Page 1

User Guide

Issue 7, October 2008

This User Guide is applicable for serial numbers:

M230-00183 and later

and units upgraded with software version 1.04 and higher

Copyright © 2008 by Studio Technologies, Inc., all rights reserved

www.studio-tech.com

50321-1008, Issue 7

Page 2

This page intentionally not left blank.

Page 3

Table of Contents

Introduction ................................................................... 5

System Features ...........................................................

Installation and Setup ................................................... 12

Configuration ................................................................

Operation ...................................................................... 29

Advanced Operation ..................................................... 36

Technical Notes .............................................................

Specifications ................................................................

Appendix A .................................................................... 53

Block Diagram

6

18

37

52

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 3

Page 4

This page intentionally not left blank.

Issue 7, October 2008 Model 230 User Guide

Page 4 Studio Technologies, Inc.

Page 5

Introduction

What This User Guide Covers

This User Guide is designed to assist you

when installing, configuring, and using

the Model 230 Announcer’s Console. Additional background technical information

is also provided. A product block diagram

is included at the end of this guide.

System Overview

The Model 230 Announcer’s Console is

designed to serve as the audio control

“hub” for announcers, commentators, and

production personnel. The tabletop unit is

suited for numerous applications including

on-air television and radio broadcasting.

The Model 230 is compatible with essentially all broadcast and production audio

system environments. Standard connectors are used to interface microphone,

headphone, on-air, talkback, IFB, and

intercom signals.

Whether it’s the mic preamplifier, audio

switching, talkback signals, intercom interfacing, or headphone cue feed, superior

audio quality is maintained throughout. A

microprocessor provides the Model 230’s

logic power, allowing precise control of

the unit’s operation. With extensive flexibility built in, creating the desired operating

configuration is a simple matter. While the

operating features of the unit can be carefully tailored, the user is presented with an

easy-to-use set of controls and indicators.

A wide range of resources, great performance, and simplicity during use—these

are the hallmarks of the Model 230.

A truly next-generation product, exhaustive

research into the needs and desires of field

production personnel was integral to the

Model 230’s creation. Providing a veritable

“tool kit” of features, the unit supports a

wide variety of applications that include

on-air television and radio broadcasting,

stadium announcement, and simultaneous

Figure 1. Model 230 front panel

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 5

Page 6

Figure 2. Model 230 back panel

interpretation. In addition, with the unit’s

broad range of capabilities many other

specialized “behind-the-scenes” applications can also be implemented.

System Features

Microphone Input

A high-performance microphone preamplifier circuit provides low-noise/lowdistortion amplification over a 20 to 60

dB gain range. The gain is adjustable in

10 dB steps. The input is compatible with

balanced dynamic and condenser microphones. The microphone power source

is 48 volts nominal and meets the worldwide P48 phantom power standard. An

LED indicator serves as an aid for optimizing the preamplifier’s gain setting. The output of the microphone preamplifier is used

by the main output as well as being routed

to the compressor circuit that supports the

talkback functions.

Main Output

The Model 230 provides a main output that

is designed to serve as the on-air, stadium

announcement, or other primary audio

feed. Nominally –2 dBu, it is designed as

a fully professional interface with high

output capability, low distortion, and low

noise. The output circuitry features a

high-performance output transformer

expressly designed for professional

audio applications.

Talkback Functions

The talkback functions are intended

to provide personnel associated with

production trucks, control rooms, liveperformance, and sports venues with

talent-originated cue signals. The Model

230 contains two pushbutton switches that

control the talkback functions. Each button can be configured to allow talkback

audio to be routed to one of three locations: intercom channel 1, intercom channel 2, or a line-level talkback output. The

line-level talk-back output is transformercoupled with a +4 dBu nominal signal

level. It contains resistors in series with

the output connector, allowing line-level

talkback outputs from multiple units to be

directly “summed.”

For non-on-air applications, special Model

230 features can be enabled by placing

the unit in one of two “production” modes.

These software-based modes allow the

main output to be used either as a “hot

Issue 7, October 2008 Model 230 User Guide

Page 6 Studio Technologies, Inc.

Page 7

mic output” or as an additional talkback

output. These features make the unit even

more powerful when used in live-event

applications, such as serving as a master

console for an orchestra conductor or

production director.

With all the available talkback flexibility,

the exact needs of many specific applica

tions can easily be met. And, of course,

whatever configuration is implemented,

the audio quality will be excellent.

-

Dynamic Range Control

To enhance the Model 230’s talkback

functions, a studio-quality compressor

circuit is provided to control the dynamic

range of the signal coming from the microphone preamplifier. Far from a simple

“clipper,” the circuit utilizes a sophisticated

laser-trimmed voltage-controlled-amplifier

(VCA) integrated circuit for quiet, lowdistortion level control. The signal from

the compressor is used by the talkback

functions. This ensures that talkback

audio signals remain clear and intelligible

under all real-world conditions. In addition, dynamic range control is especially

important when talkback signals are being

routed to intercom channels.

User Controls and Status

Indicators

Three pushbutton switches, four LED

indicators, and two rotary controls provide

the user with a clear, easy-to-use interface.

One pushbutton switch controls the status

of the main output. This is the audio output intended for on-air, announcement,

or other primary uses. Two LEDs display

the on/off status of the main output. Two

additional pushbutton switches control the

status of the talkback functions. These are

the audio cue signals used to communicate with producers, directors, “spotters,”

or other behind-the-scenes production

personnel. A status LED is associated with

each talkback button. Two rotary controls

allow the user to adjust the level of the

headphone output.

Flexibility

A large part of the Model 230’s unique

power is the ability to configure the

operation of the main output and talkback

functions. To meet the needs of the many

specific broadcast and production applications, a variety of button operating

modes is available. The main output

button can be selected to operate from

among four modes. In the “push-to-mute”

mode the button performs a momentary mute of the main output. In this way

a “cough” button function is created,

something typically required for television

sports broadcasting. In the “push-to-talk”

mode the button provides a momentary

active function for the main output. This

mode would be appropriate for applications such as stadium announcement. An

alternate action “latching” configuration

allows the button to enable or disable the

main output as desired. This is useful in

radio broadcasting, announce-booth, or

voice-over applications. The fourth mode

provides a hybrid function, supporting

both push-to-talk and tap-to-enable/tap-todisable operation. This operation is similar

to that found in many broadcast intercom

system user stations.

The two buttons associated with the talkback functions can be configured to operate from either of two modes. One of the

modes supports a “push-to-talk” function.

This is typically used for on-air broadcast

applications. The other mode provides a

hybrid function, the operation of which is

discussed in the previous paragraph. The

hybrid mode is especially useful when the

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 7

Page 8

Model 230 is used in a production-support

application.

The main button mode configures how the

main output, when it is in the “latched” on

state, responds to talkback activity. One

choice momentarily turns off the main

output when talkback is active, returning

the main output to the on state when the

talkback function has ended. The other

choice “unlatches” the main output in

response to a talkback function.

For application flexibility, two line-level

audio sources can be connected to the

Model 230. Possible signal sources

include off-air receivers, wireless IFB

systems, and audio consoles. The connected signals can be from two independent sources, or could be from a stereo

audio feed such as would be associated

with a broadcast music event. Two level

trim potentiometers, located on the bottom

of the unit, allow signals with wide nominal

audio levels to be cleanly interfaced.

IFB Input

A broadcast-standard “wet” (DC with

audio) IFB circuit can be directly connected to the Model 230’s IFB input.

Originated by sources such as the RTS™

4000-series IFB system or IFB interface

devices from Studio Technologies, the

connected IFB circuit can provide DC

power to operate the Model 230 as well

as two channels of cue audio.

Cue Sources

The Model 230 supports the connection

of up to six audio sources, each of which

can be selected for routing to the stereo

headphone output. The sources are IFB

channel 1, IFB channel 2, line input 1, line

input 2, intercom channel 1, and intercom

channel 2. Each source can be individually assigned to the left channel, right

channel, or both left and right. This allows

a wide variety of stereo and mono headphone mixes to be created.

The two audio signals associated with

the Model 230’s IFB input can be assigned to the headphone output. Originating

in production trailers or control rooms,

the IFB circuits typically provide DC

power and program-with-interrupt audio

on one channel and program-only audio

on the other.

Audio signals associated with a single-

or dual-channel intercom system can

be routed to the headphone output. The

Model 230’s intercom interface is compatible with standard party-line intercom

systems from manufacturers such as RTS

and Clear-Com®.

