Installation, Operation & Maintenance

Instructions

Please leave this instruction booklet with the home owner as it contains

important guarantee, maintenance and safety information

Read this manual carefully before commencing installation.

This manual covers the following products:

Monsoon S2.0 bar Single

Pt. No. 46497

Monsoon S3.0 bar Single

Pt. No. 46419

Monsoon S4.5 bar Single

Pt. No. 46420

Monsoon S1.5 bar Twin

Pt. No. 46506

Monsoon S2.0 bar Twin

Pt. No. 46415

Monsoon S3.0 bar Twin

Pt. No. 46416

Monsoon S4.0 bar Twin

Pt. No. 46417

Monsoon S4.5 bar Twin

Pt. No. 46418

FOR POSITIVE HEAD APPLICATIONS ONLY

CE compliant product

PRODUCT DESCRIPTION

Electric motor driven single or twin ended peripheral pump, complete with an automatic

control system, consisting of flow switches and electronic controls.

APPLICATION

Monsoon Standard pumps are suitable for positive head installation conditions. The

pumps are designed for pressure boosting applications in vented stored hot or cold, clean

fresh water systems, where under gravity, some flow (approx. 0.6 l/min) is available. Inlet

pressures to the pump and ambient temperatures must not exceed the values given in the

technical specifications.

Monsoon Standard Single pumps are not suitable for boosting a single side of a dual flow

mixer valve or tap. Consult Stuart Turner for alternative pump.

This pump set must not be used for any other

application without the written consent of Stuart

Turner Limited and in particular, must not be

connected directly to the mains water supply.

This appliance can be used by children aged from

8 years and above and persons with reduced

physical, sensory or mental capabilities or lack

of experience and knowledge if they have been

given supervision or instruction concerning use of

the appliance in a safe way and understand the

hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not

be made by children without supervision.

Children should be supervised to ensure that they do

not play with the appliance.

Please read installation details carefully as they are intended to ensure this product

provides long, trouble free service. Failure to install the unit in accordance with the

installation instructions will lead to invalidation of the warranty.

STORAGE

If this product is not to be installed immediately on receipt, ensure that it is stored in a dry,

frost and vibration free location in its original packaging.

CONTENTS Page

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Facts - read before commencing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Technical Specifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

