LaboPress-3

Instruction Manual

Manual No.: 15087003

Date of Release 11.01.2008

LaboPress-3

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide.......................................................13

Quick Reference Card .............................................24

Always state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manual may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manual may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to changes without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual is the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

All rights reserved. © Struers 2008.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

LaboPress-3

Instruction Manual

LaboPress-3

Safety Precaution Sheet

To be read carefully

before use

1. The operator should be fully aware of the use of the machine according

to the Instruction Manual.

2. The machine must be placed in a well ventilated room on a working

table with adequate height for convenient operation.

3. Be sure that the actual voltage corresponds to the voltage stated on the

back of the machine and on the heating/cooling unit. The machine must

be earthed.

4. Be sure that the water connections are mounted correctly and without

leaks. The main water supply should be turned on when the machine is

in use.

Struers recommend that the mains water supply is shut off or

disconnected if the machine is to be left unattended

5. Be sure that the outlet hose is safely attached to the water outlet

system.

6. Be sure that the mounting unit is correctly assembled on the press

before starting the process.

7. Be sure that the top closure with upper ram is either correctly mounted

on the mounting cylinder or completely removed from the mounting

cylinder before starting the press.

8. Do not operate the mounting press with a higher force/pressure than

recommended for the actual cylinder diameter and resin in Struers

Application Guide for Hot Mounting.

9. Following a heating cycle, ensure the mounting cylinder is cooled for a

minimum of two minutes before opening.

10. Do not operate the machine whilst assembling or disassembling the

mounting unit.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

LaboPress-3

Instruction Manual

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents ..................................................................... 2

LaboPress-3................................................................................ 2

Mounting Unit ........................................................................... 2

Unpacking LaboPress-3.................................................................... 2

Placing LaboPress-3 .........................................................................2

Transport Screw Cap........................................................................ 2

Getting Acquainted with LaboPress-3............................................. 3

Noise Level........................................................................................ 4

Supplying Power...............................................................................4

Supplying Water ............................................................................... 4

Water Inlet................................................................................. 4

Water Outlet..............................................................................4

Assembling the Mounting Unit........................................................ 5

Removing the Cover ..................................................................5

Installing the Lower Ram ......................................................... 5

Installing the Mounting Unit.................................................... 5

Installing the Cover................................................................... 6

Installing the Dust Protection Ring .........................................6

Disassembling the Mounting Unit................................................... 6

Dropping the Lower Ram.......................................................... 6

Removing the Dust Protection Ring ......................................... 6

Removing the Cover ..................................................................6

Removing the Mounting Unit ..........................................................7

Removing the Lower Ram ................................................................ 7

Changing the Mounting Unit........................................................... 7

2. Basic Operations

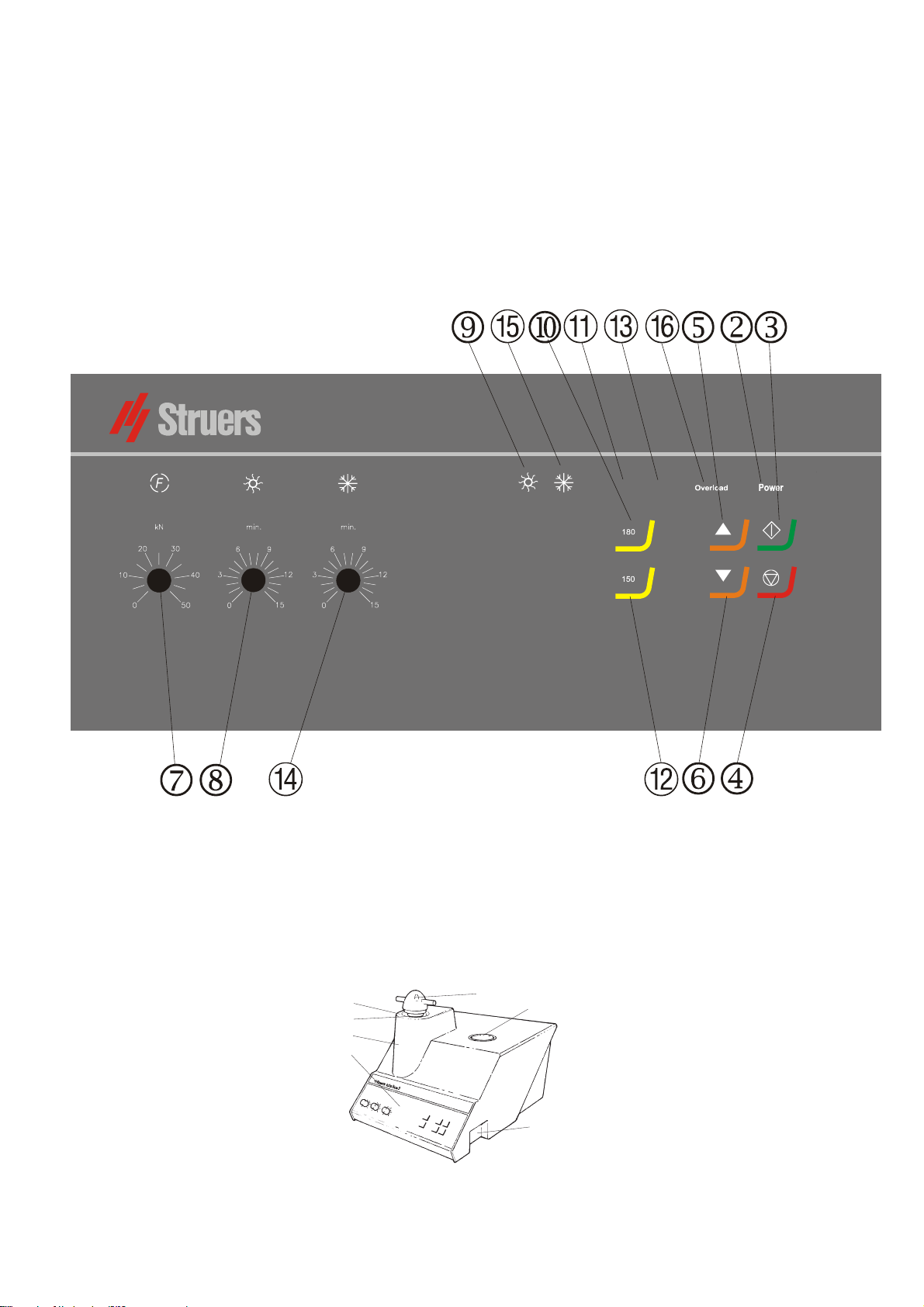

Using the Controls............................................................................ 8

Front Panel Controls of LaboPress-3 .......................................8

Acoustic Signals......................................................................... 8

Main Switch............................................................................... 8

Placing the Specimen .....................................................................10

Pouring Resin over the Specimen........................................... 10

Placing Two Specimens .................................................................. 10

Installing the Top Closure.............................................................. 11

Starting the Mounting Process ...................................................... 12

Preheating with Low Pressure ...............................................12

Stopping the Mounting Process ..................................................... 12

Removing the Top Closure ............................................................. 12

1

Checking the Contents

LaboPress-3

Instruction Manual

1. Getting Started

In the packing box you should find the following parts:

LaboPress-3

Mounting Unit

Unpacking LaboPress-3

Placing LaboPress-3

Transport Screw Cap

1 LaboPress-3 machine

1 Pressure hose

1 Filter gasket

1 Gasket

1 Reduction ring with gasket

2 Measuring spoons for mounting resin

1 Funnel

1 Air filter

1 Set of Instruction manuals

1 Mounting unit

1 Top closure with upper ram

1 Lower ram

1 Dust protection ring

1 Piston pin

1 Mould release agent (FASTI)

1 Scraper (PROAN)

LaboPress-3 is detached from the bottom of the packing case by

removing the four screws from below.

LaboPress-3 should be placed on a steady table with an adequate

working height. The machine must be placed close to the power

supply, water mains and water outlet facilities. If water

recirculation is used, there must be room under the table for the

Recirculation Cooling Unit (TRECI).

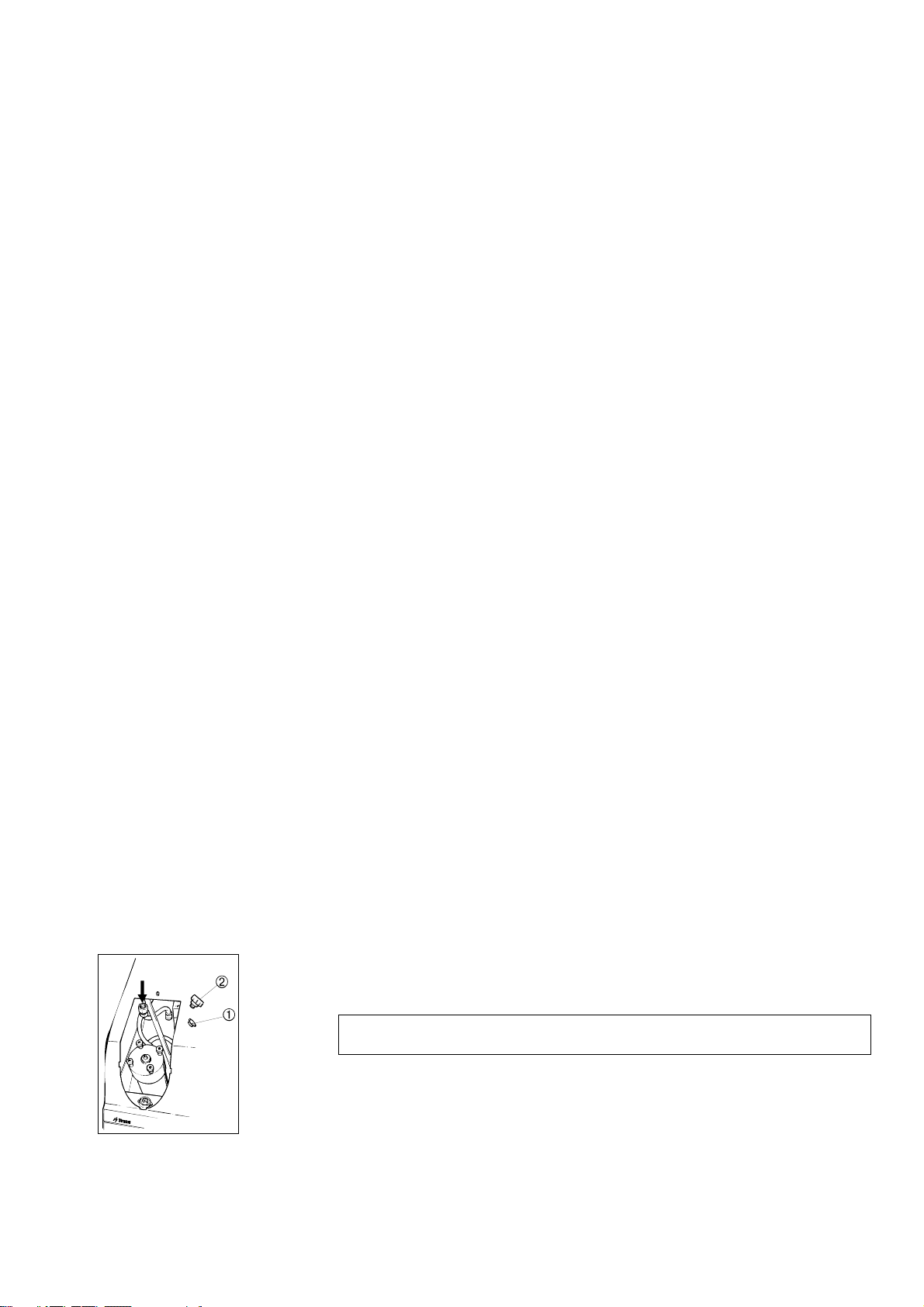

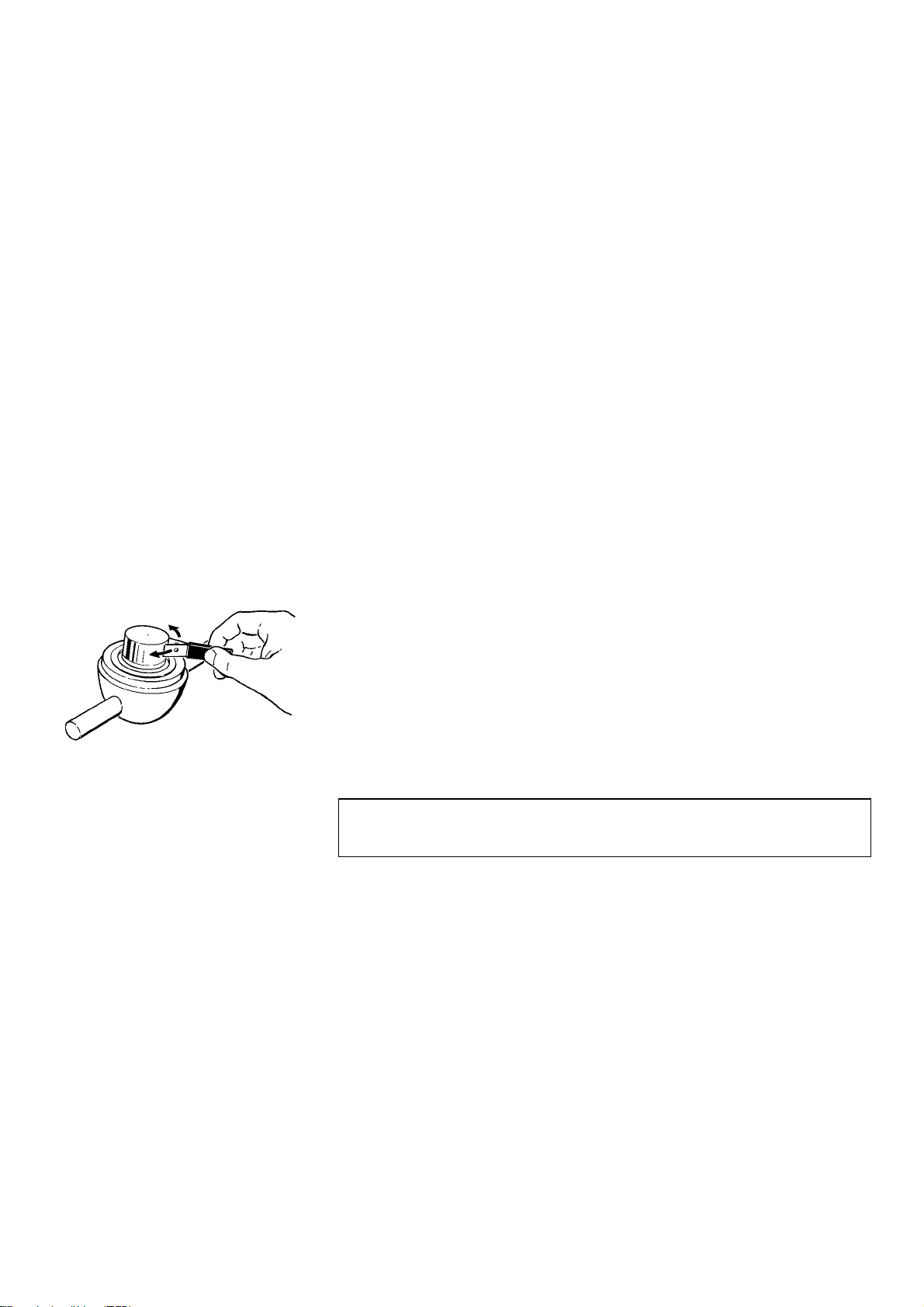

Carry out the following procedure before using the machine for

the first time. Exchange the transport screw cap with the

enclosed air filter , to equalise the pressure in the hydraulic

system.

