Stainless Peripheral Pumps

OPERATING INSTRUCTIONS

Please leave this instruction booklet with the pump as it

contains maintenance and safety information

(Original Instructions)

MODELS

Vertical Suction

RG550-2

INDEX . . . . . . . . . . . . . . . . . Page No

Application . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Description . . . . . . . . . . . . . . . . . . . 3

Limits of Application . . . . . . . . . . . . . . . . . . . 4

Technical Specifi cation . . . . . . . . . . . . . . . . 4

Siting of the Pump/Pipework . . . . . . . . . . . . 4

Electrical Installation . . . . . . . . . . . . . . . . . . 6

INDEX . . . . . . . . . . . . . . . . . Page No

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Commissioning . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 11

Trouble Shooting Guide . . . . . . . . . . . . . . . . 12

Environment Protection . . . . . . . . . . . . . . . . 12

IMPORTANT NOTES

Please read these instructions fully before starting the

installation:

The installation must comply with the relevant water supply,

electrical and building regulations and be installed by a

competent person.

If in doubt, consult Stuart Turner Ltd.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

APPLICATION

The range of stainless steel peripheral pumps is designed to pump clean fresh water.

Other clean, non aggressive, non explosive liquids with similar characteristics to water may

be pumped. Consult Stuart Turner for such applications.

The pumps can be used for pressure boosting, fluid transfer and distribution. They are

suitable for flooded suction applications. Alternatively a maximum suction lift of 4.6 m is

permitted when using a Stuart footvalve/strainer.

WARNING AGAINST MISUSE

This pump set must not be used for any other application without the

written consent of Stuart Turner Limited. In particular, it must not be

connected directly to the mains water supply, or used outside the

conditions specified in the limits of application.

- 2 -

PRODUCT DESCRIPTION

Motor:

Induction type, totally enclosed fan ventilated cooling*, continuously rated*, class ‘F’

insulation. Motors comply with IEC34-1. Single phase versions incorporate a permanent

capacitor and integral auto resetting thermal overload protection.

The standard range of motors are suitable for a supply of 230V, 1 phase, 50Hz.

Optional motors are available on certain models to suit various voltages and frequencies

(see technical specification for details).

*Variations of rating and enclosure details can be found in the technical specification

section.

Pump

All models are close coupled to motor.

RG550-2 are of single stage, peripheral design, with vertical suction and discharge ports.

