Struers Tegramin-25, Tegramin-30 Instruction Manual

Manual No.: 16037001

Date of Release 11.03.2013

Tegramin-25/-30

Instruction Manual

Tegramin-25/ -30

Instruction Manual

FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These lim i ts

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the Instruction Manual, may

cause harmful interference to radio communicat ions. Operation of this

equipment in a residential area is likely to cause harm ful interference in

which case the user will be required to correct the interference at his own

expense.

Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to

this product not expressly approved by Struers A/S could cause harmful

radio interference and void the user’s authority to operat e the equipment.

Always state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manuals may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manuals may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to change without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

Original instructions. The content of this manual are the property of Struers. Reproduction of any part of this

manual without the written permission of Struers is not allowed.

All rights reserved. © Struers 2013.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

Tegramin-25/ -30

Instruction Manual

Tegramin-25/-30

Safety Precaution Sheet

To be read carefully

before use

1. The operator(s) should be fully instructed in the use of the machine,

any connected equipment and accessories and the applied

consumables according to the relevant Instruction Manuals and

Material Safety Data Sheets.

2. The machine must be placed on a safe and stable table with an

adequate working height and which is able to car ry at least 91 kg / 200

lb. All functions on the machine and any connected equipment must be

in working order.

3. Operators should ensure that the actual voltage cor responds to the

voltage on the back of the machine. The machine must be earthed.

Follow the local regulations. Always turn the power off and remove the

plug or the cable before opening the machine or installing additional

components.

4. Connect only to cold water. Make sure that the wat er connections are

leak-proof and that the water outlet is working.

5. Struers recommend that the mains water supply is s hut off or

disconnected if the machine is to be left unatt ended.

6. Consumables: only use consumables specifically developed for use

with this type of materialographic machine.

Alcohol based consumables: follow the current saf ety rules for

handling, mixing, filling, emptying and disposal of the alcohol-based

liquids.

7. Keep clear of the rotating disc and the specimen mover during

operation. While grinding manually, be careful not to touch the grinding

disc. Do not attempt to collect a specimen from the tray while the disc is

running.

8. Keep your hands clear of the specimen holder or specimen mover plate

when moving them downwards.

9. When working at machines with rotating parts care has to be taken that

clothes and/or hair cannot be caught by the rotating parts. Appropriate

safety clothing must be used.

Tegramin-25/ -30

Instruction Manual

10. If you observe malfunctions or hear unusual noises - stop the machine

and call technical service.

11. The machine must be disconnected from the mains prior to any service.

Wait until residual potential on the capacit ors is discharged.

12. Do not cycle mains power more than once every three minutes.

Damage to the drive will result.

The equipment should only be used for its intended purpose and as detailed in the Instruction Manual.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

Tegramin-25/ -30

Instruction Manual

Disposal

Equipment marked with a WEEE symbol contain electrical and

electronic components and must not be disposed of as general

waste.

Please contact your local authorities for information on the correct

method of disposal in accordance with national legislation.

Tegramin-25/ -30

Instruction Manual

1

Table of Contents Page

1. Getting Started

Checking the Contents ....................................................................... 3

Unpacking Tegramin .......................................................................... 3

Placing Tegramin ............................................................................... 3

Getting Acquainted with Tegramin ..................................................... 4

Rear of Tegramin ...................................................................... 5

Supplying Water ................................................................................. 7

Connection to Water Mains ....................................................... 7

Connection to Water Outlet ....................................................... 7

Adjusting the Water Flow .......................................................... 8

Connecting a Recirculation Cooling Unit ............................................ 9

Connecting the Water Inlet ....................................................... 9

Connecting the Water Outlet ..................................................... 9

Connecting the Communication Cable ................................... 10

Installing the Shift Valve .......................................................... 10

Compressed Air Connections .......................................................... 11

Emptying the Water / Oil Filter ................................................ 11

Connection to an External Exhaust System ..................................... 11

Supplying Power .............................................................................. 12

Single-phase Supply ............................................................... 12

2-phase Supply ....................................................................... 12

Connection to the Machine ..................................................... 12

Mounting the Dosing Modules .......................................................... 13

2. Basic Operation of Tegramin

Front Panel ....................................................................................... 14

Front Panel Controls ............................................................... 15

Reading the Display ................................................................ 16

Manoeuvring in the menu structure ........................................ 17

Acoustic Signals ...................................................................... 17

Software Settings ............................................................................. 18

Changing the Language .......................................................... 20

Editing Numeric Values ........................................................... 22

Editing Alphanumeric Values .................................................. 23

Operation Mode ............................................................................... 25

Changing Operation Mode ...................................................... 25

