Page 1

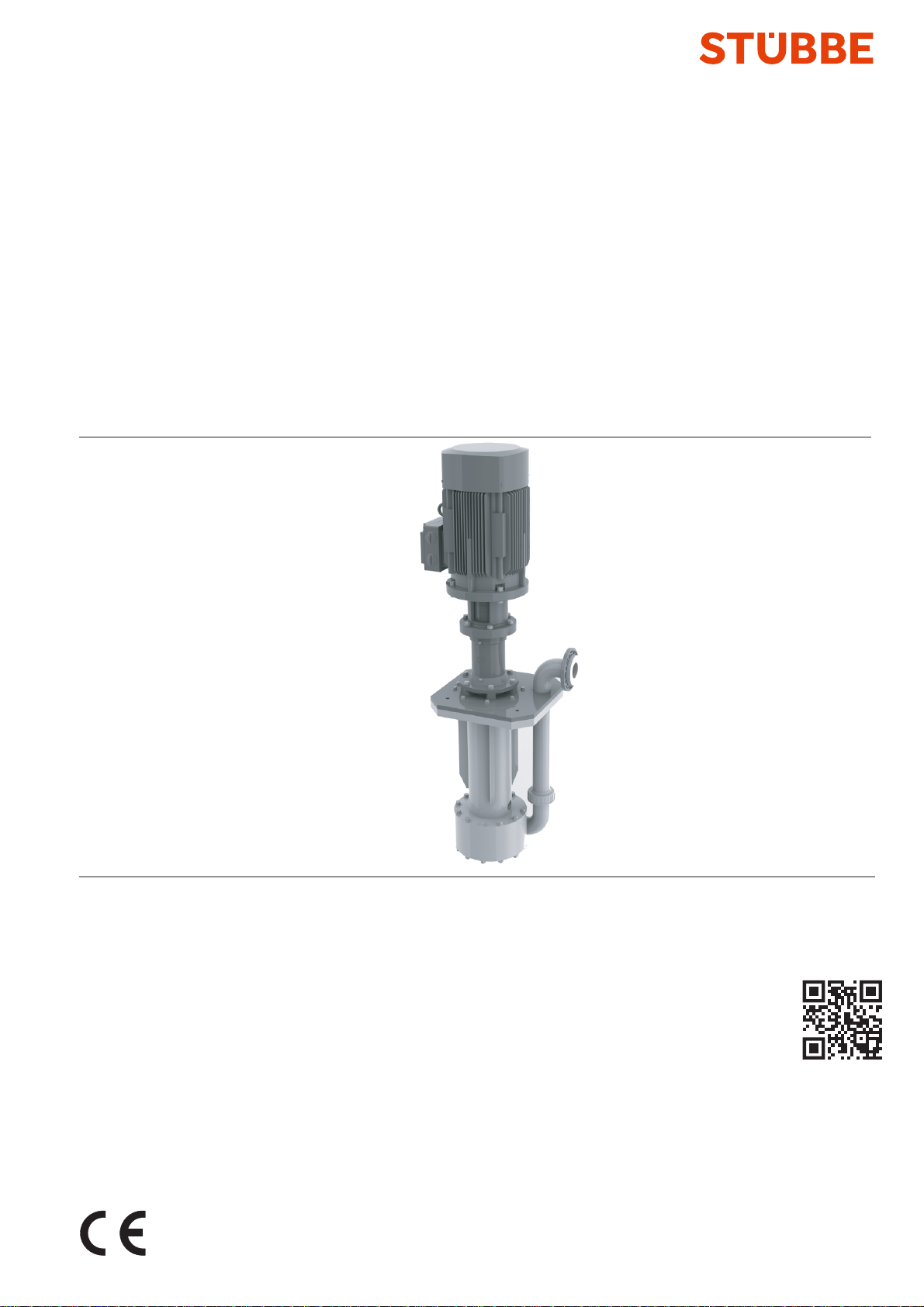

Plastic

Sump Pump

Original operating manual Series ETL

Version BA-2018.08.22 EN

Print-No. 300 106

TR MA DE Rev003

STÜBBE GmbH & Co. KG

Hollwieser Straße 5

32602 Vlotho

Germany

Phone: +49 (0) 5733-799-0

Fax: +49 (0) 5733-799-5000

E-mail: contact@stue bb e.com

Internet: w ww.stuebbe.com

Subject to technical modifications.

Read carefully before use.

Save for future use.

Page 2

Table of contents

Table of contents

1 About this document ............................... 4

1.1 Target groups .................... ............. 4

1.2 Other applicable documents ................ 4

1.3 Warnings and symbols ..... .................. 5

2 Safety ............................... .................. 6

2.1 Intended use ................................ .. 6

2.2 General safety instructions ................ .. 6

2.2.1 Product safety ................................ 6

2.2.2 Obligations of the operating company . .. .. . 6

2.2.3 Obligations of personnel ..................... 7

2.3 Specific hazards . ............................. 7

2.3.1 Hazardous pumped liquids ........... ....... 7

3 Layout and function ...................... .......... 8

3.1 Marking ............. .......................... 8

3.1.1 Name plate ...................... ............. 8

3.2 Description .... ................................ 8

3.3 Assembly ........................... .......... 8

4 Transport, storage and disposal ........... ....... 9

4.1 Transport ...................................... 9

4.1.1 Unpacking and inspection on delivery . .... . 9

4.1.2 Lifting ....................... .................. 9

4.2 Storage ............................. .......... 10

4.3 Disposal ................................... .... 10

5 Setup and connection .............................. 11

5.1 Preparing for installation ........ ............. 11

5.1.1 Check operating conditions ................. 11

5.1.2 Preparing the installation site .. ............. 11

5.1.3 Surface preparation .......................... 11

5.2 Setting up .............................. ....... 11

5.3 Planning pipelines .......................... .. 11

5.3.1 Specifying supports and flan ge

connections .............. ..................... 11

5.3.2 Specifying nominal widths ................... 12

5.3.3 Designing pipelines .......................... 12

5.3.4 Optimizing changes of cross section and

direction ....... ................................ 12

5.3.5 Providing safety and control devices

(recommended) .............................. 12

5.4 Connecting the pipes ........................ 12

5.4.1 Keeping the piping clean .. .................. 12

5.4.2 Installing the pressure pipe ................ .. 12

5.4.3 Inspection for stress-free pipe

connections .............. ..................... 12

5.5 Electrical connec

5.5.1 Connecting the motor ........................ 13

5.5.2 Check direction of rotation ................... 13

5.6 Performing the hydrostatic test .............. 13

6Operation............................... ............. 14

6.1 Preparing for commi

tion .........................

ssioning .............. ..

