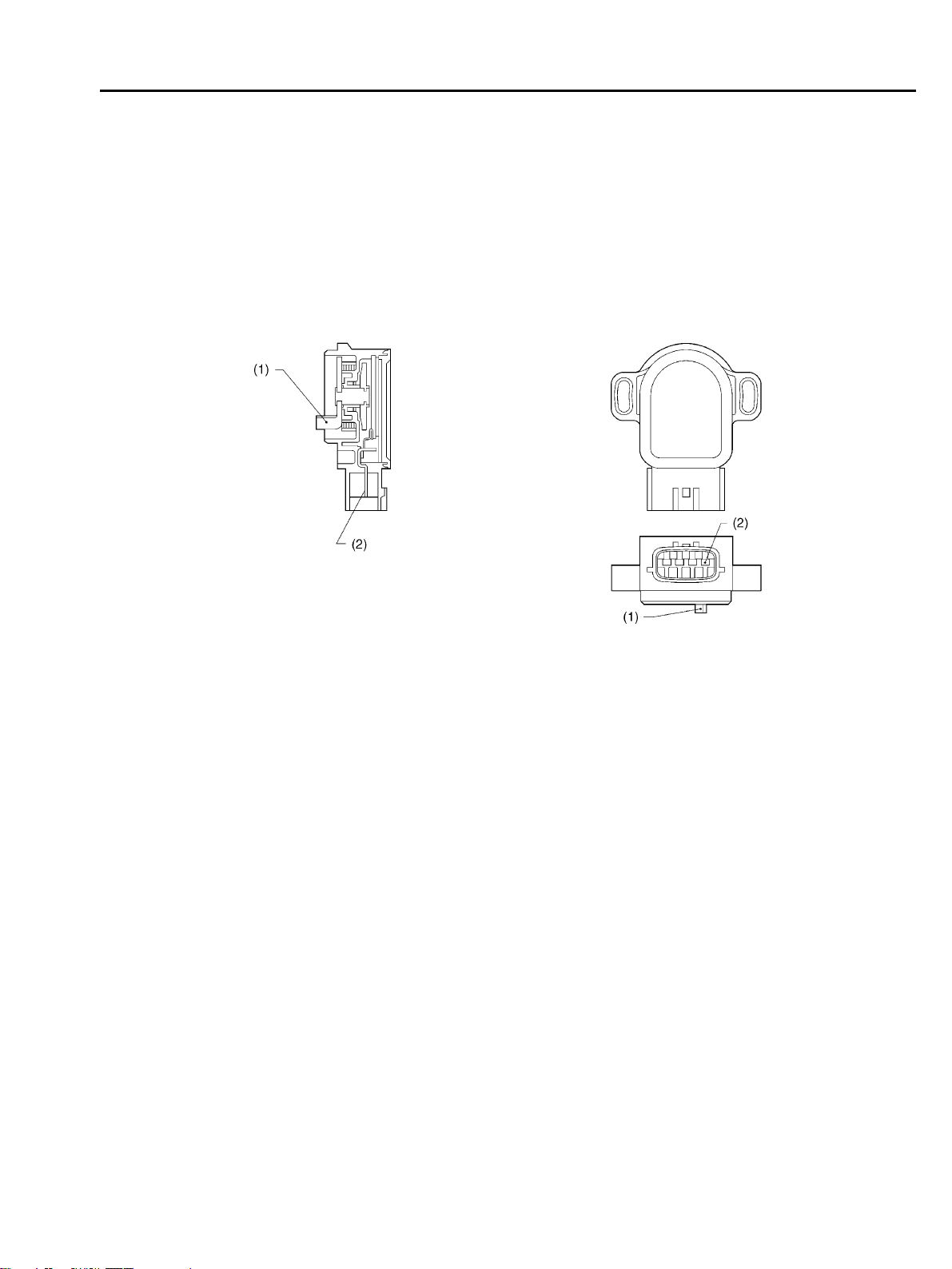

E: THROTTLE POSITION SENSOR

! The throttle position sensor is mounted in the throttle body and linked to the throttle valve.

! The throttle position sensor sends the ECM voltage signal corresponding to the opening of the

throttle valve. When the sensor’s output voltage exceeds a predetermined level, the ECM interprets it as complete closure of the throttle valve. When the output voltage is at another predetermined level, the ECM recognizes that the throttle valve is at a wide open position. Since the output

characteristics of the sensor change over years, the ECM is provided with a learning function to

be able to interpret signals into throttle valve angles always correctly.

(1) Lever

(2) Terminal

B2H2004B

FU-5

Page 26

AIR LINE

Fuel Injection (Fuel System)