New Pass Code ............................................................................... 26

Preparation Process Setup .............................................................. 27

Mounting a Disc ...................................................................... 27

Selecting a preparation mode ................................................. 28

Selecting a preparation method .............................................. 29

Creating a Preparation Method ............................................... 32

Modifying an existing preparation method .............................. 37

Locking a preparation method ................................................ 38

Unlocking a preparation method ............................................. 39

Starting the Preparation Process ..................................................... 40

Stopping the Process ....................................................................... 40

Spin Function ................................................................................... 40

Tegramin-25/ -30

Instruction Manual

2

3. Operating Tegramin

Inserting Specimen Holders or Specimen Mover Plates .................. 41

Inserting a Specimen Holder ................................................... 41

Inserting a Specimen Mover Plate .......................................... 41

Manual Preparation .......................................................................... 42

Recommendations for Grinding Single Specimens ................ 43

4. Accessories and Consumables ......................................... 44

5. Trouble-shooting .................................................................. 45

6. Maintenance

Daily Service .................................................................................... 49

Weekly Service ................................................................................ 49

Cleaning of Tubes ............................................................................ 50

Cleaning the Bowl ............................................................................ 51

Cleaning of Specimen Mover Head ................................................. 52

Calibration of Pump Capacity ........................................................... 53

Adjustment of Tube Cleaning Time .................................................. 55

Aligning the specimen holder/mover plate ....................................... 57

Reset Functions ............................................................................... 58

Reset methods ........................................................................ 58

Reset configuration ................................................................. 58

Service Information .......................................................................... 59

Changing Tubes ............................................................................... 61

7. Technical Data ...................................................................... 63

Tegramin-25/ -30

Instruction Manual

3

1. Getting Started

In the packing box you should find the following parts:

1 Tegramin-25 or Tegramin-30

(Microprocessor controlled table top machine

for automatic grinding, lapping and polishing of all mat erial s)

2 Mains c abl es

1 Water inlet hose 19mm/ ¾" (2 m)

1 Fil ter gas ket

1 Reduction ring with gasket ¾" to ½ "

1 Water outlet hose ø40/ 1½" (1.5 m)

2 Hose c l amps

1 Connection piece (p6 to 1/8")

1 Allen key w. cross handle 6x150 mm

1 Set of Instruction Manuals

Remove the Tegramin from the packing crate:

− Remove the bolts from the right transport bracket that secure

Tegramin to its transport pallet.

− Remove the bracket.

− Holding underneath the base of the machine, from the front

and the back, slide the Tegramin to the right and lift off the

pallet.

Place Tegramin on a steady table with an adequate working

height.

The table must be able to carry at least 91 kg / 200 lb.

Check that the Tegramin is resting securely with all 4 rubber feet

on the table.

The machine must be close to the power supply, water mains

and water outlet facilities.

Slide the piece of cardboard to the right.

Remove the screw holding the transport lock on the cone shaft.

Press the black release button and remove the transport lock.

Checking the Contents

Tegramin-25/ -30

Unpacking Tegramin

Placing Tegramin

Tegramin-25/ -30

Instruction Manual

4

Take a moment to familiarise yourself with the location and names of

all the Tegramin components:

A Dosing block with nozzles

B Turntable

C Front panel control(s)

Emergency Stop

- Push the red button to stop

- Turn the red button clockwise to release

Getting Acquainted with

Tegramin

Please Note,

The following illustrations are of Tegramin versions without a cover.

Installation and operation of Tegramin version s wit h or without a cover

will be identical.

Covers are also available as an optional accessory .