13

14

6.1.1 Check downtimes ........................ .... 14

6.1.2 Filling and bleeding ................... ....... 14

6.2 Commissioning ........................... .... 14

6.2.1 Switching on .................................. 14

6.2.2 Switching off .. ................................ 14

6.3 Shutting down the pump .............. ....... 15

6.4 Restoring the pump to service .............. 15

6.5 Operating the stand-by pump ............... 15

7 Maintenance ............................... .......... 16

7.1 Inspections ......... .......................... 16

7.2 Servicing ...................................... 16

7.2.1 Maintenance in accordance with maintenance

schedule .................................. .... 16

7.2.2 Cleaning the pump ........................... 16

7.3 Dismounting ..................... ............. 17

7.3.1 Preparations for dismounting ................ 17

7.3.2 Dismounting hydraulic system .. . .. .. . .. .. . . 17

7.3.3 Dismounting coupling and intermediate

ring ............................................ 18

7.3.4 Dismounting V-rings ..................... .... 18

7.3.5 Dismounting shaft bearing ................... 18

7.4 Replacement parts and return .... .......... 18

7.5 Installing ...... ................................ 19

8 Troubleshooting ............... ..................... 20

9 Appendix ........................................... .. 22

9.1 Replacement parts ........................... 22

9.1.1 Part numbers and design ations .. . .. .. . . . .. . 22

9.1.2 Drawing ETL 20-100 to 65-200 ............. 23

9.1.3 Drawing ETL 80-200 ............ ............. 24

9.2 Technical specifications ...................... 25

9.2.1 Ambient conditions .................... ....... 25

9.2.2 Flange tightening torques ......... .......... 25

9.2.3 Sole plate tightening torques . . . . .. .. . . . .. .. . 25

9.2.4 Tightening torques of casing screws . .. . . . .. 25

9.2.5 Switching frequency ............ ............. 25

9.2.6 Volumetric flow of liq uid medium - minimum

flow rate ....... ................................ 25

9.2.7 Sound pressure level ........................ 26

9.2.8 Installation dimensions and filling

heights ...................... .................. 28

9.3 Maintenance schedule ....................... 29

9.4 Lubrication ....... ............................. 30

9.4.1 Lubricating points ............. ............... 30

9.4.2 Lubricant .................... .................. 30

9.5 Declaration of conformity in accordance with

EC machinery directive ............... ....... 31

2 ETL BA-2018.08.22 EN 300 106

Page 3

Table of contents

List of figures

Fig. 1 Name plate (example) ....................... 8

Fig. 2 Assembly ....... .............................. 8

Fig. 4 Replacement parts ETL 20-100 to

65-200 .......... .............................. 23

Fig. 5 Replacement parts ETL 80-200 ............. 24

Fig. 6 Installation dimensions and filling

heights ..................... ................... 28

Fig. 7 Lubricating points ............................ 30

List of tables

Tab. 1 Other application documents, purpose and

where found ............................. ..... 4

Tab. 2 Warnings and symbols .................. ..... 5

Tab.3 Measurestobetakenifthepumpisshut

down .......................... ................ 15

Tab. 4 Measures depending on the behavior of the

pumped liquid ............. ................... 15

Tab. 5 Fault/number assignment ...... ............. 20

Tab. 6 Troubleshooting list .......................... 21

Tab. 7 Designation of components according to part

numbers ..... ................................. 22

Tab. 8 Ambient conditions ... ........................ 25

Tab. 9 Flange tightening torques ................... 25

Tab. 10 Sole plate tightening torques ................ 25

Tab. 11 Tightening torques of casing screws . .. .. .. . 25

Tab. 12 Switching frequency ......... ................ 25

Tab. 13 Volumetric flow of liquid medium ............ 25

Tab. 14 Noise level for 2-pole motors

0.25 kW to 1.5 kW ........................... 26

Tab. 15 Noise level for 2-pole motors

2.2 kW to 45 kW ................... ........... 26

Tab. 16 Noise level for 4-pole motors

0.18 kW to 1.5 kW ........................... 26

Tab. 17 Noise level for 4-pole motors

2.2 kW to 11 kW .............................. 27

Tab. 18 Installation dimensions (minimum

dimensions) .. ................................. 28

Tab. 19 Maintenance schedule ............ ........... 29

Tab. 20 Lubricant ...................................... 30

Tab. 21 Lubricant quantities ....................... ... 30

300 106 BA-2018.08.22 EN ETL 3

Page 4

About this document

1 About this document

This manual:

• is part of the e qui pment

• applies to all series referred to

• describes safe and proper operation during all operating

phases

1.1 Target groups

Operating company

• Responsibilities:

– A lways keep this manual accessible where the device

is used on the system.

– Ensure that employees read and observe this docu-

ment, particularly the safe ty instructions and warnings,

and the docume nts which also apply.

– Observe any additional country-specific rules and reg-

ulations that relate to the system.

Qualified personnel, fitter

• Mechanics qua lification:

– Qualified employees with additional training fo r fitting

therespectivepipework

• Electrical qualification:

– Qualified electrician

• Transport qualification:

– Qualified transport specialist

• Responsibility:

– Read, observe and follow this manual and the other

applicable documents, especially all safety instructions

and warnings.

1.2 Other applicable documents

Document/purpose/ Where found

Installation drawing

• Dimensions when installed, fitting

dimensions, etc.

Resistance lists

• Resistance of materials used to

chemicals

• www.stuebbe.com/pdf_resistance/

300051.pdf

CE decl aration of conformity

• Conformity with standards

Data sheet (300 134)

• Technical specifications, operating

conditions, dimensions

• www.stuebbe.com/

pdf_datasheets/300134.pdf

Spare parts list

• Ordering spare parts

Sectional drawing

• Sectional drawing, part numbers,

component designations

Supplier documentation

• Technical documentation for parts

supplied by subcontractors

Tab. 1 Other application documents, purpose

and where found

Documentation

included

(→ 9.5 Declaration of conformity in accordancewithECmachinery directi-

ve, Page 31).

Documentation

included

Documentation

included

Documentation

included

4 ETL BA-2018.08.22 EN 300 106

Page 5

1.3 Warnings and symbols

About this document

Symbol

1., 2., ... Multiple-step instructions

→

Tab. 2 Warnings and symbols

Meaning

• Immediate acute risk

• Death, serious bodily harm

• Potentially acute risk

• Death, serious bodily harm

• Potentially hazardous situation

• Minor injury

• Potentially hazardous situation

• Material damage

Safety warning sign

Take note of all information

highlighted by the safety warning

sign and follow the instru ctions to

avoid injury or death.

Instruction

Precondition

Cross reference

Information, notes

300 106 BA-2018.08.22 EN ETL 5

Page 6

Safety

2 Safety

The manufacturer accepts no liability for damage caused

by disre garding any of the documentation.

2.1 Intended use

• Only use the pump with suitable media (→ resistance lists).

• Do not use pump for combustible or explosive fluids.

• Adhere to the operating limits and size-dependent minimum flow rates.

• Avoid cavitation:

– Open the suction-side fitting and do not use it to regu-

late the flow.

– Do not open the pressure-side fitting beyond the

agreed operating point.

• Avoid overheating:

– Do not operate the pump while the pressure-side fitting

is closed.

– Note mi nimum flow (→ Data sheet).

• Avoid damage to the motor:

– Do not open the pressure-side fitting beyond the

agreed operating point.

– Note the maximum permissible number of times the

motor can be switched on per hour (→ manufacturer's

specifications).

• Consult with the manufacturer regarding any other use of

the device.

• If pumps are delivered without motors, then final assembly

as a pump assembly must take place in a ccordance with

the provisions of the Machinery Directive 2006/42/EC.

• Use the pump only as part of a large system/tool.

Prevention of obvious misuse (examples)

• Observe pump limits of use regarding temperature, pressure, flow and speed (→ data sheet).

• The power consumption of the pump increases as the spe

cific gravity of the pumped fluid increases. Adher

permissible specific gravity in order to elimin

sibility that the pump, coupling and motor bec

loaded (→ data sheet).

A lower specific gravity is permis

systems accordingly.

• When conveying fluids containing solids, observe the limit

values for proportions of solid particles and particle size

(→ Data sheet, technical description).

• When using auxiliary plant systems:

– Ensure c ompatibility of the operating medium with the

product medium.

– Ensure constant supply of the relevant operating

medium.

• Pumps used wi

used for foo

ing wate

th water as the pumped liquid must not be

dstuffs or drinking water. Use for food or drink-

r only if specified in the data sheet.

sible. Adapt the auxiliary

etothe

ate the pos-

ome over-

• The type of installation should be selected only in accordance with these operating instructions. For example, the

following are not allow ed:

– Hanging base plate pumps in the pipe

– Overhead installation

– Installation in the immediate vicinity of extreme heat or

cold sources

– Installation too close to a wall

2.2 General safety instructions

Observe the following regul ations before carrying out any

work.

2.2.1 Product safety

The pump has been built according to state-of-the-art technology and the recognized technical safety regulations. Nevertheless, operation of the pump can still put the life and health

of the user or third parties at risk or damage the pump or other

property.

• Operate the pu m p only if it is in perfect technical condition

and use it only as intended, staying aware of safety and

risks, and in adherence to the instructions in this manual.

• Keep this manual and all other applicable documen ts complete, legible and accessible to personnel at all t imes.

• Refrain from any pro cedures and actions that would pose

a risk t o p ersonnel or third parties.

• In the event of any safety-relevant faults, shut down the

pump immediately and have the fault corrected by appropriate personnel.

• In addition to the entire documentation for the product,

comply with statutory or other safety and accident-prevention regulations and the applicable standards and guidelines in the country where the pump is operated.

-

2.2.2 Obligations of the operating company

Safety-conscious working

• Operate the pu m p only if it is in perfect technical condition

and use it only as intended, staying aware of safety and

risks, and in adherence to the instructions in this manual.

