Page 1

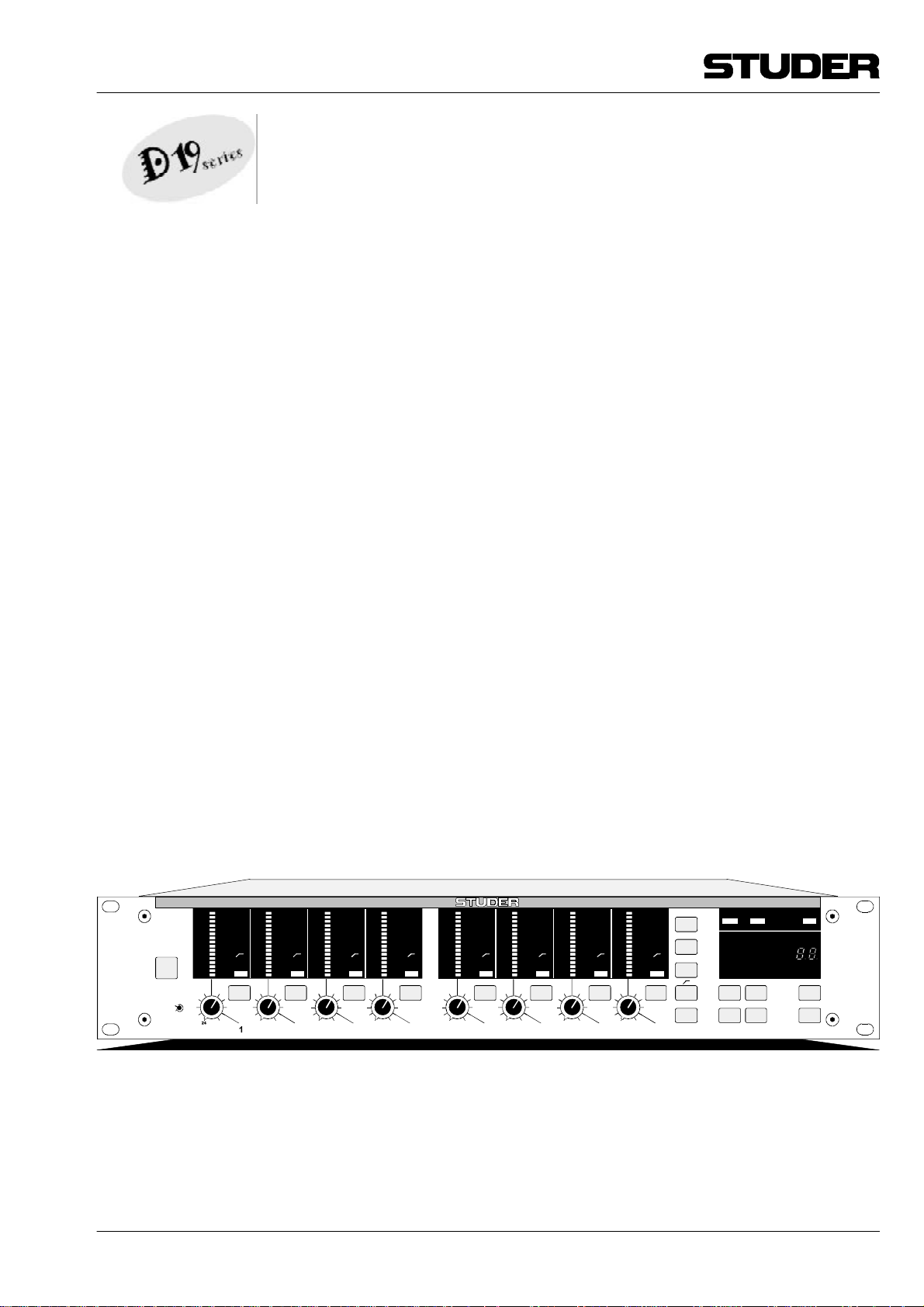

D19 MicAD

8-Channel Mic/Line Preamplifier

with Digital Outputs

Betriebsanleitung

Operating Instructions

MicAD

POWER

MIC

LINE

OVL

-1

-3

-6

-9

-12

-18

-24

-30

-40

-60

12

18

dBu/FS

LINE

OVL

-1

-3

-6

MIC

-9

-12

LINE

-18

Ø

-24

48V

-30

-40

-60

SEL

6

12

0

18

-6

24

dBu/FS

LINE

OVL

-1

-3

-6

MIC

-9

-12

LINE

-18

Ø

-24

48V

-30

LINK

-40

-60

SEL SEL SEL

6

12

0

18

-6

24

dBu/FS

2 3

LINE

OVL

-1

-3

-6

MIC

-9

-12

LINE

-18

Ø

-24

48V

-30

-40

-60

6

0

-6

6

12

18

-6

24

dBu/FS

LINE

OVL

-1

-3

-6

MIC

-9

-12

LINE

-18

Ø

-24

48V

-30

LINK

-40

-60

12

18

0

24

dBu/FS

4 5

LINE

OVL

-1

-3

-6

MIC

-9

-12

LINE

-18

Ø

-24

48V

-30

-40

-60

SEL SEL SEL SEL

6

12

0

18

-6

24

dBu/FS

LINE

MIC

LINE

Ø

48V

LINK

6

0

18

-6

6 7

OVL

-1

-3

-6

-9

-12

-18

-24

-30

-40

-60

12

24

dBu/FS

LINE

Prepared and edited by:

STUDER Professional Audio AG

Technical Documentation

Althardstrasse 30

CH-8105 Regensdorf - Switzerland

STUDER is a registered trade mark of STUDER Professional Audio AG, Regensdorf

OVL

-1

-3

-6

MIC

-9

-12

LINE

-18

Ø

-24

48V

-30

-40

-60

6

12

0

18

-6

24 -6

dBu/FS

LINE

MIC/LINE

MIC

LINE

Ø

Ø

48V

48V

LINK

6

STEREO LINK

0

PEAK HOLD SOFT CLIP REMOTE

8

D19 SERIES

HOLD SOFT REM

48

INT

44

WCLK

16DI

VAR

AES

16NS

AUTO

20BIT

MODE SYNC CTRL CH

Copyright by STUDER Professional Audio AG

Printed in Switzerland

Order no. 10.27.3781 (Ed. 0996)

Subject to change

Page 2

SAFETY / SECURITE / SICHERHEIT

To reduce the risk of electric shock, do not remove covers (or back).

No user-serviceable parts inside. Refer servicing to qualified service

personnel.

Afin de prévenir un choc électrique, ne pas enlever les couvercles (où

l’arrière) de l’appareil. Il ne se trouve à l’intérieur aucune pièce pouvant être réparée par l’usager.

Um die Gefahr eines elektrischen Schlages zu vermeiden, entfernen Sie keine Geräteabdeckungen (oder die Rückwand). Überlassen Sie Wartung und Reparatur qualifiziertem Fachpersonal.

This symbol is intended to alert the user to presence of uninsulated

“dangerous voltage” within the apparatus that may be of sufficient

magnitude to constitute a risk of electric shock to a person.

Ce symbole indique à l'utilisateur qu'il existent à l'intérieur de l'appareil des “tensions dangereuses”. Ces tensions élevées entrainent

un risque de choc électrique en cas de contact.

Dieses Symbol deutet dem Anwender an, dass im Geräteinnern die

Gefahr der Berührung von “gefährlicher Spannung” besteht. Die

Grösse der Spannung kann zu einem elektrischen Schlag führen.

This symbol is intended to alert the user to the presence of important

instructions for operating and maintenance in the enclosed documentation.

Ce symbole indique à l’utilisateur que la documentation jointe contient d'importantes instructions concernant le fonctionnement et la

maintenance.

Dieses Symbol deutet dem Anwender an, dass die beigelegte Dokumentation wichtige Hinweise für Betrieb und Wartung enthält.

CAUTION: Lithium battery. Danger of explosion by incorrect handling. Replace

by battery of the same make and type only.

ATTENTION: Pile au lithium. Danger d'explosion en cas de manipulation incorrec-

te. Ne remplacer que par un modèle de même type.

ACHTUNG: Explosionsgefahr bei unsachgemässem Auswechseln der Lithium-

batterie. Nur durch den selben Typ ersetzen.

ADVARSEL: Lithiumbatterei. Eksplosinsfare. Udskinftning ma kun foretages af en

sagkyndig of som beskrevet i servicemanualen (DK).

I

Page 3

SAFETY / SECURITE / SICHERHEIT

FIRST AID

(in case of electric shock)

1. Separate the person as quickly as

possible from the electric power

source:

• by switching off the equipment

• or by unplugging or disconnecting

the mains cable

• pushing the person away from the

power source by using dry insulating material (such as wood or

plastic).

• After having sustained an elec-

tric shock, always consult a

doctor.

WARNING!

DO NOT TOUCH THE PERSON

OR HIS CLOTHING BEFORE

THE POWER IS TURNED OFF,

OTHERWISE YOU STAND THE

RISK OF SUSTAINING AN

ELECTRIC SHOCK AS WELL!

PREMIERS SECOURS

(en cas d'électrocution)

1. Si la personne est dans l'impos-

sibilité de se libérer:

• Couper l'interrupteur principal

• Couper le courant

• Repousser la personne de l'appareil à l'aide d'un objet en matière

non conductrice (matière plastique ou bois)

• Après une électrocution, toujours

consulter un médecin.

ATTENTION!

NE JAMAIS TOUCHER UNE

PERSONNE QUI EST SOUS

TENSION, SOUS PEINE DE

SUBIR EGALEMENT UNE

ELECTROCUTION.

ERSTE HILFE

(bei Stromunfällen)

1. Bei einem Stromunfall die be-

troffene Person so rasch wie

möglich vom Strom trennen:

• Ausschalten des Gerätes

• Ziehen oder Unterbrechen der

Netzzuleitung

• Betroffene Person mit isoliertem

Material (Holz, Kunststoff) von

der Gefahrenquelle wegstossen

• Nach einem Stromunfall sollte

immer ein Arzt aufgesucht werden.

ACHTUNG!

EINE UNTER SPANNUNG STEHENDE PERSON DARF NICHT

BERÜHRT WERDEN. SIE KÖNNEN DABEI SELBST ELEKTRISIERT WERDEN!

2. If the person is unconscious:

• check the pulse,

• reanimate the person if respiration

is poor,

• lay the body down, turn it to one

side, call for a doctor immediately.

2. En cas de perte de connaissance

de la personne électrocutée:

• Controller le pouls

• Si nécessaire, pratiquer la respiration artificielle

• Placer l'accidenté sur le flanc et

consulter un médecin.

2. Bei Bewusstlosigkeit des Verun-

fallten:

• Puls kontrollieren,

• bei ausgesetzter Atmung künstlich beatmen,

• Seitenlagerung des Verunfallten

vornehmen und Arzt verständigen.

II

Page 4

SICHERHEIT / SAFETY

Installation

Vor der Installation des Gerätes müssen die hier aufgeführten und auch die weiter in dieser Anleitung mit

bezeichneten Hinweise gelesen und während der Installation und des Betriebes beachtet werden.

Untersuchen Sie das Gerät und sein Zubehör auf allfällige

Transportschäden.

Ein Gerät, das mechanische Beschädigung aufweist oder

in welches Flüssigkeit oder Gegenstände eingedrungen

sind, darf nicht ans Netz angeschlossen oder muss sofort

durch Ziehen des Netzsteckers vom Netz getrennt werden.