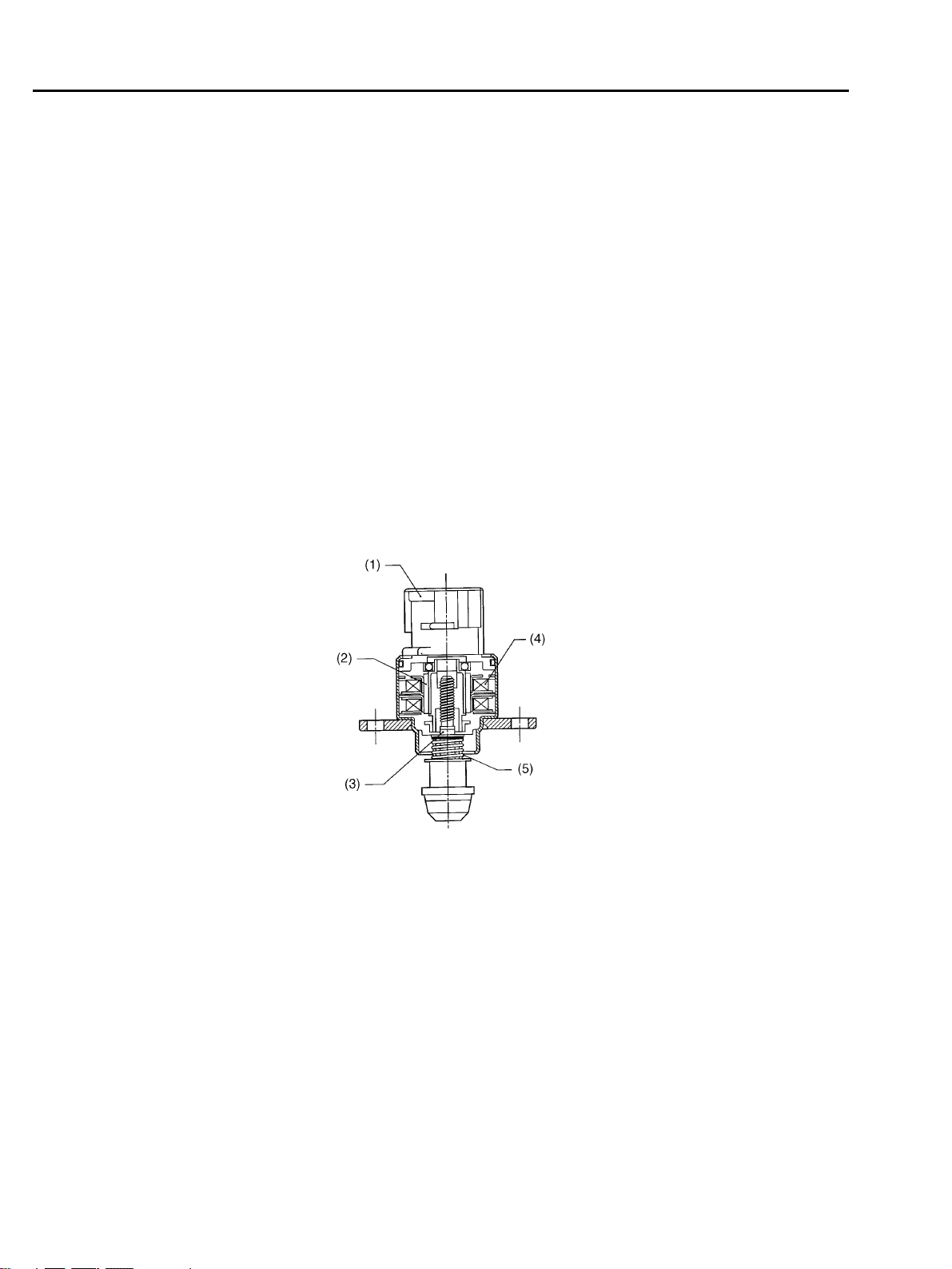

F: IDLE AIR CONTROL SOLENOID VALVE

! The idle air control solenoid valve is located in the throttle body and regulates the amount of

intake air that flows bypassing the throttle valve into the intake manifold during engine idling. It is

activated by a signal from the ECM in order to maintain the engine idling speed at a target speed.

! The idle air control solenoid valve is a stepping motor type solenoid-actuated valve which con-

sists of coils, a shaft, a permanent magnet, a spring and a housing. The housing is an integral part

of the throttle body.

! The stepping motor consists of two paired coils, the coils of each pair being arranged face to

face with a shaft in between.

! The shaft has a screw at the end around which the permanent magnets are arranged.

! As current flows in the form of pulses through the paired coils sequentially while alternating the

polarity, the N and S poles of the permanent magnets around the shaft are repelled by the same

poles of the magnetism generated by the coils. This causes a nut externally fixed to the magnets

and internally engaging with the screw of the shaft to turn.

The shaft then goes upward or downward.

! This upward and downward motions of the shaft open or close the valve port, adjusting the

amount of bypass air.

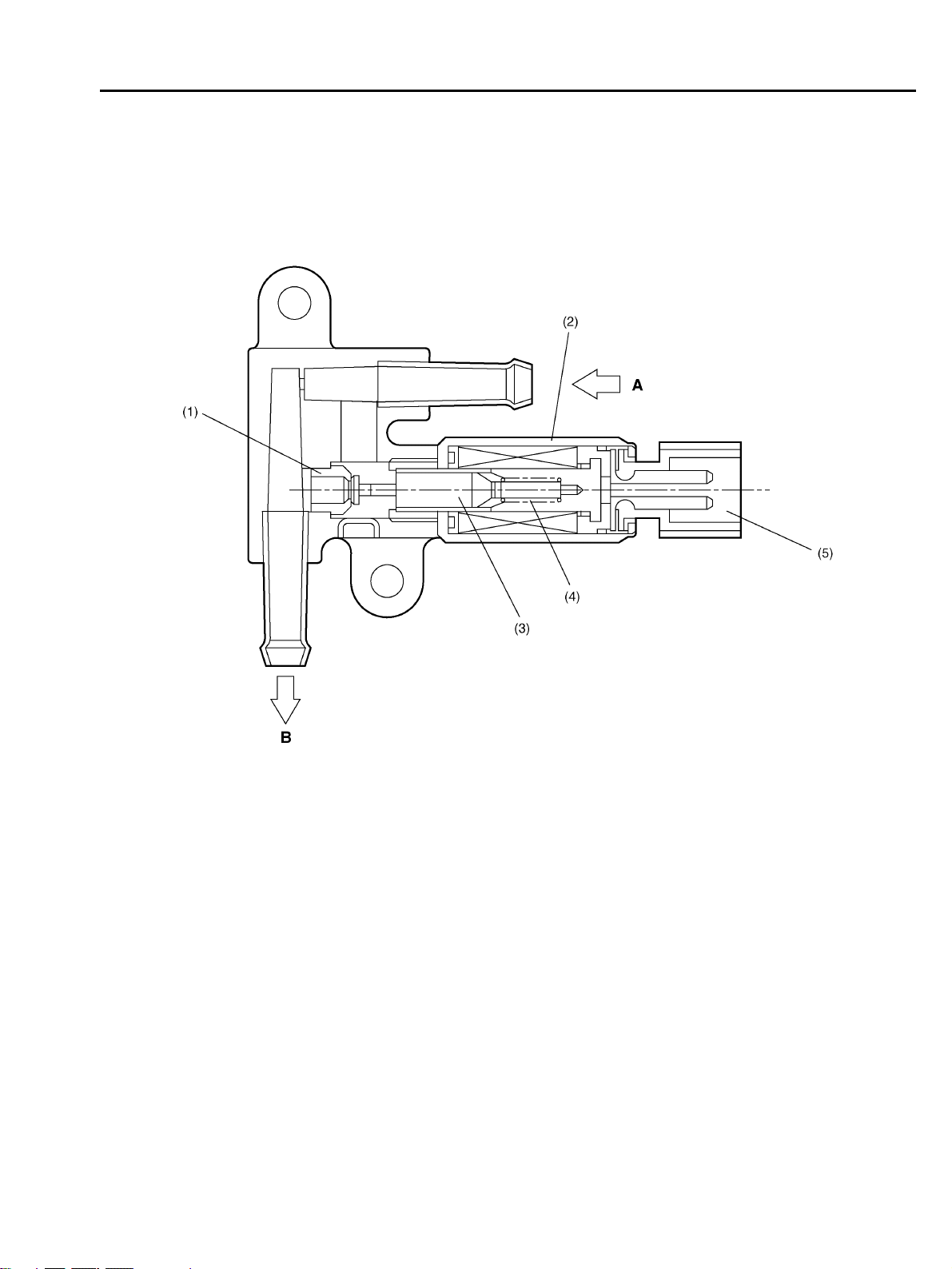

(1) Connector

(2) Permanent magnet

(3) Shaft

(4) Coil

(5) Spring

B2H2005B

FU-6

Page 27

AIR LINE

Fuel Injection (Fuel System)