Standard pump materials of construction of major wetted parts are as follows: -

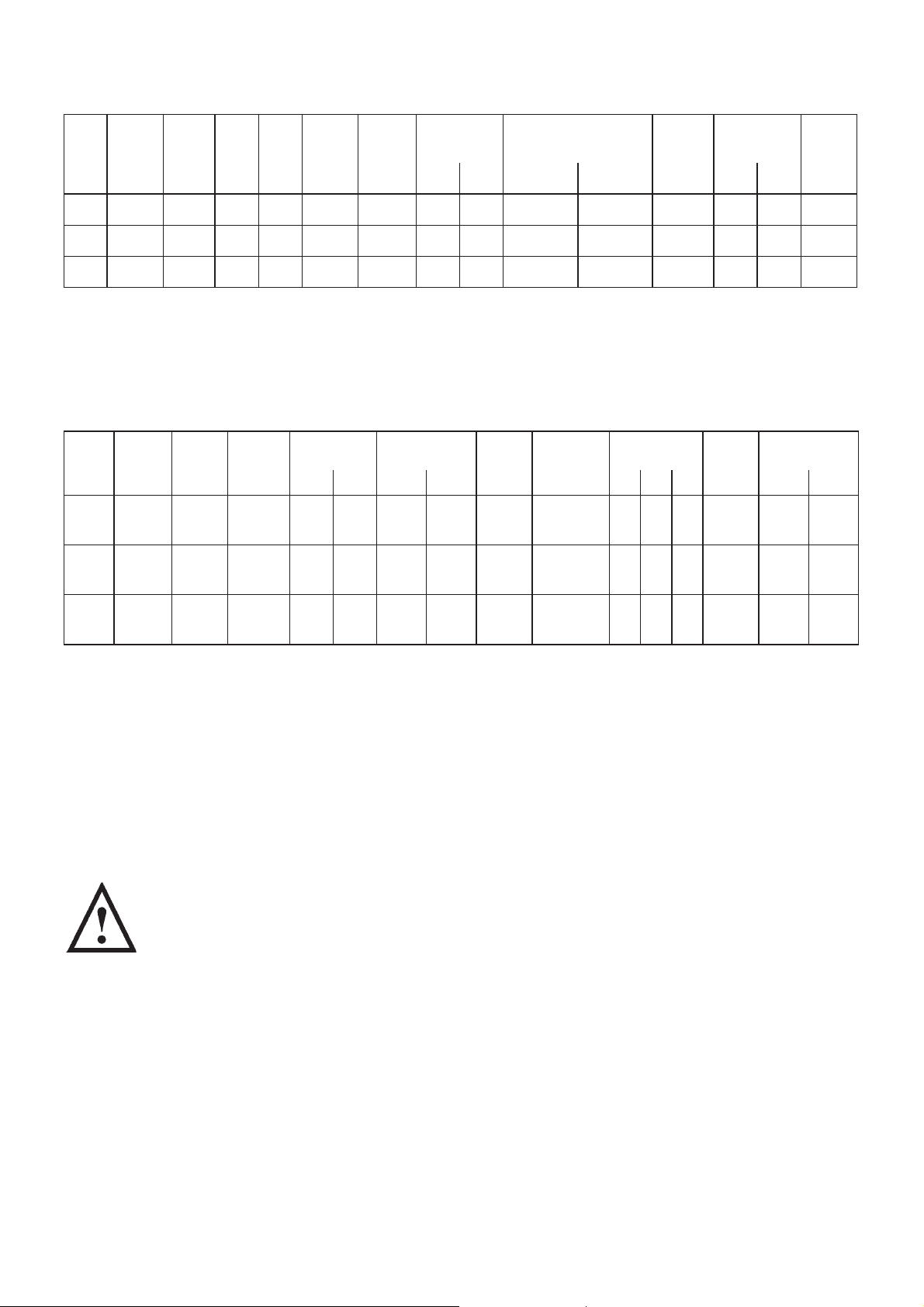

Model Body Impeller Shaft Mechanical Seal

All Variants Stainless Steel Stainless Steel Stainless Steel Nitril/Carbon

Ceramic/Stainless Steel

Other seal material options are available on certain models.

- 3 -

Cont ...

LIMITS OF APPLICATION

Part

Model Supply

No

46455 RG550-2 230/1/50 80 4 40 4.6* 40 50 9.5 600 (6) 21 60

46469 RG550-2 230/1/50 80 4 40 4.6* 40 50 9.5 600 (6) 21 60

46470 RG550-2 230/1/50 80 4 40 4.6* 40 50 9.5 600 (6) 21 60

Liquid

Temp.

o

C

Liquid

Temp.

Min.

Max.

o

C

Max.

Ambient

Air Temp

o

C

Max.

Suction

Lift (m)

Max. Head

(Pump Closed

Valve) (m)

50 Hz 60 Hz

Max. Viscosity

(Redwood

No. 1 Scale)

**Max.

Working

Pressure

Centistokes 50 Hz 60 Hz

kPa (bar)

Max. Inlet Head

(m)

Max. No.

Starts/h

* With footvalve fitted.

**Note: Max working pressure is the maximum pressure that can be applied to the

pump internal casing under any installation conditions.

TECHNICAL SPECIFICATION

Part

46455 RG550-2 230/1/50 300 455 2.0 IP44

46469 RG550-2 230/1/50 300 455 2.0 IP44

46470 RG550-2 230/1/50 300 455 2.0 IP44

No

Model Supply

Nominal

Watts

Output

(Motor)

Max. Watts

consumed

50 Hz 60 Hz 50 Hz 60 Hz L W H Suction Delivery

Full Load

(AMPS)

Enc.