- 2 -

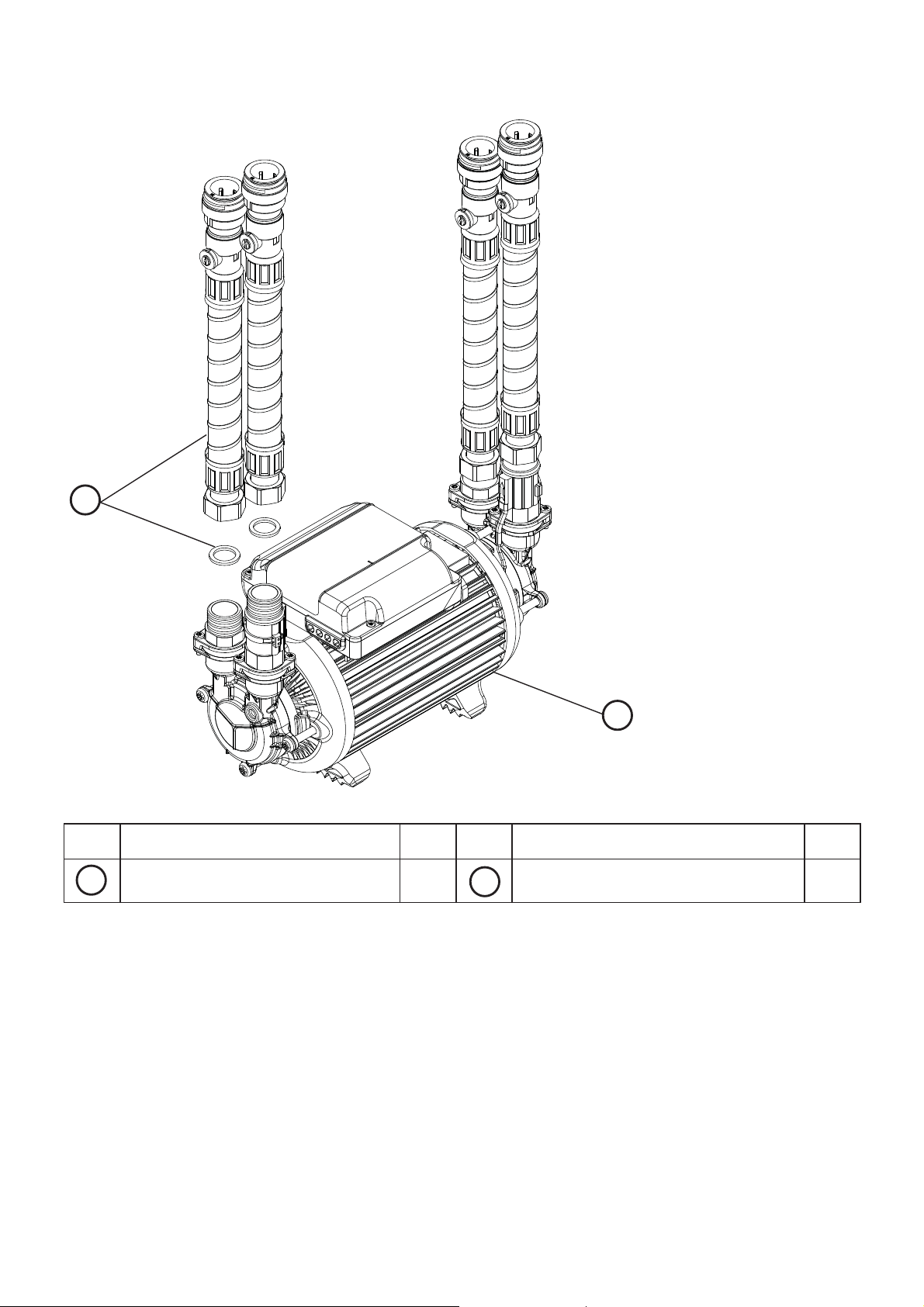

CHECKLIST

B

IMPORTANT: With the pump

removed from its packaging

check for any damage prior to

installation. If any damage is

found contact Stuart Turner Ltd

within 24 hours of receipt.

A

Fig. 1

Item

Your product may vary slightly from the picture above.

The quantities shown above are for twin pumps, (single pumps are shown in brackets).

Description Qty

A

Pump 1 Hose & sealing washer 4 (2)

Item

B

Description Qty

- 3 -

Cont ...

1 READ BEFORE COMMENCING PUMP INSTALLATION

A. Water storage capacity.

1.11 The hot and cold water storage capacity must be sufficient to meet the flow rates

required by the pumped equipment and any other water using fittings and

appliances, which may be operated simultaneously.

1.12 Ensure the pump is primed as described in the priming section before starting,

damage to the shaft seal will result otherwise. See Section 5 - Commissioning.

B. Water temperature

The water entering the pump must be controlled as follows:

o

o

C.

C.

1.13 The maximum allowable water temperature is 65

1.14 The minimum allowable water temperature is 4

1.15 DO NOT fit a pump if the hot water is heated via a method whereby the water

temperature cannot be controlled, such as solar or solid fuel you must consult the

PumpAssist team on 0844 98 000 97.

C. Minimum Flow

1.16 For this pump to operate correctly there must be a minimum gravity flow of at

least 0.6 l/min through all outlets to be pumped.

D. Pipework - General

1.17 Secure pipework: Ensure pipework to and from pump is independently

supported & clipped to prevent forces being transferred to inlet and outlet

branches of pump.

1.18 Flux: Solder joints must be completed and flux residues removed prior to pump

installation (flux damage will void any warranty).

1.19 Pipework design: Care should be taken in the design of pipework runs to

minimize the risk of air locks e.g. use drawn bends rather than 90

o

bends.

1.20 DO NOT introduce solder flux to flexible hoses, pumps or pump parts

manufactured from plastic.

1.21 DO NOT allow contact with oil or cellulose based paints, paint thinners or

strippers, acid based descalents or aggressive cleaning agents.

1.22 DO NOT install a non-return valve, or devices which contain non-return

valves, in the suction (inlet) pipework to the pump. The pump must be free

to vent to the supply tank at all times.

o

1.23 DO NOT bend the flexible hoses beyond 30

. They must be installed as

straight as possible.

1.24 DO NOT connect this pump to the mains water supply.

E. Plumbing & Electrical Installation Regulations

1.25 The plumbing installation must comply with “The Water Supply (Water Fittings)

Regulations 1999” and “BS 6700” building regulations.

1.26 The plumbing installation must be installed by a qualified person.

1.27 The electrical installation must be carried out in accordance with the current

national electrical regulations.

1.28 The electrical installation must be installed by a qualified person.

- 4 -

Cont ...

2 LOCATION - GENERAL

2.11 Access: For emergencies and maintenance the pump must be

easily accessible.

2.12 Protection: The pump must be located in a dry position, frost free and

protected from freezing, particularly when installed in a loft (not

recommended).

2.13 Ventilation: Ensure an adequate air flow to cool the pump. Separate

the pump from other appliances that generate heat. An 80 mm (3 “) air

gap must be maintained around the pump.

2.14 Safety: The motor casing can become very hot under normal

operating conditions. Care must be taken to ensure it cannot be

touched during operation.

2.15 Water retention: Site the pump in a location where in the unlikely

event of a water leak, any spillage is contained or routed to avoid

electrics or areas sensitive to water damage.

2.16 Static inlet pressure: Before deciding where to locate the unit check to ensure

the static inlet head between pump and cold water level (Figs. 4 or 5) is at least

0.5 metres and does not exceed the max inlet head of 14 metres.

2.17 Pump position: The pump must be positioned on its anti-vibration mounting feet

and as close to the water source as possible.

2.18 Ambient temperature: The pump must be sited in a location where the maximum

ambient temperature does not exceed 40

2.19 Pipework: For optimum performance pipework MUST be 22 mm.

Pipework should only reduce to 15 mm when entering terminal fitting.

2.20 Static outlet pressure: The static outlet head (Figs. 4 or 5) must also be within

the maximum requirement of 14 metres.

2.21 Noise: The anti-vibration mounting feet and flexible hoses which are supplied

as standard, and a precaution to reduce noise transmission, however care must

be taken when mounting the pump that any noise is not amplified through loose

panels or pipework. Do not screw down the pump.

2.22 Direction of flow: Ensure the water flow is in the direction of the arrow marked

on the flow switch reed clamp (vertically upwards).

2.23 Flexible hoses: Use only Stuart Turner supplied hoses.

2.24 Isolating valves: Separate isolating valves (non restrictive) must be fitted to

allow easy pump service.