Das Öffnen und Instandsetzen des Gerätes darf nur von

Fachpersonal unter Einhaltung der geltenden Vorschriften

durchgeführt werden.

Falls dem Gerät kein konfektioniertes Netzkabel

beiliegt, muss dieses durch eine Fachperson unter

Verwendung der mitgelieferten Kabel-Gerätedose

IEC320/C13 oder IEC320/C19 und unter Berücksichtigung der einschlägigen, im geweiligen Lande geltenden

Bestimmungen angefertigt werden; siehe unten.

Vor Anschluss des Netzkabels an die Netzsteckdose muss

überprüft werden, ob die Stromversorgungs- und Anschlusswerte des Gerätes (Netzspannung, Netzfrequenz)

innerhalb der erlaubten Toleranzen liegen. Die im Gerät

eingesetzten Sicherungen müssen den am Gerät angebrachten Angaben entsprechen.

Ein Gerät mit einem dreipoligen Gerätestecker (Gerät der

Schutzklasse I) muss an eine dreipolige Netzsteckdose

angeschlossen und somit das Gerätegehäuse mit dem

Schutzleiter der Netzinstallation verbunden werden (Für

Dänemark gelten Starkstrombestimmungen, Abschnitt

107).

Installation

Before you install the equipment, please read and adhere

to the following recommendations and all sections of these

instructions marked with .

Check the equipment for any transport damage.

A unit that is mechanically damaged or which has been

penetrated by liquids or foreign objects must not be connected to the AC power outlet or must be immediately

disconnected by unplugging the power cable. Repairs must

only be performed by trained personnel in accordance with

the applicable regulations.

Should the equipment be delivered without a matching

mains cable, the latter has to be prepared by a trained

person using the attached female plug (IEC320/C13 or

IEC320/C19) with respect to the applicable regulations in

your country - see diagram below.

Before connecting the equipment to the AC power outlet,

check that the local line voltage matches the equipment

rating (voltage, frequency) within the admissible tolerance. The equipment fuses must be rated in accordance with

the specifications on the equipment.

Equipment supplied with a 3-pole appliance inlet (equipment conforming to protection class I) must be connected

to a 3-pole AC power outlet so that the equipment cabinet

is connected to the protective earth conductor of the AC

supply (for Denmark the Heavy Current Regulations,

Section 107, are applicable).

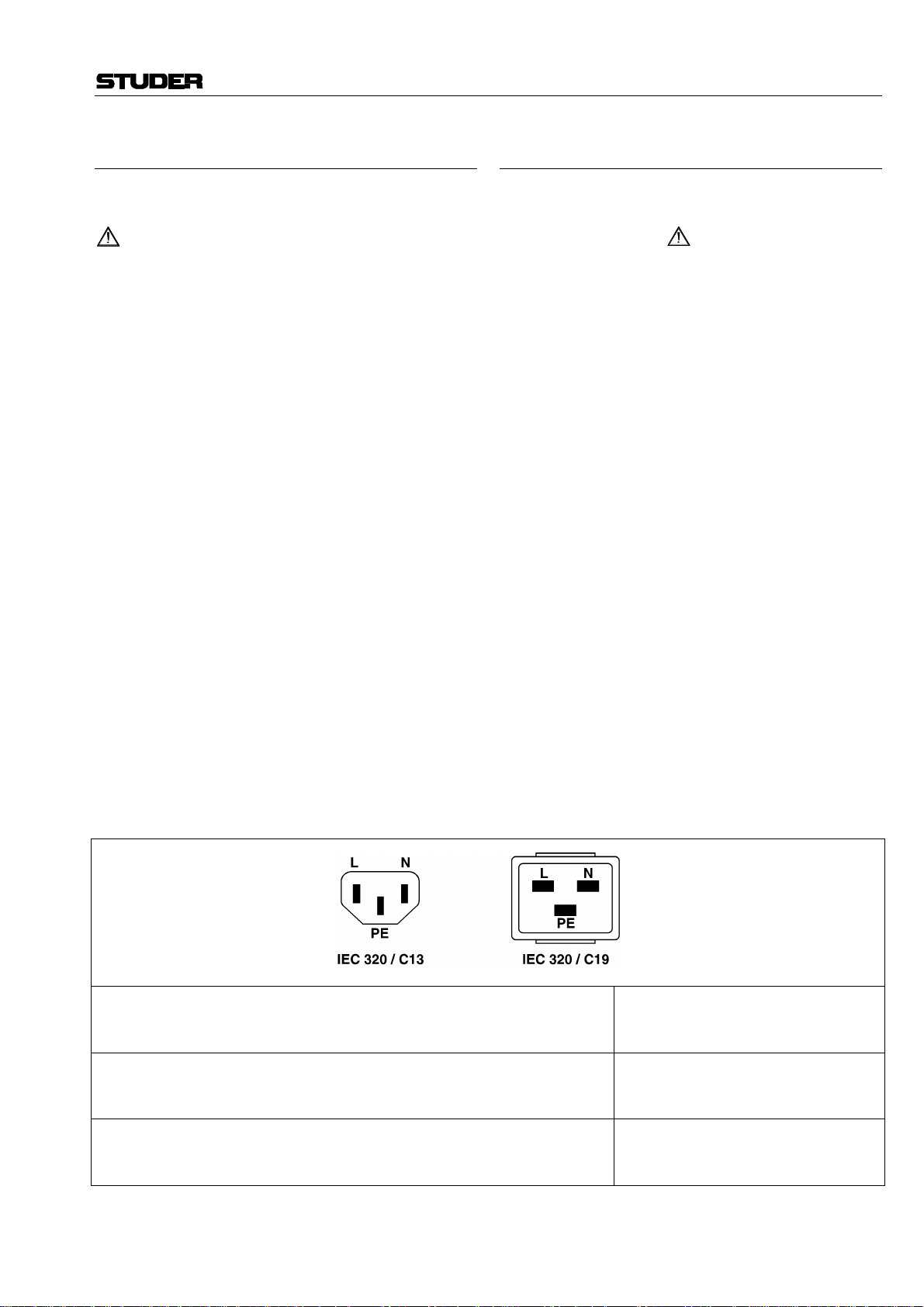

Female plug (IEC320), view from contact side:

L live; brown National American Standard: Black

N neutral; blue White

PE protective earth; green and yellow green

Connecteur femelle (IEC320), vue de la face aux contacts:

L phase; brun Standard national américain: Noir

N neutre; bleu Blanc

PE terre protective; vert et jaune Vert

Ansicht auf Steckkontakte der Kabel-Gerätesteckdose (IEC320):

L Phase; braun USA-Standard: Schwarz

N Nulleiter; blau Weiss

PE Schutzleiter; gelb/grün grün

III

Page 5

SICHERHEIT / SAFETY

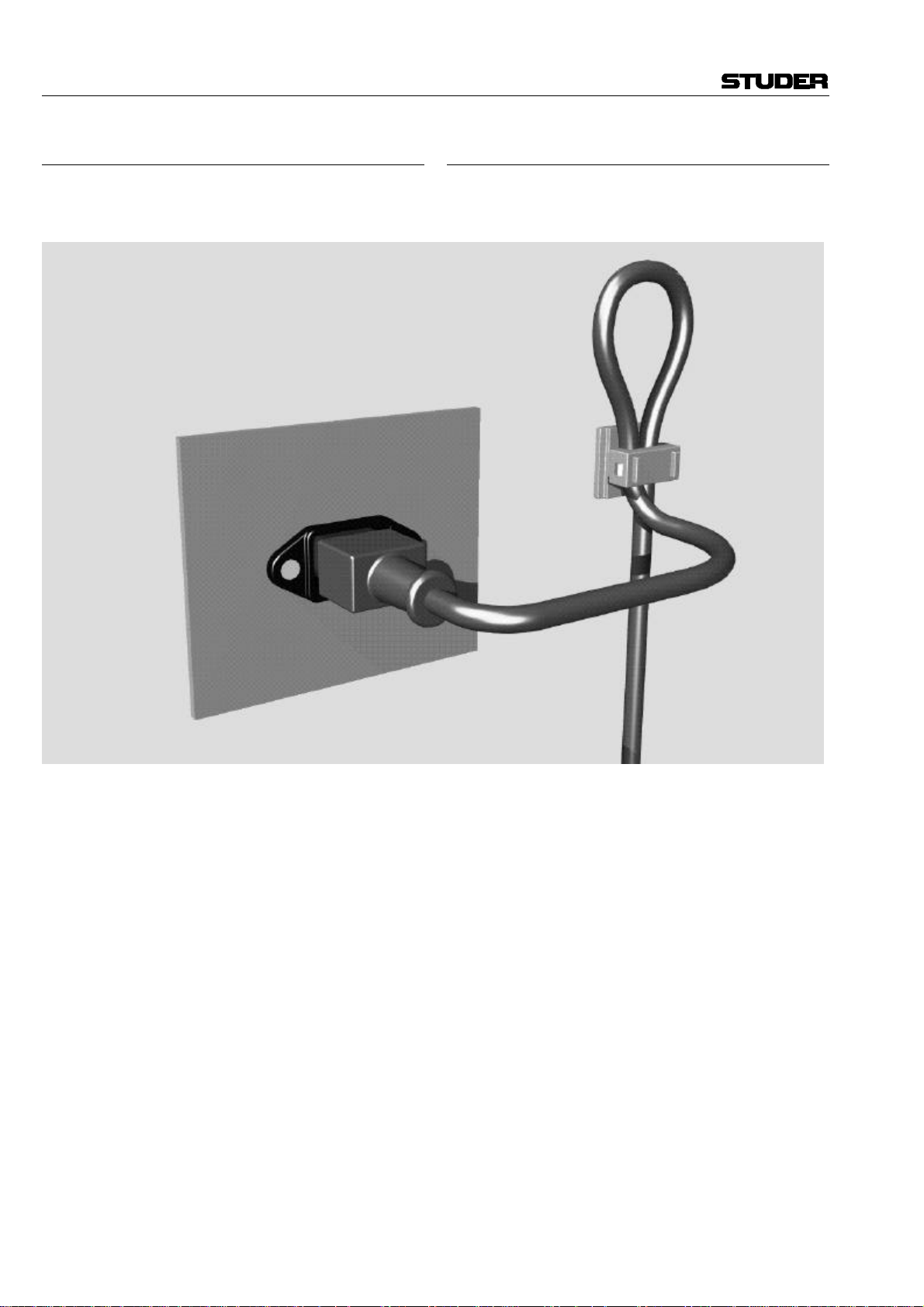

Zugentlastung für den Netzanschluss

Zum Verankern von Steckverbindungen ohne mechanische

Verriegelung (z.B. IEC-Kaltgerätedosen) empfehlen wir

die folgende Anordnung:

Mains connector strain relief

For anchoring connectors without a mechanical lock (e.g.

IEC mains connectors), we recommend the following arrangement:

Vorgehen: Der mitgelieferte Kabelhalter ist selbstklebend.

Bitte beachten Sie bei der Montage die folgenden Regeln:

1. Der Untergrund muss sauber, trocken und frei von Fett,

Öl und anderen Verunreinigungen sein. Temperaturbereich für optimale Verklebung: 20...40° C.

2. Entfernen Sie die Schutzfolie auf der Rückseite des

Kabelhalters und bringen sie ihn mit kräftigem Druck

an der gewünschten Stelle an. Lassen sie ihn unbelastet

so lange wie möglich ruhen – die maximale Klebekraft

ist erst nach rund 24 Stunden erreicht.