• Ensure that the following safety aspects are observed and

monitored:

– Intended use

– S tatutory or other safety and accident-prevention reg-

ulations

– Safety regulations governing the handling of haz-

ardous substances

– Applicable standards and guidelines in the country

where the pump is operated

– Applicable guidelines of the operator

• Make personal protective equipment available.

6 ETL BA-2018.08.22 EN 300 106

Page 7

Safety

Qualified personnel

• Make sure all personnel tasked with work on the pump

have read and understood this man ual and all other applicable documents, especially the safety, maintenance and

repair informatio n, before they start any work.

• Organize responsibilities, areas of competence and the

supervision of personnel.

• Ensure that all work is carried out by specia list technicians

only:

– Installation, repair and maintenance work

– Transportation

– Work on the electrical system

• Make sure that trainee personnel only work on the pump

under s upervision of specialist technicians.

Safety equipment

• Provide the following safety equipment and verify its functionality:

– For hot, cold and moving parts: pump safety guarding

provided by the customer

– For pumps without capability to run dry: Dry run pro-

tection

– For potential electrostatic charging: provide suitable

grounding

Warranty

• Obtain the ma nufacturer's approval prior to carrying out

any modifications, repairs or alterations during the warranty

period.

• Only use genuine parts or parts that have been approved

by the manufacturer.

• Following all work on the pump, refit safety devices in

accordance with the instructions and bring into service.

• Do not make any modifications to the device.

2.3 Specific hazards

2.3.1 Hazardous pumped liquids

• When handling hazardous fluids, observe the safety regulations for the handling of hazardous substances.

• Use personal protective equipment when carryi ng out any

work on the pump.

• Collect leaking pumped liquid and residues in a safe manner and damage them in accordance with environmental

regulations.

2.2.3 Obligations of personnel

• All directions given on the pump must be followed (and kept

legible), e.g. the arrow indicat ing the sense of rotation an d

the markings for fluid connections.

• Pump, coupling guard and components:

– Do not step on them or use as a climbing aid

– Do not use them to support boards, ramps or beams

– Do not use them as a fixing point for winches or sup-

ports

– Do not use them for storing paper or similar materials

– Do not use the hot pump o r motor components as a

heating point

– Do not de-ice the pump using gas burners or similar

tools

• Do not remove the safety guarding for hot, cold or moving

parts during operation.

• Use personal protective equipment if necessary.

• Only carry out work on the pump while it is not running.

• Before all installation and maintenance work, disconnect

the motor from the mai ns and secure it against being

switched back on again.

• Never reach into the suctio n or discharge flange.

300 106 BA-2018.08.22 EN ETL 7

Page 8

Layout and function

3 Layout and function

3.1 Marking

3.1.1 Name plate

Hollwieser Str. 5

D-32602 Vlotho

Typ:

Ser. NO.:

ID. NO.:

Mat.:

M. Seal:

8

Fig. 1 Name plate (example)

1Pumptype

2 Serial number

3 Ident. number

4 Housing / sealing material

5 Shaft seal information

6 Impeller diameter [mm]

7 Differential head

8Flow

Imp. Ø:

Q:

m

3

/h

H:

m

3.3 Assembly

1

2

3

4

5

6

7

13

12

1

11

2

10

9

8

7

3.2 Description

Non self-priming, vertical centrifugal pump

Useinopenorclosedunpressuredcontainersorpits/trenches.

Thepumpisdry-runningsafe.

6

5

Fig. 2 Assembly

1 V-ring seal

2 Discharge flange

3 Volute casing

4 Strainer (optional)

5Suctioncup

6Impeller

7Protectiontube

8Shaft

9 Immersion tube

10 Sole plate

11 Shaft bearing

12 Coupling

13 Motor

3

4

8 ETL BA-2018.08.22 EN 300 106

Page 9

4 Transport, storage and disposal

Transport, storage and disposal

4.1 Transport

The user/owner is responsible for the transport of the

pump.

Weight specifications (→ documents for the particular

order)

4.1.1 Unpacking and insp ection on delivery

1. Unpack the pump/pump assembly upon delivery and

inspect it for transport damage.

2. Check completeness and accuracy of delivery.

3. Ensure that the information on the name plate agrees with

the order/design data.

4. Re port any transportation damage to the manufacturer

immediately.

5. Dispose of packaging material according to local regulations.

Retain the transport frame for horizontal storage (recommended).

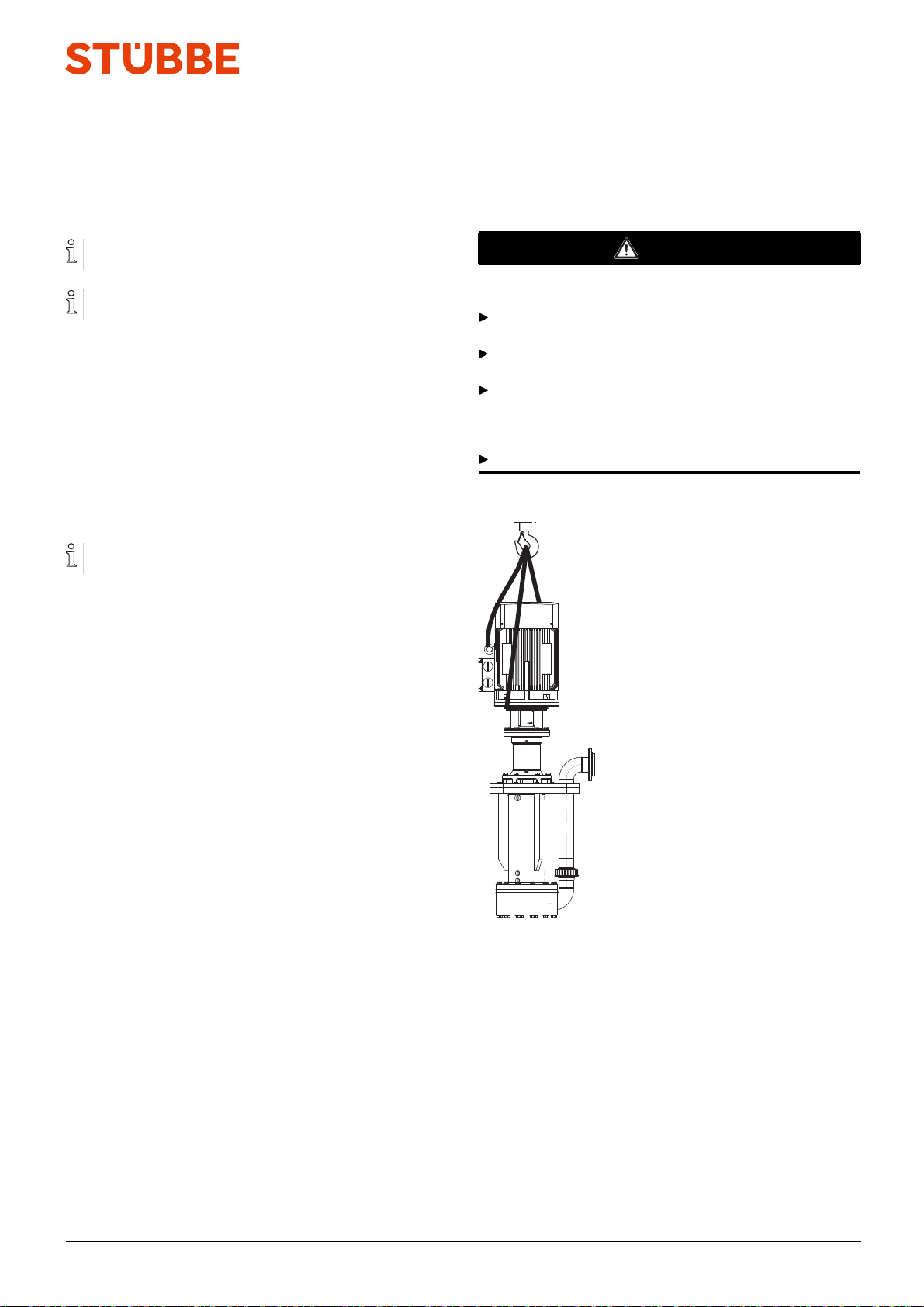

4.1.2 Lifting

DANGER

Death or limbs crushed as a result transported items

falling over!

Use lifting gear appropriate for the total weight to be transported.

Attach liftin g gear in accordance with the following diagrams.