A

B C

Tegramin-25/ -30

Instruction Manual

5

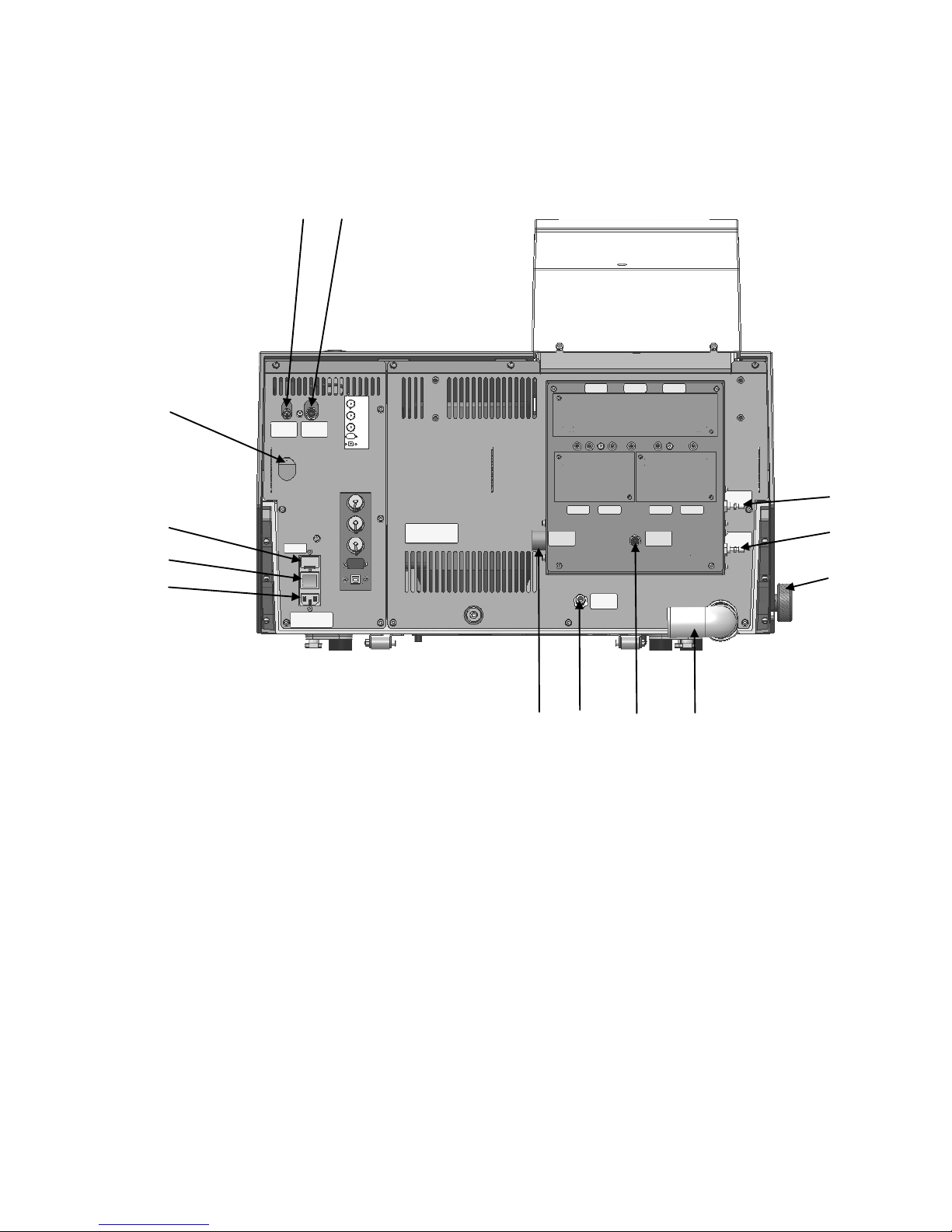

Air outlet for shift valve

Compressed air inlet

Release outlet valve from water/oil filter for compressed air

Fuses

Main switch

Mains connection

Water inlet (mains water ¾")

Water inlet (from Cooling Unit)

OP module, flushing water

Water outlet pipe

Water valve, manual

Throttle valve, disc cooling

Throttle valve, flushing water for OP

Rear of Tegramin

Tegramin-25/ -30

Instruction Manual

6

Holders for dosing tubes

(3 rows on the rear of Tegramin)

Socket for cover

Connection for shift valve)

Cooli unit connection

USB connection, for service purposes

RS 232 socket for LAN module

Tegramin-25/ -30

Instruction Manual

7

Water for wet grinding may be supplied from the water mains or a

Recirculation Cooling Unit (instructions on the next page).

Mount the 90° end of the inlet hose onto the water inlet on the

back of Tegramin (see Getting Acquainted with Tegramin):

− Insert the filter gasket in the coupling nut with the flat side

against the pressure hose.

− Tighten the coupling nut completely.

Mount the straight end of the inlet hose on the water mains tap

for cold water:

− If required, mount the reduction piece with gasket on the

water mains tap and tighten the coupling nut completely.

Mount the outlet hose onto the water outlet pipe. (Lubricate with

grease or soap to facilitate insertion.) Use a hose clamp for

fastening.

Lead the other end of the drain hose to the water outlet. Arrange

the hose so that it slopes downward towards the drain

throughout its length. Shorten the hose, if necessary.

Supplying Water

Connection to Water Mains

IMPORTANT

The cold water supply must have a head pressure in t he

range 1 – 10 bar (14.5 – 145 psi).

Connection to Water Outlet

REMEMBER

Make sure that the drain hose slopes downward towards the drain

throughout its length and avoid sharp bends in the drain hose.

Tegramin-25/ -30

Instruction Manual

8

The flow of water can be adjusted using the manual water valve.