3. Die Stabilität des Kabelhalters wird erhöht, wenn Sie

ihn zusätzlich verschrauben. Zu diesem Zweck liegen

ihm eine selbstschneidende Schraube sowie eine M4Schraube mit Mutter bei.

4. Legen Sie das Kabel gemäss Figur in den Halter ein

und pressen Sie die Klemme kräftig auf, bis das Kabel

fixiert ist.

Procedure: The cable clamp shipped with your unit is

auto-adhesive. If mounting, please follow the rules below:

1. The surface to be adhered to must be clean, dry, and

free from grease, oil or other contaminants. Best application temperature range is 20...40° C.

2. Remove the plastic protective backing from the rear

side of the clamp and apply it firmly to the surface at

the desired position. Allow as much time as possible

for curing. The bond continues to develop for as long

as 24 hours.

3. For improved stability, the clamp can be fixed with a

screw. For this purpose, a self-tapping screw and an

M4 bolt and nut are included.

4. Place the cable into the clamp as shown in the illustr a-

tion above and firmly press down the internal top cover

until the cable is fixed.

IV

Page 6

UMGEBUNGSBEDINGUNGEN / AMBIENT CONDITIONS

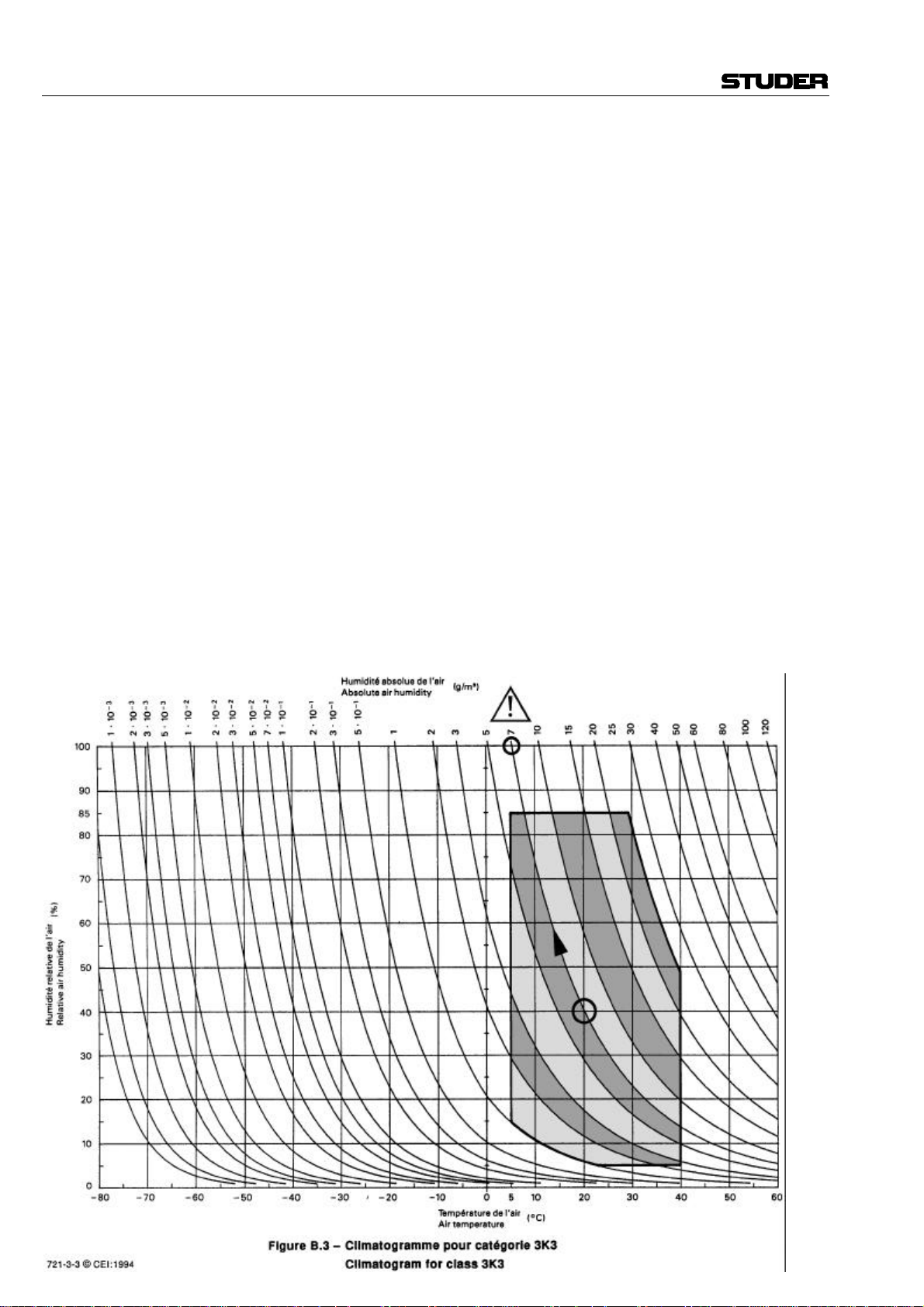

Lufttemperatur und Feuchtigkeit

Allgemein

Die Betriebstauglichkeit des Gerätes oder Systems ist unter

folgenden Umgebungsbedingungen gewährleistet:

EN 60721-3-3, Set IE32, Wert 3K3.

Diese Norm umfasst einen umfassenden Katalog von Parametern; die wichtigsten davon sind: Umgebungstemperatur

+5...+40 °C; rel. Luftfeuchtigkeit 5...85% – d.h. weder Kondensation noch Eisbildung; abs. Luftfeuchtigkeit 1...25 g/m³; Temperatur-Änderungsrate < 0,5 °C/min. In den folgenden Abschnitten wird darauf näher eingegangen.

Unter den genannten Bedingungen startet und arbeitet das

Gerät oder System problemlos. Ausserhalb dieser Spezifikationen möglicherweise auftretende Probleme sind in den folgenden

Abschnitten beschrieben.

Umgebungstemperatur

Geräte und Systeme von Studer sind allgemein für einen Umgebungstemperaturbereich (d.h. Temperatur der eintretenden

Kühlluft) von +5...+40 °C ausgelegt. Bei Installation in einem

Schrank muss der vorgesehene Luftdurchsatz und dadurch die

Konvektionskühlung gewährleistet sein. Folgende Tatsachen

sind dabei zu berücksichtigen:

1. Die zulässige Umgebungstemperatur für den Betrieb der

Halbleiter-Bauelemente beträgt 0 °C bis +70 °C (commercial

temperature range for operation).

2. Der Luftdurchsatz der Anlage muss gewährleisten, dass die

austretende Kühlluft ständig kühler ist als 70 °C.

3. Die mittlere Erwärmung der Kühlluft soll 20 K betragen,

die maximale Erwärmung an den heissen Komponenten darf

somit um weitere 10 K höher liegen.

4. Zum Abführen einer Verlustleistung von 1 kW bei dieser

zulässigen mittleren Erwärmung ist eine Luftmenge von

2,65 m³/min notwendig.

Beispiel: Für ein Rack mit einer Leistungsaufnahme P = 800 W

ist eine Kühlluftmenge von 0,8 * 2,65 m³/min nötig, entsprechend 2,12 m³/min.

5. Soll die Kühlfunktion der Anlage (z.B. auch bei LüfterAusfall oder Bestrahlung durch Spotlampen) überwacht werden, so ist die Temperatur der Abluft unmittelbar oberhalb der

Einschübe an mehreren Stellen im Rack zu messen; die Ansprechtemperatur der Sensoren soll 65 bis 70 °C betragen.

Air temperature and humidity

General

Normal operation of the unit or system is warranted under the

following ambient conditions defined by:

EN 60721-3-3, set IE32, value 3K3.

This standard consists of an extensive catalogue of parameters,

the most important of which are: ambient temperature +5...

+40° C, relative humidity 5...85% – i.e. no formation of condensation or ice; absolute humidity 1...25 g/m³; rate of temperature change < 0,5 °C/min. These parameters are dealt with

in the following paragraphs.

Under these conditions the unit or system starts and works

without any problem. Beyond these specifications, possible

problems are described in the following sections.

Ambient temperature

Units and systems by Studer are generally designed for an ambient temperature range (i.e. temperature of the incoming air) of

+5...+40 °C. When rack mounting the units, the intended air

flow and herewith adequate cooling must be provided. The

following facts must be considered:

1. The admissible ambient temperature range for operation of

the semiconductor components is 0 °C to +70 °C (commercial

temperature range for operation).

2. The air flow through the installation must provide that the

outgoing air is always cooler than 70 °C.

3. Average heat increase of the cooling air shall be 20 K, allowing for an additional maximum 10 K increase at the hot

components.

4. In order to dissipate 1 kW with this admissible average heat

increase, an air flow of 2,65 m³/min is required.

Example: A rack dissipating P = 800 W requires an air flow of

0,8 * 2,65 m³/min which corresponds to 2,12 m³/min.

5. If the cooling function of the installation must be monitored

(e.g. for fan failure or illumination with spot lamps), the outgoing air temperature must be measured directly above the modules at several places within the rack. The trigger temperature of

the sensors should be 65 to 70 °C.

Reif und Tau

Das unversiegelte System (Steckerpartien, Halbleiteranschlüsse) verträgt zwar leichte Eisbildung (Reif). Mit blossem Auge

sichtbare Betauung führt jedoch bereits zu Funktionsstörungen.

In der Praxis kann mit einem zuverlässigen Betrieb der Geräte

bereits im Temperaturbereich ab –15 °C gerechnet werden,

wenn für die Inbetriebnahme des kalten Systems die folgende

allgemeine Regel beachtet wird:

Wird die Luft im System abgekühlt, so steigt ihre relative

Feuchtigkeit an. Erreicht diese 100%, kommt es zu Niederschlag, meist in der Grenzschicht zwischen der Luft und einer

kühleren Oberfläche, und somit zur Bildung von Eis oder Tau

an empfindlichen Systemstellen (Kontakte, IC-Anschlüsse etc.).

Ein störungsfreier Betrieb mit interner Betauung, unabhängig

von der Temperatur, ist nicht gewährleistet.

Frost and dew

The unsealed system parts (connector areas and semiconductor

pins) allow for a minute formation of ice or frost. However,

formation of dew visible with the naked eye will already lead to

malfunctions. In practice, reliable operation can be expected in

a temperature range above –15 °C, if the following general rule

is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it reaches 100%, condensation will arise, usually in

the boundary layer between the air and a cooler surface, together with formation of ice or dew at sensitive areas of the

system (contacts, IC pins, etc.). Once internal condensation

occurs, troublefree operation cannot be guaranteed, independent

of temperature.

V

Page 7

UMGEBUNGSBEDINGUNGEN / AMBIENT CONDITIONS

Vor der Inbetriebnahme muss das System auf allfällige interne

Betauung oder Eisbildung überprüft werden. Nur bei sehr

leichter Eisbildung kann mit direkter Verdunstung (Sublimation) gerechnet werden; andernfalls muss das System im abgeschalteten Zustand gewärmt und getrocknet werden.

Das System ohne feststellbare interne Eisbildung oder Betauung soll möglichst homogen (und somit langsam) mit eigener

Wärmeleistung aufgewärmt werden; die Lufttemperatur der

Umgebung soll ständig etwas tiefer als diejenige der Systemabluft sein.

Ist es unumgänglich, das abgekühlte System sofort in warmer

Umgebungsluft zu betreiben, so muss diese entfeuchtet sein.

Die absolute Luftfeuchtigkeit muss dabei so tief sein, dass die

relative Feuchtigkeit, bezogen auf die kälteste Oberfläche im

System, immer unterhalb 100% bleibt.

