Stuart Turner Submersible Supersub VA User Manual

Submersible Pumps

OPERATING INSTRUCTIONS

Please leave this instruction booklet with the pump as it

contains maintenance and safety information

(Original Instructions)

SUBMERSIBLE MODELS

Supersub 150VA

Supersub 250VA

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page No

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Limits of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Siting of the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Float Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Environment Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IMPORTANT NOTES

z Please read these instructions fully before starting the

installation:

z The installation must comply with the relevant water supply,

electrical and building regulations and be installed by a

competent person.

z If in doubt, consult Stuart Turner Ltd.

APPLICATION

General

z The pumps must not be used with salt water, sewage, flammable,

corrosive or explosive liquids (eg. petroleum oil, petrol, thinners)

grease, oils or foodstuffs.

z This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

z Children should be supervised to ensure that they do not play with the

appliance.

The submersible pump range is designed for re-circulation, drainage and transfer of

fresh water in outdoor or indoor applications.

The pumps incorporate an integral float switch, which provides automatic pump control in

the form of a low level cut out to prevent the risk of dry running.

- 2 -

The pumps are suitable for dirty water applications and are capable of handling semi-

solids in suspension of up to *5 mm in diameter.

*Note: Applicable only when pump is suspended above bottom of sump. When pump is

located on the bottom of sump the inlet grille will restrict solid ingress diameters to

3 mm.

WARNING AGAINST MISUSE

This pump set must not be used for any other application without the

written consent of Stuart Turner Limited and in particular, must not be

connected directly to the mains water supply or used outside the

conditions specified in the limits of application.

PRODUCT DESCRIPTION

Electric motor driven submersible pump with float switch control.

Motor

All motors are induction type, permanent capacitor, fitted with integral auto-resetting

thermal overload protection, IPX8 enclosure, class ‘B’ insulation and continuously rated.

The motor is encapsulated in a casing and protected from water ingress by two separate

lip seals running on a shaft sleeve, lubricated with a biodegradable vegetable oil.

Pump

All models are close coupled to the motor and are of centrifugal design and are supplied

as standard with a 90o elbow and stepped hose connector.

Supersub are single stage units and are supplied pre-fitted with a 10 metre mains supply

cord.

Standard pump materials of construction of major wetted parts are as follows.

Model Body Impeller Shaft

All

Glass filled

Polypropylene

Polyamide Coated Steel

Motor

Encapsulent

Stainless Steel/

Cast Aluminium

Seal

(Lip)

Nitrile

Float Switch

Factory fitted assembly for automatic pump control, provided with a manual override.

The wetted materials of construction are glass filled polypropylene, ABS Polyamide and

Acetal.

LIMITS OF APPLICATION

Max.

Model

Supersub 150VA 35 4 7 fully submerged 30 6.5

Supersub 250VA 35 4 7 fully submerged 30 8.5

Water

Temp.

o

C

Min.

Water

Temp.

o

C

Max.

Immersion

Depth

(m)

- 3 -

Min.

Immersion

Depth

(mm)

(for cont. operation)

Max.

No.

Starts/h

Max.

Head (pump

closed valve)

(m)

TECHNICAL SPECIFICATION

Model

Supersub 150VA 230/1/50 275 180 1.2 IPX8 Continuous 260 158 320 4.6 1

Supersub 250VA

Supply

230/1/50 508 350 2.2 IPX8 Continuous 260 158 320 4.8 1

Max. Watts

Consumed

Nominal

Watts

Output

(Motor)

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

Note: For information on other voltages/frequencies which are not shown, consult any

supplementary instruction sheet supplied, or the rating label attached to the

pump.

Full

Load

Current

(AMPS)

H

Enc.