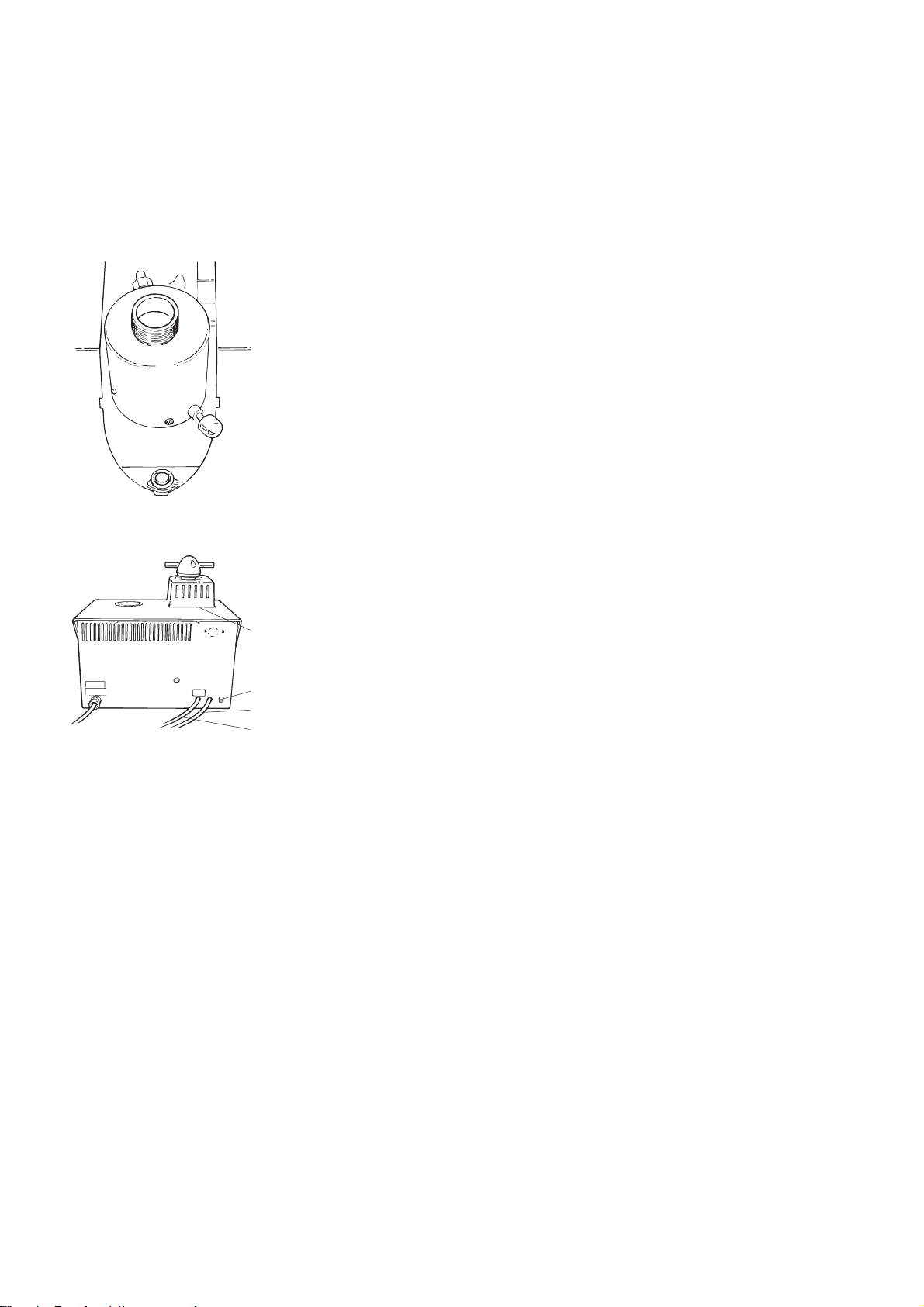

The transport screw cap is situated

underneath the cover for the mounting unit.

2

LaboPress-3

Instruction Manual

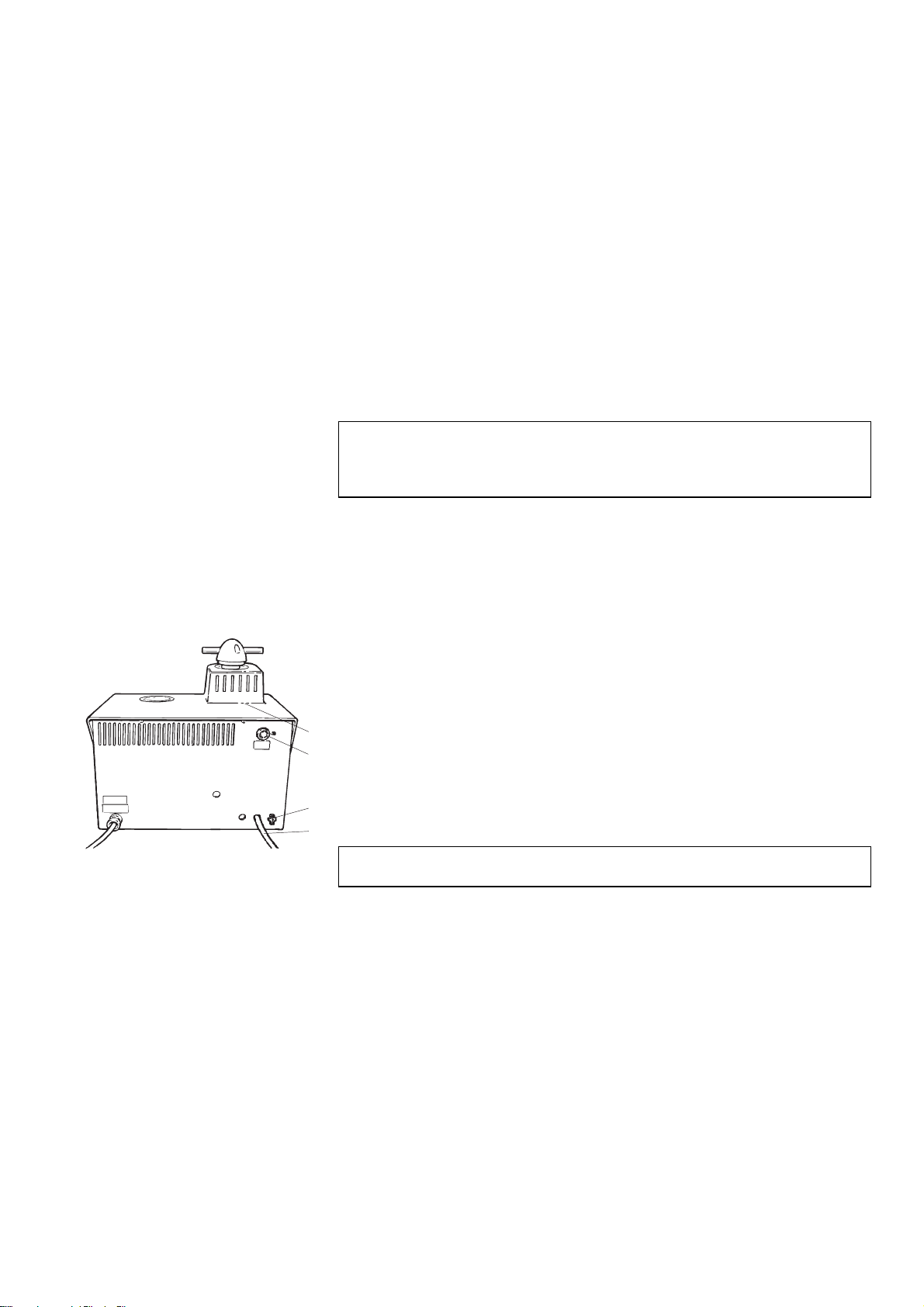

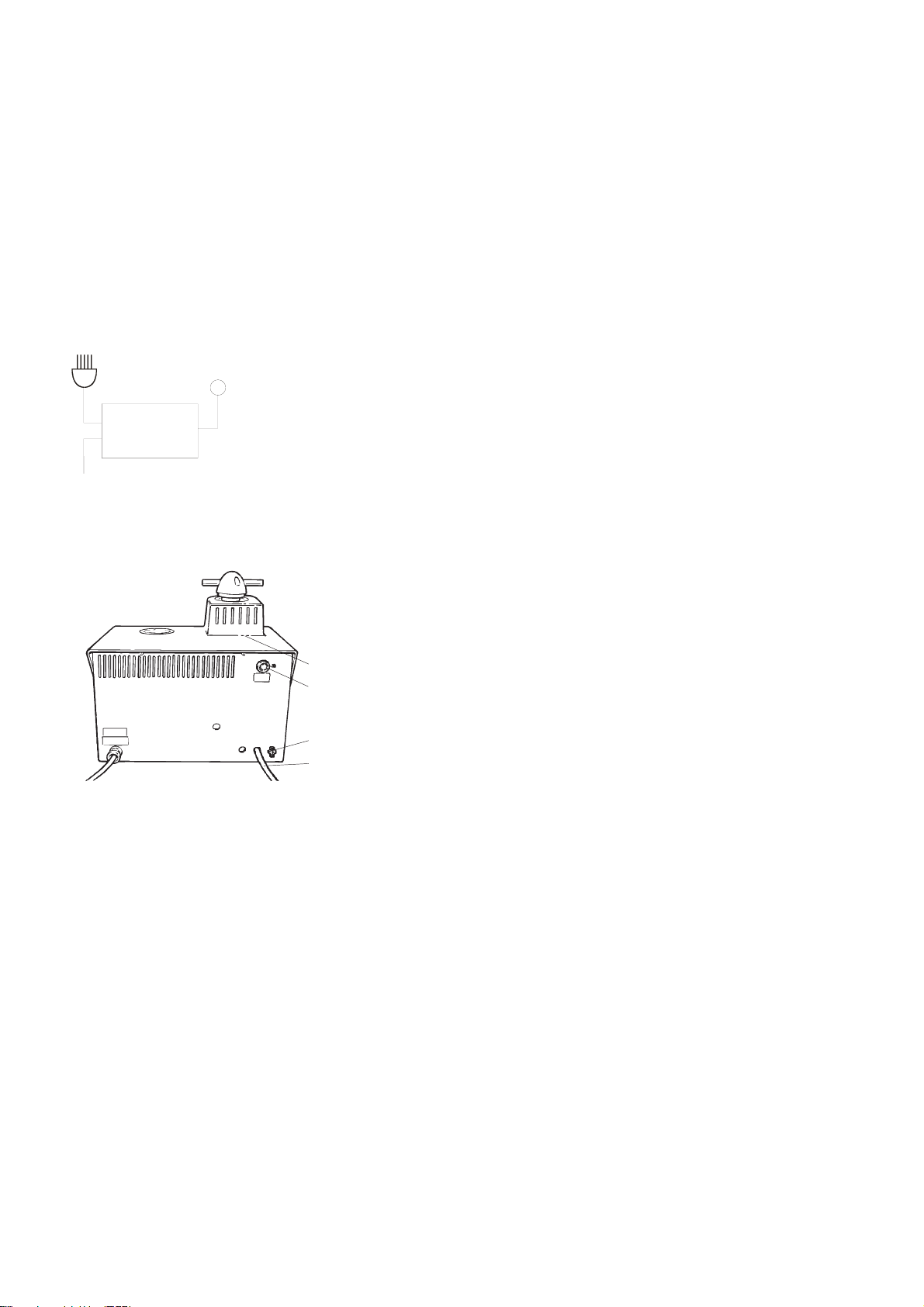

Getting Acquainted with

LaboPress-3

Take a moment to familiarise yourself with the location and

names of the LaboPress-3 components.

➁

➄

➃

➅

➀

➆

➂

Front panel

Top closure

Main switch

Mounting unit

Dust protection ring

Cover for mounting unit

Top closure holder

3

LaboPress-3

Instruction Manual

Noise Level

Supplying Power

Supplying Water

Water Inlet

Water inlet

Water outlet tube

Water Outlet

The noise level of the machine is 60 dB (A) measured when the

pump is running, at a distance of 1.0 m/39.4” from the machine.

LaboPress-3 is factory mounted with an electric cable. Mount a

plug on the cable:

Brown: phase

Blue: neutral

Yellow/green: earth

IMPORTANT

Check that the mains voltage corresponds to the voltage stated on the type

plate on the machine. Do not operate the machine before the transit screw

cap has been exchanged with the enclosed air filter.

Water for cooling may be supplied from the water mains or a

Recirculation Cooling Unit.

Mount the pressure hose onto the water inlet tube (pos.1) on the

back of the machine:

Insert the filter gasket in the coupling nut with the flat side

against the pressure hose.

Tighten the coupling nut completely.

➃

Mount the other end of the pressure hose on the water mains tap

for cold water:

➀

Mount the reduction ring with gasket on the water mains tap,

➄

➁

if necessary.

Introduce the gasket and tighten the coupling nut completely.

IMPORTANT

Only connect to cold water

Lead the water outlet tube (pos. 2) to the drain and be

absolutely sure to place the hose with a steady downward

slope and without any obstructions.

Attach the water outlet tube to the water outlet system.

4

LaboPress-3

Instruction Manual

Assembling the Mounting Unit

Removing the Cover

Installing the Lower Ram

Installing the Mounting Unit

Press the catch (pos. 4).

Press gently on both sides of the cover to release it, and lift it

up.

➃

➄

➁

➀

Catch

Place the lower ram on the top of the piston rod.

Turn the lower ram so that the holes in the axle journal on

top of the rod and ram line up, and insert the piston pin.

Make sure that the ends of the pin do not protrude.

IMPORTANT

The axle journal is part of the machine’s safety mechanism to protect

against damage to the machine. Please see: Maintenance. If it breaks, it

must only be replaced with a Struers replacement part or the safety

mechanism may not function.