Es ist dafür zu sorgen, dass beim Abschalten des Systems die

eingeschlossene Luft möglichst trocken ist (d.h. vor dem Abschalten im Winter den Raum mit kalter, trockener Luft belüften und feuchte Gegenstände, z.B. Kleider, entfernen).

Die Zusammenhänge sind im folgenden Klimatogramm ersichtlich. Zum kontrollierten Verfahren gehören Thermometer

und Hygrometer sowie ein Thermometer innerhalb des Systems.

Beispiel 1: Ein Ü-Wagen mit einer Innentemperatur von 20 °C

und 40% relativer Luftfeuchtigkeit wird am Abend abgeschaltet. Sinkt die Temperatur unter +5 °C, bildet sich Tau oder Eis.

Beispiel 2: Ein Ü-Wagen wird morgens mit 20 °C warmer Luft

von 40% relativer Luftfeuchtigkeit aufgewärmt. Auf Teilen, die

kälter als +5 °C sind, bildet sich Tau oder Eis.

Before putting into operation, the system must be checked for

internal formation of condensation or ice. Only with a minute

formation of ice, direct evaporation (sublimation) may be expected; otherwise the system must be heated and dried while

switched off.

A system without visible internal formation of ice or condensation should be heated up with its own heat dissipation, as homogeneously (and subsequently as slow) as possible; the ambient temperature should then always be lower than the outgoing

air.

If it is absolutely necessary to operate the system immediately

within warm ambient air, this air must be dehydrated. In such a

case, the absolute humidity must be so low that the relative

humidity, related to the coldest system surface, always remains

below 100%.

Ensure that the enclosed air is as dry as possible when powering off (i.e. before switching off in winter, aerate the room with

cold, dry air, and remove humid objects as clothes from the

room).

These relationships are visible from the following climatogram.

For a controlled procedure, thermometer and hygrometer as well

as a thermometer within the system will be required.

Example 1: An OB-van having an internal temperature of

20 °C and rel. humidity of 40% is switched off in the evening.

If temperature falls below +5 °C, dew or ice will be forming.

Example 2: An OB-van is heated up in the morning with air of

20 °C and a rel. humidity of 40%. On all parts being cooler than

+5 °C, dew or ice will be forming.

VI

Page 8

WARTUNG / MAINTENANCE

Wartung und Reparatur

Durch Entfernen von Gehäuseteilen, Abschirmungen etc.

werden stromführende Teile freigelegt. Deshalb müssen

u.a. die folgenden Grundsätze beachtet werden:

Eingriffe in das Gerät dürfen nur von Fachpersonal unter

Einhaltung der geltenden Vorschriften vorgenommen werden.

Vor Entfernen von Gehäuseteilen muss das Gerät ausgeschaltet und vom Netz getrennt werden.

Bei geöffnetem, vom Netz getrenntem Gerät dürfen Teile

mit gefährlichen Ladungen (z. B. Kondensatoren, Bildröhren) erst nach kontrollierter Entladung, heiße Bauteile

(Leistungshalbleiter, Kühlkörper etc.) erst nach deren

Abkühlen berührt werden.

Bei Wartungsarbeiten am geöffneten, unter Netzspannung

stehenden Gerät dürfen blanke Schaltungsteile und metallene Halbleitergehäuse weder direkt noch mit nichtisoliertem Werkzeug berührt werden.

Zusätzliche Gefahren bestehen bei unsachgemässer Handhabung besonderer Komponenten:

• Explosionsgefahr bei Lithium zellen, Elektrolyt-Kondensatoren und Leistungshalbleitern

• Implosionsgefahr bei evakuierten Anzeigeeinheiten

• Strahlungsgefahr bei Lasereinheiten (nichtioni sierend),

Bildröhren (ionisierend)

• Verätzungsgefahr bei Anzeigeeinheiten (LCD) und

Komponenten mit flüssigem Elektrolyt.

Solche Komponenten dürfen nur von ausgebildetem

Fachpersonal mit den vorgeschriebenen Schutzmitteln

(u.a. Schutzbrille, Handschuhe) gehandhabt werden.

Maintenance and Repair

The removal of housing parts, shields, etc. exposes energized parts. For this reason the following precautions should

be observed:

Maintenance should only be performed by trained personnel in accordance with the applicable regulations.

The equipment should be switched off and disconnected

from the AC power outlet before any housing parts are

removed.

Even if the equipment is disconnected from the power,

parts with hazardous charges (e.g. capacitors, picture

tubes) must not be touched until they have been properly

discharged. Touch hot components (power semiconductors, heat sinks, etc.) only when cooled off.

If maintenance is performed on a unit that is opened and

switched on, no uninsulated circuit components and metallic semiconductor housings must be touched neither with

your bare hands nor with uninsulated tools.

Certain components pose additional hazards:

• Explosion hazard from lithium batteries, electrolytic

capacitors and power semiconductors

• Implosion hazard from evacuated display units

• Radiation hazard from laser units (non-ionizing), picture tubes (ionizing)

• Caustic effect of display units (LCD) and such comp onents containig liquid electrolyte.

Such components should only be handled by trained

personnel who are properly protected (e.g. safety

goggles, gloves).

VII

Page 9

WARTUNG / MAINTENANCE

Elektrostatische Entladung (ESD)

bei Wartung und Reparatur

ATTENTION:

ATTENTION:

ACHTUNG:

Viele ICs und andere Halbleiter sind empfindlich gegen

elektrostatische Entladung (ESD). Unfachgerechte Behandlung von Baugruppen mit solchen Komponenten bei

Wartung und Reparatur kann deren Lebensdauer drastisch

vermindern.

Bei der Handhabung der ESD-empfindlichen Komponenten sind u.a. folgende Regeln zu beachten:

• ESD-empfindliche Komponenten dürfen aus schliesslich

in dafür bestimmten und bezeichneten Verpackungen

gelagert und transportiert werden.

• Unverpackte, ESD-empfindliche Komponenten dürfen

nur in dafür eingerichteten Schutzzonen (EPA, z.B.

Gebiet für Feldservice, Reparatur- oder Serviceplatz)

gehandhabt und nur von Personen berührt werden, die

durch ein Handgelenkband mit Seriewiderstand mit dem

Massepotential des Reparatur- oder Serviceplatzes verbunden sind. Das gewartete Gerät wie auch Werkzeug,

Hilfsmittel, EPA-taugliche (elektrisch halbleitende)

Arbeits-, Ablage- und Bodenmatten müssen ebenfalls

mit diesem Potential verbunden sein.

• Die Anschlüsse der ESD-empfindlichen Komponenten

dürfen unkontrolliert weder mit elektrostatisch aufladbaren (Gefahr von Spannungsdurchschlag), noch mit

metallischen Oberflächen (Schockentladungsgefahr) in

Berührung kommen.

• Um undefinierte transiente Beanspruchung der Komponenten und deren eventuelle Beschädigung durch unerlaubte Spannung oder Ausgleichsströme zu vermeiden, dürfen elektrische Verbindungen nur am abgeschalteten Gerät und nach dem Abbau allfälliger Kondensatorladungen hergestellt oder getrennt werden.

Electrostatic Discharge (ESD)

during Maintenance and Repair

Observe precautions for handling devices sensitive to

electrostatic discharge!

Respecter les précautions d’usage concernant la manipulation de composants sensibles à l’électricité statique!

Vorsichtsmassnahmen bei Handhabung elektrostatisch

entladungsgefährdeter Bauelemente beachten!

Many ICs and semiconductors are sensitive to electrostatic

discharge (ESD). The life of components containing such

elements can be drastically reduced by improper handling

during maintenance and repair work.

Please observe the following rules when handling ESD

sensitive components:

• ESD sensitive components should only be stored and

transported in the packing material specifically provided for this purpose.

• Unpacked ESD sensitive components should only be

handled in ESD protected areas (EPA, e.g. area for

field service, repair or service bench) and only be touched by persons who wear a wristlet that is connected

to the ground potential of the repair or service bench by

a series resistor. The equipment to be repaired or serviced and all tools, aids, as well as electrically semiconducting work, storage and floor mats should also be

connected to this ground potential.

• The terminals of ESD sensitive components must not

come in uncontrolled contact with electrostatically

chargeable (voltage puncture) or metallic surfaces

(discharge shock hazard).

• To prevent undefined transient stress of the components

and possible damage due to inadmissible voltages or

compensation currents, electrical connections should

only be established or separated when the equipment is

switched off and after any capacitor charges have decayed.

VIII

Page 10

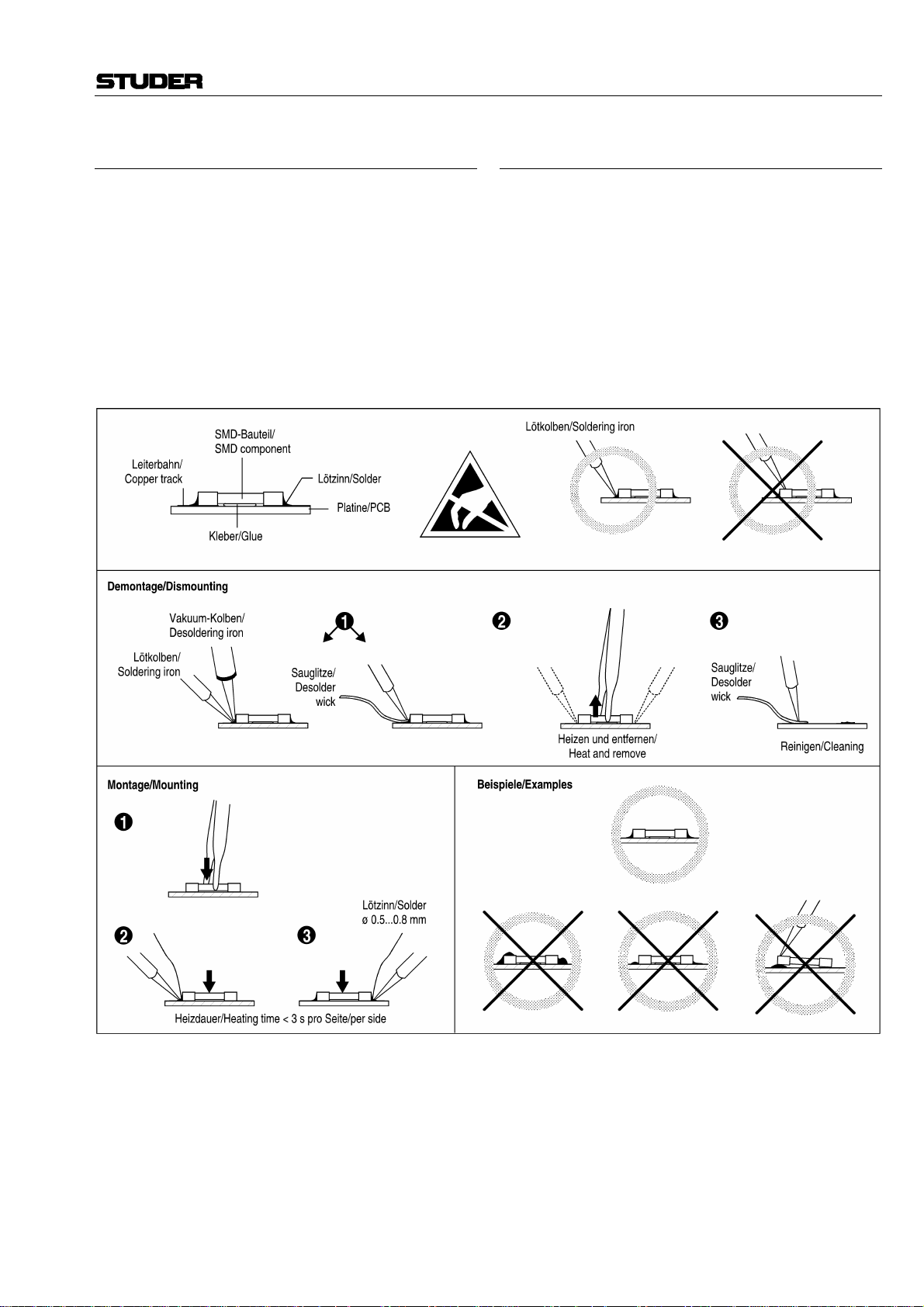

WARTUNG / MAINTENANCE

SMD-Bauelemente

Der Austausch von SMD-Bauelementen ist ausschliesslich

geübten Fachleuten vorbehalten. Für verwüstete Platinen

können keine Ersatzansprüche geltend gemacht werden.

