Merit Water Still

W4000 & W4000/EURO

water still Merit W4000

Instruction Manual

Manuel d’utilisation

Manuale d’istruzioni

Manual de instrucciones

Bedienungsanleitung

700492 / 02 2020

& W4000/EURO

EnglishMerit Water Still W4000

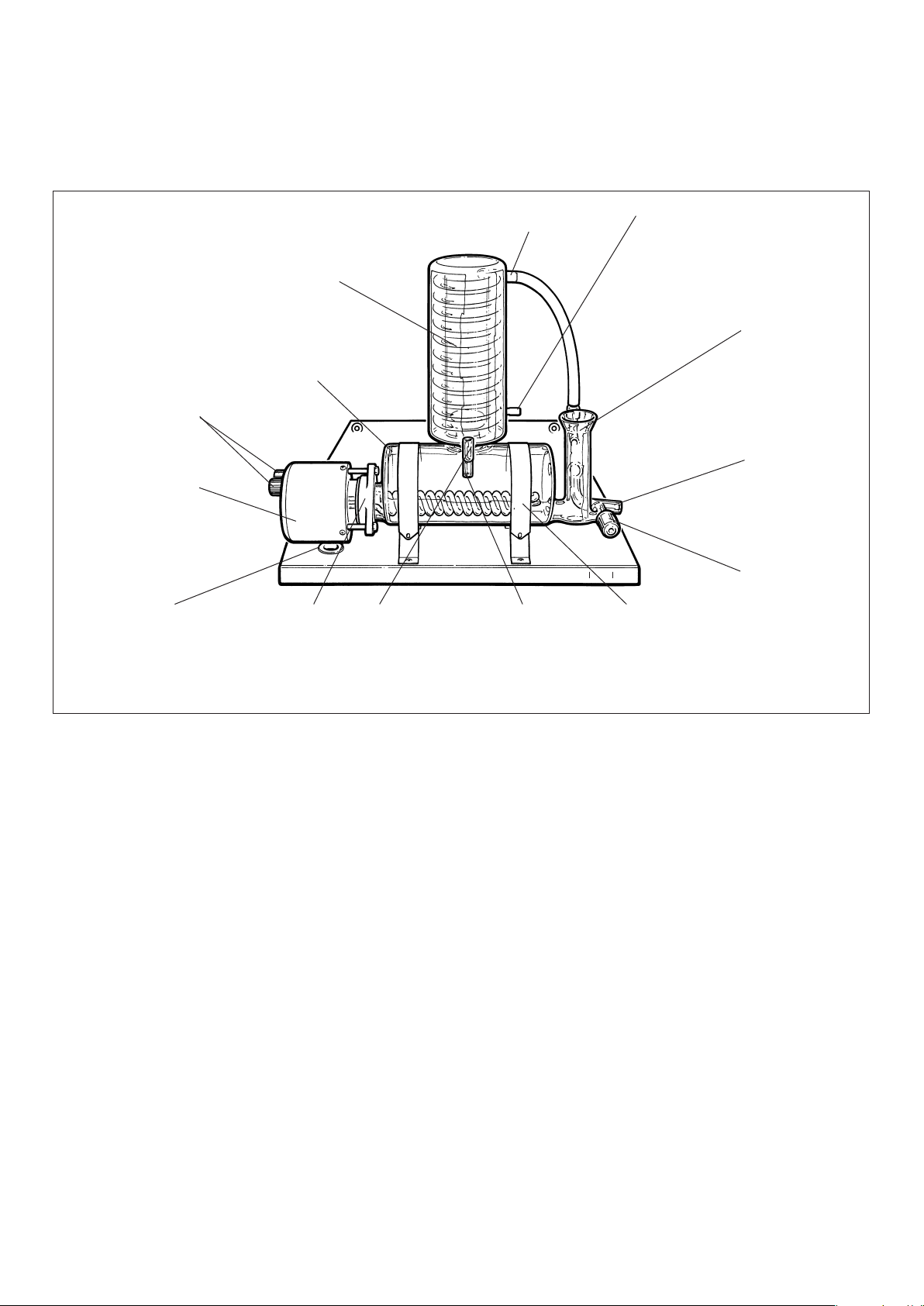

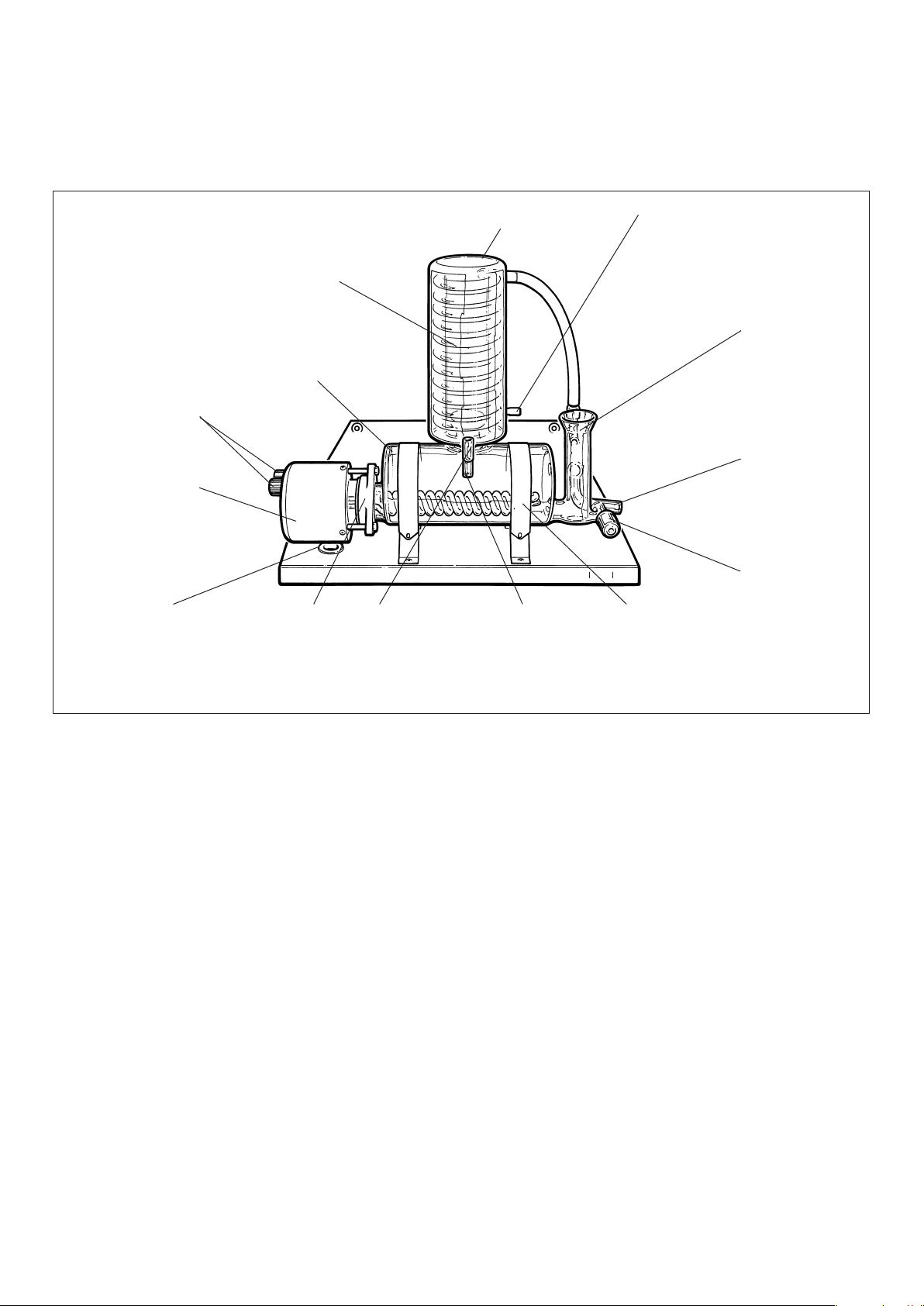

Thermostat reset

buttons

Heater

Grommet

Condenser

Boiler

Gaskets and

flange

Condenser upper outlet

Vent Distillate

outlet

water still Merit W4000

Condenser lower inlet

Constant level

control

Outlet

Stopcock

Straps

Figure 1 General assembly

Before use

If the equipment is not used in the manner described in this

manual the protection provided by the equipment may be

impaired.

Note: The Merit Water Still is classified as “Permanently

Connected Equipment” and should be connected to the electricity

supply by a qualified electrician in the manner described in the

electrical installation section of this manual.

The Merit Water Still is designed to operate under the following

conditions:

❖ For indoor use only

❖ Ambient temperature range +5°C to +40°C

❖ Altitude up to 2000m

❖ Relative humidity not exceeding 80%

❖ Mains supply voltage fluctuations not

greater than ±10% of nominal

❖ Overvoltage category II IEC60364-4-443

❖ Pollution degree 2 IEC664

2

Location

The Merit Water Still can be wall or bench mounted. Select a

convenient location which has access to the following services:–

Electricity Supply

Before connection please ensure that the line supply is suitable.

The Merit Water Still W4000 is suitable for supplies rated at

3kW, 220-240V, 50/60Hz~ single phase.

W4000/Euro is suitable for supplies rated at 3.5kW, 200-240V,

50/60Hz~ single phase. Supplies should be fitted with a 30mA RCD

circuit breaker.

Water Supply

A cold water supply capable of providing a minimum flow rate of 60 l/

hr. Ensure all water supplies are earth bonded.

Drain

A waste water drain located below the level of the still so that the

drain pipe can fall away straight without kinks or bends, to allow an

unimpeded flow. Ensure all drainage systems are earth bonded.

Reservoir

A distillate collection reservoir should be located beneath the still.

Assembly

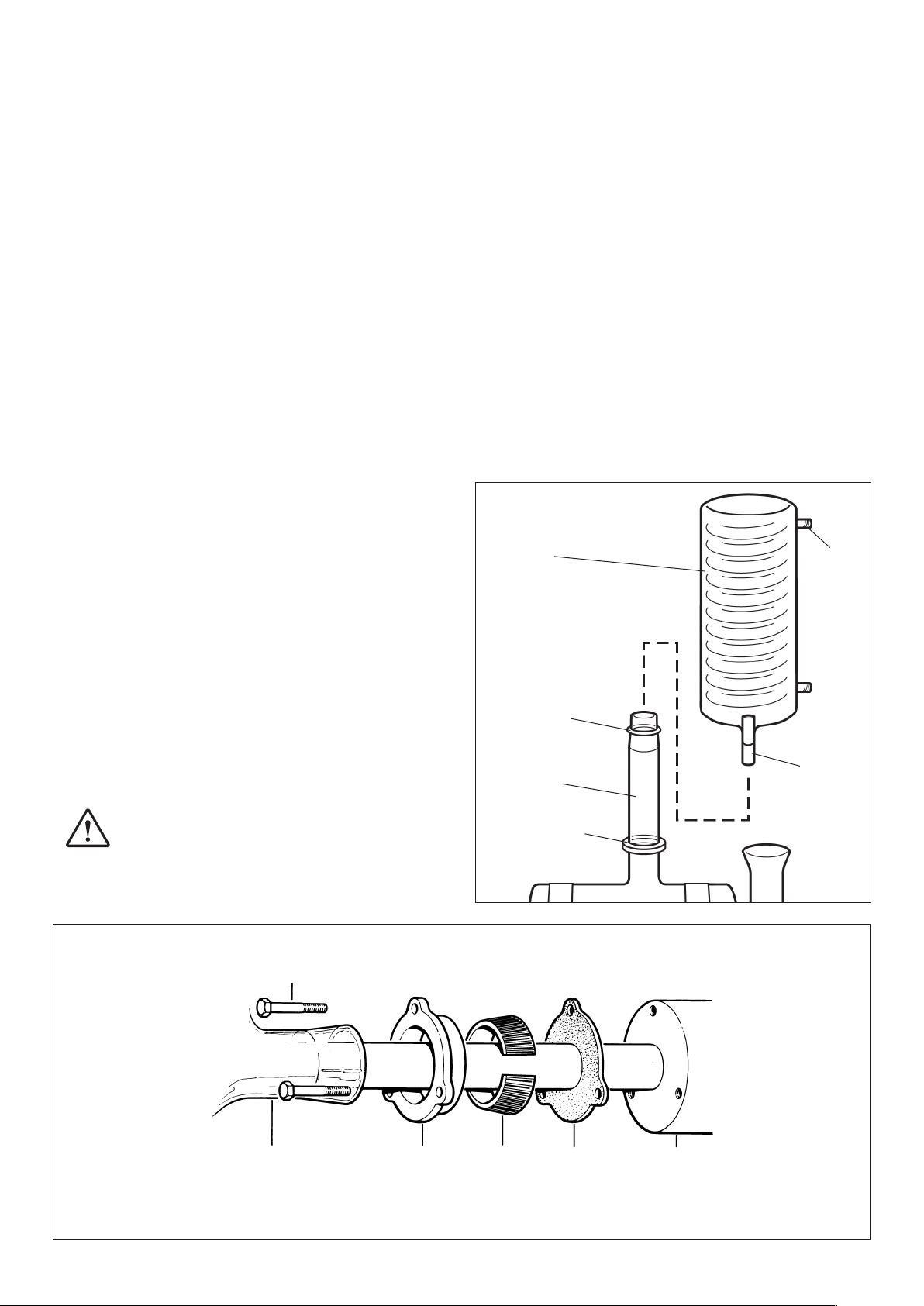

i) Insert the 3 bolts provided into the holes in the metal flange

and place the metal flange over the tapered glass tube of the

boiler – ensuring that the flat side of the flange faces the

boiler.

