FLOAT SWITCH

OPERATING INSTRUCTIONS

Please leave this instruction booklet with the pump as it

contains maintenance and safety information

(Original Instructions)

MODELS F1 20/8

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page No

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Limits of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Switch Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pre-Assembly of Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Siting of the Switch & Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IMPORTANT NOTES

Please read these instructions fully before starting the

installation:

The installation must comply with the relevant water supply,

electrical and building regulations and be installed by a

competent person.

If in doubt, consult Stuart Turner Ltd.

APPLICATION

Stuart float switches are suitable for operation in most water based liquids and provide

automatic control of electrically driven pumps of all types. They can be used for direct

switching of small single phase motors with built in thermal overload protection. They can

also be used to switch larger motors via a contact starter.

WARNING AGAINST MISUSE

This switch must not be used for any other application without the

written consent of Stuart Turner Limited.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

- 2 -

Cont ...

PRODUCT DESCRIPTION

The switch consists of a polypropylene casing, brass counterbalance weights, nylon float

cord and polystyrene float.

The electrical contact is made using mechanical micro switches which are suitable for

operation on voltages up to 250V AC. The switch operation is achieved by the rocking

motion of the arm caused by the rise and fall of the float.

LIMITS OF APPLICATION

Maximum liquid temperature 50oC

Minimum liquid temperature 4

Maximum ambient air temperature 50

o

C

o

C

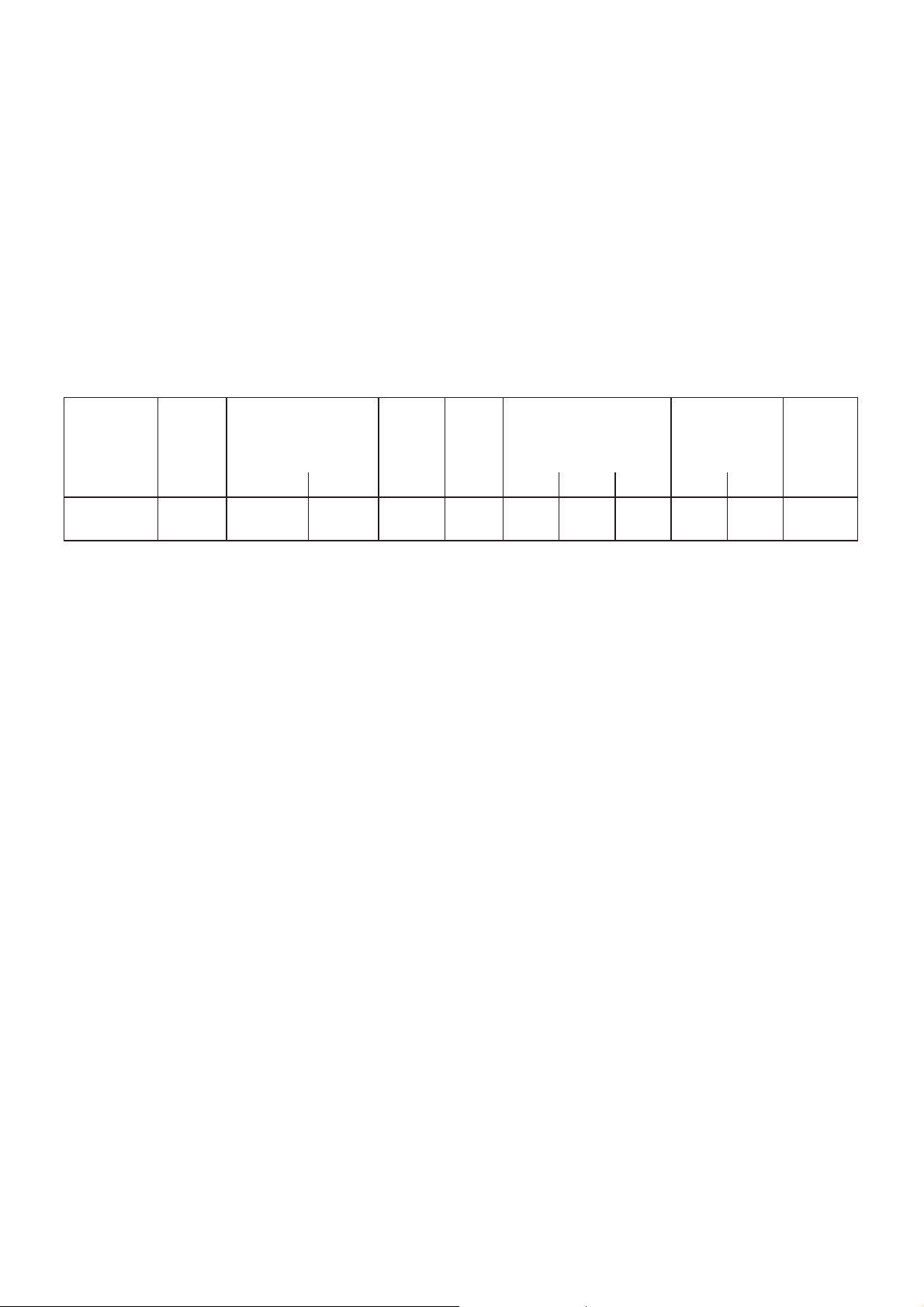

TECHNICAL SPECIFICATIONS

Gross

Model

F1 20/8 250V a.c. 20 amp 8 amp

Max

Voltage

Current Rating Type

Resistive Inductive H W L Dia L

Single

Pole

Enc.

Rating

IP22 59 56 132 63 125 0.6

Dims (Switch) Dims (Float)

Weight

(packed)