Rating

Duty

Rating

Dims (mm)

L W H

Gross

Weight

(packed)

kg

No. of

Pump

Stages

L

W

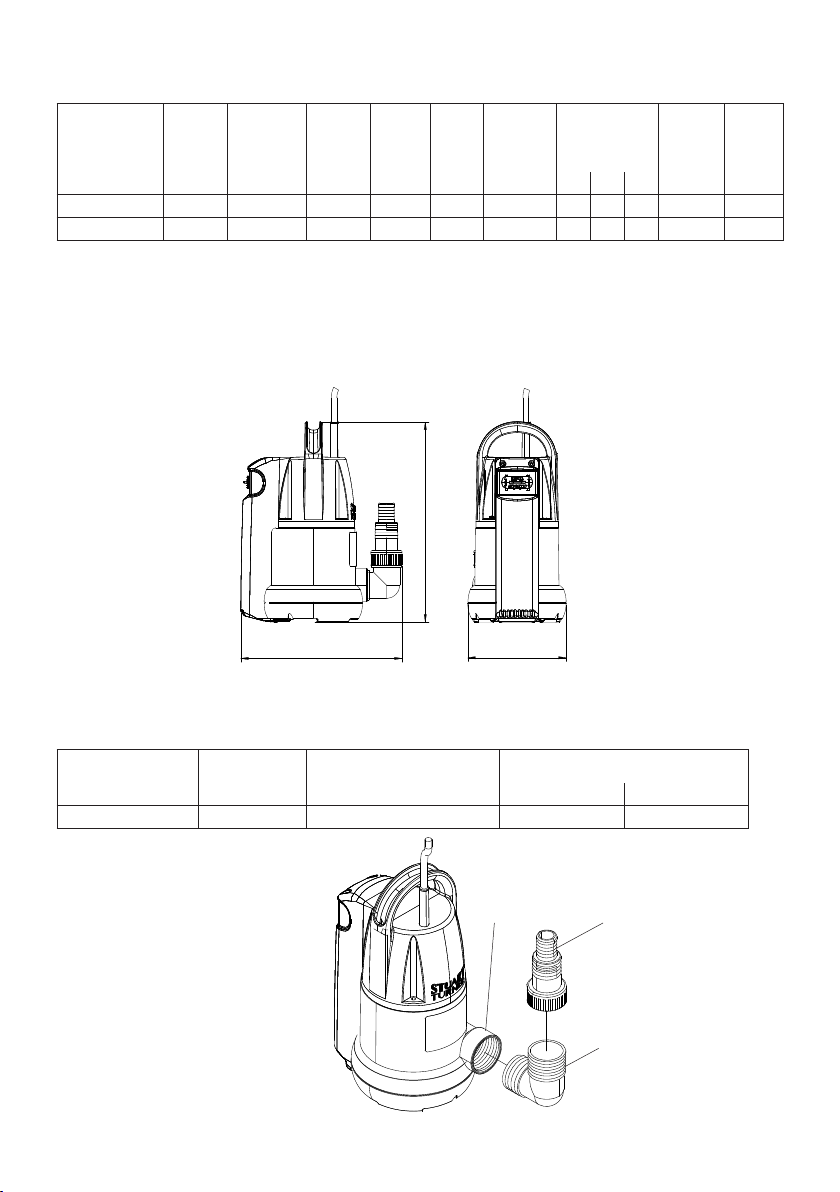

Fig. 1 (Dimension Key)

CONNECTIONS

Supersub pumps are supplied with an elbow and stepped hose connector which can be

screwed to the pump outlet port.

Pump Type

Supersub G1½ F G1½ M x G1½ M x 90

Pump

Outlet

Fig. 2

Elbow Hose Connector

o

Thread Hose Bore (mm)