Headphone Output

Two rotary controls are provided for user

adjustment of the headphone output

levels. For application flexibility the actual

function of the two “pots” is configurable.

For traditional on-air sports applications

they can be selected to the dual level

control mode which provides independent

control of the left and right channel volume. For use with stereo cue signals, or to

support user preference, the level/balance

mode can be selected. In this mode one

control adjusts the overall level of both

the left and right channels, while the other

allows adjustment of the left/right level

balance. To help minimize the chance of

broadcast cues being missed, both level

control modes can be configured so that a

minimum headphone output level is maintained. Alternately, the headphone output

can be set to fully mute when the controls

are at their minimum position.

Issue 7, October 2008 Model 230 User Guide

Page 8 Studio Technologies, Inc.

Page 9

A headphone control reverse mode is

provided specifically for on-air television

applications where a headset with boom

microphone is used. The reverse mode

ensures that no matter which headset orientation is used by the talent, the controls

will always work intuitively. This results in

a comfortable work environment, allowing the left control to impact the level to

the talent’s left ear while the right control

impacts the right.

Provision has been made to support applications where a monaural cue feed

is desired. A configuration switch allows

the summing (combining) of the selected

left and right headphone sources. In addition to creating a dual-channel mono

output it also allows the level controls

to be configured as a simple 2-channel

mixer. For applications where a single

“muff” headset or IFB-type earpiece is

connected, another configuration switch

can be used to disable the headphone

output’s right channel.

The headphone output is optimized to

meet the needs of contemporary headphones and headsets. Specifically, the

output circuits act as voltage, rather than

power, drivers. In this configuration they

can provide high output levels with very

low distortion and noise, along with minimal current consumption. The output circuits are configured to safely drive stereo

or mono loads. This ensures that all types

of headphones, headsets, and earpieces

can be directly connected.

Intercom Interface

Of special note is the Model 230’s sophisticated intercom interface. It’s designed

to work correctly with industry-standard

single- and dual-channel party-line intercom systems, including those from RTS

and Clear-Com. An intercom line connected to the Model 230 can serve three

functions: providing cue audio signals to

the headphone output, allowing talkback

audio to be sent to intercom users, and as

a Model 230 power source. Audio signals

present on the single- or dual-channel

intercom line can be flexibly routed to the

headphone output. Talkback audio can

be sent to either or both intercom channels. Trim potentiometers, located on the

bottom of the unit, allow adjustment of the

talkback-to-intercom null (“sidetone”) level.

Other announcer console products can

exhibit talkback-to-intercom-related audio

oscillations (“squeals”) that end up in

the headphone output. A special Model

230 feature ensures that this will never

occur. This is accomplished by means

of a special “auto-terminate” circuit that

becomes active whenever an intercom

line is not connected to the Model 230.

Active Sidetone Function

The Model 230 includes a unique active

sidetone function that’s available whenever

the unit is configured for one of the two

production modes. By routing audio from

the microphone input to the headphone

output a user confidence (“sidetone”)

signal is provided. This allows a user to

always hear what they are saying, a critical

requirement for effective communications.

The word “active” is part of the function’s

name because it involves active circuitry,

under software control, to achieve excellent

audio performance. The sidetone level is

dynamically configurable, allowing the user

to adjust the level as required.

Audio Quality and Protection

The Model 230’s circuitry is carefully

tailored to provide excellent audio performance. Professional-quality components

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 9

Page 10

are featured throughout. For reliability all

audio routing is performed using solidstate devices under microcontroller direction. In all critical audio paths, “clickless”

electronic switches provide noise-free

control. All audio inputs and outputs make

extensive use of protection components.

This limits the chance of damage from

ESD and other undesirable, yet real-world,

hazards.

Power Sources

The Model 230 can derive its operating

power from an IFB circuit, an intercom

line, or an external 24 volt DC source. For

redundancy, all three power sources can

be connected simultaneously. An internal

switch-mode power supply ensures that

all Model 230 features are available, including phantom power, when the unit

is powered by any of the three sources.

The Model 230 is compatible with IFB

circuits provided by most standard broadcast systems. However, maximum performance can often be obtained by using the

IFB interface devices available from Studio

Technologies. Single-channel and fourchannel units are available, each providing

high-quality audio along with an excellent source of DC power. They’re directly

compatible with most matrix intercom systems, as well as standard line-level audio

signals. Refer to the Studio Technologies

website for details.

Auxiliary Relay

Model 230 resources include a generalpurpose relay, allowing specialized configurations to be created. Under software

control, the relay can be configured to follow the state of the main output, talkback

1, or talkback 2 buttons. Taking advantage

of the back-panel locations provided for

additional XLR-type connectors, a technician may easily implement a variety of

functions such as an “on-air” indicator or

performing loudspeaker muting during

talkback. Special configuration modes are

even included to allow direct control of the

relay using the talkback 1 or talkback 2

buttons without impacting any of the unit’s

audio signals.

Configuration

Model 230 configurations are made using

a number of DIP-type switches and four

trim potentiometers. One 8-position switch

array is used to set the gain of the microphone preamplifier, the on/off status of

phantom power, and control of the headphone output modes. A 12-position switch

array configures which of the six cue

audio sources are routed to the headphone outputs. Two 8-position switch

arrays communicate the desired operating modes to the microprocessor. Two rotary trim pots are used to adjust the input

sensitivity of the line inputs. Two additional

rotary trim pots are provided to adjust the

“sidetone” level for the intercom interface’s talkback functions. All switches and

trim pots are accessible via the bottom of

the Model 230’s enclosure; the unit does

not have to be disassembled. Changes

made to any of the configuration parameters become active immediately. To prevent access to the configuration controls a

security panel, included with each unit, is

attached to the bottom of the enclosure.

Connectors

The Model 230 uses standard connectors

throughout. The microphone input, line

inputs, IFB input, and intercom interface

functions use 3-pin female XLR-type connectors. The main output and line-level

talkback output functions use 3-pin male

Issue 7, October 2008 Model 230 User Guide

Page 10 Studio Technologies, Inc.

Page 11

XLRs. The headphone output utilizes a

¼-inch 3-conductor jack. The external

source of 24 volt DC power is connected

by way of a 2.1 x 5.5 mm “locking” coaxial

power jack.

Additional Connector Locations

In the world of broadcast and production audio it’s fair to say that applications

vary widely. To this end, up to three additional XLR-type connectors can be easily

mounted into the Model 230’s back panel.

Multiple 3-position “headers” located on

the Model 230’s circuit board provide

technician-access to literally every input

and output connection. Using a factoryavailable interface cable kit, these allow

a Model 230 to be optimized to meet the

exact needs of specific applications. For

example, some applications may prefer

to use a multi-pin XLR-type connector to

interface with a headset. This could be

easily accomplished by adding the appropriate 5-, 6-, or 7-pin XLR-type connector

and making a few simple connections.

Other applications may benefit from having “mult” or “loop-through” connections,

something easily incorporated into a

Model 230.

Options

The Model 230’s standard resources are

more than sufficient to directly support a

large number of applications. But in the “real

world” of audio and intercommunications

special needs always seem to arise. To that

end, Studio Technologies offers a number of

option cards. In addition to passive or active

components, each card contains an integral

connector, allowing simple installation into

a spare connector location on the Model

230’s back panel. For interest, the resources

provided by some of these option cards are

worth describing.

• The direct microphone output card pro

vides access to the dynamic or condenser

microphone that is connected to the

Model 230’s mic input. Passive components, along with the auxiliary relay contact, create a “click-free” microphone-level

audio signal.

• The line output card allows the Model 230

to provide a second line-level talkback

output.

• The remote switch input card uses a 4-pin

XLR connector to provide access to the

Model 230’s remote switch inputs.

-

Multi-Pin Headset Connectors

As previously mentioned, some broadcast

applications use headsets that interface

using a multi-pin connector. In most cases

these connectors are 6- or 7-pin male

XLR-type wired to an industry-standard

pin out scheme. Studio Technologies

offers headset connector assemblies that

allow fast and painless installation into

a spare connector location in the Model

230’s back panel. Details about these

optional assemblies are available on the

Studio Technologies website.

• The tally/remote switch input card pro

vides a current-limited DC voltage that

serves as a main output status signal.

It also provides a remote switch input

connection.

Other general purpose option cards provide

3-pin XLR, 4-pin XLR, and 8-pin EtherCon®

connectors. With the range of option cards

available it’s hard to imagine an application

that can’t be served. But you’re welcome

to try to “stump the chumps” in the Studio

Technologies technical support department!