ii) Take the plastic insert and place this round the glass tube

and into the metal flange. Pull the flange and insert towards

the end of the glass tube so that they press onto the glass.

iii) Place the rubber gasket over the heater coils and then insert

the heating element through the tapered glass tube and into

the boiler.

iv) Now secure the heater using the 3 bolts. Do not over tighten.

4. Feed the electric cable of the heater through the hole in the base

of the support stand. Place the boiler and heater assembly in the

‘cradle’ of the stand. Ensure the stopcock on the boiler is facing to

the front. Secure with the 2 straps provided.

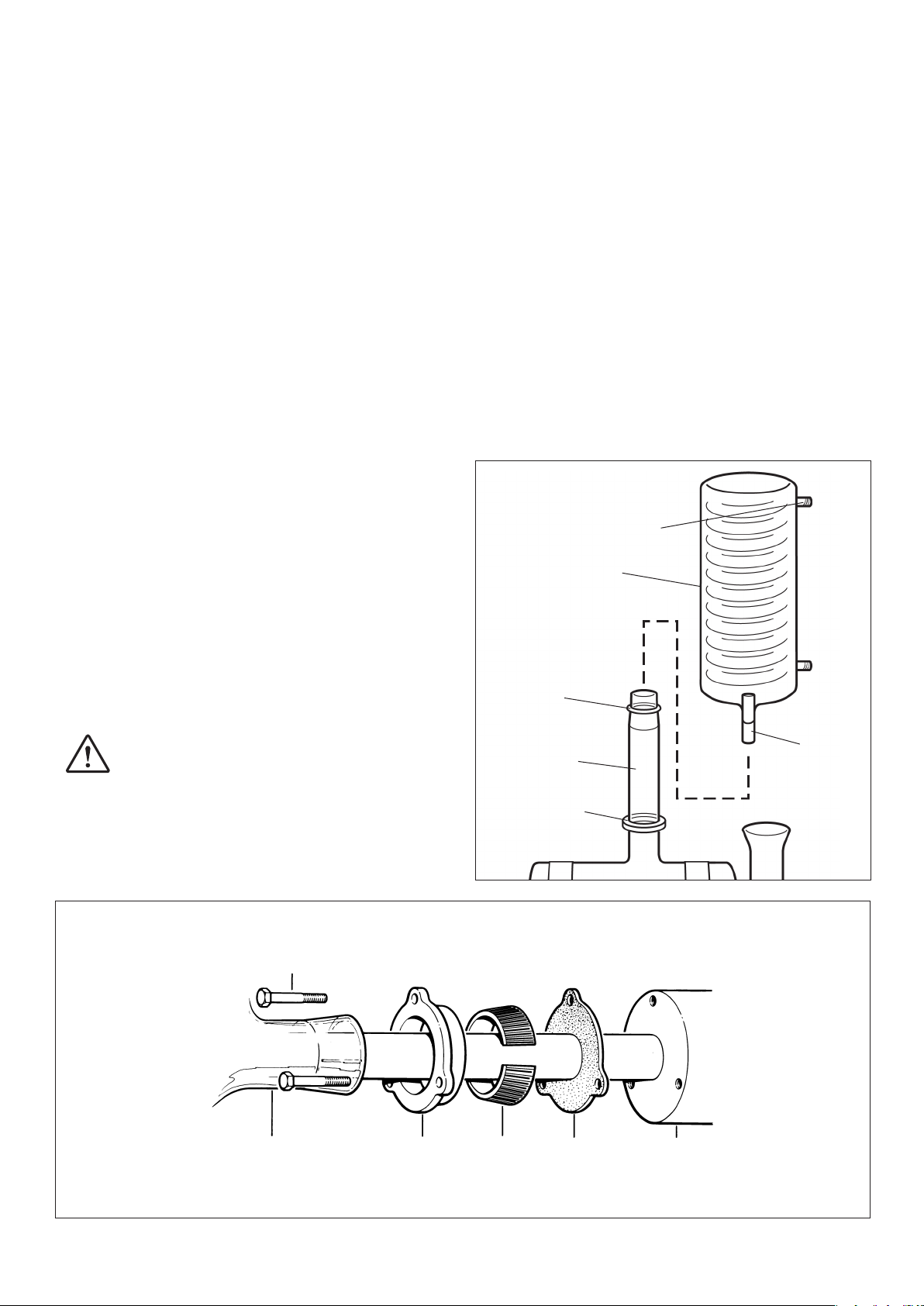

5. Ensure that the sealing o-ring and stabilising o-ring are correctly

positioned, as shown in Figure 3. Fit the condenser WC48/M2 by

mounting it onto the vapour tube of the boiler. Ensure the

distillate outlet tube of the condenser faces the front and the

cooling outlet faces parallel to the unit.

Your Merit W4000 has been designed with ease of assembly

specifically in mind, but before commencing assembly please study

the illustrations and text to familiarise yourself with the general

lay¬out. During assembly, follow the sequence of instructions and do

not connect the mains electricity supply until directed.

1. Unpack the water still and identify the following components:–

Qty. Component Catalogue No.

1

Support stand with 2 boiler straps

Boiler

1

Condenser

1

Heater

1

or

Hose Kit

1

Gasket Kit

1

2. Take the metal stand and place in the desired location.

Note that 2 screw holes are provided for wall fitting.

If wall mounting you must ensure you use appropriate

wall fixings that can hold a minimum weight of 28KG. If

you are in any doubt seek professional advice.

3. Take the boiler W4000/B, the heater and gasket kit W4000/GK.

Assemble the heater into the boiler as shown in Figure 2.

W4000/S

W4000/B

WC48 M2

A6/6 (240V)

A6/6/EURO (220V)

W4000/HK

W4000/GK

Figure 3

Condenser

Sealing o-ring

Vapour tube

Stabilising o-ring

Cooling

water

outlet

Outlet

tube

Figure 2 Flange assembly

Bolts

Tapered

glass

tube

Metal

flange

Plastic

insert

Rubber

gasket

Heater

3

6. From the hose kit take the 225mm length of 8mm bore plastics

hose fitted with screwthread connectors at either end. Referring to

Figure 1, screw one end of the hose to the upper outlet of the

condenser and the other end to the glass thread on the constant

level control. If the Still has been correctly assembled the hose

should comfortably reach, without any strain.

7. Take the 1000mm length of 16mm bore plastic hose and carefully

connect to the outlet of the constant level control. For easy

connection first warm the hose with hot water.

Secure with a tie strap.