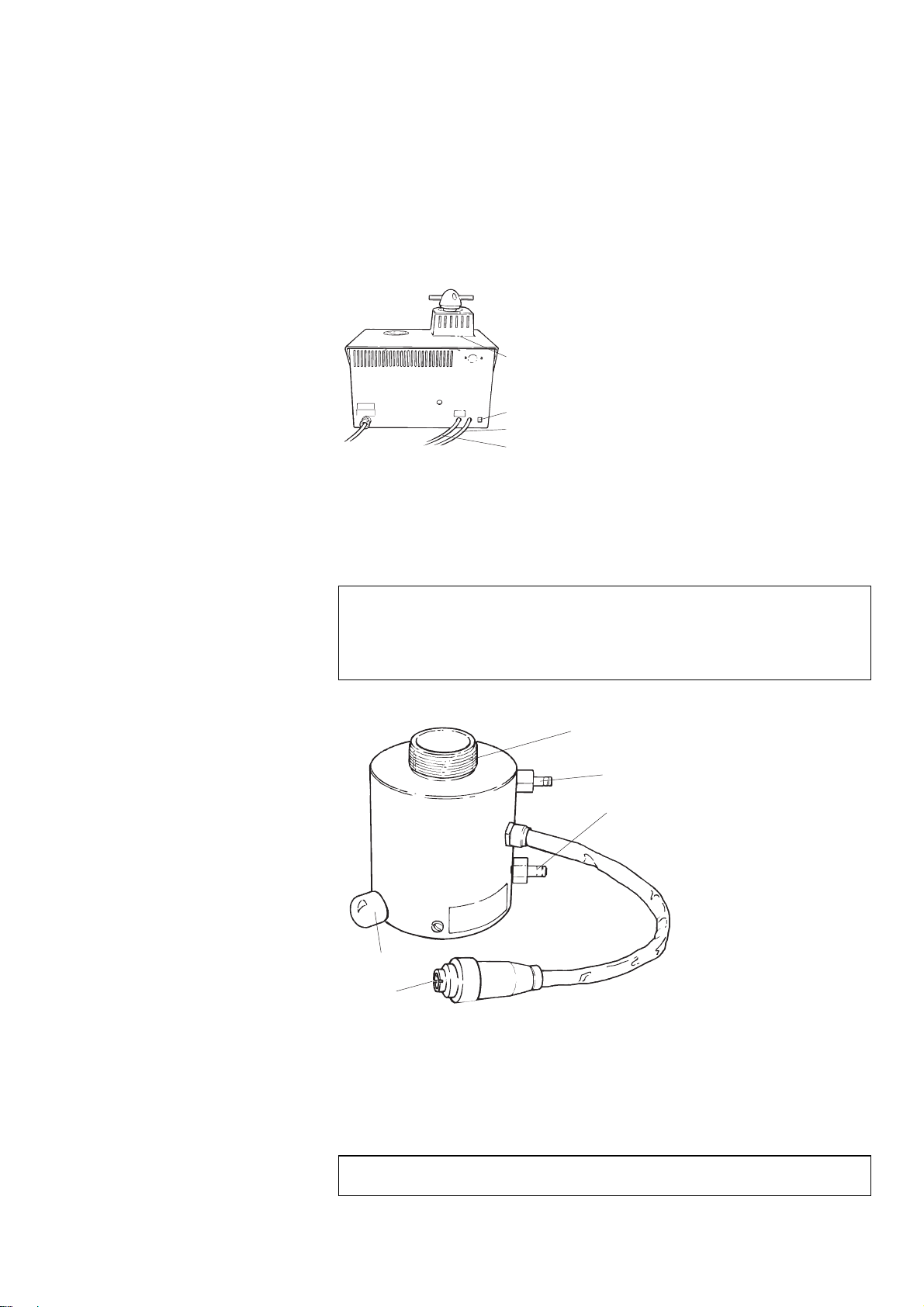

➀

➂

➃

➁

➄

Mounting cylinder

Fixation screw

Upper quick coupling for cooling water

Lower quick coupling for cooling water

Plug

IMPORTANT

Do not operate the machine whilst installing the mounting unit

5

Installing the Cover

➃

➄

➁

➀

Catch

Installing the

Dust Protection Ring

Disassembling

the Mounting Unit

Dropping the Lower Ram

Removing the

Dust Protection Ring

Removing the Cover

LaboPress-3

Instruction Manual

Unscrew the fixation screw about 10 mm.

Place the mounting cylinder over the lower ram with the

fixation screw in the position shown.

Turn the mounting unit in a clockwise direction until it stops.

Tighten the fixation screw completely.

Mount the tube with the straight quick coupling on the lower

quick coupling (position 4) of the mounting unit and push to

connect. Make sure that the ring comes to stop in the extreme

end of the quick coupling.

Mount the tube with the elbow quick coupling on the upper

quick coupling of the mounting unit (pos. 3) and push to

connect. Make sure that the ring comes to stop in the extreme

end of the quick coupling.

Mount the plug (pos. 5) in the socket. Tighten the coupling

nut.

Insert the barb into the front of the opening for the cover.

Insert the barbs on both sides of the cover into the cabinet.

Press the sides of the cabinet gently.

Press the rear end of the cover in so that the catch engages.

Place the dust protection ring around the mounting cylinder. The

concave side should face upwards.

Switch on the main power of the machine.

Press the key RAM DOWN

N to lower the ram to its lower

limit.

Lift out the dust protection ring.

Press the catch (position 4 above).

Press gently on both sides of the cover, to release it, and lift it

up.

6

LaboPress-3

Instruction Manual

Removing the Mounting Unit

➀

➂

➃

➁

➄

Removing the Lower Ram

Changing the Mounting Unit

IMPORTANT

Do not operate the machine whilst removing the mounting unit

Mounting cylinder

Fixation screw

Upper quick coupling for cooling water

Lower quick coupling for cooling water

Plug

Disconnect the plug (pos. 5) in the socket. Loosen the coupling

nut and pull.

Disconnect the tube with elbow quick coupling on the upper

quick coupling on the mounting unit (pos. 3). Pull the ring.

Wait 5 seconds to allow the water to flow out of the cooling

coil.

Disconnect the tube with straight quick coupling on the lower

quick coupling on the mounting unit (pos. 4). Pull the ring.

Unscrew the fixation screw about 10 mm.

Turn the mounting unit in an anti-clockwise direction until it

stops.

Lift the mounting unit.

Push the piston pin out of the lower ram and lift it off.

IMPORTANT

The axle journal is part of the machine’s safety mechanism to protect

against damage to the machine. Please see: Maintenance. If it breaks, it

must only be replaced with a Struers replacement part or the safety

mechanism may not function.

Follow the instructions for Removing the Mounting Unit and

Installing the Mounting Unit.

7

Using the Controls

A

Front Panel Controls of

LaboPress-3

LaboPress-3

Instruction Manual

2. Basic Operations

180°C

LaboPress-3

150°C

coustic Signals

Main Switch

8

Short Beep: when a key is pressed, a short beep indicates

that the command has been accepted.

Long Beep: a long beep indicates that the key is inactive at

that moment.

Three long beeps: indicate that the mounting process is

finished.

➄

➃

➅

➀

➁

➆

c Front panel

e Main switch

➂

LaboPress-3

Instruction Manual

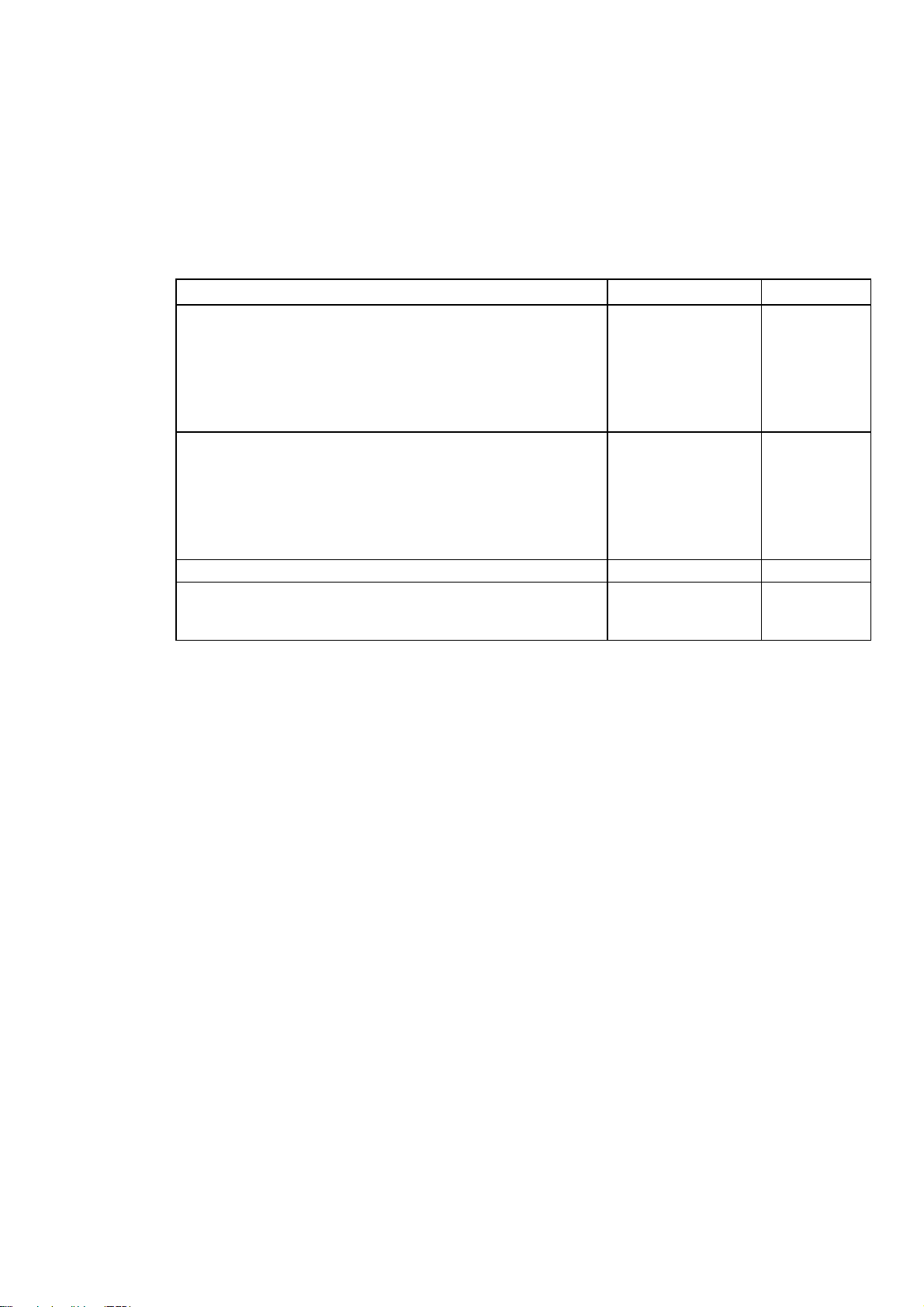

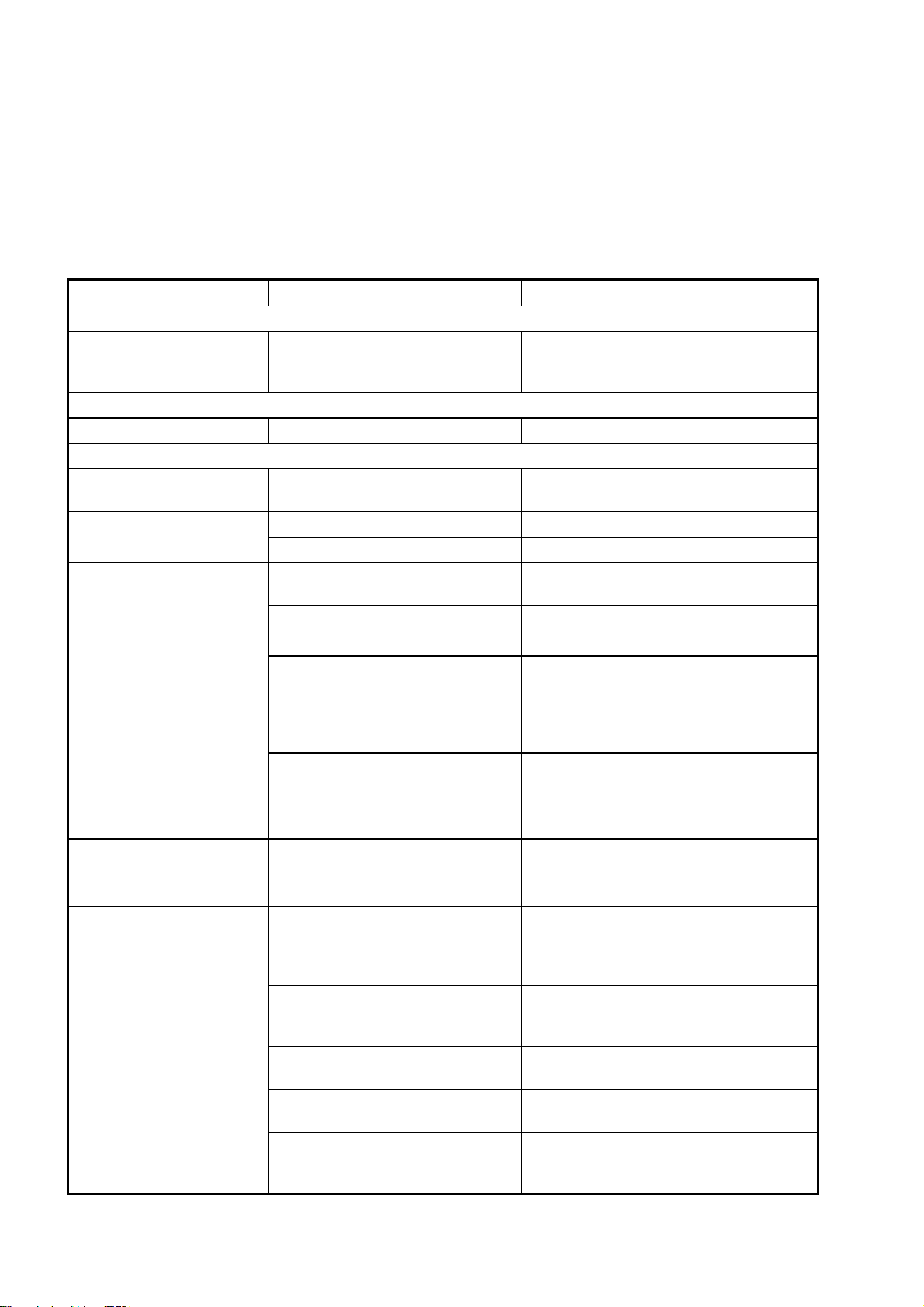

Pos. No. Key/Knob Function Pos. No. Key/Knob Function

MAIN

SWITCH

Turns the main power of the machine

on/off. The main switch is located to

the right of the cabinet.

HEATING

INDICATOR

¹

Lights up when heating is on.

POWER

POWER

START

s

STOP

o

RAM

UP

O

RAM

DOWN

N

Lights up when the main power is on.

Starts the automatic mounting

process.

Stops the mounting process,

followed by automatic release of

pressure. Stops the movement of the

lower ram.

Starts the upward movement of

lower ram. When started: stops the

upward movement of the lower ram.

The ram automatically stops when

the upper limit is reached.

Starts the downward movement of

lower ram. When started: Stops the

downward movement of the lower

ram. The ram automatically stops

when the lower limit is reached.

HEATING

1

HEATING

INDICATOR

2

HEATING

3

HEATING

INDICATOR

4

COOLING

180°C

180°C

150°C

150°C

¸

Selects a heating temperature of

180°C.

Lights up when the heating

temperature is set to 180°C.