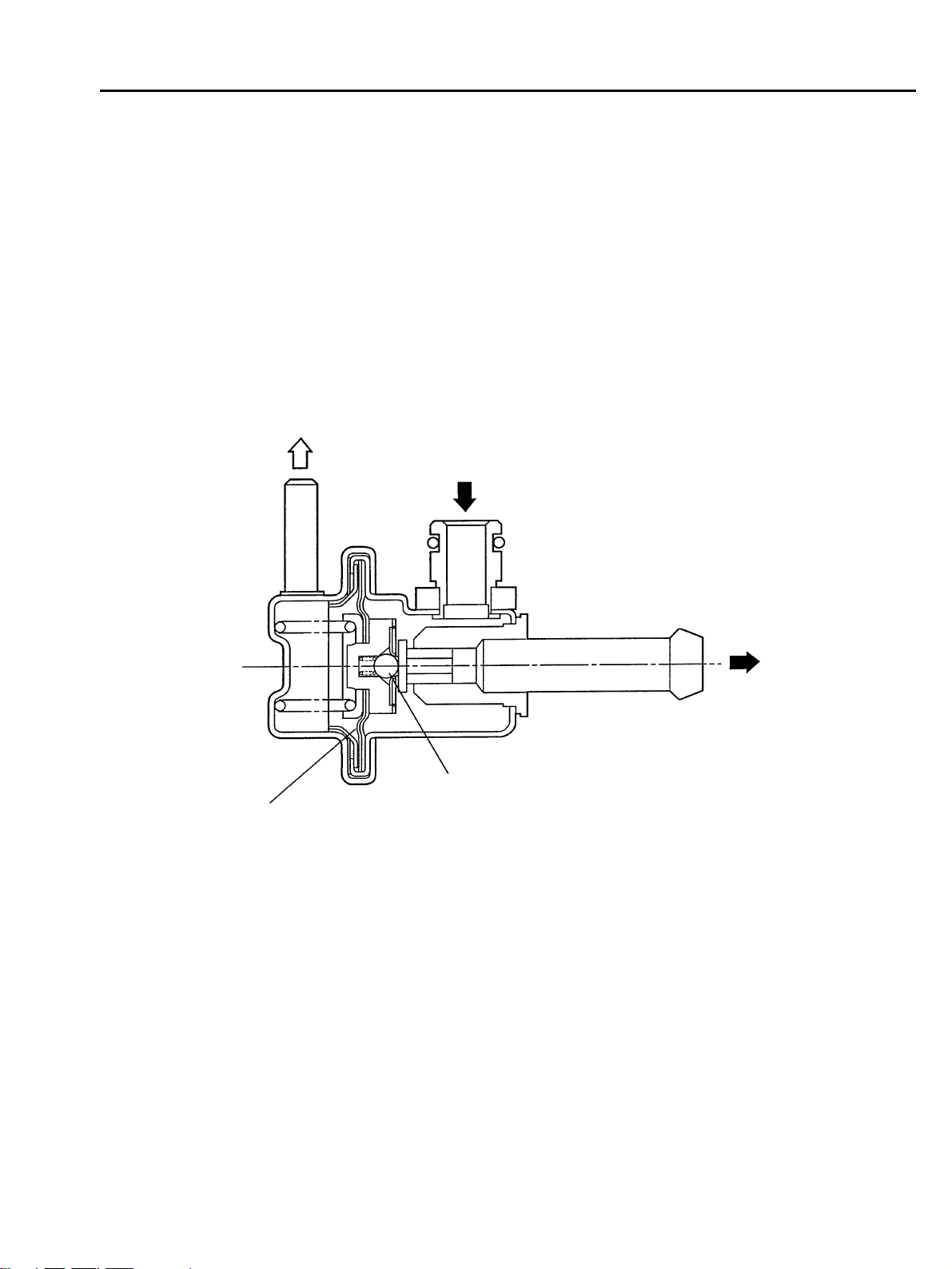

G: AIR ASSIST INJECTOR SOLENOID VALVE

The air assist injector solenoid valve is located in the piping between the throttle body and the injector and secured to the intake manifold.

This solenoid valve is opened or closed by the signals from the ECM, adjusting the flow rate of air

supplied to the injector.

(1) Valve seat A: From idle air control solenoid valve

(2) Solenoid B: To inj ec to r

(3) Plunger and valve

(4) Spring

(5) Connector

FU-7

B2H3447B

Page 28

FUEL LINE

Fuel Injection (Fuel System)

3. Fuel Line

A: GENERAL

! The fuel pressurized by the fuel tank inside pump is delivered to each fuel injector by way of the

fuel pipe and fuel filter. Fuel injection pressure is regulated to an optimum level by the pressure

regulator.

! Each injector injects fuel into the intake port of the corresponding cylinder where the fuel is

mixed with air. The mixture then enters the cylinder.

Fuel injection amount and timing are regulated by the ECM.

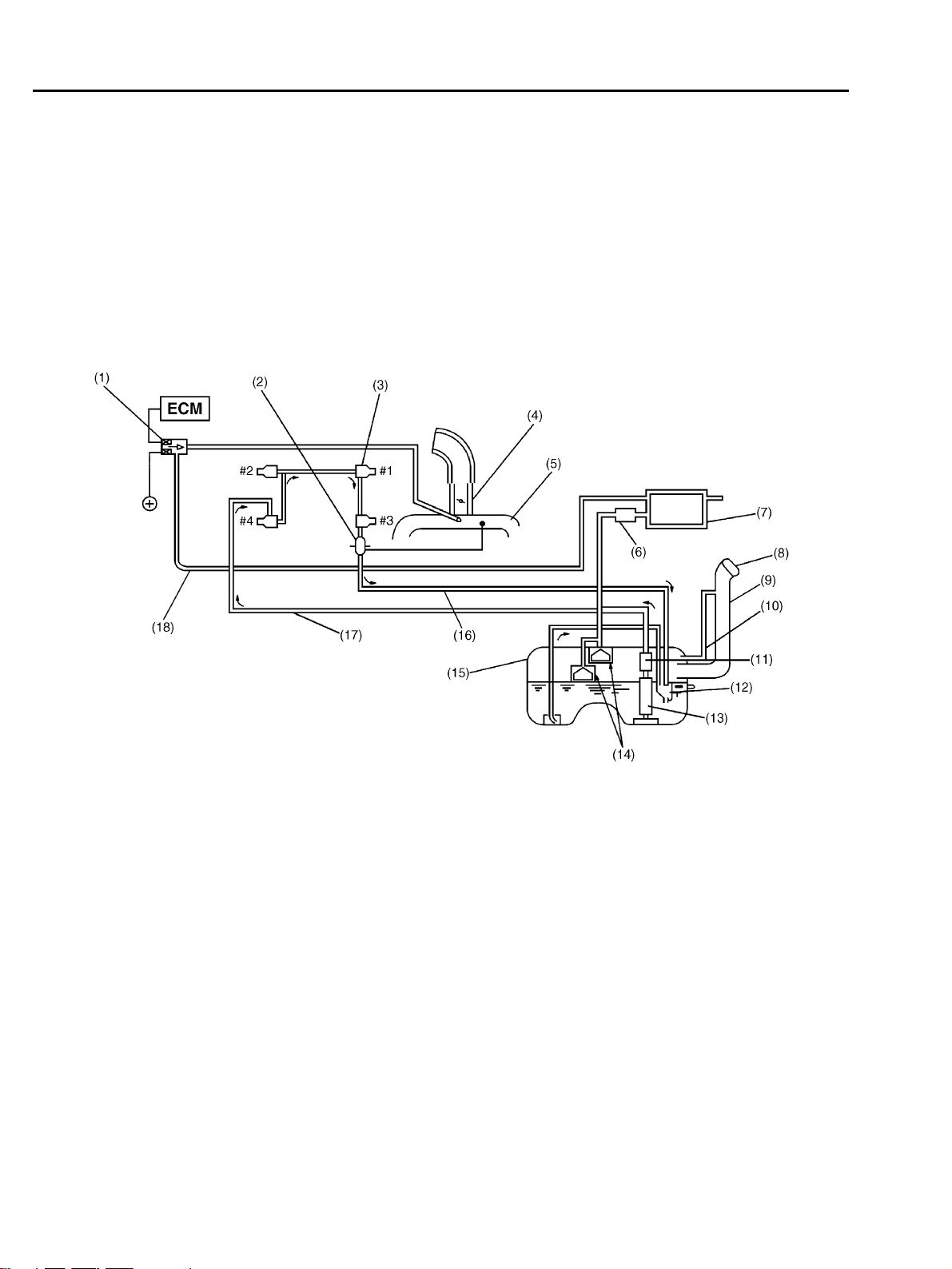

(1) Purge control solenoid valve (10) Air vent pipe

(2) Pressure regulator (11) Fuel filter

(3) Fuel injector (12) Jet pump

(4) Throttle body (13) Fuel pump

(5) Intake manifold (14) Fuel cut valve

(6) Two-way valve (15) Fuel tank

(7) Canister (16) Fuel return line

(8) Filler cap (17) Fuel delivery line

(9) Filler pipe (18) Fuel evaporation line

FU-8

B2H2907B

Page 29

FUEL LINE

Fuel Injection (Fuel System)