But first please check the complete list of

-

the available option cards listed on the

Studio Technologies website.

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 11

Page 12

200-Series Announcer

Console Products

The Model 230 is just one in a series of

announcer console products available

from Studio Technologies. The Model 230

was designed to support a variety of applications where a wide range of features

and flexibility is required. For applications

whose requirements are more limited in

scope, other products in the 200-series

should be reviewed. Complete information

is available on the Studio Technologies

website.

Installation and

Microphone Input

The Model 230 is compatible with

balanced dynamic and condenser microphones. Depending on the application,

the microphone may be part of a headset,

or be an independent handheld or standmounted model. The Model 230’s 48 volt

nominal power source will support essentially all phantom-powered microphones.

The quality of the Model 230’s microphone

preamplifier and associated circuitry is

such that special applications may benefit

from using “high-end” microphones. If

selected appropriately, models from manufacturers such as AKG, Beyerdynamic,

Neumann, Sennheiser, and Shure will perform very well in Model 230 applications.

Setup

In this section interconnections will be

made using the input and output connectors located on the Model 230’s back

panel. Microphone, IFB, line-level audio

source, intercom, main output, and linelevel talkback output signals are interfaced

by way of 3-pin XLR-type connectors. A

¼-inch 3-conductor phone jack is provided for the headphone output. A 2.1 x 5.5

mm coaxial jack allows connection of an

external 24 volt DC power source.

System Components

Included in the shipping carton are the following: Model 230 Announcer’s Console,

user guide, button label sheet, and 24 volt

DC power supply. For units shipped to

destinations in Japan and North America

the power supply will have a nominal AC

mains input of 120 volts. For all other destinations a power supply compatible with

220/240 volt AC mains will be included.

Microphone interconnection is made by

way of a 3-pin female XLR-type connector which is located on the Model 230’s

back panel. The mating connector (male)

should be wired so that pin 2 is signal

high (+ or hot), pin 3 is signal low (– or

cold), and pin 1 is shield. It’s possible that

an unbalanced microphone will also work

correctly. In this case, the mating connector (male) should be wired so that pin 2

is signal high (+ or hot), and signal

common/shield is connected to both

pins 1 and 3.

The Model 230 is not compatible with

unbalanced “electret”-type microphones

that require a source of low-voltage DC

for operation. These microphones, sometimes found in low-cost headsets, are

not generally suitable for on-air or other

demanding applications.

As of the writing date of this user guide,

the Sennheiser HMD25 headset is very

popular for on-air sports broadcasting

use. A fine product, it works very well with

the Model 230. Note that adding the suffix

Issue 7, October 2008 Model 230 User Guide

Page 12 Studio Technologies, Inc.

Page 13

“-XQ” to the headset’s part number

(HMD25-XQ) specifies a 3-pin male XLRtype connector for the dynamic microphone and a ¼-inch 3-conductor plug for

the stereo headphones. This configuration is very useful, allowing the headset

to work directly “out of the box” with the

Model 230.

If the writer may digress for a moment to

recount a story… an audio dealer once

shared a secret with me concerning headsets. He loved selling the “lower-end” (less

expensive) models of name-brand headsets, which he did by the veritable “boatload.” Why? Because these usually broke

soon after going into service! He knew

that on a regular basis he’d receive orders

for more of them. Had these users, from

the beginning, purchased only premiumquality headsets, their total cost of ownership would have been much less. Enough

said…

Headphone Output

The Model 230’s headphone output is

compatible with stereo or mono headphones, headsets, or earpieces. Connecting devices with a nominal impedance

of 100 ohms or greater is preferred. This

shouldn’t be an issue as essentially all

contemporary devices already meet this

condition.

Devices are connected to the headphone

output by way of a ¼-inch 3-conductor

phone jack located on the Model 230’s

back panel. As is standard for stereo

headphones, the left channel is connected

to the “tip” lead of the ¼-inch headphone

jack. The right channel is connected to

the “ring” lead of the jack. Common

for both channels is connected to the

“sleeve” lead.

Devices with ¼-inch 2-conductor “mono”

plugs can also be used with the Model

230’s headphone output. In this arrangement only the tip lead (left channel) will

be active. The 2-conductor plug will physically connect (“short”) the ring lead (right

channel) to the sleeve lead (common).

Technically this won’t damage the circuitry associated with the right-channel

headphone output. (51 ohm protection

resistors are electrically in series with the

headphone output circuits.) However,

energy will be wasted if an audio signal

coming out of the right channel goes into

a “dead” short. There is a simple means

of eliminating this issue; a configuration

setting allows the right channel of the

headphone output to be disabled. Refer

to the Configuration section of this user

guide for details.

Main Output

The main output is intended to be the “onair” signal that connects to the input of an

audio console. The output is transformer

balanced with a nominal signal level of

–2 dBu. The actual level will depend on

the gain setting of the microphone preamplifier, sensitivity of the microphone,

and how loudly the talent speaks into

the microphone. The transformer used

in the main output is intended for professional broadcast applications. It has a low

source impedance and can drive lengthy

cable runs with no difficulty. It is capable

of driving 600 ohm loads but performs

best with loads of 2 k ohms or greater.

(This should not prove to be an issue as

virtually all contemporary audio equipment

has a relatively high input impedance.)

As the secondary winding of the output

transformer connects directly to the main

output connector, care should be taken

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 13

Page 14

so that DC voltage is never present on the

interconnecting cable.

The main output is interfaced by means of

a 3-pin male XLR-type connector located

on the Model 230’s back panel. The interconnecting cable’s mating connector

(female) should be wired so that signal

high (+ or hot) is on pin 2 and signal low

(– or cold) is on pin 3. The cable’s shield

can be connected to pin 1, but it will have

no function. To limit the chance of grounding interaction between the Model 230 and

connected equipment, pin 1 on the main

output’s connector is isolated from any

point in the Model 230. The fact that pin 1

“floats” will minimize the chance of hums,

noises, or buzzes being present on the

equipment connected to the main output.

Line-Level Talkback Output

The line-level talkback output is intended to

be connected to control rooms, production

trailers, or other locations where talentoriginated voice cues are required. The output is transformer balanced with a nominal

level of +4 dBu. To enhance talkback audio

quality, a compressor circuit controls the

dynamic range of the signal coming from

the microphone preamplifier.

For protection against accidental connec

tion to cables that have DC power present,

the line-level talkback output is capacitor

coupled. In series with the talkback output

leads are 300 ohm resistors, making the

effective output impedance approximately

600 ohms. These resistors create a passive summing network, allowing talkback

outputs on multiple Model 230 units to be

connected together.

The line-level talkback output is connected

by way of a 3-pin male XLR-type connector which is located on the Model 230’s

back panel. The mating connector (female)

-

should be prepared so that signal high (+

or hot) is expected on pin 2. Signal low

(– or cold) should be expected on pin 3.

The cables’ shields can be connected to

pin 1. But, like the main output, in order

to minimize the chance that groundinteraction problems will arise, pin 1 on

the line-level talkback output connector is

isolated from the Model 230’s chassis and

circuitry. By making pin 1 “float,” an oftenfeared “ground loop” problem shouldn’t

arise.

The line-level talkback output is intended

to drive lengthy cable runs that are

frequently part of a remote broadcast

application. While the output circuitry is

not intended to be “on-air” quality, overall audio performance should be very

good. Devices connected to the line-level

talkback output can range from amplified loudspeakers to analog inputs on

intercom systems, and input channels

associated with audio consoles. Connecting the output to devices that allow easy

control of the signal level can be helpful.

For example, connecting to a spare input

module on an audio console provides

the flexibility to add gain or attenuate as

required. A dedicated talkback-associated

output on the audio console can then be

connected to the final destination(s).

As previously mentioned, the line-level

talkback output on multiple Model 230

units can be directly connected together.

Using a simple “Y” or “W” cable, this

passive summing (adding together) of

talkback signals allows one audio cable

to serve as a master talkback path. A side

effect from using this passive summing

technique is that signal attenuation will

occur. The audio quality won’t suffer, but

an audio “pad” is created. If two line-level

talkback outputs are connected together,

Issue 7, October 2008 Model 230 User Guide

Page 14 Studio Technologies, Inc.

Page 15

a signal attenuation of 6 dB can be expected. Connecting three outputs together

will result in 9.5 dB of attenuation. And

four outputs “multed” together will lead to

12 dB of attenuation. In most cases this attenuation won’t pose a problem. Typically

a device that receives the talkback signal,

such as an amplified loudspeaker, will

have an adjustable input sensitivity.

