Page 1

Installation, Operation & Maintenance

Instructions

Please leave this instruction booklet with the owner as

it contains important guarantee, maintenance and safety

information

Read this manual carefully before commencing installation.

This manual covers the following products.

CE compliant product

PH35

Pt. No. 46563

PH45

Pt. No. 46564

Page 2

- 2 -

PRODUCT DESCRIPTION

Electric motor driven single stage end suction centrifugal pump.

APPLICATION

The range of centrifugal pumps is designed to pump clean fresh water. Other clean, non

aggressive, non explosive liquids with similar characteristics to water may be pumped.

Consult Stuart Turner for advice on such applications.

The pumps can be used for pressure boosting, fluid transfer and distribution. They are

suitable for flooded suction applications. Alternatively a maximum suction lift of

4.6 metres is permitted when using a Stuart footvalve/strainer.

Inlet pressures to the pump and ambient temperatures must not exceed the values

given in the technical specifications.

This pump set must not be used for any other application without the

written consent of Stuart Turner Limited.

This pump must not be connected directly to the mains water supply.

This product should not be used for the supply of water to more than

one dwelling (house, apartment, flat).

Please read installation details carefully as they are intended to ensure this product

provides long, trouble free service. Failure to install the unit in accordance with the

installation instructions will lead to invalidation of the warranty.

STORAGE

If this product is not to be installed immediately on receipt, ensure that it is stored in a dry,

frost and vibration free location in its original packaging.

CONTENTS Page

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technical Specifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHECKLIST

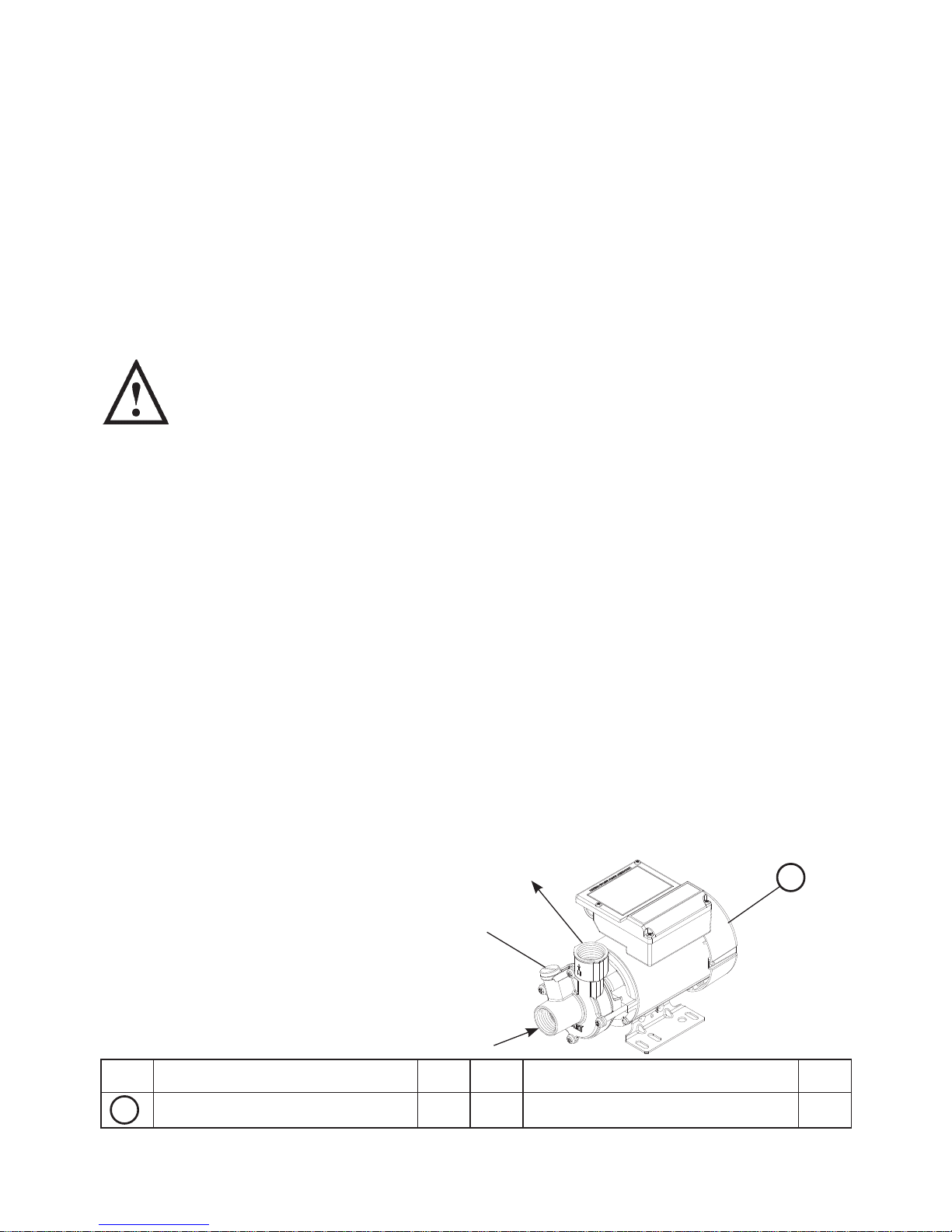

Your product may vary slightly from the picture above.

Item

Description Qty

Item

Description Qty

Pump 1

A

A

Fig. 1

G 1 Outlet

Priming

Plug

G 1 Inlet

IMPORTANT: With the pump

removed from its packaging

check for any damage prior to

installation. If any damage is

found contact Stuart Turner Ltd

within 24 hours of receipt.

Page 3

- 3 -

2.13 Fuses: The power cord must be sourced and supplied by the installer. Cable

selection and fuse size should be based on the motor full load current and the

surrounding conditions (supplied with 250 mm flying

lead for local requirements).