Never use the lifting eye of the motor as the attachment

point for lifting the enti re pump (the lifting eye of the motor

may be used for securing a pumpassemblywithahigh

center of gravity against being knocked over).

Do not stand un der suspended loads.

1. Attach lifting gear in accordance with the above diagram.

2. Lift the pump/pump assembly appropriately.

300 106 BA-2018.08.22 EN ETL 9

Page 10

Transport, storage and disposal

4.2 Storage

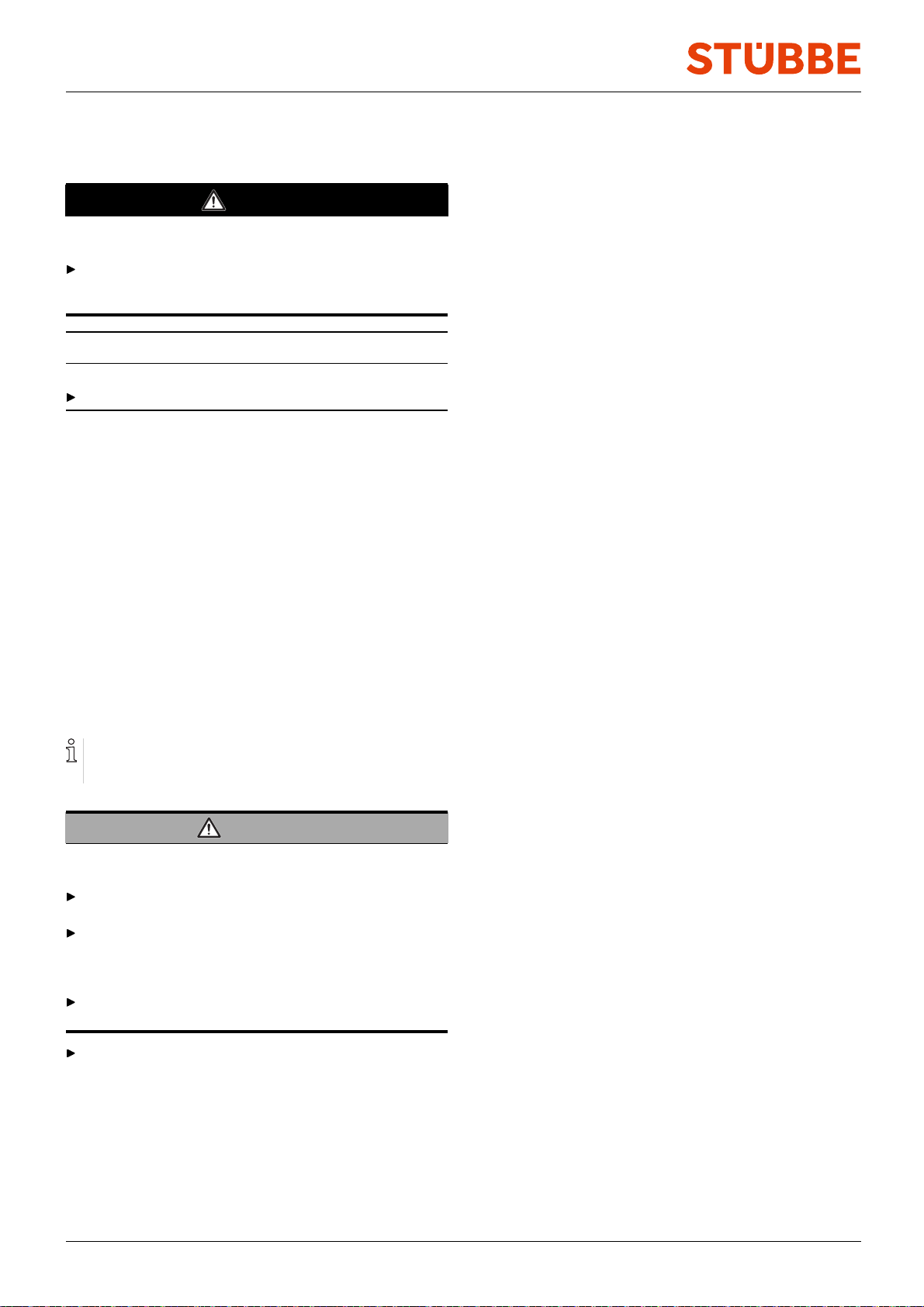

DANGER

Death or limbs crushed as a result of the pump overturning!

For vertical storage:

– Place pump on a horizontal underground and secure

against overturning.

NOTE

Material damage due to inappropriate storage!

Store the pump properly.

1. Sea l all openings with blind flanges, blind plugs or plastic

covers.

2. Make sure the storage room meets the following conditions:

–Dry

– F rost-free

– Vibration-free

–UVprotected

3. Fo r horizontal storage:

– Protect pump against sagging by means of proper sup-

port.

4. Rotate the pump shaft twice a month.

5. Make sure the shaft and bearing change their rotational

position in the process.

4.3 Disposal

Plastic parts can be contaminated by poisonous or radioactive pumpe d liquids to such an extent that cleaning will be

insufficient.

WARNING

Risk of poisoning and environmental damage by the

pumped liquid or oil!

Use personal protective equipment when carrying out any

work on the pu mp.

Prior to the disposal of the pump:

– Collect and d amage any escaping pumped liquid or oil

in accordance with local regulations.

– Neutralize residues of pumped liquid in the pump.

Remove plastic parts and damage them in accordance with

local regulations.

Dispose of the pump in accordance with local regulations.

10 ETL BA-2018.08.22 EN 300 106

Page 11

5 Setup and connection

Setup and connection

NOTE

Material damage due to distortion or passage of electrical

current in the bearing!

Do not make any structural modifications to the pump

assembly or pump casing.

Do not carry out any welding work on the pump assembly

or pump casing.

NOTE

Material damage caused by dirt!

Do not remove the transport seals until immediately before

installing the pump.

Do not remove any covers or transport and sealing covers

until immediately before connecting the pipes to the pump.

5.1 Preparing for installation

5.1.1 Check operating conditions

1. Ensure the required operating conditions are me t:

– Resistance of body and seal material to the medium

(→ resistance lists).

– Required ambient conditions

(→ 9.2.1 Ambien t conditions, Page 25).

2. Ensure necessary dimensions for tank cut-out (→ data

sheet).

3. Ensure safe aeration and venting of the container in all

operating phases.

4. Ensu re required installation dimensions and f illing levels (→ 9.2.8 Installation dimensions and filling heights,

Page 28).

– Minimum distances

– Maximum filling height

– Minimum filling height

5.1.3 Surface preparation

Aids, tools, materia ls:

– Spirit level

1. Make sure the surface meets the following conditions:

– Level and horizontal

– Clean (no oil, dust or other impurities)

– Capable of bearing the weight of the pump assembly

and all operating forces

– Stability of the pump ensured

– Resonance-free

2. Clean containers, basins or pits carefully a nd protect from

further contamination, e.g. by installing overflow wall in

front of the container or pit inlet.

5.2 Setting up

1. Remove the suction-side cover if present.

2. Lift pump/pump assembly (→ 4.1 Transport, Page 9).

3. Place pump/pump assembly on the contact surface of the

container/pit.

4. Attach sole plate to the contact surface.

– Pump must not be mechanically under stress as a

result of being attached

5. Screw on the sole plate (→ 9.2.3 Sole plate tightening

torques, Page 25).

5.3 Planning pipelines

Water hammer may damage the pump or the system. Plan

the pipe s and fittings as far as possible to prevent water

hammer occurring.

5.3.1 Specifying supports and flange connections

5.1.2 Preparing the installation site

Ensure the installation site meets the following conditions:

– Pump is freely accessible from all sides

– Sufficient space for the installation/removal of the pipes

and for maintenance and repair work, especially for the

removal and installation of the pump and the motor

– Pump not exposed to external vibration (damage to

bearings)

– No corrosive exposure

– Frost protection

300 106 BA-2018.08.22 EN ETL 11

Material damage due to excessive forces and torques on

the pump.

Ensure pipe connection without stress.

1. Plan pipes safely:

– No pulling or thrusting forces

– No bending moments

– Adjust for changes in length due to temperature

changes (compen sators, expansion shanks)

2. Support pipes in front of the pump.

3. Ensure the pipe supports have permanent l ow-friction

properties and do not seize up due to corrosion.