kg

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

- 3 -

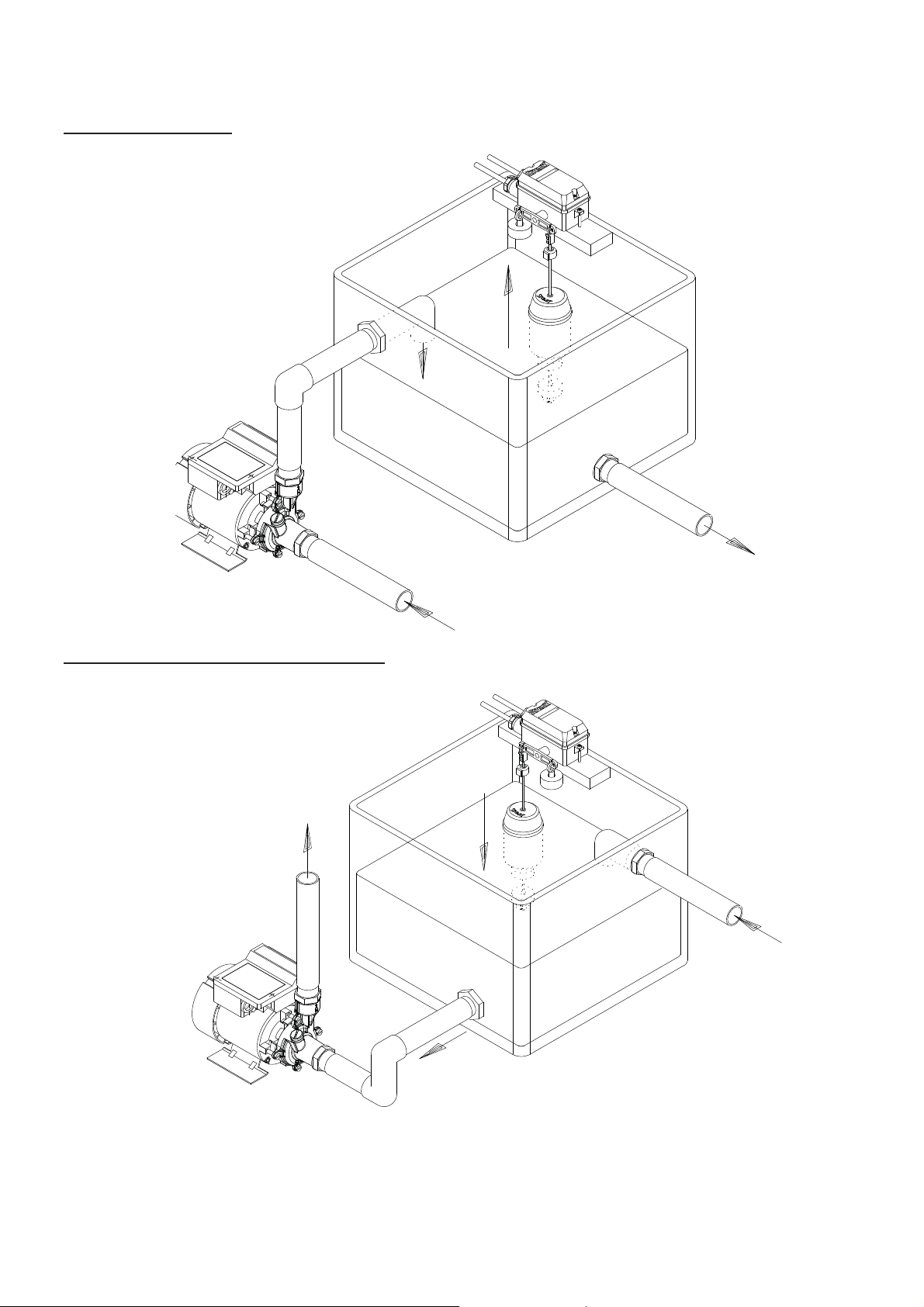

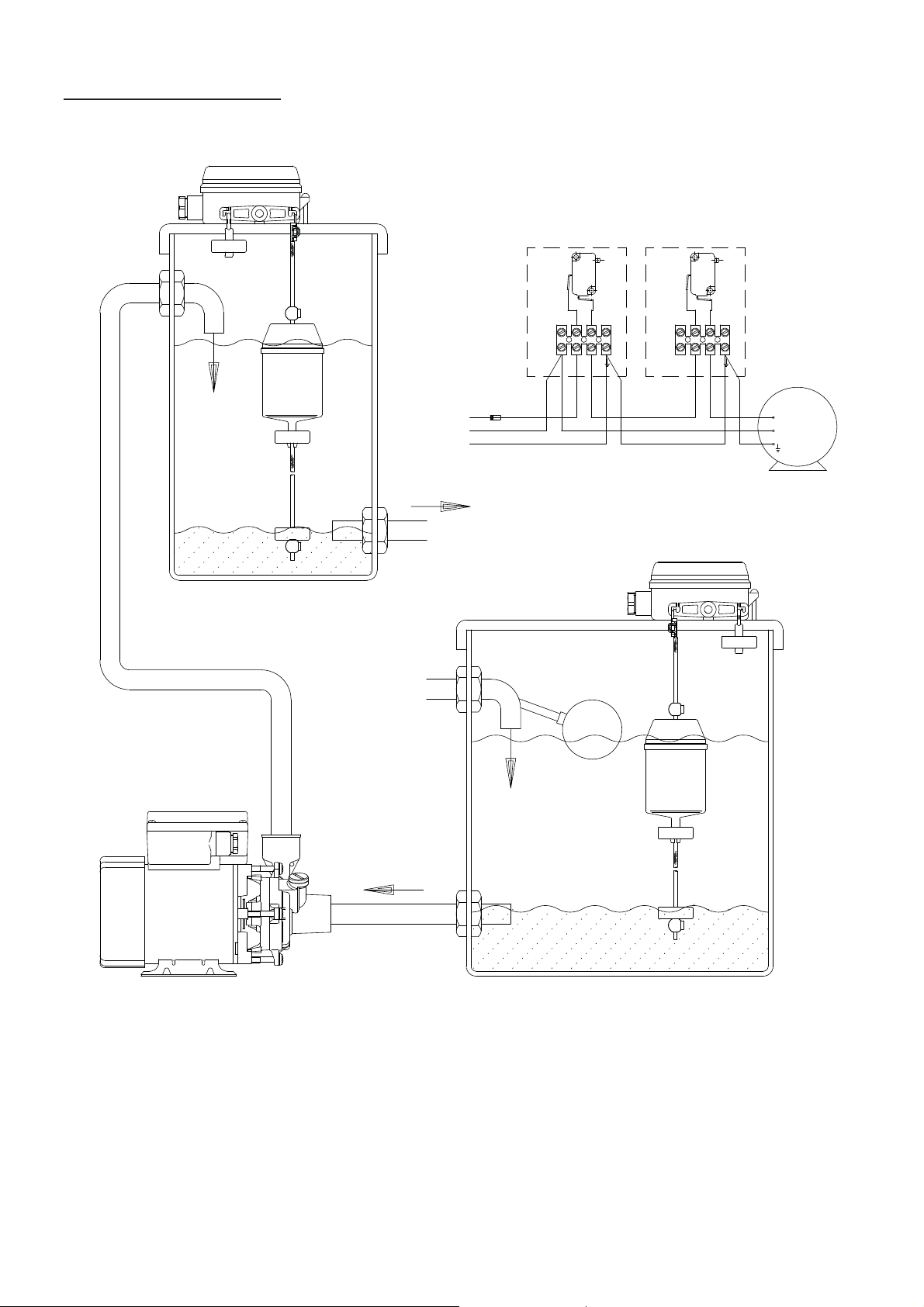

TYPICAL SWITCH INSTALLATIONS

High level cut out (tank filling)

Low level cut out (tank emptying)

Fig. 1

Fig. 2

NOTE : Different positions of float and counter balance, relevant to the operation the

switch is required to carry out.

- 4 -

Cont ...

Two switch installation (providing low level cut out protection)

FLOAT SWIT CH 2

FLOAT SWITC H 1

FUSE

L

N

E

SUPPLY 220/240-1PH-AC

WATER SUPPLY

OUTLET

NOTE:D.O.L. SWITCHING RECOMMENDED

FOR MOTORS UP TO 370 WATT THAT ARE

PROTECTED BY AN INTEGRAL THERMAL TRIP

N1

N1 L2 L1N2

L2 L1N2

FLOAT SWIT CH 1

Fig. 3

FLOAT SWITC H 2

MOTOR

WATER SUPPLY

INLET

Fig. 4

For installations where an erratic water supply can be a problem, two switches can be