Selects a heating temperature of

150°C.

Lights up when the heating

temperature is set to 150°C.

Adjustable knob for setting the

cooling time.

FORCE

f

HEAT

¹

Adjustable knob for setting the force

(pressure).

Adjustable knob for setting the

heating time.

5

COOLING

INDICATOR

6

OVERLOAD

¸

OVERLOAD

Lights up when cooling is on.

Lights up if the motor has been

overloaded.

9

LaboPress-3

Instruction Manual

Placing the Specimen

Pouring Resin over the Specimen

Placing Two Specimens

Press and hold RAM UP

limit.

Apply “Mould Release Agent” to the surface of the lower ram.

Place the specimen on the ram. The specimen must be clean,

dry and free from grease. The distance between the specimen

and the cylinder wall must be minimum 3 mm to avoid cracks

in the resin.

Press and hold RAM DOWN

limit.

Fill a suitable amount of resin into the cylinder by means of

the enclosed funnel.

Always make sure there is sufficient resin to cover the sample

after compression. Please note that the volume of the resin

reduces when the granulate becomes compressed. If insufficient

resin is used, the rams may come in contact with the sample, and

the cylinder may be damaged.

The “Mould Release Agent” must always be applied to the mounting rams

as a thin layer to prevent the resins sticking to the surface. By means of

Struers AntiStick a thin layer of stearate powder can easily be dabbed on

Follow the instructions in Placing the Specimen.

Apply “Mould Release Agent” to all surfaces of the

intermediate ram.

Place the intermediate ram on top of the resin.

Place the second specimen on the intermediate ram and fill

the cylinder with an adequate quantity of resin.

Again, make sure you use adequate resin!

O to raise the lower ram to its upper

N to lower the ram to its lower

Important

the rams.

10

LaboPress-3

Instruction Manual

Installing the Top Closure

Remove resin dust from the upper part of the mounting

cylinder.

Clean the cylindrical surface of the upper ram. Cured resin

can easily be removed without damage to the surface of the

ram using the scraper supplied.

Apply “Mould Release Agent” to all accessible surfaces of the

upper ram.

Place the top closure with the upper ram on the mounting

cylinder.

Press the top closure straight down, turning it counter-

clockwise until you hear a click.

Press the top closure down and turn it clockwise until its

lower limit.

Turn the top closure a quarter of a turn back.

Important

If the ram does not fit in the cylinder then check ram and cylinder for cured

resin. The tolerance between the cylinder and the ram is very fine and even

small amounts of resin from previous mounting may cause problems.

11

LaboPress-3

Instruction Manual

Starting the Mounting Process

Preheating with Low Pressure

Stopping the Mounting Process

Removing the Top Closure

Set the force.

Set the heating time.

Set the heating temperature (180/150°C).

Set the cooling time.

Press START

The mounting process can be followed on the heating and

cooling indicators.

Set the force to a low value to begin with. Adjust the force after

the desired period of preheating.

The machine automatically stops and relieves the pressure

when the cooling time has elapsed. The machine can be

stopped at any time during the mounting process by pressing

STOP

Cool the mounting cylinder in minimum 2 min before opening, after a

heating period. Please note that the mount possibly will be destroyed.

When the mounting process is finished:

Turn the top closure counter-clockwise until released from the

threads.

Press RAM UP

Place the top closure in the top closure holder.

o.

If you have stopped the machine during the mounting process:

s, and the process will run automatically.

O to raise the lower ram to its upper limit.

12

LaboPress-3

Instruction Manual

Reference Guide

Table of Contents Page

1. Advanced Operations

Installation of Recirculation Cooling Unit (Optional) ..................14

Socket for Recirculation ..........................................................14

2. Struers Metalog Guide™

............................................... 15

3. Application Guide for Hot Mounting

........................ 15

4. Accessories

......................................................................... 16

5. Consumables

....................................................................... 17

6. Trouble-Shooting

............................................................... 18

7. Maintenance

Daily Service ................................................................................... 20

Monthly Service .............................................................................. 20

Cleaning under the Lower Ram.............................................. 20

Cleaning the Rams .........................................................................20

Removing the Upper Ram .............................................................. 21

Lubricating the Threads for the Top Closure................................ 21

Decalcifying the Cooling Coil in the Mounting Unit..................... 21

Replacing the Cooling Water.......................................................... 22

Checking the Recirculating Cooling Unit...................................... 22

8. Technical Data

................................................................... 23

13

Installation of Recirculation

Cooling Unit (Optional)

LaboPress-3

Instruction Manual

1. Advanced Operations

A Recirculation Cooling Unit (TRECI) can be connected by means

of a Recirculation Cooling Unit Connector (ROPRE).

TRECI

ROPRE

LaboPress-3/

ProntoPress-10/ProntoPress-20

Socket for Recirculation

Outlet hose

Socket for recirculation

Connect the cable from the pump in TRECI to ROPRE, according

to the diagram of ROPRE.

Connect the cable with plug from ROPRE to the socket

(pos. 5) on the back of the mounting press.

Connect the cable from ROPRE to the mains.

Check that the pump rotates in the direction indicated on the

pump. If the direction is incorrect, switch two of the phases in

the connection to the pump in TRECI (3-phase versions only).

Replace the outlet tube on the pump in TRECI with the non-

➃

➀

➄

➁

return valve with elbow and hexagon nipple from ROPRE.

Struers recommends that you seal the threads.

Connect the pressure hose of the mounting press to the

hexagon nipple. Remember to mount the gasket.

Lead the outlet hose (pos. 2) to the inlet on TRECI. Be

absolutely sure to place the hose with a steady downward

slope and without obstructions.

Attach the water outlet to the inlet of TRECI.

14

LaboPress-3

Instruction Manual

2. Struers Metalog Guide™

Struers Metalog Guide

common materials, based on a simple analysis of two key properties: hardness and ductility. Finding the right method, including

choice of consumables is easy. Always consult Struers Metalog

Guide

mens.

for the correct preparation method for the actual speci-

offers preparation methods for the most

Metalogram

Metalog Method:

Preparation Philosophy

Metalog Process

Metalog Master

Metalog Code

Struers Metalog Guide

A quick and safe guide to the right preparation method.

A complete catalogue of preparation methods, based on Struers’

extensive materialographic experience, and employing Struers’

range of consumables.

The basics of modern specimen preparation, seen from a

professional point of view.

The materialographic preparation process from start to finish,

logically explained.

A combined trouble-shooting guide and supply of in-depth

information on the processes of mechanical preparation, including

an expert system for the solving of preparation problems.

Quick access to the relevant consumables for the chosen

preparation methods.

contains 6 useful chapters:

Struers Metalog Guide

A complete guide to materialographic specimen preparation. Contact your

local dealer for a free copy of Metalog Guide.

3. Application Guide for Hot Mounting

Useful mounting data and hints can be found in the Struers

Application Guide for Hot Mounting or visit the Struers website

on http://www.struers.com

and see the section on Knowledge

15

LaboPress-3

Instruction Manual

4. Accessories

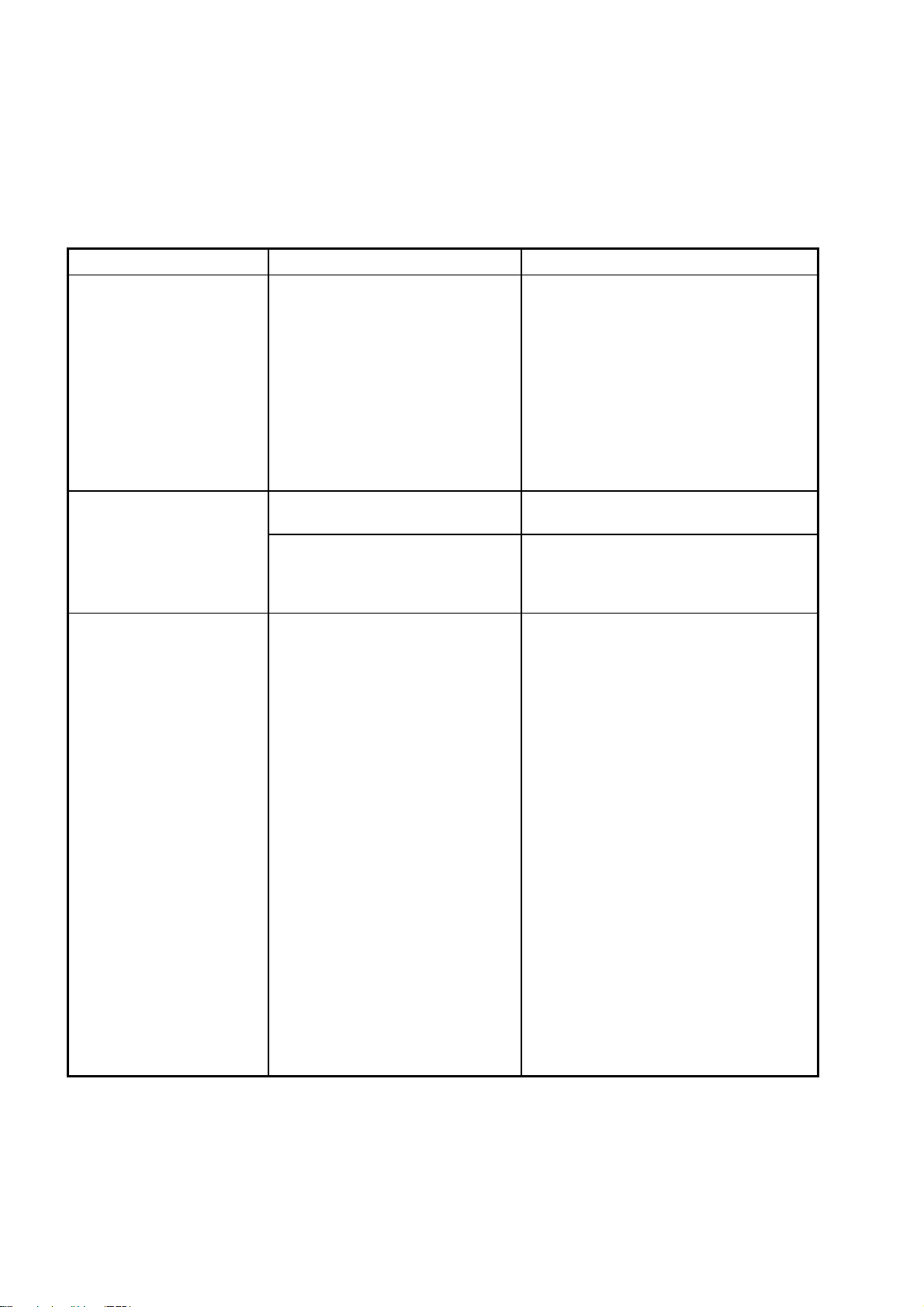

Type Description Code

Mounting Unit

consisting of cylinder, upper and lower ram, heating/cooling

unit and top closure

Intermediate Ram

for making 2 simultaneous mounts

Recirculation Cooling Unit

Recirculation Cooling Unit Connector

for connection of Recirculation Cooling Unit (TRECI) to

LaboPress-3.

25 mm dia.

30 mm dia.

1 ¼” dia.

1 ½” dia.

40 mm dia.

50 mm dia.

25 mm dia.

30 mm dia.

1 ¼” dia.

1 ½” dia.

40 mm dia.

50 mm dia.

TRECI

ROPRE

CYNMI

CYNTE

CYNQU

CYNHA

CYNIF

CYNAM

CYLDO

CYLDO

CYLDO

CYLDO

CYLDO

CYLDO

16

LaboPress-3

Instruction Manual

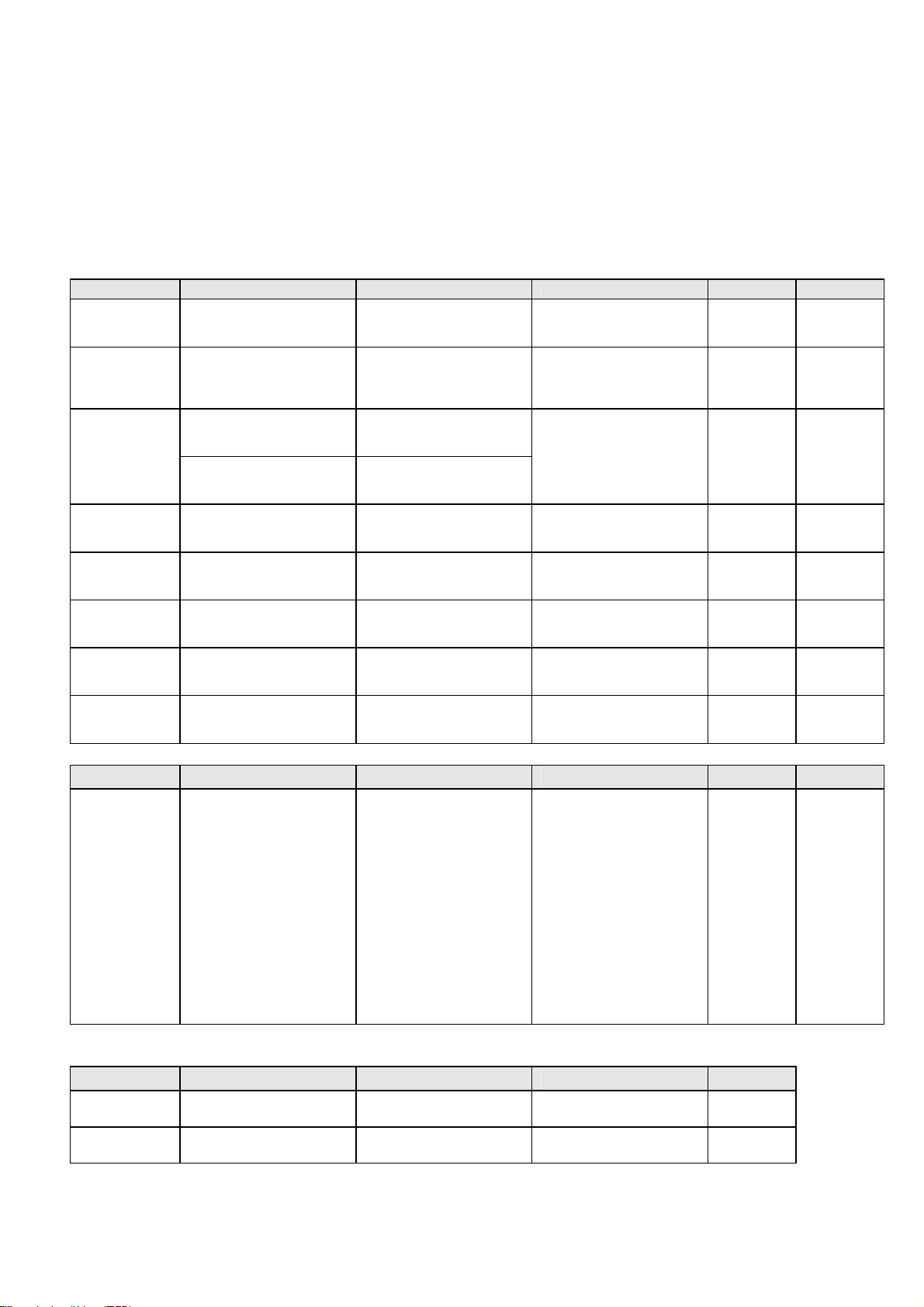

5. Consumables

Resin Application Specific property Material Contents Code

ConduFast

(Resin 1)

SpeciFast

(Resin 3)

PolyFast Edge retention Very low shrinkage

Examination in scanning

IsoFast

(Resin 4)

DuroFast

(Resin 5)

MultiFast Routine examination,

MultiFast

Green

MultiFast

Brown

Product Application Specific property Material Contents Code

Pre-Mount

Product Application Material Contents Code

Mount

Release Wax

AntiStick

Electropolishing Electrically conductive

Glass clear mounts

Porous samples

Surface electrical insulator

for ConduFast

electron microscope

Edge retention

Planeness

Edge retention

Planeness

Backup resin

Routine examination

Colour marking

Routine examination

Colour marking

Very low shrinkage

Transparent

Medium shrinkage

Medium removal rate

Electrically conductive

Low emission in the

vacuum chamber.