IFB Input

The Model 230’s IFB input is designed

to directly connect with “wet” (DC-biased)

IFB circuits. These circuits provide DC

power and one or two channels of audio

over a standard 3-conductor microphonestyle cable. Typically, the IFB circuit’s

interface connector is a 3-pin male XLRtype wired so that common is on pin 1,

DC with channel 1 audio is on pin 2, and

channel 2 audio is on pin 3. Some IFB

circuits may only have one audio channel.

In this case, audio will generally be on pin

3 with pin 2 providing only DC power.

The power supplied by an IFB circuit,

normally in the range of 28 to 32 volts DC,

is usually sufficient to operate the Model

230’s circuitry. The acceptable input range

is 24 to 32 volts, with a required current

of 125 milliamperes. Note that the specified input voltage is given when measured

directly at the Model 230’s IFB input connector, not at the source of the IFB circuit.

The one or two audio signals provided

by the IFB circuit can serve as the audio

sources for the headphone outputs.

In North American field and in-studio

broadcast applications it is common to

find RTS 4000-series IFB equipment being used to provide the IFB circuits. The

Model 230 can be directly connected to,

and function correctly with, one of these

circuits. For reliable operation, especially

when using lengthy cable runs, it’s strongly recommended that no other device be

connected to a 4000-series IFB circuit that

is specified for connection to a Model 230.

This requirement is due to the currentlimited DC source that is supplied by the

4010 IFB Controller.

With 4000-series IFB circuits channel 1

(XLR pin 2) provides program audio

that is “interrupted” with cue signals.

This channel is sometimes referred to

as “program-with-interrupt.” It’s important

to note that the program audio source

fully mutes whenever directors or producers are communicating with on-air talent.

Channel 2 (XLR pin 3) of the IFB circuit

provides a “program-only” audio feed. It

is never interrupted with cue signals.

While the Model 230’s IFB input was

designed for connection to a “wet” IFB

circuit, it’s also possible to connect linelevel audio sources. Please refer to the

Technical Notes section of this user guide

for details.

Line Inputs

The Model 230 allows two line-level audio

sources to be connected. These sources

can be individually routed to the leftchannel, right-channel, or both the leftand right-channel headphone outputs.

The inputs are balanced, transformercoupled with a nominal impedance of 10 k

ohms. Capacitors, in series with the transformer’s input leads, prevent a DC voltage

present on a connected source from

impacting performance. The line inputs

are compatible with signals that have a

nominal level of –12 dBV to +6 dBu. Two

trim potentiometers, located on the bottom of the Model 230’s enclosure, allow

signals over this wide nominal level range

to be effectively utilized. Audio sources are

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 15

Page 16

connected to the line inputs by way of

3-pin female XLR-type connectors which

are located on the unit’s back panel.

Prepare the mating connectors (males) so

that pin 2 is signal high (+ or hot), pin 3

is low (– or cold), and pin 1 is shield. If

connecting a source in this manner results

in hum or noise, it’s possible that removing the shield connection from pin 1 can

eliminate the issue. With an unbalanced

source connect pin 2 to signal high (+

or hot) and both pins 1 and 3 to shield. If

connecting an unbalanced source in this

manner results in hum or noise, connect

pin 2 to high (+ or hot) and pin 3 to shield;

leave pin 1 unterminated.

Intercom Interface

The Model 230’s intercom interface is

designed to directly connect with standard

single- and dual-channel party-line intercom lines. The one or two audio signals

provided by the intercom line can serve

as audio sources for the headphone

outputs. Each signal can be individually

assigned to the left channel, the right

channel, or both the left and right channels. The Model 230 can be configured

to send talkback audio to either or both

of the intercom channels. In addition, the

intercom line can also provide the DC

power required to operate the Model 230’s

circuitry.

The intercom line is connected to the

Model 230 by way of a 3-pin female XLRtype connector which is located on the

back panel. The mating connector (male)

should be wired so that common is on

pin 1, DC with channel 1 audio is on pin

2, and channel 2 audio is on pin 3. With

single-channel intercom lines common is

on pin 1, DC power is on pin 2, and audio

is connected to pin 3.

The Model 230’s intercom interface is

directly compatible with broadcast and

production party-line intercom lines associated with systems from manufactures

such as RTS and Clear-Com. Intercom

lines associated with other systems

should be equally compatible. RTS TW

series systems are normally interfaced

using 3-pin XLR-type connectors. These

connectors are wired with common on

pin 1, DC power and channel 1 audio on

pin 2, and channel 2 audio on pin 3. With

many Clear-Com systems, common is on

pin 1, DC power is provided on pin 2, and

audio is provided on pin 3.

The DC power supplied by the connected

intercom line is generally sufficient to

operate the Model 230’s circuitry. The

acceptable input range is 24 to 32 volts,

with a required current of 125 milliamperes. Note that the specified input voltage is given when measured directly at

the Model 230’s intercom connector, not

at the source of the intercom line.

External Power Input

An external source of 24 volt DC power

can be connected to the Model 230 by

way of a 2.1 x 5.5 mm coaxial power jack

which is located on the back panel of

the unit. The center pin of the jack is the

positive (+) connection. While the requirement for the external source is nominally

24 volts, correct operation will take place

over a 20 to 30 volt range. The Model 230

requires 90 milliamperes at 24 volts DC

for correct operation. Included with each

Model 230 is a 24 volt DC external power

supply. The power supply’s DC output

cable has been terminated with a Switchcraft® S760K coaxial power plug. This

“locking” type of plug correctly mates

with the Model 230’s 24 Vdc input jack.

The locking feature is important, allowing

Issue 7, October 2008 Model 230 User Guide

Page 16 Studio Technologies, Inc.

Page 17

the external power source to be securely

attached to the Model 230.

As previously discussed in this user guide,

an IFB circuit or intercom line connected

to the Model 230 can serve as the unit’s

power source. Alternately, an external 24

volt DC source can be connected. For

redundancy, the IFB circuit, the intercom

line, and the external source can be connected at the same time. If one of them

becomes inoperative, one of the remaining sources can provide all Model 230

power.

The Model 230’s circuitry establishes the

priority in which the unit draws its operating power. If an external source of 24

volt DC power is connected, it will always

serve as the primary source. This minimizes the impact that the unit’s power

draw could have on a connected IFB circuit or intercom line. If no external source

of 24 volt DC is connected and both an

IFB circuit and an intercom line is connected, power will be drawn only from the

intercom line. This is because intercom

lines, by design, are better able to supply

power to devices such as the Model 230.

Multiple devices, such as intercom belt

packs, are expected to be connected to,

and powered by, a single intercom line.

IFB circuits are quite different, typically designed to only supply a limited amount of

energy. This limitation can be compounded by the fact that IFB circuits are often

distributed using very long cable “runs.”

So in conclusion, the Model 230’s power

draw priority was established so as to

minimize the chance that IFB circuit

performance would be impaired. And,

of course, no matter which source is providing power, audio signals from the IFB

circuit and intercom line can still serve

as headphone output audio sources.

Pushbutton Labeling

The three pushbutton switches used in

the Model 230 were selected for several

reasons. Foremost was the fact that they

are highly reliable, using gold-plated contacts for long life in less-than-ideal environments. A second reason was that applying

customized labels to the button caps

would be very simple. The labels, text

printed on clear material, are placed under

the clear caps on the top of the buttons.

From the factory the left button is labeled

COUGH, the center button is labeled

TALKBACK 1, and the right button is

labeled TALKBACK 2. This was selected

to be appropriate for many on-air applications in English-speaking locations. But

it’s expected that these may need to be

changed to meet the needs of specific

applications.

As a “head start” for some applications,

a clear sheet with a number of commonly

used button designations printed on it

is included in the shipping carton. These

were created at the factory using a standard personal computer graphics program

and laser printed onto 3M CG3300 transparency film. The desired button labels

can be cut out with a pair of scissors, following the printed guide lines that indicate

the required size.

The clear lens on top of each button cap

can be removed with a fingernail or small

screwdriver. Be certain not to scratch the

button if a screwdriver or other small tool

is used. The clear label can be removed

and replaced. The button cap is then

snapped back into the top of the button

housing using finger-pressure only. No

tool is required to replace the button cap.

If you need to make your own labels the

process is quite simple. Use a personal

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 17

Page 18

computer to create the desired text. The

finished label size should be 0.625-inches

(15.8 mm) square. The completed artwork can then be printed on transparency

film sheets using a laser or inkjet printer.