2.25 Preferred pump location: The preferred pump location is at floor level next to

the water source or a level that is below the secondary tapping that feeds

the pump. The Pump location is also dependent on limitations of the static inlet

and outlet heads of the installation. For guidance on limitations and

recommended location, consult the following relevant section for hot or cold water

installation.

o

C.

- 5 -

Cont ...

2.26 Non-Preferred Pump Location: The pump must be located with at least

0.5 metres flooded suction at all times.

If it is not possible to locate the pump in the preferred area due to site limitations

and it is necessary to position the unit in the loft, or in a position above the

secondary tapping that feeds the pump, then there is an increased risk of air

locks. This risk must be eliminated.

The following method will help to overcome the problem:

A “U” bend or downward loop in the supply pipe to the pump of 350 mm depth

before rising to the pump should ensure the cylinder vents its air up the

expansion pipe, not up the pump feed (Fig. 2 for Twins and Fig. 3 for Singles).

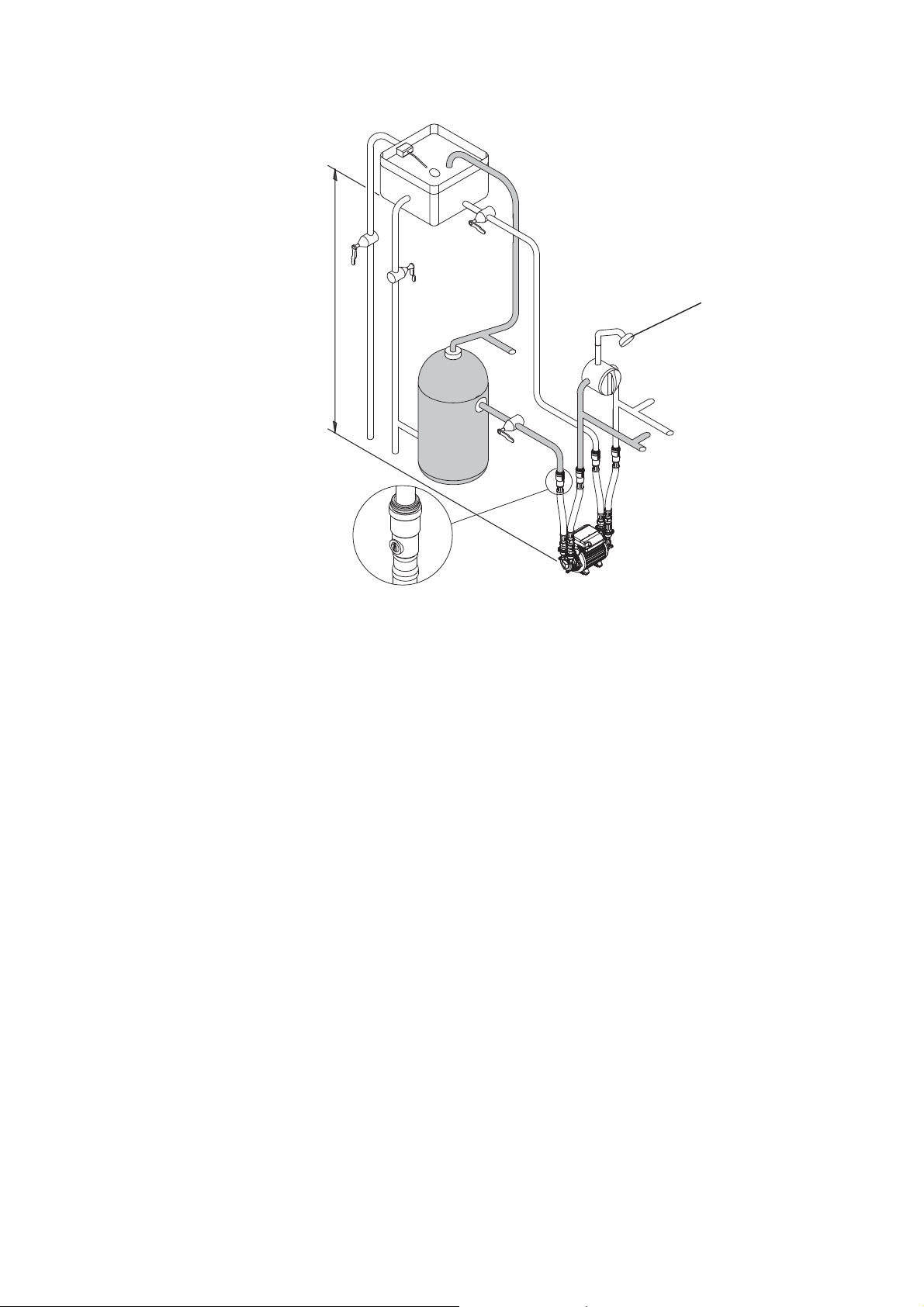

200 mm

Max. inlet head 14 m

Min. inlet head 0.5 m

min

Max. inlet head 14 m

Min. inlet head 0.5 m

200 mm

min

hot water

services

Fig. 2 (Twin Pump)

2 LOCATION - SINGLE PUMP

Max. static inlet pressure 14 m

least preferred area

350 mm

min

hot water

services

Fig. 3 (Single Pump)

Outlet head must be

below bottom of cold

water tank and able

to pass a minimum

of 0.6 l/min of gravity

flow

least preferred area

350 mm

min

Positive Duty Single Pump System

Fig. 4

Cont ...