used as illustrated. Float switch 2 is controlling the start and stopping of the pump, whilst

float switch 1 is providing low level protection by preventing the operation of the pump in

the case of water shortage.

- 5 -

Cont ...

PRE-ASSEMBLY OF WEIGHTS

The switch assembly includes three weights, the position of which relative to the switch

assembly is important for correct functionality of the switch.

a) Counterbalance weight

This is the heaviest of the three (approx

112 g) and is pre-fitted at the factory as

shown in Fig. 6.

If ever there is a need to remove or replace

this weight, it must be re-fitted with the

chamfer upwards as shown in Fig. 7.

Counterbalance

weight

(112 g)

Chamfer

Fig. 6

Fig. 7

b) Float weight and stop weight

These two weights are the same size (approx

90 g), are supplied loose and are

interchangeable.

The float weight must be assembled to the

float with the chamfer upwards as shown in

Fig. 8.

The stop weight must also be assembled

with the chamfer upwards as shown in Fig. 9.

Chamfer

Float

weight

(90 g)

Stop

weight

(90 g)

Fig. 5

Fig. 8

Chamfer

Fig. 9

- 6 -

SITING OF THE SWITCH & INSTALLATION

WARNINGS:

When used on a sump, make sure that it is kept clean. Aggressive

mediums such as concrete dust and cinders may cause damage.

When installing the main float switch casing ensure the mounting

holes (to suit M4 screws) are used. Do not drill the switch casing as

water ingress may subsequently occur which will damage the switch.

Do not allow plastic parts to come into contact with oil or cellulose

based paints, paint thinners or strippers, acid based descalents or

aggressive cleaning agents.