These sheets are readily available from

most office supply stores. A pair of scissors

or an X-ACTO® knife will complete the task.

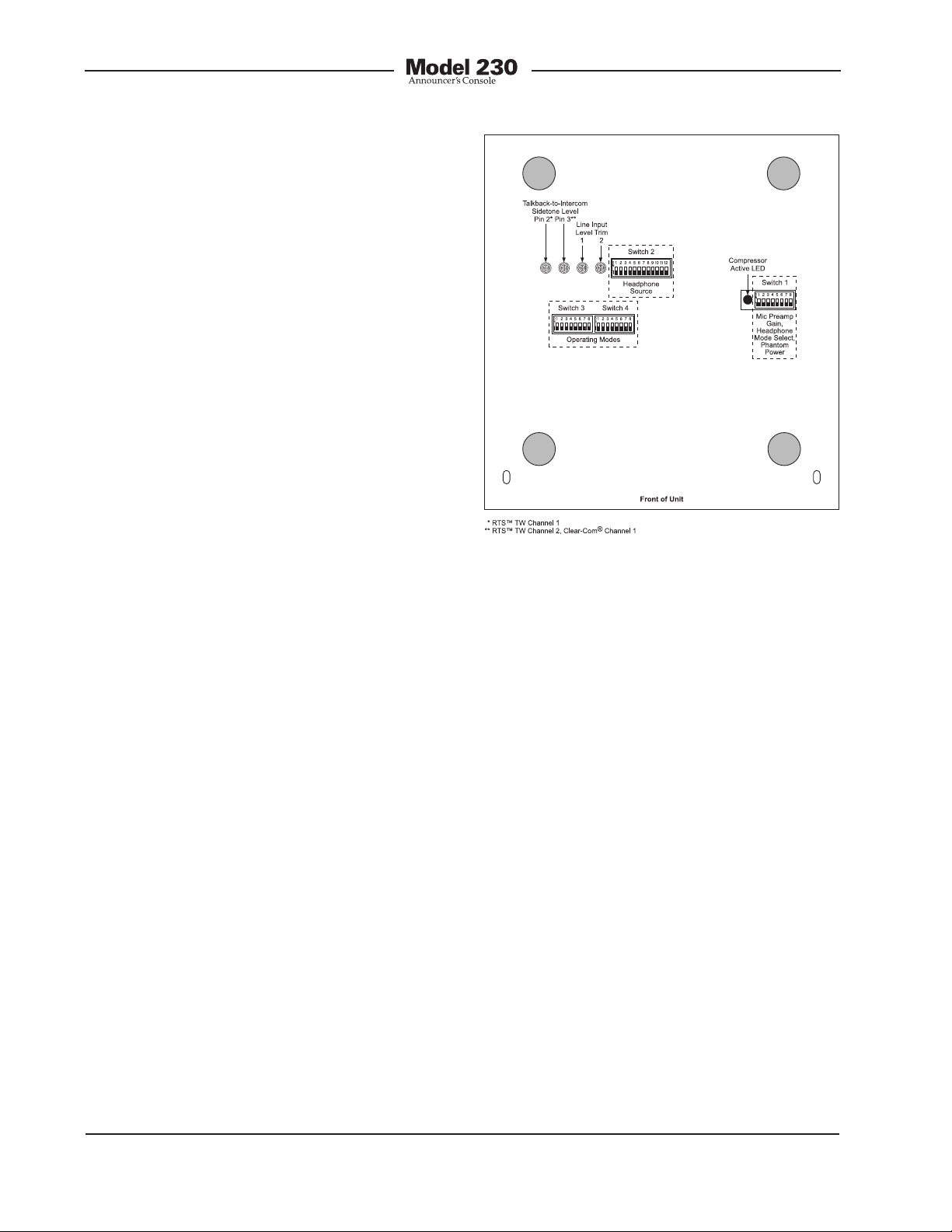

Configuration

For the Model 230 to support the needs

of specific applications a number of operating parameters must be configured.

These include microphone preamplifier

gain, phantom power on/off, headphone

source and output mode selection, and

operating modes. One 12-position and

three 8-position DIP-type switch assemblies

are used to establish the desired configuration. These switch assemblies are referred

to as SW1 through SW4, with individual

switches designated as SW1-1, SW1-2,

etc. The switch assemblies are accessed

through openings in the bottom of the

Model 230’s enclosure. The enclosure

does not have to be disassembled to gain

access to the switches.

To prevent unauthorized personnel from

changing the configuration settings, a

security plate is attached to the bottom

of the Model 230’s enclosure. For convenience, attached to the security plate is a

configuration settings label. It provides a

summary of the configurable parameters

and related information. Refer to Appendix

A for a representative view of the label. The

security plate is held in place by means

of four rubber bumpers (“feet”) that have

built-in screws. Using your fingers, remove

the four bumpers so that the plate can be

removed. Refer to Figure 3 for a detailed

view of the configuration switch assemblies.

Figure 3. Bottom view of Model 230 showing

configuration switches, trim pots, and

compressor active LED

Microphone Preamplifier Gain

and Phantom Power

Five switches are used to set the gain of

the microphone preamplifier. One switch is

used to select the on/off status of the phantom power supply.

Microphone Preamplifier Gain

Switches SW1-1 through SW1-5 are used to

select the gain of the microphone preamplifier. The choices are 20, 30, 40, 50, and 60

dB. Only one switch should be enabled at a

time. There’s no problem changing the gain

setting while the unit is operating. Audio

clicks or pops might occur during gain transitions, but this shouldn’t be a major issue

as long as associated monitor loudspeakers

are temporarily attenuated or muted.

Selecting the correct amount of gain for an

application might take a little experimentation. The goal is to bring the microphone’s

Issue 7, October 2008 Model 230 User Guide

Page 18 Studio Technologies, Inc.

Page 19

Figure 4. Microphone preamplifier gain switch

settings

signal up to line level, nominally –2 dBu,

on the Model 230’s main output. Operating at this signal level will help to ensure

the delivery of “clean” audio to the connected device. The output of the Model

230’s microphone preamplifier is used

by both the main output and, by way of

the compressor circuit, the talkback functions. So creating a nice “hot” signal will

help maintain audio quality, specifically

the signal-to-noise ratio, when driving the

often-lengthy cable runs.

Unfortunately, there’s no “perfect” gain

setting that this guide can recommend.

The two issues that impact the setting

are output sensitivity of the connected

microphone and the acoustical output

level of the microphone’s user. With

some headset microphones, such as the

Sennheiser HMD25, selecting an initial

setting of 40 dB is appropriate. Users who

speak loudly might need to have the gain

reduced to 30 dB. Quiet users might

need 50 dB of gain.

An LED indicator is provided as an aid

in correctly setting the gain of the microphone preamplifier. Red in color, this LED

is located adjacent to switch assembly 1.

It is visible by observing the bottom of the

Model 230’s enclosure when the security

plate has been removed. Technically, this

red LED lights whenever the compressor

circuitry is controlling the dynamic range

of the signal coming from the microphone

preamplifier. The threshold is set to be 2

dB above the Model 230’s nominal internal

operating level. So a good “rule of thumb”

is to adjust the gain of the microphone

preamplifier so that the compressor active

LED lights (“flashes”) when the connected

microphone is sending signal peaks. During normal operation the LED should not

remain fully lit when audio is present on

the mic input.

It’s important to remember that the compressor active LED is used to assist in setting the gain to the optimal value. It doesn’t

indicate that the main output’s signal is

being compressed. With the Model 230,

unless specifically modified to perform

otherwise, the output of the compressor is

only used for the talkback output functions.

It’s expected that the 20 and 60 dB gain

settings will not often be used. But there are

always exceptions and that’s why they were

included. It’s possible that with a very “hot”

microphone, such as a phantom-powered

condenser-type, 20 dB of gain could be

correct. It’s also possible that a microphone with a very low-level output, such

as a ribbon-type, would need 60 dB of gain.

But in general, the 30, 40, and 50 dB gain

settings will serve most applications.

Note that if no gain switch is set to its active

(on) position the preamplifier will operate at

unity (0 dB) gain. In this mode the preamplifier remains stable, but is intended for use

only during factory testing. A valid exception would be where a line-level signal is

connected to the microphone input. This

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 19

Page 20

could occur with special Model 230 applications. But with a microphone connected

as the input source one should never use

the 0 dB setting. The issue is that with no

gain added to the microphone input signal, the relative noise floor on the circuitry

associated with the main output and

talkback functions will be much too high.