B: PRESSURE REGULATOR

The pressure regulator is installed at the injector end of the fuel supply line. It has a fuel chamber

and spring chamber separated by a diaphragm. Fuel chamber is connected to the fuel supply line

and the spring chamber is connected to the intake manifold. Fuel chamber also has a relief valve

connected to the fuel return line through which fuel returns to the fuel tank. When the intake manifold vacuum increases, the diaphragm is pulled and the relief valve opens to decrease the fuel

supply line pressure (or fuel injection pressure). When the intake manifold vacuum decreases, the

diaphragm is pushed by the spring to increase the fuel supply line pressure. Thus, the difference

between the fuel injection pressure and the intake manifold vacuum is kept at a constant level of

294 kPa (3.00 kgf/cm

hicles to precisely control the amount of injected fuel.

2

, 43.0 psi) for MT vehicles or 299.1 kPa (3.05 kgf/cm2, 43.4 psi) for AT ve-

A

B

(1)

(2)

(1) Relief valve A: To intake manifold

(2) Diaphragm B: Fuel IN

C: Fuel OUT

C

S2H0623C

FU-9

Page 30

FUEL LINE

Fuel Injection (Fuel System)

C: FUEL INJECTORS

! The MFI system employs top feed type fuel injectors with an air assist feature.

! Each injector is installed in the fuel pipe in such a way that the injector is cooled by fuel.

! The features of this type of fuel injector are as follows:

1) High heat resistance

2) Low driving noise

3) Easy to service

4) Small size

! The injector injects fuel according to the valve open signal from the ECM. The needle valve is

lifted by the solenoid which is energized on arrival of the valve open signal.

! Since the injector’s nozzle hole area, the lift of valve and the fuel pressure are kept constant,

the amount of fuel injected is controlled only by varying the duration of the valve open signal from

the ECM.

! Fuel atomization is enhanced using assist air supplied from the idle air control solenoid valve

passing through the passage formed in the intake manifold at the area in which each injector is

installed. This contributes not only to higher combustion efficiency and higher output but also to

cleaner exhaust emissions.

FU-10

Page 31

FUEL LINE

Fuel Injection (Fuel System)

(1) Filter (4) Seal

(2) O-ring (5) O-ring

(3) Plunger (6) Connector

S2H1943A

FU-11

Page 32

FUEL LINE

Fuel Injection (Fuel System)

D: FUEL TANK

The fuel tank utilizes a two-compartment design to ensure sufficient capacity without interfering

with the rear differential. It is provided with a suction jet pump (included in the fuel pump and fuel

level sensor assembly) which transfers fuel from one compartment to the other. Each compartment has an individual fuel level sensor.

(5)

(1)

(6)

A

(2)

(3)

(4)

(1) Fuel pump and fuel level sensor assembly (5) Quick connector

(2) Nylon tube (6) Fuel cut valve (Main compartment)

(3) Fuel cut valve (Sub-compartment)

(4) Fuel level sensor (Sub-compartment) A: To two way valve

(5)

B2H2908C

FU-12

Page 33

FUEL LINE

Fuel Injection (Fuel System)

The fuel tank is located under the rear seat and secured with hold-down bands.

(1)

(2)

(1) Band

(2) Cushion

(3) Steel

(3)

B2H2913C

FU-13

Page 34

FUEL LINE

Fuel Injection (Fuel System)

E: FUEL PUMP AND FUEL LEVEL SENSOR ASSEMBLY

1. FUEL PUMP

The fuel pump consists of a motor, impeller, pump casing, pump cover, check valve and filter. It is

located in the fuel tank and combined with the fuel level sensor into a single unit. The operation of

this impeller type pump is very quiet.

E

B

A

C

(1)

(2)

(3)

(7)

(8)

(9)

(1) Fuel level sensor (7) Pump casing A: To engine (delivery line)

(2) Fuel pump (8) Fuel passage B: From engine (return line)

(3) Pump cover (9) Impeller C: From sub tank

(4) Jet pump (10) Motor armature D: Suction

(5) Cartridge filter (11) Check valve E: Discharge

(6) Mesh filter

(4)

(5)

(6)

D

(10)

(7)

(11)

(9)

D

B2H2909C

FU-14

Page 35

FUEL LINE

Fuel Injection (Fuel System)

! When the ignition switch is turned ON, fuel pump relay is activated. Then the motor operates to

rotate the impeller.

! As the impeller rotates, fuel in a vane groove of the impeller flows along the fuel passage into

the next vane groove by centrifugal force. When fuel flows from one groove to the next, a pressure

difference occurs due to friction. This creates a pumping effect.

! The fuel pushed up by rotation of the impeller then passes through the clearance between the

armature and the magnet of the motor and is discharged through the check valve.

! When the fuel discharge pressure reaches the specified level, the relief valve opens and excess

fuel is released into the fuel tank. In this manner, the relief valve prevents an abnormal increase

in fuel pressure.

! When the engine and the fuel pump stop, spring force acts on the check valve to close the dis-

charge port, so that the fuel pressure in the fuel delivery line is retained.

FU-15

Page 36

FUEL LINE

Fuel Injection (Fuel System)

2. JET PUMP

! The jet pump utilizes the velocity of fuel returning from the engine to produce negative pressure

in it.

! Using the pumping effect produced by the negative pressure, the jet pump transfers fuel from

the sub-compartment to the main compartment of the fuel tank.

! When the return line nozzle is clogged, the fuel sent back through the return line flows back into

the fuel tank via the relief valve.

(1)

B

(1)

A

(2)

(3)

(4)

A

(1) Jet pump A: Return line

(2) Relief valve B: From sub tank compartment

(3) Silencer

(4) Nozzle

FU-16

B2H2911C

Page 37

FUEL LINE

Fuel Injection (Fuel System)

3. FUEL FILTERS

There are two different types of fuel filters inside fuel tank, forming integral part of the fuel pump.

The filter at the inlet of the fuel pump is a mesh type which removes relatively large particles in the

fuel before it enters the pump. The filter at the outlet of the pump is a pressure resistant cartridge

type whose inside filtering element can remove small particles in the pressurized fuel.