Beispiele für korrekte und falsche SMD-Lötverbindungen

in der Abbildung weiter unten.

Bei Studer werden keine handelsüblichen SMD-Teile

bewirtschaftet. Für Reparaturen sind die notwendigen

Bauteile lokal zu beschaffen. Die Spezifikationen von

Spezialbauteilen finden Sie in der Serviceanleitung.

SMD Components

SMDs should only be replaced by skilled specialists. No

warranty claims will be accepted for circuit boards that

have been ruined. Proper and improper SMD soldering

joints are depicted below.

Studer does not keep any commercially available SMDs in

stock. For repair the corresponding devices should be

purchased locally. The specifications of special components can be found in the service manual.

IX

Page 11

EMV / EMC

Störstrahlung und Störfestigkeit

Das Gerät entspricht den Schutzanforderungen auf dem

Gebiet elektromagnetischer Phänomene, wie u.a. in den

Richtlinien 89/336/EWG und FCC, Part 15, aufgeführt:

1. Vom Gerät erzeugte elektromagnetische Strahlung ist

soweit begrenzt, dass bestimmungsgemässer Betrieb

anderer Geräte und Systeme möglich ist.

2. Das Gerät weist eine angemessene Festigkeit gegen

elektromagnetische Störungen auf, so dass sein bestimmungsgemässer Betrieb möglich ist.

Das Gerät wurde getestet und erfüllt die Bedingungen der

im Kapitel „Technische Daten“ aufgeführten EMVStandards. Die Limiten dieser Standards gewährleisten mit

angemessener Wahrscheinlichkeit sowohl den Schutz der

Umgebung wie auch entsprechende Störfestigkeit des

Gerätes. Absolute Garantie, dass keine unerlaubte elektromagnetische Beeinträchtigung während des Betriebes

entsteht, ist jedoch nicht gegeben.

Um die Wahrscheinlichkeit solcher Beeinträchtigung

weitgehend auszuschliessen, sind u.a. folgende Massnahmen zu beachten:

• Installieren Sie das Gerät gemäss den Angaben in der

Betriebsanleitung, und verwenden Sie das mitgelieferte

Zubehör.

• Verwenden Sie im System und in der Umgebung, in

denen das Gerät eingesetzt ist, nur Kom ponenten (Anlagen, Geräte), die ihrerseits die Anforderungen der

obenerwähnten Standards erfüllen.

• Sehen Sie ein Erdungskonzept des Systems vor, das

sowohl die Sicherheitsanforderungen (die Erdung der

Geräte gemäss Schutzklasse I mit einem Schutzleiter

muss gewährleistet sein), wie auch die EMV-Belange

berücksichtigt. Bei der Entscheidung zwischen sternoder flächenförmiger bzw. kombinierter Erdung sind

Vor- und Nachteile gegeneinander abzuwägen.

• Benutzen Sie abgeschirmte Kabel, wo vorgesehen.

Achten Sie auf einwandfreie, grossflächige, korrosionsbeständige Verbindung der Abschirmung zum entsprechenden Steckeranschluss und dessen Gehäuse. Beachten Sie, dass eine nur an einem Ende angeschlossene

Kabelabschirmung als Sende- bzw. Empfangsantenne

wirken kann (z.B. bei wirksamer Kabellänge von 5 m

oberhalb von 10 MHz), und dass die Flanken digitaler

Kommunikationssignale hochfrequente Aussendungen

verursachen (z.B. LS- oder HC-Logik bis 30 MHz).

• Vermeiden Sie Bildung von Masseschleifen oder vermindern Sie deren unerwünschte Auswirkung, indem

Sie deren Fläche möglichst klein halten und den darin

fliessenden Strom durch Einfügen einer Impedanz (z.B.

Gleichtaktdrossel) reduzieren.

Electromagnetic Compatibility

The equipment conforms to the protection requirements

relevant to electromagnetic phenomena that are listed in

the guidelines 89/336/EC and FCC, part 15.

1. The electromagnetic interference generated by the

equipment is limited in such a way that other equipment

and systems can be operated normally.

2. The equipment is adequately protected against electromagnetic interference so that it can operate correctly.

The unit has been tested and conforms to the EMC standards applicable to residential, commercial and light industry, as listed in the section „Technical Data“. The limits

of these standards reasonably ensure protection of the

environment and corresponding noise immunity of the

equipment. However, it is not absolutely warranted that

the equipment will not be adversely affected by electromagnetic interference during operation.

To minimize the probability of electromagnetic interference as far as possible, the following recommendations

should be followed:

• Install the equipment in accordance with the operating

instructions. Use the supplied accessories.

• In the system and in the vicinity where the equipment is

installed, use only components (systems, equipment)

that also fulfill the above EMC standards.

• Use a system grounding concept that satisfies the safety

requirements (protection class I equipment must be

connected with a protective ground conductor) that also

takes into consideration the EMC requirements. When

deciding between radial, surface or combined grounding, the advantages and disadvantages should be carefully evaluated in each case.

• Use shielded cables where shielding is specified. The

connection of the shield to the corresponding connector

terminal or housing should have a large surface and be

corrosion-proof. Please note that a cable shield connected only single-ended can act as a transmitting or receiving antenna (e.g. with an effective cable length of

5 m, the frequency is above 10 MHz) and that the edges

of the digital communication signals cause highfrequency radiation (e.g. LS or HC logic up to

30 MHz).

• Avoid ground loops or reduce their adverse effects by

keeping the loop surface as small as possible, and reduce the noise current flowing through the loop by inserting an additional impedance (e.g. common-mode rejection choke).

X

Page 12

Class A Equipment - FCC Notice

Konformitätserklärungen / Declarations of conformity

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide a

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residen-

CE-Konformitätserklärung

Der Hersteller,

Studer Professional Audio AG,

CH-8105 Regensdorf,

erklärt in eigener Verantwortung, dass die Produkte

Studer D19 MicAD, 8-Channel Mic/Line Preamplifier

with Digital Outputs (ab Serie-Nr. 101),

Studer D19 MicAD Stage, Remote Controlled 8-Channel

Mic/Line Preamplifier with Digital Outputs (ab SerieNr. 1001),

Studer D19 MicAD Master, Remote Control (ab Serie-

Nr. 1001),

auf die sich diese Erklärung bezieht, entsprechend den

Bestimmungen der EU-Richtlinien und Ergänzungen

• Elektromagnetische Verträglichkeit (EMV):

89/336/EWG + 92/31/EWG + 93/68/EWG

• Niederspannung:

73/23/EWG + 93/68/EWG

mit den folgenden Normen und normativen Dokumenten

übereinstimmen:

• Sicherheit:

Schutzklasse 1, EN 60950:1992 + A1/A2:1993

• EMV:

EN 50081-1:1992, EN 50082:1992.

Regensdorf, 6. Februar 1996

tial area is likely to cause harmful interference in which

case the user will be required to correct the interference at

his own expense.

Caution:

Any changes or modifications not expressly approved by

the manufacturer could void the user's authority to operate

the equipment. Also refer to relevant information in this

manual.

CE Declaration of Conformity

The manufacturer,

Studer Professional Audio AG,

CH-8105 Regensdorf,

declares under his sole responsibility that the products

Studer D19 MicAD, 8-Channel Mic/Line Preamplifier

with Digital Outputs (from serial no. 101),

Studer D19 MicAD Stage, Remote Controlled 8-Channel

Mic/Line Preamplifier with Digital Outputs (from serial no. 1001),

Studer D19 MicAD Master, Remote Control (from serial

no. 1001),

to which this declaration relates, according to following

regulations of EU directives and amendments

• Electromagnetic Compatibility (EMC):

89/336/EEC + 92/31/EEC + 93/68/EEC

• Low Voltage (LVD):

73/23/EEC + 93/68/EEC

are in conformity with the following standards or other

normative documents:

• Safety:

Class 1, EN 60950:1992 + A1/A2:1993

• EMC:

EN 50081-1:1992, EN 50082:1992.

Regensdorf, February 6, 1996

B. Hochstrasser, Geschäftsleiter

P. Fiala, Leiter QS

B. Hochstrasser, Managing director

P. Fiala, Manager QA

XI

Page 13

Studer D19 MicAD

Corrigendum

Section “Technical specifications”

Please note the following correction in the technical specifications:

Crosstalk:

Line-Line/Mic-Mic

< –96 dB @ 1 kHz; < –92 dB @ 20 Hz...20 kHz

Kapitel “Technische Daten”

Bitte beachten Sie die folgende Korrektur der

technischen Daten:

Übersprechen:

Line-Line/Mic-Mic

< –96 dB bei 1 kHz; < –92 dB, 20 Hz...20 kHz

Page 14

NEUE FUNKTION FÜR MICAD MASTER

Zum Begrenzen der Anzahl der Fernsteuerkanäle (d.h. der Anzahl der

durch den MicAD MASTER gesteuerten Geräte) wurde eine neue Funktion implementiert. Bisher mussten zur Wahl des gewünschten Gerätes

immer alle 16 Adressen «durchgeblättert» werden, auch wenn nur zwei

oder drei Geräte am MicAD MASTER angeschlossen waren.

Zum Begrenzen der Anzahl der Fernsteuerkanäle gehen Sie wie folgt

vor:

• CTRL CH-Taste so oft wie nötig drücken, damit im Display die gewünschte Anzahl ferngesteuerter Einheiten angezeigt wird.

• MODE-Taste drücken und festhalten, anschliessend SYNC-Taste drükken und festhalten, dann CTRL CH-Taste drücken.

Danach wird beim Blättern mit der Taste CTRL CH nur bis zur gewählten Fernsteuerkanal-Nummer gezählt und anschliessend wieder bei 1

begonnen.

Ausschalten der Funktion:

• MODE-Taste drücken und festhalten, anschliessend SYNC-Taste drükken und festhalten, dann REMOTE-Taste drücken.

Nun können wieder alle Fernsteuerkanäle mit der CTRL CH-Taste gewählt werden.

D19 MicAD

NEW FUNCTION FOR MICAD MASTER

For limiting the number of remote control channels (i.e. the number of

units controlled by the MicAD MASTER), a new function has been

created. Up to now, all 16 addresses had to be toggled through when

selecting a particular unit for control, even if only two or three units

were connected to the MicAD MASTER.

To limit the number of remote control channels, proceed as follows:

• Press the CTRL CH key as many times as required until the display

indicates the desired number of units.

• Press and hold the MODE key, then press and hold the SYNC key, then

press the CTRL CH key.