These circuits are designed for handling

line-level signals, expecting to receive

audio from the output of the microphone

preamplifier. In conclusion, the 0 dB gain

setting doesn’t highlight a problem, but

simply reflects the unit’s gain structure.

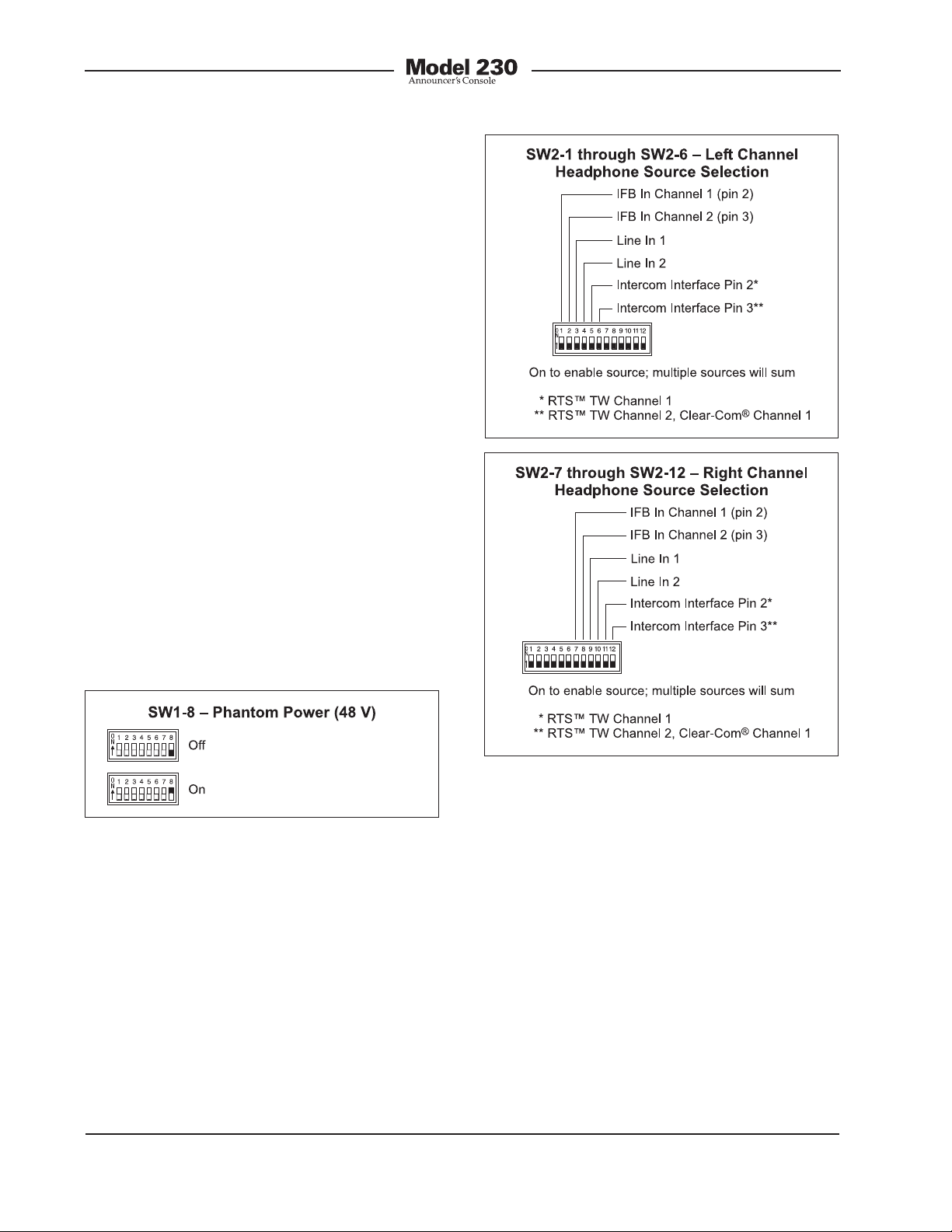

Phantom Power On/Off

The Model 230 can provide nominal 48

volt phantom power to the microphone

input. Switch SW1-8 controls whether or

not phantom power is active. By phantom

power’s very nature it could be left applied

to the microphone input at all times. But

generally people prefer to turn it off unless

required for a specific microphone.

Figure 6. Left and right channel headphone

source selection settings

Figure 5. Phantom power switch settings

The line inputs are connected using two

connectors also located on the back pan-

Headphone Source Selection

Switch assembly SW2 is used to configure the source or sources that are routed

to the stereo headphone output. The six

headphone sources are IFB channel 1,

IFB channel 2, line input 1, line input 2,

intercom channel 1, and intercom channel

2. The IFB channels are provided by way

of the IFB input connector located on the

Model 230’s back panel.

Issue 7, October 2008 Model 230 User Guide

Page 20 Studio Technologies, Inc.

el. Associated with line inputs 1 and 2 are

level trim potentiometers. They are provided so that audio sources with a wide

range of nominal levels can be effectively

used as cue sources. Please refer to the

Advanced Operation section of this user

guide for details on using the trim pots.

Audio associated with intercom channels

1 and 2 is provided by way of the intercom

interface whose connector is also located

Page 21

on the back panel. Two trim pots are

associated with the intercom channels.

They allow adjustment of the user’s sidetone level—the talkback audio signal that

is returned to a headphone output when

a talkback-to-intercom function is active.

Each of the available input sources can

be assigned to the headphone output’s

left channel, right channel, or both the

left and right channels. The Model 230’s

circuitry allows any combination of input

assignments to be made. For example,

consider the situation where a singlechannel intercom line, with audio present

only on pin 3, is connected. In this case

it may be desirable to assign this intercom audio source to both the left and

right channels. This would entail setting

switches SW2-6 and SW2-12 to their on

positions. All other switches would remain

in their off positions.

A more complex application might have

a 2-channel IFB circuit connected to the

IFB input and a line-level audio signal from

a golf event “spotter” connected to line

input 1. In a case such as this, it would be

typical for IFB channel 1 to be assigned to

the headphone’s left channel, IFB channel

2 assigned to the right channel, and line

input 1 also assigned to the right channel.

This would allow both IFB channel 2 and

“spotter” audio to be heard in the headphone’s right-channel output. To achieve

this would require that switches SW2-1,

SW2-8, and SW2-9 be placed in their on

positions.

occurs is when on-air talent needs to have

a headset’s boom microphone come across

the right side of their face, rather than

the more-typical left side. In this case

it’s important to select the left- and rightchannel headphone source assignment

accordingly. With the Model 230’s flexible

source selection there’s no reason why

users, such as on-air talent, shouldn’t

have their cue sources assigned correctly.

Special applications may benefit by us

ing the Model 230 in a special “2-channel

headphone output mixer” mode. This is

accomplished by first configuring the headphone output to monaural. (Details on how

to accomplish this are described later in

this section of the user guide.) Next the cue

source whose level is to be adjusted by the

rotary control on the left side of the front

panel is assigned to the left channel. Finally,

the cue source whose level is to be adjusted

by the right control is assigned to the right

channel. During operation the user will create their desired cue mix using the two frontpanel controls.

There may also be cases where a monaural

“single-muff” headset or headphone will be

connected to the Model 230’s headphone

output. In this case the desired source

must be routed only to the left channel.

This is because the 2-conductor plug that’s

typically associated with a mono headset

or headphone will connect only to the tip

lead (left channel) of the headphone output.

Signals assigned to the right channel will

not be heard by the user.