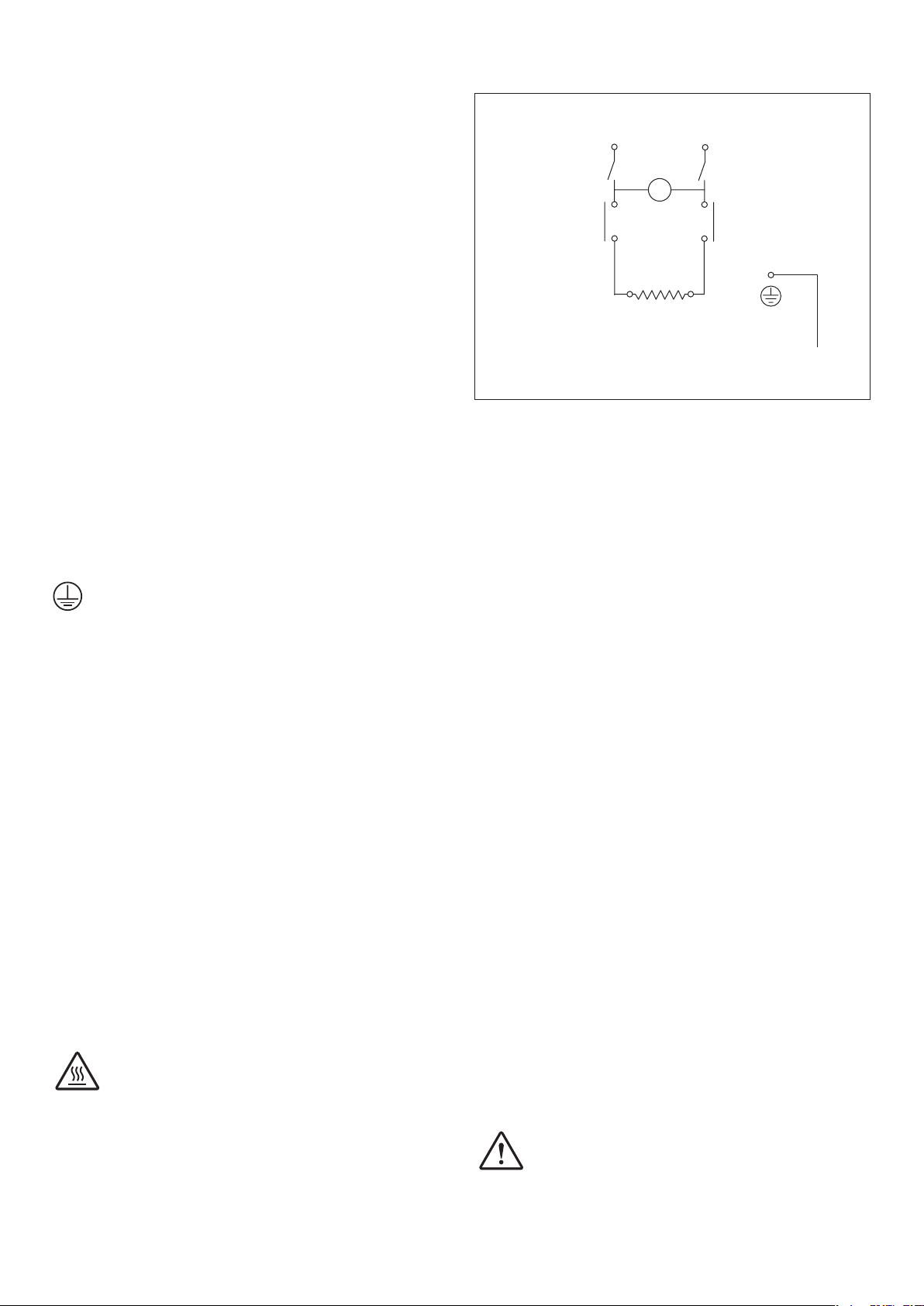

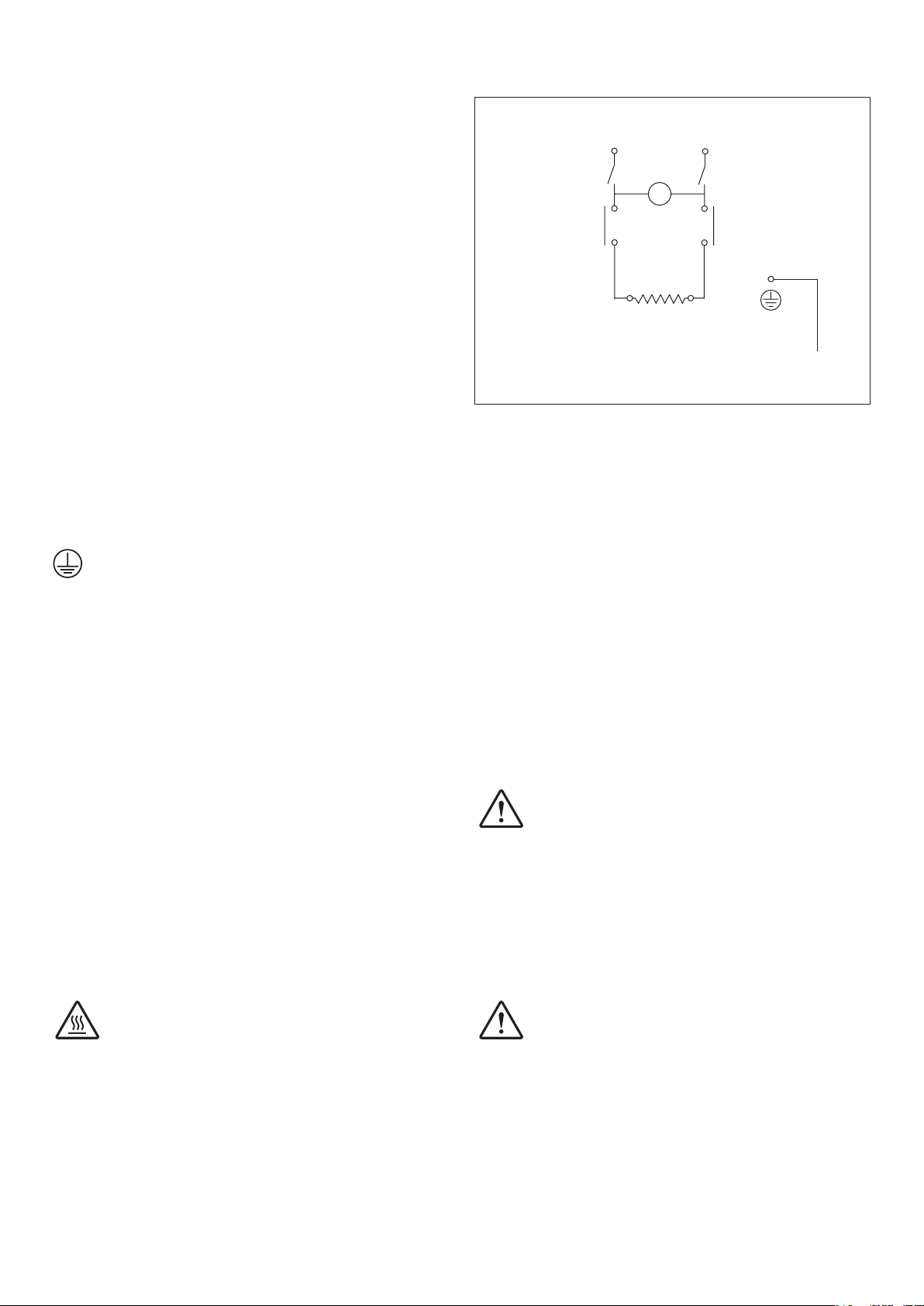

Circuit diagram

L N

(S)

Switch

(W4000/EURO only)

(S)

Thermostat

~240V

Lamp

(S)

Thermostat

8. Lead the free end of the tubing to drain, ensuring it falls away

from the still with no kinks or bends to impede water flow.

9. Ensure the stopcock on the constant level control is closed.

10. Connect the lower inlet of the condenser to the cold water feed

supply. A plastic screwthread connector is provided for easy

attachment to the condenser.

Select good quality tubing and ensure all connections are secured

with hose clips.

11. Connect the distillate outlet on the condenser to a suitable

collection reservoir.

12. Turn on the water supply and test for leaks then turn off the water

supply.

Electrical installation

THIS EQUIPMENT MUST BE EARTHED!

The electrical installation should only be carried out by a qualified

electrician.

The equipment is supplied with 1.7m of flexible triple core circular

cable to CMA 3183 TQ specification. The conductors are 1.5mm2 to BS

6360 Class 5 insulated with E.P.R. The outer sheath is 85°C heat

resisting type C.S.P. to HOFR, BS 6500 Table 9.

Connection to the mains electrical supply, should be via a double pole

30mA RCD isolation circuit breaker with a continuous current carrying

capacity of 15A at 250v and overcurrent protection of 15A, 250V .

These devices should be sited near to the equipment and clearly

marked – “Disconnect device for Merit Water Still“

Connect to the line supply noting that the wires in the instrument lead

are coloured in accordance with the following code:–

Brown – Live

Blue – Neutral

Yellow/Green – Earth

E

Element

Heater flange

(S) Denotes safety critical component.

Operation

1. Turn on the cold water supply and adjust the flowrate to approx.

60 l/h.

Note: It is strongly recommended to measure the flow rate,

failure to do so can result in possible injury from hot water

exiting from the Still. If a flow meter isn't available a simple

measurement can be performed with a 1L beaker.

timed period of five minutes the beaker should be completely

filled five times.

Observe that the water flows via the condenser and into the boiler.

Wait until the boiler has attained its correct operating level and

make sure that the excess water is flowing freely to drain.

2. Switch on the electricity supply to the heating element at the

mains isolation switch.

For the W4000/EURO version, switch on the switch situated on the

heater.

3. After a few minutes the water will start to boil and distillate will

emerge from the condenser. With new glassware, or after cleaning,

it is advisable to allow this to run to drain for approximately 30

minutes before beginning collection.

4. To turn off the still, first turn off the heating element but allow the

cooling water to continue for a further 10 minutes to allow the still

to cool.

Over a

Mains Cable Replacement

If the mains cable requires replacement, only specially prepared spare

mains lead obtained from Cole-Parmer should be used.

Hot warning

Some parts of the product may become hot during

use. These are clearly marked with 'Hot Warning

Labels. Avoid touching these parts.

4

WARNING!

Do not use this equipment to distil any liquid other than

water.

Safety cut-outs

The Merit Water Still is protected by two safety cut-outs:

Boiler heater thermostats

Should the boiler water level fall and expose the

element the thermostats will operate and turn off the

electricity supply to the element.

After operation of either of the thermostats, normal operation may be

resumed by resetting the thermostats by means of their respective

reset buttons mounted on the end of the heater end cover.

Remove the black plastic cover and then press the button – a slight

click will be heard if the thermostat had operated.

Before resetting either thermostat the still should be

allowed to cool completely and the cause of cut-out

operation identified and rectified.

If the thermostats continue to operate consult a qualified electrician or

the Service Department of Cole-Parmer.

Care and maintenance

Note: Before commencing any maintenance, cleaning or fault

finding the equipment should be isolated from the mains electricity

supply. These operations should be only carried out by suitably

qualified personnel.

Only spare parts supplied or approved by Cole-Parmer, or its agent

should be used. Fitting of non-approved parts may affect the

performance or safety of the equipment.

Maintenance

Due to the nature of these parts it is necessary to periodically check

the quality of the plastic connectors and hoses. There should be no

strain on the connectors or hoses. Both the hoses and connectors

should be intact without any cracking. If any damage is discovered on

these parts the Still should immediately be turned off, as detailed

under the "Operation" section of this manual, and not used again

before these parts are replaced. Please refer to the "List of spare parts"

section of this manual for order codes.

5. Into the open funnel of the constant level control carefully add

about 1 litre of 10% formic acid solution or kettle descaler.

Do not use strong acids such as hydrochloric, this can cause severe

corrosion of the metal heating element.

WARNING!

ALWAYS HANDLE ACIDS WITH GREAT CARE. PROTECTIVE

CLOTHING, GLOVES AND FACE-MASKS SHOULD BE WORN

DURING THE DESCALING OPERATION.

REMOVE ANY ACID SPILLS IMMEDIATELY.

Turn on the water supply and fill the boiler to the normal

operating level. The water will flush the acid into the boiler. The

water supply should be turned off when the level in the boiler is

slightly below the overflow.

6. Leave the acid in the boiler to desolve the scale. This may take

some time depending on the severity of the build-up.

7. Open the stopcock and allow the boiler to drain.

Note: If the acid in the boiler has not been completely

neutralised

necessary safety precautions should be observed around the

drain and any effluent control procedures followed.

8. Close the stopcock, turn on the water and allow the boiler to fill

with cold water. Turn off the water, re-open the stopcock and allow

the boiler to drain. Repeat this procedure three times.

9. The Merit Water Still may now be restarted by referring to the

instructions given under “Operation” in this manual.

Note: The stand and outer surfaces of the glassware should be

cleaned using a damp cloth and a mild detergent solution.

the liquid flowing to drain may be highly acidic. All

List of spare parts

Cleaning

Over a period of operation scale deposits will build up inside the

boiler. To obtain optimum performance from the still, the scale should

be removed on a regular basis.

The time span between cleaning depends greatly on the hardness of

the water supply and the amount of use. Frequently used stills in hard

water areas may need descaling once a week whereas in a soft water

area several weeks may elapse before descaling is necessary.

Note: Heavy scaling will reduce distilled water quality and can

shorten the life of the heating element.

It is possible to descale the Merit Water Still without dismantling the

glassware by following these instructions in conjunction with Control

of Substances Hazardous to Health regulations (COSHH) 1988.

1. Switch off the electricity supply to the still and allow it to cool

completely.

2. Turn off the cooling water supply.

3. Open the stopcock on the constant level control and allow the

boiler to drain completely, Close stopcock.

4. Turn on the cooling water supply and allow the boiler to fill to

approximately half way to its normal operating level. Turn off

the water supply.

The following components are available from most laboratory

suppliers. In case of difficulty, please contact Cole-Parmer.

Cat. No.

Boiler

Condenser

Heater (complete with thermostats) 240V

(complete with thermostats) 220V

Set of heater fixings (flange, gasket, insert and bolts)

Hose kit

W4000/B

WC48/M2

A6/6

A6/6/EURO

W4000/GK

W4000/HK

Warranty

Cole-Parmer Ltd. warrants this instrument to be free from defects in

material and workmanship, when used under normal laboratory

conditions, for a period of three (3) years. In the event of a justified

claim Cole-Parmer will replace any defective component or replace

the unit free of charge.

This warranty does NOT apply if damage is caused by fire, accident,

misuse, neglect, incorrect adjustment or repair, damage caused by

incorrect installation, adaptation, modification, fitting of non

approved parts or repair by unauthorised personnel.

This Warranty does not include the heater element which is only

guaranteed for 1 year.

5

Fault finding

In the event of operating difficulties with your Merit Still, please consult the following notes. If

these fail to identify and remedy the fault, then you are advised to seek the help of your

supplier or the Service Department of Cole-Parmer.

Note – Fault finding should only be carried out by suitably qualified people.

Symptom Cause Remedy

1. Water level in boiler is too

LOW. e.g. – heater exposed.

2. Water level in boiler is too

HIGH. e.g. – boiling water

surging into condenser.

3. Water in boiler is “pumped”

out of boiler to drain.

4. Distillate temperature is Flow of cooling water is insufficient.

high, e.g. – above 50°C.

a) Supply of feed/cooling water is

insufficient.

b) Stopcock on boiler inadvertently

left open.

a) Supply of feed/cooling water

is excessive.

b) Flow of drainage water

is constricted.

a) Tubing from condenser distillate

outlet to reservoir is constricted.

b) Vent on condenser distillate

outlet is blocked.

c) Supply of feed/cooling water

is insufficient.

a) Increase flowrate of water to

approx. 60 litres/hour.

b) Close stopcock.

a) Reduce flowrate of water to

approx. 60 litres/hour.

b) Ensure drainage tubing falls

freely.

a) Ensure tubing falls freely to

reservoir without kinks or bends.

b) Remove obstruction.

c) Increase flowrate of water to

approx. 60 litres/hour.

