Stuart Turner 12/50 12 V User Manual

12/50

CENTRIFUGAL PUMPS

FOR DC SUPPLY

OPERATING INSTRUCTIONS

Please leave this instruction booklet with the pump as it

contains maintenance and safety information

(Original Instructions)

MODELS

12/50

INDEX . . . . . . . . . . . . . . . . . Page No

Application . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Description . . . . . . . . . . . . . . . . . 2

Limits of Application . . . . . . . . . . . . . . . . . 3

Technical Specifi cation . . . . . . . . . . . . . . 3

Siting of the Pump/Pipework . . . . . . . . . . 4

Electrical Installation . . . . . . . . . . . . . . . . 5

INDEX . . . . . . . . . . . . . . . . . Page No

Commissioning . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . 10

Trouble Shooting Guide . . . . . . . . . . . . . . 13

Performance Information . . . . . . . . . . . . . 14

Environment Protection . . . . . . . . . . . . . . 14

IMPORTANT NOTES

Please read these instructions fully before starting the

installation:

The installation must comply with the relevant water supply,

electrical and building regulations and be installed by a

competent person.

If in doubt, consult Stuart Turner Ltd.

APPLICATION

The range of centrifugal pumps is designed to pump clean fresh water. Other clean,

non aggressive, non explosive liquids with similar characteristics to water may be pumped.

Consult Stuart Turner for advice on such applications.

The pumps can be used for pressure boosting, fluid transfer and distribution. They are

suitable for flooded suction applications. Alternatively a maximum suction lift of 4.6 metres

is permitted when using a Stuart footvalve/strainer.

WARNING AGAINST MISUSE

This pump set must not be used for any other application without the

written consent of Stuart Turner Limited. In particular, it must not be

connected directly to the mains water supply, or used outside the

conditions specified in the limits of application.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

PRODUCT DESCRIPTION

Motor:

Permanent magnet D.C. motor, totally enclosed self vent cooling, continuously rated,

class ‘F’ insulation. Motors comply with IEC 34-1. Enclosure ratings are given in the

technical specification section.

The standard range of motors are suitable for a supply of either 12 V d.c. or 24 V d.c.

dependant upon which model selected. Optional motors are available to suit different

voltages, consult Stuart Turner Ltd for further details.

- 2 -

Pump:

Close coupled, end suction configuration and of single stage, centrifugal design.

Standard pump materials of construction of major wetted parts are as follows:

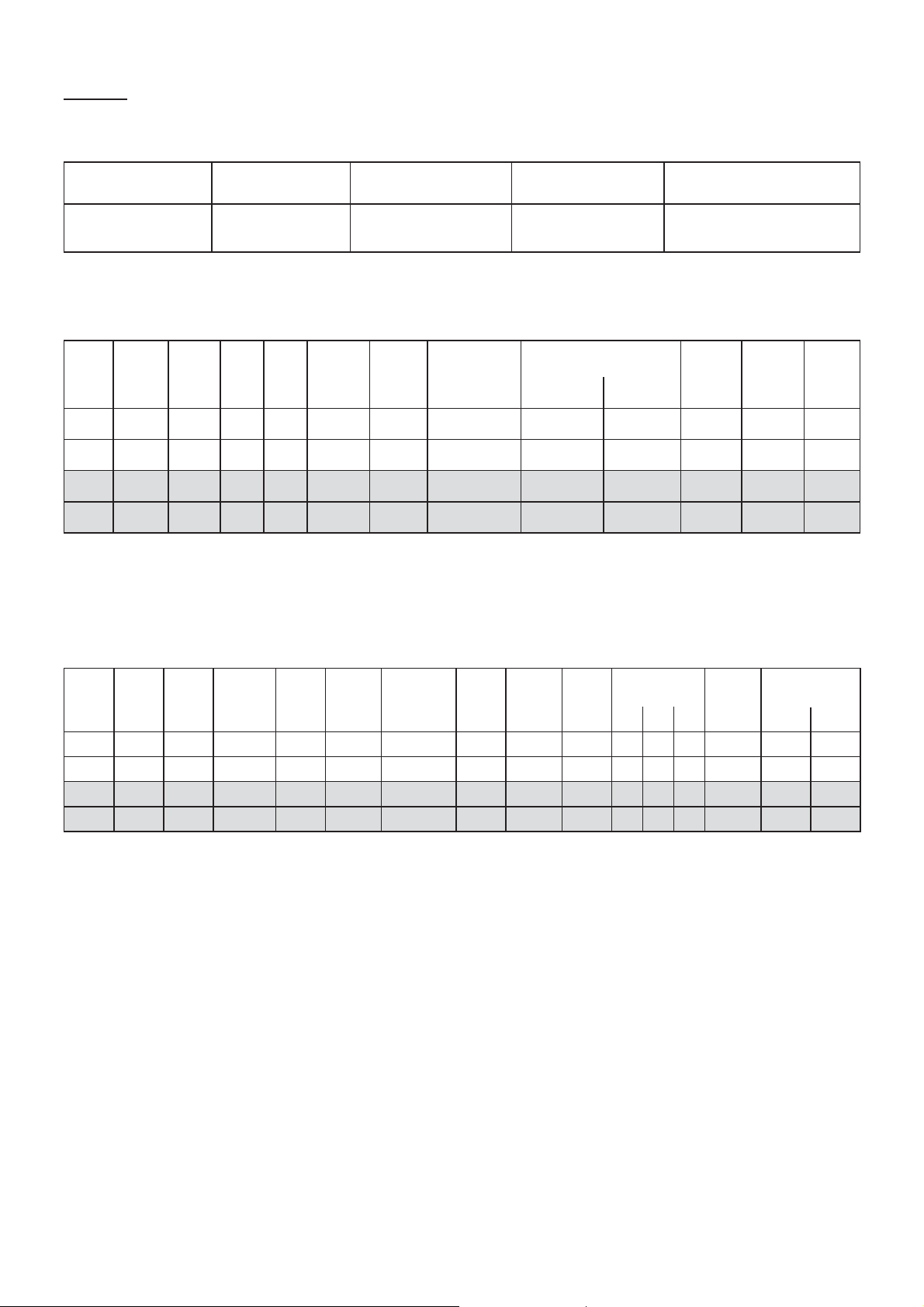

Model Body Impeller Shaft Mechanical Seal

2/50 Brass Acetal or Brass Stainless Steel Nitrile/Carbon

Ceramic/Stainless Steel

Other seal options are available. Consult Stuart Turner for further details.

LIMITS OF APPLICATION

Model Impeller Voltage

12/50 Plastic 12 80 4 40 4.6* 13.0 50 9.5 500 (5) 38 30

12/50 Brass 12 80 4 40 4.6* 13.0 50 9.5 500 (5) 38 30

12/50 Plastic 24 80 4 40 4.6* 13.8 50 9.5 500 (5) 37 30

12/50 Brass 24 80 4 40 4.6* 13.8 50 9.5 500 (5) 37 30

Liquid

Temp.

o

C

Temp.

o

Min.

Max.

Liquid

C

Max.

Ambient

Air Temp

o

C

Max.

Suction

Lift (m)

Max. Head

(Pump Closed

Valve) (m)

Max. Viscosity

(Redwood

No. 1 Scale)

Centistokes

**Max.

Working

Pressure

kPa (bar)

Max. Inlet

Head (m)

Max. No.

Starts/h

*With footvalve fitted.

**Note: Max working pressure is the maximum pressure that can be applied to the

pump internal casing under any installation conditions.

TECHNICAL SPECIFICATION

Nominal

Model Impeller Voltage Rating

12/50 Plastic 12 Cont. (S1) 4300 160 228 19.0 170 IPX4 229 104 117 3.4 G ¾ G ¾

12/50 Brass 12 Cont. (S1) 4300 160 228 19.0 170 IPX4 229 104 117 3.4 G ¾ G ¾

12/50 Plastic 24 Cont. (S1) 4300 175 196 8.2 83 IPX4 229 104 117 3.4 G ¾ G ¾

12/50 Brass 24 Cont. (S1) 4300 175 196 8.2 83 IPX4 229 104 117 3.4 G ¾ G ¾

Motor

Speed

(r.p.m.)

Nominal

Watts

Output

(Motor)

Max. Watts

consumed at

full flow

Full

Load

(AMPS)

Starting

Current

(AMPS)

Enc.

Rating

Dims (mm)

L W H Suction Delivery

Gross

Weight

(packed)

kg

Connections

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

Note: For information on other voltages which are not shown, consult any

supplementary instruction sheet supplied, or the rating label attached to the

pump.

Cont ...

- 3 -

SITING OF THE PUMP/PIPEWORK

WARNINGS:

Pump Location

If possible site the pump in a location where in the unlikely event of a

liquid leak, any spillage is contained or routed to avoid electrics or

areas sensitive to liquid damage.

Care should be taken to protect the pump from frost and freezing.

Ensure pipework to and from pump is independently supported to

prevent stress on the pump inlet and outlet branches.

Do not fit a non-return valve, or devices which contain non-return

valves, in the suction (inlet) pipework to the pump. Exceptions can

be made in the case of suction lift installations when a footvalve is

required.

Always install isolating valves to both suction and delivery pipework.

When a footvalve is required on installations that incorporate

automatic pump control, it is recommended that a suitable pressure

relief valve be fitted in the discharge (outlet) pipework from the pump.

Do not run against a closed valve for periods longer than 5 minutes.

Do not allow plastic pump parts to come into contact with oil or

cellulose based paints, paint thinners or strippers, acid based

descalents or aggressive cleaning agents.

Do not introduce solder flux to pumps or pump parts manufactured

from plastic. All solder joints should be completed and flux residues

removed prior to pump connection.

The motor casing can become very hot under normal operating

conditions. Care should be taken to ensure it cannot be touched

during operation.

Site the pump in a dry, frost-free position where it cannot be sprayed with water and as

close to the liquid source as possible.

The pump enclosure must be ventilated and there should be a minimum clearance of 80

mm between the pump and housing on all sides.

To prevent loss of pressure through pipework, use pipe size to match pump whenever

possible, minimising 90° bends.

It must be ensured that storage capacity of the liquid supply is adequate for the flow

rates required by the pump.

The pipework feeds to the storage tank should be of adequate size to ensure

replenishment rate of tank is sufficient to meet the needs of the pump.

Isolating valves should be fitted in suction and delivery pipework to enable easy isolation

and access to the pump.

When the pump is to be installed in areas where there is a risk of debris or scale build up

within the system, it is recommended that the inlet pipework is fitted with an inline strainer.

Pump Mounted Above Liquid Source (Suction Lift)

The pumps can be used in a suction lift installation providing the height of lift is within the

limits specified in the limits of application section.

A footvalve and strainer must always be used and the suction pipework size must match

the pump.

- 4 -

Loading...

Loading...