Water flow for disc cooling and flushing after OP can be adjusted

using the throttle valves.

Adjusting the Water Flow

Throttle valve, flushing water for OP

Throttle valve, disc cooling

Manual Water valve

Tegramin-25/ -30

Instruction Manual

9

To ensure optimal cooling, Tegramin can be fitted with a Struers

Recirculation Cooling Unit.

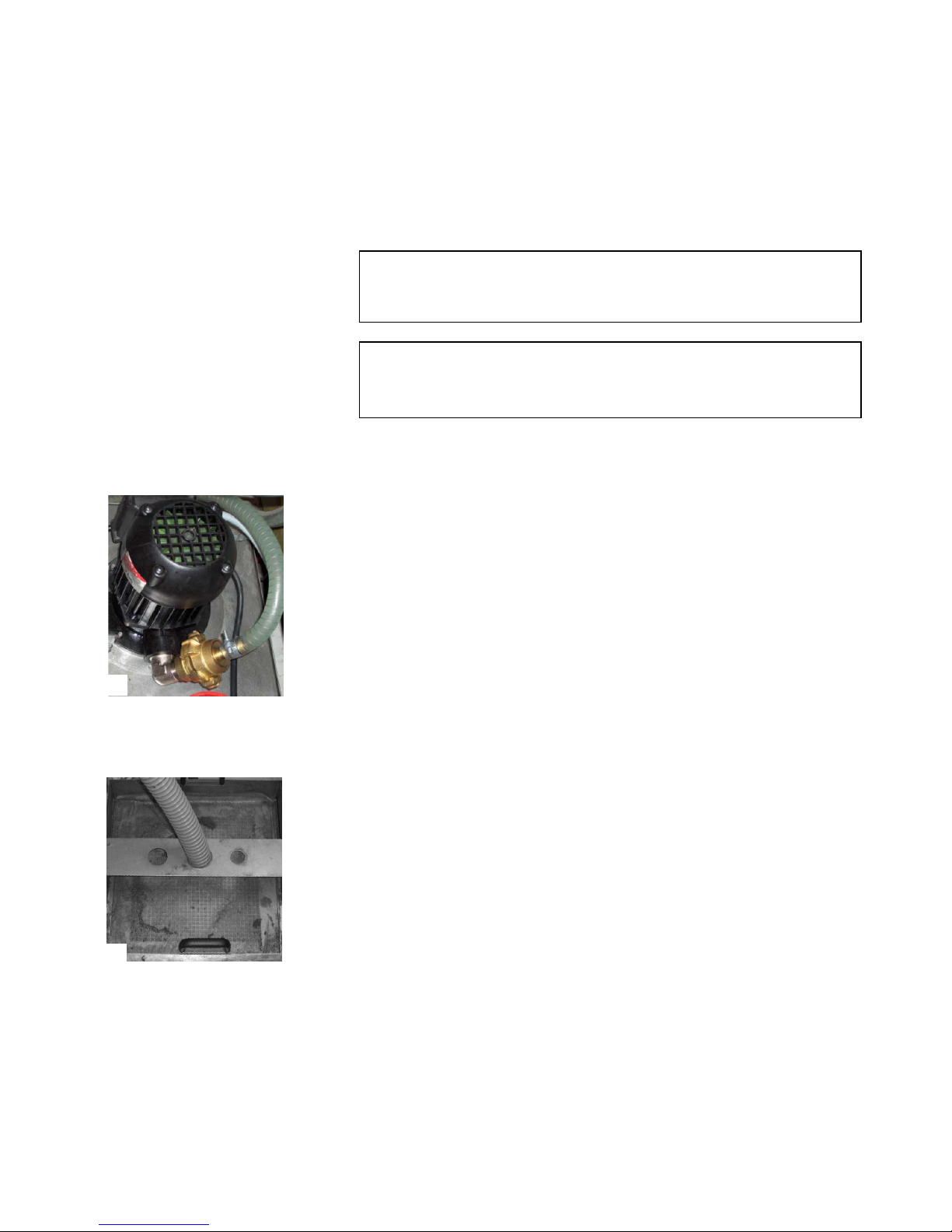

Take the hose delivered with the pump and remove the quick

coupling from one end.

Slide the hose clamp onto the hose and connect to the back of the

Tegramin. Tighten the hose clamp.

Connect the quick coupling on the other side of the inlet hose

directly to the cooling unit’s pump outlet (A).

Mount the water outlet hose onto the water outlet pipe. Use a

hose clamp to secure the hose.

Lead the other end into the mounting hole in the bracket on top of

the static filter unit (B).