- 6 -

2 LOCATION - TWIN PUMP

Max. static inlet pressure 14 m

Outlet head must be

below bottom of cold

water tank and able

to pass a minimum

of 0.6 l/min of gravity

flow

Positive Duty Twin Pump System

Fig. 5

Cold water connection:

2.27 The cold water supply: Must be a DEDICATED AIR FREE supply via a tank

connector , and must be positioned at a slightly lower level (25 mm minimum) than

the feed pipe to the hot water cylinder.

Do not connect to the mains.

2.28 Location: The pump must, for optimum performance, be sited as close as

possible to and never more than 4 metres from the HOT WATER cylinder. The

pump should always be sited BELOW the HOT WATER take-off from the cylinder.

- 7 -

Cont ...

Hot water connection:

(Applicable to S1.5, S2.0, S3.0 and S4.0 bar Twins, S2.0, S3.0 and S4.5 bar Singles)

2. 29 Hot water cylinder or storage tank: When a hot water cylinder or storage tank

is used, ensure the pipework size from the cold water storage to the hot water

storage is of adequate size and a minimum of 22 mm for all models except the

S4.5 bar twin which should be a minimum of 28 mm.

2.30 Hot water supply: The pump must be supplied with a dedicated feed direct

from the hot water cylinder or storage tank, ensuring an air free connection to the

cylinder, which can be made by one of the methods shown in Fig. 6 .

recommend the use of the Stuart flange top entry (TE) Part No 27800

We

(for all

models except the S4.5 bar Twin) (S4.5 bar Twin should only use ‘a’ or ‘d’).

2.31 Expansion pipe: When the method of connection is to be made via the

expansion pipe, the BASE of the cold water storage tank MUST be at least

1 metre above the connection/take off of the hot water storage cylinder feeding

the pump.

Fig. 6

ab

Off expansion

pipe with rising

28 mm offset

reducing to

22 mm pipework

to pump and

expansion pipe.

Off expansion

pipe with rising

22 mm offset

and 22 mm

pipework to

pump.

c

G 1 Stuart flange

top entry (TE) (Part

No. 27800) with 22

mm pipework to

pump.

d

Factory installed G ¾

secondary tapping with

22 mm pipework to

pump.

or

Side mounted Stuart

flange side entry (SE)

(Part No. 27900) with

22 mm pipework to

pump.

- 8 -

Cont ...

3 PUMP CONNECTIONS

Do not use stainless steel, chrome or nickel plated pipe with the

flexible hose push-in plumbing connections.

Do not introduce solder flux into the joint or surrounding area as

connectors will be attacked and may fail.

All solder joints should be completed and flux residues removed

before final connection to push-in connections, on the flexible hose.

Do not allow contact with oil or cellulose based paints, paint

thinners or strippers, acid based descalents or aggressive cleaning

agents.

Never operate pump with inlet and/or outlet isolating valves in the

closed position. Damage will occur!

3.11 Hose to pump: The pump inlet and outlet ports have factory assembled fittings

which are specifically designed for connection to the G ¾ female running nuts on

the flexible hoses. The hose end is fitted with a rubber sealing washer which is

held captive within the nut assembly. Locate the hose into position and

screw the nut fully onto the fitting by hand. Finally nip tight with a spanner

(4/5 Nm) for a water tight seal (do not overtighten).

Flexible hose

Fig. 7

G ¾ running nut

assembly

Rubber sealing washer

Port fitting

29 mm AF

Reed

switch

clamp

assembly

Anti-rotation flats

28 mm AF

Note: When tightening or loosening the

hose nut assembly, the anti-rotation

flats provided on the inlet and outlet

fittings should be used for placement

of a second spanner as shown. This is

to prevent complete assembly rotation.

It may be necessary to partially rotate

the reed switch clamp assembly on the

outlet fitting to avoid damage during

placement of the second spanner.

- 9 -

Cont ...

3.12 Hose to pipework:

1. The hoses are fitted with plastic push-in connectors, which must only be

connected with the following:

a) 22 mm diameter copper pipe to BS EN 1057 - R250 (half hard) - Table 3.

b) 22 mm plastic pipe to BS 7291 part 1 and part 2 (Table 1), or part 3

(Table 1) plus internal support sleeve*.

* The internal bore of the plastic pipe must be supported against collapse

with the pipe manufacturers recommended support sleeve (pipe insert).

c) Appropriate plumbing fittings that are compatible and will provide a water

tight connection.

Ensure the pipe is free from all score marks and deformities in the area of the

insertion depth (Fig. 8) and cut the pipe square removing all burrs and sharp

edges to prevent damage to the sealing ‘O’-ring.

2. Prior to inserting pipe into fitting mark the insertion depth on the wall of the

pipe with a soft pencil at a distance of 33 mm from the end to be inserted.

Pencil

mark

33 mm

Insert depth

22 mm Pipe

Fig. 8

3. Check in the mouth of the fitting that ‘O’-ring, nylon washer and collet are in

position.

Body

Collet

Washer

‘O’-Ring

Pipe Stop

Hose

Fig. 9

Isolating Valve

4. Push pipe firmly into fitting, until pencil mark is level with the top of the collet

and the pipe stop resistance is felt. Pull on pipe to check it is secure and

correctly fitted.

Cont ...

- 10 -

5. To break the joint, push pipe firmly into fitting, hold collet down and gently

remove pipe. If the system has been filled with water care should be taken to

isolate pump and towels used to absorb spilled water.

3.13 Typical Low Level Installation:

In certain installations it may be necessary to install a 90° bend on the inlet

or outlet connections of the pump before the flexible hose to accommodate a low

level installation.