(1)

(2)

(3)

(1) Fuel pump

(2) Cartridge filter

(3) Mesh filter

B2H2910D

FU-17

Page 38

FUEL LINE

Fuel Injection (Fuel System)

F: SUB-COMPARTMENT FUEL LEVEL SENSOR

This sensor detects the level of the fuel in the sub-compartment (the compartment in which the

fuel pump is not located) and acts as part of the fuel transfer line when the jet pump is in operation

to maintain the fuel in both compartments at the same level.

(3)

(1)

(2)

(1) Fuel level sensor (Sub) (3) To jet pump

(2) Float

B2H2912B

FU-18

Page 39

SENSORS AND SWITCHES

4. Sensors and Switches

A: FRONT OXYGEN (A/F) SENSOR

Fuel Injection (Fuel System)

! The front oxygen sensor uses zirconium oxide (ZrO

) which is a solid electrolyte, at portions ex-

2

posed to exhaust gas.

! The zirconium oxide has the property of generating electromotive force when its both sides are

exposed to oxygen ions of different concentration and the magnitude of this electromotive force

depends on how much the difference is.

! The front oxygen sensor detects the amount of oxygen in exhaust gases by making use of this

property of the zirconium oxide material.

! The zirconium oxide material is formed into a closed end tube and its external surface is ex-

posed to exhaust gases with smaller oxygen ion concentration, whereas its internal surface is exposed to atmospheric air. The external surface has a porous platinum coating. The sensor housing

is grounded to the exhaust pipe and the inside is connected to the ECM through the harness to

be able to use the current output from the sensor.

! The sensor incorporates a ceramic heater to improve its performance at low temperatures.

(1) Sensor element

(2) Sensor housing

(3) Protection tube

(4) Gasket

S2H1791B

FU-19

Page 40

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

! When rich air-fuel mixture is burnt in the cylinder, the oxygen in the exhaust gases is almost

completely used in the catalytic reaction by the platinum coating on the external surface of the zirconia tube. This results in a very large difference in the oxygen ion concentration between the inside and outside of the tube, and the electromotive force generated is large.

! When a lean air-fuel mixture is burnt in the cylinder, relatively large amount of oxygen remains

in the exhaust gases even after the catalytic action, and this results in a small difference in the

oxygen ion concentration between the tube’s internal and external surfaces. The electromotive

force in this case is very small.

! The difference in oxygen concentration changes drastically in the vicinity of the stoichiometric

air-fuel ratio, and hence the change in the electromotive force is also large. By using this information, the ECM can determine the air-fuel ratio of the supplied mixture easily. The front oxygen sensor does not generate much electromotive force when the temperature is low. The output

characteristics of the sensor stabilize at a temperature of approximately 700°C (1,292°F).

Atmospheric air

Lean Air-fuel ratio Rich

B2H2006B

FU-20

Page 41

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

B: REAR OXYGEN SENSOR

! The rear oxygen sensor is used to sense oxygen concentration in the exhaust gas. If the air-fuel

ratio is leaner than the stoichiometric ratio in the mixture (i.e., excessive amount of air), the exhaust gas contains more oxygen. To the contrary, if the fuel ratio is richer than the stoichiometric

ratio, the exhaust gas contains almost no oxygen.

! Detecting the oxygen concentration in exhaust gas using the oxygen sensor makes it possible

to determine whether the air-fuel ratio is leaner or richer than the stoichiometry.

! The rear oxygen sensor has a zirconia tube (ceramic) which generates voltage if there is a dif-

ference in oxygen ion concentration between the inside and outside of the tube. Platinum is coated

on the inside and outside of the zirconia tube as a catalysis and electrode material. The sensor

housing is grounded to the exhaust pipe and the inside is connected to the ECM through the harness.

! A ceramic heater is employed to improve performance at low temperatures.

(1) Protection tube (4) Gasket

(2) Ceramic heater (5) Sensor housing

(3) Zirconia tube (6) Harness

B2H3810C

FU-21

Page 42

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

! When rich air-fuel mixture is burnt in the cylinder, the oxygen in the exhaust gases is almost

completely used in the catalytic reaction by the platinum coating on the external surface of the zirconia tube. This results in a very large difference in the oxygen ion concentration between the inside and outside of the tube, and the electromotive force generated is large.

! When a lean air-fuel mixture is burnt in the cylinder, relatively large amount of oxygen remains

in the exhaust gases even after the catalytic action, and this results in a small difference in the

oxygen ion concentration between the tube’s internal and external surfaces. The electromotive

force in this case is very small.

! The difference in oxygen concentration changes drastically in the vicinity of the stoichiometric

air-fuel ratio, and hence the change in the electromotive force is also large. By using this information, the ECM can determine the air-fuel ratio of the supplied mixture easily. The rear oxygen sensor does not generate much electromotive force when the temperature is low. The output

characteristics of the sensor stabilize at a temperature of approximately 300 to 400°C (572 to

752°F).

To be judged

as lean

Lean Air-fuel ratio

Rich

G2H0038B

FU-22

Page 43

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

C: ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor is located on the engine coolant pipe. The sensor uses a

thermistor whose resistance changes inversely with temperature. Resistance signals as engine

coolant temperature information are transmitted to the ECM to make fuel injection, ignition timing,

purge control solenoid valve and other controls.

(1) Connector (2) Thermistor element

S2H1113B

FU-23

Page 44

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

D: CRANKSHAFT POSITION SENSOR

! The crankshaft position sensor is installed on the oil pump which is located in the front center

portion of the cylinder block. The sensor generates a pulse when one of the teeth on the perimeter

of the crankshaft sprocket (rotating together with the crankshaft) passes in front of it. The ECM

determines the crankshaft angular position by counting the number of pulses.

! The crankshaft position sensor is a molded type which consists of a magnet, core, coil, termi-

nals and other components as illustrated below.

(1) Terminal (4) Coil

(2) Yoke core (5) Core

(3) Magnet (6) Cover

B2H0407B

FU-24

Page 45

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

! As the crankshaft rotates, each tooth aligns with the crankshaft position sensor. At that time, the

magnetic flux in the sensor’s coil changes since the air gap between the sensor pickup and the

sprocket changes. This change in magnetic flux induces a voltage pulse in the sensor and the

pulse is transmitted to the ECM.

(1)

A

(2)

(1) Crankshaft position sensor A: Crankshaft half rotation

(2) Crankshaft sprocket

B2H1995C

FU-25

Page 46

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

E: CAMSHAFT POSITION SENSOR

! The camshaft position sensor is located on the left-hand camshaft support. It detects the com-

bustion cylinder at any given moment.

! The sensor generates a pulse when one of the bosses on the back of the left-hand camshaft

drive sprocket passes in front of the sensor. The ECM determines the camshaft angular position

by counting the number of pulses.

Internal construction and the basic operating principle of the camshaft position sensor are similar

to those of the crankshaft position sensor. A total of seven bosses are arranged at equally spaced

four locations (one each at two locations, two at one location, and three at one location) of the

sprocket as shown below.

B2H3812C

(1) Boss A: Camshaft one rotation (Crankshaft two rotations)

(2) Camshaft sprocket B: Cylinder identification signal

(3) Air gap

(4) Camshaft position sensor

FU-26

Page 47

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

F: KNOCK SENSOR

! The knock sensor is installed on the cylinder block, and senses knocking that occurs in the en-

gine.

! The sensor is a piezo-electric type which converts vibration resulting from knocking into electric

signals.