The switch housing must be securely fixed in a horizontal position and should be

protected from being sprayed with water. To permit free action of the switch, a sump

should not be less than 20 cm diameter and at least 45 cm deep. This will permit a

reasonable distance to be obtained between adjustment stops, which in turn will prevent

constant stop / start conditions which could cause damage to motor. See sketch below for

float operating range.

Float Operating Range

70 cm Max

5 cm Min

Fig. 10

Install unit so that the cord, float and the counterbalance weight cannot foul or rub

against anything. The top of the float is marked ‘TOP’. It is important to fit it the right way

up. The float must slide easily up and down the cord . Control the movement of the float

by adjusting the upper and lower level stops. Ensure that when in the lower position the

float and stop weight are clear of the bottom of the sump or tank. The counterbalance

operates the switch when the float lifts up the weighted cord. When the tank is emptied,

the weighted cord plus float must overcome the counterbalance and operate the switch in

the reverse direction. A 0.92 metre nylon cord is provided as standard.

- 7 -

To set switch for sump emptying:

For draining a sump (low level cut out) assemble the float on the left hand side of the

operating lever (as shown in Fig. 11).

Float Switch

Upper level

stop

Counterbalance

weight

Float

weight

Lower level

stop

Float

Cord

Stop weight

Fig. 11

To set switch for sump filling:

Assemble the float on the right hand side of the operating lever (as shown in Fig. 12).

The pump will switch off when the tank is full.

Float Switch

Upper level

stop

Counterbalance

weight

Stop weight

Fig. 11

Float

Float

weight

Cord

Lower level

stop

Cont ...

- 8 -

To change function of switch:

To change the function of the switch from sump emptying to sump filling or vice versa,

proceed as follows:-

Switch lever

Counterbalance

weight support clip

Float cord

support clip

Fig. 13

The counterbalance weight and float assembly must be interchanged. This is done by

manoeuvring both component support clips to the position where easy exit is provided on

the switch lever. Re-assembly is the reversal of this procedure.

ELECTRICAL INSTALLATION

WARNINGS:

The electrical installation must be carried out in accordance with the

current national electrical regulations and installed by a competent

person.

Before starting work on the electrical installation ensure the power

supply is isolated.

The switch and wiring must not be exposed to liquid.

Do not operate switch without terminal box lid correctly fitted.

The F1 switch is suitable for directly switching small output, single phase AC motors

up to 370 watt (0.5 HP), providing the motors are fitted with integral thermal overload

protection. Motors above 370 watt up to 750 watt (1HP) can also be directly switched,

provided the motors are fitted with some means of overload protection and the motor full

load current does not exceed the switch maximum (see technical specification section).

Larger single phase and three phase motors can be controlled by the switch via a

contact starter. The starter should be fitted with hand reset thermal overload protection

and the switch wired in series with the starter coil circuit (see wiring diagram section).

For installations in the United Kingdom, means for disconnection must be incorporated in

the fixed wiring according to the Wiring Regulations.

- 9 -

Cont ...

Earthing

WARNING: Earthing continuity between the supply cords to and from the

switch must be maintained.

The switch is provided with internal earthing terminals which are suitable for the

connection of the earthing conductors within the flexible supply cords.

Wiring

The switch is provided with a set of terminals which allow the connection of flexible

supply cords.

The supply cords should be of the PCP rubber insulated type (HO5RN-F) which is

suitable for a wet environment. Cable and fuse size must be appropriately selected. For

information on cable fitting consult the wiring diagrams and cable gland & supply cord

fitting instructions.

Ensure the electrical connections are securely made and that the micro switch is

connected in to the live line, not the neutral.

Cable Gland & Supply Cord Fitting Instructions (Single phase supply)

The cable gland assembly Fig. 15 (items 1 & 2) provides the necessary protection

against ingress of solid objects and moisture as well as providing cable retention.

Assembly instructions are as follows: -

1. Ensure selected cable sheath

diameter is within the permitted range

(6.5 to 9.5 mm).

2. Strip and prepare the cable sheath

E

and insulators as shown in Fig. 14.