Note that in some cases a user may wish

to wear a headset or a pair of headphones

in a left/right orientation opposite of what’s

usual. In this situation the transducer designated for the left ear would actually supply audio to the user’s right ear, and vice

versa. A specific application where this

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 21

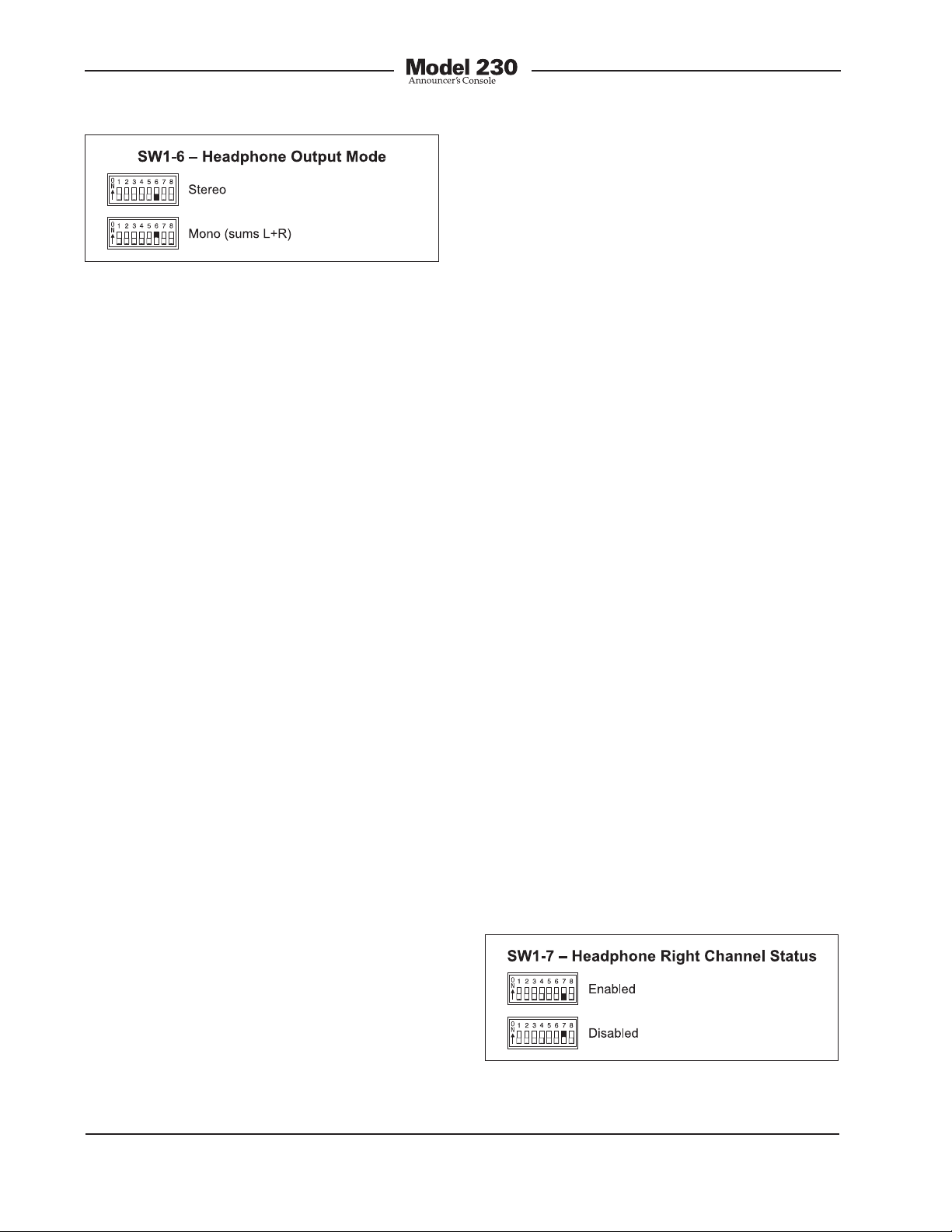

Headphone Output Mode

Switch SW1-6 allows a monaural headphone output to be created. This is

accomplished by summing (adding) the

selected left- and right-channel cue signals.

The combined signals are sent to both the

Page 22

Figure 7. Headphone output mode settings

left- and right-channel headphone output

driver circuits. The outputs of these circuits connect, by way of 51 ohm series

protection resistors, to the headphone

output jack.

The headphone output monaural mode

feature was specifically included so that

a special “2-channel headphone mix”

mode can be created. By enabling the

mono mode, the two front-panel user level

controls (“pots”) can be used to create

the desired “mix” of signals being sent

to the headphone outputs. Many, many

applications, especially in production

settings, can benefit from this capability.

The desired cue sources must be carefully

assigned to take advantage of the monaural mode. The first cue source should be

assigned, using the DIP-type switches,

to the left channel. Its output level will be

adjusted by the left control. The second

cue source should be assigned to the

right channel. Its output level will be adjusted by the right control.

There is one limitation related to the headphone output mode. It’s the fact that the

output will be 2-channel monaural. Whatever signal is present on the headphone

output’s left channel will also be present

on the right channel. (The exception is

if the right channel output is disabled.)

A stereo headphone mix can’t be created.

But in most cases this limitation won’t

overshadow the benefit of being able to

create the mix. For signal-flow clarification

please review the block diagram located

at the end of this user guide.

Headphone Output—Right

Channel Status

Switch SW1-7 allows the right channel

of the headphone output to be disabled.

This is provided for applications where

monaural headsets or headphones are

going to be connected. In general, monaural devices use 2-channel (tip and

sleeve) ¼-inch plugs. When inserted into

the Model 230’s stereo (3-conductor)

headphone output jack the right channel,

electrically connected to the jack’s ring

lead, will be shorted. While this condition

should not damage the output circuit, it

will cause current to flow unnecessarily.

To minimize this possibility disable the

right channel output by placing switch

SW1-7 to its on position.

It’s important to note that the circuitry

that disables the right channel is electrically just prior to the right channel output

circuit. It is after (“post”) all other circuitry,

including the source assignment DIPtype switch, level controls, and monaural

function. It will not impact normal use of

the other functions, including the ability to

create the special “2-channel headphone

mix” mode previously discussed. For

signal-flow clarification please review the

block diagram located at the end of this

user guide.

Figure 8. Headphone output—right channel

status settings

Issue 7, October 2008 Model 230 User Guide

Page 22 Studio Technologies, Inc.

Page 23

Operating Modes

The sixteen switches associated with

switch assemblies SW3 and SW4 are

used to configure the Model 230’s operating modes. Technically, these switches

“talk” to the microcontroller integrated

circuit and associated software that give

the Model 230 its “smarts.” The software

has been carefully designed to provide

a number of different ways in which the

unit can function. It’s critical to carefully

review the available options and choose

the ones that best meet the needs of a

specific application. Note that switches

can be changed even while the Model 230

is powered up and operating. The unit’s

operating characteristics will change in

“real-time” in response to configuration

changes.

Main Output Button Mode

Switches SW3-1 and SW3-2 configure

how the main output button functions.

• Push to talk: In this mode the main out

put is normally muted. The main output

will become active whenever the button

is pressed and held.

• Alternate action: In this mode the main

output will change between its active

and muted state whenever the button

is pressed. Upon power up the main

output will be in its muted state.

• Hybrid: This mode is a combination

of push to talk and alternate action. It’s

similar to the way talk buttons function

on user stations associated with broadcast and production intercom systems.

If the button is pressed and held, the

main output will become active until

the button is released. If the button is

momentarily “tapped” the main output

will change state. Upon power up the

main output will be in its muted state.

Talkback 1 Button Mode

Switch SW3-3 configures how the talkback

1 button functions.

Figure 10. Talkback output 1 button mode

settings

Figure 9. Main output button mode settings

Two modes are available:

There are four available modes:

• Push to mute: In this mode the main

output is normally active. The main

output will mute whenever the button is

• Push to talk: In this mode the talkback

1 button is normally off. The function

becomes active whenever the button

is pressed and held.

pressed and held. This is the “cough”

mode typically used for on-air sports

broadcasting applications.

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 23

Page 24

• Hybrid: This mode is a combination of

push to talk and alternate action. If the

button is pressed and held, the talkback

1 button will become active until the

button is released. If the button is

momentarily “tapped” the state will

change. Upon power up the talkback 1

button will be in its off state.

Talkback 2 Button Mode

Switch SW3-4 configures the way the talk

-

back 2 button functions.

Figure 11. Talkback output 2 button mode

settings

Two modes are available:

• Push to talk: In this mode the talkback 2

button function is normally off. The func

tion will become active whenever the

button is pressed and held.

• Hybrid: This mode is a combination

of push to talk and alternate action.

If the button is pressed and held, the

talkback 2 button will become active

until the button is released. If the button

is momentarily “tapped” the state will

change. Upon power up the talkback 2

button will be in its off state.

Talkback 1 Function Mode

Switches SW3-5 and SW3-6 configure the

overall operation of the talkback 1 button.

Figure 12. Talkback output 1 function mode

settings

Four modes are available:

• Disabled: In this mode the talkback 1

button is disabled. The exception is if

the auxiliary relay is configured to follow

the status of the talkback 1 button. In

this case the button will control the relay; no other functions will be impacted.

• Talk to talkback output: In this mode the

talkback 1 button will control the routing

of audio to the line-level talkback output.

• Talk to intercom interface pin 2: In this

mode the talkback 1 button will control

the routing of talkback audio to pin 2 of

the intercom interface. Pin 2 is channel 1

of an RTS intercom system.