NOTE

Page 12

Setup and connection

5.3.2 Specifying nominal width s

Keep the flow resistance in the pipes as low as possible.

1. Make sure the suction extension is not smaller than the

nominal width of the suction branc h.

2. Make sure the nominal pressure line width is not smaller

than the nomi nal discharge flange wi dth.

– Ensure the flow velocity is less than 3 m/s.

5.3.3 Designing pipelines

Plan pipes safely:

– No pulling or thrusting forces

– No bending moments

– Adjust for changes in le ng th due to temperature

changes (compensators, expansi on shanks)

5.3.4 Optimizing changes of cross section and

direction

1. Avoid radii of curvature of less than 1.5 times the nominal

pipe diameter.

2. Avoid abrupt changes of cross-section along the piping.

5.3.5 Providing safety and control devices

(recommended)

Avoid reverse running

1. Install a non-return valve between the discharge flange and

stop valve, to ensure that the medium does not flow back

after the pump is switched off.

2. In order to enable venting, include vent connection

between discharge flanges and non-return valve.

Make provisions for isolating and shutting off the pipes

For maintenance and repair work.

Provide shut-off devices in the pressure pipe.

Allow m easurements of the operating conditions

1. Provide a pressure gauge in the pressure line for pressure

measurement.

2. Provide pressure measurement on the pump side.

5.4 Connecting the pipes

NOTE

Material damage due to excessive forces and torqu es on

the pump.

Ensure pipe connection wi thout stress.

5.4.1 Keeping the piping clean

NOTE

Material damage due to impurities in the pump!

Make sure no impurities can enter the pump.

1. Clean all piping parts and fittings prior to assembly.

2. Flush all pipes carefully with neutral medium.

3. Ensure no flange seals protrude inwards.

4. Remove any blin d flanges, plugs, protective foils and/or

protective paint from the flanges.

5.4.2 Installing the pressure pip e

1. Remove the transport and sealing covers from the pump.

2. Fit the pressure line stress-free and sealed

(→ 9.2.2 Flange tightening torques, Pa ge 25).

3. Ensure no seals protrud e inwards.

5.4.3 Inspection for stress-free pipe connections

Piping installed and cooled down

1. Disco nnect the pipe connecting flanges from the pump.

2. Chec k whether the pipes can be moved freely in all directions within the expected range of expansion:

– Nominal width < 150 mm: by h an d

– Nominal width > 150 mm: with a small lever

3. Make sure the flange surfaces are parallel.

4. Reconnect the pipe connecting flanges to the pump.

5. If present, check s upport foot for stress.

12 ETL BA-2018.08.22 EN 300 106

Page 13

5.5 Electrical connection

DANGER

Risk of electrocution!

All electrical work must be carried out only by qualified electricians.

Before all work on the electrical system, disconnect the

motor from the mains and secure against being switched

back on again.

5.5.1 Connecting the motor

Follow the instructions of the motor manufacturer.

1. Connect the motor according to the connection diagram.

2. Make sure no danger arises due to electric power.

3. Install an EMERGENCY STOP switch.

5.5.2 Check direction of rotation

Setup and connection

DANGER

Danger to life from rotating parts.

Use personal protective equipment when carrying out any

work on the pump.

Maintain an adequate distance from rotating parts.

1. Switch on motor for max. 2 seconds and switch it off again

immediately.

2. Check whether the sense of r otation of the motor matches

the direction of rotation on the fan impel ler.

3. If the sense of rotation is different: Change over any two

phases.

5.6 Performing the hydrostatic test

Only necessary if the entire system needs to be tested

under pressure.

NOTE

Material damage due to bursting of pump casing.

Testing pressure must not exceed the permissible pump

pressure (→ documents for the particular order).

Make sure the testing pressure does not exceed the permissible pump pressure.

– If necessary, do not perform pressure test on the pump.

300 106 BA-2018.08.22 EN ETL 13

Page 14

Operation

6Operation

6.1 Preparing for commissioning

6.1.1 Check downtimes

Check downtimes (→ 6.4 Restoring the pump to service,

Page 15).

6.1.2 Filling and bleeding

WARNING

Risk of injury and poisoning due to hazardous pumped

liquids!

Use protective equipment for any work on the pump.

Collect leaking liquid safely and damage fitting in accor-

dance with local regulations.

1. Clos e the pressure-side fitting.

2. Fill pump and, if present, suction pipe with fluid.

Ensure minimum filling height when doing so (→ Ta b.

18 Installation dimensions (minimum dimensions),

28 P age).

3. Verify that no pipe connections are leaking.

6.2 Commissioning

6.2.1 Switching on

Pump set up and connected properl y

Motor set up and connected properly

All connections s tress-free an d seale d

All safety equipment installed and tested for functionality

Pump prepared, fill ed and vented correctly

Container is filled sufficiently up to minimum height

“Z” (→ 9.2.8 Installation di mensions and filling heights,

Page 28).

NOTE

Risk of cavitation if suction flow is restricted!

Open the suction-side fitting and do not use it to regulate

the flow.

Do not open the pressure-side fitting beyond the o perating

point.

NOTE

Material damage due to overheating.

Do not operate the pump for long periods with the pressureside fitting closed.

Observe minimum flow ( → order data sheet).

1. Open the suctio n-side fitting.

2. Clos e the pressure-side fitting.

3. Switch on the motor and check it for smooth running.

4. Once the motor has reached its nominal speed, open

the pressure-side fitting slowly until the operating point is

reached.

5. Make sure tempera tu re change i s smaller tha n 5 K/min for

pumps with hot fluids.

6. After the initial stress due to the pressure and operating

temperature, check that the pump is not leaking.

6.2.2 Switching off

Pressure-side fitting closed (recommended)

WARNING

Risk of injury due to hot pu mp parts!

Use personal protective equipment when carrying out any

work on the pu mp.

1. Switch off motor.

DANGER

Risk of injury due to running p ump!

Do not touch the pump when it is running.

Do not carry out any work on the pump when it is running.

Allow the pump to cool down completely before starting any

work.

2. Check all connecting bolts and tighten them if necessary

(only after initial commissioning).

DANGER

Risk of injury and poisoning due to pumped liquid spraying out!

Use personal protective equipment when c

work on the pu mp.

14 ETL BA-2018.08.22 EN 300 106

arrying out any

Page 15

Operation

6.3 Shutting down the pump

DANGER

Risk of injury due to running pump!

Do not touch the pump when it is running.

Do not carry out any work on the pump w hen it is running .

Before all installation and mainte nance work, disconnect

the motor from the mai ns and secure it against being

switched back on again.

DANGER

Risk of electrocution!

All electrical work must be carried out only by qualified electricians.

Before all work on the electrical system, disconnect the

motor from the mains and secure against being switched

back on again.

WARNING

Risk of injury and poisoning due to hazardous pumped

liquids!

Use protective equipment for any work on the pump.

Collect leaking liquid safely and damage fitting in accor-

dance with local regulations.

Take the following measures whenever the pump is shut

down:

Pump is Action

shut down

…emptied

…dismounted

…put into

storage

Tab. 3 Measures to be taken if the pump is shut down

Take measures appropriate for

the fluid (→ Ta b. 4 Me as u re s

depending on the behavior of

the pumped liquid, 15 Page).

Close suction and pressure-side

fitting.

Isolate the motor from its power

supply and secure it against

unauthorized switch-on.

Note measures for storage.

Behavior of the

pumped liquid

Crystallized or

polymerized,

solids

sedimenting

Solidifying/

freezing,

non-corrosive

Solidifying/

freezing,

corrosive

Remains liquid,

non-corrosive

Remains liquid,

corrosive

Tab. 4 Measures depending on the behavior

of the pumped liquid

Duration of shutdown (depending

on process)

Short

Flush the

pump.

Heat up or

empty the

pump and

containers.

Heat up or

empty the

pump and

containers.

––

–

Long

Flush the

pump.

Empty the

pump and

containers.

Empty the

pump and

containers.

Empty the

pump and

containers.

6.4 Restoring the pump to service

1. Complete all steps as for commissioning

(→ 6.2 Commissi oni ng, Page 14).

2. If th e pump is shut down for over 1 year, replace elastomer

seals (O-rings, shaft sealing rings).

6.5 Operating the stand-by pump

Stand-by pump filled and bled

Operate the stand-by pump at le ast once a week.