3. Disassemble cable gland as shown in

Fig. 15 and insert cable into position

ensuring ‘O’-ring (item 1) is placed

over the cable before the clamping

insert (item 2) is tightened.

4. Consolidate the stranded conductor

ends by twisting.

5. Insert the phase, neutral and earthing

conductors into the appropriate terminal

block connections (see wiring diagram)

and secure, ensuring all conductor strands

are clamped.

N

L

8

100

70

8

8

70

Fig. 14

- 10 -

Fig. 15

Cont ...

Wiring Diagrams

WIRING DIAGRAM OF F1 MK4

FLOAT SWITCH D.O.L.

SWITCHING OF SINGLE

PHASE MOTOR

Fig. 16

WIRING DIAGRAM OF F1 MK4 FLOAT

SWITCH C/W STARTER AND SINGLE

PHASE MOTOR

- 11 -

Fig. 17

Cont ...

Wiring Diagrams Cont.

WIRING DIAGRAM OF F1 MK4 FLOAT

SWITCH C/W STARTER AND THREE

PHASE MOTOR

Fig. 18

MAINTENANCE

1. No routine maintenance of the switch unit is required, although dependent upon

conditions, a periodical clean of the float and cord should ensure trouble free

operation.

2. Isolate electricity supply before attempting maintenance.

STORAGE

If this product is not installed immediately on receipt, ensure that it is stored in a cool dry

place.

FOR FURTHER TECHNICAL SUPPORT

Phone the Stuart Turner Pump Assist team on 0844 98 000 97. Our staff are trained to

help and advise you over the phone or arrange for a service engineer to call.

- 12 -

Cont ...

YOUR 1 YEAR GUARANTEE

Stuart Pumps are guaranteed by Stuart Turner Limited to be free from defects in

materials or workmanship for the applicable guarantee period from the date of purchase.

The applicable guarantee period is stated in the installation booklet supplied with the

pump. Within the guarantee period we will repair, free of charge, any defects in the pump

resulting from faults in material or workmanship, repairing, exchanging parts or exchanging

the whole unit as we may reasonably decide.

Not covered by this guarantee: Damage arising from incorrect installation, improper use,

unauthorised repair, normal wear and tear and defects which have a negligible effect on

the value or operation of the pump.

Reasonable evidence must be supplied that the pump has been purchased within the

applicable guarantee period prior to the date of claim (such as proof of purchase or the

pump serial number).

This guarantee is in addition to your statutory rights as a consumer. If you are in any

doubt as to these rights, please contact your local Trading Standards Department or

Citizen’s Advice Bureau.

In the event of a claim please telephone Stuart Turner Limited on 0844 980 0097 or

return your pump and flexible hoses with accessories removed, plugs, pipes etc. If you

have any doubt about removing a pump, please consult a professional.

Proof of purchase should accompany the returned pump to avoid delay in investigation

and dealing with your claim.

- 13 -

Cont ...

NOTES

- 14 -

Cont ...

NOTES

- 15 -

Cont ...

DECLARATION OF CONFORMITY

2006/95/EC

BS EN 60335-1, BS EN 60204-1

1999/519/EC

BS EN 62233

2011/65/EU

IT IS HEREBY CERTIFIED THAT THE STUART FLOAT SWITCH COMPLIES WITH THE

ESSENTIAL REQUIREMENTS OF THE ABOVE E.E.C. DIRECTIVE AND STANDARDS.

RESPONSIBLE PERSON

AND MANUFACTURER STUART TURNER LIMITED

HENLEY-ON-THAMES, OXFORDSHIRE

RG9 2AD ENGLAND.

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stuart Turner are an approved company to BS EN ISO 9001:2000

Business Development Director

Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND

Tel: +44 (0) 1491 572655, Fax: +44 (0) 1491 573704

email: pumps@stuart-turner.co.uk web: www.stuart-turner.co.uk

V.A.T. REG. No. 199 0987 92. Registered in England No. 88368. Registered Offi ce: Market Place, Henley-on-Thames

Issue No. 2612/9-08 Pt. No. 17481

Loading...

Loading...