After that, the display will count up only to the number entered before

when toggling with the CTRL CH key, and then restarts with 1.

To cancel this function:

• Press and hold the MODE key, then press and hold the SYNC key, then

press the REMOTE key.

After that, all remote control channels can be accessed again when

toggling with the CTRL CH key.

Edition:

17.02.98

Addendum

Page 15

19.02.01

CONTENTS

D19 MicAD

1 Come in! ........................................................................E1/1

1.1 Basic information ......................................................... E1/1

1.2 General ....................................................................... E1/2

1.2.1 Scope of delivery ..................................................... E1/2

1.2.2 D19 MicAD versions................................................ E1/2

1.2.3 Options ...................................................................E1/2

1.2.4 Accessories ..............................................................E1/3

1.3 Safety and connections ................................................ E1/4

1.3.1 Utilization for the purpose intended .........................E1/4

1.3.2 Power connection ....................................................E1/4

1.3.3 Connector panel ...................................................... E1/5

1.4 Technical specifications ............................................... E1/6

1.4.1 Audio specifications ................................................. E1/6

1.4.2 Peripheral connections ............................................. E1/7

1.4.3 Power supply ........................................................... E1/7

1.4.4 Primary fuse ............................................................. E1/7

1.4.5 Operating conditions ............................................... E1/7

1.4.6 Safety and EMC standards ........................................ E1/7

1.4.7 Mechanical data MicAD/MicAD STAGE................... E1/8

1.4.8 Mechanical data MicAD MASTER ............................ E1/8

2 Operation ......................................................................E2/1

2.1 Operating elements ...................................................... E2/1

2.2 Audio and sync connections, pin assignments ............. E2/5

2.2.1 Mic and line inputs ..................................................E2/5

2.2.2 Digital outputs ......................................................... E2/5

2.2.3 External AES/EBU synchronization ........................... E2/5

2.2.4 Word clock in/out .................................................... E2/5

2.2.5 Using the TDIF-1 8-channel interface ....................... E2/6

2.2.6 Using the optical ADAT 8-channel interface............. E2/7

2.3 Application ideas and examples .................................. E2/8

2.3.1 Wiring for external synchronization ....................... E2/10

2.4 Remote control .......................................................... E2/11

2.4.1 General, hardware .................................................E2/11

2.4.2 RS422 .................................................................... E2/11

2.4.3 MIDI ...................................................................... E2/13

2.4.4 Programming ......................................................... E2/15

2.4.4.1 Recognized MIDI messages ..................... E2/15

2.4.4.2 Control change ....................................... E2/15

2.4.4.3 System exclusive ..................................... E2/16

2.4.4.4 Transmitted MIDI messages ..................... E2/17

2.4.4.5 MicAD internal system status field........... E2/17

Edi tion:

Contents E 0/1

Page 16

19.02.01

D19 MicAD

3 Additional information ...................................................E3/1

3.1 What the heck is Noise Shaping? ................................. E3/1

3.2 Block diagrams ............................................................ E3/3

3.2.1 Global audio block diagram ..................................... E3/3

3.2.2 Synchronization block diagram ................................E3/3

4 Appendix: MIDI protocol ................................. yellow pages

E 0/2 Contents

“ADAT” is a trade mark of Alesis Corporation.

“TDIF-1” is a trade mark of Tascam Corporation.

Edi tion:

Page 17

19.02.01

1 COME IN!

1.1 Basic information

D19 MicAD

We are happy to welcome you in the steadily growing circle of the

Studer D19 MicAD's users, and we felicitate you on your selection.

Thanks to Studer's experience collected during more than 40 years of

business in the professional audio products field, you may expect that

the performance of your new unit will fulfill your highest demands.

The MicAD is a simple, reliable, selfcontained eight-channel microphone preamplifier with digital outputs.

MicAD combines the renowned low-distortion Studer transformer-balanced microphone inputs with high-performance 20 bit A/D converters.

For optimum sound quality even in 16 bit mode, DSP dithering and noise

shaping are used instead of simple truncating.

MicAD features AES/EBU outputs plus a choice of TDIF-1 or optical

ADAT format outputs.

Remote control is possible via the dedicated MicAD Master or via external equipment using MIDI-RS 422 or MIDI.

Edi tion:

Come in! E 1/1

Page 18

19.02.01

D19 MicAD

1.2 General

1.2.1 Scope of delivery

The D19 MicAD is supplied with a power cord (or an IEC 320/C13

socket), a 2.5 mm hex-socket screwdriver, and this operating manual.

1.2.2 D19 MicAD versions Order No.

D19 MicAD Self-contained 8-channel Mic/Line preamplifier 66.650.00000

with digital outputs

• 8 high-quality Mic/Line preamps with separate

XLR inputs.

• 4 AES/EBU outputs on XLR.

• 20-bit high-performance A/D converters.

• Switchable DSP Dithering and Noise Shaping.

• Local or remote control of individual GAIN,

MIC/LINE, Phase, 48 V Phantom Power and

High-pass filter settings.

• Local or remote control of global Soft-clip,

Mode, Sync, and Sampling Frequency settings.

• Built-in 100...240 V power supply.

D19 MicAD STAGE Remote controlled 8-channel Mic/Line preampli- 66.651.00000

fier with digital outputs

as D19 MicAD (above), except:

• Remote control for all functions of the unit.

• Front panel controls: Only Power switch,

CTRL CH and REMOTE keys.

D19 MicAD MASTER Dedicated remote controller for up to 16 MicAD 66.653.00000

units.

1.2.3 Options Order No.

Digital Audio Output Options:

ADAT Interface: 8-channel optical digital audio output card 1.650.050.20

for connecting with the ADAT and compatible

8-channel recorders or other equipment featuring

the ADAT standard connectors.

TDIF-1 Interface: 8-channel digital audio output card 1.650.052.20

for connecting with the DA-88 and compatible

8-channel recorders or other equipment featuring

the TDIF-1 standard connectors.

E 1/2 Come in!

Edi tion:

Page 19

D19 MicAD

19.02.01

Control Port Options:

MIDI Merge Module: For connection with MIDI compatible controllers 1.650.060.20

featuring MIDI In, Out, Thru, Return connectors

for simple remote control daisy-chaining of up to

16 MicAD units.

MIDI RS422 Module: For connection with the MicAD MASTER or other 1.650.065.20

RS422 compatible controllers

featuring In/Out and Thru/Return connectors for

simple remote control daisy-chaining of up to

16 MicAD units.

1.2.4 Accessories Order No.

Accessories/Spares: Kit, consisting of: 20.020.302.48

• Mating XLR connectors (10 pcs. male,

4 pcs. female)

• Mic/Line Gain knobs (2 pcs. each)

• Rack mounting screws with washers

(4 pcs. each)

• Identification strip (1 pc.)

• 9-pin D-Type connectors (2 pcs.)

Interface cables: ADAT/Alesis optical interface cable, 10.325.010.00

length 1.0 m

ADAT/Alesis optical interface cable, 10.325.011.00

length 5.0 m

TDIF-1/Tascam interface cable F-10.025.031.08

“PW 88D”, length 1.0 m

TDIF-1/Tascam interface cable F-10.025.031.09

“PW 88D”, length 5.0 m

RS422 Remote control cable, length 15.0 m 1.023.745.81

For interconnection between D19 MicAD

MASTER and D19 MicAD STAGE or D19 MicAD

units or other compatible RS422 controllers.

RS422 Remote control cable, length 1.0 m 1.023.754.00

For interconnection between several D19 MicAD

STAGE or D19 MicAD units (or D19 MicAD

MASTER, if required).

Edi tion:

Come in! E 1/3

Page 20

19.02.01

D19 MicAD

1.3 Safety and connections

1.3.1 Utilization for the purpose intended

The Studer D19 MicAD 8-channel Mic/Line preamplifier is designed for

professional use. It is presumed that the unit is operated only by trained

personnel; servicing must be performed by qualified experts.

The electrical connections may be connected only to the appropriate

voltages and signals specified in this manual. Please consult the “Safety

and EMC” section at the very beginning of this manual.

1.3.2 Power connection

There is no need to select a specific mains voltage setting because the

Studer D19 MicAD can be operated on mains voltages from 100 through

240 VAC.

Caution! Repair work may only be performed by a trained service technician. The

primary fuse of the D19 MicAD must be replaced by a spare fuse of

exactly the same type. The D19 MicAD must not be opened by the user

because of the risk of a severe electric shock hazard!

Power cable The supplied power socket has to be fitted with a mating power cable

incl. plug by an electrician, if your local Studer agency or your dealer

should not have added a fitting power cable.

☛ Please consult the “Safety” section at the very beginning of this

manual.

E 1/4 Come in!

Edi tion:

Page 21

19.02.01

1.3.3 Connector panel

D19 MicAD

MIDI REMOTE

1

3

4

5

2

RETURNIN OUTTHRU

RS422 REMOTE CONTROL

[2]

LINE INPUTS

MIC INPUTS SYNCHRONIZATION

8 AES 3/4AES 1/2 AES 7/8

7

36

45

1245 3678

2

1

IN/OUT RETURN/THRU

DIGITAL OUT

WCLK OUTWCLK INAES IN

[7] [8] [7] [1][3]

DIGITAL MCH OUT

DIGITAL MCH OUT

[9]

[1] AC POWER Connector for socket IEC 320/C13.

Supply voltage range 100...240 V

(without voltage selector); mains fre-

AC

quency 50...60 Hz.

For connecting to the mains, please consult the Safety section at the

very beginning of this manual.

OPTICAL OUT

[5][6]

TDIF-1

AES 5/6

[2] LINE INPUTS Analog Line inputs on female XLR connectors. Sensitivity for full-scale

input level of the A/D converter adjustable from –5 dBu to +24 dBu.

Input impedance 11 kΩ, transformer-balanced.

[3] MIC INPUTS Microphone inputs on female XLR connectors. Sensitivity for full-scale

input level of the A/D converter adjustable from –49 dBu to +20 dBu.

Input impedance 1 kΩ, transformer-balanced.

[4] DIGITAL OUT AES/EBU Outputs on male XLR connectors, transformer-balanced. Out-

put impedance 110 Ω.

[5] Optional Digital Outputs TDIF-1 eight-channel format or optical ADAT eight-channel format.

[6] Remote Control Options For installation of optional remote modules: Either MIDI-RS422 module

or MIDI merge module .

[7] AES IN Input for external synchronization via AES/EBU (female XLR connector).

[8] WCLK IN Input for external Word Clock synchronization (BNC connector).

[9] WCLK OUT Output of the Word Clock Sync signal (BNC connector).

Edi tion:

Come in! E 1/5

Page 22

19.02.01

D19 MicAD

1.4 Technical specifications (subject to change without notice)

1.4.1 Audio specifications (all measurements at f

Frequency response: Microphone 20 Hz...20 kHz, ±0.4 dB

Line 20 Hz...20 kHz, ±0.1 dB

A/D converter: Delta-Sigma, 64 × oversampling, resolution 20 bit, linear.

Mic input noise figure: typ. < 3.5 @ max. gain, 20 Hz...20 kHz, 24°C

Signal/noise ratio: A/D converter > 106 dBFS, CCIR 468-3

THD + Noise: Line < –85 dBFS @ 20 Hz...24 kHz, Full Scale

Crosstalk: Line-Line/Mic-Mic

< –96 dB @ 1 kHz; < –92 dB @ 20 Hz...20 kHz

Analog inputs: 8 separate Mic and Line inputs on XLRs, transformer-balanced and float-

ing.