Low shrinkage

Low removal rate

Very low shrinkage

Good adhesion

Very low removal rate

Low shrinkage

Medium removal rate

Low shrinkage

Medium removal rate

Low shrinkage

Medium removal rate

Serial mounting of

uncomplicated shapes

Easy to handle

Low shrinkage

Medium removal rate

To avoid sticking of the

mounts to the rams

To avoid sticking of the

mounts to the rams

Wax 24 g PREWA

Very fine stearate powder 8 g FASTI

Acrylic resin with iron

powder filler

Thermoplastic, Grey

Acrylic

Thermoplastic

Phenolic resin with carbon

filler

Thermosetting, Black

Dialylphtalate with glass

fibre filler

Thermosetting, Green

Epoxy with mineral filler

Thermosetting, Black

Phenolic resin with wood

flour filler

Thermosetting, Black

Phenolic resin with wood

flour filler

Thermosetting, Green

Phenolic resin with wood

flour filler

Thermosetting, Brown

Phenolic resin with wood

flour filler

In tablet form

Thermosetting, Black

1 kg RESFE

1.5 kg

7.5 kg

25 kg

1 kg

7.5 kg

1 kg

7.5 kg

1 kg

7.5 kg

2.5 kg

7.5 kg

25 kg

2.5 kg

7.5 kg

25 kg

2.5 kg

7.5 kg

25 kg

25 mm/

1” dia.

approx.

1100 pcs.

10 kg

30 mm/

1.1/4” dia.

approx.

760 pcs.

10 kg

40 mm/

1 ½” dia.

approx.

460 pcs.

10 kg

RESTH

RESYV

RESFA

FAPSA

FAPME

RESDI

RESTY

RESIF

RESEN

RESRU

RESUK

RESLA

FAGSA

FAGME

FAGLA

FABSA

FABME

FABLA

RESUN

RESGI

RESAM

17

LaboPress-3

Instruction Manual

6. Trouble-Shooting

Display/error Cause Action

Error Message

Overload The motor has been overloaded. Let the motor cool down and start the

mounting press again. If this does not

help: Call a Struers service technician.

Acoustic Signals

Long beep. The command can not be accepted. Check User’s Guide, Section 2.

Machine Problems

Process will not start. Heating time and cooling time are

set at zero.

Incorrect setting of force/pressure. Set the correct parameter. Insufficient compression.

Defect in the pressure system. Call a Struers service technician.

Incorrect setting of time or

temperature for heating.

Defect in the heating system. Call a Struers service technician.

Insufficient cooling.

Cooling water drips

underneath the machine.

The top closure will not start

threading on the mounting

cylinder.

Incorrect setting of time for cooling. Set the correct parameter.

Mains tap supplying cooling water

is either closed or not opened

sufficiently.

Filter at the water inlet is blocked.

The water is too hot.

Insufficient water within the

Recirculation Cooling Unit. The

water is too hot.

Defect in the cooling system. Call a Struers service technician.

The quick coupling is not mounted

correctly.

The top closure is not mounted

correctly.

The upper ram is too hot. Let the top closure and the upper ram cool

Cured resin inside the mounting

cylinder.

Cured resin on the cylindrical

surface of the upper ram.

The top closure has been dropped

on the floor/table, causing a bulge

in the edge of the ram.

Set the correct times.

Set the correct parameters. Insufficient heating.

Open the tap.

Clean the filter.

Fill to the correct water level. See the

section: Maintenance.

Remove the cover from the mounting unit

and check the quick coupling connections.

Press the top closure straight down,

turning it counter-clockwise until you hear

a click.

Turn the top closure clockwise.

down.

Reduce the mounting temperature.

Clean the mounting cylinder with a brass

wire brush.

Clean the ram with the scraper supplied.

Replace the upper ram.

18

LaboPress-3

Instruction Manual

Error Cause Action

Damage to the threaded connection

in the top closure or to the upper

ram.

The top closure cannot be

screwed down completely.

The top closure can not be

loosened.

Dirt in the threads on the top

closure and the mounting cylinder.

The disc for thermal insulation,

placed on the top of the upper ram,

has a larger diameter than the

upper ram.

The top closure has not been

turned ¼ turn back before starting

the process.

Cured resin on the cylindrical

surface of the top ram.

Dirt in the threads of the top

closure.

Remove the upper ram from the top

closure (see instructions in chapter

Maintenance). Try both the following

procedures to identify the problem:

Try to mount the top closure, without

the upper ram. If this is not possible,

call a Struers service technician.

Try to insert the disconnected upper

ram into the mounting cylinder. If this is

not possible, call a Struers service

technician.

Clean the threads.

Use only a dry lubricant powder.

Call a Struers service technician.

To release the top closure:

- Move the lower ram up and down

several times.

If this does not help:

- Put heating on for 1 min. and try

again.

If this does not help:

- Complete a mounting process without

force, but with heating and cooling

time of about 15 min.

If this does not help:

- Remove the two handles on the top

closure.

- Remove the plastic cover from the top

closure (See Maintenance).

- Loosen the top closure with a fork

spanner.

19

Daily Service

Monthly Service

Cleaning under the Lower Ram

Cleaning the Rams

LaboPress-3

Instruction Manual

7. Maintenance

Clean all accessible surfaces with a moist cloth.

When mounting, some old cured resin will fall down from the

lower ram and built up underneath. The cured resin must be

cleaned away, to avoid it harming the machine. The axle journal

securing the lower ram has been designed to break in this case,

thus preventing serious damage to the machine.

Remove the mounting unit. See this section.

Remove the resin under the lower ram with a cloth or a soft

brush.

Install the mounting unit. See this section.

Before each mounting, check that there is no resin left on the flat

surface of the rams from previous operations. Clean the cylindrical surface of the upper ram and optional intermediate ram as

this may cause problems with travel in the cylinder and mounting

the top closure. Cured resin can easily be removed without any

damage to the surface of the rams using the scraper supplied.

If the rams have been scratched on the polished surfaces,

disassemble and polish them with 6 or 3 µm diamonds on a

polishing cloth.

IMPORTANT

Do not polish the surface on the sides of the rams. If the sides of the rams

are heavily scratched, they must be scrapped.

20

LaboPress-3

Instruction Manual

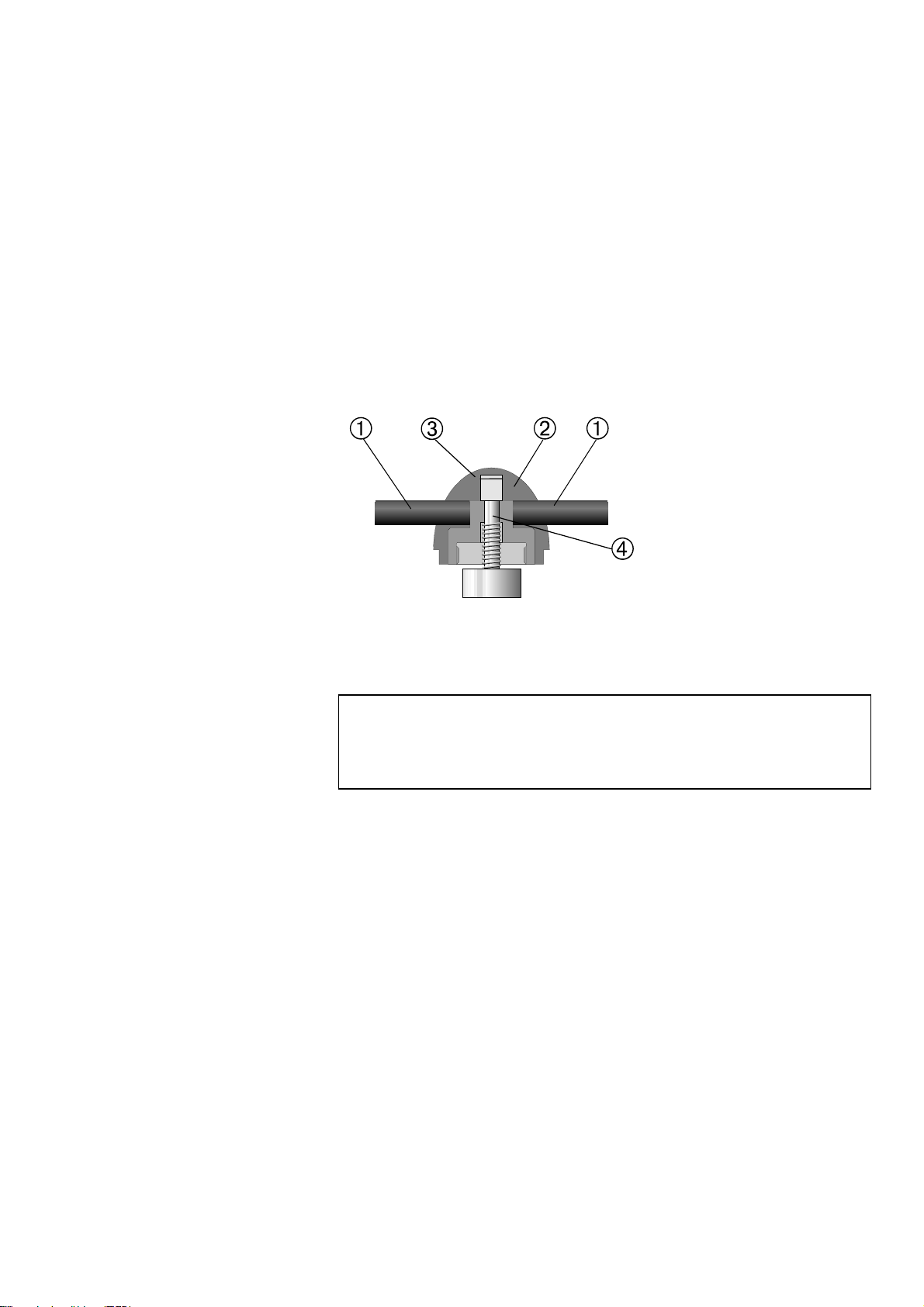

Removing the Upper Ram

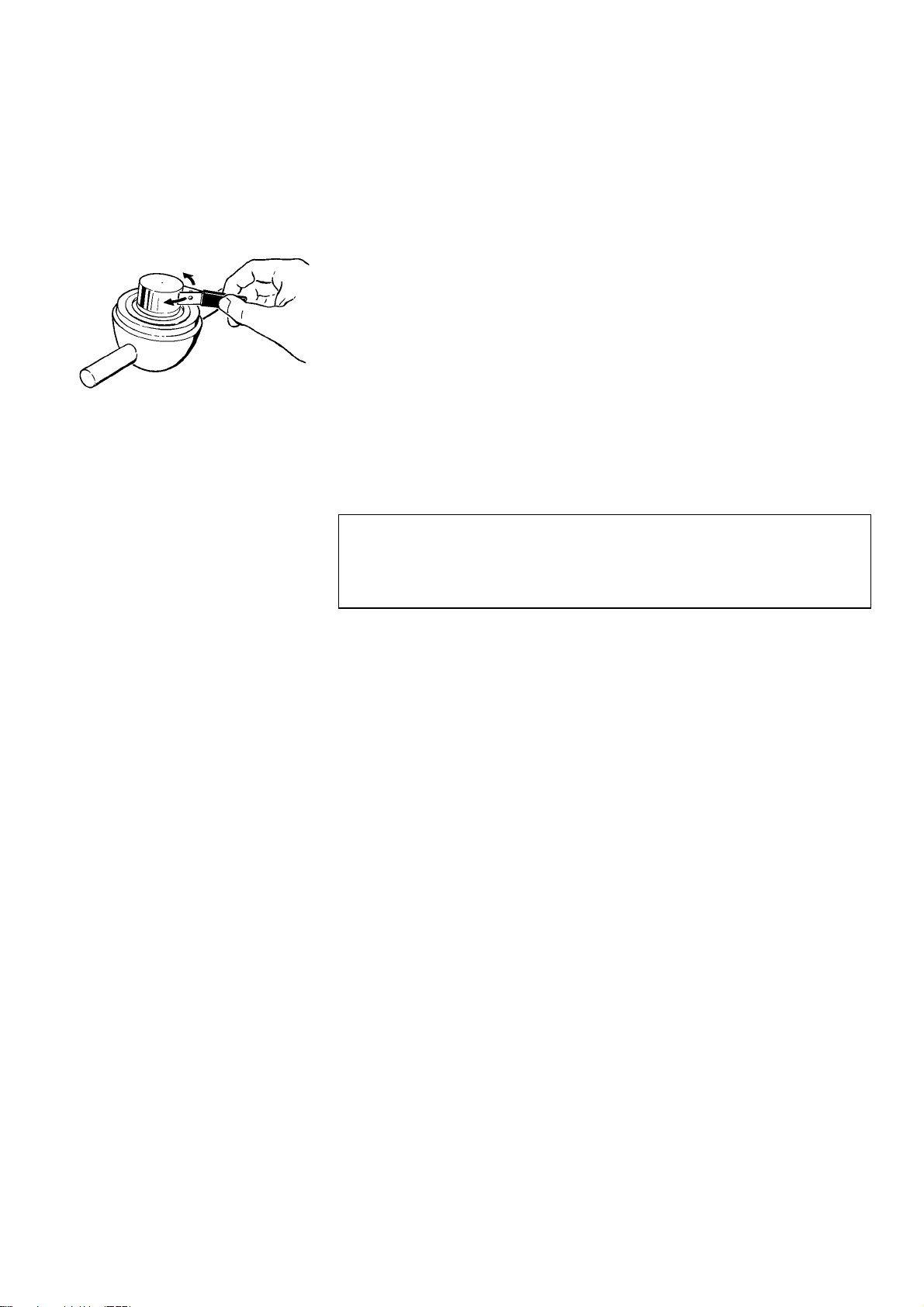

Lubricating the Threads for the

Top Closure

Take the cover plugs out of the ends of the handles and

unscrew them with an allen key. (pos. 1).

Remove the plastic cover (pos.2).

Lift the upper ram and remove the lock washer (pos.3).

Pull out the upper ram. Do not remove the rod (pos. 4) from

the upper ram unless absolutely necessary.

