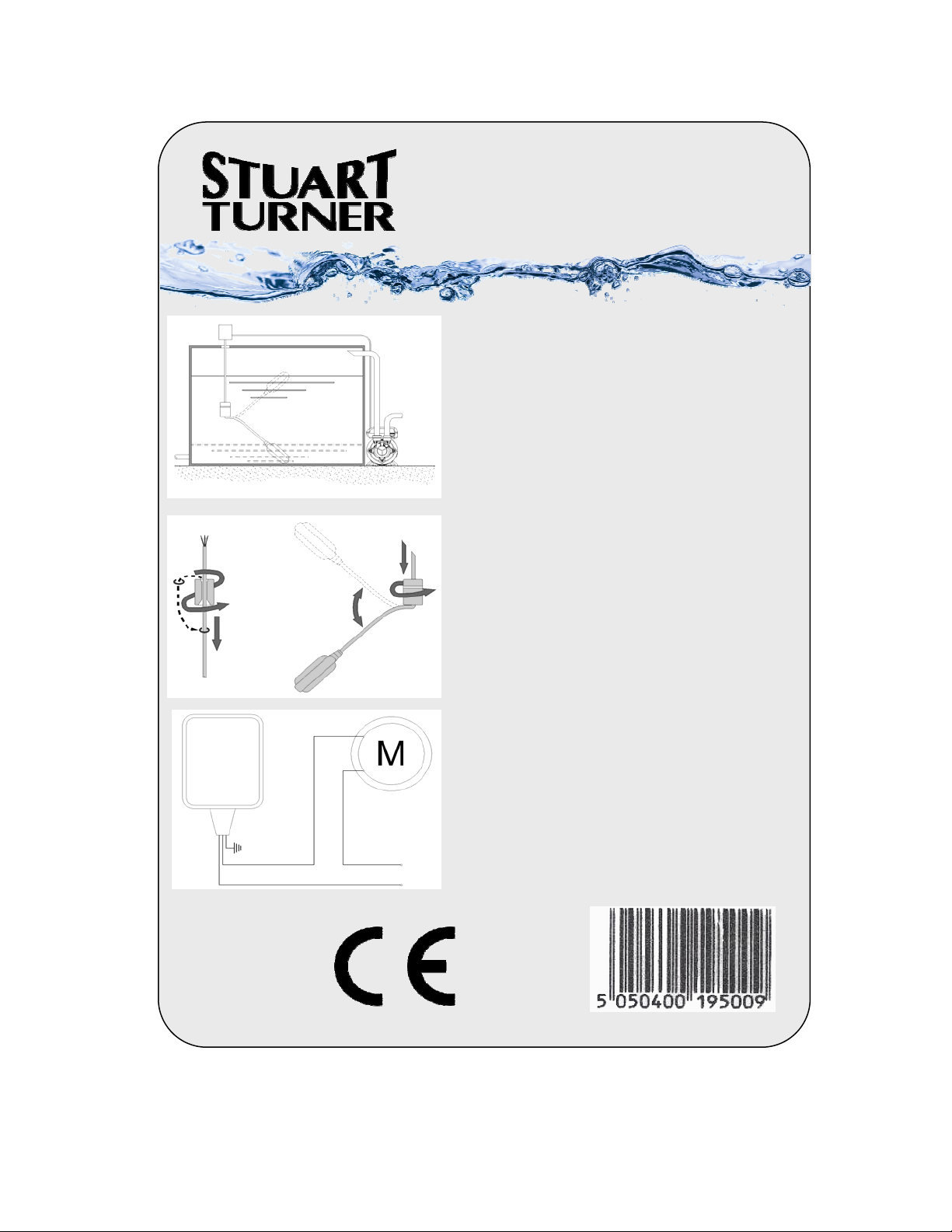

TANK FILLING

FLOAT SWITCH

3M CABLE

Installation:

STOP

START

Fig: 1

1

Fig: 2

To ensure the efficient function of the switch it is

necessary to fix the electric cable inside the tank or

well as illustrated in fig: 1.

The length of the cable section between the Pivot

Point (counterweight) and the float will determine

the length of time the pump runs between starting

and stopping

The switch must be free from obstructions within

the area of the float arc.

No joins should be made to the cable that may

become immersed in water.

Height Counterweight Installation

For correct counterweight installation refer to the

procedure as illustrated in fig: 2.

2

1. Insert the cable into the counterweight, from the

conical shaped end, turning it as shown. This will

result in the detachment of the plastic ring inserted

in the mouth (if required aid detachment by using a

screwdriver) Place the ring at the point of the cable

where the counterweight is to be fixed.