Rating

Duty Rating

Continuous

(S1) @ 2.5

l/min & above

Continuous

(S1) @ 2.5

l/min & above

Continuous

(S1) @ 2.5

l/min & above

Dims (mm)

242 126 180 6.3 G¾ M G¾ M

242 126 180 6.3 G¾ M G¾ M

242 126 180 6.3 G¾ M G¾ M

Gross

Weight

(packed)

kg

Connections

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

Note: For information on other voltages/frequencies which are not shown, consult any

supplementary instruction sheet supplied, or the rating label attached to the

pump.

SITING OF THE PUMP/PIPEWORK

WARNINGS:

Pump Location

If possible site the pump in a location where in the unlikely event of a

liquid leak, any spillage is contained or routed to avoid electrics or

areas sensitive to liquid damage.

Care should be taken to protect the pump from frost and freezing.

Ensure pipework to and from pump is independently supported to

prevent stress on the pump inlet and outlet branches.

Do not fit a non-return valve, or devices which contain non-return

valves, in the suction (inlet) pipework to the pump. Exceptions can be

made in the case of suction lift installations when a footvalve is

required.

- 4 -

When a footvalve is required on installations that incorporate

automatic pump control, it is recommended that a suitable pressure

relief valve be fitted in the discharge (outlet) pipework from the pump.

Do not run against a closed valve for periods longer than 5 minutes.

Do not allow plastic pump parts to come into contact with oil or

cellulose based paints, paint thinners or strippers, acid based

descalents or aggressive cleaning agents.

Do not introduce solder flux to pumps or pump parts manufactured

from plastic. All solder joints should be completed and flux residues

removed prior to pump connection.

Always install isolating valves to both suction and delivery pipework.

The motor casing can become very hot under normal operating

conditions. Care should be taken to ensure it cannot be touched

during operation.

Site the pump in a dry, frost-free horizontal position where it cannot be sprayed with

water and as close to the liquid source as possible.

The pump enclosure must be ventilated and there should be a minimum clearance of

80 mm between the pump and housing on all sides.

To prevent loss of pressure through pipework, use pipe size to match pump whenever

possible, minimising 90° bends.

It must be ensured that storage capacity of the liquid supply is adequate for the flow

rates required by the pump.

The pipework feeds to the storage tank should be of adequate size to ensure

replenishment rate of tank is sufficient to meet the needs of the pump.

Isolating valves should be fitted in suction and delivery pipework to enable easy isolation

and access to the pump.

When the pump is to be installed in areas where there is a risk of debris or scale build up

within the system, it is recommended that the inlet pipework is fitted with an inline strainer.

Pump Mounted Above Liquid Source (Suction Lift)

The pumps can be used in a suction lift installation providing the height of lift is within the

limits specified in the limits of application section.

A footvalve and strainer must always be used and the suction pipework size should be

22 mm throughout.

Lay the suction piping over the shortest possible distance and ensure there is a constant

rise from the liquid source to the pump. Any high spots will cause air pockets to form,

reducing system efficiency.

Ensure all joints in suction pipework are completely airtight. Failure to comply will result

in loss of prime.

The intake of the footvalve/strainer should be positioned such that is cannot be blocked

with debris or silt that are frequently found in the bottom of sumps and wells.

- 5 -

Cont ...

When a footvalve is installed on installations that incorporate automatic pump control,

it is recommended that a suitable pressure relief valve be fitted in the discharge (outlet)

pipework from the pump.

Fig. 1

ELECTRICAL INSTALLATION

WARNINGS:

The electrical installation must be carried out in accordance with the

current national electrical regulations by a competent person.

Before starting work on the electrical installation ensure the power

supply is isolated.