Below are some preferred connection options. All connections seal on the pump

body using a fibre or rubber sealing washer. Tap connector fittings should be

used which must be of an appropriate pressure and temperature rating.

It is essential when using any of the fittings shown below, that a correct water tight

seal is obtained between the pump body and selected fitting and also the

flexible hose and selected fitting. If in doubt contact the fitting manufacturer and

confirm compatibility with the connection to be sealed.

Carefully check connections and pipework for leaks whilst pump running and

stationary before leaving the installation unattended.

G ¾ female x 22 mm

elbow tap connector.

Fibre washer.

22 mm

elbow.

22 mm

copper

pipe

Fig. 10

22 mm compression to

G ¾ male.

22 mm copper pipe.

G ¾ female x 22 mm

tap connector.

Fibre washer.

G ¾ female flexible hose

(supplied in kit).

G ¾ female flexible hose

(supplied in kit).

22 mm compression to

G ¾ male.

G ¾ female x 22 mm

swivel tap connector

with rubber sealing

washer.

22 mm to G ¾

male.

22 mm stem elbow.

G ¾ female x 22 mm tap

connector with rubber

sealing washer.

Sealing washer (sometimes

captured in fitting)

G ¾ female

flexible hose

(supplied in

kit).

If you have any concern either about using push-in fittings or should the joint

leak on final test isolate the water supplies and contact PumpAssist on

0844 98 000 97.

Cont ...

- 11 -

4 ELECTRICAL INSTALLATION / EARTHING

4.11 Regulations: The electrical installation must be carried out in

accordance with the current national electrical regulations and installed

by a qualified person.

4.12 Safety: In the interests of electrical safety a 30 mA residual current

device (R.C.D. not supplied) should be installed in the supply circuit.

This may be part of a consumer unit or a separate unit.

4.13 Before starting work on the electrical supply ensure power supply is

isolated.

4.14 DO NOT allow the supply cord to contact hot surfaces, including the

motor shell, pump body or pipework. The cord should be safely routed

and secured by cable clips.

4.15 Adjacent pipes: Adjacent suction and delivery pipes should be fitted with

earthing clamps to BS 951 and connected with earthing wire size 4 mm

Diagram of

earth continuity

connections

2

(Fig. 11).

Fig. 11

4.16 Earthing: This appliance must be earthed via the supply cord, which must be

correctly connected to the earth point located in the terminal box.

4.17 Pipework: Copper or metallic pipework must have supplementary earth bonding

where the continuity has been broken by flexible hoses or plastic components.

4.18 Additional earthing: Certain installations may require additional earthing

arrangements such as equipotential bonding. Reference should be made to the

relevant regulations concerning this subject to ensure compliance.

4.19 Connections: The pump must be permanently connected to the fixed wiring of

the mains supply using the factory fitted supply cord, via a double pole switched

fused spur off the ring main and NOT connected to the boiler or the immersion

heater circuits.

4.20 Wiring of connection unit:

WARNING: This appliance must be earthed.

The wires in the mains lead are coloured in accordance with the following code:

Green and Yellow: Earth Blue: Neutral Brown: Live

As the colours of the wires in the mains lead of this appliance may not correspond

with the coloured markings identifying the terminals in your connection unit

proceed as follows:

The wire which is coloured green and yellow must be connected to the terminal

in the connection unit which is marked with the letter E or by the earth symbol:

or coloured green or green and yellow.

- 12 -

Cont ...

The wire which is coloured blue must be connected to the terminal which is

marked with the letter N or coloured black.

The wire which is coloured brown must be connected to the terminal which is

marked with the letter L or coloured red.

4.21 Wiring Diagrams:

Parallel wiring of two single pumps is not recommended.

S1

MAIN WINDING

THERMOTRIP

START WINDING

L

N

BLUE

BROWN

GREEN/

YELLOW

RED

CAPACITOR

BLACK

N

230 VAC/1PH/50Hz

L

SUPPLY

E

FLOWSWITCH REED (S2)

FLOWSWITCH REED (S1)

BROWN

LINK WIRE (BLUE)

N

MA

S1S2S2

N

S1

Single Models

Fig. 12

MAIN WINDING

THERMOTRIP

START WINDING

L

BLUE

BROWN

GREEN/

YELLOW

RED

CAPACITOR

BLACK

N

230 VAC/1PH/50Hz

L

SUPPLY

E

FLOWSWITCH REED (S2)

BROWN

LINK WIRE (BLUE)

N

MA

S1S2S2

Twin Models

Fig. 13

4.22 Fuses: The following fuse size should be used with the appropriate pump:

Model Fuse Size (AMPS)

S4.0 bar Twin

13

S4.5 bar Twin

All other models 5

4.23 Supply Cord Replacement:

The supply cord and internal wiring within the terminal box are

routed and secured to ensure compliance with the electrical

standard EN 60335-1. It is essential that prior to any disturbance

of this internal wiring, all cable routing and securing details are

carefully noted to ensure re-assembly to the same factory pattern

is always maintained.

If the supply cord is to be changed or is damaged, it must be replaced with a

special cord assembly available from Stuart Turner or one of their approved

repairers.

On disassembly note the cord retention and routing system. Re-assemble to the

same pattern.

For information on cable connection consult the wiring diagram and cable gland

fitting instructions.

- 13 -

4.24 Cable Gland Fitting Instructions:

1

2

Fig. 14

To enable correct assembly of the cable gland the ‘O’-ring (Fig. 14 item 1) must

be placed over the cable before the clamping insert (Fig. 14 item 2) can be

tightened.