Arrange the hose so that it slopes downward towards the drain

throughout its length. Shorten the hose, if necessary.

Connecting a Recirculation

Cooling Unit

Oxide Polishing:

A Shift Valve is REQUIRED when using a Recirculation Cooling Unit

with Tegramin units running methods that include the dosing of

oxide polishing suspensions -OP.

Note

Before connecting the cooling unit to the Tegrami n,

follow the instructions in the Struers Cooling Unit s I nstruction Manual

to prepare it for use.

Connecting the Water Inlet

Connecting the Water Outlet

B A

Tegramin-25/ -30

Instruction Manual

10

Connect the communication cable to the Cooli Control Box and

then connect to the socket at the rear of the Tegramin.

With the outlet hose mounted onto Tegramin's water outlet pipe,

mount the other end of the hose onto the pipe labelled From

Tegramin on the shift valve.

Mount a 1.5 m piece of hose onto the pipe marked Cooli and

lead the other end to the recirculation cooling unit. Use a hose

clamp for fastening.

Mount the second 1.5 m piece of hose onto the pipe marked

Drain and lead the other end to the drain. Use a hose clamp for

fastening.

Connect the blue compressed air hose to the air outlet on

Tegramin and fit the other end to the shift valve, marked Connect

to Tegramin.

Connect the plug to the socket at the back of the Tegramin

marked Shift valve.

Connecting the Communication

Cable

IMPORTANT

Before connecting to power, check that the mains voltage corresponds to

the voltage stated on the type plate on the side of t he machine.

Installing the Shift Valve

(Accessory)

IMPORTANT

When connecting Tegramin to both mains water AN D the recirculation

cooling unit you also must install the shift valve for the drain.

Failure to do this may result in emptying or overflowing

the recirculation cooling unit.

Note:

The Shift Valve for Tegramin set includes some extra pieces

not used for Tegramin-25/-30

(1 short piece of hose, 1 reduction piece and 2 hose cl am ps)

REMEMBER

Make sure that the hoses slope downward throug hout their length, from

Tegramin to the shift valve and from shift valv e to Cooli (or drain).

Avoid sharp bends in the hoses. Shorten the hoses, if necessary.

Tegramin-25/ -30

Instruction Manual

11

The quality of the air in the compressed air system used with this

machine must meet the standards stated in ISO 8573-1.

To connect compressed air:

Mount the quick coupling on the compressed air hose and

secure it with the hose clamp supplied.

Connect the air inlet hose to the quick coupling and fit the other

end into the compressed air inlet on Tegramin.

Tegramin is fitted with a water / oil filter that removes excessive

amounts of these substances from the compressed air supply. As a

result of this, it is necessary to empty the filter periodically:

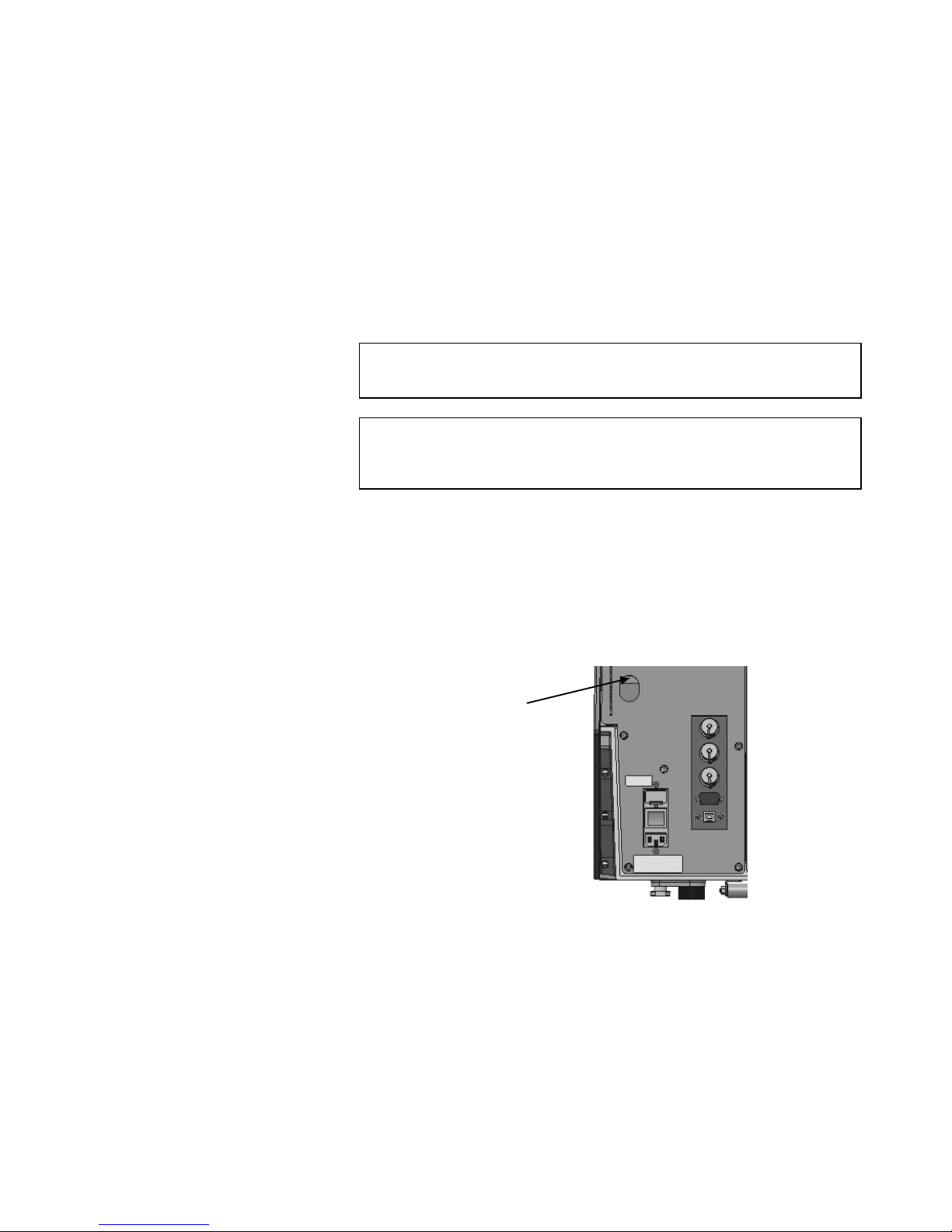

Locate the release outlet valve at the back of the machine.

Hold a cloth under the filter to retain any water released and

press the release valve.

An exhaust system should be connected when using alcohol based

suspensions or lubricants.

Connect a 50 mm pipe to the outlet at the rear of the machine,

on the left and connect to the exhaust system.

Recommended capacity for exhaust system: 180m

3

/h at 0mm water

gauge.

Compressed Air Connections

IMPORTANT

The air pressure must be between 6 bar (87 psi) and 10 bar (145 psi) and

have a quality equal to or better than Class-3, as specified in ISO 8573-1.

Note:

Tegramin requires a continuous flow of compres sed air

through the regulator valve –

a faint hissing sound does not mean that there is an air leak.

Emptying the Water / Oil Filter

Connection to an External

Exhaust System

Tegramin with Cover

(optional/accessory)

Release Outlet Valve

Tegramin-25/ -30

Instruction Manual

12

Always remember to switch the power off when installing electrical

equipment.