Open pressure-side fitting far enough so that the stand-by

pump operating temperature is achieved and heating is

even (→ 6.2.1 Switching on, Page 14).

300 106 BA-2018.08.22 EN ETL 15

Page 16

Maintenance

7 Maintenance

Trained servic e technicians are available for fitting and

repair work. Sub mit evidence of conveyed medium on

request (DIN safety data sheet or safety certificate).

7.1 Inspections

The inspection intervals depend on the operational strain

on the pump.

DANGER

Risk of injury due to running p ump!

Do not touch the pump when it is running.

Do not carry out any work on the pump when it is running.

WARNING

Risk of injury and poisoning due to hazardous pumped

liquids!

Use protective equipment for any work on the pump.

1. Chec k at appropriate intervals:

– Adherence to the minimum flow rate

– Normal operating con ditions unch anged

– Filling level of the container

2. Fo r trouble-free operation, always ensure the following :

–Noleaks

–Nocavitation

– Free and clean filters

– No unu sual running noises or vibrations

– No inadmissi ble leaks on the shaft seal

7.2 Servicing

Operating life of antifriction bearings when operated within

the permissible range: >2 years.

Intermittent operation, high temperatures, low viscosities

and aggressive ambient and process conditions reduce the

service life of antifriction bearings.

Plain bearings are subject to natural wear and tear which

is heavily dependent on the respective operating conditions. It is therefore not possible to make general statements about the operating life.

DANGER

Risk of injury due to running p ump!

Do not touch the pump when it is running.

Do not carry out any work on the pump when it is running.

Before all in s tallation and maintenance work, disconnect

the motor from the mains and secure it again st being

switched back on again.

DANGER

Risk of electrocution!

All electrical work must be carried out only by qualified electricians.

Before all work on the electrical system, disconnect the

motor from the mains and secure against being switched

back on again.

WARNING

Risk of injury and poisoning due to hazardous or hot fluid!

Use protective equipment for any work on the pump.

Allow the pump to cool down completely before commenc-

ing any work.

Make sure the pump is depressurized.

Empty the pump, safely collect the pumped liquid and dam-

age it in accordance with environmental rules and requirements.

7.2.1 Maintenance in accordance with maintenance schedule

Perform maintenance work in accordance with the maintenance schedule (→ 9.3 Maintenance schedule, Page 29).

7.2.2 Cleaning the pump

NOTE

High water pressure or spray water can damage bearings!

Do not clean bearing areas with a water or steam jet.

Clean l arge-scale grime from the pump.

16 ETL BA-2018.08.22 EN 300 106

Page 17

Maintenance

7.3 Dismounting

DANGER

Risk of injury due to running pump!

Do not touch the pump when it is running.

Do not carry out any work on the pump w hen it is running .

Before all installation and mainte nance work, disconnect

the motor from the mai ns and secure it against being

switched back on again.

DANGER

Risk of electrocution!

All electrical work must be carried out only by qualified electricians.

Before all work on the electrical system, disconnect the

motor from the mains and secure against being switched

back on again.

DANGER

Death or limbs crushed as a result of the pump overturning!

Place pump on a horizontal underground and secure

against overturning.

WARNING

Risk of injury and poisoning due to hazardous or hot fluid!

Use protective equipment for any work on the pump.

Allow the pump to co ol down completely before commenc-

ing any work.

Make sure the pump is depressurized.

Empty the pump, safely collect the pumped liquid and dam-

age it in accordance with environmental rules and requirements.

WARNING

Risk of injury due to heavy components!

Pay attention to the comp onent weight. Lift and transport

heavy components using suitable lifting gear.

Set down components safely and secure them against

overturning or rolling away.

WARNING

Risk of injury during disassembly!

Secure the pressure-side gate valve against accidental

opening.

Depressurize the blocking pressure system, if available.

Wear protective gloves, components can become very

sharp-edged due to wear or damage.

Remove spring-l oaded components carefully (e.g.

mechanical seal, stressed bearing, valves etc.), as components can be ejected by the spring stress.

Observe the manufacturer's specifications (e.g. for the

motor, coupling, mechanical seal, blocking pressure system, cardan shaft, drives, belt drive etc.).

NOTE

Material damage due to incorrect dism ounting/installation

of the pump.

Only specialist mechanics should complete dismounting/

installation work.

7.3.1 Preparations for dismounting

Pump is depressurized

Pump completely empty, flushed and decontaminated

Electrical connections disconnected and motor secured

against switch-on

Pump cooled down

Pressure gauge lines, pressure gauge and fixtures dis-

mounted

When dismounting, observe the following:

– Mark the precise orientation and position of all c ompo-

nents before dismounting them.

– Dismount compon ents concentrically without canting.

–Dismountpump(→ sectional drawing).

7.3.2 Dismounting hydraulic system

1. Undo the pressure pipe screw connection between spiral

casing and sole plate.

2. Screw out the hexagon screws or stud bolts (901.2 or

902.1) from the spiral casing (102).

3. Pull the spiral casing (102) to the bottom.

– Do not tilt the spiral casing

– Do not damage the centering and impeller

4. Remove the impeller cap (260) including O-ring (412.4).

5. Screw out the hexagon nut (920.1), remove spring ring

(934.0) a nd disc (550).

6. Screw out the impeller (230) from the shaft (211).

7. Remove the key (940.2) and O-ring (412.3).

300 106 BA-2018.08.22 EN ETL 17

Page 18

Maintenance

7.3.3 Dismounting coupling and intermediate ring

1. Screw out screws on the motor flange, remove motor (801)

and motor-side coupling half (840.1).

2. Screw out screws (901.3) and remove motor bell housing

(341).

3. Remove intermediate ring.

4. Undo stud bolt (8 40.2) and remove pump-side coupling

half.

7.3.4 Dismounting V-rings

1. Screw out nuts (920.4) and screws (554.3) and remove

motor (801).

2. Dismounting hydraulic system (→ 7.3.2 Dismounting

hydraulic system, Page 17).

3. Remove the housing cover (161).

4. Remove shaft protection tube (714).

5. Screw out fastening screws (901.7).

6. Remove the sus pension pipe (713) including reinforcement

plate (893.2) from the drive assembly group.

7. Remove intermediate ring (509) and V-ring.

8. Remove sealing washer (444 ).

9. Pull off the sealing flange (490) from the bearing bracket

mounting (330).

10. Remove V-ring in the bearing cover (360.2).

7.4 Replacement parts and return

1. Have the following information ready to hand when ordering spare parts (→ type plate).

–Devicetype

– ID number

– Nominal pressure and diameter

– Body and seal material

2. Please complete and enclose the document of compliance

for returns

(→ www.stuebbe.com/en/service/download ).

3. Use only spare parts from Stübbe.

7.3.5 Dismounting shaft bearing

1. Remove V-rings step 1 to 9 (→ 7.3 .4 Dismounting V-rings,

Page 18).

2. Press out the spring dowel sleeves (531) in the shaft sleeve

area (523.1).

3. Remove the shaft sleeve (523.1) from the shaft.

4. Screw out socket head cap screws (914.4).

5. Remove bearing cover (360.2).

6. Bend the stem of the securing plate (931.1 ) to one side and

undo the shaft nut (921.1).

7. Press the shaft assembly group (211) includi ng distance

sleeve (525) and the shaft bearing (321.1) out of the bearing s upport towards the hydraulics side .

8. Screw out headless setscrews (904.1).

9. Remove the sleeve (525) from the shaft.

10. Press out shaft bearin g (321.1) and labyrinth disc (555).

11. Remove the circlip (932.2) from the bearing support.

12. Press the bearing (321.1) including the top lab

(555) out of the bearing support (330).

yrinth disk

18 ETL BA-2018.08.22 EN 300 106

Page 19

Maintenance

7.5 Installing

Install components concentrically and without tilting in

accordance with the marki ngs applied.

WARNING

Risk of injury due to heavy components!

Pay attention to the comp onent weight. Lift and transport

heavy components using suitable lifting gear.

Set down components safely and secure them against

overturning or rolling away.

WARNING

Risk of injury during assembly!

Install spring-loaded components carefully (e.g. mechanical seal, stressed bearing, valves etc.), as components can

be ejected by the spring stress.

Observe the manufacturer's specifications (e.g. for the

motor, coupling, mechanical seal, blocking pressure system, cardan shaft, drives, belt drive etc.).