Note: Cable diameter range:- 6.5 mm to 9.5 mm.

4.25 Supply Cord Extension:

The pumps are fitted with a supply cord to the following specification:-

All models . . . . . . . . . . . . . . . . . . HO5VV-F3 G 0.75 mm² - 6 Amp rated cable.

If the supply cord is to be extended, a cord of the same specification should

be used. Any connections or junction boxes used should be specifically suited for

the application and installed in accordance with the manufacturers instructions.

- 14 -

Cont ...

5 COMMISSIONING

5.11 System Flushing: This pump incorporates push-in connectors

and plastic components that must not come into contact with

solder flux, acid-based descalents or aggressive cleaning agents.

The pipework system should be flushed out prior to the pump

being connected to ensure any contaminants/chemical residues

and foreign bodies are removed from elsewhere in the system.

5.12 Water Supply: Always ensure that water storage capacity is adequate to meet

the demand. Ensure the pump chamber is full of water before starting the pump.

Failure to do this could result in seal damage. To ensure dry running does not

occur the pump must be primed as described in priming section below.

Do not run pump dry.

5.13 Priming:

Never operate pump with inlet and/or outlet isolating valves in the

closed position. Damage will occur!

The pump must be primed (filled with water) before starting. Turn on water

supply from the system service valves, prime and vent the pump by opening the

pump inlet and outlet isolating valves to allow pump to fill and vent.

In the case of twin pumps, both pump chambers must be independently primed.

5.14 Starting:

a) Ensure all outlets are closed, turn power supply ‘on’ - pump will start,

pressurise the system then stop.

b) Open and close all outlets in turn associated with the pump, (including w/c

systems) allowing water to flow from each outlet until all air is purged. As

each outlet is opened and closed, the pump will start and stop respectively.

Note: After closing the outlet there will be a small time delay before the pump

stops, which is normal.

c) Any tap or control valve within the system when opened and closed will now

turn the pump on/off. Providing this is the case the system is now operating

correctly.

d) Carefully check pump and pipework for leaks whilst pump running and

stationary before leaving the installation unattended.

5.15 For Further Technical Support: Phone the Stuart Turner PumpAssist team

on 0844 98 000 97. Our staff are trained to help and advise you over the phone.

- 15 -

Cont ...

6 MAINTENANCE

6.11 Turn off water supplies to the pump and release pressure by

opening water outlets before attempting maintenance.

6.12 Inlet strainer: The inlet strainers may require periodical cleaning. The frequency

of this operation is dependent upon installation conditions.

The strainer is located in the inlet assembly of the pump casing (Fig. 15) and is

removed as follows: a) Isolate pump electrically.

b) Release all system pressure.

c) Isolate hot and cold water supplies via the integral pump isolating valve

located in the flexible hoses and release hose nuts connected to the pump

(see Section 3 - Pump Connections).

d) Remove M4 screws (2 off) from inlet assembly, lift brass inlet fitting (with ‘O’-

ring) and clamp away from pump casing (Fig. 15).

e) Remove strainer with long nose pliers noting location lug position upon

removal (Fig. 15) and clean thoroughly.

f) Refit strainer taking care to position lug in body inlet port location slot (Fig. 15)

and re-assemble pipework. Tighten M4 clamp screws to 1.5 Nm torque.

g) Re-connect flexible hoses and tighten (see Section 3 - Pump Connections).

h) After maintenance is completed refer to Section 5 - Commissioning section for

instructions on re-starting pump.

Inlet fitting

Inlet port

M4 screws

Manifold clamp

‘O’-ring

Strainer

Fig. 15

- 16 -

Location detail

Cont ...

6.13 No other routine maintenance is required.

6.14 Water scale: As water is heated scale deposits are released in areas of hard

water, scale can cause the mechanical seal to stick if left without use for long

periods. The pump must be run for at least 5 minutes every four weeks to

“exercise” all working parts. Run on cool water. See Section 7 - Technical

Specification for note on water temperature. This particularly applies to guest

bathrooms used infrequently.

6.15 Cleaners, Disinfectants and Descalents:

Acid based descalents and aggressive cleaning agents must not

come into contact with the pump. The pump must be removed from

the system prior to the use of these products. The system should be

flushed to remove all chemicals before the pump is re-connected.

If in any doubt as to the suitability of the chemical solutions, please

contact our PumpAssist helpline.

- 17 -

Cont ...

7 TECHNICAL SPECIFICATION (Single Models)

Model S2.0 bar Single S3.0 bar Single S4.5 bar Single

Power supply

Volts/phase freqency

Enclosure IPX4 IPX4 IPX4

Type of motor Induction Induction Induction

Power consumption 245 Watts 385 Watts 555 Watts

Electrical

Full load current 1.1 Amps 1.7 Amps 2.4 Amps

Rating

Max. No Starts per hour 60 60 60

Max inlet head 8 metres 14 metres 14 metres

Max head (closed valve) 20 metres 30 metres 45 metres

Max working pressure* 600 kPa (6.0 bar) 600 kPa (6.0 bar) 600 kPa (6.0 bar)

Max ambient air temperature 40

Mechanical

Max water temperature** 65

Min water temperature 4

230/1/50 230/1/50 230/1/50

Continuous (S1) @

9 l/min & above

o

C 40 oC 40 oC

o

C 65 oC 65 oC

o

C4

Continuous (S1) @

9 l/min & above

o

C4

Continuous (S1) @

9 l/min & above

o

C

Length 200 mm 200 mm 200 mm

Width 126 mm 126 mm 126 mm

Height (excluding flexible hoses) 202 mm 202 mm 202 mm

Weight (incl. flexible hoses) 6.5 Kg 6.5 Kg 7.1 Kg

Pump

Dimensions

Pump connections: Inlet G ¾ G ¾ G ¾

Outlet G ¾ G ¾ G ¾

- 18 -

Cont ...