! In addition to a piezo-electric element, the sensor has a weight and case as its components. If

knocking occurs in the engine, the weight in the case moves causing the piezo-electric element to

generate a voltage.

! The knock sensor harness is connected to the bulkhead harness.

(1) Nut A: To knock sensor harness

(2) Weight

(3) Resistor

(4) Housing

(5) Piezo-electric element

B2H1998B

FU-27

Page 48

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

G: VEHICLE SPEED SENSOR

1. MT VEHICLES

! The vehicle speed sensor is mounted on the transmission.

! The vehicle speed sensor generates a 4-pulse signal for every rotation of the front differential

and send it to the ECM and the combination meter.

(1) Combination meter

(2) ECM

(3) Vehicle speed sensor

(4) Transmission

B2H2458C

FU-28

Page 49

SENSORS AND SWITCHES

Fuel Injection (Fuel System)

2. AT VEHICLES

! The vehicle speed sensor is mounted on the transmission.

! The vehicle speed sensor generates a 16-pulse signal for every rotation of the front differential

and send it to the transmission control module (TCM). The signal sent to the TCM is converted

there into a 4-pulse signal, and then sent to the ECM and the combination meter.

(1) Combination meter

(2) ECM

(3) TCM

(4) Vehicle speed sensor

(5) Transmission

B2H2459B

FU-29

Page 50

CONTROL SYSTEM

Fuel Injection (Fuel System)

5. Control System

A: GENERAL

The ECM receives signals from various sensors, switches, and other control modules. Using these

signals, it determines the engine operating conditions and if necessary, emits signals to one or

more systems to control them for optimum operation.

Major control items of the ECM are as follow:

! Fuel injection control

! Ignition system control

! Idle air control

! Canister purge control*

! Radiator fan control*

! Fuel pump control

! On-board diagnosis function

*1: Canister purge control is described under “EC – Emission Control (Aux. Emission Control Devices) Evaporative Emission Control System”.

1

2

*2: Radiator fan control is described under “CO – Cooling”.

FU-30

Page 51

CONTROL SYSTEM

B: INPUT AND OUTPUT SIGNALS

Signal Unit Function

Input signals

Output signals

Intake air temperature and pressure

sensor

Atmospheric pressure sensor Detects the amount of intake air (Measure the atmospheric pressure).

Throttle position sensor Detects the throttle valve position.

Front oxygen (A/F) sensor Detects the density of oxygen in exhaust gases at the upstream of the

Rear oxygen sensor Detects the density of oxygen in exhaust gases at the downstream of

Crankshaft position sensor Detects the crankshaft angular position.

Camshaft position sensor Detects the combustion cylinder.

Engine coolant temperature sensor Detects the engine coolant temperature.

Knock sensor Detects engine knocking.

Vehicle speed sensor Detects the vehicle speed.

Ignition switch Detects operation of the ignition switch.

Starter switch Detects the condition of engine cranking.

Neutral position switch (MT) Detects that the gear is in neutral.

Park/Neutral position switch (AT) Detects shift positions.

Torque control signal (AT) Controls engine torque.

Heater circuit of front and rear oxygen

sensor

Fuel level sensor Detects the level of the fuel in the fuel tank.

Diagnostics of AT-ECU Detects the self-diagnostics of the AT-ECU.

A/C switch Detects ON-OFF operation of the A/C switch.

Small light switch Detects ON-OFF operation of the small light switch.

Blower fan switch Detects ON-OFF operation of the blower fan switch.

Rear defogger switch Detects ON-OFF operation of the rear defogger switch.

Fuel Injector Activates an injector.

Ignition signal Turns the primary ignition current ON or OFF.

Fuel pump relay Turns the fuel pump relay ON or OFF.

A/C control relay Turns the A/C control relay ON or OFF.

Radiator fan control relay Turns the radiator fan control relay ON or OFF.

Idle air control solenoid valve Adjusts the amount of air flowing through the bypass line in the throttle

Malfunction indicator lamp Indicates existence of abnormality.

Purge control solenoid valve Controls purge of evaporative gas absorbed by the canister.

Power supply Control ON/OFF of the main power supply relay.

Detects the temperature of intake and amount of intake air (Measures

the absolute pressure).

front catalytic converter.

the front catalytic converter.

Detects abnormality in the heater circuit of the front and rear oxygen

sensors.

body.

Fuel Injection (Fuel System)

FU-31

Page 52

CONTROL SYSTEM

Fuel Injection (Fuel System)

C: FUEL INJECTION COTROL

! The ECM receives signals from various sensors and based on them, it determines the amount

of fuel injected and the fuel injection timing. It performs the sequential fuel injection control over

the entire engine operating range except during start-up of the engine.

! The amount of fuel injected depends upon the length of time the injector stays open. The fuel

injection duration is determined according to varying operating condition of the engine. For the

purpose of achieving highly responsive and accurate fuel injection duration control, the ECM performs a new feedback control that incorporates a learning feature as detailed later.

! The sequential fuel injection control is performed such that fuel is injected accurately at the time

when the maximum air intake efficiency can be achieved for each cylinder (i.e., fuel injection is

completed just before the intake valve begins to open).

1. FUEL INJECTION DURATION

Fuel injection duration is basically determined as indicated below:

! During engine start-up:

The duration defined below is used.

! Duration of fuel injection during engine start-up ..... Determined according to the engine cool-

ant temperature detected by the engine coolant temperature sensor.

! During normal operation:

The duration is determined as follows:

Basic duration of fuel injection x Correction factors + Voltage correction time

! Basic duration of fuel injection ..... The basic length of time fuel is injected. This is determined

by two factors – the amount of intake air detected by the manifold pressure sensor and the engine speed monitored by the crankshaft position sensor.

! Correction factors ..... See the next section.

! Voltage correction time ..... This is added to compensate for the time lag before operation of

injector that results from variation in the battery voltage.

FU-32

Page 53

CONTROL SYSTEM

Fuel Injection (Fuel System)

2. CORRECTION FACTORS

The following factors are used to correct the basic duration of fuel injection in order to make the

air-fuel ratio meet the requirements of varying engine operating conditions:

! Air-fuel ratio feedback factor:

This factor is used to correct the basic duration of fuel injection in relation to the actual engine

speed. (See the next section for more detail.)

! Start increment factor:

This factor is used to increase the fuel injection duration only while the engine is being cranked to

improve its startability.

! Coolant-temperature-dependent increment factor:

This factor is used to increase the fuel injection duration depending on engine coolant temperature

signals to facilitate cold starting. The lower the coolant temperature, the greater the increment.

! After-start increment factor:

! This factor is used to increase the fuel injection duration for a certain period immediately after

start of the engine to stabilize engine operation.

! The increment depends on the coolant temperature at the start of the engine.

! Wide-open-throttle increment factor:

This factor is used to increase the fuel injection duration depending on the relationship between

the throttle position sensor signal and manifold pressure sensor signal.

! Acceleration increment factor:

This factor is used to increase the fuel injection duration to compensate for a time lag between air

flow measurement and fuel injection control for better engine response to driver’s pedal operation

during acceleration.