Increase flowrate of water to

approx. 60 litres/hour.

5. Distillate rate less than 4 litres/hour. Mains voltage low Excessive

cooling water flow.

6. Distillate quality poor*. Boiler heavily scaled. Clean boiler.

7. Heater not working. a) Burnt-out heater.

b) Mains electricity fuse blown.

c) Thermostat operated.

8. Persistent tripping of the RCD The integrity of the heater Replace the RCD

* Distillate quality when determined by pH or electrical conductivity is greatly affected by temperature and the presence of absorbed carbon

dioxide.

–

Reduce to 60 litres/hour.

a) Replace heater.

b) Replace fuse.

c) Reset.

6

W4000 & W4000/EURO

Réfrigérant

Bouilleur

Boutons de

rearmement

thermostat

Elément

Chauffant

FrançaisDistillateur

Entrée inférieure de condenseurSortie supérieure de condenseur

Contrôleur

de niveau

Sortie eau de

refroidissement

Œillet

Figure 1 : Vue d’ensemble

Joint

d’étanchéité et

collier de

fixation

Event Sortie

Avant l’utilisation

Si l’appareil n’est pas utilisé de la manière décrite

ci-après, les sécurités prévues peuvent être défaillantes.

N.B. L’appareil à cau distillée MERIT est classé parmis les

«appareils connectés en permanence» et doit être raccordé par un

électricien qualifié comme décrit dans la section

«installation électrique» de ce manuel.

Le distillateur MERIT est prévu pour fonctionner dans les conditions

suivantes :

❖ Utilisation en intérier uniquement.

❖ Température d’utilisation +5°C à 40°C.

❖ Altitude < 2000m.

❖ Humidité relative < 80%.

❖ Alimentation électrique ne variant pas de ±10%

autour de la valeur nominale.

❖ Survoltage catégorie II IEC60364-4-443.

❖ Degré de pollution 2 IEC664.

distillat

water still Merit W4000

Robinet

Anneau de

fixation

7

Installation

Le distillateur MERIT peut être installé sur une paillasse ou fixé au mur.

Choisir un emplacement à proximité des dispositifs suivants:

Alimentation électrique:

Avant de connecter l’appareil, vérifier que l’alimentation électrique est

correcte. Modèle W4000 pour alimentation électrique 3kW 220V,

50/60Hz monophasé. Modèle W4000 EURO pour alimentation

électrique 3.5kW 220V, 50/60Hz monophasé. Des approvisionnements

devraient être équipés d'a 30mA RCD disjoncteur. Les fournitures

doivent être munis d'un disjoncteur de circuit RCD 30mA.

Alimentation en eau:

Source d’eau froide capable de fournir un débit minimum de 60 l/hr.

Evacuation:

Dispositif d’évacuation ou évier situé en dessous de l’appareil de façon

à ce que le tuyau d’évacuation d’eau ne présente aucun coude.

Réservoir de recette:

Un réservoir de recette du distillat pourra être installé sous l’appareil.

Montage

1. Déballer le distillateur et identifier les

composants suivants:–

Qte Designation Référence

1

Support muni de 2 anneaux

métalliques de fixation

Bouilleur

1 775421

Réfrigérant

1 775361

Elément chauffant 220V

1 775422

1 775426

1

de tuyaux

Jeu

Jeu de colliers de fixation

W4000/S

775424

i) Insérez les 3 boulons fournis dans les orifices de la bride

métallique et placez-la sur le tube en verre conique du

bouilleur en vous assurant que le côté plat de la bride est

orienté vers le bouilleur.

ii) Insérer le collier en graphite à l’intérieur du collier

métallique. Tirer le collier métaliique et son insert en

graphite vers l’extrémité du bouiller de façon à ce qui’ils

exercent une pression sur le tube évasé.

iii) Insérer le joint en caoutchouc par dessus les spires de

l’élément chauffant. Introduire l’élément chauffant dans le

bouilleur.

iv) Fixer l’élément chauffant en vissant les 3 boulons. Ne pas

serrer à bloc.

4. Placer le bouiller et l’élément chauffant sur le support. Le robinet

doit alors faire face à l’utilisateur. Faire passer le câble

d’alimentation à travers l’orifice situé à la base du support. Fixer le

bouilleur avec les 2 anneaux métalliques.

5. Enfiler le réfrigérant sur le tube vapeur du bouilleur. L’orifice de

sortie du distillat doit faire face à l’utilisateur.

Figure 3

Sortie d'eau

de refroidissement

Condenseur

2. Installer le support à l’emplacement choisi. 2 trous permettent

de le visser au mur si nécessaire.

En cas de montage mural, vous devez vous assurer

d'utiliser des fixations murales appropriées pouvant

supporter un poids minimum de 28 kg. Demandez

conseil à un professionnel en cas de doute.

3. Prendre le bouilleur, l’élément chauffant et le jeu de colliers.

Assembler selon la figure 2.

Boulon

Joint torique

d'étanchéité

Tube de vapeur

Joint torique de

stabilisation

Tube de

sortie

Figure 2

8

Tube évasé Collier

métallique

Collier en

graphite

Joint en

caoutchouc

Elément

chauffant

6.7.Dans le jeu de tuyaux, prendre le tube 225mm de long et 8mm

de diamètre équipé de connecteurs à vis à ses 2 extrémités.

Visser une extrémité du tuyau sur le raccord à vis supérieur du

réfrigérant et l’autre extrémité sur le raccord à vis du contrôleur

de niveau (voir figure 1).

Prendre le tuyau de 1000 mm de long et 16 mm de diamètre.

Fixer avec précaution son extrémité en sortie du contrôleur de

niveau. Pour faciliter cette opération, passer prélablement

l’extrémité du tuyau sous l’eau chaude. Fixer avec un collier.

8. Placer l’extrémité libre du tuyau vers l’évacuation, en s’assurant

qu’il ne présente aucun coude pouvant perturber l’écoulement

de l’eau.

9. Vérifier que le robinet du contrôleur de niveau est fermé.

Schema de principe

P N

~240V

(S

)

Interrupteur

(S

)

Thermostat

120°C

Lampe

(

S)

Thermostat

120°C

T

10. Visser le connecteur plastique sur le raccord à vis inférieur du

réfrigérant. Fixer le tuyau d’alimentation en eau froide sur ce

connecteur. Choisir un tuyau de bonne qualite et vérifier que

toutes les connexions sont renforcées par un collier.

11. Relier par un tuyau l’orifice de sortie du distillat au réservoir de

recette.

12. Ouvrez l’alimentation en eau et testez la présence de fuite puis

coupez l’alimentation en eau.

Installation electrique

CET APPAREIL DOIT ETRE RELIE A LA TERRE !

L

’installation électrique doit être effectuée par un électricien qualifié.

L’appareil est livré avec un câble de 1,7m (conforme aux spécifications

CMA 3183 TQ). Les fils conducteurs, de section 1,5mm2 (conformes aux

spécifications BS 6360 classe 5) protégés avec de l’EPR. La résistance à

la température est de 85°C et de type CSP à HOFR, BS 6500, table 9.

La connexion à l'alimentation électrique doit être un pôle double

isolation RCD 30mA disjoncteur avec un courant continu nominal de

15A à 250V et la protection de surintensité de 15A, 250V.

Cet équipement doit se trouver à proximité de l’appareil et être

clairement identifier «protection pour distillateur MERIT».

Raccorder le câble selon les indications suivantes:

Marron - Phase

Bleu - Neutre

Jaune/vert - Terre

Si le câble d’alimentation nécessite un remplacement, un câble

spécial, fournis par Cole-Parmer, doit être utilisé.

Avertissement chaud

Certaines pièces du produit peuvent chauffer à

l’utilisation. Elles sont clairement marquées avec des

étiquettes d’avertissement « Chaud ». Évitez de

toucher ces pièces.

Element

Chauffant

Couvercle

(S

) Composant de sécurité.

Mise en route

1. Ouvrir le robinet d’eau froide et régler le débit à 60 litres/heure

environ. L’eau doit circuler à travers le réfrigérant. Attendre que le

niveau d’eau dans le bouilleur soit stable. Vérifier que l’eau

s’écoule normalement vers l’évacuation.

2. Allumer l’interrupteur de l’élément chauffant.

Observer l’ébullition et vérifier que le distillat s’écoule

normalement vers le réservoir de recette.

ATTENTION !

NE PAS UTILISER CET APPAREIL POUR DISTILLER AUTRE CHOSE

QUE DE L’EAU.

Thermostats de sécurité

Le distillateur MERIT est protégé par deux thermostats de sécurité.

Thermostat de sur-chauffe du bouilleur.

Si le controleur de niveau est défectueux et expose

l’elément chauffant à une sur-chauffe, le thermostat agit

et coupe l’alimentation électrique de la résistance.

Après l’opération d’un des deux thermostats, il suffit de les réarmer

en appuyant simplement sur le bouton adéquoit situé à gauche de

l’élément chauffant.

Retirer le capuchon plastique et appuyer sur le bouton (un léger «

clic » doit se produire).

AVANT LE REARMEMENT, IL FAUT ATTENDRE LE

REFROIDISSEMENT DE L’APPAREIL, ET LA CAUSE DU

DECLENCHEMENT DES THERMOSTATS, IDENTIFIEE ET

RECTIFIEE.

Si le thermostat continue de se déclencher, consulter un électricien

qualifié ou le service technique de Cole-Parmer.

9

Entretien et maintenance

Un entretien régulier prolonge la durée de vie de l’appareil et assure

son bon fonctionnement.

Pour des raisons de sécurité, l’entretien et la maintenance de l’appareil

y compris le nettoyage ou le remplacement de composants doivent

être effectués par des personnes qualifiées.

IMPORTANT:

Débrancher l’appareil avant toute operation d’entretien ou de

maintenance.

Nettoyage

Liste des pièces detachées

Les pièces détachées suivantes sont disponibles auprès de votre

revendeur.

Référence

Bouilleur

Réfrigérant

Elément chauffant complet avec thermostat

Thermostat

Jeu de colliers de fixation de l’élément chauffant

(collier métallique, joint caoutchouç insert graphite et boulons)

7.754.21

7.753.61

7.754.22

7.754.23

7.754.24

Après un certain temps de fonctionnement, du tartre peut se déposer

à l’intérieur du bouilleur. Afin d’assurer le bon fonctionnement de

l’appareil, le tartre devra être éliminé régulièrement.

L

’intervalle de temps entre 2 nettoyages dépend de la dureté de l’eau

d’alimentation. Dans les régions où l’eau est très dure, il peut s’avérer

nécessaire de nettoyer le distillateur toutes les semaines. Dans les

régions où l’eau est plus douce, plusieurs semaines peuvent s’écouler

entre deux opérations de nettoyage.

Le tartre se dissout parfaitement dans une solution d’acide formique

diluée à 10%. Certaines solutions de détartrage à usage domestique

peuvent également être utilisées.

ATTENTION !

Il faut toujours manipuler les acides avec prudence. Des

vêtements de protection, des gants et des masques faciaux

devront être utilisés lors des opérations de nettoyage.

1. Eteindre l’interrupteur de l’élément chauffant, débrancher

l’alimentation électrique et laisser refroidir l’eau dans le bouilleur.

2. Fermer le robinet d’alimentation d’eau.

3. Ouvrir le robinet du contrôleur de niveau pour vidanger le

bouilleur. Fermer le robinet.

4. Par l’entonnoir du contrôleur de niveau, verser environ 1 litre d’une

solution d’acide formique diluée à 10%.

Remplir le bouilleur jusqu’ au niveau de fonctionnement, afin

d’éviter que la solution acide ne se déverse à l’égout par le tuyau

d’évacuation.

Garantie

Cole-Parmer Ltd. garantit cet appareil de tout défaut de fabrication

ou de montage pour une utilisation normale en laboratoire et ce

durant trois (3) ans. En cas de défaillance, Cole-Parmer s’engage à

remplacer gratuitement la pièce défectueuse ou l’appareil si ce

dernier était déclaré irréparable.