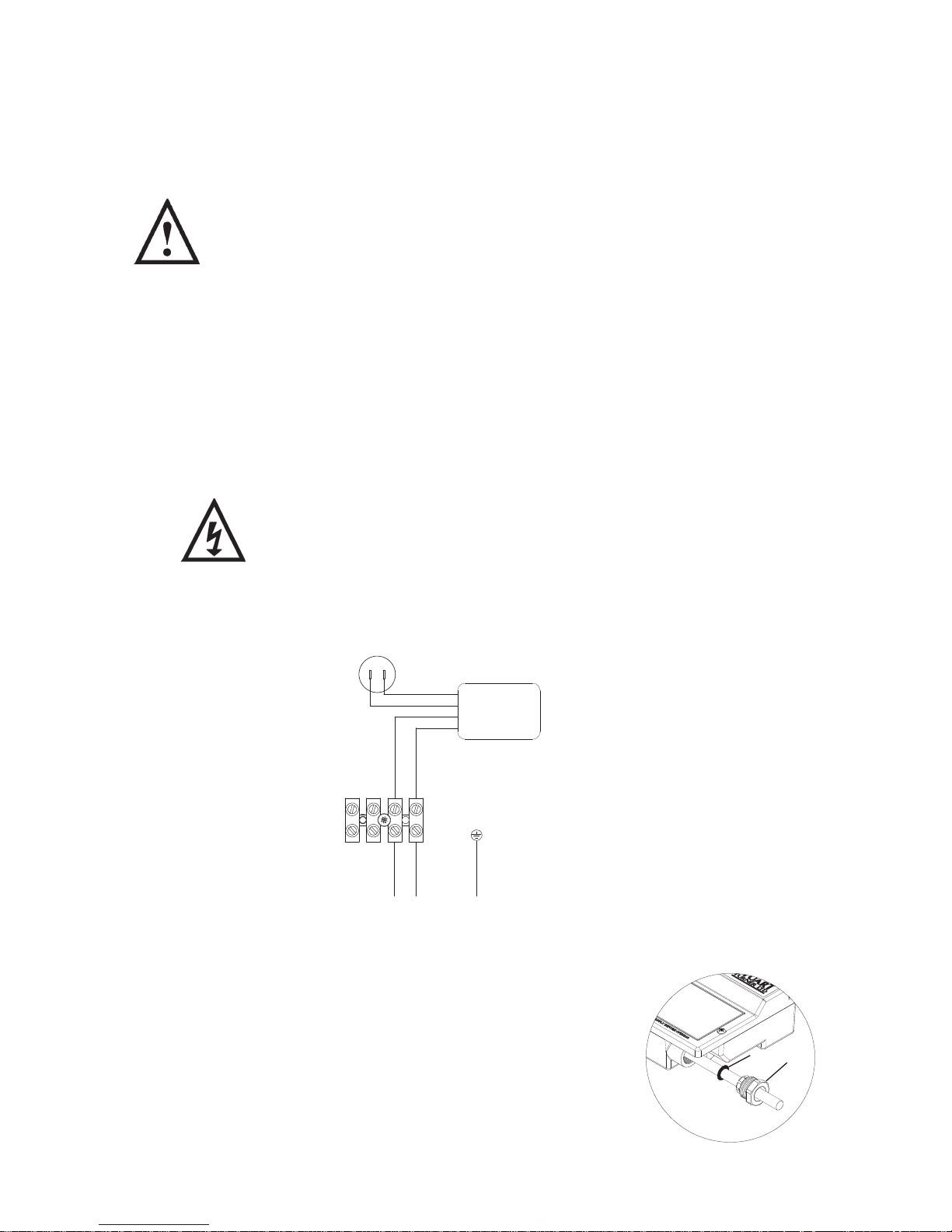

2.14 Cable Gland Fitting Instructions:

To enable correct assembly of the cable gland the

‘O’-ring (Fig. 3 item 1) must be placed over the cable

before the clamping insert (Fig. 3 item 2) can be

tightened.

Note: Cable diameter range:- 6.5 mm to 9.5 mm.

1 INSTALLATION

1.11 Secure pipework: Ensure pipework to and from pump is independently

supported & clipped to prevent forces being transferred to inlet and outlet

branches of pump.

1.12 DO NOT install a non-return valve, or devices which contain non-

return valves, in the suction (inlet) pipework to the pump. The pump

must be free to vent to the supply tank at all times.

1.13 DO NOT run against a closed valve for periods longer than 5 minutes.

1.14 DO NOT allow the supply cord to contact hot surfaces, including the

motor shell, pump body or pipework. The cod should be safely routed

and secured by cable clips.

1.15 Protection: The pump must be located in a dry position, frost free and protected

from freezing, particularly when installed in a loft (not recommended).

2 ELECTRICAL INSTALLATION

2.11 Wiring of connection unit:

WARNING: This appliance must be earthed.

The wires in the mains lead are coloured in accordance with the following code:

Green and Yellow: Earth Blue: Neutral Brown: Live

2.12 Wiring Diagram:

Fig. 3

2

1

230 VAC/1PH/50Hz SUPPLY

L N E

BROWN

BLUE

GREEN/YELLOW

RED

BLACK

CAPACITOR

MOTOR

RED

YELLOW

All models Fig. 2

Page 4

- 4 -

Cont ...

3 COMMISSIONING

3.11 Peripheral pumps should never be allowed to run dry. Before operating the

system, both pump and pipework should be primed. Further checks should

be made for leaks and when all is satisfactory the electrical supply to the pump

may be switched on. A vent/priming plug is fitted. To prime, release the vent plug

(see Fig. 1) until liquid emerges from the threads then re-tighten.

3.12 Safety: The motor casing can become very hot under normal operating

conditions, care should be taken to ensure it cannot be touched during operation.

3.13 Priming:

Never operate pump with inlet and/or outlet isolating valves in the

closed position. Damage will occur!

The pump must be primed (filled with water) before starting.

Turn on the service valves and vent/prime pump head.

(a) Loosen priming plug and allow an even flow of water this may take a

few seconds.

(b) Re-seal draining plug, nipping tight. The pump is now ready to start.

4 MAINTENANCE

4.11 No routine maintenance is required, but provision should be made for easy

access to the pump to allow for repairs due to normal wear and tear. Isolate the

pump from the electricity supply, turn off liquid supplies to the pump and release

pressure by opening liquid outlets before attempting repair.

4.12 Cleaners, Disinfectants and Descalents:

Acid based descalents and aggressive cleaning agents must not

come into contact with the pump. The pump must be removed from

the system prior to the use of these products. The system should be

flushed to remove all chemicals before the pump is re-connected.

If in any doubt as to the suitability of the chemical solutions, please

contact our Pump Assist helpline on 0844 98 000 97.

All models Fig. 4

Priming

Plug

Page 5

- 5 -

Cont ...

5 TECHNICAL SPECIFICATION

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

*Note: Max working pressure is the maximum pressure that can be applied to

the pump internal casing under any installation conditions.