FU-33

Page 54

CONTROL SYSTEM

Fuel Injection (Fuel System)

3. AIR-FUEL RATIO FEEDBACK FACTOR

The ECM creates this factor utilizing the front oxygen sensor signal. When the signal voltage is

low, the air-fuel ratio is richer than the stoichiometric ratio. The ECM then makes the fuel injection

duration shorter by modifying the factor. When the voltage is high showing that the mixture is lean,

the ECM modifies the factor to make the injection duration longer. In this way, the air-fuel ratio is

maintained at a level close to the stoichiometric ratio at which the three-way catalyst acts most

effectively.

B2H0989B

(1) Front catalyst A: Injection duration increment signal

(2) Exhaust gas B: Injection duration decrement signal

(3) Front oxygen (A/F) sensor C: High oxygen density

(4) Fuel injector D: Low oxygen density

(5) Combustion chamber E: Lean signal

(6) ECM F: Rich signal

4. LEARNING FEATURE

The air-fuel ratio feedback control includes a learning feature which contributes to more accurate

and responsive control.

! In the air-fuel ratio feedback control, the ECM calculates the necessary amount of correction

based on data from the oxygen sensor and adds the result to the basic duration (which is stored

in the ECM’s memory for each condition defined by the engine speed and various loads.)

! Without a learning feature, the ECM carries out the above-mentioned process every time. This

means that if the amount of necessary correction is large, the air-fuel ratio feedback control becomes less responsive and less accurate.

! The learning feature enables the ECM to store the amount of correction into memory and add

it to the basic fuel injection duration to create a new reference fuel injection duration. Using the

reference duration as the basic duration for the injection a few times later, the ECM can reduce the

amount of correction and thus make its feedback control more accurate and responsive to changes in the air-fuel ratio due to difference in driving condition and sensor/actuator characteristics that

may result from unit-to-unit variation or aging over time.

FU-34

Page 55

CONTROL SYSTEM

Fuel Injection (Fuel System)

D: IGNITION SYSTEM CONTROL

! The ECM determines operating condition of the engine based on signals from the pressure sen-

sor, engine coolant temperature sensor, intake air temperature sensor, crankshaft position sensor

and other sources. It then selects the ignition timing most appropriate for the condition thus determined from those stored in its memory and outputs at that timing a primary current OFF signal to

the ignitor to initiate ignition.

! This control uses a quick-to-response learning feature by which the data stored in the ECM

memory is processed in comparison with information from various sensors and switches.

! Thus, the ECM can always perform optimum ignition timing taking into account the output, fuel

consumption, exhaust gas, and other factors for every engine operating condition.

! Ignition control during start-up

Engine speed fluctuates during start of the engine, so the ECM cannot control the ignition timing.

During that period, the ignition timing is fixed at 10° BTDC by using the 10° signal from the crankshaft position sensor.

Ignition coil

and ignitor

assembly

B2H3449C

FU-35

Page 56

CONTROL SYSTEM

Fuel Injection (Fuel System)

! Ignition control after start of engine

Between the 97° and 65° crank angle signal, the ECM measures the engine speed, and by using

this data it decides the dwell set timing and ignition timing according to the engine condition.

(1) Cylinder number (5) Ignition timing at normal condition

(2) Crank angle pulse (BTDC) (6) Burning cylinder

(3) Cam angle pulse (ATDC) (7) Dwell set

(4) Ignition timing at starting (8) Ignite

B2H0410D

FU-36

Page 57

CONTROL SYSTEM

Fuel Injection (Fuel System)

E: IDLE AIR CONTROL

! The ECM activates the idle air control solenoid valve to control the bypass air flowing through

the bypass passage in the throttle body depending on signals from the crankshaft position sensor,

engine coolant temperature sensor, pressure sensor and A/C switch so that the proper idle speed

for each engine load is achieved.

! The idle air control solenoid valve uses a duty-ratio-controlled solenoid which can continuously

vary the opening area of the rotary valve. As the ECM increases the duty ratio, opening of the rotary valve increases so that the bypass air flow increases, and the engine idling speed becomes

higher as a result.

! The bypass air control is necessary for:

! Increasing idling speed when the air conditioning system and/or electrical loads are turned

on.

! Increasing idling speed during early stage of warm up period.

! Obtaining dashpot function when the throttle valve is quickly closed.

! Prevention of engine speed variation during idling.

B2H3450C

F: FUEL PUMP CONTROL

Using the signal from the crankshaft position sensor, the ECM controls operation of the fuel pump

by turning its relay ON or OFF. To improve safety, the fuel pump is stopped if the engine stalls with

the ignition switch ON.

Ignition switch ON Fuel pump relay Fuel pump

A certain period of time after ignition switch is turned ON ON Operates

While cranking the engine ON Operates

While engine is operating ON Operates

When engine stops OFF Does not operate

FU-37

Page 58

ON-BOARD DIAGNOSIS SYSTEM

Fuel Injection (Fuel System)

6. On-board Diagnosis System

A: GENERAL

! The on-board diagnosis system detects and indicates a fault by generating a code correspond-

ing to each fault location. The malfunction indicator lamp (CHECK ENGINE light) on the combination meter indicates occurrence of a fault or abnormality.

! When the malfunction indicator lamp comes on as a result of detection of a fault by the ECM,

the corresponding diagnostic trouble code (DTC) and freeze frame engine condition are stored in

the ECM.

! On the OBD-II conformable car, it is necessary to connect the Subaru Select Monitor (SSM) or

General Scan Tool (GST) to the data link connector in order to check the DTC.

! The SSM and GST can read and erase DTCs. They can also read freeze frame data in addition

to other pieces of engine data.

! If there is a failure involving sensors which may affect drive control of the vehicle, the fail-safe

function ensures minimum level of driveability.

B: FAIL-SAFE FUNCTION

For a sensor or switch which has been judged faulty in the on-board diagnosis, the ECM, if appropriate, generates an associated pseudo signal to keep the vehicle operational. (The control becomes degraded.)

FU-38

Page 59

FUEL INJECTION

w/o

(FUEL SYSTEM)

1. General ............................................................................................................ 2

2. Air Line ............................................................................................................ 3

3. Fuel Line .......................................................................................................... 6

4. Sensors and Switches .....................................................................................16

5. Control System ................................................................................................ 25

6. On-board Diagnosis System ...........................................................................33

FU

(

OBD

Page

)

Page 60

GENERAL

Fuel Injection (Fuel System)

1. General

! The Multipoint Fuel Injection (MFI) system supplies optimum air-fuel mixture under every engine

operating condition through the use of the latest electronic control technology.

This system pressurizes the fuel to a constant pressure and injects it into each intake air port in

the cylinder head. The injection quantity of fuel is controlled by an intermittent injection system

where an electro-magnetic injection valve or injector opens for a short period that is precisely controlled depending on the quantity of air appropriate for each condition of operation. In actual control, an optimum fuel injection quantity is achieved by varying the duration of an electric pulse

applied to the injector. This way of control enables simple, yet highly precise metering of the fuel.

! The engine control module (ECM) that controls the fuel injection system corrects the fuel injec-

tion amount depending on the vehicle speed, throttle opening, coolant temperature and other vehicle-operation-related information. The ECM receives the information in the form of electric

signals from the corresponding sensors and switches.