If it is necessary to remove the rod, hold the upper ram in a

vice or a similar device. The ram surface must be protected

with plastic or soft metal.

Handle

Plastic cover

Lock washer

Rod

In case there is any friction in the threads, they should be

lubricated with a dry lubricant such as MoS

2 powder or graphite.

Decalcifying the Cooling Coil in

the Mounting Unit

IMPORTANT

Please observe that the threads in the joint between the top closure and the

mounting cylinder must not be lubricated with oil or grease. As the mounting

cylinder operates at high temperatures, only a dry lubricant, resistant to high

temperatures, can be used.

When using cooling water from the mains tap in areas with a high

chalk or mineral content, deposits can build up in the cooling coil.

This may reduce the cooling effect, so once a year the cooling coil

should be decalcified.

Remove the mounting unit. (See this section.)

Flush the coil with a mild decalcifying fluid, such as that used

for coffee machines.

Flush the cooling coil with clean water.

Re-install the mounting unit.

21

LaboPress-3

Instruction Manual

Replacing the Cooling Water

Checking the Recirculation

Cooling Unit

Only relevant when a Recirculation Cooling Unit is connected:

Replace the cooling water in the Recirculation Cooling Unit at

least once a month.

Place a Disposable Plastic Container (TREPO) in the tank

and fold it over the edge.

Fill the tank with 30 l of water. NB! Too high a level of

coolant in the tank might damage the pump.

Add Struers Additive according to the instructions.

Put the lid on the tank.

Place the pump in the lid

IMPORTANT

Always maintain the correct concentration of Struers Additive in the cooling

water (percentage stated on the container of the Additive). Remember to

add Struers Additive each time you refill with water.

The cooling unit should be checked for cooling water every week

and refilled when the flushing pump cannot reach the cooling

water. Remember to add Struers Additive for Cooling Fluid: One

part of Additive for 33 parts of water.

The concentration of additive should always lie between 2.7 and

3.3%; the pH should be around 9. Replace the cooling water if pH

is T 8.0.

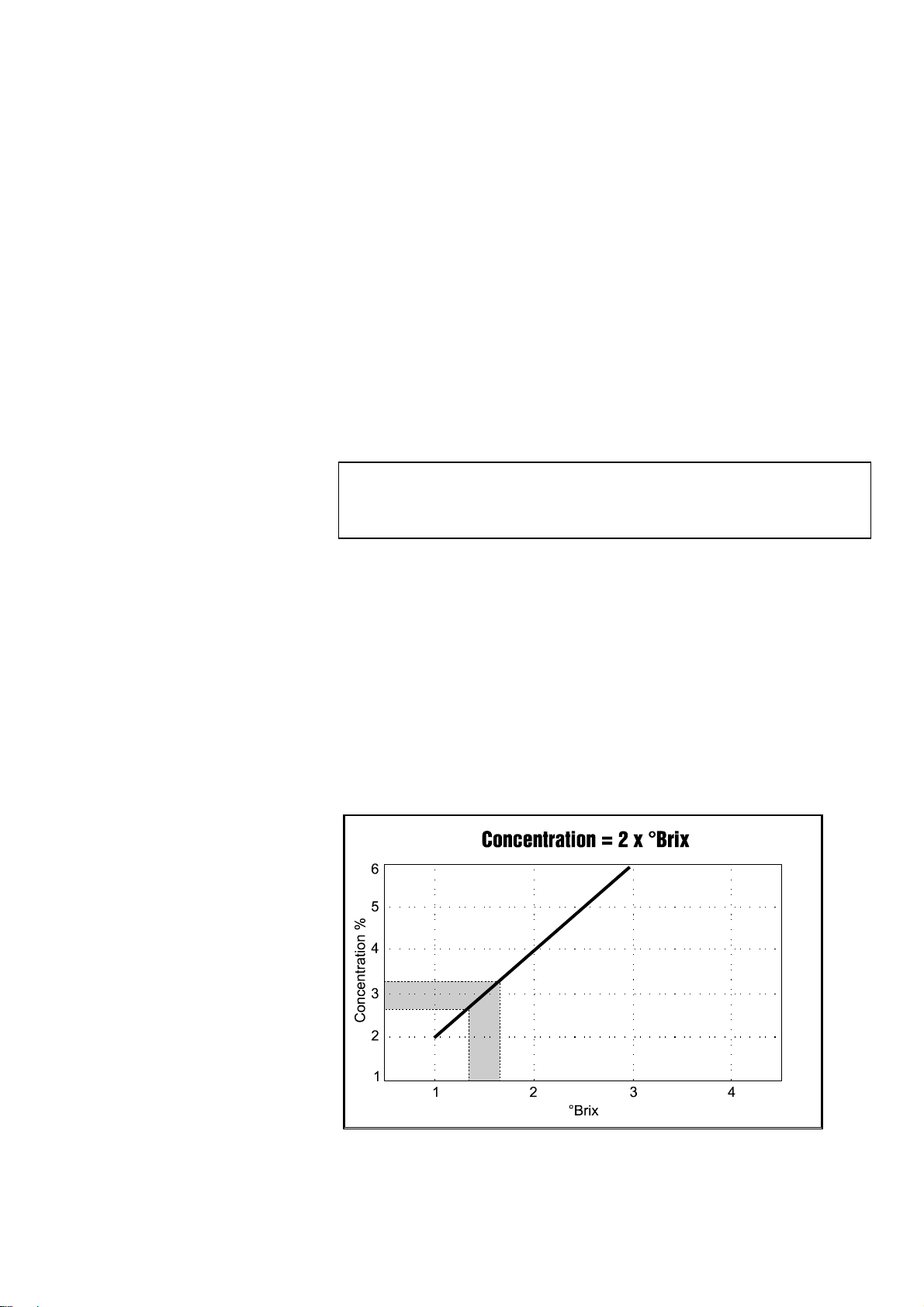

To check the concentration of additive, use a refractometer (0-10

Brix, see diagram.). Concentration = 2 x Brix. Add Struers

Additive for Cooling Fluid if the concentration is lower than 2.7%.

Add water if the concentration is higher than 3.3%.

22

LaboPress-3

Instruction Manual

8. Technical Data

Subject Specifications

Mounting Units

(Optional)

Compression Force on piston rod Variable between 0 -

Heating

(with pressure on)

Time Variable between 0 and 15 min

Cooling

(with pressure on)

Water Supply Tap Water or

Pressure for tap water 1 - 10 bar 14.5 - 145 psi

Inlet

Supply Voltage Power phases 1

Power consumption:

Diameter

Temperature 150/180 °C 302/356°F

Time Variable between 0 and 15 min

Recirculation Cooling

Unit

Max. Total

Mounting Unit

Metric/International US

25, 30, 40, 50 mm

50 kN

1

¼" 1½"

Variable between 0 12000 Lbf

½" or ¾" ½" or ¾"

1500W

750W

Voltage/frequency: Max. continuous load

100-120V / 50Hz

100-120V / 60Hz

220-240V / 50Hz

220-240V / 60Hz

Dimensions and

Weight

Width 420 mm

Depth 580 mm

Height (Mounting Unit

and Top Closure

installed)

Weight 38 kg

10A (100V) - 12A (120V)

10A (100V) - 12A (120V)

4.5A (220V)- 5.0A (240V)

4.5A (220V)- 5.0A (240V)

420 mm

23

Placing the Specimen

Pouring Resin over the

Specimen

Installing the Top Closure

Starting the Mounting Process

Stopping the Mounting Process

Removing the Top Closure

LaboPress-3

Instruction Manual

Quick Reference Card

Press and hold RAM UP

limit.

Apply “Mould Release Agent” to the surface of the lower ram.

Place the specimen on the ram.

Press and hold RAM DOWN

limit.

Fill a suitable amount of resin into the cylinder through the

funnel.

Remove resin dust from the upper part of the mounting

cylinder.

Clean the cylindrical surface of the upper ram. Cured resin

can easily be removed without damage to the surface of the

ram using the scraper supplied.

Apply “Mould Release Agent” to all accessible surfaces of the

upper ram.

Place the top closure with the upper ram on the mounting

cylinder.

Press the top closure straight down, turning it counter-

clockwise until you hear a click.

Press the top closure down and turn it clockwise until its

lower limit.

Turn the top closure a quarter of a turn back.

Set the force.

Set the heating time.

Set the heating temperature (180/150°C).

Set the cooling time.

Press START

The machine automatically stops and relieves the pressure

when the cooling time has elapsed.

When the mounting process is finished:

Turn the top closure counter-clockwise until released from the

thread.

Press RAM UP

Place the top closure in the top closure holder.

s, and the process will run automatically.

O to raise the lower ram to its upper limit.

O to raise the lower ram to its upper

N to lower the ram to its lower

24

LaboPress-3

Gebrauchsanweisung

Handbuch Nr.: 15087003

Auslieferungsdatum 11.01.2008

LaboPress-3

Gebrauchsanweisung

Inhaltsverzeichnis Seite

Benutzerhandbuch ....................................................1

Referenzhandbuch...................................................13

Schnellinformation..................................................24

Geben Sie bitte bei technischen Anfragen oder bei der Bestellung von Ersatzteilen immer die Seriennummer

und die Spannung/Frequenz an. Diese Angaben finden Sie auf dem am Gerät angebrachten Typenschild.

Datum und Artikelnummer der Gebrauchsanweisung sind uns u.U. ebenfalls mitzuteilen. Diese Information

finden Sie auf dem Deckblatt der Gebrauchsanweisung.

Beachten Sie bitte die nachstehend genannten Einschränkungen.

Gebrauchsanweisungen: Eine von der Firma Struers veröffentlichte Gebrauchsanweisung darf nur in

Zusammenhang mit den Struers Geräten benützt werden, für die diese Gebrauchsanweisung ausdrücklich

bestimmt ist.

Wartungshandbücher: Ein von der Firma Struers veröffentlichtes Wartungshandbuch darf nur von

ausgebildeten Technikern benutzt werden, die von Struers dazu berechtigt wurden. Das Wartungshandbuch

darf nur in Zusammenhang mit dem Struers Gerät benützt werden, für das dieses Wartungshandbuch

ausdrücklich bestimmt ist.

Struers übernimmt für Irrtümer in Text und Bild der Veröffentlichungen keine Verantwortung. Wir behalten

uns das Recht vor, den Inhalt der Gebrauchsanweisungen und Wartungshandbücher jederzeit und ohne

Vorankündigung zu ändern. In den Gebrauchsanweisungen und Wartungshandbüchern können Zubehör

und Teile erwähnt sein, die nicht Gegenstand oder Teil der laufenden Geräteversion sind.

Inhalt von Gebrauchsanweisungen/Wartungshandbücher ist Eigentum der Firma Struers. Kein Teil dieser

Veröffentlichungen darf ohne schriftliche Genehmigung von Struers reproduziert werden.

Alle Rechte vorbehalten © Struers 2008.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

LaboPress-3

Gebrauchsanweisung

LaboPress-3

Sicherheitshinweise

Vor Gebrauch

sorgfältig lesen

1. Der Benutzer sollte sich anhand der Gebrauchsanweisung mit dem

Gebrauch des Gerätes ausgiebig vertraut machen

2. Die Maschine muß in gut belüftetem Raum und in geeigneter

Arbeitshöhe auf einem Tisch aufgestellt werden.

3. Vergewissern Sie sich, daß die vorliegende Netzspannung mit der auf

der Rückseite des Gerätes und auf der Heiz/Kühleinheit angegebenen

Spannung übereinstimmt. Das Gerät muß geerdet sein.

4. Prüfen Sie die Wasseranschlüsse auf korrekten Anschluß und

Undichtheiten. Die Wasserversorgung muß während des Betriebs

aufgedreht sein.

Struers empfiehlt das der Wasseranschluss nach Arbeitsende

geschlossen wird.

5. Vergewissern Sie sich, daß der Abflußschlauch in geeigneter Weise an

den Abfluß angeschlossen ist.

6. Überzeugen Sie sich vor dem Start des Einbettvorgangs, ob die

Einbetteinheit korrekt montiert ist.

7. Bevor Sie die Presse in Gang setzen sollten Sie nachprüfen, ob der

obere Stempel im Einbettzylinder entweder richtig eingebaut, oder ganz

daraus entfernt ist.

8. Die Einbettpresse nicht mit höherer Kraft/Druck arbeiten lassen als es

in den Struers Anwendungshilfen für das Warmeinbetten für den

verwendeten Zylinderdurchmesser angegeben ist.

9. Bevor der Einbettzylinder im Anschluß an einen Heizzyklus geöffnet

wird, sollte er sich mindestens zwei Minuten lang abkühlen.

10. Während des Aus/Einbaus der Einbetteinheit darf das Gerät nicht in

Gang gesetzt werden.

Für die Benutzung der Geräte bzw. der Maschinen sind die Verbrauchsmaterialien von Struers vorgesehen.

Falls unzulässiger Gebrauch, falsche Installation, Veränderung, Vernachlässigung, unsachgemäße

Reparatur oder ein Unfall vorliegt, übernimmt Struers weder die Verantwortung für Schäden des Benutzers,

noch für solche am Gerät.

Die für Kundendienst und Reparatur erforderliche Demontage irgendwelcher Teile des Gerätes bzw. der

Maschine sollte immer nur von qualifiziertem Fachpersonal (Elektromechanik, Elektronik, Pneumatik usw.)

vorgenommen werden.

LaboPress-3

Gebrauchsanweisung

Benutzerhandbuch

Inhaltsverzeichnis Seite

1. Zu Beginn

Packungsinhalt prüfen ..................................................................... 2

LaboPress-3................................................................................ 2

Einbetteinheit............................................................................ 2

LaboPress-3 auspacken .................................................................... 2

LaboPress-3 aufstellen ..................................................................... 2

Transportschraubkappe ................................................................... 2

LaboPress-3 kennenlernen............................................................... 3

Geräuschpegel................................................................................... 4

Netzanschluß ....................................................................................4

Wasseranschluß................................................................................ 4

Wasserzufluß ............................................................................. 4

Wasserabfluß ............................................................................. 4

Einbetteinheit zusammenbauen...................................................... 5

Abdeckung abnehmen ............................................................... 5

Unteren Stempel einbauen ....................................................... 5

Einbetteinheit montieren.......................................................... 5

Abdeckung montieren ...............................................................6

Staubschutzring anbringen....................................................... 6

Einbetteinheit zerlegen .................................................................... 6

Unteren Stempel absenken....................................................... 6

Staubschutzring abnehmen ...................................................... 6

Abdeckung abnehmen ............................................................... 6

Einbetteinheit ausbauen..................................................................7

Entfernen des Unterstempels .......................................................... 7

Einbetteinheit auswechseln ............................................................. 7

2. Grundzüge der Bedienung

Gebrauch der Bedienelemente......................................................... 8

Bedienungsfeld des LaboPress-3 .............................................. 8

Akustische Signale .................................................................... 8

Hauptschalter ............................................................................ 8

Probe einlegen................................................................................. 10

Einbettmittel über die Probe gießen ......................................10

Zwei Proben einlegen...................................................................... 10

Verschluß aufsetzen .......................................................................11

Einbettvorgang starten ..................................................................12

Vorheizen mit niedrigem Druck .............................................12

Einbettvorgang stoppen .................................................................12

Verschluß abnehmen ...................................................................... 12

1

Packungsinhalt prüfen

LaboPress-3

Einbetteinheit

LaboPress-3 auspacken

LaboPress-3 aufstellen

Transportschraubkappe

LaboPress-3

Gebrauchsanweisung

1. Zu Beginn

Folgende Gegenstände sollten in der Verpackung enthalten sein:

1 LaboPress-3 Gerät

1 Druckschlauch

1 Filterdichtung

1 Dichtung

1 Reduktionsring mit Dichtung

2 Meßlöffeln für Einbettmittel

1 Trichter

1 Luftfilter

1 Manualsatz

1 Einbetteinheit

1 Verschluß mit oberem Stempel

1 Unterer Stempel

1 Stempelstift

1 Staubschutzring

1 Anti-Haftmittel (FASTI)

1 Schaber (PROAN)

Nehmen Sie LaboPress-3 vom Boden der Verpackung ab; dazu

entfernen Sie die vier Schrauben von der Unterseite her.