YELLOW /

GREEN

BROWN

BLUE

Fig: 3

Stuart Turner,

Henley-on-Thames,

Oxfordshire,

RG9 2AD

ENGLAND

2. Fix the counterweight on the ring using moderate

pressure and turning it as shown

Electrical Connections

L

N

Connect the float wires as shown in fig: 3

Part No:

19500

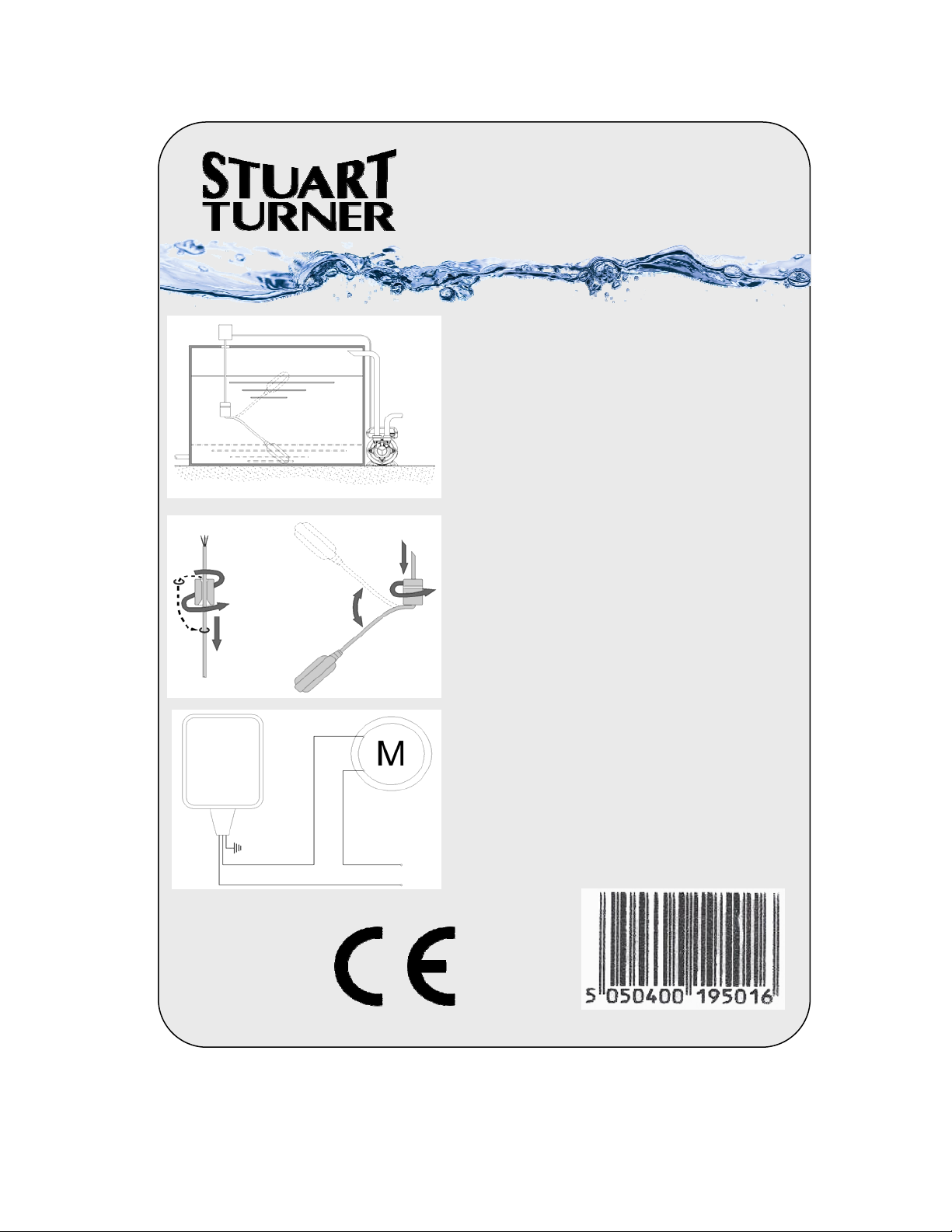

TANK FILLING

FLOAT SWITCH

5M CABLE

Installation:

STOP

START

Fig: 1

1

Fig: 2

To ensure the efficient function of the switch it is

necessary to fix the electric cable inside the tank or

well as illustrated in fig: 1.

The length of the cable section between the Pivot

Point (counterweight) and the float will determine

the length of time the pump runs between starting

and stopping

The switch must be free from obstructions within

the area of the float arc.

No joins should be made to the cable that may

become immersed in water.