Cette garantie ne s’applique pas si les dommages sont dus à un

incendie, un accident, une inondation, une négligence ou une

utilisation inadéquate. La garantie ne s’applique pas non plus si

l’appareil n’a pas été installé correctement, réparé par une personne

non qualifiée ou modifié à l’aide de pièces détachées ne provenant

pas de la société Cole-Parmer.

La garantie n’inclut pas l’élément chauffant qui est, quant à lui,

garanti 1 an.

5. Laisser agir l’acide qui doit dissoudre les dépôts de tartre. Le temps

nécessaire dépend du degré d’entartrage.

6. Ouvrir le robinet afin de vidanger complètement le bouilleur.

ATTENTION !

Si la solution de détartrage n’a pas été complètement

neutralisée, l’eau de vidange peut s’avérer être fortement acide.

Prendre les précautions nécessaires au niveau de l’évacuation.

7. Fermer le robinet et remplir le bouilleur d’eau froide. Vidanger le

bouilleur en ouvrant le robinet. Répéter 2 à 3 fois cette opération

de rinçage.

8. Recommencer à distiller l’eau, une fois le bouilleur rempli.

Le distillat obtenu pendant les dix premières minutes qui suivent

une opération de rinçage ne devra pas être utilisé.

Il est important de nettoyer regulierement l’appareil.

10

Incidents de fonctionnement

En cas d’incidents de fonctionnement, consulter le tableu ci-dessous.

Dans le cas où ces informations ne permettraient pas d’identifier

et de résoudre le problème constaté, consulter votre fournisseur ou

les services techniques de Cole-Parmer.

Nature de l’Incident Cause Solution

1. Le niveau d’eau dans le a) Alimentatation en eau insuffisante

bouilleur est trop bas.

ex: l’élément chauffant n’est

plus immergé.

2. Le niveau d’eau dans le a) Alimentation en eau excessive.

ex: l’eau bouillante monte vers

le réfrigérant.

3. L’eau en ébulliton s’écoule du

bouilleur vers l’évacuation.

4. La température du distillat est

élevée (supérieure à 50°C).

b) Robinet du contrôleur de niveau

ouvert.

b) L’évacuation de l’eau se fair mal.bouilleur est trop haut.

a) L’évacuation du distillat vers le

réservoir se fait mal.

b) L’évent sur le réfrigérant est

obstrué.

c) Alimentation en eau insuffisante.

Débit d’eau de refoidissement.

insuffisant.

a) Augmenter le débit jusqu’ à 60

litres/heure environ.

b) Fermer le robinet.

a) Reduire le débit jusqu’ à 60 litres/

heure environ.

b) Vérifier que le tuyau d’évacuation

ne présente aucun coude.

a) Vérifier que le tube reliant

l’orifice d’évacuation du distillat

au réservoir ne présente aucun

coude.

b) Déboucher l’évent.

c) Augmenter le débit jusqu’ à 60

litres/heure environ.

Augmenter le débit jusqu’ à 60

litres/heure environ.

5. Débit du distillat inférieur à

4 litres/heure.

6. Mauvaise qualité du distillat.* Bouilleur entartré. Nettoyer le bouilleur.

7. L’élément chauffant ne marche pas. a) Elément chauffant défectueux.

Déclenchement persistant du RCD Intégrité du thermoplongeur Remplacez le RCD

* Lorsque la qualité du distillat est contrôlée par des mesures de PH ou de conductivité, les valeurs

mesurées sont dépendantes de la température et de la préssence d’oxyde de carbone en solution.

Alimentation électrique inférieure à

220 volts.

b) Thermostats défectueux.

c) Fusible de la prise.

a) Remplacer l’élement chauffant.

b) Remplacer le thermostat

c) Remplacer le fusible.

11

W4000 e W4000/EURO

ItalianoMerit Water Still

Pulsanti di

azzeramento

del termostato

Riscaldatore

Guarnizione

Condensatore

Caldaia

Guarnizioni

e flangia

Uscita superiore del condensatore

Sfiato Uscita

distillato

water still Merit W4000

Entrata acqua di

raffreddamento

Controllo del livello

costante

Verso lo scarico

Rubinetto di

arresto

Cinghie

Figura 1 Montaggio generale

Prima dell'uso

Qualora il dispositivo non venga utilizzato nel modo descritto nel

presente manuale, la protezione fornita dal dispositivo stesso può

risultarne pregiudicata.

N.B. Il Merit Water Still è classificato come “Apparecchiatura a

collegamento permanente” e deve essere collegata

all’alimentazione elettrica da un elettricista qualificato nel modo

descritto nella sezione di installazione elettrica del presente

manuale.

Il Merit Water Still è stato progettato per funzionare nelle seguenti

condizioni:

❖ Da utilizzarsi esclusivamente in ambienti chiusi

❖ Temperatura ambiente compresa tra +5°C e +40°C

❖ Altitudine fino a 2.000 m

❖ Umidità relativa non superiore all'80%

❖ Fluttuazioni della tensione di alimentazione di rete non superiori a

±10% della potenza nominale

❖ Categoria di sovratensione II CEI60364-4-443

❖ Grado di inquinamento 2 CEI664.

12

Posizione

Il Merit Water Still può essere montato a parete o su banco. Scegliere

una posizione comoda con accesso alle seguenti utenze:-

Alimentazione elettrica

Prima di effettuare il collegamento, assicurarsi dell'idoneità

dell'alimentazione di linea. Il Merit Water Still W4000 è adatto ad

alimentazioni di potenza nominale di 3kW, 220-240V, 50/60Hz~

monofase. W4000/Euro è adatto ad alimentazioni di potenza nominale

di 3.5kW, 200-240V, 50/60Hz~ monofase. Forniture dovrebbero essere

dotati di un interruttore differenziale 30mA circuito disgiuntore.

Alimentazione dell'acqua

Alimentazione dell'acqua fredda in grado di fornire una portata

minima di 60 l/ora.

Scarico

Scarico dell'acqua usata posto sotto il livello dello Still in modo che il

tubo di scarico cada lontano senza attorcigliarsi o piegarsi, in modo da

consentire un flusso uniforme e senza strozzature.

Serbatoio

Sotto lo Still occorre posizionare un serbatoio di raccolta del distillato.

della caldaia, facendo in modo che il lato piatto della

flangia sia rivolto verso la caldaia.

ii) Prendere l'inserto in plastica e collocarlo attorno al tubo in

vetro e nella flangia metallica. Tirare la flangia e l'inserto

verso l'estremità del tubo in vetro in modo che premano sul

vetro.

iii) Collocare la guarnizione in gomma sopra le bobine del

riscaldatore e poi inserire l'elemento riscaldatore attraverso il

tubo in vetro conico e nella caldaia.

iv) A questo punto, fissare il riscaldatore usando i tre bulloni

forniti. Non serrare eccessivamente.

4. Collocare il gruppo caldaia e riscaldatore nel ‘supporto’ del

cavalletto. Assicurarsi che il rubinetto di arresto sulla caldaia sia

rivolto verso la parte anteriore. Alimentare il cavo elettrico del

riscaldatore attraverso il foro posto nella base del cavalletto di

supporto. Fissare con le due cinghie fornite.

5. Assicurarsi che l’O-ring di tenuta e l’O-ring ring di stabilizzazione

siano correttamente posizionati, così come illustrato in Figura 3.

Montare il condensatore WC48/M2 sul tubo del vapore della

caldaia. Assicurarsi che il tubo di uscita del distillato del

Figura 3

Bulloni

Tubo in

vetro

conico

Figura 2 Montaggio della flangia

Flangia

metallica

Inserto

in

plastica

Guarniz-

ione in

gomma

Riscaldatore

Montaggio

1. Disimballare il Water Still ed individuare i seguenti componenti:-

Q.tà Componente N. catalogo

1 W4000/S

Cavalletto di supporto con 2 cinghie per la

1 W4000/B

caldaia Caldaia

1 WC48/M2

Condensatore

1 A6/6 (240V)

Riscaldatore

oppure

1 W4000/HK

Kit tubo flessibile

1

Kit guarnizioni W4000/GK

2. Prendere il cavalletto di supporto e collocarlo nella posizione

desiderata. Notare che vi sono due fori per viti per il montaggio a

parete.

Se procedete con il montaggio al muro, assicuratevi di

usare appropriati fissanti che possono sostenere un peso

minimo di 28 Kg. Se avete qualche dubbio, affidatevi ai

consigli di un esperto.

3. Prendere la caldaia W4000/B, il riscaldatore ed il kit guarnizione

W4000/GK. Montare il riscaldatore nella caldaia come illustrato

nella Figura 2.

i) Inserire i 3 bulloni forniti nei fori nella flangia di metallo e

posizionare la flangia di metallo sul tubo di vetro affusolato

A6/6/EURO (220V)

L’uscita dell’acqua di

raffredda-mento

Condensatore

L’O-ring di tenuta

Il tubo del vapore

L’O-ring di

stabilizzazione

condensatore sia rivolto verso le parti anteriore e di

raffreddamento parallele all'unità.

6. Dal kit del flessibile prendere il flessibile in plastica con foro da 8

mm. di 225 mm. di lunghezza montato con i connettori a filetti

alle estremità. Con riferimento alla Figura 1, avvitare un'estremità

del tubo flessibile all'uscita superiore del condensatore e l'altra al

filetto in vetro sul controllo del livello costante. Se lo Still è stato

montato nel modo corretto, il flessibile deve estendersi

agevolmente e senza sollecitazioni.

7. Prendere il tubo flessibile in plastica con foro da 16 mm. di 1000

mm. di lunghezza e collegarlo con cautela all’uscita del controllo

di livello costante. Per un collegamento più agevole, scaldare

prima il tubo flessibile in acqua calda.

Fissare con una fascetta.

8. Portare l’estremità libera della tubatura allo scarico,

assicurandosi che cada lontano dallo Still senza attorcigliarsi o

piegarsi, in modo da consentire un flusso uniforme dell’acqua.

9. Assicurarsi che il rubinetto di arresto sul controllo costante di

livello sia chiuso.

Il tubo di

uscita

13

10. Collegare l'entrata inferiore del condensatore dell'alimentazione

dell'acqua fredda. Per un fissaggio agevole al condensatore, si

fornisce un connettore a filetto in plastica.

Scegliere tubature di buona qualità ed assicurarsi che tutti i

raccordi siano fissati con fascette stringitubo.

Assicurarsi dell'assenza di sollecitazioni sul connettore o sul

flessibile.

11. Collegare l’uscita del distillato sul condensatore ad un serbatoio di

raccolta idoneo.

12. Attivare la condotta di acqua e verificare che non vi siano perdite,

quindi chiudere la condotta dell'acqua.

Installazione elettrica

IL DIPOSITIVO DEVE ESSERE COLLEGATO A TERRA!

L’installazione elettrica deve essere realizzata esclusivamente da un

elettricista

L’apparecchiatura viene fornita con un cavo circolare a triplo nucleo

flessibile da 1,7 m. secondo specifiche CMA 3183 TQ. I conduttori sono

da 1,5 mm2 secondo BS 6360 Classe 5 isolati con E.P.R. IL rivestimento

esterno è resistente ad 85°C tipo C.S.P. secondo HOFR, BS 6500 Tabella

9.

Il collegamento alla rete di alimentazione elettrica, deve essere tramite

un interruttore bipolare 30mA isolamento RCD circuito con una

continua capacità di trasporto di corrente di 15A a 250V e protezione

contro le sovracorrenti di 15A, 250V.

Questi dispositivi devono essere posizionati vicino all’apparecchiatura

e chiaramente contrassegnati - “Dispositivo di scollegamento per Merit

Water Still”

Collegare l’alimentazione di linea notando come i cavi nel connettore

dello strumento siano codificati secondo il colore:-

Sostituzione del cavo di rete

Nel caso in cui occorra sostituire il cavo di rete, occorre usare

esclusivamente cavi di rete di ricambio preparati ad hoc da

Cole-Parmer.

qualificato.