Where any of the pumps are installed in an area where there is a risk

of water spillage it is recommended that a residual current circuit

breaker having a rated current not exceeding 30 mA, be installed in

the supply circuit. This may be part of a consumer unit or a separate

unit.

This appliance must be earthed.

The motor and wiring must not be exposed to water.

Do not allow the supply cord to contact hot surfaces, including the

motor shell, pump body or pipework. The cord should be safely

routed and secured by cable clips.

RG550-2

INLET

OUTLET

The standard single phase pumps are suitable for a supply of 230V, 1 Phase, 50Hz.

Other voltages and frequencies are available on certain models and it is therefore very

important to ensure the voltage and frequency on the pump rating plate matches the

supply.

When installing a 230V, 1 phase, pump in the United Kingdom, means for disconnection

must be incorporated in the fixed wiring according to the Wiring Rules. This can be done

by permanently connecting the pump to the mains supply via a double pole switched, fused

connection unit complying with BS 1363-4.

When installing a 110V, 1 phase pump it must be in accordance with the current electrical

regulations that apply to the installation.

All motors exceeding 370 watt output should be provided with control equipment

incorporating means for protection against overload.

The spur box (fused connection unit) or starter to which the pump is connected should

be mounted in an easily accessible position and labelled if confusion is possible to allow

easy isolation of the unit.

All pumps are continuously rated.

- 6 -

Earthing

This appliance must be earthed via the supply cord, which must be correctly connected

to the earth point located in the terminal box.

Metallic pipework must have supplementary earth bonding where the continuity has

been broken by flexible hoses or plastic components. Adjacent suction and delivery pipes

should be fitted with earthing clamps to BS 951 and connected with earthing wire size

4 mm² (Fig. 2).

Diagram of earth

continuity connection.

Fig. 2

Certain installations may require additional earthing arrangements such as equipotential

bonding. Reference should be made to the relevant regulations concerning this subject to

ensure compliance.

Wiring

This product range must be permanently connected to fixed wiring and is provided with a

set of terminals which allow the connection of a flexible supply cord.

Select a cord and fuse size based on the motor full load current and the surrounding

conditions.

For information on cable fitting and connection, consult the wiring diagram and cable

gland and supply cord fitting instructions.

WARNING: This appliance must be earthed.

Fuses

The power cord must be sourced and supplied by the installer. Cable selection and fuse

size should be based on the motor full load current and the surrounding conditions.

- 7 -

Cont ...

Cable Gland & Supply Cord Fitting Instructions (Single phase range)

The cable gland assembly Fig. 5 (items 1 & 2) provides the necessary protection against

ingress of solid objects and moisture as well as providing cable retention.

Assembly instructions are as follows: -

1. Ensure selected cable sheath

diameter is within the permitted range

(6.5 to 9.5 mm).

2. Strip and prepare the cable sheath

E

and insulators as shown in Fig. 3.

3. Disassemble cable gland as shown in

Fig. 5 and insert cable into position

ensuring ‘O’-ring (item 1) is placed

over the cable before the clamping

insert (item 2) is tightened.

4. Consolidate the stranded conductor

ends by twisting and shape the earth conductor

as shown in Fig. 4 (item 3).

5. Remove earth terminal post clamping

components and assemble as shown in

Fig. 4 ensuring shaped conductor is

orientated as shown and all strands of

the conductor are clamped between

the washers.

6. Insert and secure live and neutral

conductors ensuring all conductor

strands are clamped.

7. Confirm cable routing is as shown in

Fig. 5 and assemble and secure

terminal box lid.

N

L

12

110

80

8

(Dims. in mm)

8

70

Fig. 3

3

Fig. 4

- 8 -

2

1

Fig. 5

Wiring Diagrams

The internal wiring within the terminal box are routed and secured to

ensure compliance with the electrical standard EN 60335-1. It is essential

that any disturbance of this internal wiring is avoided and the factory

routing and securing of all internal wiring is always maintained.