7 TECHNICAL SPECIFICATION (Twin Models)

Model

Power supply

Volts/phase freqency

Enclosure IPX4 IPX4 IPX4 IPX4 IPX4

Type of motor Induction Induction Induction Induction Induction

Power consumption 345 Watts 425 Watts 640 Watts 890 Watts 1090 Watts

Full load current 1.5 Amps 1.9 Amps 2.8 Amps 4.0 Amps 4.9 Amps

Electrical

Rating

Max. No Starts per hour 60 60 60 60 60

Max inlet head 14 metres 14 metres 14 metres 14 metres 14 metres

Max head (closed valve) 15 metres 20 metres 30 metres 42 metres 45 metres

Max working pressure*

Max ambient air temperature 40

Mechanical

Max water temperature** 65

S1.5 bar

Twin

230/1/50 230/1/50 230/1/50 230/1/50 230/1/50

Continuous

(S1) @ 9 l/min

& above (Both

ends pumping)

600 kPa

(6.0 bar)

o

C 40 oC 40 oC 40 oC 40 oC

o

C 65 oC 65 oC 65 oC 65 oC

S2.0 bar

Twin

Continuous

(S1) @ 9 l/min

& above (Both

ends pumping)

600 kPa

(6.0 bar)

S3.0 bar

Twin

Continuous

(S1) @ 9 l/min

& above (Both

ends pumping)

600 kPa

(6.0 bar)

S4.0 bar

Twin

Continuous

(S1) @ 9 l/min

& above (Both

ends pumping)

600 kPa

(6.0 bar)

S4.5 bar

Twin

Continuous

(S1) @ 9 l/min

& above (Both

ends pumping)

600 kPa

(6.0 bar)

o

Min water temperature 4

Length 265 mm 265 mm 265 mm 300 mm 310 mm

Width 126 mm 126 mm 126 mm 126 mm 126 mm

Height (excluding flexible hoses) 202 mm 202 mm 202 mm 202 mm 202 mm

Weight (incl. flexible hoses) 8.4 Kg 8.4 Kg 8.7 Kg 10.7 Kg 11.4 Kg

Pump

Dimensions

Pump connections: Inlet G ¾ G ¾ G ¾ G ¾ G ¾

Outlet G ¾ G ¾ G ¾ G ¾ G ¾

C4

o

C4

o

C4

o

C4

o

C

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

Note: For information on other voltages/frequencies which are not shown, consult

any supplementary instruction sheet supplied, or the rating label attached to

the pump.

*Note: Max working pressure is the maximum pressure that can be applied to the

pump internal casing under any installation conditions.

**Note: In normal circumstances the temperature of stored water should never exceed

65°C. A stored water temperature of 60°C is considered sufficient to meet all

normal requirements and will minimise deposition of scale in hard water

areas.

Maximum permissible water temperature 65°C.

7.11 Noise: The equivalent continuous A-weighted sound pressure level at a distance

of 1 metre from the pump does not exceed 70 dB(A).

- 19 -

8 TROUBLE SHOOTING GUIDE

Symptoms Probable Cause Recommended Action

Pump will not start. Insufficient gravity flow. Check flow rate minimum of 0.6 l/min required on full hot and

cold.

Electrical. Check power supply.

Check fuse (see fuse section).

Check circuit breaker is set.

Check wiring connections.

Pump jammed. If motor ‘Buzzes’ switch off power and contact Stuart Turner.

Integral motor thermotrip

activated.

Reduced/intermittent flow. Incorrect or no anti-aeration

flange fitted.

Incorrect pipe sizes. Check for correct pipe sizing, see Page 8 - Section 2.29.

Blocked inlet filters. Clean inlet filters (see maintenance section).

Air in system. Run system on full hot with pump switched off (ie. gravity

Hot water temperature set to

high.

Blocked shower head spray

plate.

No hot water. Air locked water feed. Vent hot water pump of air.

Heating source not operating. Check boiler is switched ‘on’.

Wait for thermotrip to auto-reset and check that duty point and

run time is within specification (see technical specification).

Check that the installation complies with installation

instructions.

only) for several minutes. Check that vents are fitted as

detailed in instructions.

Reduce cylinder stat setting to 65

Clean in accordance with manufacturers instructions.

Check cold feed to hot water cylinder.

Check water level in cold water tank and that all stopcocks

and isolating valves are open.

Check cylinder thermostat.

Check immersion heater.

Check cylinder contains hot water.

o

C max.

All hot water has been used. Check tank volume is adequate.

Faulty thermostatic mixer valve. Consult makers instructions.

Pump runs on with outlets

closed.

Pump starts with all outlets

closed.

Flexible hose leaks Not fitted correctly. Check that the hose is pushed firmly onto the pump inlet/

Jammed flow switch. Remove outlet hoses and check that flow switch sits in lowest

position. Check float for free movement.

Damaged reed switch or P.C.B. If pump continues to run, this indicates a closed circuit in

either the flow switch reed or P.C.B. in the terminal box.

Contact Stuart Turner.

Leak in system. Check tap washers, w/c valve washers, pipe joints.

Air in system. Bleed through system without pump running until hot and cold

services run with no air.

outlet connections and pipework.