Marrone - Sotto tensione

Blu - Neutro Giallo/

Verde - Terra

Avvertimento caldo

Alcune parti del prodotto possono riscaldarsi durante

l'uso e sono contrassegnate in modo chiaro con

etichette di avviso di elementi caldi. Non toccare queste

parti.

Diagramma del circuito

S N

~240V

(S)

Interruttore

(solo W4000/EURO)

(S)

Termostato

Lampada

(S)

Termostato

Funzionamento

1. Accendere l’alimentazione dell'acqua fredda e regolare il flusso su

circa. 60 l/ora.

Nota: si consiglia vivamente di misurare la portata; la

mancata osservanza di tale norma potrebbe dare luogo a

infortuni causati dall'acqua calda in uscita dallo Still. In caso

di indisponibilità di un flussometro, è possibile realizzare una

semplice misurazione usando un beaker da 1L. Occorre

riempiere il beaker completamente per cinque volte nel giro

di cinque minuti.

Osservare che l’acqua scorra attraverso il condensatore e nella

caldaia. Attendere fino a che la caldaia non abbia raggiunto il

corretto livello di funzionamento ed assicurasi che l’acqua in

eccesso scorra liberamente verso lo scarico.

2. Accendere l’alimentazione elettrica all’elemento riscaldatore con

l'interruttore di isolamento di rete.

Per la versione W4000/EURO, accendere l’interruttore posto sul

riscaldatore.

3. Dopo qualche minuto, l’acqua inizierà a bollire ed il distillato

emergerà dal condensatore. Con recipienti in vetro nuovi, o dopo

la pulizia, si consiglia di lasciarlo scorrere per circa 30 minuti prima

di iniziare la raccolta.

4. Per spegnere lo Still, prima spegnere l’elemento riscaldatore ma

lasciare che l’acqua continui a scorrere per ulteriori 10 minuti in

modo che lo Still si raffreddi.

ATTENZIONE!

Non usare questa apparecchiatura per distillare liquidi che non

siano acqua.

Interruttori di sicurezza

Il Merit Water Still è protetto da due interruttori di sicurezza:

Termostati del riscaldatore della caldaia

Se il livello dell’acqua della caldaia scende e lascia

scoperto l’elemento, entreranno in funzione i

termostati ed interromperanno l’alimentazione

elettrica all’elemento.

Dopo il funzionamento di uno o l’altro dei termostati, è possibile

ripristinare il funzionamento normale azzerando i termostati

mediante i rispettivi pulsanti di azzeramento montati sul coperchio

dell’estremità del riscaldatore.

Togliere il coperchio in plastica nero e poi premere il pulsante: se il

termostato era entrato in funzione, si udrà un leggero scatto.

Prima di azzerare uno o l’altro dei termostati, occorre far

raffreddare completamente lo Still ed individuare ed

eliminare la causa dell’attivazione degli interruttori.

Se i termostati continuano ad entrare in funzione, consultare un

elettricista qualificato o il Servizio di assistenza tecnica di Cole-Parmer.

Cura e manutenzione

Elemento

(S) Denota componente fondamentale di sicurezza.

14

T

Flangia del

riscaldatore

N.B. Prima di iniziare qualsiasi intervento di manutenzione, pulizia o

guasto, occorre isolare l’apparecchiatura dall'alimentazione

elettrica di rete. Solo personale qualificato idoneo deve realizzare

queste operazioni.

Occorre usare esclusivamente parti di ricambio fornite o approvate da

Cole-Parmer o dal suo agente. Il montaggio di parti non approvate

potrebbe impattare sulle prestazioni o sulla sicurezza

dell’apparecchiatura.

Manutenzione

In ragione della natura di queste parti, occorre controllare

periodicamente la qualità dei connettori e dei flessibili in plastica. Essi

non devono presentare alcun segno di sollecitazione. Sia i flessibili che i

connettori devono essere intatti e privi di criccature. Nel caso in cui si

rilevino eventuali danni a queste parti, occorre spegnere

immediatamente lo Still, così come spiegato nella sezione

“Funzionamento” del presente manuale, e non tornare a utilizzarlo se

non dopo aver sostituito queste parti. Per i codici d’ordine, consultare la

sezione “Lista delle parti di ricambio” del presente manuale.

Pulizia

Durante un certo periodo di funzionamento, all’interno della caldaia si

depositeranno accumuli di incrostazioni. Per ottenere le prestazioni

ottimali dallo Still, occorre eliminare regolarmente le incrostazioni.

L’intervallo di tempo tra le pulizie dipende molto dalla durezza

dell’acqua e dall’uso. Le apparecchiature che sono usate

frequentemente e con acqua dura potrebbero necessitare di una pulizia

settimanale, mentre per quelle che usano acqua dolce potrebbe essere

sufficiente una pulizia ogni qualche settimana.

Nota: le incrostazioni pesanti riducono la qualità dell’acqua distillata

e possono diminuire la durata dell’elemento riscaldatore.

È possibile eliminare le incrostazioni dal Merit Water Still senza dover

smontare il recipiente in vetro seguendo queste istruzioni insieme con

le normative sul Controllo delle sostanze pericolose per la salute

(Control of Substances Hazardous to Health- COSHH) 1988.

1. Disinserire l'alimentazione elettrica allo Still e lasciarlo raffreddare

completamente.

7. Aprire il rubinetto di arresto e fare scaricare la caldaia.

Nota: se l’acido nella caldaia non è stato completamente

neutralizzato, il liquido che scorre nello scarico potrebbe essere

altamente acidico. Occorre osservare tutte le

necessarie attorno allo scarico e seguire tutte le procedure di

controllo dell’eventuale effluente.

8. Chiudere il rubinetto di arresto, accendere l’alimentazione

dell’acqua e far riempire la caldaia di acqua fredda. Spegnere

l’alimentazione dell’acqua, aprire nuovamente il rubinetto di arresto

e far scaricare la caldaia. Ripetere questa operazione per tre volte.

9. A questo punto, è possibile riavviare il Merit Water Still secondo le

istruzioni fornite nella sezione “Funzionamento” del presente

manuale. Nota: il cavalletto e le superfici esterne del recipiente in

vetro devono essere puliti usando un panno umido imbevuto in una

soluzione detergente delicata.

precauzioni

Lista di parti di ricambio

I seguenti componenti sono disponibili presso la maggior parte dei

fornitori di materiale da laboratorio. In caso di difficoltà, contattare

Cole-Parmer.

Cat. N.

Caldaia

Condensatore

Riscaldatore (completo di termostati) 240V

(completo di termostati) 220V

Set di accessori di fissaggio per il riscaldatore

(flangia, guarnizione, inserto e bulloni)

Kit tubo flessibile

W4000/B

WC48/M2

A6/6

A6/6/EURO

W4000/GK

W4000/HK

2. Spegnere l'alimentazione dell’acqua di raffreddamento.

3. Aprire il rubinetto di arresto sul controllo di livello costante e far

scaricare completamente la caldaia, poi chiudere il rubinetto di

arresto.

4. Accendere l’alimentazione dell’acqua di raffreddamento e riempire

la caldaia fino a circa la metà del suo livello di funzionamento

normale. Spegnere l’alimentazione dell’acqua.

5. Aggiungere delicatamente 1 litro di 10% soluzione di acido

formico o di anticalcare per pentolini nell’imbuto aperto del

controllo di livello costante. Non usare acidi forti come l’acido

cloridrico, in quanto potrebbe provocare una grave corrosione

dell’elemento di riscaldamento metallico.

ATTENZIONE!

MANEGGIARE SEMPRE GLI ACIDI CON GRANDE ATTENZIONE.

DURANTE LE OPERAZIONI DI ELIMINAZIONE DELLE INCROSTAZIONI,

OCCORRE INDOSSARE ABBIGLIAMENTO PROTETTIVO, GUANTI E

MASCHERINA PER IL VOLTO. ELIMINARE IMMEDIATAMENTE

EVENTUALI PERDITE DI ACIDO.

Accendere l’alimentazione dell’acqua e riempire la caldaia fino al livello

di funzionamento normale. L’acqua farà scorrere l’acido nella caldaia.

Quando il livello nella caldaia è leggermente sotto quello di troppopieno,

occorre spegnere l’alimentazione dell’acqua.

6. Lasciare l’acido nella caldaia in modo che sciolga le incrostazioni.

Questa operazione potrebbe richiedere un tempo variabile a

seconda della quantità di incrostazioni presenti.

Garantie

Cole-Parmer Ltd. garantisce che questo strumento è esente da difetti di

materiali e lavorazione, se usato in normali condizioni di laboratorio, per

un periodo di tre (3) anni. In caso di richiesta giustificata,

Cole-Parmer sostituirà qualsiasi componente difettoso o l’apparecchio

gratuitamente.

La presente garanzia NON si applica in caso di danni causati da incendio,

incidente, uso improprio, negligenza, regolazione o riparazione

incorretta, danni causati da installazione, adattamento, modifica,

installazione di parti non approvate o riparazione realizzate da

personale non autorizzato.

Questa garanzia non comprende l'elemento riscaldante che è

garantita solo per 1 anno.

15

Ricerca guasti

In caso di difficoltà di funzionamento del Merit Still, consultare le seguenti note.

Nel caso in cui queste non riescano ad individuare ed eliminare il guasto, si consiglia di chiedere aiuto al proprio

rivenditore o al Servizio di assistenza tecnica di Cole-Parmer.

Nota - La ricerca guasti deve essere realizzata esclusivamente da persone idoneamente preprarate.

Sintomo Causa Rimedio

1. Il livello dell'acqua nella caldaia è troppo

BASSO, ad es. riscaldatore in vista.

2. Il livello dell’acqua nella caldaia è troppo

ALTO. ad es. acqua bollente

che si solleva nel condensatre.

3. L’acqua nella caldaia viene “pompata”

fuori dalla caldaia per scaricare.

alto, ad es. - sopra i 50°C.

a) Fornire acqua di alimentazione/raffreddamento

è insufficiente.

b) Rubinetto di arresto sulla caldaia

inavvertitamente lasciato aperto.

a) Fornire acqua di alimentazione/raffreddamento

è eccessivo.

b) Il flusso dell’acqua di scarico

si restringe.

a) La tubatura proveniente dall’uscita del distillato

del condensatore al serbatoio è ristretta..

attorcigliarsi o piegarsi.

b) Lo sfiato sull’uscita del distillate del condensatore

è bloccato.

c) Fornire acqua di alimentazione/raffreddamento è

insufficiente.

Il flusso dell’acqua di raffreddamento è insufficiente.

circa 60 litri/ora.

a) Aumentare la portata dell’acqua a

circa 60 litri/ora.

b) Chiudere il rubinetto di arresto.

a) Ridurre la portata dell’acqua a

circa 60 litri/ora.

b) Assicurarsi che la tubatura di scarico cada

liberamente.

a) Assicurarsi che la tubatura cada

liberamente sul serbatoio senza

b) Eliminare l’ostruzione.

c) Aumentare la portata dell’acqua a

circa 60 litri/ora.

Aumentare la portata dell’acqua a4. La temperatura del distillato è

5. Velocità del distillato inferiore a

4 litri/ora.

6. Qualità del distillato scadente*. Caldaia molto incrostata. Pulire la caldaia.

7. Riscaldatore fuori uso. a) Riscaldatore bruciato.

Scatto persistente dell'RCD L'integrità del riscaldatore Sostituire l'RCD

Tensione di rete bassa.

Flusso dell’acqua di raffreddamento eccessivo.

b) Fusibile elettricità di rete bruciato.

c) Termostato azionato.

-

Ridurre a 60 litri/ora.

a) Sostituire il riscaldatore.

b) Sostituire fusibile.

c) Azzerare.

*La qualità del distillato quando è stabilita dal pH o dalla conduttività elettrica è molto influenzata dalla temperatura e dalla presenza di

anidride carbonica assorbita.

16

Alambique de agua Merit

W4000 & W4000/EURO

Espano~l

Botones de reajuste de

temperatura

Calefactor

Salida

Condensador

Caldera

Juntas y

brida

Salida superior del condensador

Respiradero Salida de

destilado

water still Merit W4000

Entrada de agua de

refrigeración

Control de nivel

constante

Para evacuar

Llave de paso

Correas

Figura 1 Montaje general

Antes del uso

Si el equipo no se utiliza de la forma descrita en este manual, se

puede reducir la protección que proporciona el equipo.