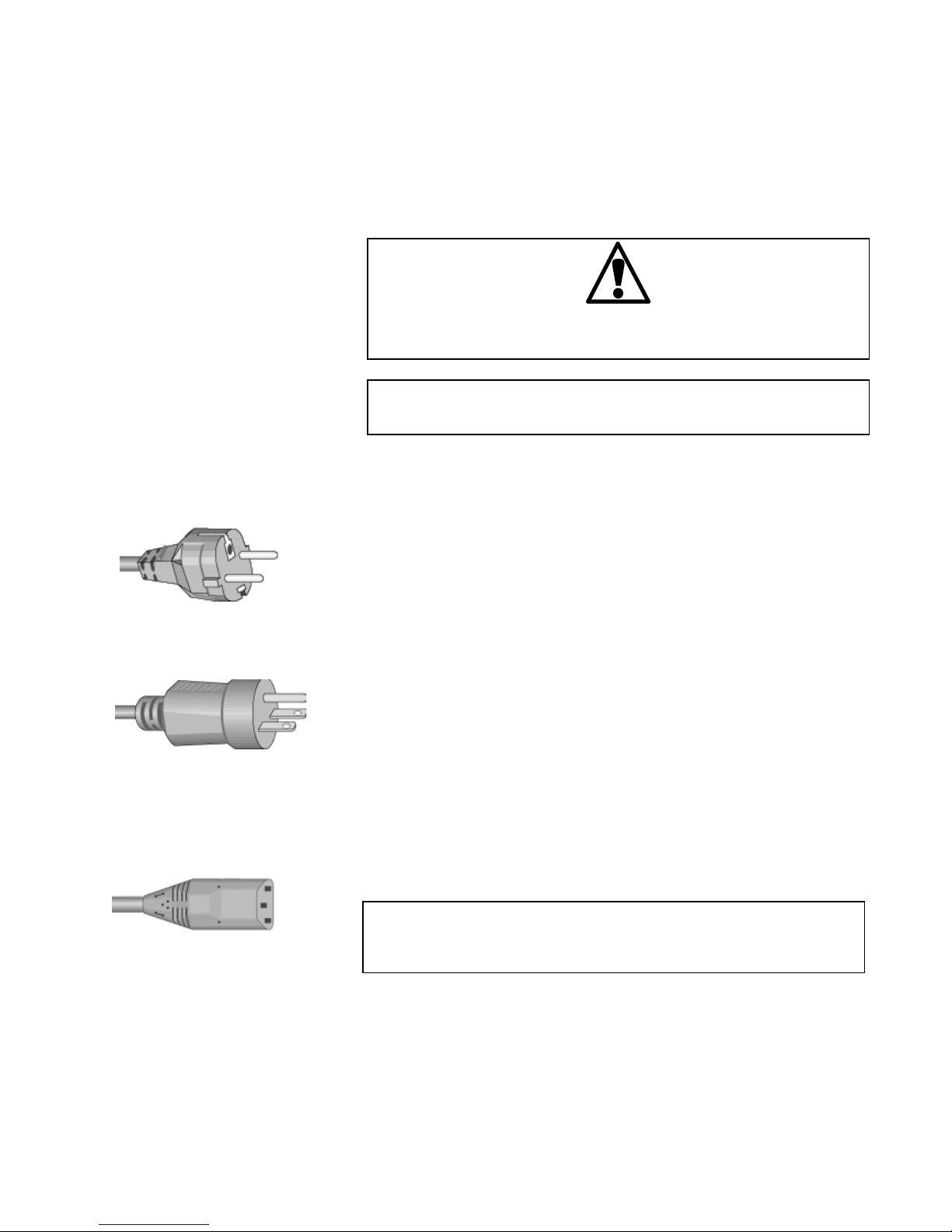

The Tegramin is shipped with 2 types of Mains cables:

The 2-pin (European Schuko) plug is for use on single-phase

connections.

If the plug supplied on this cable is not approved in your country,

then the plug must be replaced with an approved plug. The leads

must be connected as follows:

Yellow/green: earth

Brown: line (live)

Blue: neutral

The 3-pin (North American NEMA) plug is for use on 2-phase power

connections.

If the plug supplied on this cable is not approved in your country,

then the plug must be replaced with an approved plug. The leads

must be connected as follows:

Green: earth (ground)

Black: line (live)

White: line (live)

Both cables are on the other end equipped with an IEC 320 cable

connector that has to be connected to the Tegramin.

Supplying Power

DANGER!

The machine must be earthed

IMPORTANT

Check that the mains voltage corresponds to the v oltage stated

on the type plate on the back of the machine.

Single-phase Supply

2-phase Supply

Connection to the Machine

WARNING!

The output voltage from this cable is 200 – 240V and not 110V.

DO NOT use this cable to connect equipment t hat use a 110V power

supply. Failure to adhere to this may result in material damage.

Tegramin-25/ -30

Instruction Manual

13

Remove the cover plates.

Slide the dosing module(s) into the correct position at the back of

Tegramin.

Secure the module(s) with the attached screws.

Connect the short piece of tube with the 90° angle and the clear

tube to the connectors at the back of the Tegramin.

Lead the long tubes from the pumps to the bottles of

lubricant/abrasive and connect them to the nipple on top of the

bottles.

The tubes can be pressed into place in the dosing tube holders

on the rear of Tegramin.

When mounting a module with an OP pump:

Push the connector disc inwards and remove the blue plug from

the OP Flush water connector.

Lead the tube from the OP pump (Pump No. 7 in the picture),

press the connector disc inwards and insert the tube into the

connector.

Mounting the Dosing Modules

OP dosing

NOTE!

The tubes from the 2 DP-dosing modules are numbered 1/3 or 2/4.

Depending on the position the dosing modules are placed in please remove

the numbers that do not match, on both ends of the t ube.