LaboPress-3 sollte auf einem stabilen Tisch in geeigneter

Arbeitshöhe aufgestellt werden. Das Gerät muß sich in Nähe des

Netzanschlusses, der Wasserversorgung und des Wasserabflusses

befinden. Falls eine Wasserkühlung verwendet wird, muß für die

Umlaufkühlung (TRECI) unter dem Tisch ausreichend Platz zur

Verfügung stehen.

Folgender Vorgang muß duchgeführt werden, bevor das Gerät in

Betrieb genommen wird:

Die Transportschraubkappe mit dem Luftfilter austauschen

um den Druck im hydraulischen System auszugleichen.

Die Transportschraubkappe ist unter dem Deckel für die Einbetteinheit

angebracht.

2

LaboPress-3

Gebrauchsanweisung

LaboPress-3 kennenlernen

Nehmen Sie sich einen Augenblick Zeit, um Lage und

Bezeichnung aller Teile des LaboPress-3 kennenzulernen.

➁

➄

➃

➅

➀

➆

➂

Bedienungsfeld

Verschluß

Hauptschalter

Einbetteinheit

Staubschutz

Abdeckung der Einbetteinheit

Halterung für den Verschluß

3

LaboPress-3

Gebrauchsanweisung

Geräuschpegel

Netzanschluß

Wasseranschluß

Wasserzufluß

Wasserzufluß

Wasserabfluß

Wasserabfluß

Der Geräuschpegel der Maschine beträgt etwa 60 dB (A),

gemessen bei laufender Pumpe in einer Entfernung von 1,0

m/39.4" zum Gerät.

LaboPress-3 wird mit elektrischem Anschlußkabel geliefert.

Bringen Sie einen Stecker am Kabel an, und schließen Sie die

Maschine an das Netz an:

Braun: Phase

Blau: Neutral

Gelb/grün: Erde

WICHTIG

Das Typenschild des Gerätes gibt die zulässige Spannung an. Prüfen Sie

bitte nach, ob diese mit der vorliegenden Netzspannung übereinstimmt. Das

Gerät darf nicht gestartet werden bevor die Transportschraubkappe nicht

gegen den Luftfilter ausgetauscht wurde.

Kühlwasser kann aus dem Leitungsnetz oder einer

Umlaufkühlung bezogen werden.

Bringen Sie den Druckschlauch am Wassereintritt (Pos. 1) auf der

Rückseite des Gerätes an:

Legen Sie die Filterdichtung so in die Verschraubung der

Kupplung, daß deren flache Seite am Druckschlauch anliegt.

Ziehen Sie die Verschraubung der Kupplung ausreichend fest

an.

➃

Das andere Ende des Druckschlauchs verbinden Sie mit dem

➀

Wasserhahn der Kaltwasserversorgung:

Falls erforderlich, schrauben Sie den Reduktionsring samt

➄

➁

Dichtung an den Wasserhahn.

Legen Sie die Dichtung ein, und ziehen Sie die

Verschraubung der Kupplung ausreichend fest an.

WICHTIG

Nur an die Kaltwasserversorgung anschließen

Führen Sie den Rücklaufschlauch (Pos. 2) zum Abfluß.

Vergewissern Sie sich, daß er auf ganzer Länge ein

gleichmäßiges Gefälle aufweist und nirgendwo abgeknickt ist.

Bringen Sie den Abflußschlauch am Abflußsystem an.

4

LaboPress-3

A

Gebrauchsanweisung

Einbetteinheit zusammenbauen

bdeckung abnehmen

Unteren Stempel einbauen

Einbetteinheit montieren

Den Schnappverschluß lösen (Pos. 4).

Durch leichten Druck rechts und links auf die Abdeckung

kommt diese frei; heben Sie sie ab.

➃

➀

➄

➁

Schnappverschluß

Den Untertempel auf die Stempelstange anbringen

Den Unterstempel so drehen, daß die Löcher in der Stange

und der Stempel übereinstimmen und setzen Sie den

Stempelstift ein

Vergewissern Sie sich, daß der Stift nicht herausragt.

WICHTIG

Der Achszapfen ist ein Teil des Sicherheitsmechanismus des Gerätes, um

das Gerät gegen Schäden zu schützen. Sehen Sie: Wartung. Falls er bricht

darf er nur mit einem originalen Struers Ersatzstift erstattet werden, da die

Sicherheitsmechanismen sonst nicht optimal sind.

➀

➂

➃

➁

➄

Einbettzylinder

Feststellschraube

Obere Schnellkupplung für das Kühlwasser

Untere Schnellkupplung für das Kühlwasser

Stecker

WICHTIG

Beim Einbau der Einbetteinheit darf das Gerät nicht eingeschaltet werden.

5

A

bdeckung montieren

A

➃

➀

➄

➁

Schnappverschluß

Staubschutzring anbringen

Einbetteinheit zerlegen

Unteren Stempel absenken

Staubschutzring abnehmen

bdeckung abnehmen

LaboPress-3

Gebrauchsanweisung

Schrauben Sie die Feststellschraube etwa 10 mm heraus.

Führen Sie den Einbettzylinder so über den unteren Stempel,

daß die Feststellschraube die in der Zeichnung gezeigte Lage

einnimmt.

Drehen Sie die Einbetteinheit im Uhrzeigersinn bis sie stoppt.

Ziehen Sie die Feststellschraube vollständig an.

Bringen Sie den Schlauch mit dem geraden Kupplungsstück

an der unteren Schnellkupplung der Einbetteinheit (Pos. 4)

an, und stellen Sie die Verbindung durch Zusammenschieben

der Kupplungsstücke her. Achten Sie darauf, daß der Ring bis

zum Anschlag in die Schnellkupplung hineingeschoben wird.

Bringen Sie den Schlauch mit dem abgewinkelten

Kupplungsstück an der oberen Schnellkupplung der

Einbetteinheit (Pos. 3) an, und stellen Sie die Verbindung

durch Zusammenschieben der Kupplungsstücke her. Achten

Sie darauf, daß der Ring bis zum Anschlag in die

Schnellkupplung hineingeschoben wird.

Verbinden Sie den Stecker (Pos. 5) mit der Stellvorrichtung.

Ziehen Sie die Überwurfmutter an.

Haken Sie die vorne liegende Klaue der Abdeckung in die

entsprechende Aussparung am Rand des Gehäuses ein.

Führen Sie die beiden seitlich an der Abdeckung liegenden

Klauen in das Gerätegehäuse ein. Drücken Sie leicht auf die

Seiten der Abdeckung.

Die Rückseite des Deckels festdrücken, so daß der

Schnappverschluß einschnappt.

Bringen Sie den Staubschutzring um den Einbettzylinder herum

an. Die konkave Seite soll dabei nach oben zeigen.

Schalten Sie das Gerät mit dem Hauptschalter ein.

Mit der Taste STEMPEL AB

N bewegen Sie den unteren

Stempel in seine tiefste Lage.

Nehmen Sie den Staubschutzring ab.

Den Schnappverschluß lösen (Pos. 4).

Durch leichten Druck rechts und links auf die Abdeckung

kommt diese frei; heben Sie sie ab.

6

LaboPress-3

Gebrauchsanweisung

Einbetteinheit ausbauen

➀

➂

➃

➁

➄

Entfernen des Unterstempels

Einbetteinheit auswechseln

WICHTIG

Beim Ausbau der Einbetteinheit darf das Gerät nicht eingeschaltet werden.

Einbettzylinder

Feststellschraube

Obere Schnellkupplung für das Kühlwasser

Untere Schnellkupplung für das Kühlwasser

Stecker

Lösen Sie die Überwurfmutter der Steckverbindung. Ziehen

Sie den Stecker (Pos. 5).

Nehmen Sie den Schlauch mit dem abgewinkelten

Kupplungsstück von der oberen Schnellkupplung der

Einbetteinheit (Pos. 3). Ziehen Sie den Ring ab. Warten Sie 5

Sekunden lang, bis das Wasser aus der Kühlschlange

ausgeflossen ist.

Nehmen Sie den Schlauch mit dem geraden Kupplungsstück

von der unteren Schnellkupplung der Einbetteinheit (Pos. 4).

Ziehen Sie den Ring ab.

Drehen Sie die Feststellschraube etwa 10 mm heraus.

Drehen Sie die Einbetteinheit so lange gegen den Uhrzeiger,

bis sie stoppt.

Heben Sie die Einbetteinheit ab.

Den Stempelstift aus dem Unterstempel drücken.

WICHTIG

Der Achszapfen ist ein Teil des Sicherheitsmechanismus des Gerätes, um

das Gerät gegen Schäden zu schützen. Sehen Sie: Wartung. Falls er bricht

darf er nur mit einem originalen Struers Ersatzstift erstattet werden, da die

Sicherheitsmechanismen sonst nicht optimal sind.

Folgen Sie den Anweisungen zum Aus/Einbau der Einbetteinheit.

7

Gebrauch der Bedienelemente

A

Bedienungsfeld des

LaboPress-3

LaboPress-3

Gebrauchsanweisung

2. Grundzüge der Bedienung

180°C

LaboPress-3

150°C

kustische Signale

Hauptschalter

8

Ein kurzer Ton zeigt an, daß die erfolgte Tastatureingabe

registriert wurde.

Ein langer Ton weist darauf hin, daß der Befehl dieser Taste

augenblicklich nicht zur Verfügung steht.

Drei lange Töne signalisieren die Beendigung des

Einbettvorgangs.

➄

➃

➅

➀

➁

➆

c Bedienungsfeld

e Hauptschalter

➂

LaboPress-3

Gebrauchsanweisung

Pos. Nr. Taste Funktion Pos. Nr. Taste Funktion

HAUPTSCHALTER

Schaltet die Stromversorgung

ein/aus. Der Hauptschalter liegt

rechts am Gehäuse der Maschine.

ANZEIGE

HEIZUNG

¹

Leuchtet bei eingeschalteter

Heizung.

NETZ

POWER

START

s

STOP

o

STEMPEL

AUF

O

STEMPEL

AB

N

Leuchtet bei eingeschaltetem Netz.

Startet den automatischen

Einbettvorgang.

Stoppt den Einbettvorgang mit

automatischem Druckabfall. Stoppt

die Bewegung des unteren

Stempels.

Startet Aufwärtsbeweg. des unteren

Stempels. Nach dem Start: stoppt

die Aufwärtsbewegung des unteren

Stempels. Stempel stoppt autom.

bei Erreichen der obersten Lage.

Startet Abwärtsbeweg. des unteren

Stempels. Nach dem Start: stoppt

die Abwärtsbewegung des unteren

Stempels. Stempel stoppt autom. bei

Erreichen der unterste Lage.

HEIZEN

1

ANZEIGE

HEIZEN

2

HEIZEN

3

ANZEIGE

HEIZEN

4

KÜHLUNG

180°C

180°C

150°C

150°C

¸

Heiztemperatur von180°C wird

eingestellt.

Leuchtet, wenn die Heiztemperatur

180°C eingestellt ist.

Heiztemperatur von 150°C wird

eingestellt.

Leuchtet, wenn die Heiztemperatur

150°C eingestellt ist.

Knopf zum Einstellen der Kühlzeit..

KRAFT

f

HEIZUNG

¹

Knopf zum Einstellen der Kraft

(Druck).

Knopf zum Einstellen der Heizzeit.

5

ANZEIGE

KÜHLUNG

6

ÜBERLAST

OVERLOAD

¸

Leuchtet bei eingeschalteter

Kühlung.

Leuchtet bei Überlastung des

Motors.

9

LaboPress-3

Gebrauchsanweisung

Probe einlegen

Einbettmittel über

die Probe gießen

Zwei Proben einlegen

Drücken und halten Sie die Taste STEMPEL AUF

unteren Stempel in seine oberste Lage zu fahren.

Tragen Sie das Anti-Haftmittel auf die Oberfläche des

unteren Stempels auf.

Legen Sie die Probe auf den unteren Stempel. Die Probe muß

sauber, trocken und fettfrei sein. Damit Risse im

Einbettmittel vermieden werden, muß der Abstand der Probe

von der Zylinderwand mindestens 3 mm betragen.

Drücken und halten Sie die Taste STEMPEL AB

unteren Stempel in seine unterste Lage zu fahren.

Mit Hilfe des beiliegenden Trichters gießen Sie die geeignete

Menge Einbettmittel in den Zylinder.

Es muß immer genügend Resin im Zylinder sein um die Probe

auch unter Druck zu decken. Bedenken Sie bitte daß das Volumen

des granulieren Resines kleiner wird, wenn es unter Druck

kommt. Ist zu wenig Resin eingefüllt können die Stempel auf die

Probe drücken und der Zylinder kann zerstört werden

WICHTIG

Damit das Anti-Haftmittel ein Kleben des Einbettmittels an der Oberfläche

verhindert, muß es immer in einer dünnen Schicht auf die Oberflächen der

Einbettstempel aufgetragen werden. Mit dem Struers AntiStick kann eine

dünne Schicht Pulver auf die Stempel getupft werden.

Gehen Sie vor, wie oben unter Proben einlegen beschrieben

ist.

Tragen Sie das Anti-Haftmittel auf die beiden Oberflächen

des Zwischenstempels auf.

Legen Sie den Zwischenstempel oben auf das Einbettmittel.

Legen Sie die zweite Probe auf den Zwischenstempel, und

füllen Sie die geeignete Menge Einbettmittel in den Zylinder.

Nochmals, versichern Sie sich, daß genügend Resin eingefüllt ist!

O, um den

N, um den

10

LaboPress-3

Gebrauchsanweisung

Verschluß aufsetzen

Entfernen Sie den Staub des Einbettmittels vom oberen Teil

des Einbettzylinders.

Die zylindrische Oberfläche des oberen Stempels reinigen.

Gehärtenes Einbettmittel läßt sich einfach entfernen, ohne

die Oberfläche des Stempels zu beschädigen, wenn der

mitgelieferte Schaber verwendet wird.