N.B. El alambique de agua Merit se clasifica como “Equipo

conectado permanentemente” y debe conectarse a un suministro

eléctrico por un electricista cualificado de la forma descrita en la

sección de instalación eléctrica de este manual.

El alambique de agua Merit está diseñado para utilizarse para las

siguientes condiciones:

❖ Sólo para uso el interior

❖ Intervalo de temperatura ambiente +5°C a +40°C

❖ Altitud hasta 2.000m

❖ Humedad relativa no superior a 80%

❖ Fluctuación de voltaje del suministro eléctrico no superior a

±10% del voltaje nominal

❖ Categoría de sobrevoltaje II IEC60364-4-443

❖ Nivel de contaminación 2 IEC664

17

Colocación

El alambique de agua Merit se puede colocar en la pared o en una

mesa. Seleccione una ubicación adecuada que tenga acceso a los

servicios siguientes:

Suministro eléctrico

Antes de realizar la conexión, asegúrese de que el suministro de red

sea adecuado. El alambique de agua Merit W4000 se puede utilizar con

suministros con un régimen de 3kW, 220-240V, 50/60Hz~ monofásico.

W4000/Euro es adecuado para suministros con un régimen de 3.5kW,

200-240V, 50/60Hz~ monofásico. El producto debe ser cabido con a

30mA RCD disyuntor.

Suministro de agua

El suministro de agua debe ofrecer un caudal mínimo de 60 litros/hora.

Desagüe

El desagüe de aguas residuales debe situarse debajo del nivel del

alambique, de tal forma que el tubo de desagüe caiga sin que tenga

dobleces ni pliegues y permita un caudal sin restricciones.

Depósito

Es necesario situar un depósito de recogida de destilado debajo del

alambique.

Tornillos

ii) Coja la pieza de plástico y colóquela alrededor del tubo de

vidrio y dentro de la brida metálica. Tire de la brida e insértela

hacia el extremo del tubo de vidrio, de tal forma que presione

sobre el vidrio.

iii) Coloque la junta de goma sobre las bobinas del calefactor y

luego inserte el elemento calefactor a través del tubo de

cristal y dentro de la caldera.

iv) Fije el calefactor con los 3 tornillos suministrados. No los

apriete demasiado.

4. Coloque la caldera y la unidad del calefactor en el bastidor del

soporte. Asegúrese de que la llave de paso de la caldera está

orientada hacia la parte delantera. Pase el cable eléctrico del

calefactor por el orificio situado en la base del soporte de apoyo.

Fíjelo con las 2 correas suministradas.

5. Asegúrese de que la junta tórica de sellado y la junta tórica

estabilizadora estén correctamente colocadas, según se muestra

en la Figura 3. Monte el condensador WC48/M2 montándolo en el

tubo de vapor de la caldera. Asegúrese de que tubo de salida de

destilado del condensador está orientado hacia la parte delantera

y que la salida de refrigeración esté paralela a la unidad.

Figura 3

Condensador

La salida de

refrigeración

de aqua

Tubo de

vidrio cónico

Figura 2 Montaje de la brida

Brida

metálica

Pieza

plástico

de

Junta

de

goma

Calefactor

Montaje

1. Desembale el alambique de agua e identifique los siguientes

componentes:

Cant. Componente Nº catálogo

1 W4000/S

Soporte de apoyo con dos correas de

1 W4000/B

caldera Caldera

1 WC48/M2

Condensador

1 A6/6 (240V)

Calefactor

o

1 W4000/HK

Kit de tubos

1

Kit de juntas W4000/GK

2. Coloque el soporte de apoyo en un lugar adecuado. Los dos

orificios roscados están destinados al montaje en pared.

En caso de que lo fije a una pared, debe asegurarse de

que utiliza sujeciones adecuadas que puedan soportar un

peso mínimo de 28 kg. Si tiene cualquier duda, consulte a

un profesional.

3. Coja la caldera W4000/B, el calefactor y el kit de juntas W4000/GK.

Monte el calefactor en la caldera según se muestra en la Figura 2.

i) Inserte los 3 pernos suministrados en los orificios de la brida

metálica y sitúe la brida metálica sobre el tubo cónico de

vidrio de la caldera, asegurándose de que el lado plano de la

brida mire hacia la caldera.

A6/6/EURO (220V)

La junta

tórica de

sellado

El tubo de vapor

La junta tórica

estabilizadora

6. En el kit de tubos, coja el tubo de plástico de 225 mm de longitud

y 8 mm de diámetro que tiene las uniones roscadas en los dos

extremos. Según la Figura 1, rosque un extremo del tubo en la

salida superior del condensador, y el otro extremo en la rosca de

vidrio del control de nivel constante. Si el alambique está montado

correctamente, el tubo debe llegar cómodamente, sin tensiones.

7. Coja el tubo de plástico de 1000 mm de longitud y 16 mm de

diámetro y conéctelo con cuidado a la salida del control de nivel

constante. Para facilitar la conexión, caliente el tubo con agua

caliente.

Fije con una correa de unión.

8. Pase el extremo libre del tubo al desagüe, y asegúrese de que cae

del alambique sin dobleces ni pliegues que dificulten el caudal de

agua.

El tubo

de salida

18

9. Asegúrese de que la llave de paso del control de nivel constante

está cerrada.

10. Conecte la entrada inferior del condensador hasta el suministro de

entrada de agua fría. Se suministra un conector roscado de

plástico para facilitar la conexión al condensador.

Asegúrese de que no haya tensión en el conector o el tubo.

Seleccione tubos de buena calidad y asegúrese de que todas las

conexiones están fijadas con abrazaderas de tubos.

11. Conecte la salida de destilado del condensador a un depósito de

recogida adecuado.

12. Active el suministro de agua y compruebe que no haya fugas; a

continuación, desactive el suministro de agua.0

Instalación eléctrica

EL EQUIPO DEBE CONECTARSE A TIERRA.

La instalación eléctrica sólo debe realizarse por un electricista

capacitado.

El equipo se suministra con un cable circular flexible de triple núcleo

de 1,7 m en conformidad con las especificaciones CMA 3183 TQ. Los

conductores son de 1,5mm2 con aislamiento E.P.R, en conformidad

con las especificaciones BS 6360 Clase 5. La funda exterior es de tipo

C.S.P resistente a una temperatura de 85°C. en conformidad con las

especificaciones HOFR, BS 6500 Tabla 9.

La conexión a la red de alimentación eléctrica, debe ser a través de

un 30mA bipolar aislamiento RCD interruptor de circuito con una

capacidad de corriente continua de 15A a 250V y protección contra la

sobretensión de 15A, 250V.Estos dispositivos deben montarse cerca

del equipo, y deben tener la marca - “Dispositivo de desconexión

para el alambique de agua Merit”

Conecte el equipo al suministro de red y asegúrese de que los hilos

del cable del instrumento están identificados según los siguientes

colores:

Marrón - Corriente

Azul - Neutro

Amarillo/Verde - Toma de tierra

Sustitución del cable de alimentación

Si es necesario sustituir el cable de alimentación, sólo debe utilizarse

el cable de alimentación de recambio especialmente preparado que

suministra Cole-Parmer.

Diagrama de circuitos

C N

~240V

(

S)

Interruptor

(sólo W4000/EURO)

)

(S

ermostato

T

Lámpara

)

(S

ermostato

T

Alcune parti del prodotto possono riscaldarsi durante

l'uso e sono contrassegnate in modo chiaro con

etichette di avviso di elementi caldi. Non toccare queste

parti.

Funcionamiento

1. Abra el suministro de agua fría y ajuste el caudal a unos 60 l/h.

N.B.: Se recomienda encarecidamente medir el caudal; de lo

contrario, el agua caliente que sale del alambique podría producir

lesiones. Si no hay disponible un alambique de agua, se puede

realizar una medida sencilla con un recipiente de 1 litro. El

recipiente se debe llenar completamente cinco veces durante un

período de 5 minutos.

Verifique que el agua circula a través del condensador hasta el interior

de la caldera. Espere hasta que la caldera haya alcanzado su nivel

operativo correcto y asegúrese de que el exceso de agua se vacía

libremente.

2. Encienda el interruptor de corriente para conectar suministro

eléctrico en el elemento calefactor.

Para la versión W4000/EURO, encienda el interruptor situado en el

calefactor.

3. Tras unos minutos, el agua empezará a hervir y el destilado saldrá

del condensador. Con cristalería nueva o después de la limpieza,

se recomienda dejar que purge durante unos 30 minutos antes de

iniciar la recogida.

4. Para desconectar el alambique, primero apague el elemento

calefactor pero deje circular el agua de refrigeración durante

otros 10 minutos para que se enfríe el alambique.

ADVERTENCIA:

No utilice este equipo para destilar otro líquido que no sea agua.

Disyuntores de seguridad

El alambique de agua Merit está protegido mediante dos disyuntores

de seguridad:

Termostatos del calefactor de la caldera

Si el nivel del agua de la caldera disminuye y deja al

descubierto el elemento, se activarán los termostatos y

desconectarán el suministro eléctrico al elemento.

Después de que actúe uno de los termostatos, el funcionamiento

normal se puede reanudar reajustando los termostatos mediante sus

botones de reajuste correspondientes situados en el extremo de la

cubierta del calefactor.

Extraiga la cubierta de plástico negra y luego presione el botón. Se

oirá un ligero 'clic' si se ha accionado el termostato.

Antes de reajustar el termostato, se debe dejar enfriar

por completo el alambique, e identificar y solucionar la

causa del accionamiento del disyuntor.

Si los termostatos siguen actuando, póngase en contacto con un

electricista cualificado o con el Departamento de Servicio Técnico de

Cole-Parmer.

Elemento

(

S) Indica componente crítico de seguridad.

T

Brida del

calefactor

Cuidados y mantenimiento

N.B. Antes de realizar una tarea de mantenimiento, limpieza o

búsqueda de fallos, se debe desconectar el equipo del suministro

eléctrico. Estas operaciones se deben realizar únicamente por

personal debidamente cualificado.

Sólo se deben utilizar piezas de recambio suministradas o autorizadas

por Cole-Parmer o su agente. La instalación de piezas no autorizadas

puede afectar al rendimiento o a la seguridad del equipo.

19

Mantenimiento

Debido a la naturaleza de estas piezas, es necesario comprobar

periódicamente la calidad de los conectores y los tubos de plástico. No

deben existir tensiones en los conectores ni en los tubos, y no deben

presentar grietas. Si se observan daños en estas piezas, se debe

desconectar inmediatamente el alambique, según se indica en la

sección “Funcionamiento” de este manual, y no se debe utilizar hasta

que se sustituyan estas piezas. Consulte la “Lista de piezas de recambio”

en este manual para los códigos de pedido.

Limpieza

Tras un período de funcionamiento, se depositarán incrustaciones en el

interior de la caldera. Para obtener un rendimiento óptimo del

alambique, se deberá eliminar las incrustaciones a intervalos regulares.

7. Abra la llave de paso y deje que se vacíe la caldera.

Nota: Si el ácido de la caldera no se ha neutralizado

completamente, el líquido vaciado puede ser muy ácido. Es

necesario seguir todas las precauciones de seguridad necesarias

en el desagüe, así como todos los procedimientos de control del

efluente.

8. Cierre la llave de paso, abra el agua y deje que se llene la caldera

con agua fría. Apague el agua, vuelva a abrir la llave de paso y deje

que se vacíe la caldera. Repita tres veces este proceso.

9. El alambique de agua Merit puede reiniciarse siguiendo las

instrucciones de la sección “Funcionamiento” de este manual.

Nota: El soporte y las superficies exteriores de la cristalería se

deben limpiar con un paño húmedo y una solución detergente

suave.