• Talk to intercom interface pin 3: In this

mode the talkback 1 button will enable

the routing of talkback audio to pin 3 of

the intercom interface. Pin 3 is channel

2 of an RTS TW intercom system. For

a single-channel Clear-Com intercom

system it will be channel 1.

Talkback 2 Function Mode

Switches SW3-7 and SW3-8 configure the

overall operation of the talkback 2 button.

Issue 7, October 2008 Model 230 User Guide

Page 24 Studio Technologies, Inc.

Page 25

Figure 13. Talkback output 2 function mode

settings

Four modes are available:

• Disabled: In this mode the talkback 2

button is disabled. The exception is if

the auxiliary relay is configured to follow

the status of talkback button 2. In this

case the button will control the relay;

no other functions will be impacted.

• Talk to talkback output: In this mode the

talkback 2 button will control the routing

of audio to the line-level talkback output.

the way the controls function. With just

these three switches a wide range of operating modes can be configured. Carefully

reviewing the capabilities of the available

functions may prove worthwhile.

Dual-Channel or Stereo Mode

Switch SW4-1 is used to select whether

the controls provide a dual-channel

(“level/level”) or stereo (“level/balance”)

mode of operation. In the level/level mode

the two controls operate independently,

each controlling the level of one of the

headphone output channels. This mode

is generally used for on-air broadcast

applications where independent cue

signals are provided to the left- and

right-headphone channels. In the level/

balance mode the left control sets the

overall output level for both headphone

channels. The right control is used to adjust the balance (the relative levels) of the

left and right channels. This mode is generally best suited for applications where a

stereo cue source is being provided.

• Talk to intercom interface pin 2: In this

mode the talkback 2 button will control

the routing of talkback audio to pin 2 of

the intercom interface. Pin 2 is channel 1

of an RTS TW intercom system.

• Talk to intercom interface pin 3: In this

Figure 14. Headphone control mode settings

mode the talkback 2 button will enable

the routing of talkback audio to pin 3 of

the intercom interface. Pin 3 is channel

2 of an RTS TW intercom system. For

a single-channel Clear-Com intercom

system it will be channel 1.

Reverse Left/Right Mode

Switch SW4-2 is used to select whether the

rotary controls are in the normal or reverse

left/right mode of operation. When selected

to the normal mode, and level/level mode

Headphone Output Operating Modes

The user is provided with two rotary level

controls (“pots”) that are associated with

the headphone output. Switches SW4-1,

SW4-2, and SW4-3 are used to configure

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 25

is also selected, the left control adjusts the

level of headphone output’s left channel.

(This is the signal that appears on the tip

lead of the ¼-inch 3-conductor jack.) The

right control adjusts the level of the right

Page 26

Figure 15. Headphone control operation

settings

Figure 16. Headphone output minimum level

settings

channel. When selected to the normal

mode, and the level/balance mode is also

selected, turning the balance control in

the counterclockwise direction increases

the perceived level of the left channel, and

vice versa.

As you may have already guessed, when

selecting the reverse left/right mode of operation everything is reversed! To be more

specific, when selected for reverse mode,

and the level/level mode is also selected,

the left control adjusts the headphone

output’s right channel (output jack’s ring

lead) while the right control adjusts the

left channel. When selected to the reverse

mode, and the level/balance mode is also

selected, turning the balance control in

the counterclockwise direction increases

the perceived level of the right channel,

and vice versa.

The reverse mode is provided specifically

for cases where a headset’s left and right

ear pieces are placed on a user’s head

in a reverse orientation. This ensures that

the user is provided with a consistent

and easy-to-use set of headphone level

controls.

Minimum Level Mode

Switch SW4-3 is used to configure the

headphone output’s minimum level. In

the –40 dB mode the minimum headphone output level is 40 dB below maximum. The headphone output channels

will never fully mute. This ensures that any

audio signal present on the selected Model

230 inputs will always be present on the

headphone output. In most on-air broadcast

applications this is the appropriate setting.

When the full mute mode is selected and

the level/level mode is also selected, moving

either control to its fully counterclockwise

position will cause its associated channel

to fully mute.

When the full mute mode is selected and the

level/balance mode is also selected, turning

the level control to its fully counterclockwise

position will cause both headphone channels to mute. Turning the balance control

to either its fully clockwise or fully counterclockwise position will cause the appropriate

channel to mute.

Selecting the full mute mode may be appropriate for applications where minimizing the

chance of audio “leakage” is important. This

could occur when the connected headset or

headphones are at times placed on a desk

or tabletop.

Main Button Mode

Switch SW4-4 is used to configure how the

main button responds to talkback activity.

Specifically it applies only when the system

is selected for one of the on-air modes and

the main output button mode has been configured for alternate action or hybrid. When

the main button mode is set to normal and

a talkback function is active, the main output

will, if “latched” on, be temporarily placed

Issue 7, October 2008 Model 230 User Guide

Page 26 Studio Technologies, Inc.

Page 27

Four modes are available:

Figure 17. Main button mode settings

in its off (muted) state. When the talkback

function is no longer active the main output

will return to its previous latched on state.

When the talkback forces main button to

latch off mode is selected, and a talkback

function becomes active, the main output

will, if latched on, be placed in its off (muted) state and the latch condition forced off.

When the talkback function is no longer

active the main output will remain in the

latched off state.

The differences in how the main button

modes impact operation and user comfort

are relatively subtle. The nuances of both

modes should be considered before a final

selection is made. If possible, experimenting with both modes in a test environment

might prove to be very helpful.

Auxiliary Relay Control Mode

Switch SW4-5 and SW4-6 configure the

operating mode of the auxiliary relay.

• Relay disabled: In this mode the relay

is disabled and will never change state.

• Follows main output status: In this mode

the relay will follow the state of the main

output. Specifically, the relay will change

state (energize) whenever the main output is active.

• Follows talkback 1 button status: In this

mode the relay will follow the state of the

talkback 1 button. Specifically, the relay

will change state (energize) whenever the

button is active.

• Follows talkback 2 button status: In this

mode the relay will follow the state of the

talkback 2 button. Specifically, the relay

will change (energize) state whenever the

button is active.

System Modes

Switches SW4-7 and SW4-8 are used to

configure the overall operating mode of

the Model 230. Understanding how the four

modes impact overall system operation will

ensure that correct operation and maximum

usability will occur. When selected to one

of the two on-air modes, the main output

will mute whenever a talkback function is

active. The LED indicators associated with

the main output will light accordingly. An

on-air mode should be selected for all onair broadcast applications. It’s imperative

that the main output be muted whenever

on-air talent is using one of the talkback

functions to communicate with production

personnel.

The Model 230’s system mode can also

be set to on-air with special sidetone. This

is provided specifically to support on-air

applications where only a “mix-minus”

Figure 18. Auxiliary relay control mode settings

cue signal is provided to the on-air talent.

Audio from their own microphone is never

Model 230 User Guide Issue 7, October 2008

Studio Technologies, Inc. Page 27

Page 28

Figure 19. System mode settings

returned, via an external cue feed, to one

of the Model 230’s inputs. In this system

mode the buttons and LED indicators

function identically to that of the standard

on-air mode, but internal audio routing

and operation of the headphone level

controls work quite differently. Whenever

audio is being sent to the main output or

talkback functions, it is also routed to the

left and right channels of the headphone

output. This provides the on-air talent with

a confidence (“side-tone”) audio signal.

In the on-air with special sidetone mode

the two controls no longer provide a level/

level or a level/balance mode of operation.

Instead, the left control is used to adjust

the level of the sidetone signal being sent

to the left and right channels of the headphone output. The right control no longer

adjusts the level of the right channel headphone output or, if configured for “level/

balance” mode, the left/right balance. The

right control is used to adjust the level of

the external cue signals that are assigned

to the left and right channels of the headphone output. To highlight, the right rotary

control acts as a stereo level control—the

left/right balance of the externally provided

cue signals can’t be adjusted. This is a

compromise that shouldn’t pose a serious

operational problem.

Note that when the system mode is config

ured for on-air with special sidetone, two of

the three configurable headphone control

parameters continue to function in their

normal ways. The minimum level mode

performs the same functions. The reverse

left/right function selects which control is

used for sidetone level and which control

is used to adjust the level of the externally

provided cue sources. However, the headphone control mode that selects between

dual channel (“level/level”) and stereo

(“level/balance”) is no longer active.

When the system mode is set for production 1 two major changes occur as compared to the on-air mode. The first change

is that the main output becomes a “hot

microphone output.” This is created by