8 dual concentric potentiometers for MIC/LINE Gain control.

Functions selectable per channel: Phase, Phantom (Mic input only),

High-pass filter (–3 dB @ 75 Hz, 12 dB/oct.; Mic input only).

Stereo Link Control for adjacent channel pairs.

Selectable for all channels simultaneously: Soft Clip.

Input sensitivity range for Full Scale:

Mic –49...+20 dBu

Line –5...+24 dBu

= 48 kHz)

S

Maximum input level (analogue): Mic +20 dBu

Line +24 dBu

Interchannel gain deviation (stereo pairs):

Mic < 0.5 dB

Line < 0.05 dB

Input impedance: Microphone 1 kΩ

Line 11 kΩ

Metering: PPM, peak program meter with switchable Peak Hold function;

16-segment bargraph displays, range –60 dBFS...Overload.

Digital audio processing: DC reject (always on)

Output word length 20 bit, 16 bit with Dithering or 16 bit with Noise

Shaping.

Digital outputs: 4 AES/EBU outputs on XLRs, transformer-balanced and floating accord-

ing to AES3-1992, ANSI S4.40-1992

Amplitude 2...5 V

Impedance 110 Ω

Optional outputs: • TDIF-1 8-channel, 20 or 16 bit serial audio data with sampling fre-

quency information; C-MOS level.

• ADAT optical 8-channel format.

E 1/6 Come in!

Edi tion:

Page 23

19.02.01

1.4.2 Peripheral connections

Synchronization/sampling rate: Word Clock IN 30...54 kHz, TTL level, impedance 75 Ω

Word Clock OUT 30...54 kHz, TTL level, impedance 75 Ω

AES/EBU IN 30...54 kHz, transformer-balanced and floating,

impedance 110 Ω, according to AES 11-1991

Internal clock 44.1 kHz / 48 kHz

Remote control: Control ports: MIDI or MIDI-RS422 (optional)

Device number: 1...16 or OMNI mode, settable on front panel

Remote: ON/OFF, selectable on front panel

1.4.3 Power supply

Mains voltage: 100...240 VAC, 50...60 Hz

Current consumption: 0.5...0.25 A

D19 MicAD

Appliance inlet: IEC 320/C14

Primary fuse: T 2.0 A H 250 V UL, CSA

1.4.4 Primary fuse

Caution: The primary fuse is located inside the D19 MicAD/MicAD STAGE. Re-

pair work may only be performed by a trained service technician. The

primary fuse of unit must be replaced by a spare fuse of exactly the same

type. The unit must not be opened by the user – risk of a severe electric

shock hazard!

Spare fuse: T 2.0 A H 250 V UL, CSA (5 × 20 mm) Order No. 51.01.1022

1.4.5 Operating conditions

Ambient air temperature: +10°...+40°C

Relative humidity: Category F (DIN 40040)

1.4.6 Safety and EMC standards

Safety: Protection class I according to EN 60950; 1992 + A1/A2; 1993 (UL

1950)

EMC: Product family standard for audio, video, audio-visual, and entertain-

ment lighting control apparatus for professional use.

Emission: EN 50081-1; 1992

Immunity: EN 50082-1; 1992

Edi tion:

Come in! E 1/7

Page 24

19.02.01

D19 MicAD

(Knobs)

(Rubber feet)

1.4.7 Mechanical data MicAD/MicAD STAGE

Weight: approx. 6 kg, all options installed.

Dimensions: [mm]

88.3

482.4

1.4.8 Mechanical data MicAD MASTER

MicAD MASTER can be installed into the meter panel section of Studer

mixing consoles.

Weight: approx. 2.5 kg.

Dimensions: [mm]

482.4

approx. 19

(BNC)

365

approx. 19

(Knobs; MicAD only)

130

approx. 19

88.3

approx. 8

(Rubber feet)

approx. 8

E 1/8 Come in!

Remote

Edi tion:

Page 25

19.02.01

2 OPERATION

2.1 Operating elements

[4]

D19 MicAD

[3]

[5]

MicAD

POWER

OVL

–1

–3

–6

–9

–12

–18

–24

–30

–40

–60

12

MIC

18

LINE

24 -6

dBu/FS

LINE

OVL

–1

–3

–6

MIC

–9

–12

LINE

Ø

–18

48V

–24

–30

–40

–60

6

12

0

18

24 -6

dBu/FS

1

LINE

MIC

LINE

Ø

48V

LINK

SEL SEL SEL SEL SEL SEL SELSEL

6

0

18

2 3

OVL

–1

–3

–6

–9

–12

–18

–24

–30

–40

–60

12

24 -6

dBu/FS

OVL

–1

–3

–6

MIC

–9

–12

LINE

Ø

–18

48V

–24

–30

–40

–60

6

0

LINE

6

12

18

24 -6

dBu/FS

LINE

OVL

–1

–3

–6

MIC

–9

–12

LINE

Ø

–18

48V

–24

–30

LINK

–40

–60

12

18

0

24

dBu/FS

4 5

LINE

OVL

–1

–3

–6

MIC

–9

–12

LINE

Ø

–18

48V

–24

–30

–40

–60

6

12

0

18

-6

24

dBu/FS

LINE

MIC

LINE

Ø

48V

LINK

6

0

18

-6

6 7

OVL

–1

–3

–6

–9

–12

–18

–24

–30

–40

–60

12

24

dBu/FS

LINE

OVL

–1

–3

–6

MIC

LINE

Ø

48V

6

0

-6

MIC

–9

–12

LINE

Ø

–18

48V

–24

–30

LINK

–40

–60

6

12

18

0

24

-6

dBu/FS

LINE

[1] [8] [2] [6]

MIC/LINE

Ø

48V

STEREO LINK

PEAK HOLD SOFT CLIP REMOTE

8

[9] [10] [13]

[7]

[11] [12] [14]

D19 SERIES

SOFT

HOLD

INT

WCLK

16DI

AES

16NS

AUTO

20BIT

MODE SYNC CTRL CH

REM

48

44

VAR

MicAD

[1] POWER Switches the unit on or off. The unit is ready to operate with the factory

default settings. The subsequent settings remain stored in a Flash

EPROM after switching the unit off (unit contains no battery).

CHANNEL FUNCTIONS: The following functions operate on individual channels:

[2] SEL Toggle key to select or deselect one or more of the eight channels to

be operated on (Functions [3]...[7]). Multiple channel selection is possible by holding one of the SEL keys down and pressing several SEL

keys successively.

[3] MIC/LINE Toggle key to select the MIC INPUT or LINE INPUT of the selected

channel(s).

[4] Ø Toggle key to activate the phase reverse switch of the selected chan-

nel(s).

[5] 48 V Toggle key to activate the 48 V phantom power supply for the selected

microphone channel(s).

[6] Activates the high pass filter on the microphone inputs of the selected

channel(s). Cut-off frequency (–3 dB point) 75 Hz, slope 12 dB/octave.

[7] STEREO LINK Activates the STEREO LINK of the selected channel(s) in pairs (1/2, 3/

4, 5/6, 7/8). The linked channels are then controlled as a stereo pair

from the odd channel’s controls. If linked, the odd-numbered channel's gain potentiometer sets the gain of both the odd- and even-numbered channels. Mic/Line setting, Gain setting, 48 V phantom power

supply and high-pass filter setting of the odd channels are copied into

the evennumbered channels. Exception: The phase reversal function

can always be controlled individually. After having deselected the

link function, the even-numbered channel retains the settings which

have been copied from the odd-numbered channel, but all channel

functions can be controlled individually again.

Edi tion:

Operation E 2/1

Page 26

19.02.01

D19 MicAD

[8] LINE/MIC Potentiometer Adjusts the gain of the LINE INPUT (ring) and the MIC INPUT (knob) in

1 dB steps. The printed scale on the front panel corresponds to the

LINE INPUT.

LINE INPUT, Headroom The LINE potentiometer is calibrated in dBu per full-scale. It repre-

sents the dBu value of an analog input signal which causes a fullscale output of the A/D converter.

Example: A studio works with +6 dBu nominal analog level and uses 12 dB

headroom. The LINE potentiometer should then be set to 18 dBu.

Full scale

6 dBu + 12 dB =

Potentiometer

setting:

18 dBu

12 dB Headroom

Input signal

+6 dBu nom. level

(Panel) Setting [dBu] = Nominal level [dBu] + Headroom [dB].

E 2/2 Operation

Edi tion:

Page 27

D19 MicAD

19.02.01

GLOBAL FUNCTIONS: The following functions are activated for the entire unit:

[9] MODE Toggle key to select the word length of the DIGITAL OUTput. 20 Bit,

16 Bit with Noise Shaping or 16 Bit with dithering can be selected.

[10] SYNC Selects the synchronization source for the unit. Possible selections are:

INT 48 Internal quartz reference, 48 kHz

INT 44 Internal quartz reference, 44.1 kHz

WCLK Selects external Word Clock Sync

AES Selects external AES/EBU Sync

AUTO Selects sources automatically in the sequence AES-WCLK-INT

VAR Indication only, active if the external source frequency deviates from

48 or 44.1 kHz for more than approx. ±1%.

48

INT

44

WCLK

16DI

16NS

20BIT

[11] PEAK HOLD Toggle key to select the PEAK HOLD function for the PPM level me-

ters – either permanent or with automatic reset after approx. 2 s.

AES

AUTO

VAR

[12] SOFT CLIP Toggle key to activate the SOFT CLIP function in the analog paths to

reduce the danger of overloading the A/D converter with short signal

peaks. Threshold at 3 dB below full-scale, allowing for approx. 6 dB

reserve before hard clipping occurs.

[13] CTRL CH Toggle key to select a remote control channel (1...16), or Omni mode

(for MIDI control).

[14] REMOTE Toggle key to activate REMOTE MODE. Local controls and display

are disabled.To switch the REMOTE function off, press the key for more

than one second.

MicAD STAGE

The MicAD Stage version contains only the CTRL CH and REMOTE

keys and the POWER switch.

[13] CTRL CH Toggle key to select a remote control channel (1...16), or Omni mode

(for MIDI control).

[14] REMOTE Toggle key to activate REMOTE MODE. To switch the REMOTE func-

tion off, press the key for more than one second.

Edi tion:

Operation E 2/3

Page 28

19.02.01

D19 MicAD

MicAD MASTER

The MicAD MASTER can be used to control all functions of any MicAD

version. Usually, it is powered from the controlled MicAD; it has no

POWER switch. All functions work in the same way as on the MicAD

except for the following additional functions:

[8] LINE/MIC Potentiometer When a remote control channel is selected, the potentiometer settings

of the Master will usually be different from the ones of the selected

MicAD. Normally, audio levels are displayed. As soon as a potentiometer is slightly turned, the Master's display changes to indicate the

difference between the potentiometer setting and the actual gain setting on the MicAD.

OVL

–1

–3

–6

–9

–12

–18

–24

–30

–40

–60

MIC

LINE

Ø

48V

LINK

SEL

With reference to this indication, the corresponding potentiometer has

to be turned (down for our example) until only the center LED is on.

During this matching process the potentiometer does not change the

gain. As soon as only the center LED is on, the display changes to

indicate the signal level again, and the potentiometer position is

matched to the gain setting. From now on, the potentiometer is active

and controls the gain of the MicAD's corresponding input channel.

[13] CTRL CH Key to select the remote control channel to be operated.

D19 MicAD MASTER

Potentiometer

..