NOTE

Material damage due to incorrect dism ounting/installation

of the pump.

Only specialist mechanics should complete dismounting/

installation work.

3. Installing the pump in the system (→ 5 Setup and connec-

tion, Page 11).

NOTE

Material damage due to unsuitable components!

Always replace lost or damaged screws with screws of the

same strength where required.

Only replace seals with seals of the same material.

NOTE

Material damage, fragile components.

Install ceramic parts of the plain bearing and magnets of the

magnetic coupling with care, do not strike them or knock

them.

1. W hen installing please observe:

– Replace worn parts with genuine spare parts.

– Replace seals, inserting them in such a way that they

are unable to rotate.

– Do not apply synthetic or min eral oil, grease or cleaning

agents to elastomer components.

– Adhere to the prescribed tightening torques

(→ 9.2.4 Tightening torques of casing screws,

Page 25).

2. Installing the pump:

– in reverse order to the dismounting

(→ 7.3 Dismounting, Page 17).

– → sectional drawing

300 106 BA-2018.08.22 EN ETL 19

Page 20

Troubleshooting

8 Troubleshooting

If faults occur which are not specified in the following table or

cannot be traced back to the specified causes, please consult

the manufacturer.

Possible faults are identified by a fault number in the table

below. This number identifies the respective cause and remedy in the troubleshooting list.

Fault Number

Pump not pumping 1

Pumpingrateinsufficient

Pumping rate excessive 3

Pumping pressure insufficient

Pumping pressure excessive

Pump running roughly 6

Pump leaks

Excessive motor power uptake 8

Tab. 5 Fault/number assignment

2

4

5

7

Fault number

123456

–––––––

X

XX–X

–––––––

X

—

–

X

XX–X

XX–X

–

–

XX–X

–

XX

—

X

–

X

––––X––

–

X

–

X

––

X

––

–

X

—

X

X

X

X

X

–

X

–

X

–

X

–

X

–––

––––

XX

XX

7

8

––

——

––

––

––

––

X

––

––

Cause

Pressure pipe closed by fitting

Pump or suction strainer blocked or

encrusted

Transport and sealing cover still in place Remove the transport and sealing cover.

Back pressure of the system is too high,

pump selected is too small.

Suction head too large: NPSH

than NPSH

Intake/suction pipe an d pump not correctly

vented or not completely filled

Air is sucked in

Proportion of gas too high: pump is

cavitating

Temperature of fluid is too h igh: pump is

cavitating

Viscosity or specific gravity of the pumped

liquid outside the range specified for the

pump

Geodetic differential head and/or pipe flow

resistances too high

Pressure-side fitting not opened wide

enough

Pressure pipe blocked

system

pump

is larger

Remedy

Open the fitting.

Clean intake/suction pipe, pump or

suction strainer.

Consult the manufacture r.

Increase pump inlet pressure.

Consult the manufacture r.

Completely fill and vent pump and/or

pipe.

Check the filling level of the container.

Consult the manufacture r.

Increase pump inlet pressure.

Lower temperature.

Contact the manufacturer.

Consult the manufacture r.

Remove sediments from the pump

and/or pressure pipe.

Install a larger impeller and consult th e

manufacturer.

Open the pressure-side fitting.

Clean the pre ssure pip e.

20 ETL BA-2018.08.22 EN 300 106

Page 21

Troubleshooting

Fault number

X

X

7

––

––

–

123456

XX–X

XX–X

–

––

–

X

XX–X

–

––––

–

X

––X––X–

––X–

––X–

––X–

XX–X

–

–

X

X

–––

X

XX–X Motor speed too high

XX–X Impeller diameter too large

–

–

X

X

––

––

–– –– –X–

–– –– –X–

–– –– ––X–

–– –– ––X–

–– –– –

–

–

X

X

X X X Pump distorted

–

–

X

Tab. 6 Troubleshooting list

Cause

8

Pump running in the wrong direction

Motor speed too low

Pump parts worn

X

Pressure-side fitting opened too wide

X

Geodetic differential head, pipe flow

resistances and/or other resistances lower

than specified

Viscosity lower than expected

Impeller out of balance or blocked

Hydraulic parts of the pump dirty, clotted or

encrusted

X

Shaft bearing faulty

X

Defective antifriction bearing in motor

Connecting bolts not correctly tightened

Faulty housing seal

X Motor running on 2 phases

Remedy

Check sense of rotation and correct it if

necessary (→ 5.5.2 Che ck direction of

rotation, Page 13).

Compare the required motor speed with

the specifications on the pump type

plate. Replace the motor if necessary.

Increase the motor speed if speed

control is available.

Replace the worn pump parts.

Throttle down at the pressure-side fitting.

Machine th e impeller down. Consult the

manufacturer and adjust the impeller

diameter.

Throttle down the flow rate at the

pressure-side fittin g. Observe the

minimum flow rate.

Machine th e impeller down. Consult the

manufacturer and adjust the impeller

diameter.

Machine th e impeller down. Consult the

manufacturer and adjust the impeller

diameter.

Compare the required motor speed with

the specifications on the pump type

plate. Replace the motor if necessary.

Reduce the motor speed if speed control

is available.

Throttle down the flow rate at the

pressure-side fittin g. Observe the

minimum flow rate.

Machine th e impeller down. Consult the

manufacturer and adjust the impeller

diameter.

Clean the impeller.

Dismount the pump.

Clean the parts.

Replace shaft bearing.

Replace the antifriction bearing

(→ manu facturer's specificatio ns).

Tighten the connecting bolts.

Replace the housing seal

Check the pipe connections and pump

attachment.

Check the fuse and replace it if

necessary.

Check the cable connections and

insulation.

300 106 BA-2018.08.22 EN ETL 21

Page 22

Appendix

9 Appendix

9.1 Replacement parts

9.1.1 Part numbers and designations

Part no. Designation

102 Volute casing

161 Housing cover

211

230 Impeller

260 Impeller cap

321.1 Bearing

321.2 Bearing

330 Bearing bracket

341 Pump mounting bracket

360.2 Bearing cap

412.x

444

490

507.1 V-ring

509 Intermediate ring

523.1

525 D istance sleeve

531

550 Washer

554.x Disc

555

556 R ound head grooved pin

636

681.1

681.2

710

713

714

716 Pressure connection

801 Motor

840.1/2 Coupling

860 Intermediate ring

893.2

901.x Hexagon head bolt

Shaft

O-ring

Sealing washer

Sealing flange

Shaft sleeve

Clamping sleeve

Centrifugal disk

Grease nipple

Coupling guard

Contact guard

Suction extension

Sole plate with support tube

Shaft protection tube

Reinforcement plate

Part no. Designation

902.1

904.1 Headless setscrew

914.4

920.x Hexagon nut

921.1

931.x Locking plate

932.2

934

940.x Key

970.3 Name plate

Tab. 7 Designation of components according

to part numbers

Stud bolt

Cylinder screw

Shaft nut

Circlip

Spring ring

22 ETL BA-2018.08.22 EN 300 106

Page 23

9.1.2 Drawing ETL 20-100 to 65-200

A

Appendix

B

Fig. 4 Replacement parts ETL 20-100 to 65-200

ASize132

B Suction basket (optiona l)

300 106 BA-2018.08.22 EN ETL 23

Page 24

Appendix

9.1.3 Drawing ETL 80-200

Fig. 5 Replacement

24 ETL BA-2018.08.22 EN 300 106

parts ETL 80-200

Page 25

Appendix

9.2 Technical specifications

Further technical data (→ data sheet).

9.2.1 Ambient conditions

Operation under any other ambient conditions should be

agreed with the manufacturer.

Temperature [°C]

–20 to +40

Relative humidity [%]

Long-term

1)

≤ 85 ≤ 100 ≤ 1000

Short-term

Tab. 8 Ambient conditions

1) material-dependent

9.2.2 Flange tightening torques

Tightening torque1)MD [Nm] for the

versions

d

[mm]DN[mm]

Flat sealing

ring up to

max10bar

Profile

sealing ring

up to max

16 bar

20 15 10 10 10

25 20 12 12 12

32 25 15 12 12

40 32 20 15 15

50 40 25 15 15

63 50 30 20 20

75 65 35 20 20

90 80 35 20 20

Tab. 9 Flange tightening torques

1) Use a torque wrench

9.2.3 Sole plate tightening torques

Screw

M8

Md [Nm]

7

Screw

M16 63

M10 14 M20 113

M12 24 M24 193

Tab. 10 Sole plate tightening torques

Installation

height

above sea

level [m]

O-ring

max.