Fig. 6

TERMINAL

BLOCK

BROWN

LINK WIRE

BLUE

230 VAC/1PH/50Hz SUPPLY

BROWN

N

L

MAIN WINDING

THERMOTRIP

START WINDING

GREEN / YELLOW

E

BLUE

CAPACITOR

BLACK

NOISE

The equivalent continuous A-weighted sound pressure level from the pumpset does not

exceed 70 dB(A) at a distance of one metre.

COMMISSIONING

WARNINGS:

The motor casing can become very hot under normal operating

conditions, care should be taken to ensure it cannot be touched

during operation.

Do not run pump without guards and terminal box lid correctly fitted.

The pump chamber must be full of liquid at all times. Seal damage

will result if the pump runs dry.

1. System Flushing

Some pumps incorporate plastic and rubber components that must not

come into contact with solder flux, acid-based descalents or aggressive

cleaning agents. The pipework system should be flushed out prior to the

pump being connected, to ensure any contaminants/chemical residues and

foreign bodies are removed from elsewhere in the system.

- 9 -

Cont ...

2. Liquid Supply

Always ensure that liquid storage capacity is adequate to meet the demand.

Ensure the pump chamber is full of liquid before starting the pump. Failure

to do this could result in seal damage. To ensure dry running does not

occur the pumps must be primed as described in the priming section. Do

not run pump dry.

3. Ensure electrical supply is compatible with the details that are stated on the pump

rating plate. (The wrong voltage or frequency can be dangerous and may damage

the pump.)

4. Priming

a) Vertical suction models (flooded suction)

The pump must be primed (filled with liquid) before starting. Turn on liquid

supply, prime and vent the pump by unscrewing the priming plug (Fig. 7)

slowly until all air escapes and liquid emerges. Re-tighten the plug.

PRIMING PLUG PRIMING PLUGPRIMING PLUG

OUTLET

INLET

RG550-2

c/w Body Rotated

(Special Build)

Fig. 7

INLET

OUTLET

b) All models (suction lift installation)

Prime the suction pipework and pump by filling with liquid via the pump discharge

connection, or by filling the suction pipework before attaching to the pump, then

fill the pump.

5. Starting

a) Switch on power to the pump which will now be operational.

b) Carefully check pump and pipework for leaks whilst pump running and stationary

before leaving the installation unattended.

For Further Technical Support

Note: When pumps are installed in another manufacturers original equipment, please

contact the manufacturer for advice.

Phone the Stuart Turner Pump Assist team on 0844 98 000 97. Our staff are trained to

help and advise you over the phone or arrange for a service engineer to call.

- 10 -

Cont ...

MAINTENANCE

WARNINGS:

Care should be taken to protect the pump from frost and

freezing.

Pump Location

If possible site the pump in a location where in the unlikely

event of a liquid leak, any spillage is contained or routed to

avoid electrics or areas sensitive to water damage.

1. No routine maintenance is required but provision should be made for easy access to

the pump to allow for repairs due to normal wear and tear.

2. Disconnect electrical supply before working on pump.

3. Turn off liquid supplies to the pump and release pressure by opening outlets before

attempting maintenance.

4. If the installation is fitted with a footvalve and strainer or inline suction strainer, the

strainer must be cleaned as necessary to ensure the pump has unrestricted flow.

5. After maintenance is completed, refer to commissioning section for instructions on

restarting pump.

Cleaners, Disinfectants and Descalents

On installations where chemical disinfectants or descalents are periodically

used, the compatibility of the chemical solution regarding the pump must be

considered.

Acid based descalents and aggressive cleaning agents must not come into

contact with the pump. The pump must be removed from the system prior to the

use of these products. The system should be flushed to remove all chemicals

before the pump is re-connected.

If in any doubt as to the suitability of the chemical solutions refer to Stuart

Turner Ltd.

STORAGE

If this product is not installed immediately on receipt, store in a dry, frost and vibration

free location in its original packaging.