Connector Disc

Plug

Tegramin-25/ -30

Instruction Manual

14

2. Basic Operation of Tegramin

Front Panel

Tegramin-25/ -30

Instruction Manual

15

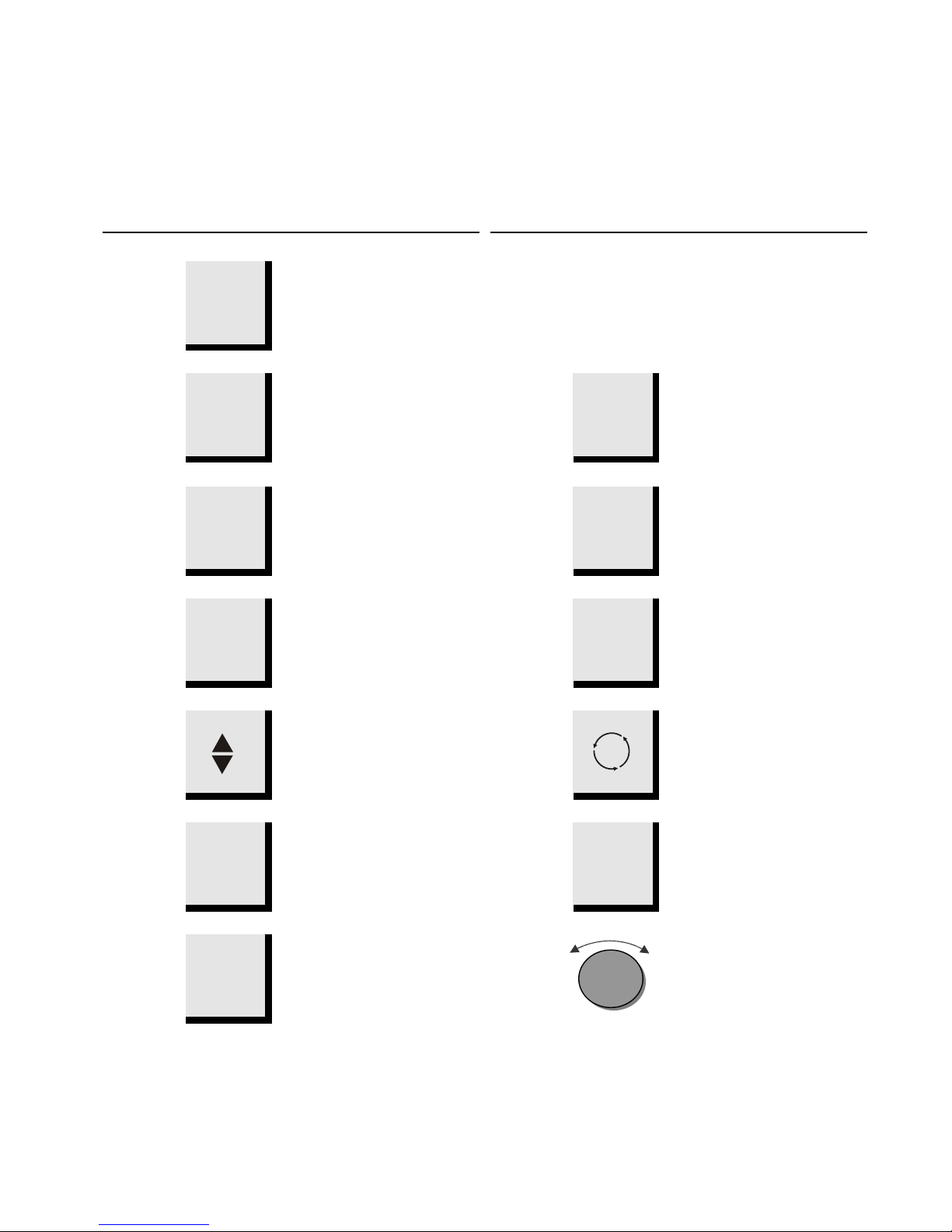

Key Function

Key Function

FUNCTION

KEY

F1-F4

Controls for various purposes.

See the bottom line of the

individual screens.

DISC

ROTATION

Starts rotation of the disc.

WATER

Manual override - push button to

apply water (applies water when

no process is running).

Push button again to stop

applying water (water will

automatically switch off after 5

min.)

LUBRICANT

Only active when dosing units

are installed.

Manual override – push button to

apply lubricant from the doser

bottle.

ABRASIVE

Only active when dosing units

are installed.

Manual override – push button to

apply diamond suspension from

the doser bottle.

LEFT

Moves the specimen holder

head left.

RIGHT

Moves the specimen holder

head right.

LOWER/

RAISE

Lowers & raises the specimen

mover head when preparing

single specimens or when

adjusting positions of specimen

mover plate or specimen holder.

ROTATE

Rotates the Specimen Mover

Plate.

START

Starts the preparation process.

STOP

Stops the preparation process.

ESC

Esc

Returns to the Main Menu or

aborts functions/changes.

Turn/Push

Knob

Used for entering and changing

steps and parameters.

Combined cursor and enter key.

Enables selected parameter

values to be activated for editing.

Saves the edited parameter

values.

Toggles when only 2 options

available.

Front Panel Controls

↵

Loading...

Loading...