16 bar

Md [Nm]

9.2.4 Tightening torques of casing screws

Apply graphite paste to metallic connections pr ior to

assembly.

Size Metal /

metal

1)

M6 9 6

M8 21

Metal /

plastic

7

2)

Metal in metal

inserts /

3)

plastic

5

6

M10 42 14 10

M12 73 24 25

M16 170 63 30

M20 340 113 32

M24 580 193 34

Tab. 11 Tightening torques of casing screws

1) Metal: Screws, nuts, housing, pipes

2) Metal: screws, nuts / Plastic: housing, pipes

3) Metal: screws in metal inserts / Plastic: housing with

screwed in or encapsulated met al inserts

9.2.5 Switching frequency

Motor power rating

Switch on / switch off

actions per hour

0.18 kW ≤ motors ≤ 7.5 kW 15

11 kW ≤ motors ≤ 30 kW 12

Tab. 12 Switching frequency

9.2.6 Volumetric flow of liquid medium -

minimum flow rate

Q

Short-time operation: 0.1 x Q

min

Continuous operation: 0.15 x Q

Q

Q

See pump capacity curve (→ data sheet)

max

Volumetric flow in pump capacity curve efficiency

opt

(approx. 5 min.)

opt

opt

optimum

Tab. 13 Volumetric flow of liquid medi

um

If operating point differs, consult the manufacturer.

300 106 BA-2018.08.22 EN ETL 25

Page 26

Appendix

9.2.7 Sound pressure level

Maximum noise level LpA for 2-pole and 4-pole 50Hz/60Hz

motors, in dB (A)

Noise level for 2-pole motors 0.25 kW to 1.5 kW

Motor power

0.25 kW 0.37 kW 0.55 kW 0.75 kW 1.1 kW 1.5 kW

rating

Frequency 50

Hz

60

Hz

50

Hz

60

Hz

50

Hz

60

Hz

50

Hz

60

Hz

50

Hz

60

Hz

50

Hz

ETL20-100 50 53 59 62 59 62 61 64

ETL25-125 59 62 61 64 61 64 66 69

ETL32-125 61 64 66 69

Tab. 14 Noise level for 2-pole motors 0.25 kW to 1.5 kW

Noise level for 2-pole motors 2.2 kW to 45 kW

Motor power

2.2kW 3kW 4kW 5.5kW 7.5kW 11kW 45kW

rating

Frequency 50

Hz

60

Hz

50

Hz60Hz

50

Hz

60

Hz50Hz

60

Hz

50

Hz

60

Hz50Hz

60

Hz

50

Hz60Hz

ETL32-125 66 69 68 71

ETL32-160 6669687170737073

ETL40-125 6669687170737073

ETL40-160 6871707370737073

ETL50-125 6871707370737073

ETL50-160 7073707370737174

ETL80-200 73 76

Tab. 15 Noise level for 2-pole motors 2.2 kW to 45 kW

60

Hz

Noise level for 4-pole motors 0.18 kW to 1.5 kW

Motor power

0.18 kW 0.25 kW 0.37 kW 0.55 kW 0.75 kW 1.1 kW 1.5 kW

rating

Frequency 50

Hz

60

Hz

50

Hz60Hz

50

Hz

60

Hz50Hz

60

Hz

50

Hz

60

Hz50Hz

ETL20-100 434545474547

ETL25-125 434545474547

ETL32-125 454745475456

ETL32-160 454754565456

ETL32-200 54 56 54 56

ETL40-125 454745475456

ETL40-160 54 56 54 56

ETL40-200

ETL50-125 54 56 54 56

ETL50-160

ETL50-200

Tab. 16 Noise level for 4-pole motors 0.18 kW to 1.5 kW

57

57

57

57

57

60

Hz

59

59

59

59

59

50

Hz

57

57

57

60

Hz

59

59

59

26 ETL BA-2018.08.22 EN 300 106

Page 27

Noise level for 4-pole motors 2.2 kW to 11 kW

Appendix

Motor power

2.2 kW 3 kW 4 kW 5.5 kW 7.5 kW 11 kW

rating

Frequency 50Hz 60Hz 50Hz 60Hz 50Hz 60Hz 50Hz 60Hz 50Hz 60Hz 50Hz 60Hz

ETL40-20061636163

ETL50-16061636163

ETL50-200616361635961

ETL65-20061636163596165676568

ETL80-200 61635961656765686669

Tab. 17 Noise level for 4-pole motors 2.2 kW to 11 kW

Measuring conditions:

• Distance to the pu mp: 1 m

• Operation: free of cavitation

• Motor: IEC standard motor

• Tolerance ±3 dB

• Determination of the sound power by the sound intensity

measurement method (DIN EN ISO 9614-2) and Determination of the workplace-related emission value (sound

pressure level) LpA to DIN EN ISO 11203

300 106 BA-2018.08.22 EN ETL 27

Page 28

Appendix

9.2.8 Installation dimensions and filling heights

Z

Size

O

VZXY

[mm]

20–100 80 110 170 100 10

25–125 80 110 170 100 10

32–125 80 140 170 125 15

32–160 80 140 170 125 15

32–200 80 140 170 125 15

40–125 80 140 170 150 10

40–160 80 160 170 150 10

40–200 80 160 170 150 10

50–125 80 160 170 125 35

50–160 80 160 170 125 35

50–200 80 160 170 125 35

65–200 80 160 170 150 35

80–200 80 180 170 170 35

Tab. 18 Installation dimensions (minimum dimensions )

Fig. 6 Installation dimensions and filling heights

Max: maximum filling height

Min: minimal filling height

Z: Minimum height

The dimensions and minimum dimensions specified in the

table must not be less than stated.

28 ETL BA-2018.08.22 EN 300 106

Page 29

9.3 Maintenance schedule

Designation Interval Maintenance

Operating temperatures

Undoable screwed

connections

Shaft bearing (only for drive

capacity ≥ 30 kW)

Coupling and intermediate

ring

Tab. 19 Maintenance schedule

Weekly

Weekly

Monthly

After the first 2,000 h (max. after

3 months)

Every 4,000 h (max. after 1 year)

3yearsIntermediate ring

Event:

• during routine inspections

• during repairs to the drive train

Check storage temperature.

Check motor temperature.

Check for co rrect and tight fitting.

Re-grease shaft bearing (→ 9.4 Lubrication,

Page 30).

Perform a visual inspection.

Replace intermediate ring

Appendix

300 106 BA-2018.08.22 EN ETL 29

Page 30

Appendix

9.4 Lubrication

Only for version with labyrinth seal.

9.4.1 Lubricating p oints

A

9.4.2 Lubricant

Manufacturer Type of lubricant

Temperature range –35 °C … +140 °C

Aral Aralub HL3

BP

Glissando Glissando FT3

Esso Beacon 3

Mobilux Mobilux EP3

Shell

Tab. 20 Lubric ant

Size Quantity [g]

40–200

Tab. 21 Lubricant quantities

Energraese LS3

Glissando 30

Alvania R3

5.5

A

Fig. 7 Lubricating points

A Lubricating points

30 ETL BA-2018.08.22 EN 300 106

Page 31

Appendix

9.5 Declaration of conformity in

accordance with EC machinery

directive

EU Declaration of Conformity

Stübbe GmbH & Co. KG, Hollwieser Straße 5, 32602 V lotho, Germany, declares on its own authority that the following products

Description

Centrifugal pumps with mechanical seal

NM, NMB, NX, SHB

Magnetically-coupled pumps

SHM

Eccentric pumps

Type F, Type L

Sump pumps

ET, ETL, ETLB, ETLB-S, ETLB-T, ETLB-ST

to which this dec laration relates, are in conformity with the following standards:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

With regard to electrical hazards the protective aims of Low Voltage Directive

2014/35/EU have been complied with according to Appendix I no. 1.5.1 of th e

Machinery Directive 2006/42/EU.

Place and date

____________________

Vlotho, 25.01.2018

Name and signature of authorized person

____________________________________

pp Achim Kaesberg,

Manager Corporate Data

300 106 BA-2018.08.22 EN ETL 31

Loading...

Loading...