El intervalo de tiempo entre la limpieza depende en gran medida de la

dureza del agua y de la cantidad de agua utilizada. Es posible que los

alambiques que se utilicen con frecuencia en áreas de aguas duras

deban desincrustarse una vez a la semana, mientras que, en un área con

aguas blandas, pueden transcurrir varias semanas hasta que sea

necesario realizar una desincrustación.

N.B. Las incrustaciones fuertes reducirán la calidad del agua

destilada disminuirán la vida útil del elemento calefactor.

Es posible desincrustar el alambique de agua Merit sin desmontar la

cristalería. Para ello, siga las siguientes instrucciones en conformidad

con la normativa de Control de sustancias peligrosas para la salud

(COSHH)?1988.

1. Apague el suministro eléctrico del alambique y déjelo enfriar

totalmente.

2. Cierre el suministro de agua de refrigeración.

3. Abra la llave de paso del control de nivel constante y deje que se

vacíe totalmente la caldera. Cierre la llave de paso.

4. Abra el suministro de agua de refrigeración y deje que se llene la

caldera hasta la mitad aproximadamente de su nivel de

funcionamiento normal. Cierre el suministro de agua.

5. En el embudo abierto del control de nivel constante, añada con

cuidado 1 litro de solución de ácido fórmico al 10% o

desincrustador para calderas.

No utilice ácidos fuertes como ácido hidroclórico, ya que pueden

producir una corrosión fuerte en el elemento calefactor de metal.

ADVERTENCIA:

MANIPULE SIEMPRE LOS ÁCIDOS CON CUIDADO EXTREMO. ES

NECESARIO LLEVAR ROPA DE PROTECCIÓN, GUANTES Y

MÁSCARAS DURANTE EL PROCEDIMIENTO DE

DESINCRUSTACIÓN.

LIMPIE INMEDIATAMENTE EL ÁCIDO DERRAMADO.

Abra el suministro de agua y llene la caldera hasta su nivel de

funcionamiento normal. El agua hará pasar el ácido a la caldera. El

suministro de agua se debe cerrar cuando el nivel de la caldera

esté ligeramente por debajo del desbordamiento.

Lista de piezas de recambio

Los siguientes componentes pueden obtenerse de la mayoría de

proveedores de laboratorio. En caso de dificultades de obtención,

póngase en contacto con Cole-Parmer.

Nº cat.

Caldera

Condensador

Calefactor (con termostatos) 240V

(con termostatos) 220V A6/6/EURO

Juego de piezas del calefactor

(brida, junta, pieza y tornillos)

1 Kit de tubos

W4000/B

WC48/M2

A6/6

W4000/GK

W4000/HK

Garantía

Cole-Parmer Ltd. garantiza que este equipo está libre de defectos en los

materiales y la fabricación cuando se utiliza en condiciones normales

de laboratorio durante un período de tres (3) años. En caso de

presentarse una reclamación justificada, Cole-Parmer sustituirá los

componentes defectuosos o la unidad sin cargo alguno.

Esta garantía NO se aplica a los daños producidos por incendios,

accidente, uso incorrecto, negligencia, ajuste o reparación incorrectos,

daños producidos por una instalación incorrecta, adaptación,

modificaciones, montaje de piezas no autorizadas o reparación

realizada por personal no autorizado.

Esta garantía no incluye el elemento calentador que sólo está

garantizado por 1 año.

6. Deje el ácido en la caldera para disolver las incrustaciones. Es

posible que tarde en disolverlas según el grado de incrustación.

20

Localización de fallos

En caso de dificultades de funcionamiento del alambique Merit, consulte las notas siguientes.

Si estas notas no permiten identificar y solucionar el fallo, debe buscar asistencia de

su proveedor o del Departamento de Servicio Técnico de Cole-Parmer.

Nota - La localización de fallos sólo debe realizarse por personal debidamente cualificado.

Síntoma Causa Solución

1. El nivel de agua de la caldera es demasiado

BAJO. ej.: - calefactor expuesto.

2. El nivel de agua de la caldera es demasiado

ALTO. ej.: - agua hirviendo

pasa al condensador.

3. El agua de la caldera se “bombea”

fuera de la caldera y se vacía.

alto, ej.: - superior a 50°C.

5. Caudal del destilado inferior a

4 litros/hora.

6. Calidad del destilado deficiente*: Caldera con muchas incrustaciones. Limpie la caldera.

a) Suministro de agua de entrada/refrigeración

insuficiente.

b) La llave de paso de la caldera

se ha dejado abierta inadvertidamente.

a) Suministro de agua de entrada/refrigeración

excesivo.

b) Caudal de agua de desagüe

restringido.

a) El tubo que va de la salida de destilado

del condensador hasta el depósito está restringido.

b) El respiradero en la salida de destilado

del condensador está bloqueado.

c) Suministro de agua de entrada/refrigeración

insuficiente.

Caudal de agua de refrigeración insuficiente. 4. La temperatura del destilado es

Voltaje de red bajo.

Caudal de agua de refrigeración excesivo.

a) Aumente el caudal de agua a

aprox. 60 litros/hora

b) Cierre la llave de paso.

a) Reduzca el caudal de agua a

aprox. 60 litros/hora

b) Asegúrese de que el tubo de

desagüe cae libremente.

a) Asegúrese de que el tubo cae

libremente al depósito sin dobleces

ni pliegues.

b) Elimine la obstrucción.

c) Aumente el caudal de agua a aprox.

60 litros/hora

Aumente el caudal de agua a

aprox. 60 litros/hora

Reduzca el caudal a 60 litros/hora.

7. El calefactor no funciona. a) Calefactor quemado.

b) Fusible de red eléctrica fundido.

c) Accionamiento del termostato.

Desconexión permanente del interruptor diferencial La integridad del calentador Sustituir el interruptor diferencial

a) Sustituya el calefactor.

b) Sustituya el fusible.

c) Reajuste.

* La calidad del destilado determinada por pH o conductividad eléctrica está muy influida por la temperatura y la presencia de dióxido de

carbono absorbido.

21

asserdestillier-Apparat

W4000 & W4000/Euro

DeutschMerit W

Thermostat

Rückstellknöpfe

Heizung

Tülle

Kondensator

Boiler

Dichtungen

und Flansch

Oberer Auslass des Kondensators

water still Merit W4000

Öffnung Destillataustritt Laschen

Kaltwasserzufuhr

Füllstandsregler

Zum Ablauf

Absperrhahn

Abbildung 1 Allgemeiner Aufbau

Vor dem Gebrauch

Wird das Gerät nicht entsprechend dieser Anleitung betrieben, so

können die Schutzfunktionen des Geräts beeinträchtigt werden.

HINWEIS: Der Merit Wasserdestillier-Apparat gilt als ortsfestes Gerät

und muss von einem Elektrofachmann entsprechend den

Anweisungen im Kapitel „Elektrischer Anschluss“ angeschlossen

werden.

Der Merit Wasserdestillier-Apparat ist für den Einsatz unter folgenden

Bedingungen ausgelegt:

❖ Nur für den Gebrauch in Innenräumen

❖ Umgebungstemperatur zwischen +5°C und +40°C

❖ Höhe: bis zu 2000 m

❖ Relative Feuchte nicht über 80%

❖ Netzspannungsschwankungen nicht über 10%

❖ Überspannungsklasse II IEC60364-4-443

❖ Verschmutzungsgrad 2 IEC664

Einsatzbeschränkungen

Dieses Produkt entspricht den geltenden EU-Normen für

Hochfrequenzstörungen so dass ein störungsfreier Betrieb in

Verbindung mit Geräten ähnlichen Standards vorausgesetzt werden

darf. Wir können jedoch nicht gewährleisten, dass im Umfeld

betriebene Geräte diesen Anforderungen entsprechen, oder dass

keine Störungen in der Praxis auftreten werden. Bei

Verletzungsgefahr, sowie bei Gefahr von Schädigung oder Verlust

durch fehlerhafte Funktionsweise aufgrund von

Hochfrequenzstörungen (aber auch für allgemeine Informationen

bezüglich des Gebrauchs) wenden Sie sich bitte an die

Kundendienstabteilung von Cole-Parmer.

22

Aufstellung

Der Merit Wasserdestillier-Apparat kann an der Wand oder auf einem

Tisch montiert werden. Wählen Sie einen zweckmäßigen Aufstellort

der folgende Anschlüsse bietet:

Stromversorgung

Kontrollieren Sie vor dem Anschließen bitte ob die Stromversorgung

für dieses Gerät geeignet ist. Der Merit Wasserdestillier-Apparat W4000

benötigt folgende Stromversorgung: 3kW, 220-240V,

50/60Hz~ einphasig. Das Modell W4000/Euro benötigt folgende

Stromversorgung 3.5kW, 200-240V, 50/60Hz~ einphasig.

Versorgungsmaterialien sollten mit a gepasst werden 30mA RCD

Stromunterbrecher

Wasserzufuhr

Eine Kaltwasserversorgung mit einem Mindestdurchsatz von 60 l/h.

Abfluss

Ein Abwasserablauf unterhalb des Destillierapparats, sodass der

Abwasserschlauch knickfrei hängen kann ohne den Ablauf zu

beeinträchtigen.

Behälter

Unter dem Destillierapparat muss sich ein Auffangbehälter für das

Destillat befinden.

ii) Nehmen Sie den Kunststoff-Sitzring und setzen Sie ihn so

auf das Glasrohr auf, dass er in den Metallflansch reicht.

Ziehen Sie Flansch und Sitzring zusammen in Richtung

Glasrohrende, sodass beide auf das Glas drücken.

iii) Positionieren Sie die Gummidichtung auf den Heizspiralen

und setzen Sie dann das Heizelement durch das verjüngte

Glasrohr in den Boiler ein.

iv) Jetzt kann die Heizung mit den 3 beiliegenden Schrauben

befestigt werden. Schrauben nicht zu stark anziehen.

4. Setzen Sie Boiler und Heizgerät in das Gestell ein. Dabei muss der

Absperrhahn nach vorne zeigen. Führen Sie das Stromkabel des

Heizgeräts durch die Öffnung unten am Ständer ein. Sichern Sie

das Gerät mit den beiden beiliegenden Laschen.

5. Achten Sie darauf, dass die beiden O-Ringe zur Abdichtung und

Stabilisierung entsprechend Abbildung 3 richtig eingesetzt sind.

Montieren Sie nun den Kondensator WC48/M2, indem Sie ihn am

Kondensschlauch des Boilers befestigen. Achten Sie darauf, dass

der Destillataustrittschlauch des Kondensators nach vorne zeigt

und dass die Kühlaustrittsflächen parallel zum Gerät verlaufen.

Abbildung 3

Schrauben

Verjüngtes

Glasrohr

Abbildung 2 Flanschmontage

Metall-flansch

Gummi-dichtung Kunststoff-

Sitzring

Heizung

Montage

1. Packen Sie den Wasserdestillier-Apparat aus und vergleichen Sie

die Komponenten mit folgender Aufstellung:

Anz. Bauteil Katalog-Nr.

1

Ständer mit 2

1

Boiler

1

Kondensator

1

Heizung

oder

1

Schlauch-Set

1

Dichtungssatz

2. Stellen Sie den Metallständer an einem geeigneten Ort auf.

Beachten Sie die beiden Schraubenlöcher für eine evtl.

Wandmontage.

Verwenden Sie bei einer Wandmontage unbedingt

passende Aufhängeelemente, die mindestens 28kg

tragen können. Sollten irgendwelche Zweifel bestehen,

suchen Sie Rat bei einem Experten.

3. Nehmen Sie den Boiler W4000/B, das Heizelement und den

Dichtungssatz W4000/GK zur Hand. Montieren Sie das Heizgerät

nach Abbildung 2.

i) Die 3 mitgelieferten Schrauben in die Löcher des

Metallflansches einsetzen, und den Metallflansch auf das

konische Glasrohr des Heizkessels setzen. Dabei sicherstellen,

dass die flache Seite des Flansches in Richtung des

Heizkessels zeigt.

Boiler-Laschen

W4000/S

W4000/B

WC48/M2

A6/6 (240V)

A6/6/EURO (220V)

W4000/HK

W4000/GK

Kondensator

O-Ringe zur

Abdichtung

Kondensschlauch