**Note: In normal circumstances the temperature of stored water should never

exceed 65 °C. A stored water temperature of 60°C is considered

sufficient to meet all normal requirements and will minimise deposition of

scale in hard water areas.

5.11 Noise: The equivalent continuous A-weighted sound pressure level at a distance

of 1 metre from the pump does not exceed 70 dB(A).

Model PH35 PH45

Electrical

Power supply

Volts/phase frequency

230/1/50 230/1/50

Enclosure IPX4 IPX4

Type of motor Induction Induction

Power consumption 380Watts 540 Watts

Full load current 1.6 Amps 2.4 Amps

Rating Continuous (S1) Continuous (S1)

Max. No Starts per hour 60 60

Mechanical

Min inlet head 1 metres 1 metres

Max inlet head 10 metres 10 metres

Max head (closed valve) 25 metres 42 metres

Max working pressure* 600 kPa (6.0 bar) 900 kPa (9.0 bar)

Max ambient air temperature 50

o

C 50 oC

Max water temperature** 80

o

C 80 oC

Min water temperature 4

o

C4

o

C

Cut in flow 1 l/min (approx) 1 l/min (approx)

Pump

Dimensions

Length (max) 241 mm 270 mm

Width (max) 130 mm 130 mm

Height (excluding flexible hoses) 167 mm 167 mm

Gross Weight (including accessories) 4.9 Kg 6.5 Kg

Pump Connections: Inlet G 1 Female G 1 Female

Outlet G 1 Female G 1 Female

Materials

Body Brass Brass

Shaft Stainless Steel Stainless Steel

Mechanical Seal Nitrile/carbon/ceramic Nitrile/carbon/ceramic

Page 6

- 6 -

6 YOUR 1 YEAR GUARANTEE

Stuart Pumps are guaranteed by Stuart Turner Limited to be free from defects in

materials or workmanship and the guarantee period starts from the date of purchase

or date of manufacture. Within the guarantee period we will repair, free of charge,

any defects in the pump resulting from faults in material or workmanship, repairing,

exchanging parts or exchanging the whole unit as we may reasonably decide.

Not covered by this guarantee: Damage arising from incorrect installation, improper

use, unauthorised repair, normal wear and tear and defects which have a negligible

effect on the value or operation of the pump.

Reasonable evidence must be supplied that the pump has been purchased within the

applicable guarantee period prior to the date of claim (such as proof of purchase or the

pump serial number).

In the event of a claim please telephone Stuart Turner Limited on 0844 980 0097

before taking any further action. If you have any doubt about removing a pump, please

consult a professional.

Proof of purchase should accompany the returned pump to avoid delay in investigation

and dealing with your claim.

Please record here for your records.

TYPE NO. SERIAL NO. DATE PURCHASED

Page 7

- 7 -

NOTES

Page 8

Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND

Tel: +44 (0) 1491 572655, Fax: +44 (0) 1491 573704

email: pumps@stuart-turner.co.uk web: www.stuart-turner.co.uk

V.A.T. REG. No. 199 0987 92. Registered in England No. 88368. Registered Offi ce: Market Place, Henley-on-Thames

DECLARATION OF CONFORMITY

2006/42/EC

BS EN ISO 12100-1, BS EN ISO 12100-2, BS EN 809

2006/95/EC

BS EN 60335-1, BS EN 60335-2-41

2004/108/EC

BS EN 55014-1, BS EN 55014-2, BS EN 55022, BS EN 61000-3-2, BS EN 61000-3-3,

BS EN 61000-4-2, BS EN 61000-4-3, BS EN 61000-4-4, BS EN 61000-4-5, BS EN 61000-4-6,

BS EN 61000-4-11

1999/519/EC

BS EN 62233

2011/65/EU

IT IS HEREBY CERTIFIED THAT THE STUART ELECTRIC MOTOR DRIVEN PUMP AS

SERIAL NUMBER BELOW, COMPLIES WITH THE ESSENTIAL REQUIREMENTS OF THE

ABOVE E.E.C. DIRECTIVES.

RESPONSIBLE PERSON

AND MANUFACTURER STUART TURNER LIMITED

HENLEY-ON-THAMES, OXFORDSHIRE

RG9 2AD ENGLAND.

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Business Development Director

Stuart Turner are an approved company to BS EN ISO 9001:2000

Issue No. 4413/2-01 Pt. No. 19547

Loading...

Loading...