G1½ / G1 F 30 / 25

Pump Outlet

Port

Stepped Hose

Connector

90o Elbow

- 4 -

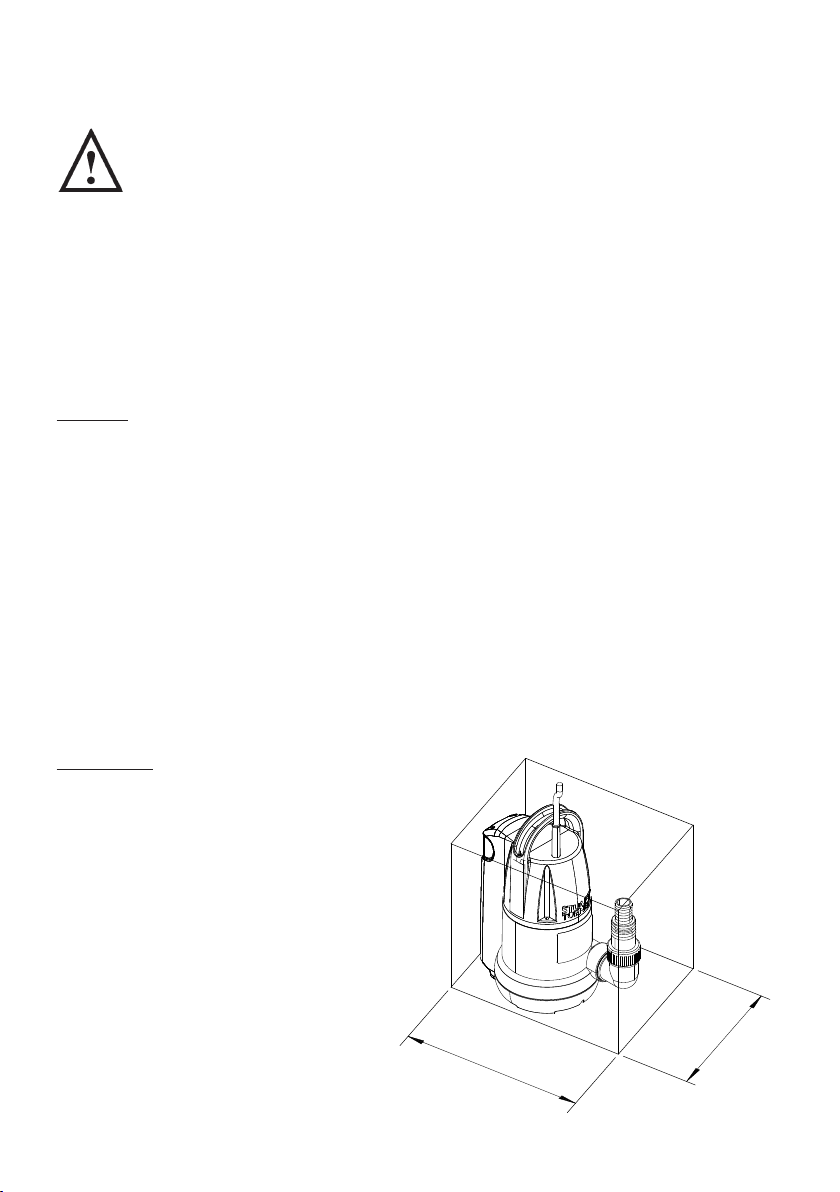

SITING OF THE PUMP

WARNINGS:

z Do not run against a closed valve for periods longer than 5 minutes.

z The water in and around the pump must not be allowed to freeze. This

will result in pump damage.

z Do not under any circumstances use the supply cord fitted, as a

means to carry or lower the pump into position on installation. Attach

a rope sling to handle.

z Do not allow plastic pump parts to come into contact with solder flux,

oil or cellulose based paints, paint thinners or strippers, acid based

descalents or aggressive cleaning agents.

z When siting the pump ensure its base is raised slightly from the

bottom of the sump reducing the possibility of blocking the filter with

debris or drawing in small stones.

General

The pump must be installed in the vertical position and must be fully submerged at all

times when operating continuously to avoid overheating of the motor. However, when the

automatic float switch option is selected, the pump may be operated partially submerged

for short periods (see float switch operation section for further details).

When siting the pumps in a location where organic or general debris is likely, ensure the

pump is placed on its base on a flat horizontal surface (eg. on a paving slab) to enable full

functionality of the inlet filter grille and to prevent the force of the pump from drawing in

small stones. This will result in pump damage.

FLOAT SWITCH

The pumps incorporate an integral automatic float switch which has two modes of

operation, auto and manual.

The float switch consists of a float which moves up and down on a vertical axis within a

housing.

Sump Size

The minimum possible sump size is

270 mm x 170 mm.

Fig. 3

- 5 -

70

2

70

1

Loading...

Loading...