- 11 -

TROUBLE SHOOTING GUIDE

Symptoms Probable Cause Recommended Action

Pump will not start. Electrical supply. Check power to motor.

Check the circuit breaker is set.

Check the correct fuse is being used.

Pump runs, but no

liquid.

Starter thermal

overload tripped.

Internal motor

thermotrip activated.

Air locked. Bleed pipework and pump to clear air.

No liquid supply. Check the supply valves are turned on.

Connections

reversed.

No flooded suction. Check the pump has a flooded suction

Check overload in starter (if applicable).

Investigate cause of problem.

Wait for thermotrip to cool and autoreset. Investigate cause of problem.

Check outlet not restricted or blocked.

Check liquid connections are on the right

way round.

and is primed.

If a suction lift exists fit a Stuart footvalve/

strainer and ensure suction is airtight.

Prime the pump and suction pipe (see

commissioning section).

ENVIRONMENT PROTECTION

Your appliance contains valuable materials which can be recovered or recycled.

At the end of the products’ useful life, please leave it at an appropriate local civic waste

collection point.

- 12 -

YOUR 1 YEAR GUARANTEE

Stuart Pumps are guaranteed by Stuart Turner Limited to be free from defects in

materials or workmanship for the applicable guarantee period from the date of purchase.

The applicable guarantee period is stated in the installation booklet supplied with the

pump. Within the guarantee period we will repair, free of charge, any defects in the pump

resulting from faults in material or workmanship, repairing, exchanging parts or exchanging

the whole unit as we may reasonably decide.

Not covered by this guarantee: Damage arising from incorrect installation, improper use,

unauthorised repair, normal wear and tear and defects which have a negligible effect on

the value or operation of the pump.

Reasonable evidence must be supplied that the pump has been purchased within the

applicable guarantee period prior to the date of claim (such as proof of purchase or the

pump serial number).

This guarantee is in addition to your statutory rights as a consumer. If you are in any

doubt as to these rights, please contact your local Trading Standards Department or

Citizen’s Advice Bureau.

In the event of a claim please telephone Stuart Turner Limited on 0844 980 0097 or

return your pump and flexible hoses with accessories removed, plugs, pipes etc. If you

have any doubt about removing a pump, please consult a professional.

Proof of purchase should accompany the returned pump to avoid delay in investigation

and dealing with your claim.

- 13 -

NOTES

- 14 -

NOTES

- 15 -

DECLARATION OF CONFORMITY

2006/42/EC

BS EN ISO 12100-1, BS EN ISO 12100-2, BS EN 809

2006/95/EC

BS EN 60335-1, BS EN 60335-2-41, EN 50366

2004/108/EC

BS EN 55014-1, BS EN 55014-2, BS EN 55022, BS EN 61000-3-2, BS EN 61000-3-3,

BS EN 61000-4-2, BS EN 61000-4-3, BS EN 61000-4-4, BS EN 61000-4-5, BS EN 61000-4-6,

BS EN 61000-4-11

IT IS HEREBY CERTIFIED THAT THE STUART ELECTRIC MOTOR DRIVEN PUMP AS

SERIAL NUMBER BELOW, COMPLIES WITH THE ESSENTIAL REQUIREMENTS OF THE

ABOVE E.E.C. DIRECTIVES.

RESPONSIBLE PERSON

AND MANUFACTURER STUART TURNER LIMITED

HENLEY-ON-THAMES, OXFORDSHIRE

RG9 2AD ENGLAND.

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stuart Turner are an approved company to BS EN ISO 9001:2000

Customer Relationship Manager

Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND

Tel: +44 (0) 1491 572655, Fax: +44 (0) 1491 573704

email: pumps@stuart-turner.co.uk web: www.stuart-turner.co.uk

V.A.T. REG. No. 199 0987 92. Registered in England No. 88368. Registered Offi ce: Market Place, Henley-on-Thames

Issue No. 3910/4-14 Pt. No. 17730

Loading...

Loading...