Tragen Sie das Anti-Haftmittel auf die Oberfläche des oberen

Stempels auf.

Setzen Sie den Verschluß mit dem oberen Stempel auf den

Einbettzylinder.

Drücken Sie den Verschluß nach unten und drehen Sie ihn

dabei im Uhrzeigersinn bis Sie ein Klicken hören.

Drehen Sie den Verschluß eine Vierteldrehung zurück.

WICHTIG

Falls der Stempel nicht in den Zylinder paßt, kontrollieren Sie ob sich

ausgehärtetes Einbettmittel auf Stempel und Zylinder befindet. Die Toleranz

des Spiels zwischen Zylinder und Stempel ist ziemlich gering, weshalb

selbst geringe Einbettmittelrückstände Probleme verursachen können.

11

LaboPress-3

Gebrauchsanweisung

Einbettvorgang starten

Vorheizen mit niedrigem Druck

Einbettvorgang stoppen

Stellen Sie die Kraft ein.

Stellen Sie die Heizzeit ein.

Stellen Sie die Heiztemperatur ein (180/150°C).

Stellen Sie die Kühlzeit ein.

Drücken Sie die Taste START

automatisch ab.

Der Ablauf des Einbettvorgangs kann mit Hilfe der

Kontrollanzeigen für Heizung und Kühlung verfolgt werden.

Stellen Sie die Kraft auf einen niedrigen Wert. Erhöhen Sie die

Kraft auf den richtigen Wert nach Ablauf der gewünschten

Vorheizzeit.

Nach Ablauf der Kühlzeit stoppt die Maschine automatisch

und der Druck wird abgebaut. Während des Einbettvorgangs

können Sie die Maschine jederzeit mit der Taste STOP

stoppen.

Bevor Sie den Einbettzylinder nach einer Heizperiode öffnen,

sollte er sich mindestens 2 Minuten lang abkühlen. Beachten Sie bitte, daß

andernfalls die Einbettung beschädigt werden könnte.

s, und der Vorgang läuft

o

Verschluß abnehmen

Wenn der Einbettvorgang beendet ist:

Drehen Sie den Verschluß im Gegenuhrzeigersinn, und

nehmen Sie ihn aus der Verschraubung heraus.

Mit der Taste STEMPEL AUF

Stempel in seine höchste Lage.

Legen Sie den Verschluß in die dafür vorgesehene Halterung.

O fahren Sie den unteren

12

LaboPress-3

Gebrauchsanweisung

Referenzhandbuch

Inhaltsverzeichnis Seite

1. Details und Besonderheiten der Bedienung

Installation...................................................................................... 14

Umlaufkühleinheit (Optional) ................................................ 14

Steckverbindung für Umlaufkühleinheit............................... 14

2. Struers Metalog Guide™

............................................... 15

3. Anwendungshilfen für das Warmeinbetten

.......... 15

4. Zubehör

.................................................................................. 16

5. Verbrauchsmaterialien

................................................... 17

6. Fehlersuche

......................................................................... 18

7. Wartung

Tägliche Pflege................................................................................ 20

Monatliche Reinigung ....................................................................20

Raum unter dem unteren Stempel reinigen .......................... 20

Stempel reinigen............................................................................. 20

Entfernen des Oberstempels.......................................................... 21

Schmieren der Gewinde des Verschlusses ....................................21

Entkalken der Kühlspirale in der Einbetteinheit......................... 21

Kühlwasser ersetzen ......................................................................22

Umlaufkühleinheit überprüfen...................................................... 22

8. Technische Daten

............................................................. 23

13

Installation

Umlaufkühleinheit (Optional)

TRECI

ROPRE

LaboPress-3/

ProntoPress-10/ProntoPress-20

Steckverbindung für

Umlaufkühleinheit

Abflußschlauch

Steckverbindung für

Umlaufkühlung

LaboPress-3

Gebrauchsanweisung

1. Details und Besonderheiten der Bedienung

Die Umlaufkühleinheit (TRECI) wird über einen Adapter

(ROPRE) an die Einbettpresse angeschlossen.

Das Kabel verbinden, das von der TRECI-Pumpe kommt, mit

ROPRE, wie es das Anschlußdiagramm für ROPRE zeigt.

Den Stecker des Anschlußkabels von ROPRE stecken Sie in

die Steckverbindung (Pos. 5) auf der Rückseite der

Einbettpresse.

Das Kabel schließen, das von ROPRE kommt, an das Netz an.

Vergewissern Sie sich, daß die Pumpe in der Richtung rotiert,

die auf der Pumpe angegeben ist. Falls die Drehrichtung nicht

stimmt, vertauschen Sie zwei der Phasen des

➃

➀

➄

➁

Pumpenanschlusses an der Umlaufkühleinheit (nur

dreiphasige Version).

Ersetzen Sie das Austrittsrohr der TRECI-Pumpe durch ein

Rückschlagventil mit Krümmer und sechseckigem

Übergangseinschraubstutzen von ROPRE. Es empfiehlt sich,

die Gewinde abzudichten.

Verbinden Sie den Druckschlauch der Einbettpresse mit dem

Einschraubstutzen. Denken Sie daran, die Dichtung

einzubauen.

Führen Sie den Abflußschlauch (Pos. 2) zum Einlaß am

TRECI. Vergewissern Sie sich, daß der Abflußschlauch auf

der gesamten Länge Gefälle besitzt und nicht geknickt ist.

Verbinden Sie den Abflußschlauch mit dem Einlaß am

TRECI.

14

LaboPress-3

Gebrauchsanweisung

2. Struers Metalog Guide™

Der Struers Metalog Guide™ bietet für die meisten gängigen

Materialien Präparationsmethoden an, die sich an der einfachen

Untersuchung zweier Schlüsseleigenschaften orientieren: Härte

und Duktilität. Die richtige Methode ist ebenso leicht

herauszufinden, wie die Wahl der Verbrauchsmaterialien. Wenn

Sie für Ihre vorliegenden Proben die geeignete

Präparationsmethode suchen, sollten Sie immer den Struers

Metalog Guide™ zu Rate ziehe.

Der Struers Metalog Guide™ umfaßt 6 hilfreiche Kapitel:

Metalogram

Metalog Methoden

Präparationsphilosophie

Metalog Verfahren

Metalog Master

Metalog Code

Führt Sie rasch, sicher und ohne Umwege zur richtigen

Präparationsmethode.

Eine komplette Sammlung von Präparationsmethoden, die auf

der reichen materialographischen Erfahrung von Struers beruht

und dabei die Verbrauchsmaterialien von Struers berücksichtigt.

Die Grundlagen moderner Probenpräparation aus Expertensicht.

Materialographische Präparation logisch von A-Z erklärt.

Dieses Expertensystem berät Sie nicht nur bei der Problemlösung

von Präparationsschwierigkeiten, sondern versorgt Sie auch mit

breitem Hintergrundwissen über die Verfahren mechanischer

Präparation.

Hilft Ihnen beim schnellen Zugriff auf die passenden

Verbrauchsmaterialien zur ausgewählten Methode.

Struers Metalog Guide

Ihr ausführlicher Ratgeber für materialographische Probenpräparation.

Fragen Sie Ihren Fachhändler nach einem kostenlosen Exemplar des

Metalog Guide™

3. Anwendungshilfen für das Warmeinbetten

Die Struers Anwendungshilfen für das Warmeinbetten liefern

Ihnen Einbettdaten, Tips und Tricks oder Besuchen Sie die

Struers Website auf http://www.struers.com

Abschnitt unter Know How.

und sehen Sie den

15

LaboPress-3

Gebrauchsanweisung

4. Zubehör

Gegenstand Beschreibung Kennwort

Einbetteinheit

bestehend aus Zylinder, unterem und oberem Stempel,

Heiz/Kühleinheit und Verschluß

Zwischenstempel

für die gleichzeitige Herstellung von 2 Einbettungen

Umlaufkühleinheit

Adapter

für die Umlaufkühleinheit für den Anschluß der

Umlaufkühleinheit (TRECI) an LaboPress-3

25 mm Durchm.

30 mm Durchm.

1 ¼" Durchm.

1 ½" Durchm.

40 mm Durchm.

50 mm Durchm.

25 mm Durchm.

30 mm Durchm.

1 ¼" Durchm.

1 ½" Durchm.

40 mm Durchm.

50 mm Durchm.

TRECI

ROPRE

CYNMI

CYNTE

CYNQU

CYNHA

CYNIF

CYNAM

CYLDO

CYLDO

CYLDO

CYLDO

CYLDO

CYLDO

16

LaboPress-3

Gebrauchsanweisung

5. Verbrauchsmaterialien

Name Anwendung

ConduFast

(Resin 1)

SpeciFast

(Resin 3)

PolyFast Randschärfe Sehr geringe Schrumpfung

Untersuchung im

IsoFast

(Resin 4)

DuroFast

(Resin 5)

MultiFast Routineuntersuchungen

MultiFast

Green

MultiFast

Brown

Name Anwendung

Pre-Mount

Elektrolytisches Polieren Elektrisch leitend

Glasklare Einbettungen

Poröse Proben

Isolieren der Oberfläche bei

ConduFast

Rasterelektronenmikroskop

Randschärfe

Planheit

Randschärfe

Planheit

Auffüll Einbettmittel

Routineuntersuchungen

Farbmarkierung

Routineuntersuchungen

Farbmarkierung

Serieneinbettung von

unkomplizierten Formen

Produkt Anwendung Material Inhalt Kennwort

Mould Release

Wax

AntiStick

Um Haftung der Einbettung

an den Stempel zu

vermeiden

Um Haftung der Einbettung

an den Stempel zu

vermeiden

Spezifische Eigenschaften Material Inhalt Kenn-

Sehr geringe Schrumpfung

Transparent

Mittlere Schrumpfung

Mittlere Abtragsrate

Elektrisch leitend

Niedrige Emission in der

Vakuumkammer

Geringe Schrumpfung

Niedrige Abtragsrate

Sehr geringe Schrumpfung

gute Haftung

Mittlere Abtragsrate

Geringe Schrumpfung

Mittlere Abtragsrate

Geringe Schrumpfung

Mittlere Abtragsrate

Geringe Schrumpfung

Mittlere Abtragsrate

Spezifische Eigenschaften Material Inhalt Kenn-

Einfach zu handhaben

Geringe Schrumpfung

Mittlere Abtragsrate

Wachs 24 g PREWA

Sehr feines Stearatpulver 8 g FASTI

Akryl mit Eisenpulver

Füllstoff

Thermoplastisch, Grau

Akryl

Thermoplastisch

Phenol mit Kohle Füllstoff

Warmaushärtend, Schwarz

Dialylphtalat mit Glasfaser

Füllstoff

Warmaushärtend, Grün

Epoxid mit Mineral Füllstoff

Warmaushärtend, Schwarz

Phenol mit Holzmehl

Füllstoff

Warmaushärtend, Schwarz

Phenol mit Holzmehl

Füllstoff

Warmaushärtend, Grün

Phenol mit Holzmehl

Füllstoff

Warmaushärtend, Braun

Phenol mit Holzmehl

Füllstoff

Warmaushärtend, Schwarz

In Tablettenform

1 kg RESFE

1,5 kg

7,5 kg

25 kg

1 kg

7,5 kg

1 kg

7,5 kg

1 kg

7,5 kg

2,5 kg

7,5 kg

25 kg

2,5 kg

7,5 kg

25 kg

2,5 kg

7,5 kg

25 kg

25 mm/

1"

Durchm.

etwa.

1100 Stk.

10 kg

30 mm/

1.1/4"

Durchm.

etwa.

760 Stk.

10 kg

40 mm/

1 ½"

Durchm.

etwa.

460 Stk.

10 kg

wort

RESTH

RESYV

RESFA

FAPSA

FAPME

RESDI

RESTY

RESIF

RESEN

RESRU

RESUK

RESLA

FAGSA

FAGME

FAGLA

FABSA

FABME

FABLA

wort

RESUN

RESGI

RESAM

17

LaboPress-3

Gebrauchsanweisung

6. Fehlersuche

Anzeige/Fehler Grund Maßnahme

Fehlermeldung

Überlastung Motor überlastet Lassen Sie den Motor abkühlen und starten

Sie die Einbettpresse erneut.

Falls dies nicht hilft, rufen Sie den Struers

Kundendienst an.

Akustische Signale

Langer Ton. Befehl steht nicht zur Verfügung. Lesen Sie in der Gebrauchsanweisung das

Kapitel Grundzüge der Bedienung.

Maschinenprobleme

Start nicht möglich Heiz- und Kühlzeit sind auf Null Stellen Sie die richtige Zeit ein.

Druck unzureichend. Kraft/Druck sind falsch eingestellt. Stellen Sie die Parameter richtig ein.

Drucksystem schadhaft. Rufen Sie den Struers Kundendienst an.

Heizung unzureichend. Zeiten für Vorwärmen/Heizen sind

falsch eingestellt.

Heizsystem schadhaft. Rufen Sie den Struers Kundendienst an.

Kühlung unzureichend. Kühlzeit falsch eingestellt. Stellen Sie den Parameter richtig ein.

Wasserhahn des Leitungswassers ist

nicht/zu wenig geöffnet.

Filter am Wassereintritt ist verstopft.

Wassertemperatur zu hoch.

Wasserstand in der Umlaufkühleinheit

zu gering. Wassertemperatur zu hoch.

Kühlsystem schadhaft. Rufen Sie den Struers Kundendienst an.

Kühlwasser tropft unten aus

der Maschine.

Der Verschluß kann nicht in

das Gewinde des Einbettzylinders eingedreht werden

Der Oberstempel ist zu warm. Lassen Sie den Verschluß und den

Ausgehärtetes Resin im Einbettzylinder. Den Einbettzylinder mit einer Metallbürste

Ausgehärtetes Resin sitzt auf dem

Der Verschluß ist heruntergefallen und

Schnellkupplung ist nicht richtig

montiert.

Der Verschluß ist nicht richtig montiert Den Verschluß direkt nach unten drücken und

Oberstempel

die Kante des Oberstempels ist

beschädigt.

Stellen Sie die Parameter richtig ein.

Wasserhahn öffnen.

Filter reinigen.

Wasser bis zur Füllhöhe nachfüllen. Siehe

Kapitel Wartung.

Nehmen Sie die Abdeckung von der

Einbetteinheit und prüfen Sie die Anschlüsse

der Schnellkupplungen.

ihn gegen den Uhrzeigersinn drehen bis ein

Klicken zu hören ist. Dann den Verschluß im

Uhrzeigersinn drehen.

Oberstempel abkühlen.

Einbetttemperatur herabsetzen

reinigen

Den Stempel mit dem mitgelieferten Schaber

reinigen.

Ersetzen Sie den Oberstempel.

18

LaboPress-3

Gebrauchsanweisung

Anzeige/Fehler Grund Maßnahme

Das Gewinde zwischen Verschluß und

Zylinder oder der Oberstempel sind

beschädigt.

Der Verschluß kann nicht völlig

zugedreht werden

Die Scheibe für die Wärmeisolation auf

Der Verschluß kann nicht

abgenommen werden.

Schmutz auf dem Gewinde des