Height Counterweight Installation

For correct counterweight installation refer to the

procedure as illustrated in fig: 2.

2

1. Insert the cable into the counterweight, from the

conical shaped end, turning it as shown. This will

result in the detachment of the plastic ring inserted

in the mouth (if required aid detachment by using a

screwdriver) Place the ring at the point of the cable

where the counterweight is to be fixed.

YELLOW /

GREEN

BROWN

BLUE

Fig: 3

Stuart Turner,

Henley-on-Thames,

Oxfordshire,

RG9 2AD

ENGLAND

2. Fix the counterweight on the ring using moderate

pressure and turning it as shown

Electrical Connections

L

N

Connect the float wires as shown in fig: 3

Part No:

19501

Fig: 1

TANK FILLING /

EMPTYING

FLOAT SWITCH

3M CABLE

Installation:

To ensure the efficient function of the switch it is

necessary to fix the electric cable inside the tank or

well as illustrated in fig: 1.

The length of the cable section between the Pivot

Point (counterweight) and the float will determine

the length of time the pump runs between starting

and stopping

The switch must be free from obstructions within

the area of the float arc.

No joins should be made to the cable that may

become immersed in water.

Height Counterweight Installation

For correct counterweight installation refer to the

procedure as illustrated in fig: 2.

1

Fig: 2

Stuart Turner,

Henley-on-Thames,

Oxfordshire,

RG9 2AD

ENGLAND

1. Insert the cable into the counterweight, from the

conical shaped end, turning it as shown. This will

2

result in the detachment of the plastic ring inserted

in the mouth (if required aid detachment by using a

screwdriver) Place the ring at the point of the cable

where the counterweight is to be fixed.

2. Fix the counterweight on the ring using moderate

pressure and turning it as shown

Electrical Connections

See Reverse Of Sheet

Part No:

19638

TANK FILLING /

EMPTYING

FLOAT SWITCH

3M CABLE

START

STOP

STOP

START

Fig: 3

BROWN BLUE

BLUE

BLACK

Fig: 4

Electrical Connections

Emptying (Fig 3 & 4)

To empty a tank or well:

Connect ‘Brown’ and ‘Black’

This will allow the switch to:Open when Down

Close when Up

Rating

= 16(4)A 230V

L

N

Electrical Connections

Filling (Fig 5 & 6)

To fill a tank or well:

Connect ‘Blue’ and ‘Black’

This will allow the switch to:Open when Up

Close when Down

Fig: 5

BROWN

BLACK

Fig: 6

Note: - If used with pumps having a continuous rating of 4 Amps or more

the switch must be connected through a relay or contactor.

- Always ensure the wire that is not used is correctly and fully insulated

L

N

Fig: 1

TANK FILLING /

EMPTYING

FLOAT SWITCH

5M CABLE

Installation:

To ensure the efficient function of the switch it is

necessary to fix the electric cable inside the tank or

well as illustrated in fig: 1.

The length of the cable section between the Pivot

Point (counterweight) and the float will determine

the length of time the pump runs between starting

and stopping

The switch must be free from obstructions within

the area of the float arc.

No joins should be made to the cable that may

become immersed in water.

Height Counterweight Installation

For correct counterweight installation refer to the

procedure as illustrated in fig: 2.

1

Fig: 2

Stuart Turner,

Henley-on-Thames,

Oxfordshire,

RG9 2AD

ENGLAND

1. Insert the cable into the counterweight, from the

conical shaped end, turning it as shown. This will

2

result in the detachment of the plastic ring inserted

in the mouth (if required aid detachment by using a

screwdriver) Place the ring at the point of the cable

where the counterweight is to be fixed.

2. Fix the counterweight on the ring using moderate

pressure and turning it as shown

Electrical Connections

See Reverse Of Sheet

Part No:

19639

TANK FILLING /

EMPTYING

FLOAT SWITCH

5M CABLE

START

STOP

STOP

START

Fig: 3

BROWN BLUE

BLUE

BLACK

Fig: 4

Electrical Connections

Emptying (Fig 3 & 4)

To empty a tank or well:

Connect ‘Brown’ and ‘Black’

This will allow the switch to:Open when Down

Close when Up

L

N

Electrical Connections

Filling (Fig 5 & 6)

To fill a tank or well:

Connect ‘Blue’ and ‘Black’

This will allow the switch to:Open when Up

Close when Down

Fig: 5

BROWN

BLACK

Fig: 6

Rating = 16(4)A 230V

Note: - If used with pumps having a continuous rating of 4 Amps or more

the switch must be connected through a relay or contactor.

- Always ensure the wire that is not used is correctly and fully insulated

L

N

Loading...

Loading...