No. 2

Remote Control Channel

No. 3

Audio Channel

No. 18

In the example above, 3 MicAD units are remotely controlled by a

MicAD Master. The audio channels are numbered in succession: Unit

no. 1 holds the audio channels no. 1...8, unit no. 2 holds the audio

channels no. 9...16, and so on.

If the gain of audio channel 18 has to be adjusted, select remote control channel no. 3 by pressing CTRL CH as many times as required

until a “3” is displayed. Then, the potentiometer no. 2 adjusts the gain

of audio channel no. 18.

D19 MicAD No. 1

Audio Ch. 1...8

D19 MicAD No. 2

Audio Ch. 9...16

D19 MicAD No. 3

Audio Ch. 17...24

E 2/4 Operation

Edi tion:

Page 29

19.02.01

2.2 Audio and sync connections, pin assignments

2.2.1 Mic and line inputs

Pin assignment (XLR, 3-pin, female):

Pin Description

1

2

1

3

Ground

2

Input +

3

Input -

-

Chassis

2.2.2 Digital outputs

Pin assignment (XLR, 3-pin, male):

Pin Description

1

1 2

3

Ground

2

Output +

3

Output -

-

Chassis

D19 MicAD

2.2.3 External AES/EBU synchronization

Pin assignment (XLR, 3-pin, female):

Pin Description

1

12

3

Ground

2

Input +

3

Input -

-

Chassis

2.2.4 Word clock in/out

Input Pin assignment (BNC, 75 Ω):

Pin Description

Center

Output Pin assignment (BNC, 75 Ω):

Center

center

outer

Word Clock Input (TTL level)

Ground

Pin Description

center

outer

Word Clock Output (TTL level)

Ground

Edi tion:

Operation E 2/5

Page 30

19.02.01

D19 MicAD

2.2.5 Using the TDIF-1 8-channel interface

The Tascam TDIF-1 digital I/O format interface is used for sending digital audio data from the D19 MicAD to Tascam DA-88 and compatible

units.

Basic characteristics: 8-channel audio data with sampling frequency information, emphasis

information, and sync signal.

Signal transmission level is C-MOS, unbalanced.

Note: The maximum cable length should not exceed 10 m.

Pin assignment:

1425

DIGITAL MCH OUT

Recorder

e.g. DA-88

TDIF-1

or compatible

Cables: Order No.: F-10.025.031.08 (1.0 m)

F-10.025.031.09 (5.0 m)

Only the specified connecting cables should be used (order numbers

above).

Pin Designation

113

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

*) DA-88 ignores

**) IF-88 SD ignores

***) DA-88 ignores except “DIGITAL IN” and “FORMAT” modes

****) DA-88 displays only warning except “DIGITAL IN” and “FORMAT” modes

DOUT 1/2

DOUT 3/4

DOUT 5/6

DOUT 7/8

LRCK OUT

FS 0 OUT

GND

(FS 1 IN) **) ****)

(LRCK IN) *)

(DIN 7/8)

(DIN 5/6)

(DIN 3/4)

(DIN 1/2)

GND

GND

GND

GND

EMPHASIS OUT

FS 1 OUT

(FS 0 IN) **) ****)

(EMPHASIS IN) ***)

GND

GND

GND

GND

E 2/6 Operation

Edi tion:

Page 31

D19 MicAD

19.02.01

Cable configuration:

25-pin D-Type,

male

1

14

2

15

3

16

4

17

5

9

7

18

6

19

8

20

21

Shield + housing

10

22

11

23

12

24

13

25

Cable colours (twisted pairs)

org/red 1

org/blk 1

gry/red 1

gry/blk 1

wht/red 1

wht/blk 1

yel/red 1

yel/blk 1

pnk/red 1

pnk/blk 1

org/red 2

org/blk 2

gry/red 2

gry/blk 2

wht/red 2

wht/blk 2

yel/red 2

yel/blk 2

pnk/red 2

pnk/blk 2

org/red 3

org/blk 3

gry/red 3

gry/blk 3

wht/red 3

wht/blk 3

25-pin D-Type,

male

13

25

12

24

11

23

10

22

9

5

7

21

8

20

6

19

18

Shield + housing

4

17

3

16

2

15

1

14

2.2.6 Using the optical ADAT 8-channel interface

The ADAT format is a serial 8-channel format. It uses a single line

cable with fibre optic.

DIGITAL MCH OUT

OPTICAL OUT

Plug type: TOCP 155 k

Optical fibre: TOFC 100

The maximum cable length specified by Alesis is 1 m. However, in

most cases, operation with a cable length up to 10...15 m is possible.

Recorder

e.g. ADAT

or compatible

Edi tion:

Operation E 2/7

Page 32

19.02.01

D19 MicAD

2.3 Application ideas and examples

The D19 MicAD is perfectly suitable for a whole range of applications. Here are some suggestions:

Studio-in-a-box front end

for STUDER Dyaxis or

other DAWs.

DAW (DYAXIS)

Mic/Line front end, re-

motely controlled from a

digital mixing console or a

router

Studer

Mixing

Console

DYAXIS

DYAXIS

DYAXIS

Digital Audio Links

AES / EBU (8 lines)

or

OPTICAL 8-CH (2 lines)

2 or 8

AES / EBU

MicAD

POWER

1.023.717.00

MicAD

POWER

POWER

MIDI Control

MIC

LINE

D19 SERIES

REM

48

INT

44

WCLK

VAR

AES

AUTO

CTRL CH

REMOTE

D19 MicAD STAGE

MICRS422 Control

LINE LINE

D19 SERIES

REM

48

INT

44

WCLK

VAR

AES

AUTO

CTRL CH

REMOTE

D19 SERIESMicAD

REM

48

INT

44

WCLK

VAR

AES

AUTO

CTRL CH

REMOTE

D19 MicAD STAGE

E 2/8 Operation

Portable studio with an

8-CH Recorder (ADAT,

DA88, or compatibles), for

direct cuts from the mics

to the digital tracks.

8CH OPTICAL

(ADAT),

10.325.011.00

or

8CH TDIF-1,

F-10.025.031.09

MIC

LINE

,

D19 MicAD and 8 TRACK RECORDER

Edi tion:

Page 33

19.02.01

Optical 8-CH

Stacked Mic/Line studio

interface system, control-

led via the dedicated

remote controller MicAD

MASTER

Universal studio tool,

controlled via

a MIDI controller

MicAD

POWER

MicAD

POWER

MicAD

POWER

up to 16 MicAD STAGE

D19 MicAD

D19 SERIES

REM

48

INT

44

WCLK

VAR

AES

AUTO

CTRL CH

REMOTE

D19 SERIES

REM

48

INT

44

WCLK

VAR

AES

AUTO

CTRL CH

REMOTE

D19 SERIES

REM

48

INT

44

WCLK

VAR

AES

AUTO

CTRL CH

REMOTE

CONTROL

1.023.717.00

UP TO 128 MIC INPUTS

UP TO 128 LINE INPUTS

UP TO 128 DIGITAL

OUTPUT CHANNELS

MicAD MASTER

Front end for Studer D940

Digital Mixing Console,

also to be used as a

stage box.

MIDI Controller

MicAD

MicAD

AES/EBU

MicAD

MicAD

MicAD

REMOTE

MUX

MicAD

STAGE BOX

EXTENSION

D19 SERIESMicAD

D19 SERIESMicAD

D19 SERIES

D19 SERIES

MADI

UP TO 56CH

MADI

MIDI Control

AES/EBU and

TDIF or

D940

DSP RACK

MicAD

MicAD

MIC LINE LINE

Control

LOCAL MUX

AES/EBU

D19 SERIESMicAD

LOCAL MIC/LINE INPUTS

D19 SERIESMicAD

D19 MicAD

D940 DESK

Edi tion:

Operation E 2/9

Page 34

19.02.01

D19 MicAD

2.3.1 Wiring for external synchronization

External synchronization –

recommended practice

Sync Generator

External synchronization,

alternative wiring methods –

not expressly recommended

but possible

Sync Generator

or

AES

AES

AES

AES

WCLK

D19 MicAD

SYNCHRONIZATION

AES IN WCLK OUTWCLK IN

AES IN

SYNCHRONIZATION

AES IN

SYNCHRONIZATION

AES IN

AES IN WCLK OUTWCLK IN

AES IN WCLK OUTWCLK IN

D19 MicAD

D19 MicAD

D19 MicAD

SYNCHRONIZATION

OUT

WCLK OUTWCLK IN

AES IN

WCLK IN

or

SYNCHRONIZATION

AES IN

WCLK IN

OUT

WCLK IN

WCLK OUT

D19 MicAD

D19 MicAD

SYNCHRONIZATION

AES IN

WCLK IN

OUT

WCLK OUTWCLK IN

E 2/10 Operation

Edi tion:

Page 35

19.02.01

2.4 Remote control

2.4.1 General, hardware

IN: Input

OUT: Output

RETURN: Input, received data is contained in the output data stream

THRU: Buffered, but unchanged input signal

2.4.2 RS422

D19 MicAD

The D19 MicAD can be equipped optionally with a remote control

interface. Two types are available, with the following features and

electrical standards:

RS422 (31.25 kBaud)

MIDI (31.25 kBaud)

RS422 is an industry standard allowing for interference-free communication even in rough environments. Owing to the balanced-mode

implementation the data rate can be up to 10 Mb/s over a distance of

up to 1000 m, provided that good quality, twisted-pair cable is used.

For the RS422 interface 9-pin D-Sub connectors are used.

Input and output are located together with the 24 V supply for the

MicAD Master on the female 9-pin connector. The supply voltage can

be switched on or off with a jumper; the supply current must not exceed 375 mA.

The RETURN input is located together with the THRU output on the

male 9-pin connector.

Connector panel: Jumper:

RS422 REMOTE CONTROL

+24 V ON

IN/OUT RETURN/THRU

Pin assignment:

9-pin, female (IN/OUT) 9-pin, male (RETURN/THRU)

Pin 1 0 V Pin 1 0 V

Pin 2 OUT+ Pin 2 RETURN+

Pin 3 IN- Pin 3 THRU-

Pin 4 0 V Pin 4 0 V

Pin 5 +24 V* Pin 5 --

Pin 6 0 V Pin 6 0 V

Pin 7 OUT- Pin 7 RETURN-

Pin 8 IN+ Pin 8 THRU+

Pin 9 +24 V* Pin 9 --

*connected in parallel; activated with jumper on RS422 board

Edi tion:

Operation E 2/11

Page 36

19.02.01

D19 MicAD

The MicAD uses the MIDI data rate; the following specifications apply:

31.25 kBaud; ±1%, asynchronous

1 start-, 1 stop bit, 8 data bits

Remote powering: Since the MicAD Master can only be supplied by the MicAD it is

directly connected to, usually for shorter distances also the supply

voltage is taken through the RS422 cable.

The minimum supply voltage of the MicAD Master may be as low as

21 VDC, i.e. the voltage drop at maximum current (375 mA) must not

exceed 3 V

. The cable resistance must be less than 8 Ω. The maxi-

DC

mum distance with a specific type of cable depends on the copper

resistance per meter of the cable and can easily be calculated using

the cable's specs. Please consider that the DC power is wired to two

pins of the 9-pin Sub-D connector for each leg, so that two wires each

can be used.

In the MicAD supplying the MicAD Master the supply jumper has to

be set to “24 V ON” (refer to the preceding page). In all remaining

MicADs the jumper must be set to “24 V OFF”.

Wiring for

MIDI-RS422 control

RS422 REMOTE

D19 MicAD Master

e.g. STUDER 1.023.717.00 (15 m)

D19 MicAD (or D19 MicAD Stage)