The MFI system also has the following features:

! Reduced exhaust emissions

! Reduced fuel consumption

! Increased engine output

! Quick response to accelerator and brake pedal operation

! Superior startability and warm-up performance in cold weather due to corrective controls made

according to coolant and intake air temperatures

FU-2

Page 61

AIR LINE

Fuel Injection (Fuel System)

2. Air Line

A: GENERAL

The air filtered by the air cleaner enters the throttle body where it is regulated in the volume by the

throttle valve and then enters the intake manifold. It is then distributed to each cylinder where the

air is mixed with fuel injected by the injector. During idling operation, air flows into the cylinder

through the idle air control solenoid valve, bypassing the throttle valve. This enables controlling the

engine idling speed properly.

B: INTAKE MANIFOLD PRESSURE AND AIR TEMPERATURE SENSORS

The intake manifold pressure sensor and the intake air temperature sensor are integrated into a

single unit. The unit is mounted on the intake manifold and measures the absolute air pressure in

the intake manifold as well as the temperature of the intake air.

The measured pressure and temperature are converted into electrical signals and sent to the

ECM. The ECM uses these signals to control injection and ignition timing as well as the fuel injection amount.

H2H2825B

(1) Pressure sensor

(2) Intake air temperature sensor

C: THROTTLE BODY

In response to operation of the accelerator pedal, the throttle valve in the throttle body opens/closes to regulate the volume of the air drawn into the combustion chamber.

During idling, the throttle valve is almost fully closed and the volume of air passing through the

throttle body is less than that passing through the idle air control solenoid valve.

More than half of the air necessary for idling is supplied to the intake manifold via the idle air control solenoid valve which controls properly the engine idling speed, so the idling speed needs not

be adjusted.

FU-3

Page 62

AIR LINE

Fuel Injection (Fuel System)

D: THROTTLE POSITION SENSOR

! The throttle position sensor is mounted in the throttle body and linked to the throttle valve.

! The throttle position sensor sends the ECM voltage signal corresponding to the opening of the

throttle valve. When the sensor’s output voltage exceeds a predetermined level, the ECM interprets it as complete closure of the throttle valve. When the output voltage is at another predetermined level, the ECM recognizes that the throttle valve is at a wide open position. Since the output

characteristics of the sensor change over years, the ECM is provided with a learning function to

be able to interpret signals into throttle valve angles always correctly.

(1) Lever

(2) Terminal

B2H2004B

FU-4

Page 63

AIR LINE

Fuel Injection (Fuel System)

E: IDLE AIR CONTROL SOLENOID VALVE

! The idle air control solenoid valve is located in the throttle body and regulates the amount of

intake air that flows bypassing the throttle valve into the intake manifold during engine idling. It is

activated by a signal from the ECM in order to maintain the engine idling speed at a target speed.

! The idle air control solenoid valve is a stepping motor type solenoid-actuated valve which con-

sists of coils, a shaft, a permanent magnet, a spring and a housing. The housing is an integral part

of the throttle body.

! The stepping motor consists of two paired coils, the coils of each pair being arranged face to

face with a shaft in between.

! The shaft has a screw at the end around which the permanent magnets are arranged.

! As current flows in the form of pulses through the paired coils sequentially while alternating the

polarity, the N and S poles of the permanent magnets around the shaft are repelled by the same

poles of the magnetism generated by the coils. This causes a nut externally fixed to the magnets

and internally engaging with the screw of the shaft to turn.

The shaft then goes upward or downward.

! This upward and downward motions of the shaft open or close the valve port, adjusting the

amount of bypass air.

(1) Connector

(2) Permanent magnet

(3) Shaft

(4) Coil

(5) Spring

B2H2005B

FU-5

Page 64

FUEL LINE

Fuel Injection (Fuel System)

3. Fuel Line

A: GENERAL

! The fuel pressurized by the fuel tank inside pump is delivered to each fuel injector by way of the

fuel pipe and fuel filter. Fuel injection pressure is regulated to an optimum level by the pressure

regulator.

! Each injector injects fuel into the intake port of the corresponding cylinder where the fuel is

mixed with air. The mixture then enters the cylinder.

Fuel injection amount and timing are regulated by the ECM.

(1) Purge control solenoid valve (10) Air vent pipe

(2) Pressure regulator (11) Fuel filter

(3) Fuel injector (12) Jet pump

(4) Throttle body (13) Fuel pump

(5) Intake manifold (14) Fuel cut valve

(6) Two-way valve (15) Fuel tank

(7) Canister (16) Fuel return line

(8) Filler cap (17) Fuel delivery line

(9) Filler pipe (18) Fuel evaporation line

FU-6

B2H2907B

Page 65

FUEL LINE

Fuel Injection (Fuel System)

B: PRESSURE REGULATOR

The pressure regulator is installed at the injector end of the fuel supply line. It has a fuel chamber

and spring chamber separated by a diaphragm. Fuel chamber is connected to the fuel supply line

and the spring chamber is connected to the intake manifold. Fuel chamber also has a relief valve

connected to the fuel return line through which fuel returns to the fuel tank. When the intake manifold vacuum increases, the diaphragm is pulled and the relief valve opens to decrease the fuel

supply line pressure (or fuel injection pressure). When the intake manifold vacuum decreases, the

diaphragm is pushed by the spring to increase the fuel supply line pressure. Thus, the difference

between the fuel injection pressure and the intake manifold vacuum is kept at a constant level of

294 kPa (3.00 kgf/cm

hicles to precisely control the amount of injected fuel.

2

, 43.0 psi) for MT vehicles or 299.1 kPa (3.05 kgf/cm2, 43.4 psi) for AT ve-

A

B

(1)

(2)

(1) Relief valve A: To intake manifold

(2) Diaphragm B: Fuel IN

C: Fuel OUT

C

S2H0623C

FU-7

Page 66

FUEL LINE

Fuel Injection (Fuel System)

C: FUEL INJECTORS

! The MFI system employs top feed type fuel injectors with an air assist feature.

! Each injector is installed in the fuel pipe in such a way that the injector is cooled by fuel.

! The features of this type of fuel injector are as follows:

1) High heat resistance

2) Low driving noise

3) Easy to service

4) Small size

! The injector injects fuel according to the valve open signal from the ECM. The needle valve is

lifted by the solenoid which is energized on arrival of the valve open signal.

! Since the injector’s nozzle hole area, the lift of valve and the fuel pressure are kept constant, the

amount of fuel injected is controlled only by varying the duration of the valve open signal from the

ECM.

(1)

(1) Filter

(2) O-ring

(3) Connector

(3)

(2)

B2H1991B

FU-8

Page 67

FUEL LINE

Fuel Injection (Fuel System)

D: FUEL TANK

The fuel tank utilizes a two-compartment design to ensure sufficient capacity without interfering

with the rear differential. It is provided with a suction jet pump (included in the fuel pump and fuel

level sensor assembly) which transfers fuel from one compartment to the other. Each compartment has an individual fuel level sensor.

(5)

(1)

(6)

A

(2)

(3)

(4)

(1) Fuel pump and fuel level sensor assembly (5) Quick connector

(2) Nylon tube (6) Fuel cut valve (Main compartment)

(3) Fuel cut valve (Sub-compartment)

(4) Fuel level sensor (Sub-compartment) A: To t w o wa y va lv e

(5)

B2H2908C

FU-9

Page 68

FUEL LINE

Fuel Injection (Fuel System)

The fuel tank is located under the rear seat and secured with hold-down bands.

(1)

(2)

(1) Band

(2) Cushion