Damaged ‘O’-rings. Check copper pipe ends are cleanly cut and deburred.

Cont ...

- 20 -

8.11 Flow Switch Circuit Test:

1. First confirm visually that the flow switch reed clamps have not been

dislodged during handling or installation. The clamps must be fully located

within their flow switch body groove as shown.

2. To carry out the following test you will need to obtain a magnet, a typical fridge

magnet is suitable.

3. Ensure the power supply is switched on.

4. Position the magnet directly in front of the reed clamp as shown. If pump

does not start, then slowly move the magnet up and down to a position that

exceeds the extent of the reed clamp. The pump should instantaneously start

at some point during this extent of movement. If this does not happen, this

indicates a possible fault with the reed switch or the P.C.B which is located

within the terminal box. These should be checked electrically. Consult Stuart

Turner for further instructions.

Body

Reed Clamp

Groove

Fig. 16

Magnet

8.12 Environment Protection: Your appliance contains valuable materials which can

be recovered or recycled.

At the end of the products’ useful life, please leave it at an appropriate local civic

waste collection point.

- 21 -

Cont ...

9 THE MONSOON GUARANTEE

Congratulations on purchasing a Stuart Turner pump.

We are confident this pump will provide many years of trouble free service as all our

products are manufactured to the very highest standard.

All Monsoon Pumps are guaranteed to be free from defects in materials or

workmanship for 3 years from the date of purchase.

EXTEND YOUR PUMP GUARANTEE

Register your pump details on-line now (within 30 days of date of purchase) and the

standard 3 year guarantee will be extended FREE of charge for a further two years.

www.stuart-turner.co.uk

If you do not have on-line access or would like us to help you register your pump then

simply call our ‘PumpAssist’ helpline on 0844 98 000 97.

Please note that to validate your extended warranty we will require the following

information:

1. Full pump serial number (including last 3 digits) which can be found on the pump

rating label and the back page of the installation instructions.

2. Your name/address/telephone/e-mail.

3. The date of installation.

Within the guarantee period we will repair, free of charge, any defects in the pump

resulting from faults in material or workmanship, repairing or exchanging the whole unit

as we may reasonably decide.

Not covered by this guarantee: Damage arising from incorrect installation, improper

use, unauthorised repair, normal wear and tear and defects which have a negligible

effect on the value or operation of the pump.

Reasonable evidence must be supplied that the product has been purchased within

the guarantee term prior to the date of claim (such as proof of purchase or the pump

serial number).

This guarantee is in addition to your statutory rights as a consumer. If you are in any

doubt as to these rights, please contact your local Trading Standards Department.

Cont ...

- 22 -

In the event of a claim please telephone ‘PumpAssist’ or return the pump and flexible

hoses with the accessories removed e.g pipes etc. If you have any doubt about

removing a pump, please consult a professional.

0844 98 000 97

Proof of purchase should accompany the returned unit to avoid delay in investigation

and dealing with your claim.

You should obtain appropriate insurance cover for any loss or damage which is not

covered by Stuart Turner Ltd in this provision.

Please record here for your records.

TYPE NO. SERIAL NO. DATE PURCHASED

Installers – Register with Stuart Turner and move up to Approved

Installer status

We receive thousands of enquiries every month from people seeking a Stuart

Turner installer and by registering your details with us, we can offer consumers the

opportunity to quickly locate an installer in their area.

Registration is free - simply click on the ‘register as an installer’ link on

our homepage at www.stuart-turner.co.uk and complete a short form

which will enable visitors to find your contact details on our web site

‘installer finder’. Alternatively use your smartphone to scan this QR code

and go straight to the form.

We’ll do the rest!

In addition we will ensure you receive advance notice on all new product launches and

access to any special offers or promotions.

Following initial registration, Stuart Turner offers a professional training programme,

enabling you to achieve Approved Installer status and opening the door to a range of

additional benefits.

Contact approvedinstaller@stuart-turner.co.uk for further details.

- 23 -

DECLARATION OF CONFORMITY

2006/42/EC

BS EN ISO 12100-1, BS EN ISO 12100-2, BS EN 809

2006/95/EC

BS EN 60335-1, BS EN 60335-2-41

2004/108/EC

BS EN 55014-1, BS EN 55014-2, BS EN 55022, BS EN 61000-3-2, BS EN 61000-3-3,

BS EN 61000-4-2, BS EN 61000-4-3, BS EN 61000-4-4, BS EN 61000-4-5, BS EN 61000-4-6,

BS EN 61000-4-11

1999/519/EC

BS EN 62233

2011/65/EU

IT IS HEREBY CERTIFIED THAT THE STUART ELECTRIC MOTOR DRIVEN PUMP AS

SERIAL NUMBER BELOW, COMPLIES WITH THE ESSENTIAL REQUIREMENTS OF THE

ABOVE E.E.C. DIRECTIVES.

RESPONSIBLE PERSON

AND MANUFACTURER STUART TURNER LIMITED

HENLEY-ON-THAMES, OXFORDSHIRE

RG9 2AD ENGLAND.

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stuart Turner are an approved company to BS EN ISO 9001:2000

Business Development Director

Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND

Tel: +44 (0) 1491 572655, Fax: +44 (0) 1491 573704

info@stpumps.co.uk www.stuart-turner.co.uk

V.A.T. REG. No. 199 0987 92. Registered in England No. 88368. Registered Offi ce: Market Place, Henley-on-Thames

Issue No. 1614/2-01 Pt. No. 19227

Loading...

Loading...